Page 1

For the installer

Installation and maintenance manual

ecoMAX

Wall hung room sealed fan assisted condensing boiler

ecoMAX 665

GB

Page 2

Contents

Information on the documentation ........................... 3

Other relevant documentation and service aids ........... 3

Service aids ............................................................................. 3

Attachment and storage of the documents ................... 3

Symbols used .......................................................................... 3

1 Description of the appliance ........................... 4

1.1 Design .......................................................................... 4

1.3 Data badge .................................................................. 5

1.4 CE mark ....................................................................... 5

1.5 Intended use ............................................................... 5

1.6 Declaration of conformity ....................................... 6

2 Safety instructions and regulations .............. 7

2.1 Safety instructions ................................................... 7

2.1.1 Installing and setting the appliance ..................... 7

2.1.2 Smell of gas ................................................................ 7

2.1.3 Changes to the surroundings of the boiler ........ 7

2.2 General requirements .............................................. 7

2.2.1 Preliminary remarks for roomsealed appliances 7

2.2.2 Related documents ................................................... 7

3 Mounting ............................................................ 8

3.1 Scope of delivery and accessories ....................... 8

3.2.1 Select position of boiler .......................................... 9

3.2.2 Unpack the boiler ...................................................... 9

3.2.3 Using boiler template ............................................... 9

3.4 Required minimum gaps/assembly clearances . 11

3.5 Mounting the appliance ........................................... 11

3.6 Removing/Attaching the appliance casing ......... 11

5.2.2 Gas inlet working pressure ..................................... 21

5.2.3 Checking the CO

needed (air ratio setting) ........................................ 22

5.3 Functional test ........................................................... 23

5.4 Instructing the user .................................................. 23

5.4.1 Instructing the user about the heating system . 24

5.4.2 Vaillant warranty ........................................................ 24

6 Adapting the appliance to the heating

system ................................................................ 25

6.1 Setting central heating output (range rating) ... 25

6.2 Setting the pump over-run time ........................... 26

6.3 Setting the burner anti-cycle time ....................... 26

6.4 Adapting the appliance to larger flue pipe

lengths ......................................................................... 26

7 Inspection and maintenance ........................... 27

7.1 Inspection and maintenance intervals ................. 27

7.2 Inspection and maintenance instructions ........... 27

7.2.1 Servicing the compact thermal module .............. 29

7.2.2 Clean the heat exchanger ...................................... 30

7.2.3 Cleaning the condensate paths and siphon ....... 30

7.2.4 Checking the burner ................................................. 30

7.3 Draining the appliance and the system ............... 31

7.3.1 Draining the appliance ............................................. 31

7.3.2 Draining the entire system ..................................... 31

7.3.3 Cleaning the air separator ...................................... 31

7.4 Filling and venting the system ............................... 31

7.5 Checking the gas rate check .................................. 31

7.6 Test operation............................................................ 31

content and adjusting it if

2

4 Installation ......................................................... 12

4.1 Preparing the installation ....................................... 12

4.2 Technical instructions for the heating system .. 12

4.2.1 Connection to heating system via a low loss

header .......................................................................... 12

4.3 Technical instructions for recharging ................. 13

4.4 Gas connection .......................................................... 13

4.5 Heating side connection .......................................... 13

4.6.1 Flue termination ........................................................ 14

4.6.2 Flue pipe ...................................................................... 14

4.7 Condensate discharge ............................................. 15

4.8 Electrical connection ................................................ 15

4.8.1 Mains connection ...................................................... 16

4.8.2 Connecting controllers ............................................ 16

4.8.3 Connecting accessories and external system

components ................................................................ 16

4.8.4 Connection diagram ................................................. 18

4.8.5 Wiring diagram .......................................................... 19

5 Putting the boiler into service ........................ 20

5.1 Water circulation system ........................................ 20

5.1.1 Treating the heating water..................................... 20

5.1.2 Heating side filling and bleeding ........................... 20

5.1.3 Final system flush (”Hot”) ...................................... 20

5.1.4 Filling the siphon ....................................................... 21

5.2 Checking the gas setting ......................................... 21

5.2.1 Factory gas setting ................................................... 21

8 Troubleshooting ................................................ 32

8.1 Diagnostics ................................................................. 32

8.1.1 Status codes ............................................................... 32

8.1.2 Diagnosis codes ......................................................... 33

8.1.3 Error codes ................................................................. 34

8.1.4 Error memory ............................................................ 34

8.1.5 Test programs ............................................................ 36

9 Vaillant Service ................................................. 36

10 Recycling and disposal ..................................... 36

10.1 Appliance ..................................................................... 36

10.2 Packaging .................................................................... 36

11 Technical data ................................................... 37

Benchmark gas boiler commissioning checklist .... 38

2 Installation and maintenance manual ecoMAX 665 / 0020020159_03

Page 3

Information on the documentation

The following information is intended to guide you through

the entire documentation.

Further documents apply in combination with this installation and maintenance manual.

We accept no liability for any damage caused by not

following these instructions.

Other relevant documentation and service aids

For the owner of the system

1 brief operating instructions no. 00 20 00 64 61

1 operating manual no. 00 20 01 46 08

For the installer

1 installation instructions

flue accessories no. 00 20 01 46 06

1 sticker with name of appliance no. 83 42 24

1 installation instructions for siphon no. 83 53 11

1 checklist for start-up no. 00 20 02 01 61

1 installation template no. 17 90 73

1 safety sticker no. 83 55 93

Information on the documentation

Service aids

The following test and measuring equipment is required

for inspection and maintenance:

– Flue gas analyser

– manometer (u gauge)

– auxiliary tool for gas fitting (comes with appliance)

Attachment and storage of the documents

Please pass on this installation and maintenance manual

as well as the aids to the owner of the system, whose

responsibility it is to ensure that the manuals and auxiliary equipment are available whenever required.

Symbols used

Please observe the safety instructions in this installation

manual when installing the appliance!

Danger!

d

Immediate risk of serious injury or death.

Caution!

a

Potentially dangerous situations for the product

and environment.

Note!

h

Useful information and instructions.

• Symbol for a necessary task

3Installation and maintenance manual ecoMAX 665 / 0020020159_03

Page 4

1 Description of the appliance

1 Description of the appliance

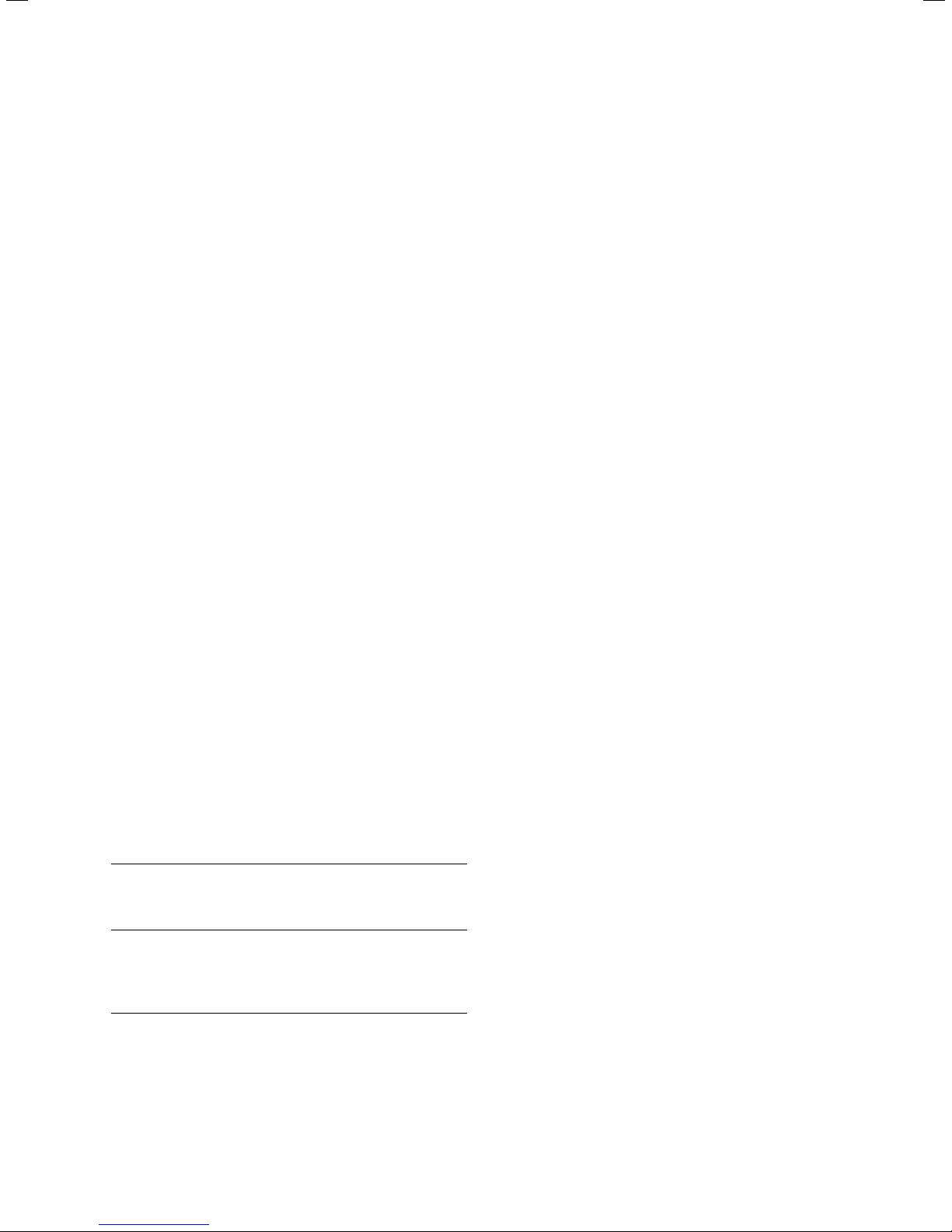

1.1 Design

13

1

2

3

4

12

11

10

9

Fig. 1.1 Function elements

5

6

7

8

1 Connection to flue pipe 80/125

2 Primary heat exchanger

3 Air intake pipe

4 Compact thermal module with burner, flange,

mixing tube, fan and electronic gas valve

5 Ignition electrode

6 Pump

4 Installation and maintenance manual ecoMAX 665 / 0020020159_03

7 Drain valve point

8 Electronics box

9 Water pressure switch

10 Discharge for supply

11 Electronic gas valve

12 Air separator with strainer

13 Water flow switch

Page 5

Description of the appliance 1

Appliance type Country of destination

(designations

according to ISO 3166)

ecoMAX 665 GB (Great Britain)

IE (Eire)

License

category

I

2H

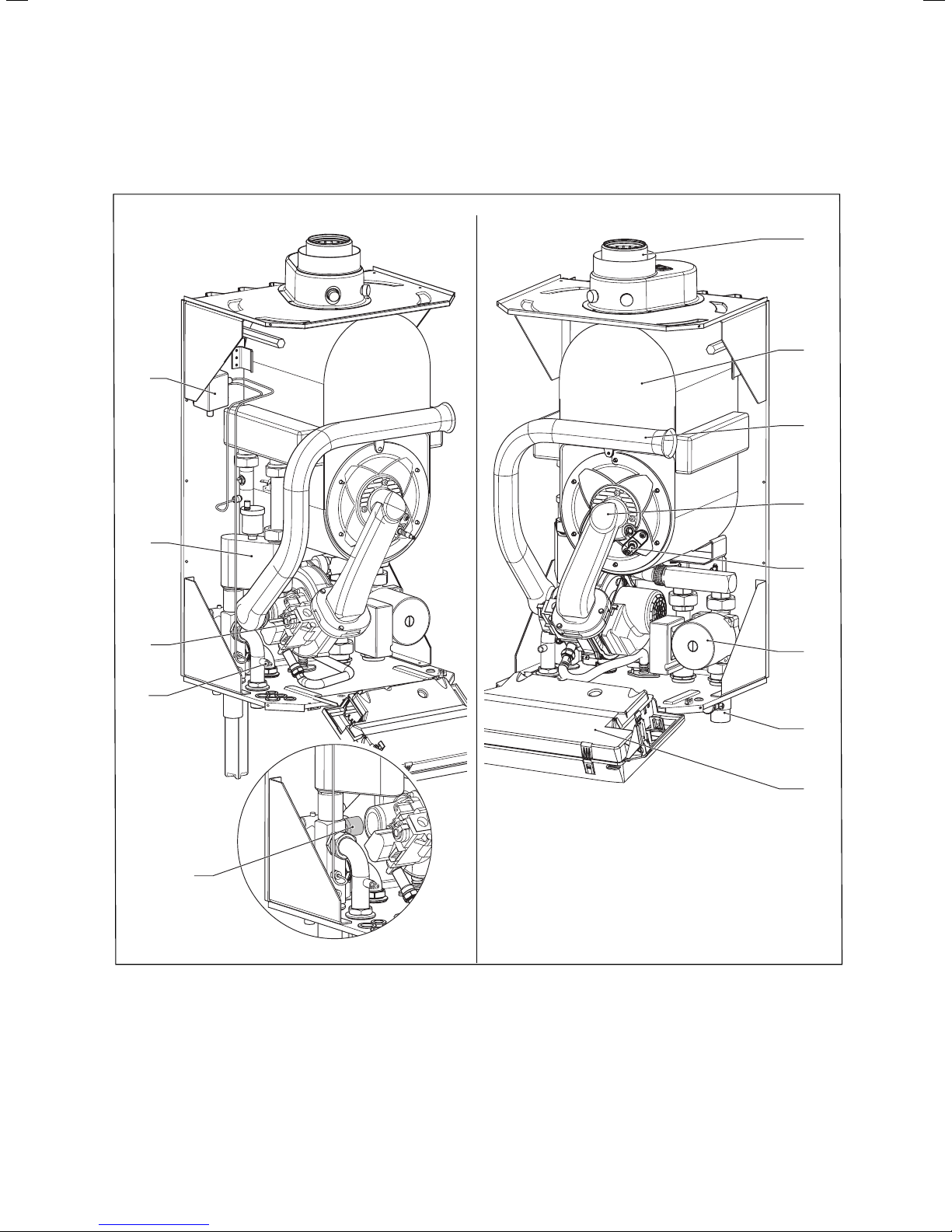

1.3 Data badge

The data badge of the Valliant ecoMAX 665 is attached

at the factory to the bottom of the appliance.

Type of gas Nominal heat output

range P (kW)

Natural gas H - G

20 - 20 mbar

15.0 - 69.6 (40/30 °C)

13.7 - 63.7 (80/60 °C)

Storage charging output

(kW)

65.0

1.5 Intended use

The Vaillant ecoMAX 665 is a state-of-the-art appliance

which has been constructed in accordance with recognised technical safety regulations. Nevertheless, danger

to the life and limb of the user or third parties can still

occur or the appliance or other material assets be damaged when using it.

The appliance is designed to be used as a boiler for

closed hot water central heating systems. Any other

use or extended use is considered to be improper. The

manufacturer/supplier is not liable for any resulting

damage. The user alone bears the risk.

Appropriate use includes the observance of the operating and installation manual and the adherence to the inspection and maintenance conditions.

Fig. 1.2 Data badge (example)

1.4 CE mark

CE marking is used to document the fact that the appliances, in accordance with the type summary, meet the

basic requirements of the directive on appliances burning gaseous fuels (Council Directive 90/396/EEC) and

the EC directive on electromagnetic compatibility

(Council Directive 89/336/EEC).

The appliances meet the basic requirements of the efficiency requirements directive (Council Directive 92/42/EEC)

as condensing appliances.

The appliances named above emit less than 80 mg/kWh

nitrogen dioxide (NOx) when natural gas is used.

5Installation and maintenance manual ecoMAX 665 / 0020020159_03

Page 6

1 Description of the appliance

1.6 Declaration of conformity

6 Installation and maintenance manual ecoMAX 665 / 0020020159_03

Page 7

Safety instructions and regulations 2

2 Safety instructions and regulations

2.1 Safety instructions

2.1.1 Installing and setting the appliance

Important!

The appliance must be installed and serviced by

a competent person as stated in the Gas Safety

(Installation and Use) Regulations 1998. In IE,

the installation must be in accordance with the

current edition of IS 813 ‚Domestic Gas Installations‘, the current Building Regulations and

reference should be made to the current ETCI

rules for electrical installation.

2.1.2 Smell of gas

If you smell gas, the following safety instructions should

be observed:

• don‘t switch on any electrical switch in the danger area

• don‘t smoke in the danger area

• don‘t use a telephone in the danger area

• close the gas stop cock

• air the danger area

• Contact your gas supplier or national Grid Transco

0800 111999

2.1.3 Changes to the surroundings of the boiler

No changes must be made to the following:

– the boiler

– the gas, air, water and electricity supply pipes

– the flue system

– the discharge pipe and the safety valve for the hot water

– the constructional conditions that could affect the op-

erational reliability of the appliance.

Important!

a

When tightening or slackening screwed connections always use suitable open-ended spanners

(not pipe wrenches or extensions etc.). Incorrect use and/or unsuitable tools can lead to

damage being caused (e.g. gas or water leakage)!

2.2 General requirements

2.2.1 Preliminary remarks for roomsealed appliances

This appliance should only be installed in conjunction

with either a Vaillant flue system or an alternative approved system (details of flue approval categories can be

found in the technical section of the installation manual).

Install the flue system as detailed in the separate flue

installation instructions supplied with this boiler.

2.2.2 Related documents

The installation of the boiler must be in accordance with

the relevant requirements of Gas Safety (Installation

and Use) Regulations 1998, Health and Safety Document

No. 635 (The Electricity at Work Regulations 1989), BS

7671 (IEE Wiring Regulations) and the Water Supply

(Water Fitting) Regulations 1999, or The Water Bylaws

2000 (Scotland). It should also be in accordance with the

relevant requirements of the Local Authority, Building

Regulations, The Building Regulations (Scotland). The

Building Regulations (Northern Ireland) and the relevant

recommendations of the following British Stan-dards:

BS 6700: Services supplying water for domestic use

within buildings and their curtilages.

BS 6798: Specification for installation of gas fired boil-

ers not exceeding 60 kW input.

BS 6891: Specification for installation of low pressure

gas pipework up to 28 mm (R1) in domestic

premises (2nd family gas).

BS 7593: Treatment of water in domestic hot water

central heating systems. Institute of Gas

Engineers Publication IGE/UP7 Edition 2

BS. 5482 Pt. 1 Domestic butane and propane gas bur-

ning installations.

IGE/UP1 Soundness testing and purging of industrial

and commercial gas installation.

IGE/UP2 Gas installation pipework, boosters and com-

pressors on industrial and commercial premises.

IG/UP/7 Edition 2 "Gas installations in timber framed

and light steel framed buildings"

IGE/UP10 Installation of gas appliances in industrial and

commercial premises.

BS. 6644 Installation of gas fired hot water boilers of

rated inputs between 60 kW and 2 MW (2nd

and 3rd family gases).

BS. 5449 Forced circulation hot water central heating

systems for domestic premises.

Note: only up to 45 kW.

BS. 6880 Low temperature hot water heating systems

of output greater than 45 kW.

Part 1 Fundamental and design considerations.

Part 2 Selection of equipment.

Part 3 Installation, commissioning and maintenance.

BS. 4814 Specification for: Expansion vessels using

an internal diaphragm, for sealed hot water

heating systems.

BS. 5440 Installation and maintenance of flues and ventila-

tion for gas appliances of rated input not exceeding 70 kW net (1st, 2nd and 3rd family gases).

Part 1 Specification for installation of flues.

Part 2 Specification for installation and maintenance of ventilation for gas appliances.

Important!

a

When tightening or loosening screwed connections always use suitable open-ended spanners

(not pipe wrenches or extensions etc.). Incorrect

use and/or unsuitable tools can lead to damage

being caused (e.g. gas or water leakage)! Preliminary remarks: This appliance should only be

installed in conjunction with a Vaillant flue system. Install the flue system as detailed in the

separate flue installation instructions supplied

with this boiler.

7Installation and maintenance manual ecoMAX 665 / 0020020159_03

Page 8

2 Safety instructions and regulations

3 Mounting

Boiler location

The location chosen for the boiler must permit the provision of a satisfactory flue termination. The location

must also provide adequate space for servicing and air

circulation around the boiler. The boiler may be installed

in any room, although particular attention is drawn to

the requirements of BS7671 (IEE Regulations), the electrical provisions of the Building Regulations (Scotland)

and in IE the current edition of IS 813 and the current

ETCI rules, in respect of the installation of a boiler in

a room containing a bath or shower.

Note!

h

Where a room sealed boiler is installed in a

room containing a bath or shower, any electrical switch or boiler control utilising mains electricity should be so situated that it cannot be

touched by a person using the bath or shower.

Where the installation of the boiler will be in an unusual

location, special procedures may be necessary and

BS 5546 and BS 6798 give detailed guidance on this

aspect. The boiler must be mounted on a flat, vertical

wall, which must be sufficiently robust to take the

weight of the boiler. The boiler may be installed on a

combustible wall, subject to the requirements of the

Local Authorities and Building Regulations. A compartment used to enclose the boiler must be designed and

constructed specifically for this purpose. (An existing

cupboard or compartment may be used provided that

it is modified for the purpose).

Details of essential features of cupboard/compartment

design including airing cupboard installations are given

in BS 6891. In IE the current edition of IS 813.

Note!

h

If the boiler is to be installed in a timber framed

building, it should be fitted in accordance with

IGE/UP7 Edition 2 "Gas installations in timber

framed and light steel framed buildings".

Gas Supply

The gas supplier should ensure the availability of an

adequate supply of gas. A gas meter may only be connected to the service pipe by the supplier of gas or their

contractor. An existing meter should be checked to

ensure that it is capable of passing the rate of gas supply required. Installation pipes should be fitted in accordance with BS 6891. Pipework from the meter to the

boiler must be of an adequate size. Do not use pipes of

a smaller size than the boiler gas connection. The complete installation must be tested for soundness and

purged as described in BS 6891.

3 Mounting

The Vaillant ecoMAX 665 is delivered in a package unit.

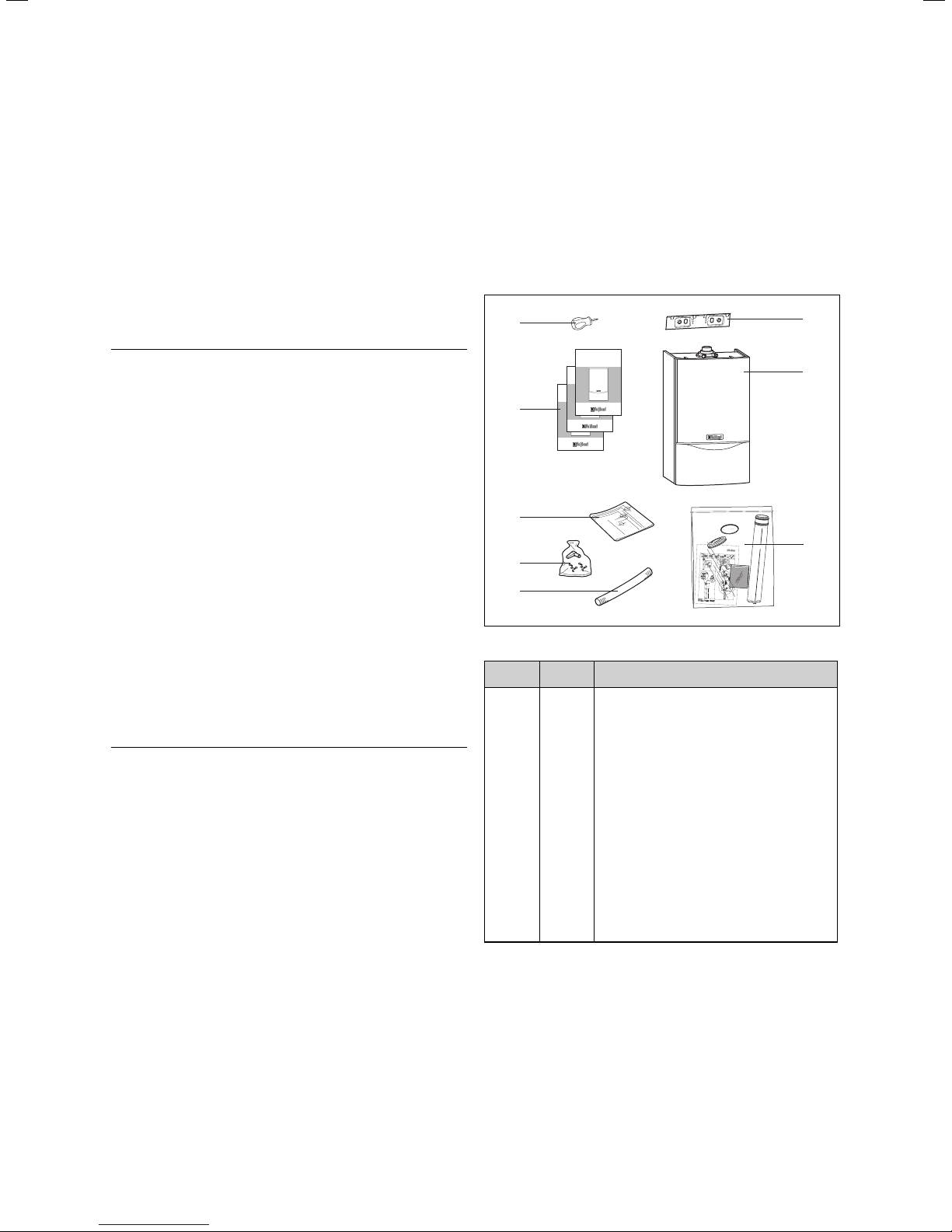

3.1 Scope of delivery and accessories

Scope of delivery

Check that all the parts have been delivered intact (see

fig. 3.1 and table 3.1).

8

7

6

5

4

Fig. 3.1 Scope of delivery

Position Number Name

1

2

3

4

5

6

7

1

1

1

1

1

1

3

Hanging bracket

Boiler

Siphon

Condensate discharge hose

Bag with fixing screws, wall plugs and washers

Installation template

Manuals:

Operating manual

Installation instructions

Assembly manual for flue pipe

8

1

Auxiliary tool for gas valve adjustment

Table 3.1 Scope of delivery

e

co

T

E

C

3

1

a.

2

1

/

3

b

.

c

.

2

/

3

4

200

10

0

1_0

31

5

3

8

1

2

3

8 Installation and maintenance manual ecoMAX 665 / 0020020159_03

Page 9

Mounting 3

3.2 Installation site

Please note the following safety instructions below before choosing where to install the appliance:

Caution!

a

Do not install the appliance in rooms prone to

frost. In rooms with aggressive steam or dust,

the appliance should be room sealed, to prevent

damage.

When choosing the place of installation and while operating the appliance, make sure that the combustion air is

technically free of chemical substances containing fluorine, chlorine, sulphur etc. Sprays, solvents and cleaning

agents, paints, adhesives etc. contain these kinds of

substances, which - in the worst case scenario - can lead

to corrosion, even in the exhaust system, during ambient

air dependent operating of the appliance.

The appliance must be operated independently of the

ambient air particularly in hairdressing salons, carpenter‘s shops or paint shops, cleaning companies.

Caution!

a

When the appliance is installed on an open flue

type system ventilation requirements shall be

taken from BS 6644 and IGE UP10. Design

consideration for the cooling of plant rooms

shall also be taken from BS 6644 and IGE UP10

Packed in the boiler carton are the following:

• Boiler

• Boiler installation template

• Boiler hanging bracket

• Fixing screws, wall plugs and washers

• Installation and user instructions

• Flue installation instructions

• Guarantee card and envelope

3.2.3 Using boiler template

Fix the paper template to the wall ensure that the

template is vertical.

The template shows:

– The position of the fixing holes for the boiler mount-

ing bracket.

– The position of the connections.

– The position of the flue exit hole.

• Mark the position of the hanging bracket fixing holes

• Drill 2 holes Ø 8 mm for the hanging bracket.

Note!

h

Use alternative fixing holes where necessary.

3.2.1 Select position of boiler

Refer to section ‘Boiler location’ for information regarding siting the appliance. In general the boiler must be

positioned such that:

• There is adequate space around the boiler for service

and maintenance

• The boiler can be correctly flued, i.e. the flue terminal

position is sited in accordance with these instructions

and the air/flue duct can be installed in accordance

with the flue installation instructions supplied.

• All necessary pipework can be connected, including

the pressure relief valve and condensate drain.

3.2.2 Unpack the boiler

To unpack the boiler, cut both plastic carton straps,

open box and lift out the polystyrene top packing. Lift

the cardbox upwards.

Note!

h

Care should be taken not to scratch the white

surface of the boiler casing.

9Installations- und Wartungsanleitung ecoMAX 665

Page 10

3 Mounting

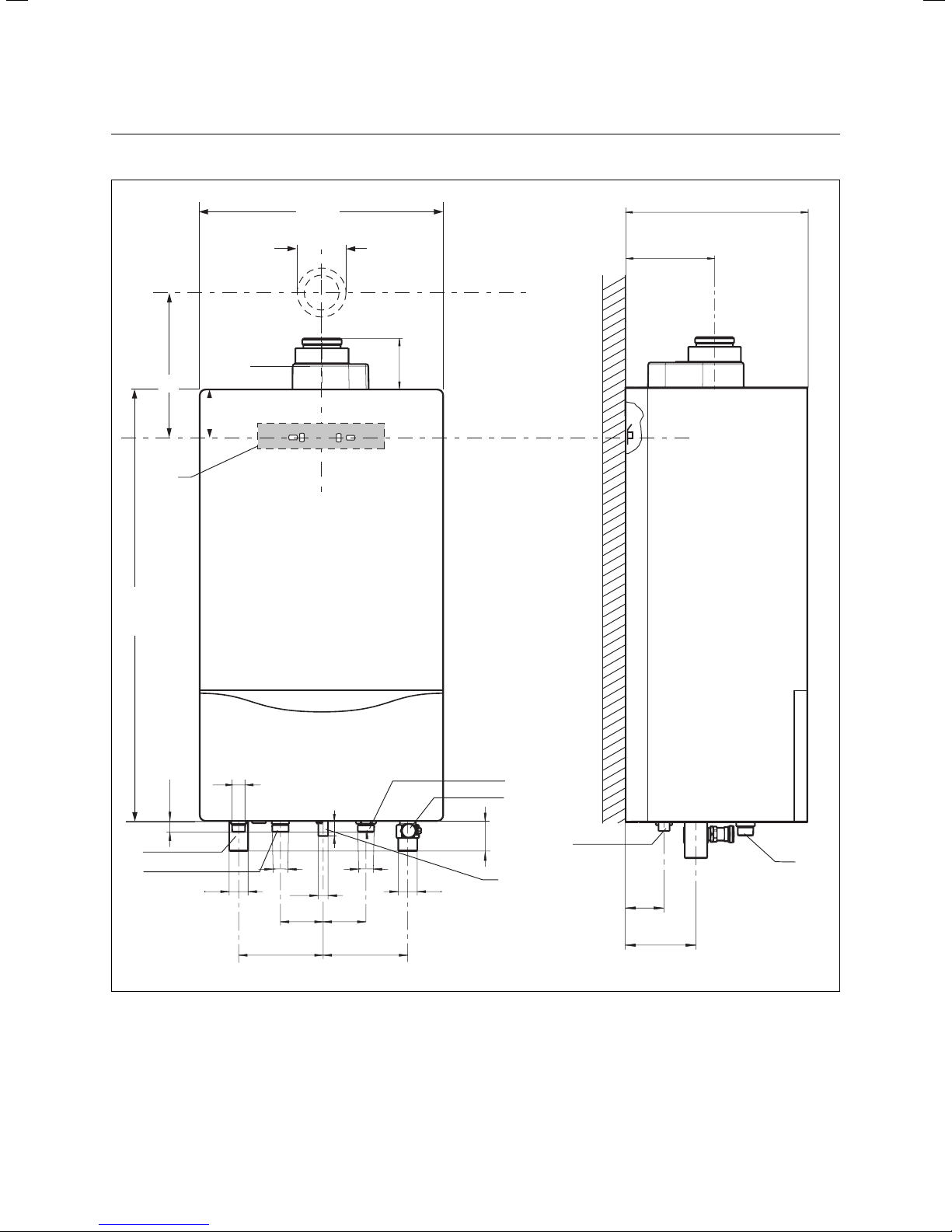

3.3 Dimensional drawing and connection dimensions

800

480

472

Ø 80/125

211

A

1

119

94

2

R3/4

23,2

7

6

Rp1 Rp1

R1

Ø2

5

87

172 172

Fig. 3.2 Connection dimensions

1 Flue connection Ø 80/125 mm

Dimension A with 87° elbow: 297 mm

2 Mounting bracket

3 Heating return

4 DHW primary return (only in conjunction with cylinder)

10 Installation and maintenance manual ecoMAX 665 / 0020020159_03

31

R1

87

4

3

61,5

8

5

66

121

5 Gas connection

6 DHW primary flow (only in conjunction with cylinder)

7 Heating flow

8 Siphon connection

9 Connection safety valve 3/4”

9

Page 11

Mounting 3

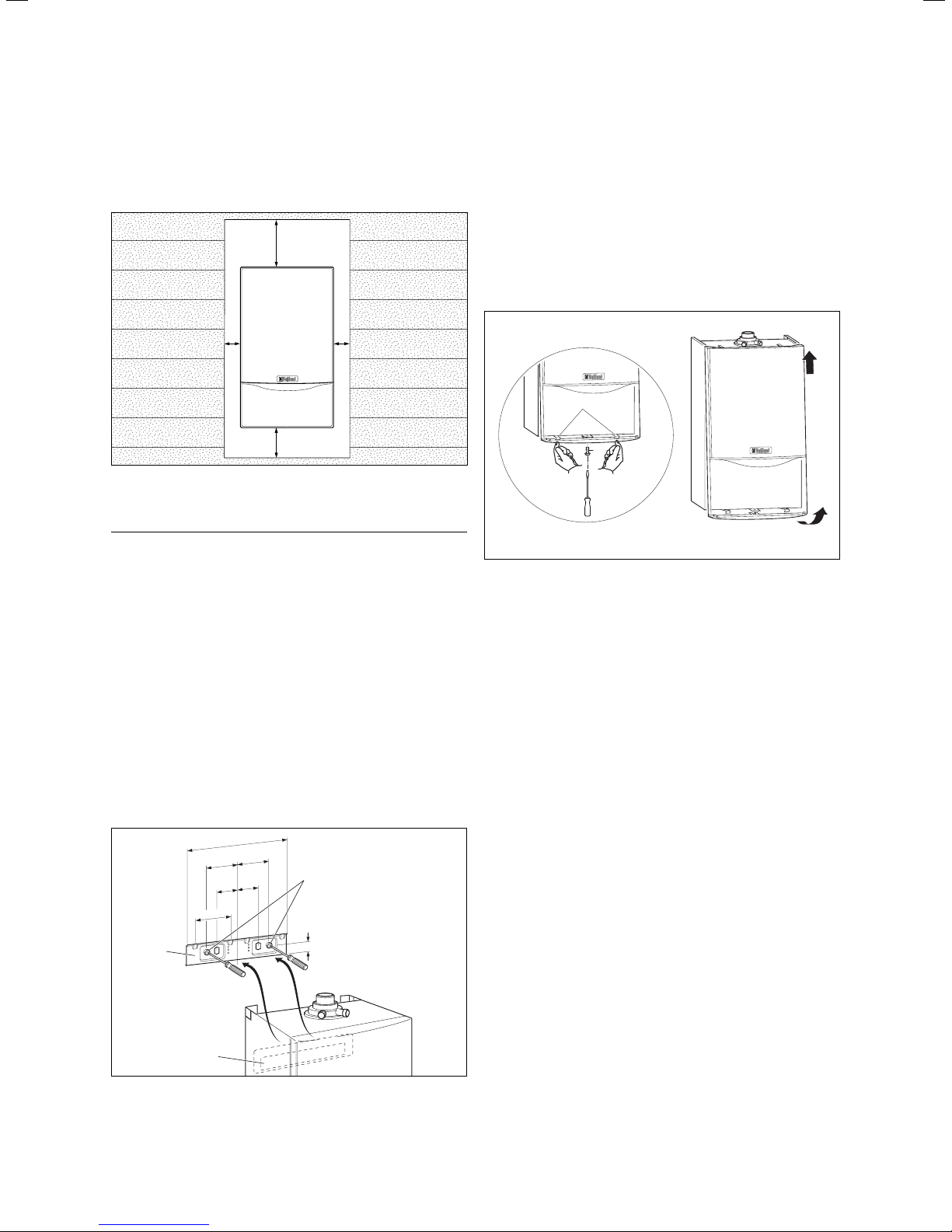

3.4 Required minimum gaps/assembly clearances

Both for the installation/assembly of the appliance and

for carrying out maintenance tasks later, you need the

minimum gaps and assembly clearances given below:

,''

, ,

+''

Fig. 3.3 Required minimum gaps/assembly clearances (mm)

Note!

h

It is very important that you keep the prescribed gap below the appliance in order to

make sure you will be able to mount and service the siphon.

Combustible materials may be safely placed next to the

appliance provided the minimum side clearance of 5 mm

is maintained for servicing, and if required ventilation

purposes. The external temperature of the appliance will

never be such as to cause combustion.

3.5 Mounting the appliance

• Hang the appliance up onto the bracket (1) from above

with the bracket (3).

• Mount the cable connections to the appliance, making

sure they are disconnected from the power supply.

3.6 Removing/Attaching the appliance casing

Removing the casing

To dismount the front casing of the appliance, proceed

as follows:

• Loosen the screw (1) on the bottom of the appliance.

• Press in both retaining clips (2) on the bottom of the

appliance so that the casing is released.

• Pull the casing (3) forwards by its bottom edge and lift

the casing up and off (4).

4

2

1

3

Fig. 3.5 Removing/Attaching the appliance casing

Attaching the casing

To mount the casing, proceed as follows:

• Place the casing on the upper appliance ensuring that

the casing and appliance lips engage.

• Push the casing onto the appliance so that the retaining clips (2) on the casing click into place.

• Fix the casing by tightening the screw (1) on the bottom of the appliance.

240

75

75

50

50

85

1

3

Fig. 3.4 Mounting the appliance on the bracket

2

23

11Installation and maintenance manual ecoMAX 665 / 0020020159_03

Page 12

4 Installation

4 Installation

When installing, please observe the following points in

particular:

- ensure that the isolation valve with the non return

valve is installed on the flow connection.

- mount the siphon cartridge

When used with direct connection to an indirect DHW

cylinder using the connections provided:

• Install a primary loading pump

• Install a non-return valve in both heating and DHW

primary flows to prevent reverse circulation

• please also refer to section 4.3

AB

JJ

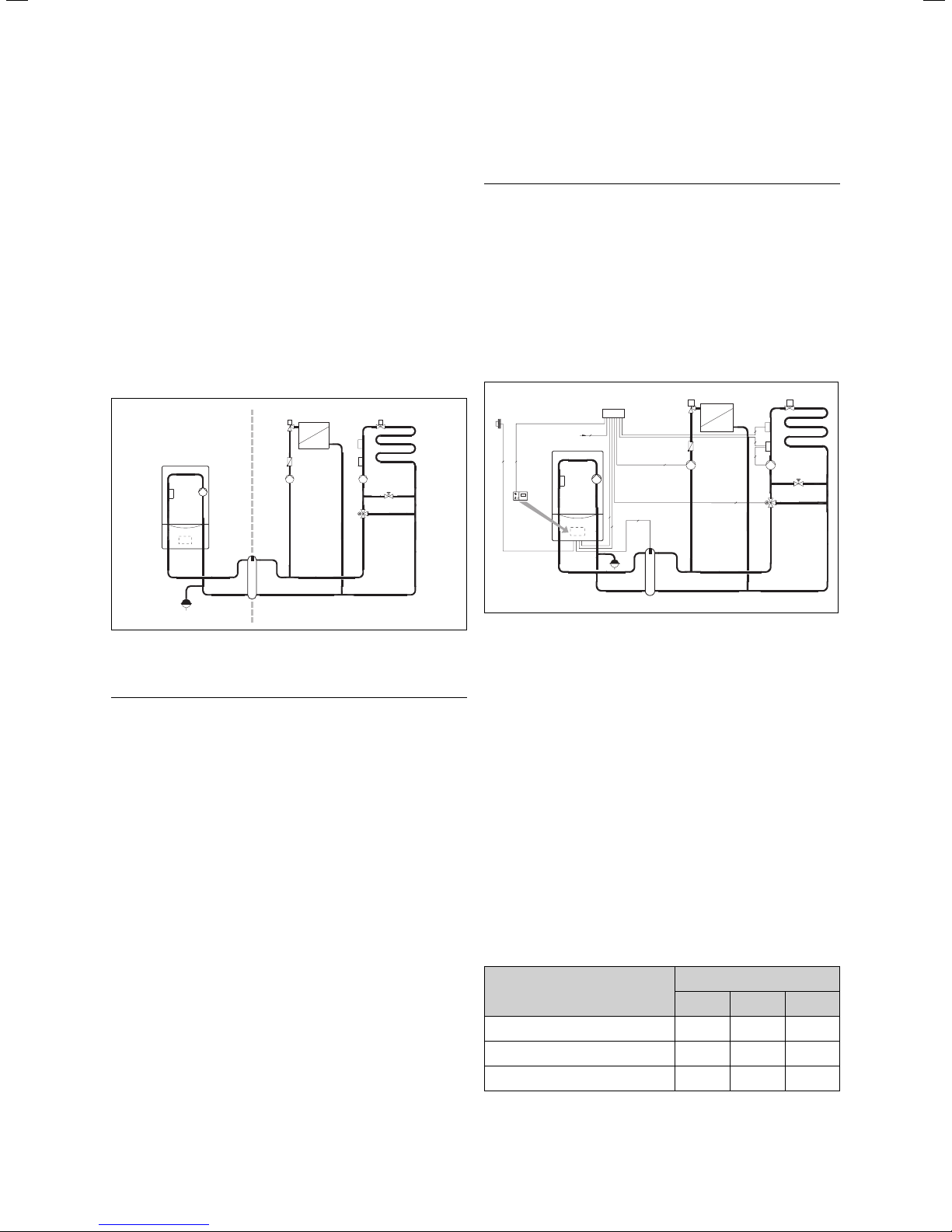

4.2 Technical instructions for the heating system

Caution!

a

The schematics are for diagrammatical representation only. - the system may demand further safety devices and depends fully on the

control system employed. Unvented cylinders

must comply with the building regulations document G3. Always refer to British Standards,

Good Practice Guides and CIBSE guidelines

4.2.1 Connection to heating system via a low loss

header

OS

3

230V~

3

1

3

13

2

2

3

3

J

3

4

17a

45

J

2

3

3

13a

Fig. 4.1: Appliance circuit (A) and heating circuit (B)

Caution!

a

The ecoMAX 665 may only be put into operation when a sufficiently dimensioned low loss

header has been installed between appliance

circuit and heating circuit.

4.1 Preparing the installation

Safety equipment for an emergency

• The outlet of the pressure relief valve must be suitably

terminated in accordance with BS 6798 or BS 6644

• The boiler is suitable for connection to plastic central

heating pipes. It is preferred that the connections to

the boiler are made in copper for the first 1.5 metres

prior to the transition to plastic.

• Should a system be found to include non-oxygen barrier

pipe then it is essential that a plate heat exchanger be

installed in between the boiler and the non-oxygen barrier pipe. It is then essential that the boiler and the system have provision for water make up and expansion.

Fig. 4.2 Example 2: radiator heating and floor heating, low loss

header, appliance-internal pump

1 ecoMAX 665

2 integral boiler pump

13 weather-compensated controller VRC 630

13a mixer valve

17a supply temperature sensor

45 low loss header

OS outside sensor

The pump is sized adequately to provide the correct

amount of flow through the primary circuit.

Selection of the hydraulic switch

A suitable WH model low loss header (accessories) can

be selected with the aid of table 4.1.

A sufficiently large water volume (minimum circulating

water volume) is constantly supplied through the boiler

via the low loss header in conjunction with the Vaillant

system pump (item no. 178 728) built into the boiler.

heating system output heating system spread

10 K 15 K 20 K

ecoMAX 665 WH 160 WH 95 WH 95

double cascade WH 280 WH 160 WH 95

triple cascade WH 280 WH 280 WH 160

12 Installation and maintenance manual ecoMAX 665 / 0020020159_03

Table 4.1: Selection of the low loss header, WH model

Page 13

Installation 4

4.3 Technical instructions for recharging

OS

3

Fig. 4.3 Example 3: use of a cylinder, direct heating circuit

1 ecoMAX 665

2 Pump (internal within the appliance)

45 Low Loss header

OS outside sensor

1

2

3

230V~

3

3

45

Cylinder connection specification

It is imperative to keep to the minimum volume flow of

the charging circuit of 2,200 l/h. A pump with a constant

speed must be used.

When designing such a system, consideration must be

made for the pressure losses of any non-return valves

and piping to the system.

Caution!

a

Risk of damaging the gas control block by

exceeding the testing pressure. The gas control block may only be tested for leaks up to

a maximum pressure of 110 mbar. The operating

pressure may not exceed 60 mbar. If these

pressures are exceeded, the electronic gas

valve may be damaged.

• Screw the appliance‘s gas supply pipe (1) gas-tight

with the (pre-installed) gas ball cock (2). To do this,

use the R1 compression fitting supplied with the appliance. This is suitable for the connection of a R1 gas

ball cock.

• Inspect the gas connection for leakage.

1

2

Pressure [mbar]

1000

900

800

700

600

500

400

300

200

100

0

0 250 500 750 1000 1250 1500 1750 2000 2250 2500 2750

Fig. 4.4 Pressure loss characteristics of connecting a DHW

cylinder.

Min. volume flow

Pressure loss in

storage charging

circuit of the boiler

2200

3000

Volume flow [l/h]

4.4 Gas connection

Caution!

a

Ensure the gas line is unstressed when mounting it so that no leaks are caused.

Fig. 4.5 Gas connection (only surface installation possible)

4.5 Heating side connection

Caution!

a

Ensure the connection lines are unstressed

when mounting them so that no leaks are

caused in the heating system.

The appliance is connected to the heating flow and

return via maintenance cocks.

Caution!

a

Ensure that a filling loop or pressurisation

device is installed in the return to maintain

pressure in the system.

Note!

h

When installing a direct connection to a DHW

cylinder (indirect type) ensure that the non

return valve in the isolation valve is installed in

the correct orientation.

• Screw in flow (3) and return (4) with the maintenance

cocks.

13Installation and maintenance manual ecoMAX 665 / 0020020159_03

Page 14

4 Installation

3 4

Fig. 4.6 Mounting the heating flow and return service valves

4.6.1 Flue termination

A

G

F

J

H, I

E

Fig. 4.7 Flue termination

Terminal position mm

A Directly below an opening, above an opening or ho-

rizontal to an opening, air brick, opening window, etc.

B Below gutters, soil pipes or drain pipes 75

C Below eaves 200

D Below balconies 200

E From vertical drain pipes and soil pipes 25

F From internal or external corners 300

G Above ground, roof or balcony 300

H From a surface facing a terminal 600

I From a terminal facing a terminal 1200

K Vertically from a terminal on the same wall 1500

L Horizontally from a terminal on the same wall 300

M Distance from adjacent for vertical Flue 500

Table 4.2 Terminal position for a fan assisted concentric flue

BCD

A

A

G

F

A

F

The following details refer to both flue systems.

a. The terminal must be positioned such that the prod-

ucts of combustion can disperse freely at all times.

b. A plume of water vapour will sometimes be visible

from the flue terminal. Positions where this could be

a nuisance should be avoided.

c. If the terminal is fitted less than 2 m above a balcony,

above ground or above a flat roof to which people have

access then a suitable terminal guard must be provided and

fitted (contact Tower Flue Components, Tonbridge, TN9 1TB).

5

B

F

M

G

L

K

K

L

300

Note!

Vertical flues must not terminate within 600

mm of an openable window, air vent or any

other ventilation opening.

The flue assembly shall be so placed or sheilded as to

prevent ignition or damage to any pary of the building.

Note!

In addition, the terminal should not be nearer

than 150 mm to an opening in the building fabric formed for the purpose of accommodating a

built–in element such as a window.

BS 5440–1 It is recommended that the fanned flue terminal should be positioned as follows:

a) at least 2m from an opening in the building directly

opposite, and

b) so that the products of combustion are not directly

directed to discharge across a boundary.

1) Dimensions B, C and D:

These clearances may be reduced to 25 mm without

affecting the performance of the boiler. In order to

ensure that the condensate plume does not affect

adjacent surfaces the terminal should be extended as

shown in fig. 4.8.

2) Dimension F:

This clearance may be reduced to 25 mm without

affecting the performance of the boiler. However, in

order to ensure that the condensate plume does not

affect adjacent surfaces a clearance of 300 mm is

preferred. For IE, recommendations are given in the

current edition of IS 813.

balcony/eaves

gutter

flue adequately

supported

Fig. 4.8

flue extended to

clear any overhang

4.6.2 Flue pipe

Danger!

d

Only Vaillant original 80/125 mm flue pipes may be

used when installed in a room sealed application

(type C). Malfunctions can occur if you use other

accessories. These may result in damage and injury.

14 Installation and maintenance manual ecoMAX 665 / 0020020159_03

Page 15

Fig. 4.9 Example of installation with horizontal air/flue duct

pip

Concentric systems made of plastic (diameter - 80/125 mm)

are combined with the appliance as flue pipes.

The most suitable system depends on the specific installation and application conditions (see also the installation manual 0020014606_00GB for the flue pipes).

• Mount the flue pipes consulting the installation manual contained in the scope of delivery of this appliance.

Installation 4

be achieved by maintaining an offset between branch

pipes of at least 110 mm on a 100 mm diameter stack

and 250 mm on a 150 mm diameter stack.

b) connecting into the internal discharge branch (e.g. sink

waste) with an external termination, the condensate

discharge pipe should have a minimum diameter of 22

mm with no length restriction and should incorporate a

trap with a 75 mm (3) (built into the boiler) seal. The

connection should preferably be made down stream of

the sink waste trap. If the connection is only possible

upstream, then an air break is needed between the two

traps. This is normally provided by the sink waste.

c) terminating in a gully (5) below grid level (6) and

above the water level. The external pipe length

should be kept as short as possible to minimise the

risk of freezing and should not be more than 3 m.

d) at a condensate absorption point (soakaway) (7). The

external pipe length should not be more than 3 m.

4.7 Condensate discharge

4

ab c d

6

3

Internal

stack

Fig. 4.10.1

The condensate generated during combustion is led

from the condensate discharge pipe to the waste water

connection via a draining funnel.

The condensate discharge pipe must terminate in a suitable position, e.g.:

a) preferably the discharge pipe should run and termi-

e

Note!

The discharge pipe from the boiler condensate

drain must have a continuous fall (45 mm per

meter) and preferably be installed and terminated

within the building to prevent possible freezing.

nate internally to the house soil and vent stack (at

least 450 mm above the invert of the stack). A trap

giving a water seal of at least 75 mm (3) (built into

the boiler) should be incorporated into the pipe run,

and there must be an air break (4) in the discharge

pipe upstream of the trap. The connection to the

stack should not be made in a way that could cause

cross flow into any other branch pipe, or from that

branch pipe into the condensate drainpipe. This can

3

5

Internal

discharge system

7

Gulley Soakaway

1

2

Fig. 4.10.2 Condensate discharge

Refer to ‘BS 6798 Specification for installation of gas–

fired boilers of rated input not exceeding 70 kW net’ for

further information. Before operating the boiler the condensate trap (1) must be filled with water as described in

relevant section.

Danger!

d

Before connecting the condensate discharge it

is absolutely important to install the syphon kit

included correctly and filling up with water.

4.8 Electrical connection

Danger!

d

Risk of fatal electric shock from touching live

connections. Always switch off the power supply to the boiler first. Only once this is done

may you carry out the installation.

There is continuous operating voltage at the

power supply terminals L and N even when the

appliance on/off switch is switched off.

Attention - this appliance must be earthed!

15Installation and maintenance manual ecoMAX 665 / 0020020159_03

Page 16

4 Installation

4.8.1 Mains connection

Caution!

a

Supplying power to the wrong plug terminals of

the Pro E system can destroy the electronics.

Only connect the 230 Vac live supply to boiler

terminal connections marked LNE.

The rated voltage of the mains must be 230 V; at rated

voltages above 253 V and under 190 V, damage may occur.

The mains supply must be connected via a fixed connection and a separator with a contact opening of at least

3 mm (e.g. fuses, circuit breakers).

4.8.2 Connecting controllers

Mounting is to be carried out as stated in the relevant installation manual. The necessary connections to the boiler‘s

electronics (e.g. when using external controllers, external

sensors or similar devices) are to be performed as follows:

• Remove the front casing of the appliance and lower

the electronics box (1) forward.

• Unclip the back cover (2) of the electronic box from

its fixings (3) and lift it up (see fig. 4.9).

• Pass the connecting cables of each of the components

to be connected through the grommets (4) located on

the bottom of the appliance to the left.

• Then insert the connecting cables (5) into the electronics box and cut them to length (see fig. 4.9).

• Strip the connecting cable by about 2-3 cm and bare

the wires (see fig. 4.10).

• Connect the connecting cables as shown by fig. 4.10/4.11

to the corresponding ProE plugs or slots of the electronics.

Vaillant controllers are intended to be plugged into the

front of the appliance without the need for additional

wiring. If a remote wall mounted controller is required

then the patress box provided can be used Additional

wiring will be required as described.

4

3

Fig. 4.11 Opening the rear of the electronics box

4.8.3 Connecting accessories and external system

components

5

LN

230V

Caution!

a

Do not connect 230 V mains to terminals 7, 8,

or 9. The electronics could be destroyed by this!

• If no room/clock thermostat is in place, provide a jumper between terminals 3 and 4 if not already present.

Remove the jumper if a room/clock thermostat is connected to terminals 3 and 4.

• Close the rear cover of the electronics box and press

it in until you hear it click into place.

• Lift the electronics box up and press it by the two clips

on its left and right against the lateral appliance casings until you hear the clips click into place.

• Attach the front casing.

• In order to attain pump mode I (continuous pump) for

the multicircuit controller (e.g. VRC 630), increase the

pump over-run time to 15-20 minutes (diagnosis point

d.1, see chapter 6.2).

16 Installation and maintenance manual ecoMAX 665 / 0020020159_03

Fig. 4.12 Example of cable insertion

The Vaillant ProE plug in terminal system facilitates

a quick and trouble-free connection of accessories and

external system components to the appliance electronics. Proceed with the wiring up as follows:

• Take off the front casing of the appliance and lift the

electronics box forward.

• Unclip the back cover of the electronics box (1) from

its fixings (2) and lift it up.

Page 17

• Guide the connecting cables of each of the components

to be connected through the PG screw connections

(4) located on the bottom of the appliance to the left.

• Then insert the connecting cables (5) into the electronics box and cut them to length.

• Strip the connecting cable by about 2-3 cm and bare

the wires (see fig. 4.10).

• Connect the connecting cables as shown by fig.

4.10/4.11 to the ProE plugs or slots of the electronics.

Please note that the jumper on the ProE plug should be

removed when connecting a maximum thermostat (feed

thermostat) for floor heating. Should a remote safety

circuit for a mini pressurisation device or a pump flow

switch. This will prevent the boiler firing should such an

external device fail.

• Close the rear cover of the electronics box and press

it in until you hear it click into place.

• Lift the electronics box up and press it by the two

clips on its left and right against the lateral appliance

casings until you hear the clips click into place.

• Attach the front casing.

Installation 4

17Installation and maintenance manual ecoMAX 665 / 0020020159_03

Page 18

4 Installation

4.8.4 Connection diagram

X 6

Diagnostics

13

X 2

Coding Resistance

1

Contact -

The r m

R T 24 V

230V

N L

R T 230 V

9 8 7

X 10

1

X 7

PWM pump signal

Connection accessory box 306 248

and multi-function module 306 253 (1 of 5)

or multi-function module 306247 (2 of 6)

1

X 8

1

edge connector is included with the weather compensator

sensor for circulation pump/

FB - sensor for underfloor-heating system

AF - outside temperature sensor

RF - flow or return sensor

(DCF)

0

0

Sensor

for low

loss

header

Safety circuit 20V connection

24V I

230V

Vaillant controllers 24 V: connections 7, 8 and 9

Caution: Do not connect supply voltage!

Risk of electronics being destroyed!

Mains supply: 230 V/50 Hz

5 4 3

Pump 2. Pump

N L

L N

Fig. 4.13 Connection diagram ecoMAX 665

18 Installation and maintenance manual ecoMAX 665 / 0020020159_03

Room thermostat 230 V/50 Hz

(remove bridge on connection)

Connection 230 V/50 Hz fan

Boiler integral pump

Connection storage charging pump

Use of other functions via

module 1 of 5 (306 253) or

module 2 of 6 (306 247)

Page 19

4.8.5 Wiring diagram

Installation 4

Flow NTC

X 2/4 red

X 2/10 white

X 2/15 blue

X 2/8 black

X 2/20 black

Return NTC

Water pressure switch

Plug-in couplings

Water flow switch

Integral pump

Ignition electrode

Gas fitting

X 2/9 red (22 VDC)

X 2/24 blue (earth)

X 2/12 blue (earth)

X 2/7 grey (PWM)

X 2/3 black (hall signal)

X 2/17 red (22 VDC)

X 2/23 black (earth)

X 2/6 brown (signal)

X 2/24 black (earth)

X 2/2 orange (signal)

Fan

230 V connection

C1/C2 connector

(volt free switching cylinder thermostat)

Cylinder NTC connection

(Article number 306 257)

tank sensor

(plug colour: white)

Plug-in coupling

Electronics box

Fig. 4.14 Wiring diagram ecoMAX 665

X 10 X 7

X 4

1

1 1

1

X 6

13

X 2

Coding resistance

2 4V I

2 3 0V

X 8

1

Contact-

T herm

R T 2 4V

9 8 7

2 3 0V

5 4 3

N L

R T 2 3 0V

L N

N

L

Pump 2. Pump

19Installation and maintenance manual ecoMAX 665 / 0020020159_03

Page 20

5 Putting the boiler into service

5 Putting the boiler into service

Note!

h

Vaillant offer a commissioning service. If used

a 2 year warranty is given, if not only a 1 year

warranty is available

Observe the following when putting the boiler into service:

• Remove the cap of the automatic air vent (see 10 / fig.

5.1) before filling the heating circuit/DHW primary circuit.

• Start the venting program for the heating circuit/DHW

primary circuit (see chapter 8.1.5).

Caution!

a

The front cover should only be removed

• for initial installation access

• for servicing

• for testing

For continuous and safe operation the front

cover must be fitted together with a correctly

fitted and sealed flue system.

5.1 Water circulation system

Detailed recommendations for the water circulation

system are given in BS 6798 and BS 5449: Part 1 (for

small bore and micro bore central heating systems). Pipework not forming part of the useful heating surface should

be insulated to help prevent heat loss and possible freezing, particularly where pipes are run through roof spaces

and ventilated underfloor spaces. Draining points must be

located in accessible positions which permit the draining of

the whole system including the boiler and the hot water

system. Draining points should be at least 1/2 in. BSP nominal size and be in accordance with BS 2879. The boiler is

suitable for use with minibore or microbore systems. Copper tubing to BS 2871: Part 1 should be used for water carrying pipework. All capillary joints in all DHW pipework

must be made with lead free solder. Particularly where a

new boiler is to be fitted to an existing system, it is good

practice that the system is thoroughly cleansed.

Important!

To prevent the formation of deposits and

prevent serious damage to the appliance and

system, cleansers must be used carefully and

must be completely removed by thoroughly

flushing the system. Cleansers should only

be left in systems for a maximum of 24 hours.

5.1.1 Treating the heating water

If you enrich the heating water with frost or corrosion

protection fluid, changes can be caused in the seals and

noises may arise during the heating operation. Vaillant

assumes no liability for this (or for any subsequent resulting damage). Please inform the user as to how to go

about frost protection.

5.1.2 Heating side filling and bleeding

For the heating system to function perfectly, a water

pressure/filling pressure of between 1.0 and 2.0 bar is

necessary. If the heating system stretches out over

several storeys, higher values for the water level of the

system at the pressure gauge can be necessary (maximum pressure for safety valve: 3 bar).

Caution!

a

Filling the system must only be carried using

a proprietary filling loop in domestic applications.

For commercial applications a pressurisation

unit shall be installed.

5.1.3 Final system flush (”Hot”)

• Turn on the boiler for central heating and allow the

boiler and system to reach temperature.

• Check that the heating system is watertight.

• Turn the boiler off and rapidly drain both boiler and

system while still hot

• Refill the system and release all air.

• Release water from the system until the system design

pressure of 1.0 bar is attained. (The actual reading on

the pressure gauge should ideally be 0.5 bar plus an additional pressure corresponding to the highest point of

the system above the base of the boiler – 10 m head

equals an additional 1 bar reading on the pressure gauge.

The minimum pressure should not be less than1 bar in

any installation.) If the system is to be treated with an

inhibitor it should be applied at this stage in accordance

with the manufacturer’s instructions. Further information can be obtained from Sentinel, Betz Dearborn Ltd.,

Tel: 0151 4951861, or Fernox, Tel: 01483 793200

• Disconnect the temporary filling connection.

• Refit the boiler casing.

Note!

h

The venting program (“P.0”) runs for approx.

6.5 minutes.

This cleansing must take place prior to the fitting of the

new boiler and be in accordance with BS 7593. For advice on the application of system cleansers contact:

Sentinel, Betz Dearborn Ltd. Widnes,

Cheshire, WA8 8UD. Tel: 0151 495 1861 — or

Fernox, Cookson Electronics, Forsyth Road, Sheerwater,

Woking , Surrey GU21 5RZ,01483 793200

20 Installation and maintenance manual ecoMAX 665 / 0020020159_03

Caution!

a

For the venting of the system, the minimum

pressure must be 1.0 bar.

If pressure is too low, the boiler will not fire.

Do not allow the water pressure to drop below the above

minimum during venting.

Page 21

Putting the boiler into service 5

• Open the filling cock and tap valve again if necessary.

Caution!

a

If there is still too much air in the system after

the venting program has finished, the program

must be started again.

Caution!

a

After the filling process has finished

• Close the filling unit and remove the filling hose.

• Inspect all connections for leakage.

10

Caution!

a

If the installation set is not there, do not start

up the appliance, contact Vaillant customer

service.

Danger!

d

If the device is operated with an empty condensate siphon, there is the danger of poisoning

through escaping flue gases.

Therefore, it is mandatory to fill the siphon as

per the accompanying description before start-up.

5.2 Checking the gas setting

5.2.1 Factory gas setting

Caution!

a

This appliance is suitable for use on G20 natural

gas only. It is important to check the gas rate

of the appliance and perform a flue gas analysis

check.

The appliances are set ex works to the values listed in table.

• Check the CO

percentage as described in chapter 5.2.3.

2

Fig. 5.1 Bleeding the appliance

5.1.4 Filling the siphon

Mount the siphon as described in the accompanying installation instructions.

1

ecoTE

C

3

1

2

a

.

1

/

3

b

.

c

.

2

/

3

2004

00 10

311_

835

ecoMAX 665

Appliance design Natural gas H

Designation on the appliance badge I2H

Factory setting to Wobbe index Ws (in kWh/m3),

corresponding to 0 °C/1013 mbar

15.0

Factory setting of the hot water output (in kW) 65.0

Factory setting of the heating output (in kW) 60.0

Table 5.1 Overview of factory gas settings

5.2.2 Gas inlet working pressure

Check the inlet pressure as described below:

• Remove the front case from the boiler.

• Close the gas shutoff valve fitted to the boiler.

• Loosen the sealing screw marked ”in” (1) on the gas

valve assembly (Fig. 5.3).

• Connect a digital or a U gauge (2).

• Open the gas shutoff valve fitted to the boiler.

• Put the boiler into service (refer to the Instructions

for Use supplied with the boiler).

• Check the U gauge reading and ensure the inlet gas

pressure is between the pressures detailed below.

Fig. 5.2 Filling the siphon

21Installation and maintenance manual ecoMAX 665 / 0020020159_03

Page 22

5 Putting the boiler into service

1

2

Fig. 5.3 Measuring the gas inlet working pressure

Caution!

a

If the connection pressure lies outside the

range from 15 - 23 mbar, you must make sure

that the recommended pressure loss from the

meter to the appliance is not exceeded.

It may be necessary to install a test nipple to

the supply at the inlet to the boiler to correctly

measure the pressure loss.

• Press “Mains ON” or press the reset key.

• Now press the “+” key until P.0 appears in the display

(approx. 5 s).

• Then press the “+” key once. The display shows P.1.

• The test program P.1 is started by pressing the “i” key.

The appliance then runs for 15 minutes at full power.

• Wait at least 5 minutes until the appliance reaches operating temperature.

• Measure the CO2 content at the flue gas test nozzle

(3) (fig. 5.4). Compare the value measured with the

corresponding value in table 5.2.

• If a setting of the flue gas value is necessary, unscrew

the screw (4) and move the air intake pipe (5) forward

by 90°.

Do not remove the air intake pipe!

• If necessary, set the corresponding flue gas value (table

5.2) by turning the screw (6).

3

4

If the connection pressure lies within the permissible

range, proceed as follows:

• Put the appliance out of operation.

• Close the appliance‘s gas isolation valve.

• Remove the pressure gauge and screw the seal plug

(1, fig. 5.3) back on with the auxiliary tool supplied.

• Open the appliance‘s gas isolation valve.

• Check that the seal plug is re-fitted and tested for leaks.

• Put the front casing back on and start the appliance

up again.

If the connection pressure does not lie within the permissible range and you can‘t correct the error, notify

the gas supplier. Proceed as follows:

• Put the appliance out of operation.

• Close the appliance‘s gas stop cock.

• Remove the pressure gauge and replace the seal plug

(1, fig. 5.3) back on with the auxiliary tool supplied.

• Check that the seal plug is fit tight.

• Put the front casing back on.

Do not start up the appliance!

5.2.3 Checking the CO

needed (air ratio setting)

• Take off the appliance casing.

• Activate test program P.1:

content and adjusting it if

2

5

6

Fig. 5.4 Carrying out a CO2 measurement, carrying out an air

ratio setting (gas setting)

Note!

h

Adjust only in increments of 1/8 turn and wait

approx. 1 minute after each adjustment until

the value stabilises.

22 Installation and maintenance manual ecoMAX 665 / 0020020159_03

Page 23

Putting the boiler into service 5

- Turn to the left (anti-clockwise): higher CO2 content

- Turn to the right (clockwise): lower CO

Settings

CO2 after 5 minutes full-load operation 8.8 +/- 1.0

set for Wobbe index W

Table 5.2 Factory gas setting

o

content

2

Natural gas H

tolerance

15.0

• After the setting procedure, put the air intake pipe

back up.

• Check the CO

content again.

2

If necessary, repeat setting.

• Quit the P.1 test program by pressing the “+” and “i”

keys simultaneously. The measuring operation is also

quit when no key has been pressed for 15 minutes.

• Screw the screw (4) in.

• Put on the appliance casing.

5.3 Functional test

I

0

Filling the storage tank

• Switch on the appliance and the connected hot water

cylinder.

• Make sure that the cylinder thermostat is requesting heat.

• Press the “i” key.

When the cylinder is correctly charged, the status code

“S.24” appears in the display.

Fig. 5.6 Display during recharging

Heating mode

• Switch on the appliance.

• Make sure that heat is being requested.

• Press the “i” key.

When the heating is running correctly, the status code

“S.4” appears in the display.

Fig. 5.5 Functional test

After installing the appliance and setting the gas, perform a functional test before commissioning the appliance and handing it over to the user.

• Commission the appliance in accordance with the instructions in the relevant operating manual.

• Check the appliance for gas and water leaks.

• Check the flue system for leaks and that it is secured

and sealed properly.

• Check the ignition again and that the flame on the

burner is burning evenly.

• Check that the heating and hot water generation are

working properly.

• Pass the appliance on to the user.

The Vaillant ecoMAX 665 possesses status codes that

display the operating status of the appliance in the DIA

system display. A functional test of the hot water operation and heating operation can be carried out using

these status codes by pressing the “i” key.

Fig. 5.7 Display during heating mode

5.4 Instructing the user

The user of the heating system must be instructed

about its functions and how to operate it. The following

measures in particular are to be carried out here:

• Hand over any instructions intended for the user as

well as the appliance documentation.

• Inform the user that the instruction manuals should

be kept near the appliance.

Note!

When you have finished the installation, attach

the sticker supplied (835593) to the appliance

in the user’s language.

23Installation and maintenance manual ecoMAX 665 / 0020020159_03

Page 24

5 Putting the boiler into service

5.4.1 Instructing the user about the heating system

• Instruct the user about the methods used for combustion air supply and flueing. Be especially sure to point

out that these must not be altered or obstructed in

any way.

• Instruct the user on how to check the required water

level/filling pressure of the system as well as on methods of refilling and venting the heating system when

needed.

• Point out to the user the correct (economical) settings

for temperatures, controllers and thermostat valves.

• Instruct the user on the need for yearly inspection

and maintenance of the system. Recommend making

a maintenance contract.

Caution!

a

The front cover should only be removed

• for initial installation access

• for servicing

• for testing

For continuous and safe operation the front

cover must be fitted together with a correctly

fitted and sealed flue system.

5.4.2 Vaillant warranty

Vaillant provide a full parts and labour warranty for this

appliance. The appliance must be installed by a suitably

competent person in accordance with the Gas Safety

(Installation and Use) Regulations 1998, and the manufacturer’s instructions. In the UK ‘CORGI’ registered installers undertake the work in compliance with safe and

satisfactory standards.

All unvented domestic hot water cylinders must be installed by a competent person to the prevailing building

regulations at the time of installation (G3).

Failure to install and commission this appliance in compliance with the manufacturer’s instructions may invalidate the warranty (this does not affect the customer’s

statutory rights).

Note!

1 year warranty as standard.

2 year warranty available if commissioned by

Vaillant (contact 0870 8503072 for details).

24 Installation and maintenance manual ecoMAX 665 / 0020020159_03

Page 25

Adapting the appliance to the heating system 6

6 Adapting the appliance to the

heating system

6.1 Setting central heating output (range rating)

The appliances are set in the factory to the thermal load

shown in table 6.1. If you want to set a different load,

proceed as follows:

• Press the “i” and “+” keys simultaneously.

• Continue to hold the “+” key down until “d.0” appears

in the display.

• Then hold down the “i” key for about 5 seconds until

the display stops flashing.

The value is now saved. The standard display appears

again in the display (current heating supply temperature, e.g. 45 °C).

The display runs from “d.0” through to “d.99” and

starts again at “d.0”.

• Press the “i” key.

The “=” symbol appears in the display. Then the set partial load is displayed in kW.

• Quit the setting mode by pressing the “i” and “+” keys

simultaneously.

The setting mode is also quit if you do not touch a key

for 4 minutes.

ecoMAX Setting range

in kW

665 14.0 - 65.0 60.0

Factory setting

in kW

• By pressing the “+” or “-” keys you can now increase

or decrease the value in 1 kW increments.

The displayed value flashes during the setting procedure. The possible setting ranges are to be found in

table 6.1.

Table 6.1 Setting range for partial-load heating

25Installation and maintenance manual ecoMAX 665 / 0020020159_03

Page 26

6 Adapting the appliance to the heating system

6.2 Setting the pump over-run time

The pump over-run time for the heating mode is set to

5 minutes in the factory. It can be varied within a range

from 1 minute to 60 minutes or be in “continuous”

mode. In order to change the pump over-run time, proceed as follows:

• Pull the front panel of the appliance outwards.

• Switch the appliance main switch to the “l” position.

• Press the “i” and “+” keys simultaneously and hold

down the “+” key until “d.1” appears in the display.

The diagnosis code displayed is accompanied by the

plain text display “Pump over-run heating”.

• Press the “i” key.

The current pump over-run time in minutes appears in

the display.

• By pressing the “+” or “-” keys you can now increase

or decrease the value.

To set the pump mode “continuous”, do not enter a

number, rather select the symbol “--” with the “+” or “-”

key.

• Hold down the “i” key for about 5 seconds until the

display stops flashing.

The value is now saved.

• Quit the setting mode by pressing the “i” and “+” keys

simultaneously.

The standard display appears again in the display (current

heating supply temperature, e.g. 45 °C). The setting mode

is also quit if you do not touch a key for 4 minutes.

The diagnosis code displayed is accompanied by the

plain text display “max. lockout time heating”.

• Press the “i” key.

The symbol “=” now appears in the display and then the

current burner anti-cycle time in minutes.

• By pressing the “+” or “-” keys you can now increase

or decrease the value in 1 minute increments.

The displayed value flashes during the setting procedure.

• Hold down the “i” key for about 5 seconds until the

display stops flashing.

The value is now saved.

• Quit the setting mode by pressing the “i” and “+” keys

simultaneously.

The standard display appears again in the display (current

heating supply temperature, e.g. 45 °C).

The setting mode is also quit if you do not touch a key

for 4 minutes.

6.4 Adapting the appliance to larger flue pipe

lengths

For flue pipes longer than 10 m (system 80/125), the appliance fan speed can be increased.

• Call up the diagnosis point d.51 in the DIA system.

• Increase the value by 20.

The maximum speed of the fan is raised by 200 r.p.m.

(see chapter 8.1.2).

6.3 Setting the burner anti-cycle time

In order to avoid frequent switching on and off of the

burner (energy loss), an electronic block preventing

re-ignition after shut down for a pre-determined period.

The burner anti-cycle time can be adjusted to fit the

characteristics of the heating system.

The burner anti-cycle time is only activated for the

heating mode. Hot water operation during a burner anticycle time in progress does not affect the timer.

The maximum burner anti-cycle time can be set under

diagnosis point d.2 between 2 and 60 minutes (factory

setting: 20 minutes). The anti-cycle time effective in

each case is then automatically calculated from the

current set supply temperature and the set maximum

burner anti-cycle time.

The timer can be reset or deleted by pressing the appliance main switch. The burner anti-cycle time remaining

in the heating mode after a control shutdown can be

viewed under diagnosis point d.67.

In order to change the lockout time, proceed as follows:

• Pull the front panel of the appliance outwards.

• Switch the appliance main switch to the “l” position.

• Press the “i” and “+” keys simultaneously and hold

down the “+” key until the diagnosis code “d.2”

appears in the display.

26 Installation and maintenance manual ecoMAX 665 / 0020020159_03

Page 27

Inspection and maintenance 7

7 Inspection and maintenance

7.1 Inspection and maintenance intervals

Appropriate, regular inspections and maintenance and

the exclusive use of original spare parts are the decisive

factors in determining whether your Vaillant ecoMAX

665 will run problem-free and have a long service life.

Danger!

d

Inspections/Maintenance work not carried out can

result in material damage and injury to persons.

We therefore recommend the conclusion of an inspection or maintenance contract. The inspection is intended

to determine the actual condition of the respective device and compare it with the nominal condition. This is

done by measuring, checking, observing.

Maintenance is required in order to eliminate any deviations of the actual condition from the specified condition. This is usually done by cleaning, setting and, if necessary, replacing individual components subject to wear.

With regard to the Vaillant ecoMAX 665, this means it is

usually sufficient to conduct an inspection once a year.

Inspections can be performed quickly and economically

without dismounting any components thanks to the data

query in the DIA system, easy optical inspection and an

air ratio measurement.

Experience indicates that under normal circumstances it

is not necessary to clean the burner and heat exchangers yearly. These maintenance intervals and their extent

are determined by a specialist, depending on the ascertained condition of the appliance during the inspection.

All inspection and maintenance work should be performed in the order specified in table 7.1.

Caution!

a

The front cover should only be removed

• for initial installation access

• for servicing

• for testing

For continuous and safe operation the front

cover must be fitted together with a correctly

fitted and sealed flue system.

Danger!

d

The supply terminals of the appliance are under

voltage even if the appliance on/off switch is off.

Always perform the following steps prior to maintenance work:

• Switch off the appliance on/off switch.

• Disconnect the appliance from the mains supply by

de-energising the appliance by means of a separator

with a contact opening of at least 3mm (e.g. fuses or

circuit breakers).

• Close the gas shut-off valve.

• Close the heating flow and return and the cold water

inlet valve.

• Take the front casing off the appliance.

Always perform the following steps after performing

any maintenance work:

• Open the heating flow and return and the cold water

inlet valve.

• Refill the appliance, if necessary, on the hot water

side up to a pressure of between 1.0 and 2.0 bar and

bleed the heating system (see chapter 5.1).

• Open the appliance gas isolation valve.

• Reconnect the device to the mains supply and switch

on the mains switch.

• Check the appliance for gas and water leaks.

• If necessary, refill and vent the heating system.

• Put on the appliance‘s front casing.

Note!

h

The boiler is fitted with a combustion analysis

test point. A suitable combustion analyser can

be connected to this point to establish the

combustion performance of the boiler. Checking/adjustment of this value is required in the

following instances; replacement of gas valve,

or if incorrect combustion is suspected (see

section 5.2.3)

7.2 Inspection and maintenance instructions

Only original Vaillant spare parts may be used for inspections, maintenance and repair work to ensure the

perfect long-term working order of all functions of the

Vaillant appliance.

Please contact Vaillant Service Solutions 0870 850 3072

for further details.

Note!

h

If inspection and maintenance work is necessary with the mains switch on, this is indicated

in the description of the maintenance work.

27Installation and maintenance manual ecoMAX 665 / 0020020159_03

Page 28

7 Inspection and maintenance

No. Step

Disconnect the appliance from the mains supply, close the gas supply and maintenance cocks,

1

depressurize the appliance on the water side (observe the pressure gauge)

2 Dismantle thermal compact module X

3 Clean the integral condensation heat exchanger X

4 Check whether the burner is dirty X

5 Install compact thermal module. Caution: replace the seals! X

Check whether the electrical plug connections and other connections are fitted tightly

6

and make adjustments, if necessary.

7 Cleaning the air intake tube X

Open the maintenance cocks and fill the appliance/system up to about 1.0 - 2.0 bar

8

(depending on the static height of the system); start the venting program

To be carried out during:

Inspection Maintenance

XX

X

X

Check the overall condition of the appliance, remove general dirt from the appliance

9

and the vacuum chamber

10 Check the condensate siphon in the appliance, and clean and fill it if necessary. X X

11 Clean the condensate paths in the appliance X

12 Open the gas supply and switch on the appliance X X

Perform a test run on the appliance and heating system, including

13

water heating, and bleed if necessary

14 Test ignition and burner performance X X

15 Check whether the appliance is leaking flue gas, water or condensate X X

16 Check the flue system for leaks and that it is fixed properly, and make adjustments if necessary X X

17 Check appliance gas setting, reset and record if necessary. X

XX

XX

18 Complete the gas commissioning checklist (Benchmark) X X

Table 7.1: Maintenance steps

28 Installation and maintenance manual ecoMAX 665 / 0020020159_03

Page 29

Inspection and maintenance 7

7.2.1 Servicing the compact thermal module

Removing the compact thermal module

The compact thermal module consists of the speed-controlled fan, the gas fitting, the mixer tube and the burner with flange. These four components make up the assembly that is the compact thermal module. Proceed as

follows to dismount it: (see fig. 7.1)

1

2

3

4

5

6

7

8

Caution!

a

Under no circumstances may the compact thermal module be suspended from the flexible appliance gas pipe.

• Pull the entire compact thermal module (5) off the integral condensation heat exchanger (1).

Mounting the compact thermal module

Danger!

d

The seal (1) and silicate cord (2) on the compact thermal module (fig. 7.2) (SP no. 180904)

must be replaced every time the thermo compact

module is removed. The burner flange insulation

(3) on the compact thermal module (SP no.

180913) must not show any signs of damage;

if it does, it must also be replaced.

2

1

910

11

Fig. 7.1 Dismounting/Mounting the compact thermal module

Danger!

d

There is danger of being injured or scalded at

the compact thermal module and at all components carrying water. Only work on the components once they have cooled down.

The mixer tube (7) between gas control unit

and burner may not be opened. It can only be

guaranteed that this component is gas-tight

after it has been inspected at the factory.

• Cut off the gas supply to the appliance.

• Lower the electronics box.

• Undo the fastening screw of the air intake pipe (3) and

lift the air intake pipe forward (2); remove the air intake pipe from the intake socket.

• Pull the two plugs of the ignition und grounding lines

off the ignition electrode (6).

• Undo the gas supply line (10) on the underside of the

electronic gas valve (fig. 7.1).

• Pull off the cable (8) at the fan motor (coupling), the

PWM signal cable beneath the fan (9) and the cable

for the gas fitting (11).

• Undo the six nuts (4).

1

2

3

Fig. 7.2 Checking seals and burner flange insulation

• Put the compact thermal module (5) onto the heat

exchanger (1) (fig. 7.1).

• Tighten the six nuts (4) evenly and crosswise.

• Put the air intake tube (2, fig. 7.1) onto the intake

socket and tighten the screw (3).

• Connect the gas supply line (10) with a new seal to the

gas fitting. Use a suitable open-end spanner to do so.

• Connect the two plugs of the ignition and the earth

connection to the ignition electrode (6).

• Put back on the cable (8) at the fan motor (coupling),

the PWM signal cable beneath the fan (9) and the

cable for the gas fitting (11).

• Open the gas isolation valve to the boiler.

Danger!

d

Check the gas connection (10) for leaks with

leak spray.

29Installation and maintenance manual ecoMAX 665 / 0020020159_03

Page 30

7 Inspection and maintenance