Page 1

WALL MOUNTED UNITS

DMJNB7"*3

Technical Dossier

WALL MOUNTED UNITS

VAI 2-025 WN

VAI 2-035 WN

VAI 2-050 WN

VAI 2-065 WN

2010

ENG

Page 2

1- CONTENTS

1- CONTENTS ............................................................................................................................... 2

2- TECHNICAL SPECIFICATIONS .....................................................................................................

3- TEMPERATURE BY CAPACITIES .................................................................................................. 5

4- WIRING DIAGRAMS ................................................................................................................... 9

5- ERROR CODES .........................................................................................................................12

6- FLOW CHART OF DIAGNOSIS AND SOLUTIONS ..........................................................................13

7- PCB EXPLANATION ...................................................................................................................16

7.1- Abbreviation ............................................................................................................................... 16

7.2- Display function .......................................................................................................................... 16

7.3- Protection ................................................................................................................................... 16

7.4- Fan-only mode ............................................................................................................................ 17

7.5- Cooling mode .............................................................................................................................. 18

7.6- Drying mode ............................................................................................................................... 19

7.7- Heating mode ............................................................................................................................. 19

7.8- Auto mode function ..................................................................................................................... 22

7.9- Forced operation function............................................................................................................ 22

7.10- Action of 4-way valve .................................................................................................................. 22

7.11- Two speeds outdoor fan function ................................................................................................. 23

7.12- Timer function ............................................................................................................................. 23

7.13- Sleep function mode ................................................................................................................... 23

7.14- Mode conflict .............................................................................................................................. 24

7.15- Auto-restart function ................................................................................................................... 24

7.16- Ionizer/plasma dust collector function (optional)......................................................................... 24

7.17- Outdoor chassis heating cable (optional) ..................................................................................... 24

3

ENG

2

Page 3

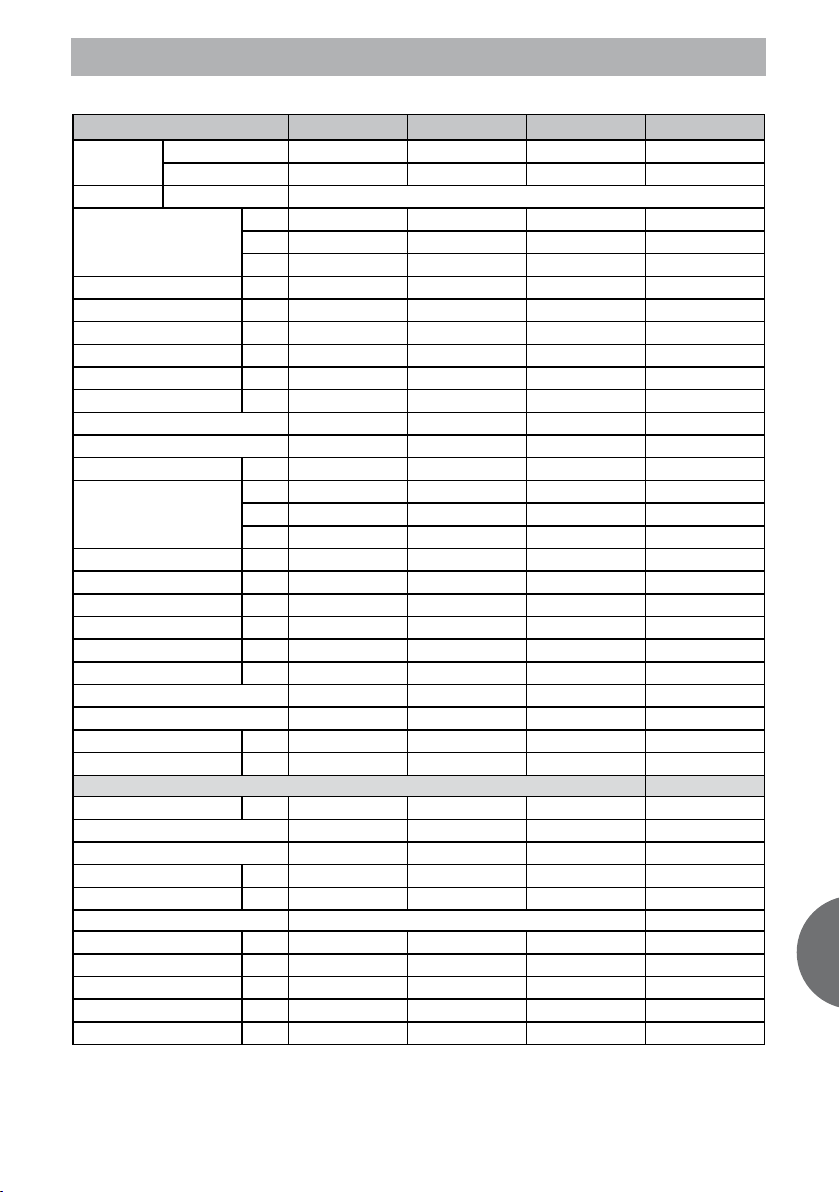

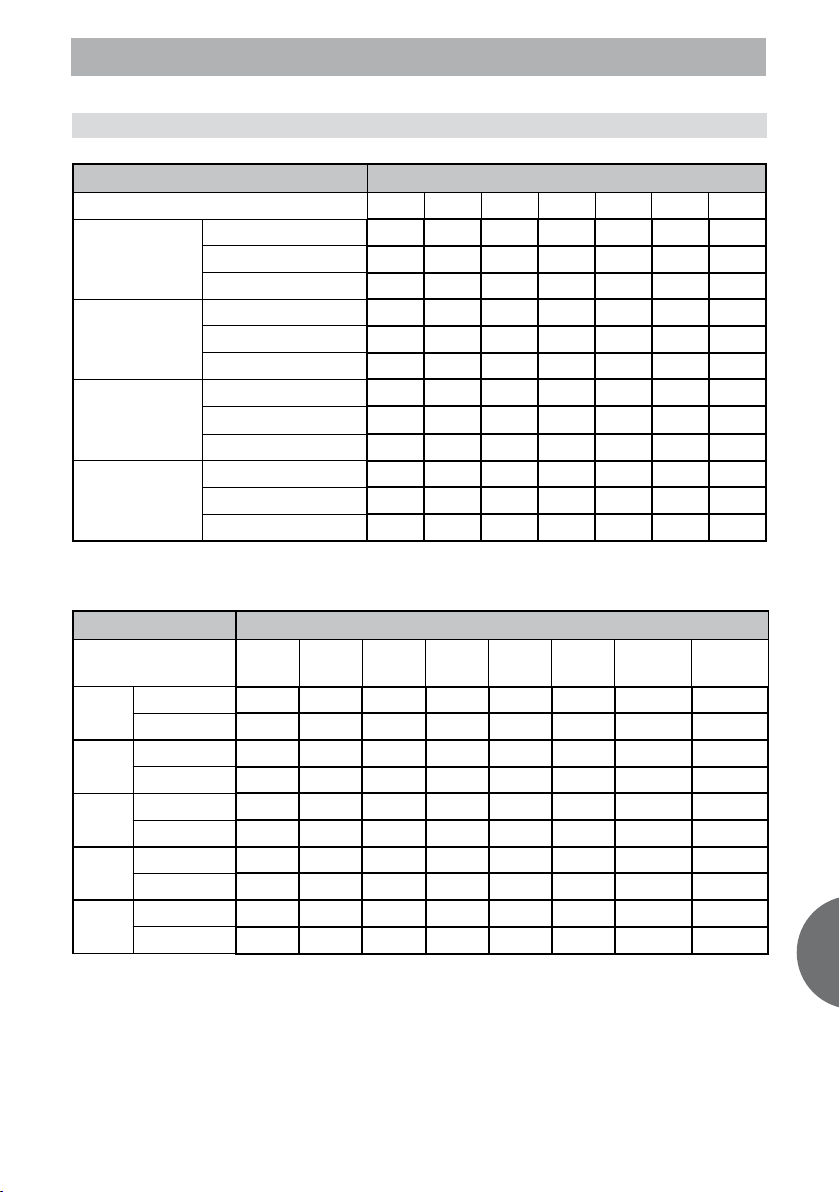

2- TECHNICAL SPECIFICATIONS

Model

Indoor unit

Outdoor unit

Power supply V/Ph/Hz

kW

Cooling capacity

Power input kW

Min-Max cooling capacity kW

Min-Max cooling power input kW

Nominal capacity (UK condit.) kW

Power input (UK conditions) kW

Operating current A

EER

Energy level class

Annual consumption kWh

Heating capacity

Power input kW

Min-Max heating capacity kW

Min-Max heating power input kW

Nominal capacity (UK condit) kW

Power input (UK conditions) kW

Operating current A

COP

Energy level class

Max power input kW

Max operating current A

INDOOR UNIT

Air flow volume m3/h

Remote control type

Remote control reference

Sound power level dB(A)

Sound pressure level dB(A)

Testing conditions for sound pressure

Dimensions HxLxD mm

Net weight Kg

Packaged dimensions HxLxD mm

Volume

Packaged weigth

BTU

Fg/h

kW

BTU

Kcal/h

VAI 2-025 WN VAI 2-035 WN VAI 2-050 WN VAI 2-065 WN

VAI 2-025 WNI VAI 2-035 WNI VAI 2-050 WNI VAI 2-065 WNI

VAI 2-025 WNO VAI 2-035 WNO VAI 2-050 WNO VAI 2-065 WNO

230/1/50

2,60 3,50 5,00 6,70

8.873 11.945 17.064 22.866

2.236 3.010 4.300 5.762

0,65 0,97 1,55 2,09

0.9-3.3 1.1-4.3 1.5-6.4 3.5-7.3

0.3-1.1 0.4-1.48 0.38-2.3 0.82-2.5

2,56 3,45 4,93 6,61

0,52 0,78 1,24 1,67

2,90 4,30 6,90 9,40

4,00 3,61 3,23 3,21

A A A A

325 485 775 1.045

2,90 3,80 5,10 7,35

9.897 12.969 17.405 25.084

2.494 3.268 4.386 6.321

0,68 0,99 1,41 2,03

1.0-3.6 1.2-4.4 1.6-6.7 3.2-7.9

0.31-1.15 0.39-1.46 0.35-2.1 0.8-2.7

2,41 3,15 4,23 6,08

0,59 0,85 1,23 1,77

3,00 4,20 6,40 9,10

4,26 3,84 3,62 3,62

A A A A

1,61 1,95 2,76 2,70

7 9 12 15

250/300/500 310/450/580 570/800/850 820/980/1080

Infrared Infrared Infrared Infrared

RG19B/E (white) RG19B/E (white) RG19B/E (white) RG19B/E (white)

40/45/51 41/47/52 49/52/56 53/57/60

25/31/37 26/33/38 31/38/42 35/42/45

265 x 790 x 200 265 x 790 x 200 295 x 920 x 225 325 x 1000 x 235

8.5 8.5 11.5 16.5

335 x 875 x 265 335 x 875 x 265 368 x 1015 x 295 400 x 1080 x 320

0,078 0,078 0,110 0,138

10,5 10,5 15,0 19,0

ENG

3

Page 4

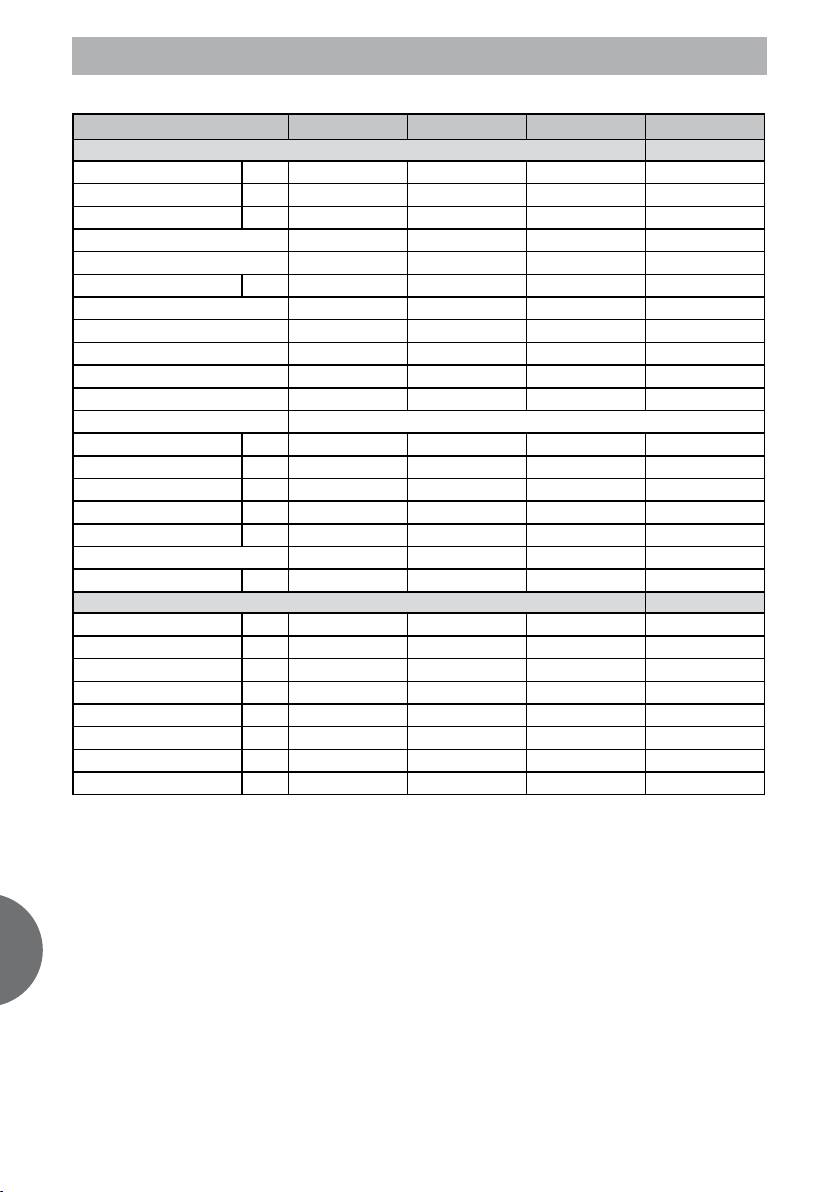

2- TECHNICAL SPECIFICATIONS

VAI 2-025 WN VAI 2-035 WN VAI 2-050 WN VAI 2-065 WN

OUTDOOR UNIT

Air flow volume m3/h

Sound power level dB(A)

Sound pressure dB(A)

Number of fans

Refrigerant

Refrigerant charge heat pump gr

Inverter DC / AC

Compressor type

Compressor Model

Compressor Brand

Expansion system

Electric_electronic protections

Dimensions HxLxD mm

Dimensions Valves A/B/C mm

Dimensions Installation I/J mm

Net weight Kg

Packaged dimensions HxLxD mm

Volume

Packaged weight heat pump Kg

INSTALLATION

Pipe connection liq/gas inches

PM (Max pressure) bar

pm (min pressure) bar

Max. Piping length m

Max. Height IU under OU m

Max. Height OU under IU m

Chargeless length m

Additional charge per meter gr

1060/1800 1060/1800 1360/2200 2000/2700

60 62 64 66

50 50 53 53

1 1 1 1

R410A R410A R410A R410A

1100 1100 1180 1950

Inverter DC Inverter DC Inverter DC Inverter DC

ROTARY ROTARY Rotary ROTARY

DA108X1C-20FZ3 DA108X1C-20FZ3 DA130S1C-20FZ DA150S1C-20FZ

TOSHIBA TOSHIBA Toshiba TOSHIBA

Capillary Capillary Capillary Capillary

Voltage,current, pressure,temperture,communication protection

600 x 760 x 285 600 x 760 x 285 600 x 760 x 285 695 x 845 x 315

60/60/145 60/60/145 60/60/145 60/60/280

290/530 290/530 290/530 335/560

38,0 38,0 39,5 52,0

655 x 887 x 355 655 x 887 x 355 655 x 887 x 355 770 x 970 x 400

0,206 0,206 0,206 0,299

40,5 40,5 42,0 57,0

1/4’’ - 3/8’’ 1/4’’ - 3/8’’ 1/4’’ - 1/2’’ 3/8” - 5/8”

42 42 42 42

15 15 15 15

20 20 25 25

10 10 10 10

10 10 10 10

7,5 7,5 7,5 7,5

20 20 20 20

ENG

4

Page 5

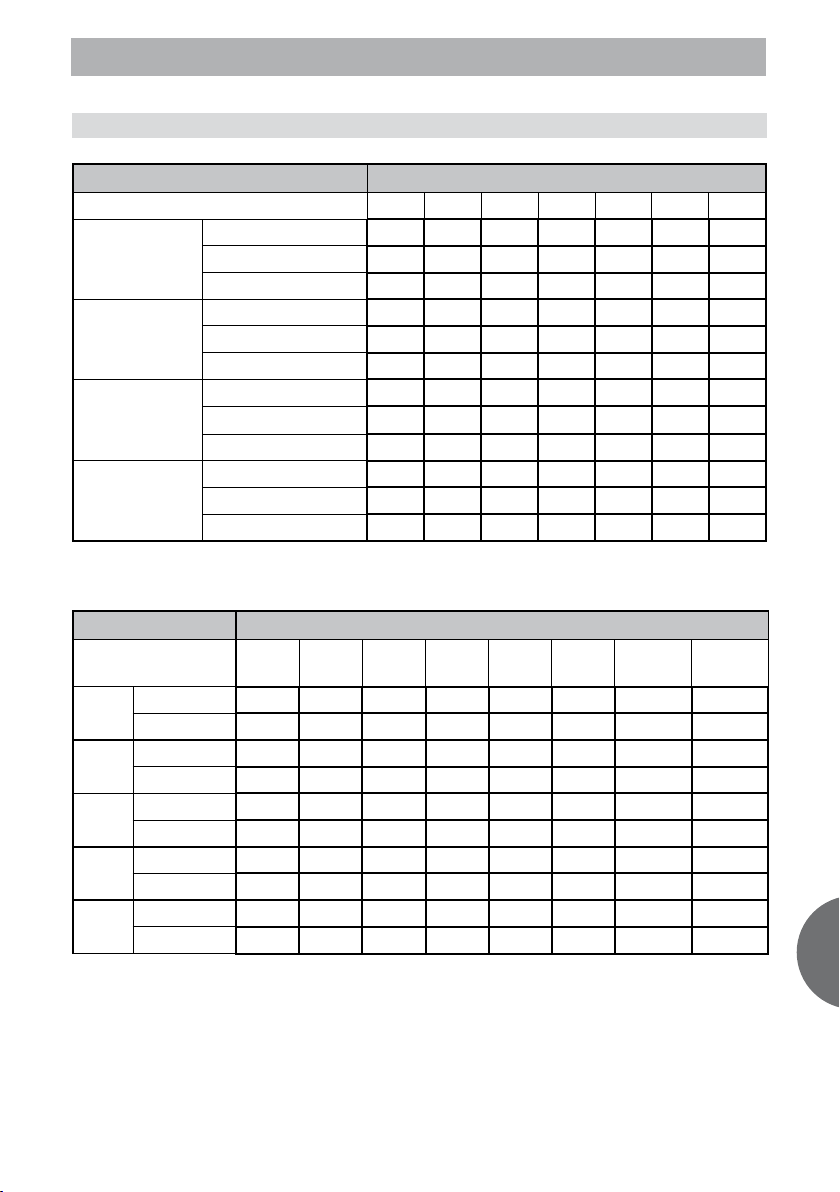

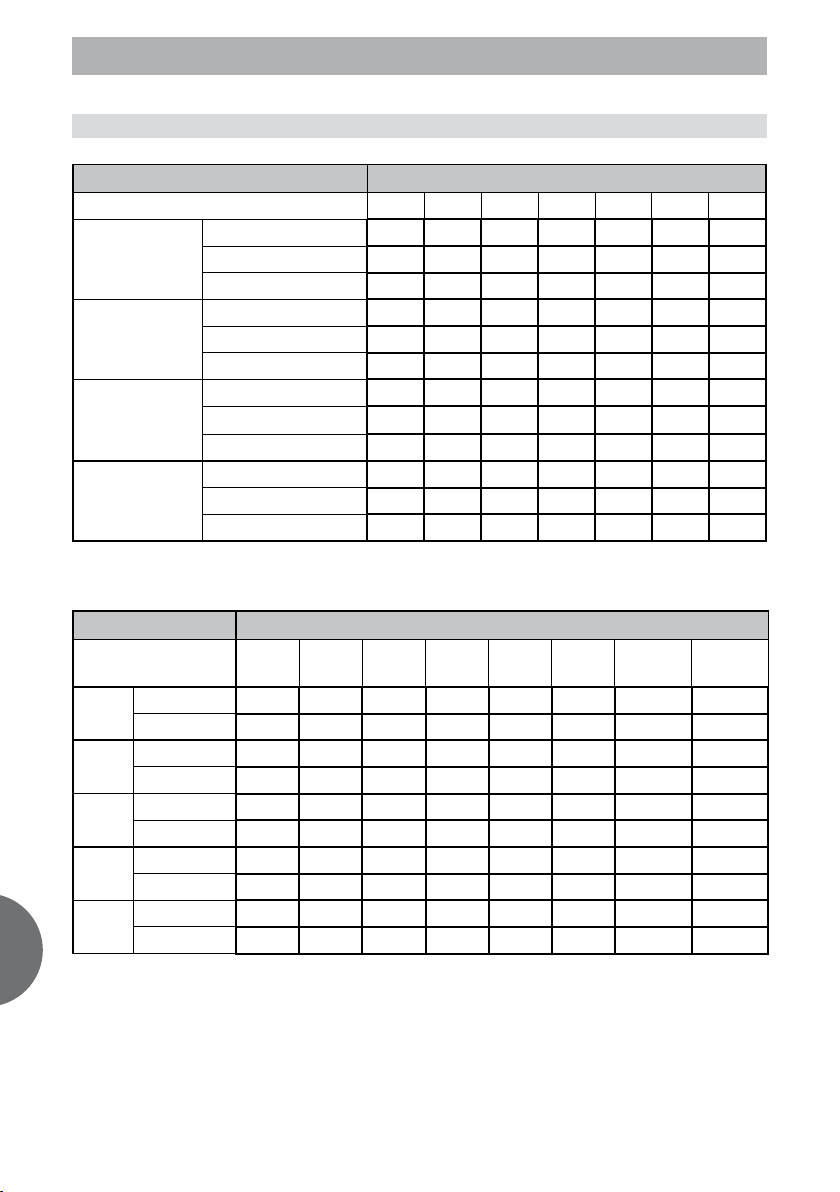

3- TEMPERATURE BY CAPACITIES

3.1 VAI 2-025 WN

COOLING

Indoor Conditions 21ºC 25ºC 30ºC 35ºC 40ºC 45ºC 50ºC

Total capacity kW 2,64 2,55 2,44 2,32 2,21 2,08 1,91

21ºC D

15ºC W

24ºC D

17ºC W

27ºC D

19ºC W

32ºC D

23ºC W

Sensitive capacity kW 2,11 2,04 1,95 1,86 1,76 1,67 1,53

Input kW. 0,53 0,54 0,54 0,55 0,56 0,57 0,66

Total capacity kW 2,80 2,71 2,60 2,47 2,35 2,22 2,03

Sensitive capacity kW 2,24 2,17 2,08 1,98 1,88 1,77 1,62

Input kW. 0,58 0,59 0,60 0,61 0,61 0,62 0,73

Total capacity kW 2,95 2,85 2,74 2,60 2,47 2,33 2,14

Sensitive capacity kW

Input kW. 0,62 0,63 0,64 0,65 0,66 0,67 0,78

Total capacity kW 3,31 3,20 3,06 2,91 2,77 2,61 2,39

Sensitive capacity kW 2,64 2,56 2,45 2,33 2,21 2,09 1,91

Input kW. 0,71 0,72 0,73 0,74 0,75 0,76 0,89

OUTDOOR TEMPERATURE DRY

2,36 2,28 2,19 2,08 1,98 1,87 1,71

HEATING OUTDOOR CONDITIONS

Indoor Conditions

Capacity kW 2,78 3,73 3,19 2,52 2,06 1,93 1,57 0,67

15ºC

Input kW. 0,75 0,90 0,73 0,66 0,62 0,61 0,61 0,53

Capacity kW 2,65 3,56 3,05 2,40 1,97 1,84 1,50 0,64

18ºC

Input kW. 0,72 0,87 0,71 0,63 0,60 0,59 0,59 0,51

Capacity kW 2,52 3,39 2,90 2,29 1,87 1,76 1,43 0,61

20ºC

Input kW. 0,69 0,84 0,68 0,61 0,57 0,57 0,56 0,49

Capacity kW 2,42 3,26 2,78 2,20 1,80 1,69 1,37 0,58

22ºC

Input kW. 0,60 0,80 0,69 0,62 0,58 0,57 0,57 0,50

Capacity kW 2,20 2,95 2,52 1,99 1,63 1,53 1,24 0,53

27ºC

Input kW. 0,73 0,88 0,72 0,64 0,60 0,60 0,59 0,52

24ºC D

18ºC W

12ºC D

11ºC W

7ºC D

6ºC W”

4ºC D

3ºC W

0ºC D

-1ºC W

-5ºC D

-6ºC W

-7ºC D

-8ºC W”

-15ºC D

-16ºC W”

ENG

5

Page 6

3- TEMPERATURE BY CAPACITIES

ENG

COOLING

Indoor Conditions 21ºC 25ºC 30ºC 35ºC 40ºC 45ºC 50ºC

Total capacity kW 3,55 3,43 3,29 3,13 2,97 2,81 2,57

21ºC D

15ºC W

24ºC D

17ºC W

27ºC D

19ºC W

32ºC D

23ºC W

Sensitive capacity kW 2,84 2,75 2,63 2,50 2,38 2,25 2,06

Input kW. 0,37 0,61 0,75 0,91 1,02 1,03 1,04

Total capacity kW 3,77 3,65 3,50 3,33 3,16 2,99 2,73

Sensitive capacity kW 3,02 2,92 2,80 2,66 2,53 2,39 2,19

Input kW. 0,38 0,63 0,77 0,94 1,05 1,06 1,07

Total capacity kW 3,97 3,84 3,68 3,50 3,33 3,14 2,88

Sensitive capacity kW

Input kW. 0,39 0,65 0,79 0,97 1,09 1,10 1,11

Total capacity kW 4,45 4,30 4,12 3,92 3,72 3,52 3,22

Sensitive capacity kW 3,56 3,44 3,30 3,14 2,98 2,82 2,58

Input kW. 0,44 0,72 0,88 1,07 1,20 1,21 1,22

OUTDOOR TEMPERATURE DRY

3,18 3,07 2,95 2,80 2,66 2,51 2,30

HEATING OUTDOOR CONDITIONS

Indoor Conditions

Capacity kW 3,86 4,32 4,18 3,45 3,24 2,93 2,65 1,25

15ºC

Input kW. 0,35 0,74 1,07 1,08 0,96 0,78 0,73 0,55

Capacity kW 3,68 4,12 3,99 3,29 3,09 2,79 2,53 1,20

18ºC

Input kW. 0,34 0,71 1,03 1,04 0,93 0,75 0,70 0,53

Capacity kW 3,51 3,93 3,80 3,13 2,94 2,66 2,41 1,14

20ºC

Input kW. 0,33 0,68 0,99 1,00 0,89 0,73 0,68 0,51

Capacity kW 3,37 3,77 3,65 3,01 2,83 2,55 2,32 1,09

22ºC

Input kW. 0,33 0,69 1,00 1,01 0,90 0,73 0,68 0,51

Capacity kW 3,05 3,42 3,31 2,73 2,56 2,31 2,10 0,99

27ºC

Input kW. 0,33 0,70 1,01 1,02 0,91 0,74 0,69 0,52

24ºC D

18ºC W

12ºC D

11ºC W

7ºC D

6ºC W”

4ºC D

3ºC W

0ºC D

-1ºC W

-5ºC D

-6ºC W

-7ºC D

-8ºC W”

-15ºC D

-16ºC W”

6

Page 7

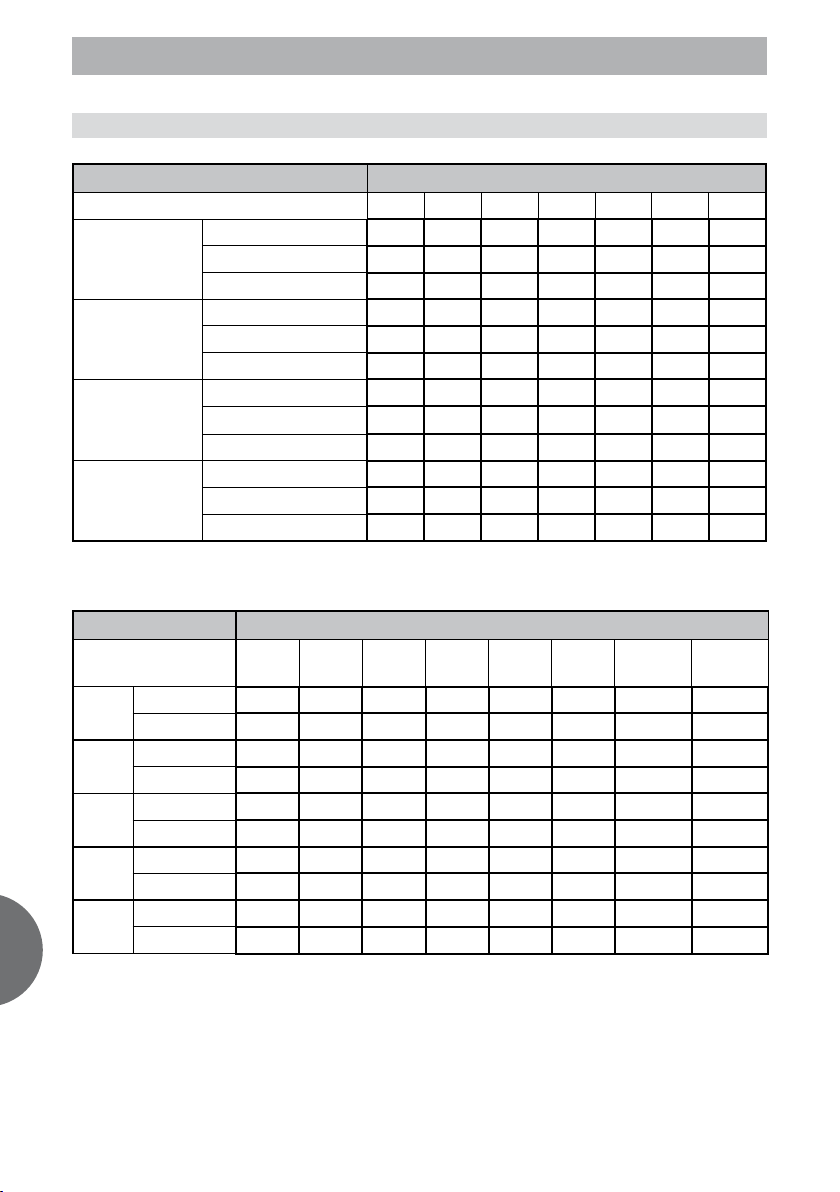

3- TEMPERATURE BY CAPACITIES

3.3 VAI 2-050 WN

COOLING

Indoor Conditions 21ºC 25ºC 30ºC 35ºC 40ºC 45ºC 50ºC

Total capacity kW 5,07 4,90 4,70 4,47 4,24 4,01 3,67

21ºC D

15ºC W

24ºC D

17ºC W

27ºC D

19ºC W

32ºC D

23ºC W

Sensitive capacity kW 4,05 3,92 3,76 3,57 3,39 3,21 2,94

Input kW. 0,59 0,98 1,19 1,46 1,63 1,65 1,66

Total capacity kW 5,39 5,22 5,00 4,75 4,51 4,27 3,90

Sensitive capacity kW 4,31 4,17 4,00 3,80 3,61 3,41 3,12

Input kW. 0,61 1,01 1,23 1,50 1,68 1,70 1,72

Total capacity kW 5,68 5,49 5,26 5,00 4,75 4,49 4,11

Sensitive capacity kW

Input kW. 0,63 1,04 1,27 1,55 1,74 1,75 1,77

Total capacity kW 6,36 6,15 5,89 5,60 5,32 5,03 4,60

Sensitive capacity kW 5,08 4,92 4,71 4,48 4,26 4,02 3,68

Input kW. 0,70 1,15 1,40 1,71 1,92 1,93 1,95

OUTDOOR TEMPERATURE DRY

4,54 4,39 4,21 4,00 3,80 3,59 3,29

HEATING OUTDOOR CONDITIONS

Indoor Conditions

Capacity kW 5,18 5,80 5,61 4,63 4,35 3,93 3,56 1,68

15ºC

Input kW. 0,50 1,05 1,52 1,54 1,37 1,12 1,04 0,78

Capacity kW 4,94 5,53 5,36 4,42 4,15 3,75 3,40 1,61

18ºC

Input kW. 0,48 1,01 1,46 1,48 1,32 1,07 1,00 0,75

Capacity kW 4,70 5,27 5,10 4,21 3,95 3,57 3,24 1,53

20ºC

Input kW. 0,47 0,97 1,41 1,42 1,27 1,03 0,96 0,72

Capacity kW 4,52 5,06 4,90 4,04 3,79 3,43 3,11 1,47

22ºC

Input kW. 0,47 0,98 1,42 1,44 1,28 1,04 0,97 0,73

Capacity kW 4,09 4,58 4,44 3,66 3,44 3,11 2,82 1,33

27ºC

Input kW. 0,48 1,00 1,44 1,46 1,30 1,06 0,99 0,74

24ºC D

18ºC W

12ºC D

11ºC W

7ºC D

6ºC W”

4ºC D

3ºC W

0ºC D

-1ºC W

-5ºC D

-6ºC W

-7ºC D

-8ºC W”

-15ºC D

-16ºC W”

ENG

7

Page 8

3- TEMPERATURE BY CAPACITIES

3.3 VAI 2-065 WN

ENG

COOLING

Indoor Conditions 21ºC 25ºC 30ºC 35ºC 40ºC 45ºC 50ºC

Total capacity kW 6,79 6,57 6,29 5,98 5,68 5,37 4,92

21ºC D

15ºC W

24ºC D

17ºC W

27ºC D

19ºC W

32ºC D

23ºC W

Sensitive capacity kW 5,43 5,26 5,04 4,79 4,55 4,30 3,93

Input kW. 0,80 1,32 1,61 1,96 2,20 2,22 2,24

Total capacity kW 7,22 6,99 6,70 6,37 6,05 5,72 5,23

Sensitive capacity kW 5,78 5,59 5,36 5,09 4,84 4,57 4,19

Input kW. 0,82 1,36 1,66 2,03 2,27 2,29 2,31

Total capacity kW 7,60 7,36 7,05 6,70 6,37 6,02 5,51

Sensitive capacity kW

Input kW. 0,85 1,40 1,71 2,09 2,34 2,36 2,39

Total capacity kW 8,52 8,24 7,89 7,50 7,13 6,74 6,17

Sensitive capacity kW 6,81 6,59 6,32 6,00 5,70 5,39 4,93

Input kW. 0,94 1,55 1,89 2,31 2,58 2,61 2,63

OUTDOOR TEMPERATURE DRY

6,08 5,89 5,64 5,36 5,09 4,81 4,41

HEATING OUTDOOR CONDITIONS

Indoor Conditions

Capacity kW 7,44 8,33 8,06 6,65 6,25 5,64 5,12 2,42

15ºC

Input kW. 0,72 1,51 2,19 2,21 1,97 1,61 1,50 1,12

Capacity kW 7,10 7,95 7,70 6,35 5,96 5,39 4,89 2,31

18ºC

Input kW. 0,70 1,45 2,11 2,13 1,90 1,55 1,44 1,08

Capacity kW 6,76 7,57 7,35 6,05 5,68 5,13 4,65 2,20

20ºC

Input kW. 0,67 1,40 2,03 2,05 1,83 1,49 1,39 1,04

Capacity kW 6,49 7,27 7,04 5,80 5,45 4,93 4,47 2,11

22ºC

Input kW. 0,68 1,42 2,05 2,07 1,85 1,50 1,40 1,05

Capacity kW 5,88 6,59 6,38 5,26 4,94 4,46 4,05 1,91

27ºC

Input kW. 0,69 1,43 2,08 2,10 1,87 1,52 1,42 1,07

24ºC D

18ºC W

12ºC D

11ºC W

7ºC D

6ºC W”

4ºC D

3ºC W

0ºC D

-1ºC W

-5ºC D

-6ºC W

-7ºC D

-8ºC W”

-15ºC D

-16ºC W”

8

Page 9

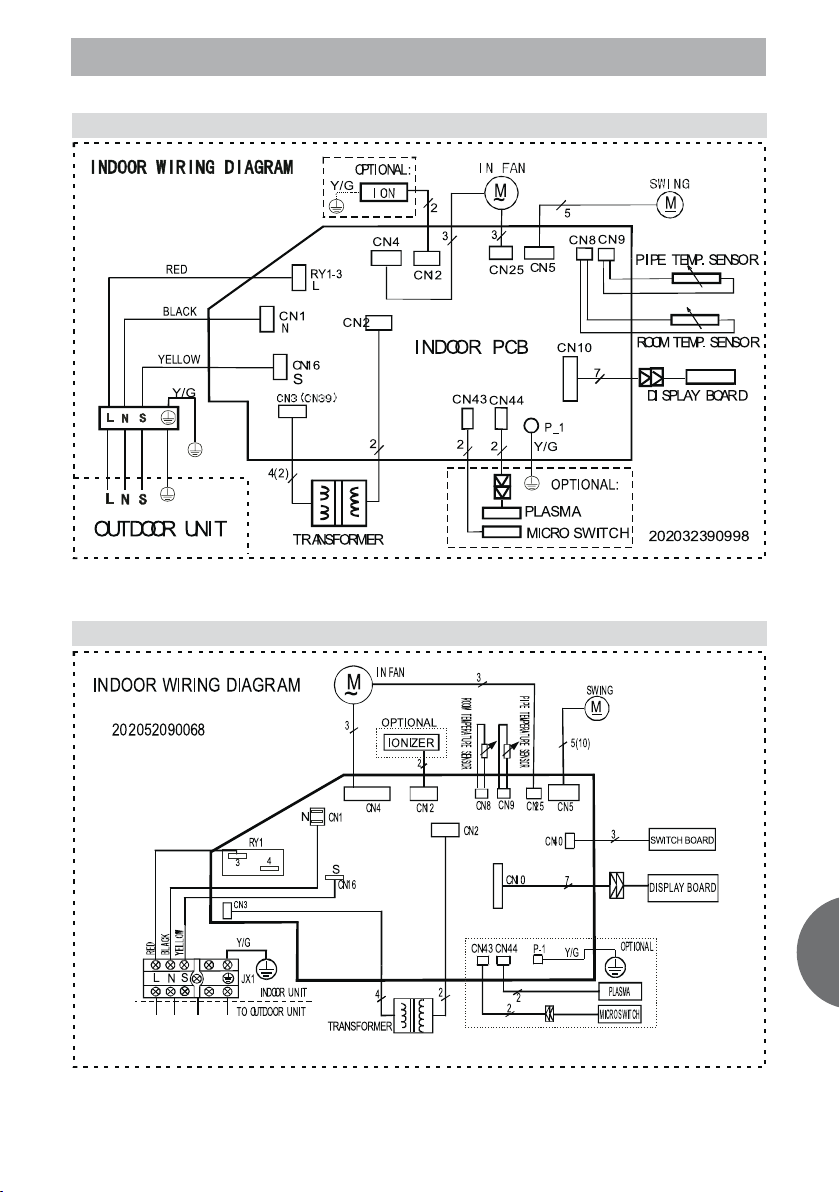

4- WIRING DIAGRAMS

4.1 Indoor unit 025/035

4.2 Indoor unit 050

ENG

9

Page 10

4- WIRING DIAGRAMS

4.3 Indoor unit 065

4.4 Outdoor unit 025/035

ENG

10

Page 11

4- WIRING DIAGRAMS

4.5 Outdoor unit 050

4.6 Outdoor unit 065

ENG

11

Page 12

5- ERROR CODES

Indoor Unit Error Display 025/035 / 050

Display LED STATUS

E0 EEPROM parameter error

E1 Indoor / outdoor units communication protection

E2 Zero-crossing signal error

E3 Indoor fan speed out of control

E5 Open or short circuit of outdoor ambient or condenser temperature sensor

E6 Open or short circuit of indoor room or evaporator temperature sensor

P0 Inverter module (IGBT) over-strong current protection

P1 Over voltage or too low voltage protection

P2 Temperature protection of compressor top.

P4 Inverter compressor drive error

Indoor Unit Error Display 065

Display LED STATUS

E0 EEPROM parameter error

E1 Indoor / outdoor units communication protection

E5

E6 Open or short circuit of indoor room or evaporator temperature sensor

P0 Inverter module (IGBT) over-strong current protection

P1 Over voltage or too low voltage protection

P2

P4

Open or short circuit of outdoor ambient or condenser temperature sensor

Temperature protection of compressor top.

Inverter compressor drive error

ENG

12

Page 13

6- FLOW CHART OF DIAGNOSIS AND SOLUTIONS

E0 (EEPROM parameter error) error diagnosis and solution

E1 (indoor / outdoor units communication protection) error diagnosis and solution

E2 (zero-crossing signal error) diagnosis and solution

13

ENG

Page 14

6- FLOW CHART OF DIAGNOSIS AND SOLUTIONS

E3 (indoor fan speed out of control) diagnosis and solution

E5 (Open or short circuit of outdoor ambient or condenser temperature sensor) diagnosis and solu-

E6 (open or short circuit of indoor room or evaporator temperature sensor) diagnosis and solu-

ENG

P0 (IGBT over-strong current protection) diagnosis and solution.

14

Page 15

6- FLOW CHART OF DIAGNOSIS AND SOLUTIONS

P1 (over voltage or too low voltage protection) diagnosis and solution.

P2 (temperature protection of compressor top) diagnosis and solution.

P4 (inverter compressor drive error) diagnosis and solution.

15

ENG

Page 16

ENG

7- PCB EXPLANATION

7.1 ABBREVIATION

T1 Indoor ambient temperature

T2 Pipe temperature of indoor heat exchanger

T3 Pipe temperature of outdoor heat exchanger

T4 Outdoor ambient temperature

7.2 DISPLAY FUNCTION

Timer indicator

This indicator illuminates when TIMER is set ON/

OFF.

DEF. Indicator

This indicator illuminates when the air conditioner

starts defrosting automatically or when the warm

air control feature is activated in heating mode.

Temperature indicator

Usually it displays the temperature settings. When

Run indicator

Flash at 0.5Hz when the unit is standby. Illuminate

when the unit is turned on.

Auto indicator

This indicator illuminates when the air conditioner

is in AUTO operation.

Ion indicator

Illuminate when Ionizer/Plasma function is activated.

LED display control function.

Pressing “LED display” button on remote controller will turn off all displays on indoor unit, while pressing

once again, all displays will resume.

change the setting temperature, this indicator

begins to flash, and stops 20 seconds later. It

displays the room temperature when the air conditioner is in FAN only operation, and the range of

that is 0~50℃. When the unit stops operation, it

returns to original factory settings. It will also display the error codes when malfunction or protection happen.

Frequency indicator

This indicator appears only when the compressor

is in operation and indicates the current operating

frequency.

7.3 PROTECTION

Protection of compressor top temperature.

When the Over-load Protector is cut due to too high temperature of compressor top, the unit will stop.

When the Over-load Protector is closed again due to decreasing of compressor top temperature, the unit

will restart( in this case the compressor is restricted by Three Minutes Delay protection).

16

Page 17

7- PCB EXPLANATION

Protection of discharge temperature (Td).

1) Compressor will stop immediately if Td>115 for 5s.

2) If 90 ≤ Td ≤ 115 , compressor will run with restricted frequency.

3) If Td<90, compressor will restart or run without restricted frequency

Three Minutes Delay at restart for compressor.

It will take 3 minutes every time when compressor starts.

It will take only 1 minute when the unit is powered on at first time.

Temperature sensor protection at open circuit or short circuit.

Protection of indoor fan speed.

When indoor fan speed is too low (lower than 300rpm for 50 seconds), the unit will stop and LED display

error code and can’t return to normal operation automatically.

Cross Zero signal error warning.

If there are no Cross Zero signal or the alternation of Cross Zero signal is not correct, the unit will stop

and LED display error code .

Inverter module Protection.

Inverter module has a protection function against current, voltage and temperature. If these protections

happened, the unit will stop and LED display error code .

Indoor fan delayed open function.

When the unit is turned on at all modes, the indoor fan will operate 10 seconds later than the action of

louver.

Compressor preheating function.

1) Preheating permitting condition:

If T4(outdoor ambient temperature) <3ºC and the machine connects to power supply newly or if T4 <

3ºC and compressor has stopped for over 3 hours, the compressor heating cable will work.

2) Preheating mode:

A weak current flows through the coil of compressor from the wiring terminal of compressor, then the

compressor is heated without operation.

3) Preheating release condition:

If T4 > 5 ºC or user turns on the machine and compressor runs, preheating function will stop.

7.4 FAN-ONLY MODE

-Temperature setting function is disabled, and no

setting temperature display.

-In this mode, the action of louver is the same as

in cooling mode.

-The action of auto fan in fan-only mode is the

same as auto fan in cooling mode with 24℃ setting

temperature.

ENG

17

Page 18

7- PCB EXPLANATION

7.5 COOLING MODE

After starting, the operation frequency of compressor submits to following rule.

When the machine is running and ΔT(=room

temp. – setting temp.) changes, the frequency of

compressor will rise or descend a grade (7 minutes after starting).

After starting, if ΔT stays in a zone for 3 minutes,

the frequency will change as follow:

Zone A: Current frequency rise a grade till the

maximum grade F8.

Zone B:

Keep the current frequency of compressor.

Zone C:

Descend the current frequency of compressor

until F1.

Zone D: Compressor stops after running as the

minimum frequency F1 for 60 minutes or

ΔT is less than -2ºC.

Indoor heat exchanger anti-freezing function.

If T2 is lower than 0ºC, the compressor stops and

resumes when T2>5ºC.

ENG

Outdoor unit current control in cooling mode(refer

to the parameter table)

Rating capacity test function

1) Set the indoor unit with remote controller as: high fan, 17ºC in cooling mode, then press “TURBO”

button on controller 6 times or more within 10 seconds(make sure indoor unit receives these signals),

the machine will turn into rating capacity test mode, the buzzer will make a “di” sound for 2 seconds

continuously. Also, indoor fan will change to rating speed, the frequency of compressor will be fixed

as rating value. Any condition of above is not satisfied, the machine can not be turned into rating

capacity test mode.

2) The machine will quit from the rating capacity test mode if running for 5 hours or changing fan speed

or setting temperature.

Turbo function(press the “TURBO” button on remote controller)

1) Elevate current frequency to a higher grade.

2) Indoor fan turns to turbo speed.

3) After running for 30 minutes the machine will turn back to previous setting mode.

Indoor fan operation rule.

1) In cooling mode, indoor fan runs all the time and the speed can be selected as high, medium, low

and auto.

2) Auto fan in cooling mode acts as follow:

18

Page 19

7- PCB EXPLANATION

Condenser high temperature protection function(in cooling and drying mode)

If T3>60ºC for 5 seconds, compressor will stop immediately, and the machine will not resume until

T3<52ºC.

7.6 DRYING MODE

Indoor fan speed is fixed at breeze grade and can’t be changed. The horizontal angle is the same as in

cooling mode.

Overlow room temperature protection: In drying mode, if room temperature is lower than 10℃, compressor will stop and not resume until room temperature climbs up to 12ºC.

Evaporator anti-freezing protection, condenser high temperature protection and outdoor unit frequency

limit are valid, and they are the same as that in cooling mode.

Horizontal louver action is the same as that in cooling mode.

7.7 HEATING MODE

Indoor fan action:

1) Anti-cold-wind function.

2) If the compressor stops caused by room temperature rising, indoor fan will be forced to run

127 seconds with breeze. During this period,

anti-cold-wind is disabled. After this, anti-cold

–wind function is available.

3) If the machine runs in rating capacity test

mode, indoor fan runs with rating speed, and

anti-cold-wind is disabled.

ENG

19

Page 20

7- PCB EXPLANATION

Indoor fan speed can be set as high, medium, low

or auto grade, but anti-cold-wind function is preferential.

Auto fan action in heating mode.

After start the operation frequency of compressor

submits to following rule:

When the machine runs, if ΔTh stays in a zone for

3 minutes, action of frequency is as follow:

Zone A: Elevate the current frequency one grade,

and not stop until the maximum grade.

Zone B: Keep the current frequency.

Zone C: Descend the current frequency one grade.

Zone D: Compressor stops after running with F1 for

60 minutes or when ΔTh>61ºC.

Outdoor unit current control in heating mode.

ENG

Indoor heat exchanger high temperature protection.

If T2>60ºC, the compressor will stop and not resume until T2<48ºC.

Defrosting mode.

1) Condition of defrosting.

Condition 1: If T4>0ºC, When the units are running, if the following two items are satisfied the units start

defrosting:

a) The units runs with T3<3ºC for 40 minutes and T3 keeps lower than -6ºC for more than 3 minutes.

b) The units runs with T3<3ºC for 80 minutes and T3 keeps lower than -4ºC for more than 3 minutes.

Condition 2: If T4<0ºC,

The program judges according to the condition 1, if the two items are satisfied, then judges if T2 has

descended for more than 5ºC, if it has the machine starts defrosting, or continues to judge T2 and will

not defrost until T2 drops more than 5ºC.

Condition 3: No matter what value T4 is, if the machine runs with T3<3ºC for more than 120 minutes and

T3 keeps lower than -2ºC for more than 3 minutes, the machine will defrost, no matter if T2 drops for

more than 5ºC or not.

20

Page 21

7- PCB EXPLANATION

2) Condition of ending defrosting.

If any one of following items is satisfied, defrosting will finish and the machine will turn to normal

heating mode.

a) T3 rises to be higher than 12ºC.

b) T3 rises to be higher than 8ºC and remains for 80 seconds.

c) The machine has run for 10 minutes in defrosting.

Defrosting action.

Rating capacity test function.

1) Set the indoor unit with remote controller as: high fan, 30ºC in heating mode, then press “TURBO”

button on controller 6 times or more within 10 seconds(make sure indoor unit receives these signals),

the machine will turn into rating capacity test mode, the buzzer will make a “di” sound for 2 seconds

continuously. Also, indoor fan will change to rating speed, the frequency of compressor will be fixed

as rating value. Any condition of above is not satisfied, the machine cannot be turned into rating

capacity test mode.

2) The machine will quit from the rating capacity test mode if running for 5 hours or changing fan speed

or setting temperature.

Turbo function in heating mode. (press the “TURBO” button on remote controller)

1) Elevate current frequency (excluding F8) to a higher grade. If indoor fan is in low speed or pause

caused by defrosting or anti-cold-wind function, frequency of compressor will not be elevated one

grade until these limit has been released.

2) Indoor fan changes to turbo speed and anti-cold-wind function is valid.

21

ENG

Page 22

7- PCB EXPLANATION

7.8 AUTO MODE FUNCTION

This mode can be chosen with remote controller and the setting temperature can be changed between

17~30ºC.

In auto mode, the machine will choose cooling, heating or fan-only mode according to ∆T(ΔT =T1-Ts).

ΔT=T1-Ts Running mode

ΔT > 1ºC Cooling

-1≤ΔT≤1ºC Fan-only

ΔT<-1ºC Heating

Indoor fan will choose auto speed of relevant mode.

If the machine switches mode between heating and cooling, compressor will keep stopping for 15 minutes and then rechoose mode according to ΔT.

If the setting temperature is modified, the machine will rechoose running function.

7.9 FORCED OPERATION FUNCTION

Forced cooling and auto function can carry out with a touch button. In these two modes, the machine can

be changed by remote controller to any other mode at any moment.

When the machine is off, pressing the touch button once, the unit will enter forced auto mode. When the

machine is off, pressing the touch button twice within 5s, the unit will enter forced cooling mode. When

the unit is running at forced auto or forced cooling mode, pressing the touch button continuously, the

unit will be turned off.

ENG

In forced operation mode, all general protections is available.

In forced cooling mode, the unit will run with fixed frequency F2 at low speed. 30 minutes later, the unit

will turn to normal auto mode with setting temperature 24ºC.

In forced auto mode, the unit will run with setting temperature 24ºC.

7.10 ACTION OF 4-WAY VALVE

In cooling, drying, fan-only, or turning off mode, 4-way valve is off, while in heating mode 4-way valve

is on. If the machine changes operation mode from heating mode to some other mode, 4-way valve will

be delayed off 2 minutes after compressor stop. For defrosting, please refer to the passage “defrosting

mode”.

22

Page 23

7- PCB EXPLANATION

7.11 TWO SPEEDS OUTDOOR FAN FUNCTION

Outdoor fan starts at the same time with compressor, but stops 30 seconds later than compressor ‘s stop.

Outdoor fan action in heating mode(including heating in auto mode).

Outdoor fan action in cooling & drying mode(including cooling in auto & forced mode). Please refer to

the pic. above.

7.12 TIMER FUNCTION

-Timing range is 24 hours, and the minimum resolution is 15 minutes.

-Timer on. After turning off, the machine will turn on automatically when reaching the setting time.

-Timer off. After turning on, the machine will turn off automatically when reaching the setting time.

-Timer on/off. After turning off, the machine will turn on automatically when reaching the setting “on”

time, and then turn off automatically when reaching the setting “off” time.

-Timer off/on. After turning on, the machine will turn off automatically when reaching the setting “off”

time, and then turn on automatically when reaching the setting “on” time.

-The tolerance of Timer is 1 minute per hour.

7.13 SLEEP FUNCTION MODE

Operation time in sleep mode is 7 hours. After 7 hours the machine quits this mode and turns off.

Sleep function is available in cooling, heating and auto mode .

Operation process in sleep mode is as follow:

1) After pressing ECONOMIC or SLEEP button on controller, the machine will turn into sleep mode.

2) When cooling, the setting temperature rises 1ºC (be lower than 30ºC) every one hour, 2 hour later

the rising stops and indoor fan is fixed as low speed.

3) When heating, the setting temperature descends 1ºC(be lower than 30ºC) every one hour, 2 hour

later the descending stops and indoor fan is fixed as low speed, and anti-cold-wind is available.

23

ENG

Page 24

7- PCB EXPLANATION

7.14 MODE CONFLICT

The indoor units can not work cooling mode and heating at same time. Heating mode has a priority.

Definition

Cooling mode Heating Mode Fan Off

Cooling mode No Yes No No

Heating Mode Yes No Yes No

Fan No Yes No No

Off No No No No

No: No mode conflict;

Yes: Mode conflict

7.15 AUTO-RESTART FUNCTION

The indoor unit is equipped with auto-restart function. In case of a sudden power failure, the setting

conditions before the power failure will be restored. The unit will resume the previous operation setting

automatically after 3 minutes when power returns.

7.16 IONIZER/PLASMA DUST COLLECTOR FUNCTION (OPTIONAL)

The indoor unit is equipped with Ionizer/Plasma, which is controlled by the CLEAN AIR button on the

remote controller. Press the CLEAN AIR button to activate the function while the unit is turned on, press

it again to stop the function. Ionizer/Plasma will be turned off automatically if indoor fan stops running

due to malfunctions or anti-cold-wind. When indoor fan restarts after malfunctions being eliminated and

anti-cold-wind being released, Ionizer/Plasma will be available again.

ENG

7.17 OUTDOOR CHASSIS HEATING CABLE (OPTIONAL)

Heating cable is fixed on outdoor chassis to help deicing and to avoid freezing. The heating cable’s

power is 85W, rated voltage is 220V-240V, and is controlled by the program. If outdoor temperature is

lower than 5ºC, the heating cable will begin to work. If outdoor temperature is higher than 15ºC, the

heating cable will stop working.

24

Page 25

NOTES

ENG

25

Page 26

NOTES

ENG

26

Page 27

NOTES

ENG

27

Page 28

Spain:

Saunier Duval Clima S.A.

Polígono Ugaldeguren 3 · Parcela 22

48170 Zamudio (Bizkaia)

Tel: +34 94 489 62 00

Fax: +34 94 489 62 53

www.saunierduval.es

info@saunierduval.es

Saunier Duval reserves the right to modify specifications without prior notice.VAI2-WN-TD 12/2009

Loading...

Loading...