Installation and maintenance instructions

For the competent person

Installation and maintenance instructions

ecoTEC

VU 466/4

GB

Contents

Contents

1 Notes on the documentation ........................... 3

1.1 Storage of documents .............................................. 3

1.2 Safety instructions and symbols ........................... 3

1.3 Validity of the instruction manual ........................ 3

2 Description of the boiler .................................. 4

2.1 Design .......................................................................... 4

2.2 Type summary............................................................ 5

2.3 CE label ........................................................................ 5

2.4 Benchmark .................................................................. 5

2.5 Intended use ............................................................... 5

2.6 Identification plate .................................................... 5

3 Safety instructions and regulations............... 5

3.1 Safety instructions .................................................... 5

3.1.1 Installation and setting ............................................ 5

3.1.2 Gas odour .................................................................... 5

3.1.3 Changes to the surroundings of the boiler......... 6

3.1.4 Important information regarding

propane-fired appliances ......................................... 6

3.2 General requirements .............................................. 6

3.2.1 Related documents ................................................... 6

3.2.2 Installation site .......................................................... 6

3.2.3 Gas supply ................................................................... 7

3.3 Air/flue gas duct ........................................................ 7

3.3.1 Standard 125 mm air/flue gas duct ....................... 7

3.3.2 Flue termination ........................................................ 7

3.4 Air supply .................................................................... 9

3.5 Compartment ventilation ........................................ 9

3.6 Electrical supply ........................................................ 9

4 Assembly ........................................................... 10

4.1 Scope of delivery ....................................................... 10

4.2 Accessories ................................................................. 10

4.3 Installation site .......................................................... 10

4.4 Dimension drawing and

connection dimensions ............................................ 11

4.5 Required minimum gaps/

installation clearances ............................................. 12

4.6 Using the installation template .............................. 12

4.7 Mounting the boiler .................................................. 12

4.8 Removing/attaching the front casing................... 13

5 Installation ......................................................... 13

5.1 Heating mode ............................................................. 14

5.2 Cylinder charging mode .......................................... 15

5.3 Heating mode and cylinder charging mode ....... 16

5.4 Gas connection .......................................................... 17

5.5 Heating connection ................................................... 17

5.6 Expansion relief valve (safety group), heating

installation .................................................................. 18

5.7 Condensate drainage pipework ............................. 18

5.8 Electrical connection ................................................ 19

5.8.1 Mains connection ...................................................... 19

5.8.2 Connecting controllers ............................................. 20

5.8.3 Connecting a low loss header sensor................... 21

5.8.4 Additional relay (grey plug on the PCB) and

VR40 - "2 in 7“ multifunctional module .............. 21

5.8.5 Wiring diagrams ......................................................... 22

6 Start-up .............................................................. 24

6.1 Water circulation system ......................................... 24

6.2 Filling the system ...................................................... 24

6.2.1 Preparation of heating water ................................. 24

6.2.2 Filling and bleeding from the heating side ......... 25

6.2.3 Filling the condensate siphon ................................ 26

6.3 Checking the gas setting ......................................... 26

6.3.1 Checking for tightness of the flue gas

installation and flue gas recirculation.................. 27

6.3.2 Checking the gas flow rate ..................................... 27

6.3.3 Checking the gas inlet working pressure ............ 28

6.4 Checking the appliance function ........................... 28

6.4.1 Heating ........................................................................ 29

6.4.2 Cylinder charging ...................................................... 29

6.5 Handing over the boiler to the operator ............. 29

7 Adapting the boiler to the heating

installation ......................................................... 31

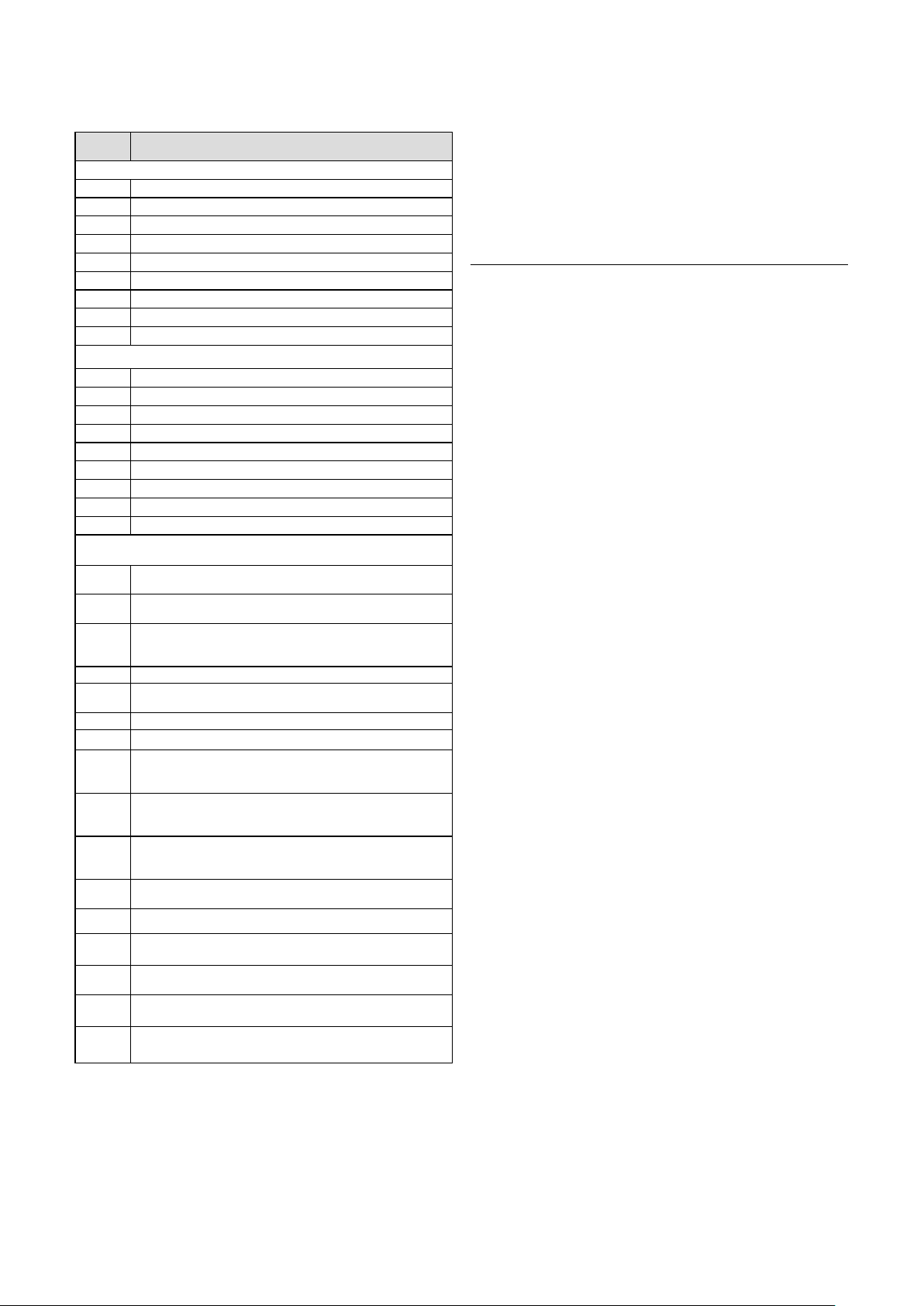

7.1 Selection and setting of parameters .................... 31

7.2 Overview of adjustable system parameters ....... 31

7.2.1 Setting the heating partial load............................. 33

7.2.2 Setting of pump overrun and pump operating

mode ............................................................................. 33

7.2.3 Setting of maximum flow temperature ................ 33

7.2.4 Setting of burner anti-cycling time ....................... 33

7.2.5 Determination of maintenance

interval/maintenance display ................................. 34

8 Inspection and maintenance............................ 35

8.1 Inspection and maintenance intervals ................. 35

8.1.1 General inspection and maintenance

instructions ................................................................. 35

8.1.2 Safety instructions .................................................... 36

8.1.3 Checking the CO

8.1.4 Adjusting the CO

concentration ........................... 36

2

concentration (or the air

2

ratio) ............................................................................. 37

.8.1.5 Inspection and maintenance work steps ............. 38

8.2 Filling/draining the boiler and heating

installation .................................................................. 39

8.2.1 Filling the boiler and the heating installation .... 39

8.2.2 Draining of the boiler ............................................... 39

8.2.3 Draining the entire system...................................... 39

8.3 Maintenance of the compact thermal module ... 39

8.3.1 Dismounting the compact thermal module ........ 39

8.3.2 Cleaning the heat exchanger ................................. 40

8.3.3 Checking the burner ................................................. 40

8.3.4 Installing the compact thermal module ............... 41

8.4 Cleaning the condensate siphon ........................... 41

8.5 Cleaning the condensate ducts ............................. 42

8.6 Cleaning the air separation system ...................... 42

8.6.1 Cleaning the filter ..................................................... 42

8.6.2 Cleaning the air separator ...................................... 42

Installation and maintenance instructions ecoTEC 0020029172_042

Contents

Notes on the documentation 1

8.7 Checking the charge pressure of the external

expansion vessel ........................................................ 42

8.8 Checking gas connection pressure

(gas inlet working pressure) ................................... 43

8.9 Checking the CO

8.10 Test operation ............................................................ 43

9 Troubleshooting ................................................. 43

9.1 Diagnostics .................................................................. 43

9.1.1 Status codes ............................................................... 43

9.1.2 Diagnosis codes ......................................................... 44

9.1.3 Fault messages........................................................... 47

9.1.4 Fault memory ............................................................. 47

9.2 Check programs ......................................................... 49

9.3 Resetting parameters to factory settings ........... 49

10 Replacing components ..................................... 50

10.1 Safety instructions .................................................... 50

10.2 Replacing the burner ................................................ 50

10.3 Replacing the fan or the gas valve ...................... 50

10.4 Replacing the heat exchanger ............................... 51

10.5 Replacing PCB and display ..................................... 52

11 Vaillant Service ................................................. 52

12 Recycling and disposal ..................................... 52

12.1 Boiler ............................................................................ 52

12.2 Packaging .................................................................... 52

13 Technical data ................................................... 53

Benchmark Commissioning and Servicing Section . 54

concentration .......................... 43

2

Other applicable documents and service auxiliaries

• Always observe all installation instructions for

structural parts and components of the system when

installing the ecoTEC VU. These installation

instructions are enclosed with the various system

components as well as additional components.

• Also observe all the operating instructions included

with the system components.

Auxiliary service equipment:

The following test and measuring equipment is required

for inspection and maintenance:

measuring instrument

– CO

2

– U tube manometer or digital

The manuals for any accessories and controllers used

also apply.

1.1 Storage of documents

Please pass on these installation and maintenance

instructions and all other applicable documents to the

operator of the installation who is responsible for

keeping these documents for future reference when

required.

1.2 Safety instructions and symbols

Please observe the safety instructions in this manual for

the installation of the appliance!

The symbols used in the manual are explained below:

Danger!

d

Immediate risk of serious injury or death!

1 Notes on the documentation

The following instructions are intended to help you

throughout the entire documentation.

Further documents apply in combination with this

installation and maintenance manual.

We accept no liability for any damage caused by

non-observe these instructions.

Danger!

e

Danger of death by electric shock!

Danger!

H

Danger of burning or scalding!

Caution!

a

Potentially dangerous situation for the product

and environment!

Note!

h

Useful information and instructions.

• Symbol for a necessary task

1.3 Validity of the instruction manual

These installation instructions apply exclusively to the

boiler with the following part number:

Type designation Article number

ecoTEC VU GB 466/4-5 H 00 1000 4139

Table 1.1 Type designation and article number

The article number of the boiler can be found on the

identification plate.

3Installation and maintenance instructions ecoTEC 0020029172_04

2 Description of the boiler

2 Description of the boiler

2.1 Design

15

1

2

14

13

12

10

3

4

5

6

11

7

9

Fig. 2.1 Functional components

Legend:

1 Connection for the air/flue gas duct

2 Heat exchanger

3 Compact thermal module

4 Flow rate sensor

5 Fan

6 Water pressure sensor

7 Pump

8 Connection for expansion vessel

9 Connection for expansion relief valve

10 Electronic box

11 Air separation system

12 Automatic air vent

13 Gas valve

14 Ignition electrode

15 Air intake pipe

Note!

h

When using accessories observe the minimum

gaps/mounting clearances (see Chapter 4.5).

Installation and maintenance instructions ecoTEC 0020029172_044

8

2.2 Type summary

Description of the boiler 2

Safety instructions and regulations 3

Boiler type Designated country

ecoTEC VU GB 466/4-5 H GB (Great Britain)

Table 2.1 Type summary

2.3 CE label

The CE label shows that the products comply with the basic requirements of all applicable directives as stated on the identification plate.

The declaration of conformity can be viewed at the manufacturer's site.

2.4 Benchmark

Note!

h

Vaillant Ltd. supports the Benchmark Initiative.

You will find the Benchmark Logbook on the

last pages of this instruction manual. It is very

important that this document be filled out properly when installing, commissioning and handing-over to the operator of the installation.

(designation in accordance with ISO 3166)

IE (Eire)

Category of permit Type of gas Nominal heat output range P

II

2H3P

(kW)

Natural gas H - G 20 - 20

mbar

Propane - G 31 - 37 mbar

The use of the product in vehicles, such as mobile

homes and caravans, is not classed as intended use.

Units that are not classed as vehicles are those that are

installed in a fixed and permanent location and that do

not have any wheels (known as "fixed installation").

Any other use that is not specified in these instructions,

or use beyond that specified in this document, shall be

considered improper use. Any direct commercial or

industrial use is also deemed to be improper.

The manufacturer/supplier is not liable for any claims or

damage resulting from improper use. The user alone

bears the risk.

Caution!

a

Improper use of any kind is prohibited.

12.3 – 44.1 (80/60 °C)

12.5 – 45.0 (60/40 °C)

12.9 – 46.4 (50/30 °C)

13.3 – 47.7 (40/30 °C)

2.5 Intended use

There is a risk of injury or death to the user or others, or

of damage to the product and other property in the

event of improper use or use for which it is not intended.

The product is intended as a heat generator for closed

hot water central heating installations and for hot water

generation. The products referred to in this manual must

only be installed and operated in conjunction with the

accessories listed in the associated flue pipe installation

manual.

Intended use includes the following:

- observance of accompanying operating, installation

and servicing instructions for Vaillant products as well

as for other parts and components of the system

- installing and fitting the product in accordance with

the product and system approval

- compliance with all inspection and maintenance condi-

tions listed in the instructions.

2.6 Identification plate

The data badge of the Valliant ecoTEC is attached at the

factory to the bottom of the boiler.

3 Safety instructions and regulations

3.1 Safety instructions

3.1.1 Installation and setting

Installation, adjustments and maintenance and repairs to

the boiler may only be carried out by a recognised

skilled trade company.

Caution!

a

To tighten or loosen screw connections, only

use suitable open-ended spanners (do not use

pipe spanners, extensions, etc.).

Improper use or unsuitable tools can cause

damage, such as gas or water leaks.

3.1.2 Gas odour

If you smell gas, the following safety instructions must

be observed:

• Open doors and windows wide, provide for ventilation,

stay out of rooms where smell of gas is present!

• Avoid naked flames, do not smoke, do not use pocket

lighters!

5Installation and maintenance instructions ecoTEC 0020029172_04

3 Safety instructions and regulations

• Do not use electric switches, plugs, doorbells,

telephones and other communication systems in the

building!

• Close gas meter isolator device or main isolator

device!

• Warn other building residents, but do not ring

doorbells!

• Vacate the building!

• If a gas leak is audible, immediately leave the building,

prevent others from entering the building, notify the

police and fire brigade from outside the building!

• Notify the gas supply company or National Grid Transco 0800 111999 by telephone from outside the building!

3.1.3 Changes to the surroundings of the boiler

Changes may not be made to the following equipment:

– the heating appliance,

– gas, supply air, water and power lines– flue gas

removal system,

– drain line and expansion relief valve for heating water,

– constructional conditions that could affect the

operational reliability of the boiler.

3.1.4 Important information regarding

propane-fired appliances

Bleeding the liquid gas tank when installing the system:

before installing the appliance, make sure that the gas

tank has been bled. The liquid gas supplier is responsible

for proper ventilation of the tank. Ignition problems can

result if the tank is not bled properly. In such cases, first

contact the person in charge of filling the tank.

Note!

h

Also observe the information on conversion to

liquid gas in Chapter 6.3 of this manual.

Caution!

a

If the incorrect type of gas is used this cause

ignition and combustion noise and fault

shutdowns!

Only use propane gas G 31.

3.2 General requirements

3.2.1 Related documents

The installation of the boiler must be in accordance with

the relevant requirements of Gas Safety

(Installation and Use) Regulations 1998, Health and

Safety Document No. 635 (The Electricity at Work

Regulations 1989), BS7671 (IEE Wiring Regulations) and

the Water Supply (Water Fitting) Regulations 1999, or

The Water Bylaws 2000 (Scotland). It should also be in

accordance with the relevant requirements of the Local

Authority, Building Regulations, The Building

Regulations (Scotland). The Building Regulations

(Northern Ireland) and the relevant recommendations of

the following British Standards:

BS 6700: Services supplying water for domestic use

within buildings and their curtilages.

BS 6798: Specification for installation of gas fired

boilers not exceeding 60 kW input.

BS 6891: Specification for installation of low pressure

gas pipework up to 28 mm (R1) in domestic

premises (2

BS 7593: Treatment of water in domestic hot water

central heating installations.

Institute of Gas Engineers Publication IGE/UP/7/1998:

„Guide for gas installations in timber framed housing”

BS. 5482 Pt. 1 Domestic butane and propane gas

burning installations.

IGE/UP1 Soundness testing and purging of industrial

and commercial gas installation.

IGE/UP2 Gas installation pipework, boosters and

compressors on industrial and commercial

premises. IGE/UP10 Installation of gas

appliances in industrial and commercial

premises.

BS. 6644 Installation of gas fired hot water boilers of

rated inputs between 60 kW and 2 MW

nd

and 3rd family gases).

(2

BS. 5449 Forced circulation hot water central heating

installations for domestic premises. Note:

only up to 45 kW.

BS. 6880 Low temperature hot water heating

installations

of output greater than 45 kW.

Part 1 Fundamental and design

considerations.

Part 2 Selection of equipment.

Part 3 Installation, commissioning and

maintenance.

BS. 4814 Specification for: Expansion vessels using an

internal diaphragm, for sealed hot water

heating installations.

BS. 5440 Installation and maintenance of flues and

ventilation for gas appliances of rated input

not exceeding 70 kW net (1st, 2

family gases).

Part 2 Specification for installation of flues.

Part 3 Specification for installation and

maintenance of ventilation for gas

appliances.

3.2.2 Installation site

The location chosen for the boiler must permit the

provision of a satisfactory flue termination. The location

must also provide adequate space for servicing and air

circulation around the boiler. The boiler may be installed

in any room, although particular attention is drawn to

the requirements of BS 7671 (IEE Regulations), the

electrical provisions of the Building Regulations

(Scotland) and in IE the current edition of IS 813 and the

current ETCI rules, in respect of the installation of a

boiler in a room containing a bath or shower.

nd

family gas).

nd

and 3rd

Installation and maintenance instructions ecoTEC 0020029172_046

Safety instructions and regulations 3

Note!

h

Where a room sealed boiler is installed in a

room containing a bath or shower, any electrical

switch or boiler control utilising mains

electricity should be so situated that it cannot

be touched by a person using the bath or

shower.

In case of installation of the boiler in an unusual

location, special procedures may be necessary and

BS 5546 and BS 6798 give detailed guidance on this

aspect. The boiler must be mounted on a flat, vertical

wall, which must be sufficiently robust to take the

weight of the boiler.

The boiler may be installed on a combustible wall,

subject to the requirements of the Local Authorities and

Building Regulations. A compartment used to enclose

the boiler must be designed and constructed specifically

for this purpose. (An existing cupboard or compartment

may be used provided that it is modified for the

purpose). Details of essential features of

cupboard/compartment design including airing cupboard

installations are given in BS 6891. In IE the current

edition of IS 813.

Note!

h

If the boiler is to be installed in a timber framed

building, it should be fitted in accordance with

"IGE/UP/7 Edition 2 Gas installations in timber

framed and light steel framed buildings".

Only for commercial appliances:

For installations in cascade arrangement using the

appliance type B23p a common non-Vaillant flue system

serving more than one appliance shall be used. The

requirements of the flue installation instructions must

be met.

3.3.1 Standard 125 mm air/flue gas duct

A concentric air/flue gas duct which has an outside

diameter of 125 mm and can be extended up to a length

of 21 m is available.

You can also get a vertical system. For more

information refer to the installation manual for the

air/flue gas duct.

1103

15

70

70

Fig. 3.1 Item No. 303 209

3.2.3 Gas supply

The gas supplier should ensure the availability of

sufficient gas flow rate. A gas meter may only be

connected to the service pipe by the supplier of gas or

their contractor. An existing meter should be checked to

ensure that it is capable of passing the rate of gas

supply required. Installation pipes should be fitted in

accordance with BS 6891, in IE in accordance with the

current issue of IS 813. Pipework from the meter to the

boiler must be of an adequate size. Do not use pipes of

a smaller size than the boiler gas connection. The

complete installation must be tested for lacks of

tighness and bled as described in BS 6891.

3.3 Air/flue gas duct

Danger!

d

Vaillant appliances are only system-certified if

genuine Vaillant air/flue gas ducts are used.

Only use genuine Vaillant air/flue gas ducts.

Malfunctions can occur if you use other

accessories. These may result in damage and

injury. You will find a list of genuine air/flue gas

ducts in the Vaillant installation manual for

air/flue gas ducts. The CE mark is valid only if

the appliance is operated with Vaillant air/flue

gas ducts.

1530

880

70

Fig. 3.2 Item No. 303 200

3.3.2 Flue termination

The following details refer to both flue systems.

a. The terminal must be positioned such that the

products of combustion can disperse freely at all

times.

b. A plume of water vapour will sometimes be visible

from the flue terminal. Positions where this could be a

nuisance should be avoided.

c. If the terminal is fitted less than 2 m above a balcony,

above ground or above a flat roof to which people

have access then a suitable terminal guard must be

provided and fitted (contact Tower Flue Components,

Tonbridge, TN9 1TB).

7Installation and maintenance instructions ecoTEC 0020029172_04

7

3 Safety instructions and regulations

Note!

h

Vertical flues must not terminate within

600 mm of an openable window, air vent or any

other ventilation terminal.

P

I

F

J

Fig. 3.3 Termination of the air/flue gas duct

L

Q

B

G

Q

C

A

I

I

The flue system shall be so placed or shielded as to

prevent ignition or damage to any part of the building.

Location

Directly below an opening, air brick, opening win-

A

dows, etc.

B Above an opening, air brick, opening window, etc. 300 mm

Horizontally to an opening, air brick, opening

C

window, etc.

Below temperature-sensitive building compo-

D

nents e.g. plastic gutters, soil pipes or drain pipes

E Below eaves 200 mm

F Below balconies or car port roof 200 mm

G From a vertical drain pipe or soil pipe 150 mm

H From an internal or external corner 200 mm

I Above ground, roof or balcony level 300 mm

J From a surface facing the terminal 600 mm

K From a terminal facing the terminal 1200 mm

From an opening in the car port (e.g. door, winL

dow) into the dwelling

M Vertically from a terminal on the same wall 1500 mm

N Horizontally from a terminal on the same wall 300 mm

O From the wall on which the terminal is mounted N/A

P From a vertical structure on the roof N/A

Q Above intersection with roof 300 mm

Table 3.1 Position of the termination in a fan-assisted air/flue

gas duct

Minimum

dimensions

300 mm

300 mm

75 mm

1200 mm

D, E

O

H

H

MM

N

Q

N

K

Note!

h

In addition, the terminal should not be nearer

than 300 mm to an opening in the building

fabric formed for the purpose of accommodating

a built–in element such as a window.

BS 5440–1 It is recommended that the fanned flue

terminal should be positioned as follows:

a) at least 2 m from an opening in the building directly

opposite, and

b) so that the products of combustion are not straightly

directed to discharge across a boundary.

1) Dimensions D, E and F:

These clearances may be reduced to 25 mm without

affecting the performance of the boiler. In order to

ensure that the condensate plume does not affect

adjacent surfaces the terminal should be extended as

shown in Fig. 3.3.

2) Dimension H:

This clearance may be reduced to 25 mm without

affecting the performance of the boiler. However, in

order to ensure that the condensate plume does not

affect adjacent surfaces a clearance of 300 mm is

preferred. For IE, recommendations are given in the

current edition of IS 813.

Installation and maintenance instructions ecoTEC 0020029172_048

Balcony/eaves

Gutter

Safety instructions and regulations 3

Flue pipe

adequately fixed

Fig. 3.4 Termination of air/flue gas duct under balcony or

eaves

Flue pipe must project

beyond every overhang

3.4 Air supply

Detailed recommendations for air supply are given in

BS 5440: Part 2. It is not necessary to have an air vent

in the room or internal space in which the boiler is

installed.

3.5 Compartment ventilation

The boilers are very high efficiency appliances. As a

consequence the heat loss from the appliance casing

during operation is very low. Compartment ventilation is

required if the flue used is not concentric and air is

supplied from the room or compartment the boiler is

installed in.

3.6 Electrical supply

A 230 V, ~ 50 Hz single phase electricity supply fused to

3 Amp. must be provided in accordance with the latest

edition of BS7671 (IEE Wiring Regulations) and any other

local regulations that may apply. In IE reference should

be made to the current edition of the ETCI rules. The

method of connection to the mains electricity supply

must provide a means of completely isolating the boiler

and its ancillary controllers. Isolation is preferably by

the use of a fused three pin plug and unswitched

shuttered socket outlet, both complying with the

requirements of BS 1363. Alternatively, a 3 Amp. fused

doublepole switch with a 3 mm contact opening on both

poles may be used.

Danger!

Risk of fatal electric shock!

The boiler must be earthed.

9Installation and maintenance instructions ecoTEC 0020029172_04

4 Assembly

4 Assembly

Caution!

a

Flush the heating installation thoroughly before

installing the boiler to remove foreign

substances such as solder and flux residue,

leftover sealant or dirt.

4.1 Scope of delivery

The Vaillant ecoTEC is delivered pre-mounted in a

package unit.

Check that all parts have been delivered and are intact

(see Fig. 4.1 and Table 4.1).

Installation instructions

ecoTEC

Installation instructions

8

7

6

ecoTEC

Installation instructions

ecoTEC

1

2

3

4.2 Accessories

Optional accessories for use in conjunction with the

installation and operation of the boiler are available.

4.3 Installation site

Please note the safety instructions below before

choosing where to install the boiler:

Caution!

a

Do not install the boiler in rooms prone to frost.

In rooms with aggressive steam or dust, the

boiler must be operated room sealed!

When choosing the installation site and while operating

the boiler, make sure that the combustion air is

technically free of chemical substances containing

fluorine, chlorine, sulphur etc. Sprays, solvents and

cleaning agents, paints, adhesives etc. contain these

kinds of substances, which may lead in the worst case to

corrosion, also in the flue system, during open flued

operation of the boiler.

Using an old chimney of an oil fired boiler may also

cause this problems.

The boiler must be operated room sealed, particularly in

hairdressing salons, carpenter‘s shops, or paint shops

and cleaning companies. Otherwise, a separate

installation room is required to guarantee that the

combustion air supply is technically free of the

substances mentioned above.

5

Fig. 4.1 Scope of delivery

Position Number Name

1 1 Hanging bracket

2 1 Boiler

Connection accessories:

3

4

5

6 1 Condensate drainage pipework

71

81

Table 4.1 Scope of delivery

- Gas isolation valve

1

- Drain valves

2

- Expansion relief valve

1

- Seals (without Fig.)

Bag containing hardware (assembly kit):

- 2 wood screws

- 2 wall plugs 10 x 60 mm

- 2 washers

- 1 seal

- 1 crimp connection

Bag with printed documents:

– Installation and maintenance instructions

– Operating manual

– Installation instructions, air/flue gas duct

system

- Installation template

- Changeover sign for liquid gas

- Miscellaneous stickers

2 x

Select boiler position

4

Refer to Chapter ‘Installation site’ for information

regarding the siting of the boiler. In general the boiler

must be positioned such that:

• There is sufficient space around the boiler for service

and maintenance.

• The boiler can be correctly flued, i.e. the flue terminal

position is sited in accordance with these instructions

and the air/flue duct can be installed in accordance

with the flue installation instructions supplied.

• All necessary pipework can be connected, including

the expansion relief valve and condensate drain.

Installation and maintenance instructions ecoTEC 0020029172_0410

4.4 Dimension drawing and

connection dimensions

Assembly 4

800

480

Ø 80/125

1

A

49

2

450

190

Ø20, R1

30

8

7

Fig. 4.2 Connection dimensions in mm

Legend:

1 Flue gas connection, 80/125 mm

diameter, dimension A (hanging bracket – centre of air/flue gas

pipe) with 87° elbow: 253 mm

2 Hanging bracket

3 gas pipe, 20 mm diameter, gas connection R1“

4 Connection for condensate drainage pipework

5 Connection for expansion vessel

6 Connection for heating return

7 Connection for heating flow

8 Connection for expansion relief valve

9 Filling device (combined filling and emptying valve)

Rp 1 Rp 1

1

/

G 1

2

R 1/

2

100

152 152

100

G 1

R 1

3

4

5

1

/

2

6

48

100

9

5, 8

Note!

h

When using accessories observe the minimum

gaps/mounting clearances (see Chapter 4.5).

11Installation and maintenance instructions ecoTEC 0020029172_04

3

75

175

270

25

44

1

2

4 Assembly

4.5 Required minimum gaps/

installation clearances

For the installation/assembly of the boiler as well as for

carrying out future maintenance tasks, you need the

minimum gaps and installation clearances given below:

350

250

4.7 Mounting the boiler

Caution!

a

When assembling the boiler make sure that the

fixing point has a sufficient load-bearing

capacity. Also take the condition/nature of the

wall into account.

Fig. 4.3 Required minimum gaps/installation clearances

It is not necessary to ensure a particular clearance

between the boiler and combustible materials or

components as the temperature of the boiler will always

Fig. 4.4 Mounting the boiler

be less than the maximum permissible temperature of

85 °C at its rated heating output. You need a minimum

of 600 mm clearance in front of the boiler to enable

easy access for servicing. This may be provided by an

openable door.

• Mount the hanging bracket (1) on the wall using the

wall plugs and screws (2) provided with the boiler.

• Hang the boiler (3) on the hanging bracket from

above using the suspension bracket.

4.6 Using the installation template

Only use the assembly template provided to mount the

boiler.

• Align the installation template vertically and fix it to

the wall.

• Mark the positions of the drill holes for the hanging

bracket and also the position of the wall opening for

the air/flue gas duct on the wall.

• Remove the assembly template from the wall.

• Drill 2 holes for the hanging bracket in the wall, each

with a diameter of 8 mm.

• If necessary cut the aperture in the wall for the air/

flue gas duct.

Installation and maintenance instructions ecoTEC 0020029172_0412

Assembly 4

Installation 5

4.8 Removing/attaching the front casing

2

1

Fig. 4.5 Removing the front casing

To dismount the front casing of the boiler, proceed as

follows:

• Unfasten the screw (1) on the bottom of the boiler.

• Push in both retaining clips (2) on the bottom of the

boiler so that the front casing is released.

• Pull the casing forwards by its bottom edge and lift

the casing up and off.

To mount the front casing of the boiler, proceed

as follows:

• Place the casing thus on the upper boiler edge that

casing and boiler edges engage.

• Push the casing onto the boiler so that both retaining

clips (2) engage with the casing.

• Fix the casing by tightening the screw (1) on the

bottom of the boiler.

5 Installation

Danger!

d

Danger of injury to persons and/or material

damage due to improper installation!

The Vaillant ecoTEC boiler may only be installed

by a recognised skilled trade company. who also

assumes the responsibility for proper installing

and initial start-up of the boiler.

Caution!

a

The ecoTEC VU 466 must be used with a

suitably sized low loss header.

Selection of the low loss header

The low loss header uncouples the boiler from the

heating installation. A sufficiently large water volume is

constantly supplied through the boiler via the low loss

header in conjunction with the boiler circulation pump.

It acts as a neutral point in the system and has minimal

hydraulic resistance, therefore the boiler circulation

pump does not affect the circuit pumps and vice-versa.

A suitable WH type low loss header can be chosen from

Table 5.1.

Temperature spread of

heating installation

Output of heating

installation

Stand-alone boiler WH 95 WH 40 WH 40

Two cascade

arrangement

Three cascade

arrangement

Four cascade

arrangement

Table 5.1 Selection of the low loss header

Note!

h

We strongly recommend the installation of a

suitably sized quality dirt filter in the return

pipe work to the low loss header (not to the

boiler!) particularly in the case of old systems.

This will help to prevent any system water

contamination from entering and blocking the

boiler and producing an additional high pressure

loss.

10 K 15 K 20 K

WH 160 WH 95 WH 95

WH 280 WH 160 WH 160

WH 280 WH 160 WH 160

No electrical accessories are required in order to use a

low loss header. Simple systems can be connected

directly inside the electronic box.

13Installation and maintenance instructions ecoTEC 0020029172_04

5 Installation

Model Article

number

WH 40 306720 1

WH 95 306721 2" BSP (f) 155 155 750 155/155 470 540 n/a 8

WH 160 306726 DN65 520* 120 1350 220/220 900 900 300 12

WH 280 306725 DN80 600* 160 1390 260/260 930 930 300 21.5

Table 5.2 Low loss headers dimensions

All dimensions in mm

* = distance between flanges

Connection

Sizes

1

1

/4" BSP (f) 115 115 500 115/115 280 340 n/a 3.5

Header

width

A

Header

depth

B

To ta l

height

C

Insulation

dimensions

To boilerDTo heating

circuit

E

Height from

floor

F

Safety devices

• The outlet of the expansion relief valve must be

suitably terminated in accordance with BS 6798 or

BS 6644.

• The boiler is suitable for connection to plastic

centralheating pipes. In this connection preferably

1.5 m copper pipes should be used prior to the

transition to the plastic pipes for the connection to

the boiler.

• Should a system be found to include non-oxygen

barrier pipe then it is essential that a plate heat

exchanger be installed in between the boiler and the

non-oxygen barrier pipe, thus preventing corrosion. It

is essential that the boiler and the system have

provision for water make up and expansion.

Maximum

volume

flow m3/hr

Fig. 5.1 Low loss header

For more detailed information on examples of systems

and system equipment contact your Vaillant sales

support point.

Caution!

a

The following system diagrams are schematic

representations. They cannot be regarded as a

substitute for professional planning! The

system diagrams do not include the isolator and

safety devices that are required to carry out a

professional installation. Observe the applicable

standards and guidelines.

The boiler can be installed in three different

configurations:

• heat only,

• cylinder only, and

• heating and cylinder.

5.1 Heating mode

In case of only one heating circuit to be operated

downstream of the low loss header, this one can directly

be controlled by the ecoTEC.

A suitable pump can be selected and installed

downstream of the low loss header. You can select a

pump that fits to your system (4 m or 6 m pump or

electronically controlled pump). In case of systems with

multiple circuits please pay additional attention to the

control system accessories.

Installation and maintenance instructions ecoTEC 0020029172_0414

Installation 5

Hydraulic schematic drawing:

Heating circuit connection using low loss header

4

1

3

2

Fig. 5.2 Heating circuit connection using low loss header

Legend:

1 Boiler with internal pump

2 Low loss header

3 External heating pump

4 Consumer (e.g. heating circuit)

The charging circuit connection downstream of the low

loss header enables the choice of an individual cylinder

size and of a charging pump.

Note!

h

Observe that non-return valves or mixer

circuits may be required in order to eliminate

cross-flow to other circuits or the effects of

high temperatures from the charging circuit.

Hydraulic schematic drawing:

Cylinder priority switching via low loss header

4

1

2

3

98

X14

X6

Fig. 5.3 Electrical connection for heating pump downstream of

the low loss header

X18

543NL

X11

X13

1

The settings for the internal pump are made at the

factory. The pump output does not require adjustment.

Use the grey ProE plug to establish the electrical

connection with the external heating pump.

To assign the "external heating pump" function to the

plug (1) (additional relay) diagnosis point "d.26" in the

nd

2

diagnosis level must be set to the value "2", see

Chapter 9.1.2.

The low loss header ensures, in conjunction with the

boiler circulation pump, that a sufficiently high minimum

quantity of water is always circulating through the

boiler.

5.2 Cylinder charging mode

The electronics of the ecoTEC are designed in such a

way that one cylinder charging circuit and one heating

circuit can be connected directly without the need for

accessories.

Fig. 5.4 Cylinder priority switching via low loss header

Legend:

1 Boiler with internal pump

2 Low loss header

3 External heating pump

4 Consumer (e.g. charging circuit)

98

X14

X6

Fig. 5.5 Electrical connection for cylinder charging pump

1

X18

543NL

X11

X13

Use the mounted ProE plug (1) to establish the electrical

connection for the cylinder charging pump.

The pink plug-in location X6 (1) on the PCB is reserved

for the cylinder charging pump. It is not necessary to do

settings at any diagnosis point.

15Installation and maintenance instructions ecoTEC 0020029172_04

5 Installation

The low loss header ensures, in conjunction with the

boiler circulation pump, that a sufficiently high minimum

quantity of water is always circulating through the

boiler.

5.3 Heating mode and cylinder charging mode

Note!

h

Also observe Chapters 5.1 and 5.2 of this

manual.

The combination of heating mode and cylinder charging

mode of the boiler can not be equated with either

heating mode or cylinder charging mode.

Other hydraulic relationships must be taken into

account in order to ensure faultless operation.

The boiler is uncoupled from the consumer circuits by

the low loss header. This means that the circuits

downstream of the low loss header can be designed

according to individual requirements (pump dimension,

cylinder position).

Hydraulic schematic drawing:

Cylinder priority switching and heating circuit via low

loss header

One direct heating circuit and one hot water cylinder

(including charging pump and non-return valve) can be

connected downstream of the low loss header to the

ecoTEC boiler without additional equipment. If additional

heating circuits are required this can be achieved with

the use of optional controllers and hydraulic accessories

(e.g. VRC630). The available pump head from the boiler

circulation pump is sufficient to pump water around the

boiler circuit between the boiler and low loss header. All

heating circuits and hot water cylinder configurations

can be connected downstream of the low loss header.

Note!

h

Observe that non-return valves or mixer

circuits may be required in order to eliminate

cross-flow to other circuits or the effects of

high temperatures from the charging circuit.

X14

98

1

X18

543NL

X13

2

4

1

3

2

Fig. 5.6 Cylinder priority switching and heating circuit via low

loss header

Legend:

1 Boiler with internal pump

2 Low loss header

3 External heating pump

4 Consumer (e.g. heating circuit)

5 External cylinder charging pump

6 Cylinder

5

6

X11

X6

Fig. 5.7 Electrical connection for cylinder charging pump and

external heating pump

Legend:

1 Plug-in location for cylinder charging pump

2 Plug-in location for external heating pump

Use the relevant mounted ProE plug to perform the

electrical connection.

The pink plug-in location X6 (1) on the PCB is reserved

for the cylinder charging pump. It is not necessary to do

settings at any diagnosis point.

To assign the "external heating pump" function to the

grey plug (2) (additional relay) the value "2" must be

specified at diagnosis point "d.26" in the 2

nd

diagnosis

level, see Chapter 9.1.2.

Installation and maintenance instructions ecoTEC 0020029172_0416

Installation 5

5.4 Gas connection

Danger!

d

Danger of injury to persons and/or material

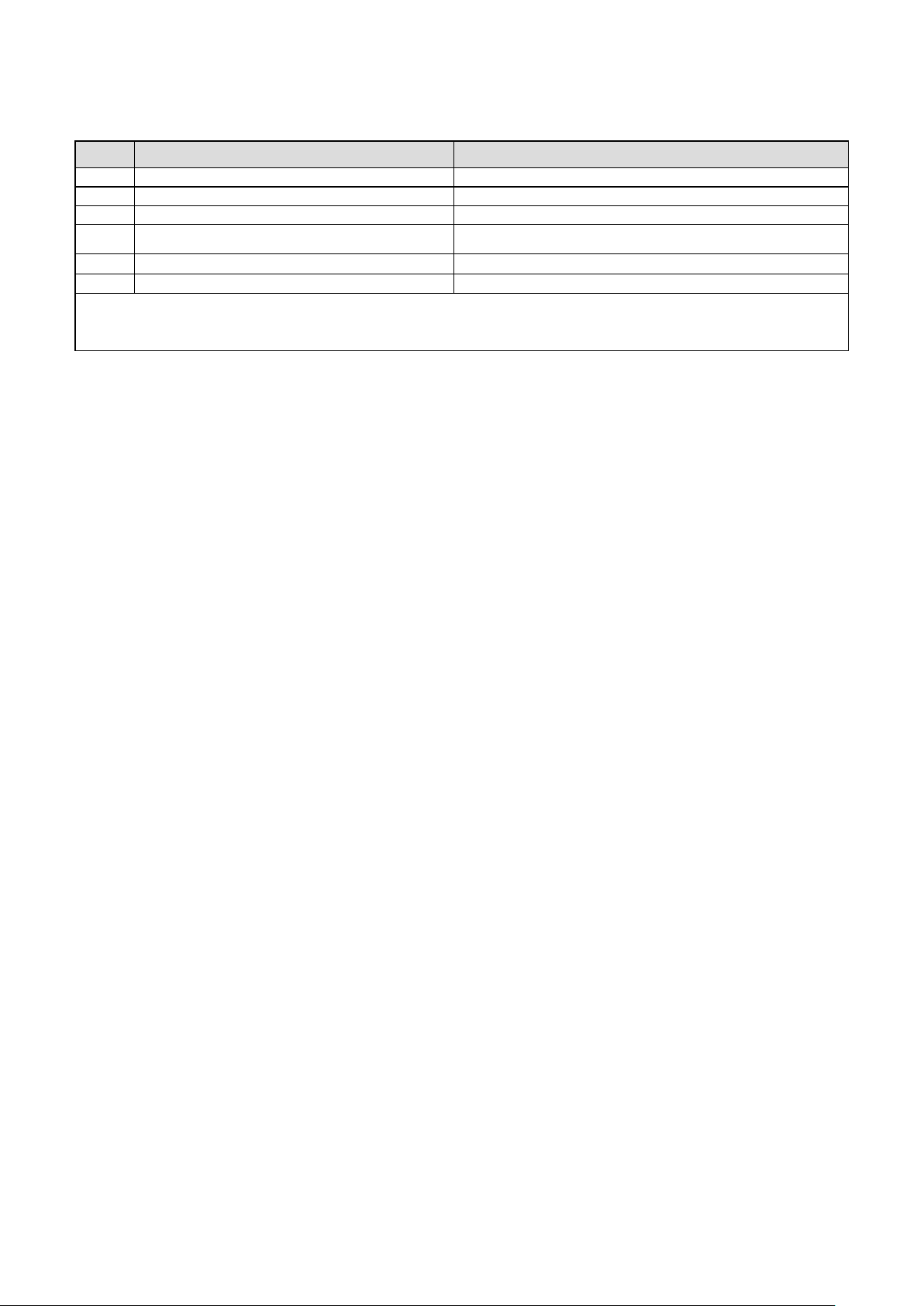

damage due to improper installation!

The Vaillant ecoTEC boiler may only be installed

by a recognised skilled trade company who also

assumes the responsibility for proper

installation and initial start-up of the boiler. The

legal directives and the local regulations for gas

supply companies must be observed.

Caution!

a

Ensure strainless assembly of the gas pipes to

avoid leakages!

Note!

h

Maintain the same gas pipe dimension all the

way to the boiler and avoid reducing the dimension downstream of the gas meter.

Caution!

a

The gas valve may be damaged if the test

pressure or operating pressure is exceeded!

You must check the tightness of the gas valve

only using a maximum pressure of 110 mbar!

5.5 Heating connection

Caution!

a

Ensure strainless assembly of the supply lines

to avoid leakages in the heating installation!

The boiler is connected to the heating flow and return

via service valves.

1

Fig. 5.8 Fitting the gas connection

The boiler must be connected to your gas pipe via a gas

isolation valve.

• Screw the boiler‘s gas supply pipe (1) gas-tight with

the gas isolation valve (5, see Fig. 5.9). To do this, use

the R3/4 crimp connection supplied with the boiler.

This is also suitable for the connection of a R3/4 gas

isolation valve.

• Inspect the gas connection for leakage.

1

5

Fig. 5.9 Heating connection

• Fit the flow, return and gas isolation valves (3, 4, 5)

including the seals onto the flow, return and gas pipes.

Do not overtighten and ensure the joints are checked

for leaks after fitting.

Caution!

a

It is essential to use the combined filling and

emptying valve (3, Fig. 5.10) in the return for

filling the boiler without fail, as otherwise the

bleeding of the boiler cannot be ensured.

Note!

h

We recommend the use of seals made of a fibrebased material similar to cardboard instead of

materials similar to rubber as the latter can

plastically deform and cause pressure losses.

4

2

3

17Installation and maintenance instructions ecoTEC 0020029172_04

5 Installation

5.6 Expansion relief valve (safety group), heating

installation

bar

1 2 3 4

Fig. 5.10 Fitting the expansion relief valve

The ecoTEC is equipped ex factory with connections for

a safety group:

• Expansion relief valve (1)

• Pressure gauge (2)

• Filling device (combined filling and emptying valve) (3)

• Connection for expansion vessel (4)

As an accessory the expansion relief valve for the

heating installation is delivered with the boiler.

• Install the expansion relief valve (1).

• Fit a sufficiently sized expansion vessel (to be

provided on site) at the designated connection (4).

Danger!

H

Danger of burning and scalding!

The expansion relief valve (1) must be

noticeable! Terminate the line in such a way

that escaping water or steam cannot cause

injury to persons.

Please note that the end of the line must be

visible.

5.7 Condensate drainage pipework

1

2

4

a

3

Fig. 5.11 Condensate drainage pipework

Legend:

a Internal stackpipe

b Internal drainage system

c Gully

d Soakaway

b

3

c

6

5

d

7

The ecoTEC boilers are equipped with a usual

condensate collector from which the condensate is

continuously removed via the drain pipe.

• Connect the condensate discharge (1) of the boiler to

a condensate drainage pipework (2) which has a

minimum internal diameter of 19 mm (22 mm outside

diameter for all external pipes) and should be made

from an acid-resistant material (e.g. plastic overflow

pipe).

Note!

h

The condensate drainage pipework connected to

the condensate discharge of the boiler must

have a fall throughout its entire length (45 mm

per metre) and should be installed and

connected within the building to prevent

freezing.

Caution!

a

Risk of damage!

The line should be terminated in such a way

that cables or other electrical components

cannot be damaged.

The condensate drainage pipework must terminate in a

suitable location, e.g.:

a) Preferably the condensate drainage pipework should

run and terminate internally to the house soil and

vent stack (at least 450 mm above the invert of the

stack). A siphon giving a water seal of at least 75 mm

(3) (built into the boiler) should be incorporated into

the pipe run, and there must be an air break (4) in the

condensate drainage pipework upstream of the

siphon.

Installation and maintenance instructions ecoTEC 0020029172_0418

Installation 5

The connection to the stack should not be made in a

way that could cause cross flow into any other branch

pipe, or from that branch pipe into the condensate

drainage pipework. This can be achieved by

maintaining an offset between branch pipes of at least

110 mm on a 100 mm diameter stack and 250 mm on a

150 mm diameter stack.

b)connecting into the internal drainage branch (e.g. sink

waste) with an external termination, the condensate

drainage pipework should have a minimum diameter

of 22 mm with no length restriction and should

incorporate a siphon with a 75 mm (3) (built into the

boiler) seal. The connection should preferably be

made down stream of the sink waste siphon. If the

connection is only possible upstream, then an air

break is needed between the two siphons. This is

normally provided by the sink waste.

c)in a gully (5) below grid level (6) and above the water

level. The external pipe length should be kept as short

as possible to minimise the risk of freezing and should

not be more than 3 m.

d)at a soakaway (condensate absorption point) (7). The

external pipe length should not be more than 3 m.

Further information can be obtained from "BS 6798

Specification for installation of gas–fired boilers of rated

input not exceeding 70 kW net“.

Danger!

d

Risk of poisoning due to escaping flue gas!

The condensate drainage pipework must be

linked to the waste water piping by an open

transition as otherwise the internal siphon

could be sucked dry. Before the boiler is

switched on the siphon must have been filled

with water to prevent flue gas from leaking via

the siphon (see Chapter 6.2.3).

5.8 Electrical connection

Danger!

e

Risk of fatal electric shock through contact

with live connections!

The electrical installation may only be carried

out by a recognised skilled trade company.

Always switch off the power supply first and

ensure that it cannot be switched back on

unintentionally. Only after this can the

installation be undertaken. Mains connection

terminals L and N remain live even if the boiler

main switch is turned off!

5.8.1 Mains connection

All electrical work shall be carried out by a heating

engineer and shall comply with BS 7671 (IEE

Regulations).

In IE, reference should be made to the current edition of

the ETCI (Electro-Technical Council for Ireland) rules.

The boiler is supplied for connection to 230 V, ~ 50 Hz

supply fused at 3 A rating. Connection to the mains

supply shall be made via a fused 3 pin plug to an

unswitched shuttered socket, both complying with the

requirements of BS 1363. (Alternatively, connection may

be made via a 3 A fused double pole isolator having a

contact opening of at least 3 mm in all poles and

supplying the boiler and controllers only). The point of

connection to the mains supply must allow complete

electrical isolation of the boiler and its ancillary

controllers. It should be readily accessible and adjacent

to the boiler. A 3 core flexible cord according to

BS 6500 tables 6, 8 or 16 (3 x 0.75 to 3 x 1.5 mm

should be used.

The nominal voltage of the mains must be 230 V; at

mains voltages greater than 253 V and less than 190 V

the functions may be impaired.

2

)

19Installation and maintenance instructions ecoTEC 0020029172_04

987+-

543NL

BUS

5 Installation

4

• Dismantle the supply line over a length of

approximately 2 - 3 cm and strip the insulation off the

wires.

Caution!

a

1

Supplying power to the wrong plug terminals of

the Pro E system can destroy the electronics.

Only connect a 230 Vac live supply to boiler

terminal connections marked LNE.

• Connect the cores to the plug-in locations in the

electronics (L, N and Earth), see Fig. 5.13, using the

2

corresponding ProE plug.

• Close the rear cover of the electronic box until it

3

audibly engages.

• Lift the electronic box up and press the two clips on

the left and right of the box against the side casing of

the boiler until they audibly engage.

• Mount the front casing (see Chapter 4.8).

Fig. 5.12 Opening back wall of the electronic box

987+-

BUS

Fig. 5.13 Example for cable routing

543NL

• Remove the front casing of the boiler (see

Chapter 4.8) and tilt the electronic box (3) forwards

(see Fig. 5.12).

• Unclip the rear cover (2) of the electronic box at the

fastening points (1) and fold it up.

• Use a commercially available mains connection cable.

• Guide the mains connection cable through a cable

duct (4). Use the grommet to seal the opening.

• Then feed the mains connection cable into the

electronic box and cut the line to the correct length.

5.8.2 Connecting controllers

Mount the controllers in accordance with the

corresponding operating and installation manuals.

The required connections to the electronic system of

the boiler (e.g. for external controllers, external sensors

etc.) should be performed as follows:

• Remove the front casing of the boiler (see

Chapter 4.8) and tilt the electronic box (3) forwards

(see Fig. 5.12).

• Unclip the rear cover (2) of the electronic box at the

fastening points (1) and lift it up (see Fig. 5.12)

• Guide the supply lines of the relevant components to

be connected through the cable ducts (4) on the

bottom of the boiler on the left (see Fig. 5.12)

• Then feed the supply lines into the electronic box and

cut the lines to the correct length.

• Dismantle the supply line over a length of

approximately 2 - 3 cm and strip the insulation off the

wires.

• Connect the cores to the corresponding ProE plugs or

plug-in locations of the electronics, as shown in

Fig. 5.13.

Caution!

a

Danger of destroying the electronics!

Do not connect a mains voltage supply to the

following terminals: 7, 8, 9, eBUS (+,-)!

Note!

h

Make sure that the cores are securely fastened

to the screw terminals of the ProE plug.

• If a roomthermostat/timer is not connected, you must

insert a bridge between terminals 3 and 4, if not

already installed. Remove the bridge if you connect a

corresponding room/thermostat timer to terminals

3 and 4.

• If a weather-compensated or room temperature

control system is connected (continuous control

Installation and maintenance instructions ecoTEC 0020029172_0420

connection terminals 7, 8, 9) the bridge between

terminal 3 and 4 must remain inserted.

• Close the rear cover of the electronic box until it

audibly engages.

• Lift the electronic box up and press the two clips on

the left and right of the box against the side casing of

the boiler until they audibly engage.

• Mount the front casing (see Chapter 4.8).

• To choose pump operating mode 1 (running on of

pump) for multi-circuit controllers, change the setting

at diagnosis point "d.18" (pump operating mode) from

3 "intermittent" to 1 "run on" (see Chapter 7.2.2).

Observe that the bridge at the ProE plug must be

removed when connecting a maximum thermostat

(contact thermostat) for underfloor heating.

5.8.3 Connecting a low loss header sensor

The low loss header sensor must either be connected to

the X41/RF according to the connection diagram

(Fig. 5.15) or to the selected controller (see

corresponding operating manual).

Installation 5

5.8.4 Additional relay (grey plug on the PCB) and

VR40 - "2 in 7“ multifunctional module

Additional relay (grey plug on the PCB)

With the ecoTEC it is possible to actuate one additional

component via the additional relay. You can select the

installed components via diagnosis point "d.26" at

diagnosis level 2 (see Chapter 9.1.2).

VR40 - "2 in 7“ multifunctional module

If you wish to connect additional components this can

be done using the Vaillant VR40 - "2 in 7"

multifunctional module.

Note!

h

Please observe the separate manual attached

to the VR40 - "2 in 7" multifunctional module.

Carry out the installation in accordance with the

corresponding operating and installation manual.

To actuate relay 1 at the multifunctional module select

diagnosis point "d.27" at diagnosis level 2, and to

actuate relay 2 select diagnosis point "d.28"

(see Chapter 9.1.2). You can select the following

components here:

1 = circulation pump

2 = external pump

3 = charging pump

4 = vapour extraction hood

5 = external solenoid valve

6 = external fault message

7 = not active

8 = remote control eBUS (not active)

9 = legionella pump (not active)

21Installation and maintenance instructions ecoTEC 0020029172_04

5 Installation

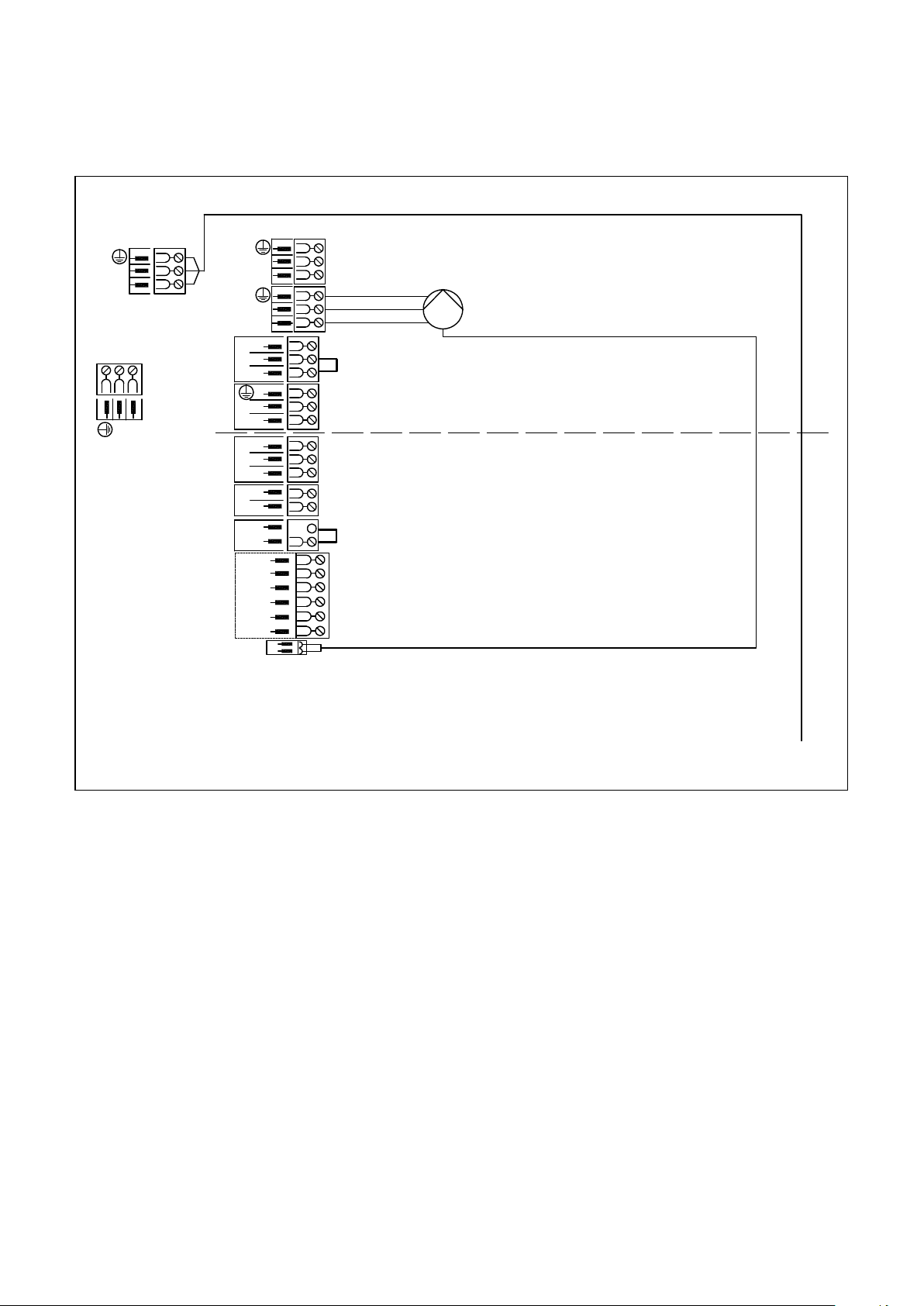

5.8.5 Wiring diagrams

X 11

14

10

4

2

5

9

11

12

X 2

13

1

17

3

4

16

5

7

8

Low-voltage plug

12

13

X20

14

brown

black

orange

violet

black

green

black

blue

black

grau

red

red

black

blue

black

black

black

red

green

red

natural

black

Cylinder thermostat (connection)

“C1-C2”

Cylinder

1)

1

2

P

Water pressure sensor

4

+

Signal

-

Flow rate sensor

Earth

Hall signal

1

2

PWM signal

3

4

+24V

5

NTC sensor

Fan

Flow temperature sensor

Return temperature sensor

1)

Mains

18

blue

red

9

Igniter

X14

Fig. 5.14 Connection diagram of ecoTEC

(continued on next page)

1) You must not use both the C1/C2 and the cylinder sensor connections!

green/yellow

+

Gas valve

Ignition electrode

Appliance earth

Installation and maintenance instructions ecoTEC 0020029172_0422

Fan

230V~

N

L

blue

X11

Cylinder

charging pump

X13

X18

5

4

3

N

L

grey

N

green

L

Installation 5

Additional relay (e.g. external heating pump)

(adjustable in d.26, see table 9.3)

Internal pump

Boiler enable connection (factory link fitted)

N

Mains voltageLow voltage

L

N

L

pink

X6

X1

X41

X22

Fig. 5.15 Connection diagram of ecoTEC (continued)

turqoise violetwhiteredblue

9

8

7

+

-

2

1

0

1

0

DCF

RF

AF

6

FB

Edge connector

230 volt mains input

Optional ext. controller/room thermostat 7-8-9

(continuous, analogue)

Bus connection for optional accesories

Safety circuit connection

Earth

Earth

DCF connection

Low loss header sensor

External sensor

Remote control, circulation pump

24 V 230 V~

Connector for controller accessories

VRC 430

PWM signal, internal pump

Fan

23Installation and maintenance instructions ecoTEC 0020029172_04

6 Start-up

6 Start-up

Caution!

a

The boiler may only be permanently operated

with its casing properly closed!

Otherwise, under unfavourable conditions, it can

result in material damage or even injury or

death.

Note!

h

When starting up particularly take the following

into consideration:

Before the heating circuit or charging circuit is

filled you must open the cap on the automatic

air vent which must remain open during

subsequent operation.

Use the bleeding program to bleed the heating

circuit or charging circuit (see Chapter 9.2).

6.1 Water circulation system

Detailed recommendations concerning the water circuit

system can be taken from BS 6798 and BS 5449, Part 1

(for "Small Bore” and "Micro Bore” central heating

installations). Lines which do not form part of the usable

heating surface should be insulated to prevent heat

losses and possible freezing up, especially where the

lines run under rooves and ventilated cellar rooms. The

drain connections must be easily-accessible, so that the

entire system including the boiler and hot water system

can be drained. The drain connections should be at least

1/2 " (BSP nominal size) and must be in accordance with

BS 2879.

The boiler is suitable for Minibore and Microbore systems. Water lines are to be copper pipes in accordance

with BS 2871, Part 1. These must be thoroughly cleaned,

especially when connecting a new boiler to an existing

system.

6.2 Filling the system

6.2.1 Preparation of heating water

Caution!

a

If anti-freeze inhibitors are to be used it has

been found that Sentinel X500 and Fernox

Alphi-11 have no known incompatibility issues

with our boilers. Vaillant cannot guarantee the

compatibility and effectiveness of these

products in the rest of the heating installation

and accepts no liability or responsibility for

damage caused by use on non-recommended

anti-freeze inhibitor products.

Risk of damage if the heating water is treated with

unsuitable frost or corrosion protection agents.

Frost and corrosion protection agents can cause changes to seals, noise during heating mode and may lead to

other consequential damage.

• Do not use any unsuitable frost or corrosion protection agents.

Mixing additives with the heating water can result in material damage. However no incompatibility with Vaillant

boilers has been detected with proper use of the following products over a long period.

• When using additives, follow the manufacturer's instructions without exception.

Vaillant accepts no liability for the compatibility of any

additive or its effectiveness in the rest of the heating installation.

Additives for cleaning measures

(subsequent flushing required)

- Fernox F3

- Sentinel X 300

- Sentinel X 400

Caution!

a

To prevent deposition and severe damage to the

boiler and heating installation the cleaning

agent must be applied carefully and

subsequently removed from the heating

installation by draining it completely. Cleaning

agents should not remain in the heating

installation longer than 24 hours.

This cleaning process must take place before a new

boiler is fitted in accordance with BS 7593.

Recommendations on the use of system cleaning agents

can be obtained from Sentinel, Betz Dearborn Ltd.

Widnes, Cheshire, WA8 8UD, Tel. 0151 420 9595, or

Fernox, Cookson Electronics, Forsyth Road, Sheerwater,

Woking, Surrey GU21 5RZ, Tel. 01483 793200.

Additives intended to remain permanently in the system

- Fernox F1

- Fernox F2

- Sentinel X 100

- Sentinel X 200

Additives for frost protection intended to remain permanently in the system

- Fernox Antifreeze Alphi 11

- Sentinel X 500

• Inform the operator of the necessary measures if you

have used these additives.

• Inform the operator about the required measures for

frost protection.

Permissible water hardness

• Observe all valid national and technical regulations

when conditioning filling and supplementary water.

Installation and maintenance instructions ecoTEC 0020029172_0424

Start-up 6

Provided the national regulations and technical standards do not stipulate more stringent requirements, the

following applies:

• You must condition the heating water in the following

cases:

- If the entire filling and supplementary water quanti-

ty during the operating life of the system exceeds

three times the nominal volume of the heating installation or

- If the limit values shown in the tables are not ob-

served.

Total heating

output

kW

< 50

> 50 to £ 200

>200 to £ 600

> 600

1) on systems with circulation water heaters and for systems with

electric heating elements

2) from the specific system volume (nominal capacity in litres/heating

output; for multiple boiler systems, the lowest individual heating

output should be used). This data only applies up to 3 times the

system volume for filling and top-up water. If 3 times the system

volume figure is exceeded, the water must be treated in exactly

the same way as if the limits quoted in table6.1 were exceeded

(softening, desalination, hardness stabilisation or desludging).

Table 6.1 Guideline values for heating water: water hardness

Overall hardness at smallest boiler heating

20 l/kW

3

mol/m

(mg/l CaCO3)

No require-

ment or

1)

< 3

< (300)

2

(200)

1.5

(150)

0.02

(2.0)

(mg/l CaCO3)

1)

2)

surface

> 20 l/kW

< 50 l/kW

3

mol/m

2

(200)

1.5

(150)

0.02

(2.0)

0.02

(2.0)

> 50 l/kW

mol/m

(mg/l CaCO3)

0.02

(2.0)

0.02

(2.0)

0.02

(2.0)

0.02

(2.0)

3

Caution!

a

Only fill the system via the boilers' built-in

combined filling and emptying valve as

otherwise problems may occur with bleeding

the system.

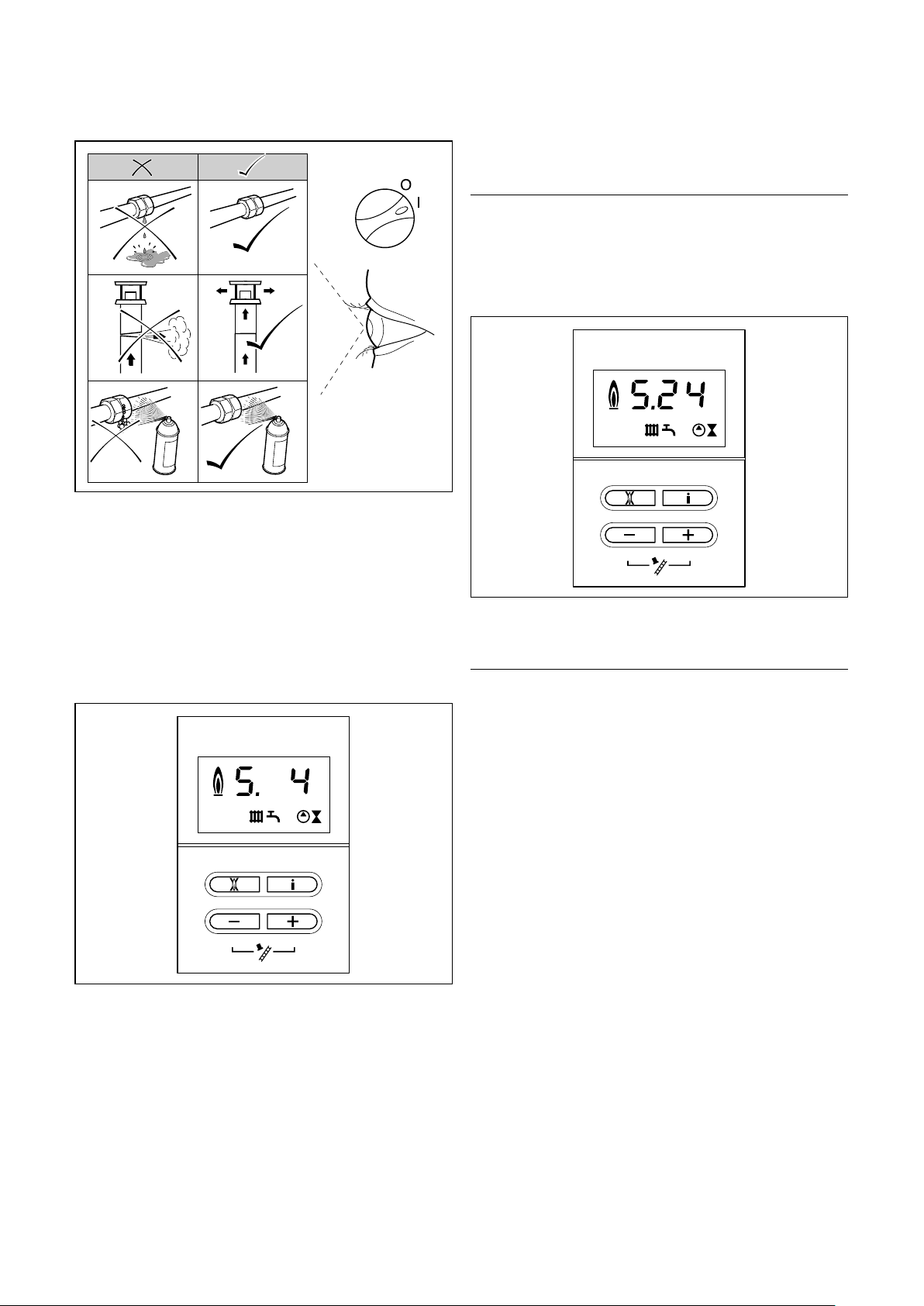

Note!

h

The ecoTEC is equipped with a pressure gauge

(1) and a digital pressure indicator. You can

display the precise filling pressure when the

boiler is switched on by pushing the "-" button

(2). You can also switch between the continuous

display of temperature or pressure by keeping

the "-" button pushed for about 5 seconds.

For the heating installation to work properly the

indicator on the pressure gauge (1) must be in the upper

half of the dark grey area when the system is cold (see

Fig. 6.1). This corresponds to a filling pressure between

1.0 and 2.0 bar.

If the heating installation serves several floors, the

values for the water pressure in the system may need

to be higher (to avoid the ingress of air).

• Flush through the heating installation throroughly

before actually filling it.

1

6.2.2 Filling and bleeding from the heating side

2

Fig. 6.1 Check the filling pressure of the heating installation

Fig. 6.2 Automatic air vent

• Unfasten the cap on the automatic air vent (1) by one

or two turns (the appliance is bled automatically while

continuously operated via the automatic air vent).

• Open all thermostatic radiator valves in the

installation.

• Connect the system's combined filling and emptying

valve to a cold water draw-off valve in accordance

with the standards.

Note!

h

1

To avoid damaging the appliance through

operation with insufficient water pressure, the

boiler is equipped with a pressure sensor.

This sensor records a lack of pressure if the

pressure value falls below 0.6 bar and the

detected pressure value flashes in the display.

If the pressure falls below 0.3 bar the boiler

switches off. Fault message F.22 ("water lack")

25Installation and maintenance instructions ecoTEC 0020029172_04

6 Start-up

appears in the display. Fill the system up with

water before you start up the boiler again. This

message also appears if you switch the boiler

on when it is empty and disappears

automatically when it is filled.

Caution!

a

Risk of damage from leaking water!

If the pressure drops frequently the reason for

the loss of heating water must be identified and

eliminated.

• Open the combined filling and emptying valve and the

draw-off valve slowly and add water until the required

system pressure is shown on the pressure

gauge/display.

• Close the draw-off valve.

Note!

h

Use the check program P.0 to bleed the heating

installation: The boiler does not start up. The

internal pump runs intermittently and bleeds

the appliance circuit. The pressure is displayed

digitally. Ensure that the system pressure does

not fall below 0.8 bar when bleeding is in progress. Otherwise the bleeding will not be carried

out properly. The bleeding program takes about

6.5 minutes to complete.

• Bleed all the radiators.

• Check the system pressure again.

6.2.3 Filling the condensate siphon

Fig. 6.3 Filling the condensate siphon

Danger!

d

If the boiler is operated with an empty

condensate siphon, there is danger of poisoning

through escaping flue gases. Therefore it is

mandatory to fill the siphon as described below

before start-up.

1

Caution!

a

If too much air is still in the system after the

bleeding program is finished it must be started

again! Once the filling procedure is complete

the system pressure should be at least 0.2 bar

above the back-pressure from the expansion

vessel (P

• Check all connections for leaks.

Note!

h

When the boiler starts operating a maintenance

or fault message may occur due to falling

system pressure. The message disappears

automatically when the boiler is refilled.

system

P

+ 0.2 bar).

ADG

• Screw off the bottom (1) of the condensate siphon.

• Fill the bottom about 3/4 with water.

• Screw the bottom back on the condensate siphon.

6.3 Checking the gas setting

Caution!

Malfunctions or reduction in working life of the

boiler!

If the boiler version does not correspond to the

local gas family, there will be malfunctions or

you have to change components of the boiler

ahead of schedule, e. g. do not use a LPG boiler

on natural gas.

• Before starting up the boiler compare the

details of the type of gas specified on the

identification plate with the type of gas

supplied at the installation site.

If the boiler version corresponds to the local gas family:

• Proceed as described below.

If the boiler version does not correspond to the local

gas family:

• Perform the gas conversion in accordance with the

gas conversion kit 0020010641.

Installation and maintenance instructions ecoTEC 0020029172_0426

Start-up 6

• Adjust the gas setting as described below

(see sections 6.3.1 to 6.3.3).

The combustion of this boiler has been checked,

adjusted and preset at the factory for operation on the

type of gas defined on the identification plate. No

measurement of the combustion is necessary to set up

the boiler.

• Do not adjust the multifunctional automatic gas valve.

• Ensure

- that the boiler has been installed in accordance with

these instructions,

- the integrity of the flue system and the flue seals,

as described in the flue installation instructions