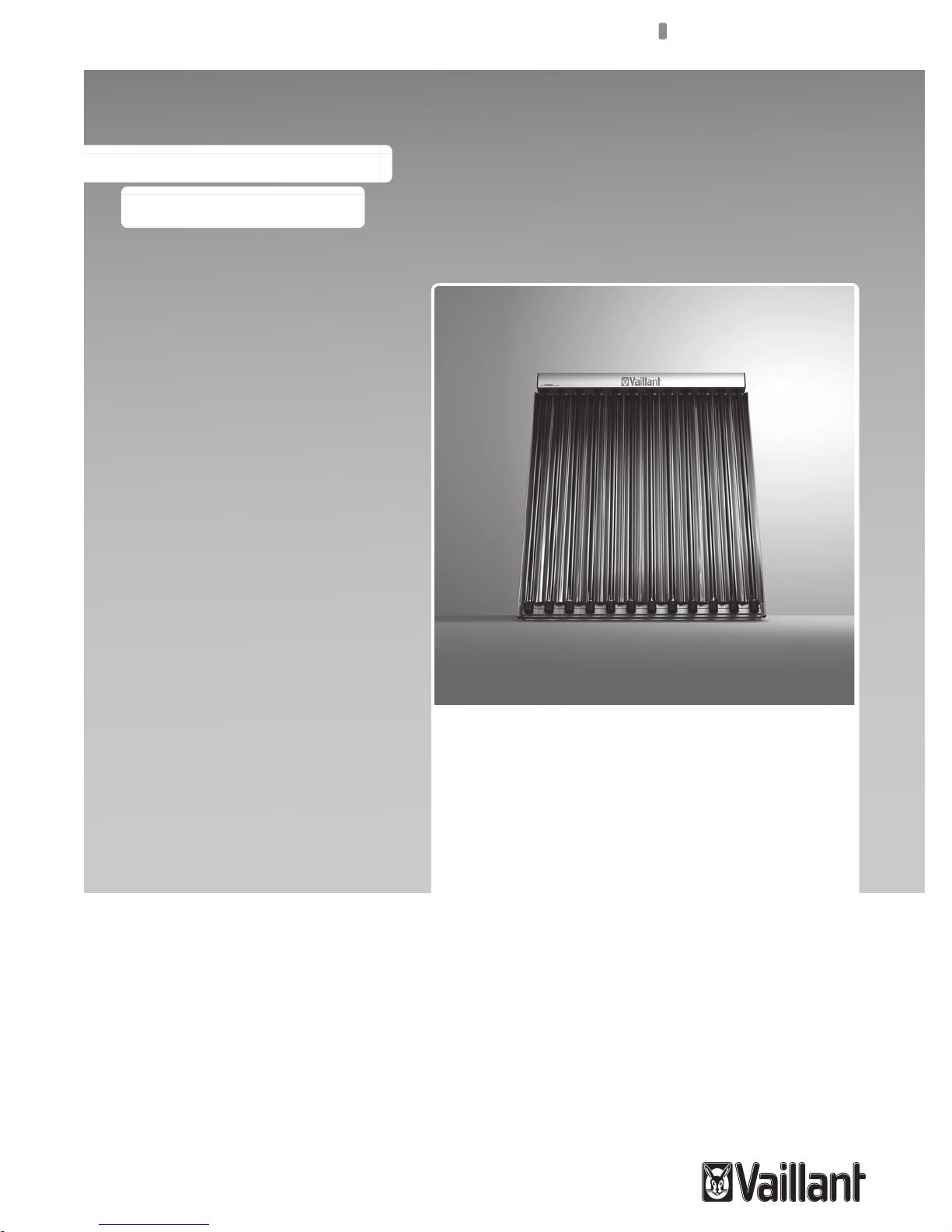

Vaillant auroTHERM exclusive VTK SERIES, auroTHERM exclusive VTK 570/2, auroTHERM exclusive VTK 1140/2 Installation Manual

Page 1

For the competent person

Installation manual

Installation manual

auroTHERM exclusive

VTK 570/2, VTK 1140/2

GB, IE

Page 2

Legal information

Document type: Installation manual

Product: auroTHERM exclusive

– VTK 570/2

– VTK 1140/2

Target group: Authorised competent person

Language: EN

Document number_version: 0020077994_03

Created on: 26.10.2012

Publisher/manufacturer

Vaillant GmbH

Berghauser Str. 40 D-42859 Remscheid

Telefon +49 21 91 18‑0 Telefax +49 21 91 18‑28 10

info@vaillant.de www.vaillant.de

© Vaillant GmbH 2012

These instructions, or extracts thereof, may only be printed with the written consent of Vaillant GmbH.

All designations of products in these instructions are brand names/trade marks of the companies in question.

We reserve the right to make technical changes.

Page 3

Contents

1 Notes on the documentation .............................. 4

1.1 Symbols used ........................................................ 4

1.2 Observing other applicable documents ................. 4

1.3 Document storage ................................................. 4

1.4 Applicability of the instructions .............................. 4

1.5 Name ..................................................................... 4

2 Safety .................................................................... 5

2.1 Action-related warnings......................................... 5

2.2 Required personnel qualifications ......................... 5

2.3 General safety information .................................... 5

2.4 Intended use.......................................................... 6

2.5 Regulations (directives, laws, standards).............. 7

2.6 CE label ................................................................. 7

3 Description of the unit......................................... 8

3.1 Type overview........................................................ 8

3.2 Information on the identification plate.................... 8

3.3 Purpose of the unit................................................. 8

4 On-roof fitting and installation ........................... 8

4.1 Preparing for fitting and installation ....................... 8

4.2 Carrying out the installation................................. 18

4.3 Completing and checking the installation ............ 25

5 Flat roof fitting and installation........................ 26

5.1 Preparing for fitting and installation ..................... 26

5.2 Carrying out the installation................................. 39

5.3 Completing and checking the installation ............ 46

6 Inspection and maintenance ............................ 47

6.1 Maintenance plan ................................................ 47

6.2 Observing inspection and maintenance

intervals ............................................................... 47

6.3 General inspection and maintenance

instructions........................................................... 47

6.4 Preparing for inspection and maintenance.......... 47

6.5 Checking collectors and connections for

damage, dirt and lack of tightness....................... 47

6.6 Cleaning collectors .............................................. 48

6.7 Checking brackets and collector components

for firm seating..................................................... 48

6.8 Check the pipe insulations for damage ............... 48

6.9 Replacing damaged pipe insulations................... 48

6.10 Disposing of damaged pipe insulations............... 48

7 Troubleshooting ................................................ 48

7.1 Spare parts for repair........................................... 48

7.2 Carrying out repairs ............................................. 48

8 Decommissioning.............................................. 49

8.1 Temporary decommissioning .............................. 49

8.2 Permanently decommissioning............................ 50

9 Customer service............................................... 50

10 Technical data.................................................... 51

10.1 Technical data table............................................. 51

10.2 Dimensions.......................................................... 52

10.3 Efficiency and pressure loss................................ 53

Index ................................................................................... 55

Contents

0020077994_03 auroTHERM exclusive Installation manual 3

Page 4

1 Notes on the documentation

n

1 Notes on the documentation

1.1 Symbols used

Symbols

The following symbols may appear:

Warning symbol (→ Page 5)

Information symbol

Symbol for a required action

Symbol for the result of an action

Symbol for the completion of records and checklists

Symbol for a required qualification

1.3 Document storage

Document handover

▶ Pass this installation manual and all other applicable

documents and, if necessary, any required tools to the

system operator.

Availability of documents

The system operator is responsible for storing the documents so that they are available whenever required.

1.4 Applicability of the instructions

These instructions apply for the following only:

Collector types and article numbers

VTK 570/2

VTK 1140/2

1.5 Name

In this manual, tube collectors are referred to as collectors.

0010002225

0010002226

Symbol for a required tool

Symbol for the specification of a technical value

Symbol for adjacent array configuration

Symbol for array configuration on top of each

other

1.2 Observing other applicable documents

▶ All installation instructions for the component parts and

components of the solar plant must be observed when

installing the collectors.

These installation instructions are enclosed with the various

system parts and supplementary components.

4 Installation manual auroTHERM exclusive 0020077994_03

Page 5

Safety 2

2 Safety

2.1 Action-related warnings

Classification of action-related warnings

The action-related warnings are classified in accordance

with the severity of the possible danger using the following

warning signs and signal words:

Warning symbols and signal words

Danger!

Imminent danger to life or risk of severe personal

injury

Danger!

Risk of death from electric shock

Warning.

Risk of minor personal injury

Caution.

Risk of material or environmental damage

2.2 Required personnel qualifications

This manual is intended for persons with the following qualifications

2.2.1 Authorised competent person

The installation, assembly and removal, start-up, maintenance, repair and decommissioning of Vaillant products and

accessories must only be carried out by authorised competent persons.

Note

Each competent person is qualified for specific

activities on the basis of their training. They must

only work on units if they have the required qualification.

When working on the units, the competent persons must

observe all applicable directives, standards, laws and other

regulations.

2.3 General safety information

2.3.1 Danger due to improper use

Vaillant auroTHERM VTK tube collectors are constructed

using state-of-the-art technology in accordance with the recognised safety rules and regulations. Nevertheless, there is

still a risk of injury or death to the user or others or of damage to the unit and other property in the event of improper

use or use for which it is not intended.

2.3.2 Risk of death due to improper fastening

systems

The collectors may fall due to improper fastening systems.

Only the combination of Vailllant collectors and Vaillant

fastening systems has been tested. This combination can

withstand the forces caused by additional wind and snow

loads.

▶ Only use the collector fastening systems that are ap-

proved by Vaillant.

2.3.3 Risk of death due to inadequate loadbearing capacity of the roof

A roof with an insufficient load-bearing capacity may collapse

due to the additional load of the collectors.

Above all, additional wind and snow loads may result in

higher forces which could cause the roof to collapse.

▶ Ensure that a structural engineer has confirmed the roof

as suitable for collector installation.

▶ Only install the collectors on a roof that has adequate

load-bearing capacity.

2.3.4 Risk of death due to falling parts

Unsecured collectors can fall from the roof and present a

danger to persons.

▶ Block off the areas in the fall area below the place of

work to a sufficient extent so that persons cannot be injured by falling objects.

▶ Indicate the working area, e.g. with information signs, in

accordance with the applicable regulations.

2.3.5 Risk of injury and material damage due to

incorrect maintenance and repairs

If maintenance or repair work is not carried out, or is carried

out incorrectly, this may result in injuries or in damage to the

solar plant.

▶ Ensure that only an approved competent person carries

out maintenance and repair work.

2.3.6 Risk of death due to inadequate fastening

of the collectors

Collectors can fall from their anchors if they are not properly

fastened on the roof. Collectors falling from the roof could

cause life-threatening accidents.

▶ Perform all work steps as described in this manual.

▶ Observe all safety precautions described in this manual.

▶ In addition, comply with all safety regulations that spe-

cifically apply in your region.

2.3.7 Risk of burns due to hot collector surfaces

In the event of solar radiation inside the units, collectors can

reach 300 °C. If you touch the collectors without protection,

you could burn yourself.

▶ Remove the sun protection film installed at the factory

only after the solar plant has been started up.

▶ Avoid performing installation and maintenance work un-

der direct sunlight.

0020077994_03 auroTHERM exclusive Installation manual 5

Page 6

2 Safety

▶ Cover the collectors before starting work.

▶ You should preferably perform the work in the morning.

▶ Wear suitable safety gloves.

2.3.8 Risk of injury due to breaking glass

The glass of the collectors may break due to mechanical

destruction or torsion.

▶ Wear suitable safety gloves.

▶ Wear suitable protective goggles.

2.3.9 Material damage caused by a high-pressure

cleaner

High-pressure cleaners may damage the collectors due to

the extremely high pressure.

▶ Never clean the collectors with a high-pressure cleaner.

2.3.10 Material damage due to lightning

Lightning can damage the collector system.

▶ Connect the collector system to a lightning protection

device in accordance with applicable regulations.

2.3.11 Frost damage due to water in the solar

circuit

Water residue in the collector may freeze in frosty conditions

and damage the collector.

▶ Never fill or flush the collector with water.

▶ Only fill and flush the collector with Vaillant ready-mixed

solar fluid.

▶ Check the solar fluid regularly with an antifreeze tester.

2.3.12 Material damage due to an unsuitable tool

An unsuitable tool may damage the solar plant.

▶ Only use a suitable tool.

▶ In particular, only use the tool specified in the work steps

of this manual.

▶ Bond the earthing pipe clamps to a busbar using 16 mm²

copper cable.

2.3.15 Risk of death and material damage due to

contact corrosion

For roofs or façade sections made of metals more precious

than aluminium (e.g. copper roof), contact corrosion may

occur on the brackets. Collectors could fall and put persons

at risk.

▶ Use suitable underlays to separate the metals.

2.3.16 Material damage due to snow falling from

roofs

If the collector field is installed below a sloping roof, then

snow falling from the roof may damage the collectors.

▶ Install snow fences above the collectors as protection

against falling snow.

2.4 Intended use

2.4.1 Intended use

Vaillant auroTHERM VTK tube collectors are used for solar

heating support and for solar-supported hot water generation.

2.4.2 Suitability of the equipment

The collectors must only be operated with Vaillant readymixed solar fluid. Passing heating water or hot water directly

through the collectors constitutes improper use.

2.4.3 Improper use

Any use which is not explicitly mentioned in the chapter "Intended use" (→ Page 6) is deemed improper.

Any other or additional use does not comply with the intended use. Any direct commercial or industrial use is also

deemed to be improper. The manufacturer/supplier is not liable for any damage resulting from such use. The user alone

bears the risk.

2.3.13 Risk of death from electric shock

Incorrect installation or a faulty power cable can result in a

supply voltage on the pipes, which can cause life-threatening

injuries.

▶ Secure earthing pipe clamps to the pipes.

▶ Connect the earthing pipe clamps to a busbar using 16

mm² copper cable.

2.3.14 Material damage due to overvoltage

Overvoltage may damage the solar plant.

▶ Earth the solar circuit to provide equipotential bonding

and overvoltage protection.

▶ Secure earthing pipe clamps to the pipes.

6 Installation manual auroTHERM exclusive 0020077994_03

2.4.3.1 Combination with other components

Vaillant auroTHERM VTK tube collectors must only be combined with components (fastenings, connections, etc.) and

system parts that are supplied by Vaillant. The use of other

components or system parts shall be considered as improper

use.

Page 7

Safety 2

2.4.3.2 Installation in or on vehicles

Installation of the Vaillant auroTHERM VTK tube collector in

or on a vehicle is not permissible and is considered improper

use. Units that are not classed as vehicles are those that are

installed in a fixed and permanent location (known as "fixed

installation").

2.4.4 Other applicable documents

Intended use includes the following:

– observance of accompanying operating, installation and

servicing instructions for Vaillant products as well as for

other parts and components of the system,

– installing and fitting the unit in accordance with the boiler

and system approval,

– compliance with all inspection and maintenance condi-

tions listed in the instructions.

2.5 Regulations (directives, laws, standards)

2.5.1 Installation regulations

Applies to: Great Britain

Technical Guidance

The system must be installed in accordance with all relevant

and applicable national regulations, and must be installed to

suit site conditions. Observe all national regulations, including:

– Working at Heights Regulations 2005

– Health and Safety at Work Act 1974

– Electricity at Work Regulations 1989

– IEE Wiring Regulations BS 7671

–

Lightning protection requirements

– Equipotential bonding of electrical installations.

Related documents

The installation of the solar system must be in accordance

with the relevant requirements of Health and Safety Document No. 635 (The Electricity at Work Regulations 1989),

BS7671 (IEE Wiring Regulations) and the Water Supply

(Water Fitting) Regulations 1999, or The Water Bylaws 2000

(Scotland). It should also be in accordance with the relevant

requirements of the Local Authority, Building Regulations,

The Building Regulations (Scotland), The Building Regulations (Northern Ireland) and the relevant recommendations

of the following British Standards:

– BS EN 806: Specification for installations inside buildings

conveying water for human consumption

– BS 6700: Services supplying water for domestic use

within buildings and their curtilages

– BS 5449 Forced circulation hot water central heating

systems for domestic premises. Note: only up to 45 kW

– BS. 6880 Low temperature hot water heating systems of

output greater than 45 kW

– Part 1 Fundamental and design considerations.

– Part 2 Selection of equipment

– Part 3 Installation, commissioning and maintenance

– BS 6114: Expansion vessels using an internal diaphragm

for unvented hot water supply systems

– BS. 4814 Specification for: Expansion vessels using an

internal diaphragm, for sealed hot water heating systems

– Unvented hot water systems must comply with building

regulation G section 3

2.5.2 Regulations for the prevention of accidents

Applies to: Great Britain

When carrying out works such as solar installation work it is

necessary to do so in a safe and workman like manner, taking due care of any aspects of the works that could result in

injuries to person in or about the building as well as workers,

passers by and the general public at large. To that end these

works must conform, but not be limited to, the current regulations in force such as the following:

– Health and Safety at Work act 1974

– Work at Height Regulations 2005

– Electricity at Work Regulations 1989

– All necessary Building Regulations

Work should be preceded by a risk assessment covering all

aspects of health and safety risks, or training requirements

that can reasonably be foreseen to be associated with the

work. All scaffolding in the UK, other than prefabricated (zipup) scaffold towers, must be designed and constructed by a

vetted contractor, and have suitable kick boards, hand rails

and where appropriate netting. Areas around the scaffolding

should be zoned off and marked with suitable warning signs

to a suitable distance to protect persons from falling objects.

Workers should have available and use personal protective equipment as necessary. This would include equipment

such as fall protection systems, safety gloves, goggles, dust

masks as well as any specialised equipment that may be in

use such as lifting and handling equipment.

The completed works shall comply with all necessary BS EN

Standards and Codes of practice as well as Building control

or planning requirements and be confirmed where necessary

by notification to building control or the appropriate competence based notification body.

2.6 CE label

The CE label documents that the appliances as

described in the type overview satisfy the basic requirements

of the following directives:

– Directive 97/23/EC of the European Parliament and

Council on the approximation of the laws of the member

states regarding pressure equipment

0020077994_03 auroTHERM exclusive Installation manual 7

Page 8

3 Description of the unit

Serial-No.

3 Description of the unit

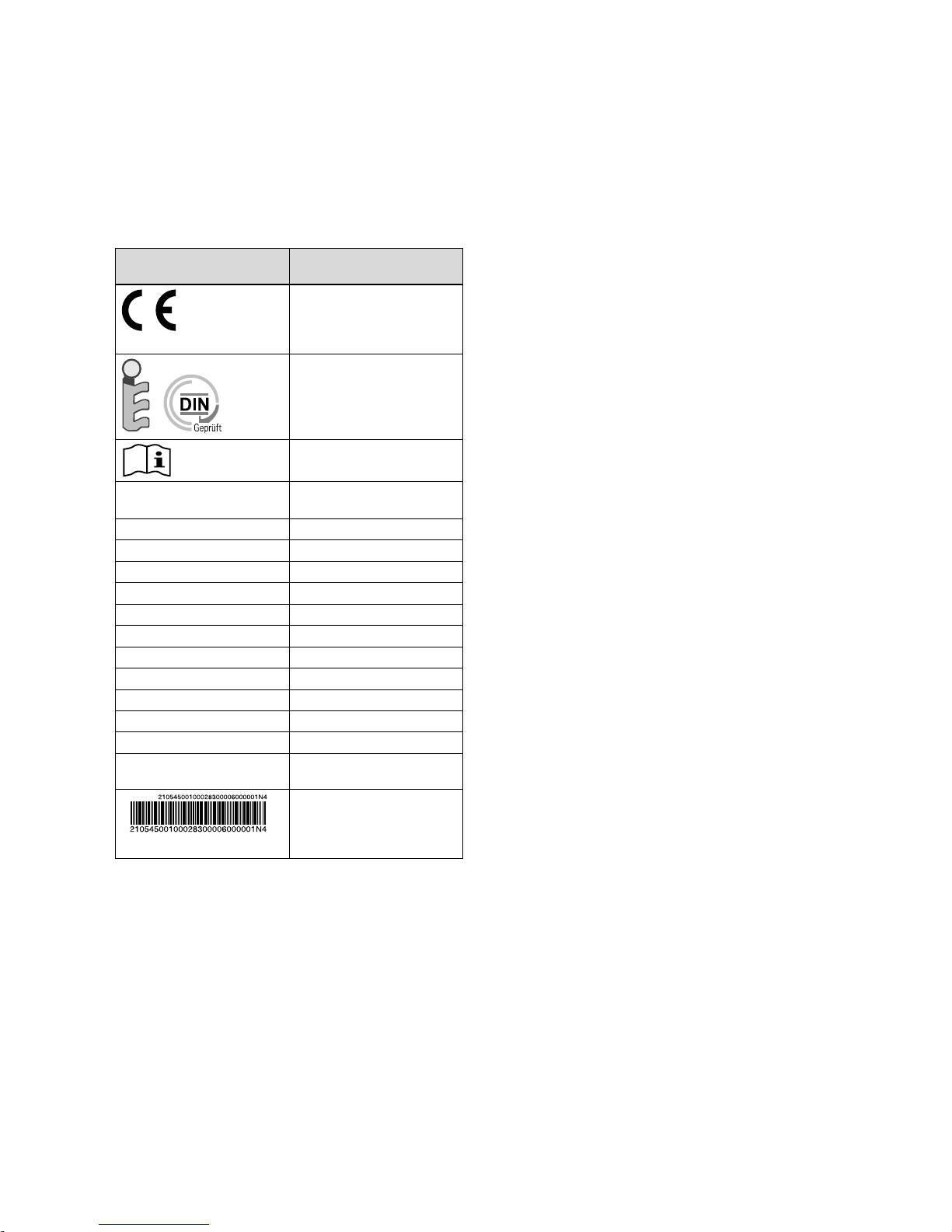

3.1 Type overview

– VTK 570/2

– VTK 1140/2

3.2 Information on the identification plate

Information on the identification plate

VTK 570/2

VTK 1140/2

VTK Vaillant tube collector

570, (1140) Collector output

/2 Unit generation

auroTHERM exclusive Unit type

Vacuum tube collector Tube collector

AG Gross area

VF Liquid volume

m Weight

l Dimensions

Qmax Max. output

tstgf Stagnation temperature

Pmax Max. permissible operating

Meaning

CE label:

The collectors comply with

the relevant product-specific

European guidelines.

Solar Keymark:

The collectors have been

successfully tested according

to the rules and requirements

for the Solar Keymark.

Read the installation manual.

Type designation

pressure

Bar code with serial number

The 7th to 16th digits of the

serial number form the article

number

4.1 Preparing for fitting and installation

4.1.1 Delivery, transport and positioning

4.1.1.1 Storing collectors

▶ To prevent moisture from penetrating into the collector,

always store the collectors dry and in a weatherproof

area.

3.3 Purpose of the unit

The collectors are used for solar heating support as well as

for solar-supported hot water generation.

4 On-roof fitting and installation

▶ When fitting and installing the collectors, you must ob-

serve the chapter "Safety".

8 Installation manual auroTHERM exclusive 0020077994_03

Page 9

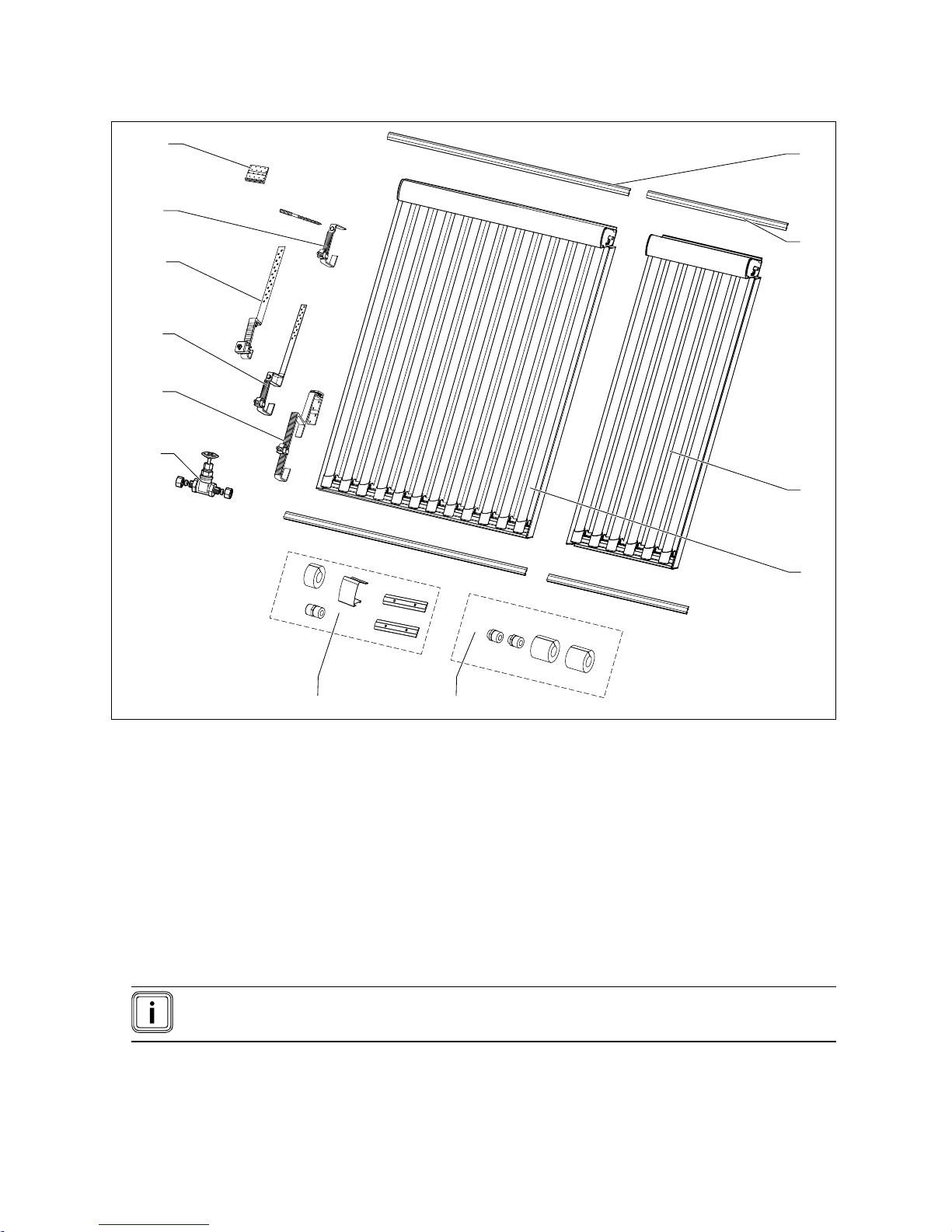

4.1.1.2 Checking the scope of delivery

1

3

2

5

8

9

10

7

11

12

4

6

On-roof fitting and installation 4

List of materials for on-roof installation

1 VTK 1140/2 rail set, 2 units

2 VTK 570/2 rail set, 2 units

3 VTK 570/2 tube collector, 1 unit

4 VTK 1140/2 tube collector, 1 unit

5 VTK installation set (basic set), 1 unit

6 VTK installation set (extension set), 1 unit

7 Stop valve, 2-way VTK for parallel connection, 1 unit

8 Roof bracket type P (for pantile) (basic set), 4 units

Roof bracket type P (for pantile) (extension set, on top of

each other), 2 units

▶ Use the image to check that the installation sets are complete.

9 Roof bracket type S (for beaver tail, etc.) (basic set),

4 units

Roof bracket type S (for beaver tail, etc.) (extension set,

on top of each other), 2 units

10 Roof bracket type S flat (for beaver tail, etc.) (basic set),

4 units

Roof bracket type S flat (for beaver tail, etc.) (extension

set, on top of each other), 2 units

11 Hanger bolt fastening set (basic set), 4 units

Hanger bolt fastening set (extension set, on top of each

other), 2 units

12 Long base, hook type P, 4 units

Note

Not all roof bracket types are available in all countries.

0020077994_03 auroTHERM exclusive Installation manual 9

Page 10

4 On-roof fitting and installation

max. 7 x VTK 1140/2

4.1.1.3 Transporting collectors

1. To protect the collectors against damage, always transport them when they are standing horizontally.

2. Transport the collectors to the roof using suitable aids.

4.1.2 Complying with clearances and installation

clearances

In order to fit the collectors correctly, the specified clearances and installation clearances must be observed.

▶ For the necessary edge clearances, see chapter "Defin-

ing edge clearances of the roof brackets".

4.1.3 Selecting suitable connection

▶ Select the appropriate connection for the collectors.

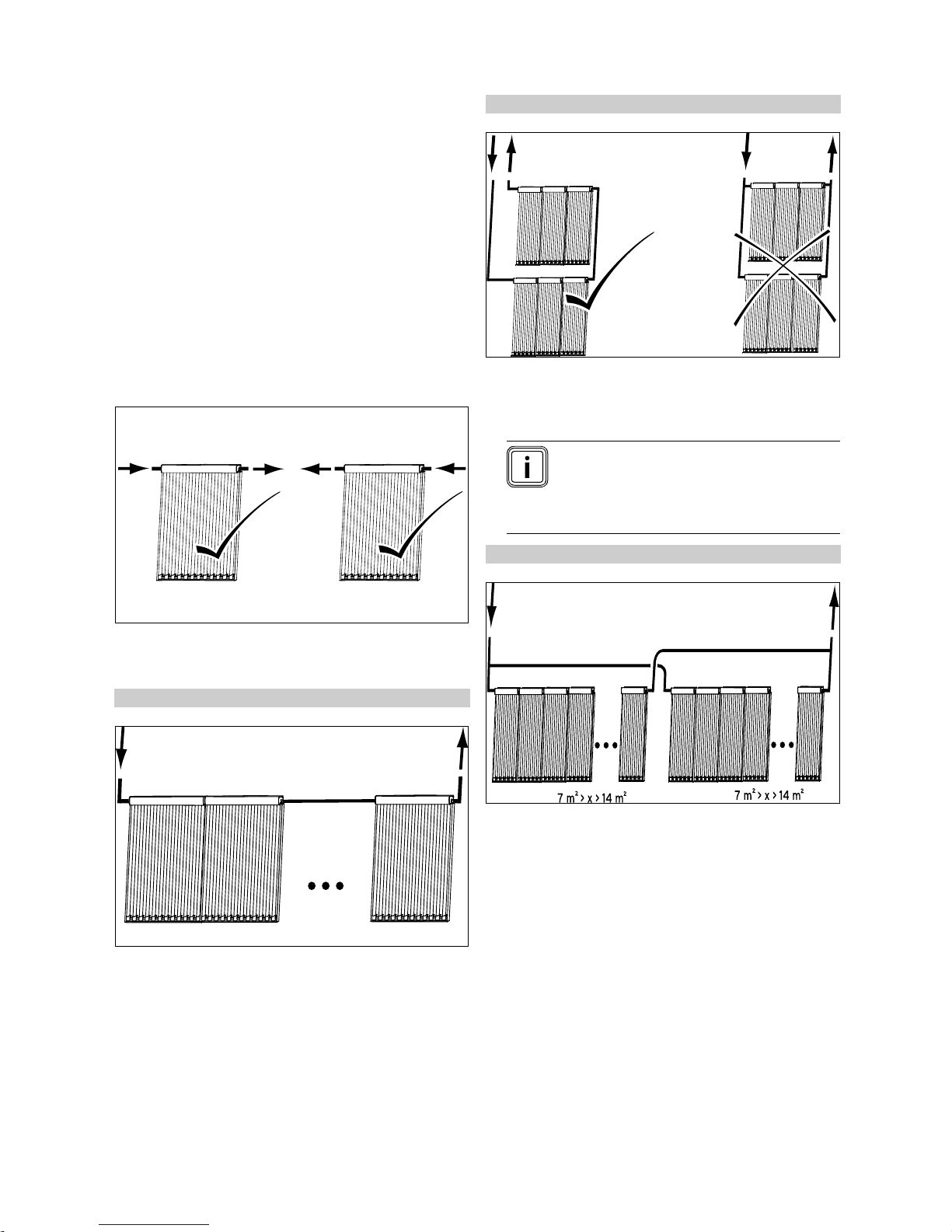

Conditions: Parallel connection, aperture surface area: ≤ 7 m²

▶ Always connect as many collectors as possible in series,

even when several collector rows are arranged on top of

each other.

Note

Up to an aperture surface area of 7 m²

(accordingly for 3 pcs VTK 1140/2 + 1 pc

VTK 570/2), you must switch the collectors in

series.

▶ Ensure that the solar fluid flows through the collectors

either from left to right or from right to left.

Conditions: Number of VTK 1140/2 collectors: 1 … 7

▶ Switch up to 7 VTK 1140/2 units in series (according to

the 14 m² aperture surface area).

Conditions: Parallel connection, aperture surface area: ≥ 14 m²

▶ Set up several parallel collector rows and connect these

hydraulically in parallel.

▶ Always connect as many collectors (at least 7 m²) as

possible in series.

10 Installation manual auroTHERM exclusive 0020077994_03

Page 11

Conditions: Parallel connection

▶ To avoid pressure losses in the sub-collector fields, only

use parallel connection for collector rows with the same

number of collectors.

▶ Ensure that each sub-collector field has the same total

tube length in the flow and return (Tichelmann system), in

order to avoid pressure losses in the connection tubes.

On-roof fitting and installation 4

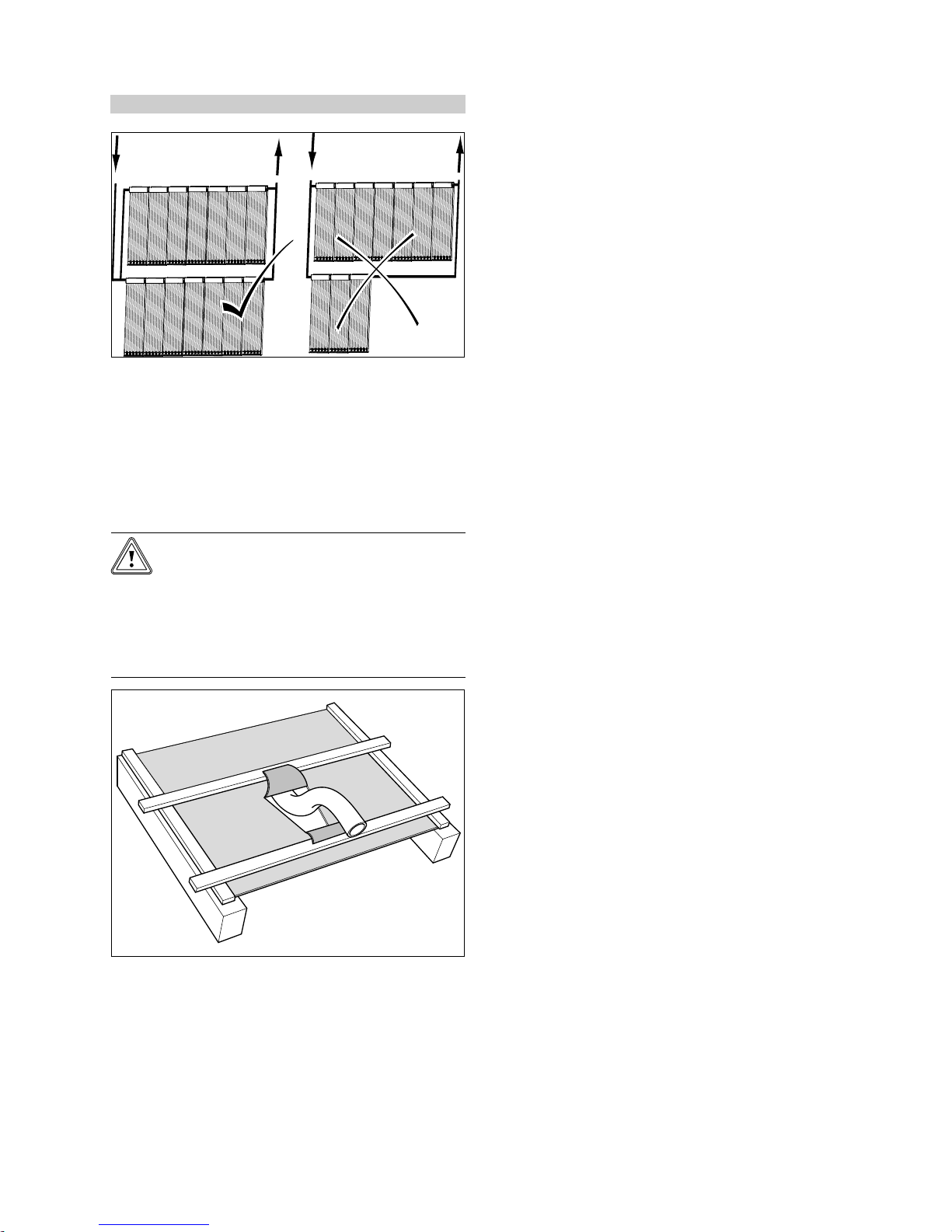

4.1.4 Preparing the roof duct

Caution.

Building damage due to penetrating wa-

ter.

If the roof duct is not prepared properly, water

may penetrate the building interior.

▶ Ensure that the roof duct is prepared prop-

erly.

1. Make a v-shaped cut in the roofing felt membrane.

2. Fold the upper, wider flap onto the roof batten above,

and fold the lower, narrower flap onto the roof batten

below.

3. Fix the roofing felt membrane tight to the roof batten, so

that any moisture runs off to the side.

0020077994_03 auroTHERM exclusive Installation manual 11

Page 12

4 On-roof fitting and installation

4.1.5 Putting together components

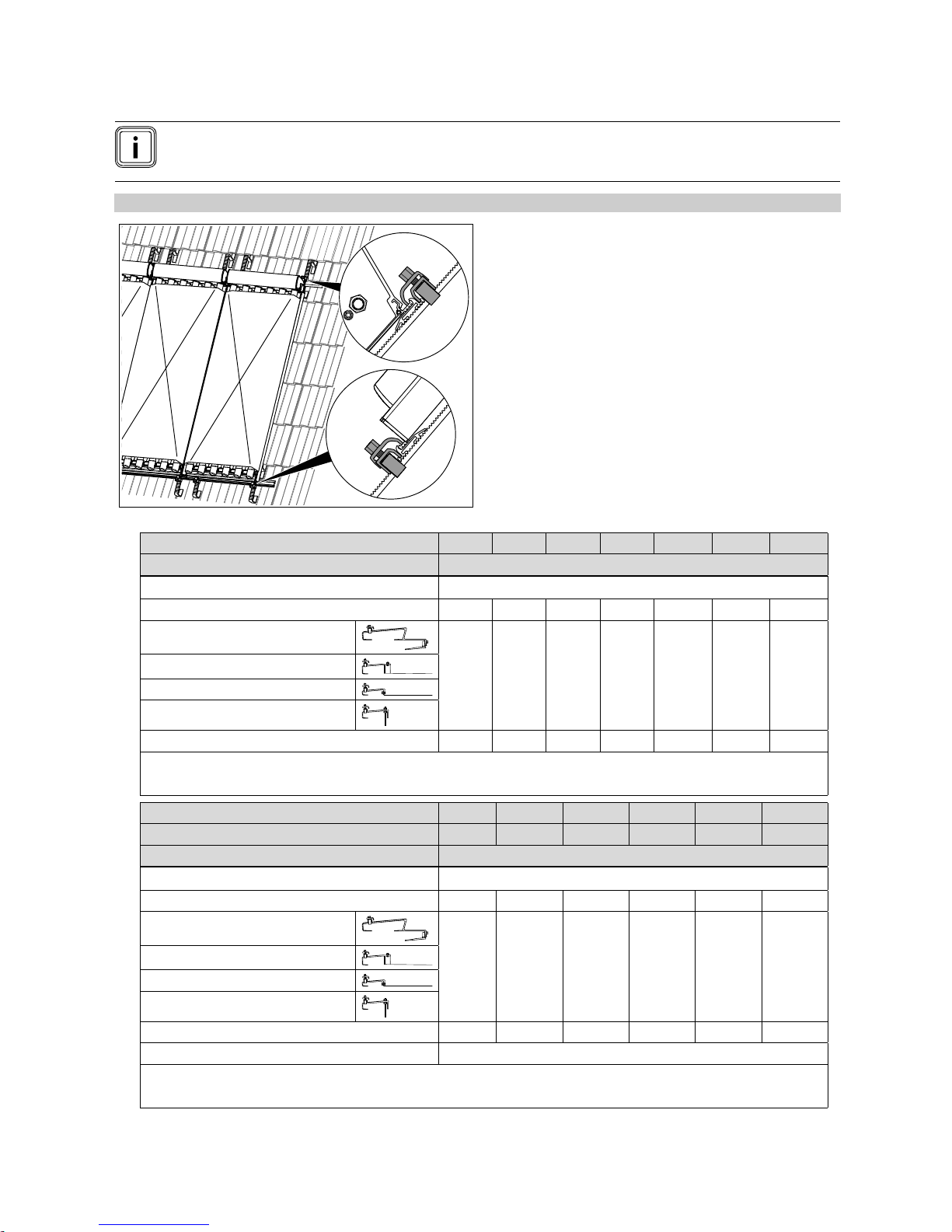

Note

In the case of roof batten clearances greater than 460 mm, the 2-row and 3-row installations are not possible. In

this case, you can install the 2 or 3 rows individually (without using the same central roof anchor).

Conditions: Collector rows: 1

▶ Use the following table to put together the components for installation.

Number of VTK 1140/2 collectors 1 2 3 4 5 6 7

Components Required sets

VTK installation set (basic set)

VTK installation set (extension set)

Roof bracket set type P (pantile)

Roof bracket set type S (slate)

Roof bracket set type S, flat (slate)

Roof anchor set, hanger bolt

Rail set (2 pcs), VTK 1140/2

1

1 set for connecting to the pipelines; the collectors are connected together using the extension set

2

valid up to 700 m above sea level

Number of VTK 1140/2 collectors 1 2 3 4 5 6

Number of VTK 570/2 collectors 1 1 1 1 1 1

Components Required sets

VTK installation set (basic set)

VTK installation set (extension set)

Roof bracket set type P (pantile)

Roof bracket set type S (slate)

Roof bracket set type S, flat (slate)

Roof anchor set, hanger bolt

− 1 2 3 4 5 6

2

1

2

2

2

3

1 2 3 4 5 6 7

1 2 3 4 5 6

2

2

2

3

2

4

1

1

2

4

1

1

2

5

2

5

2

6

2

6

2

7

2

7

VTK 1140/2 rail set

VTK 570/2 rail set

1

1 set per row for connecting to the pipelines; the collectors are connected together using the extension set

2

Valid up to 700 m above sea level

12 Installation manual auroTHERM exclusive 0020077994_03

1 2 3 4 5 6

1

Page 13

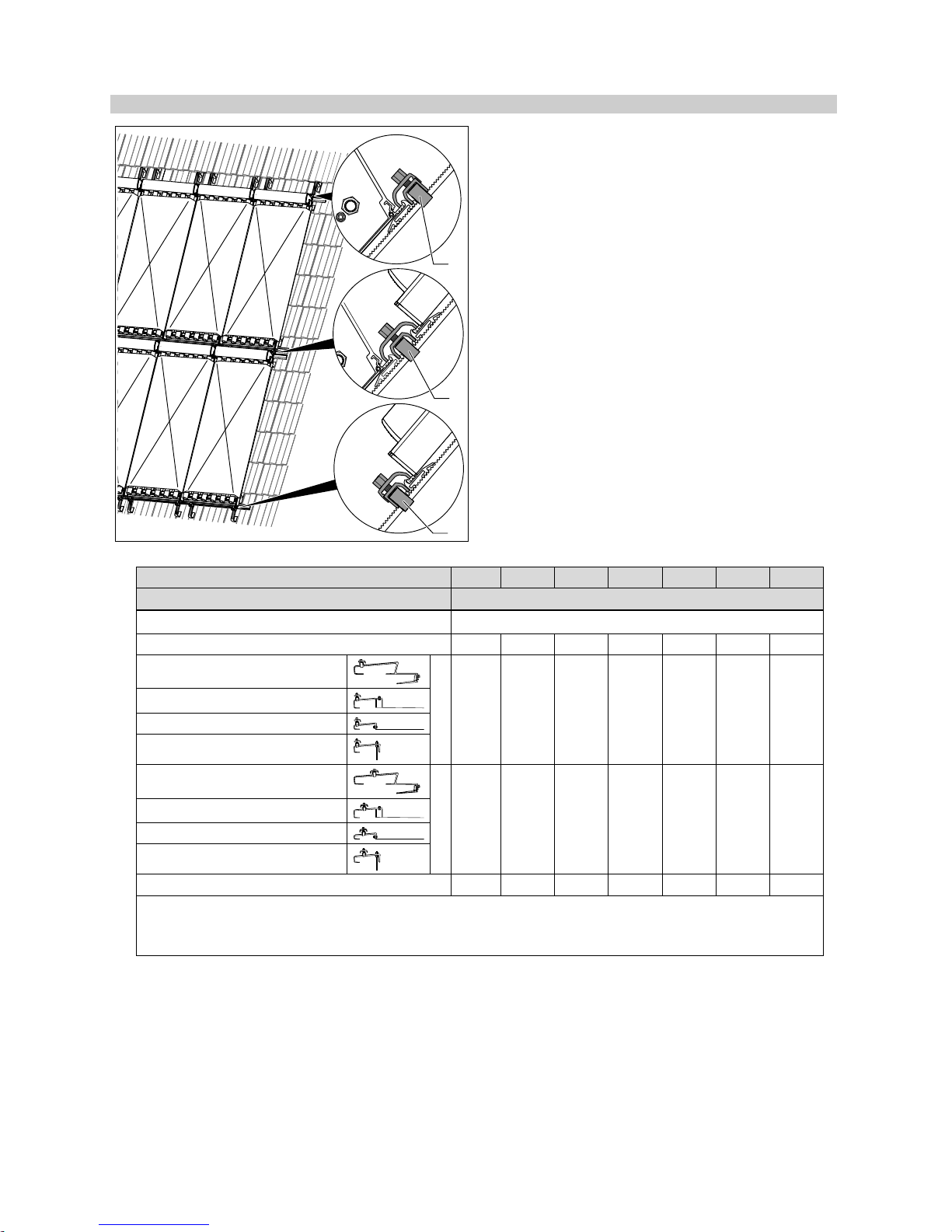

Conditions: Collector rows: 2

A

B

A

On-roof fitting and installation 4

▶ Use the following table to put together the components for installation.

Number of VTK 1140/2 collectors per row 1 2 3 4 5 6 7

Components Required sets

VTK installation set (basic set)

VTK installation set (extension set)

− 2 4 6 8 10 12

Roof bracket set type P (pantile)

Roof bracket set type S (slate)

Roof bracket set type S, flat (slate)

2

1

A

2

2

2

3

Roof anchor set, hanger bolt

Roof bracket set type P (pantile)

Roof bracket set type S (slate)

Roof bracket set type S, flat (slate)

2

1

B

2

2

2

3

Roof anchor set, hanger bolt

Rail set (2 pcs), VTK 1140/2

1

1 set per row for connecting to the pipelines; the collectors are connected together using the extension set – if the rows are also

connected together so that they are flat-sealed.

2

Valid up to 700 m above sea level

2 4 5 6 10 12 14

1

2

2

4

2

4

2

5

2

5

2

6

2

6

2

7

2

7

0020077994_03 auroTHERM exclusive Installation manual 13

Page 14

4 On-roof fitting and installation

A

B

B

A

Conditions: Collector rows: 3

▶ Use the following table to put together the components for installation.

Number of VTK 1140/2 collectors per row 1 2 3 4 5 6 7

Components Required sets

VTK installation set (basic set)

VTK installation set (extension set)

Roof bracket set type P (pantile)

Roof bracket set type S (slate)

− 3 6 9 12 15 18

2

1

A

2

2

2

3

Roof bracket set type S, flat (slate)

Roof bracket set type P (pantile)

2

2

Roof bracket set type S (slate)

Roof bracket set type S, flat (slate)

Rail set (2), VTK 1140/2

1

1 set per row; the collectors are connected together using the extension set – if the rows are also connected together so that

they are flat-sealed.

2

Valid up to 700 m above sea level

B

3 6 9 12 15 18 21

2

4

2

6

1

3

2

4

2

8

10

2

5

2

12

2

6

2

14

2

7

2

14 Installation manual auroTHERM exclusive 0020077994_03

Page 15

On-roof fitting and installation 4

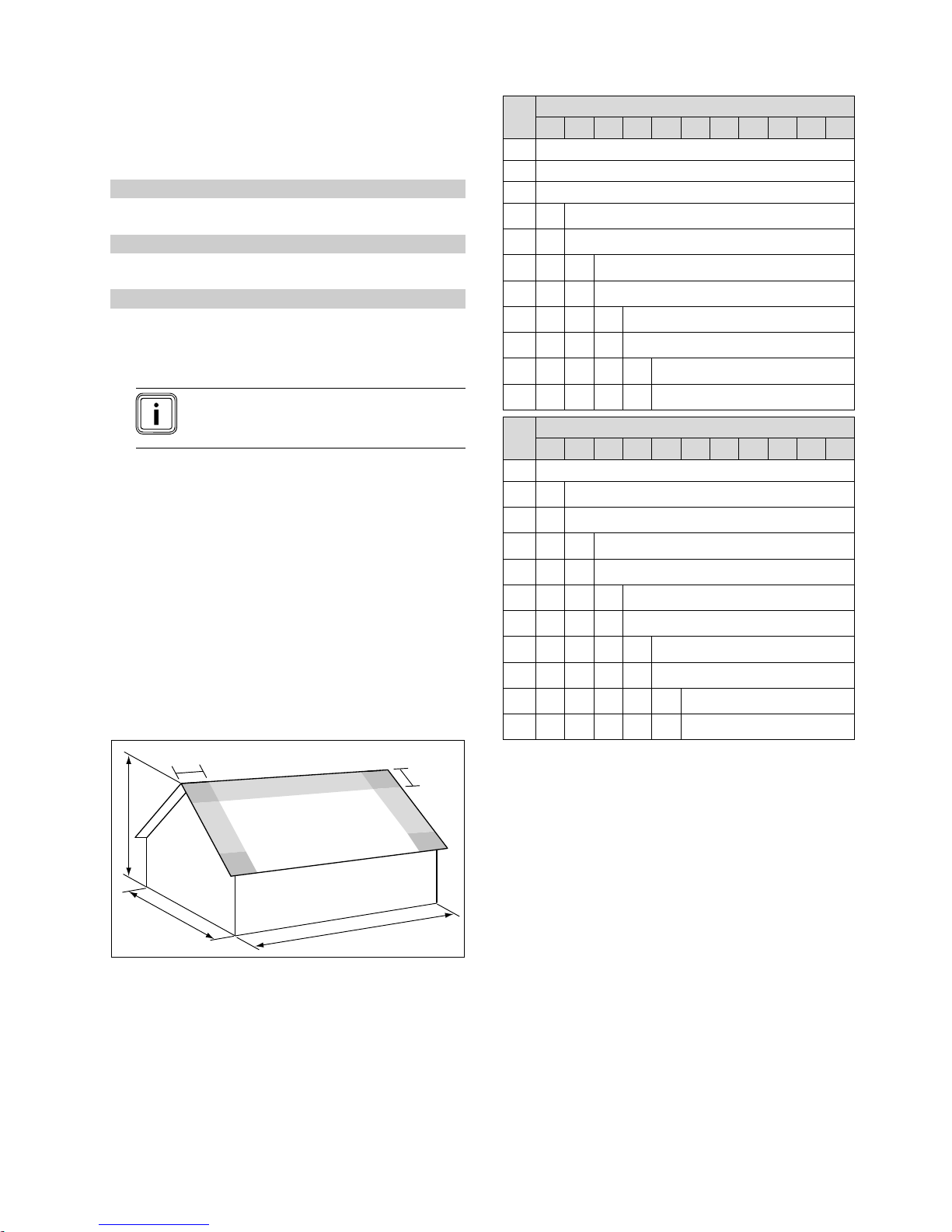

e

lang

e

kurz

h

b

l

4.1.6 Determining the number of required roof

brackets

1. Ask the local building authority for the regional maximum snow load sk.

Conditions: Maximum snow load: ≤ 3 kN/m²

▶ Install 4 roof brackets per collector.

Conditions: Maximum snow load: 3 < × ≤ 4.5 kN/m²

▶ Install 6 roof brackets per collector.

Conditions: Maximum snow load: > 4.5 kN/m²

▶ Compile statistics for the individual case.

▶ Ensure that the maximum permissible snow load per

collector is 5.4 kN/m².

Note

The maximum permissible load per roof

bracket type S/type P is: F

2. If you are using extension sets, ensure that the roof

bracket is positioned centrally with equal clearances.

4.1.7 Defining the edge clearances of the roof

brackets

Maximum lift points caused by wind loads can occur at

the cut-away edges of wall and roof areas (e.g. verge and

eaves). These maximum lift points result in high loads on the

collectors and installation systems.

Areas in which lift points occur are called edge areas. Corner

areas are zones in which edge areas overlap and especially

high pull forces occur.

Edge and corner areas must not be used as installation

areas.

= 1.875 kN.

max

b

[m]

5 6 7 8 9 10 11 12 13 14 15

8 1.0

9 1.0

10 1.0

11

1.0

12

1.0

13

1.0 1.2

14

1.0 1.2

15

1.0 1.2 1.4

16

1.0 1.2 1.4

17

1.0 1.2 1.4 1.6

18

1.0 1.2 1.4 1.6

l

[m]

5 6 7 8 9 10 11 12 13 14 15

10 1.0

11

1.0

12

1.0

13

1.0 1.2

14

1.0 1.2

15

1.0 1.2 1.4

16

1.0 1.2 1.4

17

1.0 1.2 1.4 1.6

18

1.0 1.2 1.4 1.6

19

1.0 1.2 1.4 1.6 1.8

20

1.0 1.2 1.4 1.6 1.8

H [m]

1.1

1.2

1.3

1.4

1.5

1.6

1.7

1.8

h [m]

1.1

1.2

1.3

1.4

1.5

1.6

1.7

1.8

1.9

2.0

▶ When installing the roof brackets, observe the calculated

edge clearances.

b Building width

h Building height

▶ Calculate the building width w, building height h and

building length l.

▶ The values for the edge clearances to be observed, e

and e

0020077994_03 auroTHERM exclusive Installation manual 15

can be found in the following tables.

long

l Building length

4.1.8 Defining the roof bracket clearances

The roof brackets have different clearances depending on

the array configuration of the collectors (adjacent or on top of

each other).

short

Page 16

4 On-roof fitting and installation

n

A

C

D

B B B B

A

A

E

A

C

D

B B B B

A

E

A

E

4.1.8.1

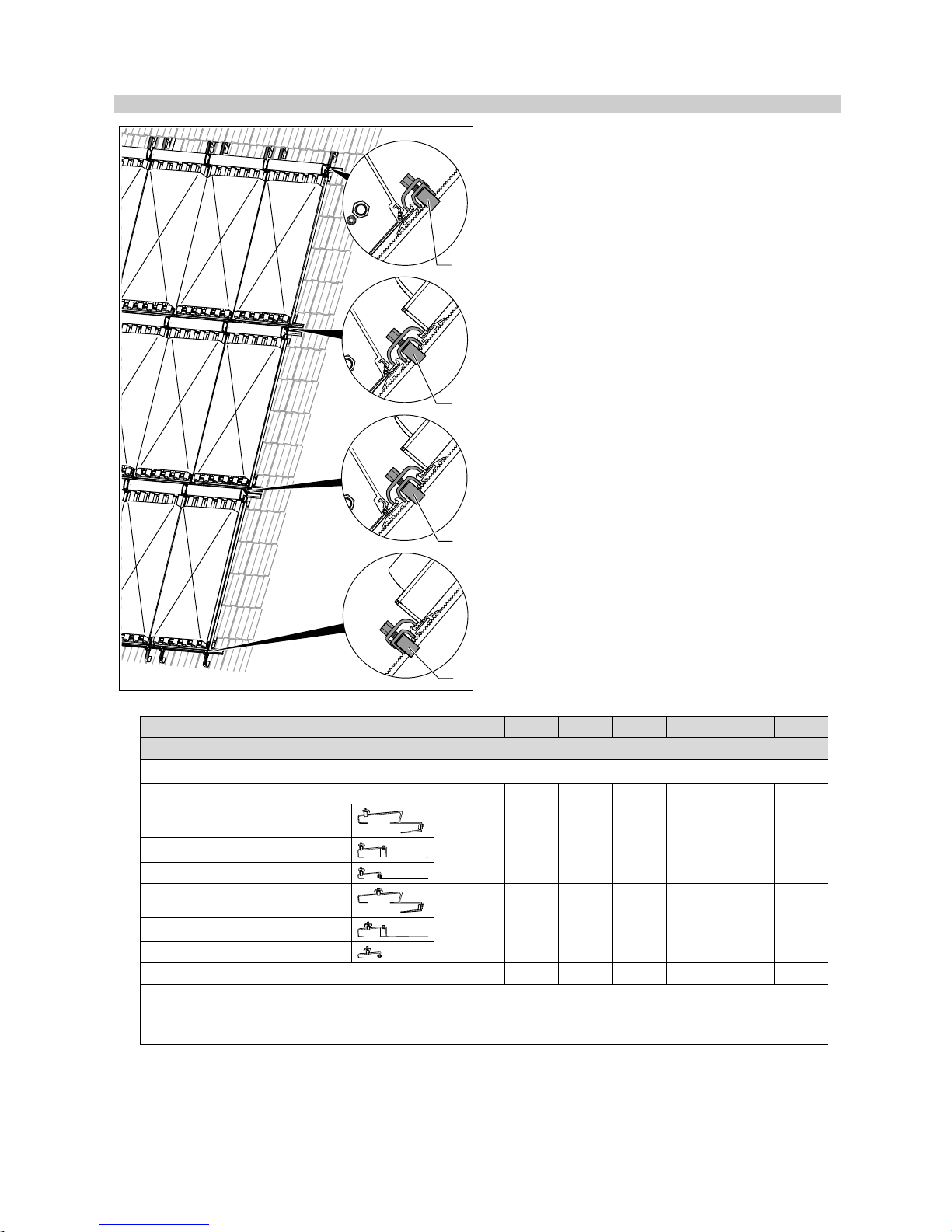

Adjacent array configuration

4.1.8.2 Array configuration on top of each

other

Note

In the case of roof batten clearances greater than

460 mm, the 2-row and 3-row installations are not

possible. In this case, you can install the 2 or 3

rows individually (without using the same central

roof anchor).

Conditions: Collector rows: 2

1. Define the clearances of the roof brackets.

Quantity

VTK

570/2

2. Ensure that there is sufficient play for the anchors.

– Pre-installation dimension (*): = Finished installation

VTK

1140/2

‑ 1

‑ 2

‑ 3

‑ 4

‑ 5

‑ 6

‑ 7

1 1

1 2

1 3

1 4

1 5

1 6

A B C D

VTK

1663 * /

1638 **

100 -

200

VTK

dimension (**) + 20-25 mm

997 1197

‑‑‑‑‑

507 -

607

1140

570

1397

2794

4191

5588

6985

8382

9779

2104

3501

4898

6295

7692

8382

▶ Define the clearances of the roof brackets.

Quantity

VTK

570/2

VTK

1140/2

‑ 1

‑ 2

‑ 3

‑ 4

‑ 5

‑ 6

‑ 7

1 1

1 2

1 3

A B C D E

VTK

1140

997 -

200

1197

‑‑‑‑‑

VTK

507 -

607

570

1663 * /

1638 **

100 -

1397

2794

4191

5588

6985

8382

9779

2104

3501

4898

3322

16 Installation manual auroTHERM exclusive 0020077994_03

Page 17

On-roof fitting and installation 4

E

A

C

D

B B B B

A

E

A

E

Quantity

VTK

570/2

VTK

1140/2

1 4

1 5

1 6

A B C D E

VTK

1140

1663 * /

1638 **

100 -

200

997 1197

VTK

507 -

‑‑‑‑‑

607

6295

7692

570

8382

▶ Ensure that there is sufficient play for the anchors.

– Pre-installation dimension (*): = Finished installation

dimension (**) + 20-25 mm

Conditions: Collector rows: 3

3322

▶ Define the clearances of the roof brackets.

Quantity

VTK

570/2

VTK

1140/2

‑ 1

‑ 2

‑ 3

‑ 4

‑ 5

‑ 6

‑ 7

A B C D E

1397

VTK

1140

1663 * /

1638 **

100 -

200

997 1197

VTK

507 -

‑‑‑‑‑

607

2794

4191

5588

6985

570

8382

9779

5006

0020077994_03 auroTHERM exclusive Installation manual 17

Page 18

4 On-roof fitting and installation

1

3

2

A

2

1

B

5 mm

1

2

3

4

Quantity

VTK

570/2

▶ Ensure that there is sufficient play for the anchors.

– Pre-installation dimension (*): = Finished installation

VTK

1140/2

1 1

1 2

1 3

1 4

1 5

1 6

A B C D E

1663 * /

1638 **

dimension (**) + 20-25 mm

100 -

200

VTK

997 -

1197

‑‑‑‑‑

VTK

507 -

607

1140

570

2104

3501

4898

6295

7692

8382

5006

4.2 Carrying out the installation

The installation steps and notes in these instructions apply

for both array configurations. Any different installation steps

are clearly indicated in individual cases.

4.2.1 Installing roof brackets

4.2.1.1 Installing type P (for pantile)

1 Lower roof bracket

2 Top roof bracket

1. Use the top, middle and lower type P roof brackets

shown.

3 Middle roof bracket

2. Secure the type P roof bracket either to the rafters (A)

or to the roof batten (B).

3. To do this, loosen the bolt (1) on the base of the roof

bracket with the enclosed bit and unscrew the bolt by

approx. 5 mm.

4. If you wish to secure the roof bracket onto the rafters,

turn the base (2) outwards (A).

5. If you wish to secure the roof bracket onto the roof batten, turn the base (2) inwards (B).

Conditions: Fastening type: To rafters

▶ Define the clearances of the roof brackets. (→ Page 16)

▶ Expose the rafters at the corresponding position (1).

▶ Position the roof bracket (2). Ensure the correct position

of the top, middle and lower roof brackets.

18 Installation manual auroTHERM exclusive 0020077994_03

▶ Undo the top bolt until the height of the roof bracket can

be adjusted (3).

– Working materials: SW 13 spanner

Page 19

▶ Adjust the roof bracket to the height of the pantiles, so

5

6

A

B

1

3

2

4

5

6

A

2

1

that the top part of the roof bracket lies on the roofing

(4).

▶ Tighten the top bolt.

– Working materials: SW 13 spanner

▶ Screw the roof bracket onto the rafters using the three

bolts supplied (5).

▶ Slide the pantiles into their original position again (6).

▶ To ensure that the tiles lie tightly together, notch gut-

tering onto the underside (A) or the top side (B) of the

pantile using a hammer, if necessary.

On-roof fitting and installation 4

▶ Adjust the roof bracket to the height of the pantiles, so

that the top part lies on the roofing and the bottom part is

pushed tight against the roof batten from the bottom (4).

▶ Ensure that the roof bracket fits securely around the roof

batten and pantile when it engages.

Note

For some roof types, it may be necessary to

offset the roof bracket laterally opposite the

rafters.

To do this, use the accessory "long base"

article number 0020080177 (not available in

all countries).

Conditions: Fastening type: To roof batten

▶ Tighten the top bolt (5).

– Working materials: SW 13 spanner

▶ Slide the pantiles into their original position again (6).

▶ To ensure that the tiles lie tightly together, notch gutter-

ing onto the underside of the pantiles (A) using a hammer, if necessary.

4.2.1.2 Installing type S (for slate)

▶ Define the clearances of the roof brackets. (→ Page 16)

▶ Slide one to two pantiles upwards at the corresponding

position above the roof batten (1).

▶ Undo the top bolt until the height of the roof bracket can

be adjusted (2).

– Working materials: SW 13 spanner

▶ Hang the roof bracket on the roof batten (3). Ensure that

the top, middle and lower roof brackets are positioned

correctly.

1. Define the clearances of the roof brackets. (→ Page 16)

2. At the appropriate position, expose the rafters or roof

batten (1).

3. Position the roof bracket. Ensure the correct position of

the top, middle and lower roof brackets (2).

0020077994_03 auroTHERM exclusive Installation manual 19

Page 20

4 On-roof fitting and installation

4

3

2

1

4

3

1

2

3

6

4

5

4. Screw the roof bracket onto the roof batten or rafters

using the three screws supplied (3).

5. Slide the pantiles into their original position again (4).

4.2.1.3 Installing type S flat (for slate)

4.2.1.4 Installing the hanger bolt type

1. Define the clearances of the roof brackets. (→ Page 16)

2. At the corresponding position, drill a hole in the pantile

(1).

3. Tighten the hanger bolt onto the rafters through the

pantile(2).

1. Define the clearances of the roof brackets. (→ Page 16)

2. At the appropriate position, expose the rafters or roof

batten (1).

3. Position the roof bracket. Ensure that the top, middle

and lower roof brackets (2) are positioned correctly.

4. Screw the roof bracket onto the roof batten or rafters

using the three screws supplied (3).

5. Slide the pantiles into their original position again (4).

4. Position the central nut so that, after inserting the upper

part of the roof bracket, the front contact area lies on

the roofing (3). Ensure the correct positioning of the top,

middle and lower roof brackets.

5. Position the roof bracket on the central nut (4).

6. Screw the second nut on and tighten (5).

– Working materials: SW 17 spanner

7. Disconnect the threaded rod directly above the nut (6).

8. Deburr the interface.

20 Installation manual auroTHERM exclusive 0020077994_03

Page 21

On-roof fitting and installation 4

1

2

1

4.2.2 Installing collectors

Danger!

Personal injury and material damage due

to a falling collector.

Improper fastening may cause a collector to

fall.

▶ Tighten the clamping elements.

▶ Check for proper tensioning by shaking

the clamping blocks.

▶ If a clamping block is mobile, tighten the

nut again.

1. Install the collectors on the roof as specified in the following sections.

Note

Mounting rails and clamping elements cannot

be moved at the same time.

Installing mounting rails

Taring mounting rails

7. Secure the mounting rails horizontally.

8. Compensate for any height differences by moving the

clamping elements.

9. To do this, pull the clamping element upwards (1),

move it (2) and release it so that it engages.

Laying and hooking collectors

2. Secure the mounting rails with the clamping elements to

the roof anchors.

3. Position the lower rail as far as possible downwards on

the roof bracket.

Connecting mounting rails

4. Insert the connecting elements laterally into the mounting rails until you feel them engage .

5. Connect the mounting rails underneath each other.

6. Secure the mounting rails with the clamping elements to

the roof anchors.

Danger!

Risk of burns and scalding!

In the event of solar radiation inside the units,

collectors can reach 300 °C.

▶ Avoid working in direct sunlight.

▶ Cover the collectors before starting work.

▶ You should preferably perform the work in

the morning.

▶ Wear suitable safety gloves.

10. Position the collector on the lower mounting rail (top

collector).

11. Hook the collector in on the clamping elements.

12. Ensure that the top clamping block (1) of the clamping

element is above the rail of the collector.

13. Tighten the clamping elements of the lower mounting

rail.

– Working materials: SW 13 spanner

0020077994_03 auroTHERM exclusive Installation manual 21

Page 22

4 On-roof fitting and installation

1

1

1

2

A

B

Loosening the sun protection film

14. To ensure that the sun protection film can be easily removed after starting up the unit, loosen the sun protection film from the edges of the collector.

Removing the carrying strap

Fitting connectors

18. Screw the double nipple (A) (from installation set VTK

extension set, article number 0020076779) in the

thread of the second collector (B) with the cap nut (2) of

the first collector.

19. Push the collectors together.

Tightening the clamping ring connection

15. Remove the carrying strap.

Installing additional collectors

Caution.

Risk of damage to the collectors as a res-

ult of improper installation.

If the hydraulic connections are not installed

properly, the stainless steel tubes inside the

collector may become damaged.

▶ When tightening the clamping ring con-

nection, hold a second spanner against it.

20. Screw the two cap nuts securely onto the double

nipple.

21. Tighten the clamping elements of the lower mounting

16. Position the next collector on the lower mounting rail.

17. Ensure that the upper clamping block (1) of the clamping element is above the rail of the collector.

rail.

– Working materials: SW 13 spanner

Completing collector rows

22. Install an additional collector. (→ Page 22)

23. Fit the connectors. (→ Page 22)

24. Tighten the clamping ring on the connection for both

collectors. (→ Page 22)

22 Installation manual auroTHERM exclusive 0020077994_03

Page 23

On-roof fitting and installation 4

1

3

1

2

2

1

3

Positioning the top mounting rails

25. Slide the upper mounting rails until they are flush with

the collectors.

26. Ensure that the clamping block (1) of the clamping elements lies over the collector rails.

27. Tighten the clamping elements of the top mounting

rails.

– Working materials: SW 13 spanner

Positioning the central mounting rail

Conditions: Collector rows: 2 … 3

Installing the upper collectors

Conditions: Collector rows: 2 … 3

▶ Place the upper collector (1) into the central mounting

rail (2).

▶ Tightly screw in the clamping elements (3) of the central

rail.

– Working materials: SW 13 spanner

▶ Install the collector row in the same way as for the first

collector row.

▶ Complete the collector row. (→ Page 22)

▶ Position the top mounting rails. (→ Page 23)

▶ Slide the central mounting rail until it is flush with the

lower collector (3).

▶ Ensure that the top clamping block of the clamping ele-

ment (2) is above the edge of the collector.

▶ Secure the mounting rail (1) for the next collector row to

the clamping element.

4.2.3 Installing hydraulic connections

Caution.

Lack of tightness due to incorrect ac-

cessories.

Incorrect accessories may result in lack of

tightness of the solar circuit and cause material damage.

▶ Only work in the solar circuit with hard

soldered connections, flat seals, compression fittings or press fittings which have

been approved by the manufacturer for

0020077994_03 auroTHERM exclusive Installation manual 23

Page 24

4 On-roof fitting and installation

13

2

use in solar circuits and at correspondingly high temperatures.

Caution.

Risk of damage to the collectors as a res-

ult of improper installation.

If the hydraulic connections are not installed

properly, the stainless steel tubes inside the

collector may become damaged.

▶ When tightening the clamping ring con-

nection, hold a second spanner against it.

1. Connect the collector flow and return to the system with

the connection tubes.

Conditions: System with collector sensor

▶ Insert the collector sensor into the opening provided on

the collector flow side ("hot side").

Note

In general, the collector sensor can be attached to the right or left side of the collector

field because the collectors on both sides

have a corresponding opening.

Conditions: Collector rows: 2 … 3

▶ Insulate the hydraulic system connections using the in-

sulation (2) (from installation set VTK extension set, article number 0020076779).

▶ Connect the collectors in accordance with the connec-

tion regulations (→ Page 10).

▶ Connect the collector flow and return to the system with

the connection tubes.

▶ To do this, connect the clamping ring connection (from

the installation set VTK basic set, article number

0020076776) to the collector.

▶ Connect the clamping ring connection with the connec-

tion pipework.

▶ Check the connections for tightness.

Insulating hydraulic connections

Conditions: Start-up carried out

▶ Insulate the hydraulic connections using the insulation

(1) (from installation set VTK extension set, article number 0020076779).

▶ Cover the insulation with the cover plate (3) (from

installation set VTK extension set, article number

0020076779).

24 Installation manual auroTHERM exclusive 0020077994_03

Page 25

On-roof fitting and installation 4

4.3 Completing and checking the installation

4.3.1 Checking installation

Use the following checklist to ensure that all work steps have been performed.

Operations Yes No Comments

All hydraulic connections tightened

Hydraulic connections routed correctly

VR 11 collector sensor connected

(Only for systems WITH a collector sensor)

All clamping elements tightened

Collectors connected to lightning protection device

(Optionally for lightning protection device)

Pressure testing performed

(Ideally with compressed air)

All connections tight

Date Signature

All installation work has been

performed correctly. ˍ ˍ . ˍ ˍ . ˍ ˍ ˍ ˍ

☐ ☐

☐ ☐

☐ ☐

☐ ☐

☐ ☐

☐ ☐

☐ ☐

0020077994_03 auroTHERM exclusive Installation manual 25

Page 26

5 Flat roof fitting and installation

4.3.2 Disposing of the packaging

The transport packaging consists largely of recyclable materials.

▶ Observe the applicable regulations.

▶ Dispose of the transport packaging properly.

5 Flat roof fitting and installation

▶ When fitting and installing the collectors, you must ob-

serve the chapter "Safety".

5.1 Preparing for fitting and installation

5.1.1 Delivery, transport and positioning

5.1.1.1 Storing collectors

▶ To prevent moisture from penetrating into the collector,

always store the collectors dry and in a weatherproof

area.

26 Installation manual auroTHERM exclusive 0020077994_03

Page 27

5.1.1.2 Checking the scope of delivery

1

2

3

7

6

8

9

10

5

4

Flat roof fitting and installation 5

List of materials for flat roof installation

1 VTK 1140/2 rail set, 2 units

2 VTK 570/2 rail set, 2 units

3 Frame set, 1 unit

4 Load plates from load plate set, 4 units

5 Hammer-head bolt and nut from load plate set, 2 units

6 VTK 570/2 tube collector, 1 unit

7 VTK 1140/2 tube collector, 1 unit

8 Stop valve, 2-way VTK for parallel connection, 1 unit

9 VTK installation set (basic set), 1 unit

10 VTK installation set (extension set), 1 unit

▶ Use the image to check that the installation sets are complete.

0020077994_03 auroTHERM exclusive Installation manual 27

Page 28

5 Flat roof fitting and installation

max. 7 x VTK 1140/2

5.1.1.3 Transporting collectors

1. To protect the collectors against damage, always transport them when they are standing horizontally.

2. Transport the collectors to the roof using suitable aids.

5.1.2 Complying with clearances and installation

clearances

During storms, strong wind forces occur along the edges of

flat roofs.

▶ When defining the installation position, maintain an edge

clearance of at least 1 m from the roof edge.

5.1.3 Selecting suitable connection

▶ Select the appropriate connection for the collectors.

Conditions: Parallel connection, aperture surface area: ≤ 7 m²

▶ Always connect as many collectors as possible in series,

even when several collector rows are arranged on top of

each other.

Note

Up to an aperture surface area of 7 m²

(accordingly for 3 pcs VTK 1140/2 + 1 pc

VTK 570/2), you must switch the collectors in

series.

▶ Ensure that the solar fluid flows through the collectors

either from left to right or from right to left.

Conditions: Number of VTK 1140/2 collectors: 1 … 7

▶ Switch up to 7 VTK 1140/2 units in series (according to

the 14 m² aperture surface area).

Conditions: Parallel connection, aperture surface area: ≥ 14 m²

▶ Set up several parallel collector rows and connect these

hydraulically in parallel.

▶ Always connect as many collectors (at least 7 m²) as

possible in series.

28 Installation manual auroTHERM exclusive 0020077994_03

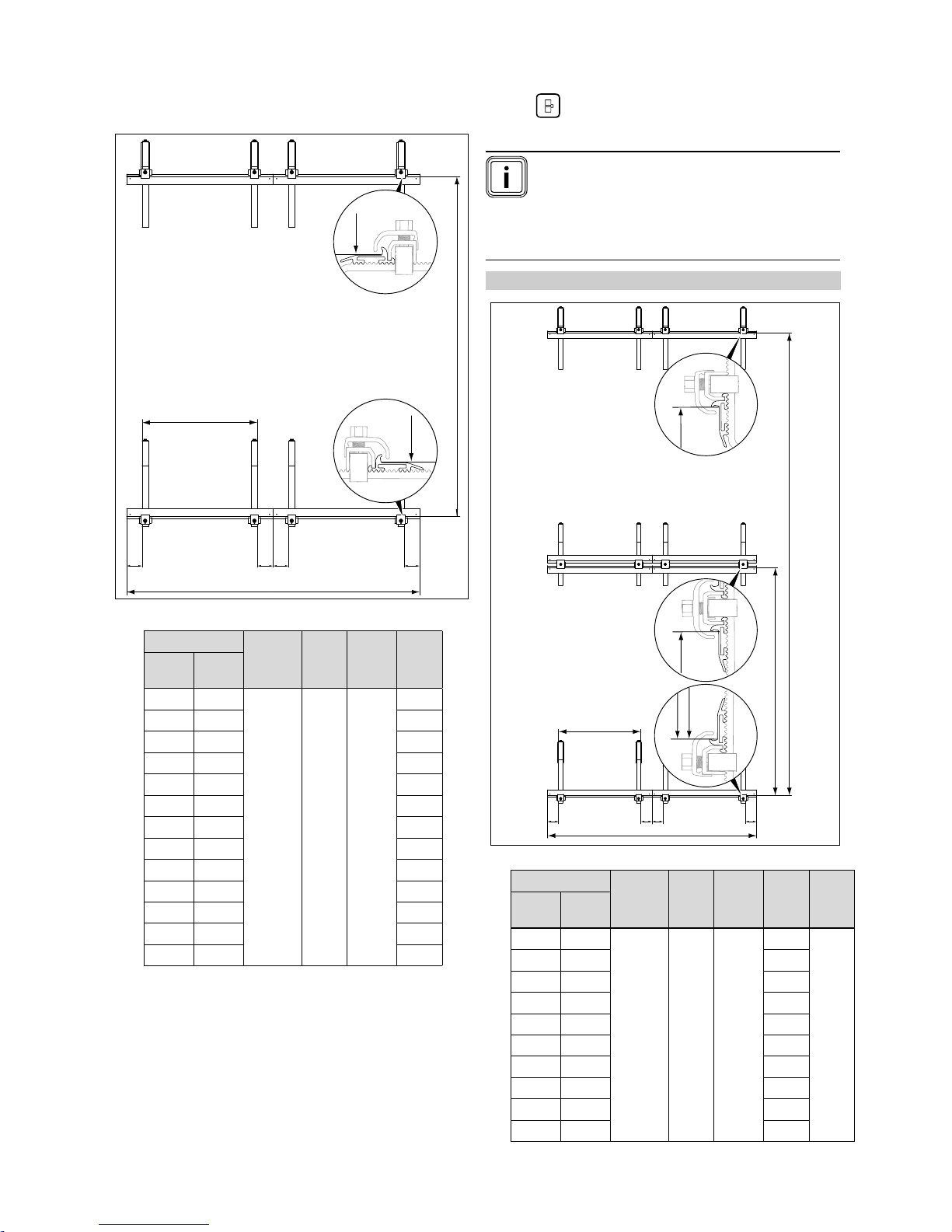

Page 29

Flat roof fitting and installation 5

A

B

C

Conditions: Parallel connection

▶ To avoid pressure losses in the sub-collector fields, only

use parallel connection for collector rows with the same

number of collectors.

▶ Ensure that each sub-collector field has the same total

tube length in the flow and return (Tichelmann system), in

order to avoid pressure losses in the connection tubes.

5.1.4 Preparing the roof duct

Caution.

Lack of tightness due to destruction of the

roof skin.

In the event of destruction of the roof skin,

water may penetrate the building.

▶ Ensure adequate protection of the roof

skin during installation on roof sealing

surfaces.

▶ Place large-area building protection mats

underneath the installation system.

▶ After installation, check the tightness of

the building shell where there are directly

connected racks.

Installation variants Meaning

A

B

C Rack screwed directly onto the roof.

Floating installation with load plates and

load weights.

Floating installation without load plates.

The rack must be screwed onto suitable

load weights.

▶ Commission a roofer to prepare the roof duct.

5.1.5 Selecting the installation variant

▶ Make a selection from the three available installation

variants:

0020077994_03 auroTHERM exclusive Installation manual 29

Page 30

5 Flat roof fitting and installation

5.1.6 Putting together components

▶ Use the following table to put together the components for installation.

Number of VTK 1140/2 collectors 1 2 3 4 5 6 7

Components Required sets/quantity

VTK installation set (basic set)

VTK installation set (basic set)

Installation set for open-air/flat-roof installation

Required rack

Rail set (2 pcs), VTK 1140/2

1)

1 set each per collector field for connecting to the pipelines; the collectors are connected together using the extension set

Number of VTK 1140/2 collectors 1 2 3 4 5 6

Number of VTK 570/2 collectors 1 1 1 1 1 1

Components Required sets/quantity

VTK installation set (basic set)

VTK installation set (extension set)

Installation set for open-air/flat-roof installation

Required rack

Rail set (2 pcs), VTK 1140/2

Rail set (2 pcs), VTK 570/2

1)

1 set each per collector field for connecting to the pipelines; the collectors are connected together using the extension set

− 1 2 3 4 5 6

2 3 4 5 6 7 8

2 3 4 5 6 7 8

1 2 3 4 5 6 7

1 2 3 4 5 6

3 4 5 6 7 8

3 4 5 6 7 8

1 2 3 4 5 6

1)

1

1)

1

1

5.1.7 Determining the ballast load (floating installation)

Danger!

Risk of death and material damage due to excessive basic wind speeds!

The racks are designed for basic wind speeds of up to 108 km/h. If the basic wind speed at the site is

greater than 108 km/h, then there can be no guarantee claim for the system.

▶ Only install the rack in locations where the basic wind speed is a maximum of 108 km/h.

1. Please note the following for floating installation:

Installation variants Please note

Weights that are firmly screwed onto the

B

A and B All weights must be weatherproof.

2. For detailed determination of the basic wind speed at the site and the required weights for the rack, use the Vaillant tool

for dimensioning the wind and snow loads.

3. For quick determination of the basic wind speed at the site, use the following map.

4. For quick dimensioning of the required weights, use the following tables.

Note

The map and tables are used for quick dimensioning of the ballast loads. Detailed dimensioning of the ballast

loads is only possible using the Vaillant tool for dimensioning the wind and snow loads. If you have any questions on this subject, please contact your responsible Vaillant sales partner.

rack must consist of material capable of

screw connections.

30 Installation manual auroTHERM exclusive 0020077994_03

Page 31

Flat roof fitting and installation 5

IS

IE

SE

FI

GB

BE DE

PL

CH

AT

CZ

HU

SK

SI

HR

BA

RS

RO

BG

MK

ME

TR

GR

AL

NL

PT

ES

FR

IT

NO

DK

BY

UA

MD

EE RU

LV

LT

LU

AD

< 72 km/h

< 81 km/h

< 90 km/h

< 99 km/h

< 108 km/h

> 108 km/h

5. Use the map to determine the basic wind speed at the site.

0020077994_03 auroTHERM exclusive Installation manual 31

Page 32

5 Flat roof fitting and installation

L

1

L

2

.............

.............

L

1

L

2

L

1

L1½

L

1

½

L

2

½

L

2

½

L

2

L

1

L

2

6. Use the tables to determine the required weights.

Horizontal collector position

Installation angle 30°

To secure against sliding and

Note

When there are at least two collectors in a row, the ballast loads can be reduced by half for the outer rack.

lifting

Weights/rack [kg]

To secure only against lifting

(if secured/anchored against

sliding)

Basic wind speed [km/h] Position

up to 72 Inland

up to 72 Coast and islands

up to 81 Inland

up to 81 Coast and islands

up to 90 Inland

up to 90 Coast and islands

up to 99 Inland

up to 99 Coast and islands

up to 108 Inland

up to 108 Coast and islands

Building height Building height

up to 10m10-18 m 18-25 m up to 10m10-18 m 18-25 m

L₁

L₂

L₁

L₂

L₁

L₂

L₁

L₂

L₁

L₂

L₁

L₂

L₁

L₂

L₁

L₂

L₁

L₂

L₁

L₂

286

184

392

259

339

221

499

334

445

296

586

395

550

370

727

494

656

444

868

593

359

235

461

307

445

296

588

396

550

370

691

469

656

444

833

568

797

543

974

667

407

269

505

345

515

345

643

435

621

419

762

518

762

518

903

617

903

617

1079

741

30

184

43

259

35

221

58

334

50

296

71

395

66

370

91

494

81

444

112

593

38

235

53

307

50

296

71

396

66

370

86

469

81

444

107

568

101

543

127

667

45

269

59

338

61

345

79

435

76

419

96

518

96

518

117

617

117

617

142

741

32 Installation manual auroTHERM exclusive 0020077994_03

Page 33

Flat roof fitting and installation 5

L

1

L

2

L

1

L

2

Horizontal collector position

Installation angle 45°

Basic wind speed [km/h] Position

up to 72 Inland

up to 72 Coast and islands

up to 81 Inland

up to 81 Coast and islands

up to 90 Inland

up to 90 Coast and islands

up to 99 Inland

up to 99 Coast and islands

up to 108 Inland

up to 108 Coast and islands

Weights/rack [kg]

To secure against sliding and

lifting

Note

When there are at least two collectors in a row, the ballast loads can be reduced by half for the outer rack.

Building height Building height

up to 10m10-18 m 18-25 m up to 10m18-25 m 18-25 m

L₁

L₂

L₁

L₂

L₁

L₂

L₁

L₂

L₁

L₂

L₁

L₂

L₁

L₂

L₁

L₂

L₁

L₂

L₁

L₂

299

213

406

301

352

257

515

391

459

345

602

462

566

433

745

579

673

521

888

697

372

274

476

359

495

345

604

464

566

433

709

550

673

521

852

667

816

638

995

785

421

314

521

396

531

404

661

510

638

492

781

609

781

609

923

726

923

726

1102

873

To secure only against lifting

(if secured/anchored against

sliding)

30

191

30

265

30

228

30

341

30

303

30

402

30

377

30

502

30

452

30

601

30

242

30

315

30

303

30

404

30

377

30

477

30

452

30

576

30

551

30

675

30

276

30

346

30

352

30

443

30

427

30

526

30

526

30

626

30

626

30

750

Horizontal collector position

Installation angle 60°

Basic wind speed [km/h] Position

up to 72 Inland

0020077994_03 auroTHERM exclusive Installation manual 33

Weights/rack [kg]

To secure against sliding and

lifting

Note

When there are at least two collectors in a row, the ballast loads can be reduced by half for the outer rack.

Building height Building height

up to 10m10-18 m 18-25 m up to 10m10-18 m 18-25 m

L₁

L₂

268

297

334

377

378

430

To secure only against lifting

(if secured/anchored against

sliding)

30

196

37

247

45

281

Page 34

5 Flat roof fitting and installation

L

1

L

2

L

1

L

2

Horizontal collector position

Installation angle 60°

Basic wind speed [km/h] Position

up to 72 Coast and islands

up to 81 Inland

up to 81 Coast and islands

up to 90 Inland

up to 90 Coast and islands

up to 99 Inland

up to 99 Coast and islands

up to 108 Inland

up to 108 Coast and islands

Weights/rack [kg]

To secure against sliding and

lifting

Note

When there are at least two collectors in a row, the ballast loads can be reduced by half for the outer rack.

Building height Building height

up to 10m10-18 m 18-25 m up to 10m10-18 m 18-25 m

L₁

L₂

L₁

L₂

L₁

L₂

L₁

L₂

L₁

L₂

L₁

L₂

L₁

L₂

L₁

L₂

L₁

L₂

365

414

316

355

468

532

413

472

555

628

519

589

696

783

625

705

838

939

430

491

413

472

557

630

519

589

661

744

625

705

802

900

767

861

944

1056

474

539

484

550

613

691

590

667

731

822

731

822

873

978

873

978

1050

1172

To secure only against lifting

(if secured/anchored against

sliding)

43

271

33

233

61

346

52

308

76

407

70

382

100

506

88

456

124

605

54

320

52

308

76

408

70

382

94

481

88

456

118

580

112

556

142

680

62

351

64

357

85

448

82

432

106

531

106

531

130

630

130

630

160

754

Vertical collector position

Installation angle 30°

Basic wind speed [km/h] Position

up to 72 Inland

up to 72 Coast and islands

34 Installation manual auroTHERM exclusive 0020077994_03

Weights/rack [kg]

To secure against sliding and

lifting

Note

When there are at least two collectors in a row, the ballast loads can be reduced by half for the outer rack.

Building height Building height

up to 10m10-18 m 18-25 m up to 10m10-18 m 18-25 m

L₁

L₂

L₁

L₂

301

167

413

234

378

213

487

279

429

244

534

307

To secure only against lifting

(if secured/anchored against

sliding)

44

167

67

234

40

213

81

279

70

244

90

307

Page 35

Flat roof fitting and installation 5

L

1

L

2

L

1

L

2

Vertical collector position

Installation angle 30°

Basic wind speed [km/h] Position

up to 81 Inland

up to 81 Coast and islands

up to 90 Inland

up to 90 Coast and islands

up to 99 Inland

up to 99 Coast and islands

up to 108 Inland

up to 108 Coast and islands

Weights/rack [kg]

To secure against sliding and

lifting

Note

When there are at least two collectors in a row, the ballast loads can be reduced by half for the outer rack.

Building height Building height

up to 10m10-18 m 18-25 m up to 10m10-18 m 18-25 m

L₁

L₂

L₁

L₂

L₁

L₂

L₁

L₂

L₁

L₂

L₁

L₂

L₁

L₂

L₁

L₂

357

201

527

303

469

268

619

358

581

335

768

448

694

403

918

537

469

268

621

359

581

335

731

425

694

403

881

515

843

492

1030

605

544

313

680

395

656

380

806

470

806

470

955

560

955

560

1143

672

To secure only against lifting

(if secured/anchored against

sliding)

56

201

89

303

78

268

107

358

100

335

137

448

122

403

166

537

78

268

108

359

100

335

129

425

122

403

159

515

152

492

188

605

92

313

119

395

115

380

144

470

144

470

174

560

174

560

211

672

Vertical collector position

Installation angle 45°

Basic wind speed [km/h] Position

up to 72 Inland

up to 72 Coast and islands

up to 81 Inland

Weights/rack [kg]

To secure against sliding and

lifting

Note

When there are at least two collectors in a row, the ballast loads can be reduced by half for the outer rack.

Building height Building height

up to 10m10-18 m 18-25 m up to 10m10-18 m 18-25 m

L₁

L₂

L₁

L₂

L₁

L₂

321

191

437

270

379

230

401

245

513

321

495

309

454

281

562

354

572

361

To secure only against lifting

(if secured/anchored against

sliding)

30

173

30

241

30

207

30

220

30

286

30

275

30

251

30

314

30

320

0020077994_03 auroTHERM exclusive Installation manual 35

Page 36

5 Flat roof fitting and installation

L

1

L

2

L

1

L

2

Vertical collector position

Installation angle 45°

Basic wind speed [km/h] Position

up to 81 Coast and islands

up to 90 Inland

up to 90 Coast and islands

up to 99 Inland

up to 99 Coast and islands

up to 108 Inland

up to 108 Coast and islands

Weights/rack [kg]

To secure against sliding and

lifting

Note

When there are at least two collectors in a row, the ballast loads can be reduced by half for the outer rack.

Building height Building height

up to 10m10-18 m 18-25 m up to 10m10-18 m 18-25 m

L₁

L₂

L₁

L₂

L₁

L₂

L₁

L₂

L₁

L₂

L₁

L₂

L₁

L₂

555

350

495

309

650

414

611

388

804

519

727

466

959

624

652

415

611

388

766

493

727

466

920

598

882

571

1075

703

713

4547

688

440

843

545

843

545

998

650

998

650

1191

781

To secure only against lifting

(if secured/anchored against

sliding)

30

310

30

275

30

365

30

342

30

455

30

410

30

546

30

366

30

342

30

433

30

410

30

523

30

500

30

613

30

402

30

388

30

478

30

478

30

568

30

568

34

681

Vertical collector position

Installation angle 60°

To secure against sliding and

lifting

Note

When there are at least two collectors in a row, the ballast loads can be reduced by half for the outer rack.

Building height Building height

Basic wind speed [km/h] Position

up to 72 Inland

up to 72 Coast and islands

up to 81 Inland

up to 81 Coast and islands

L₁

L₂

L₁

L₂

L₁

L₂

L₁

L₂

up to 10m10-18 m 18-25 m up to 10m10-18 m 18-25 m

297

267

406

372

352

319

516

479

372

339

477

441

460

424

607

566

Weights/rack [kg]

To secure only against lifting

(if secured/anchored against

421

387

522

485

532

494

664

621

30

179

30

246

30

212

35

315

sliding)

30

225

30

291

30

280

45

372

37

256

35

325

37

325

52

407

36 Installation manual auroTHERM exclusive 0020077994_03

Page 37

Flat roof fitting and installation 5

L

1

L

2

B

D

E

A

C

F

C

Vertical collector position

Installation angle 60°

Basic wind speed [km/h] Position

up to 90 Inland

up to 90 Coast and islands

up to 99 Inland

up to 99 Coast and islands

up to 108 Inland

up to 108 Coast and islands

Weights/rack [kg]

To secure against sliding and

lifting

Note

When there are at least two collectors in a row, the ballast loads can be reduced by half for the outer rack.

Building height Building height

up to 10m10-18 m 18-25 m up to 10m10-18 m 18-25 m

L₁

L₂

L₁

L₂

L₁

L₂

L₁

L₂

L₁

L₂

L₁

L₂

460

424

604

564

568

529

749

704

677

634

893

844

568

529

713

669

677

634

857

809

821

774

1002

949

641

599

785

739

785

739

930

879

930

879

1110

1054

To secure only against lifting

(if secured/anchored against

sliding)

30

280

45

370

41

348

62

461

54

415

80

551

41

348

58

438

54

415

75

528

71

506

92

619

49

393

67

483

67

483

84

573

84

573

105

686

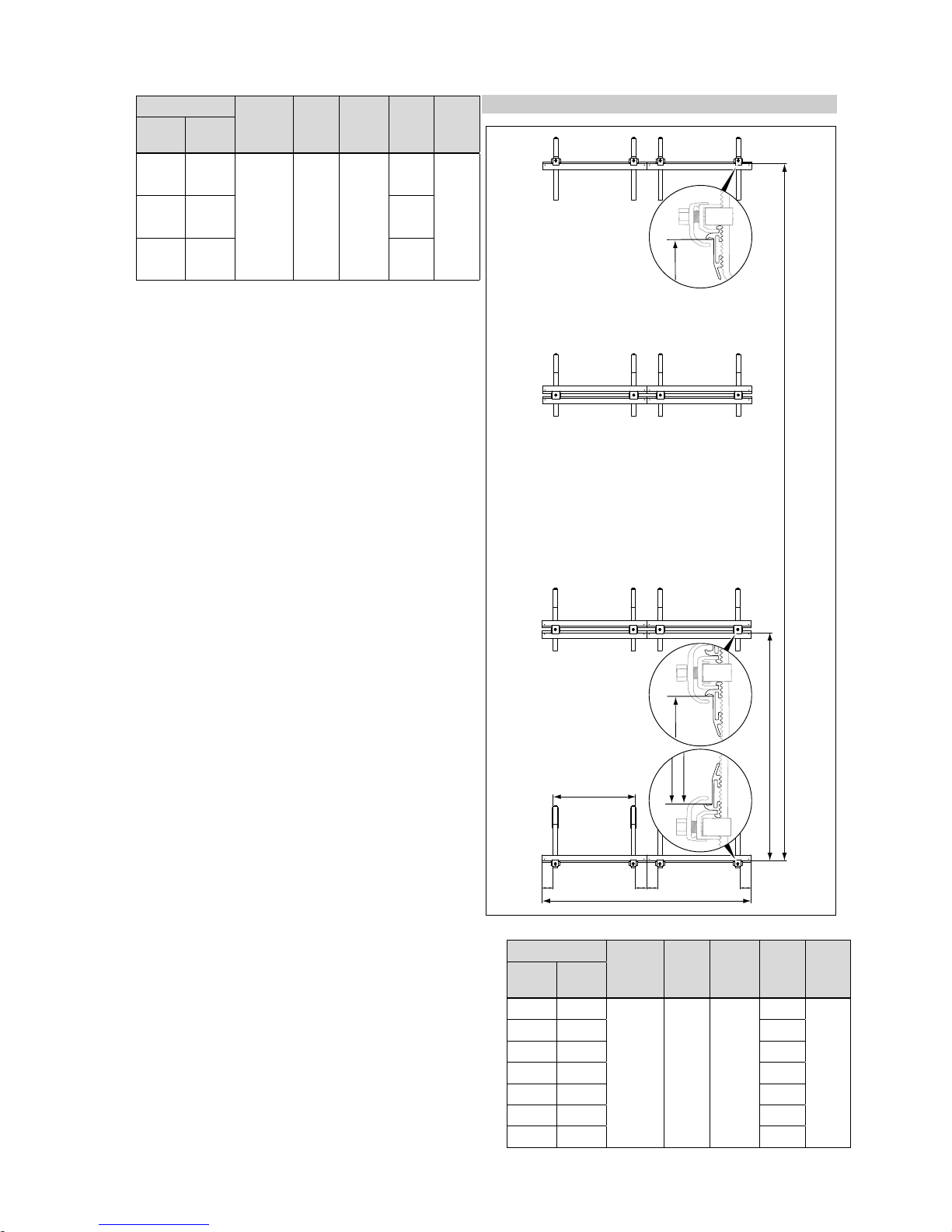

5.1.8 Defining the rack clearances

Conditions: Installed collectors: VTK 1140/2

▶ Define the rack clearances.

Quantity A

1 1088

0020077994_03 auroTHERM exclusive Installation manual 37

2 2466

3 3863

4 5260

5 6657

6 8054

1106 2420 1476 3001 1749 3267 1684

30° 45° 60°

1)

B F

1)

B

1)

F

C D EB F

− −

1233 1397

Page 38

5 Flat roof fitting and installation

B

D

E

G

A

C

F

C

30° 45° 60°

Quantity A

7 9451

1)

Sun elevation of 20° (winter sun)

Conditions: Installed collectors: VTK 570/2 and VTK 1140/2 in combination

1106 2420 1476 3001 1749 3267 1684 1233 1397

▶ Define the rack clearances.

Quantity

VTK

570/2

1)

VTK

1140/2 B F

A

1 1 1776

1 2 3173

1 3 4570

1 4 5967

1106 2420 1476 3001 1749 3267 1684 543 1397 1233

1 5 7364

1 6 8761

Sun elevation of 20° (winter sun)

1)

B F

30° 45° 60°

1)

B F

1)

1)

B

B F

1)

F

1)

C D EB F

C D E G

38 Installation manual auroTHERM exclusive 0020077994_03

Page 39

5.2 Carrying out the installation

60°

45°

30°

1

2

1

2

3

1

5.2.1 Installing racks

Danger!

Risk of death due to falling collectors!

Unsecured collectors may fall from the flat

roof due to the wind and present a danger to

persons.

▶ Perform the following safety precautions

according to the installation type.

▶ For direct connection, screw the rack

properly onto the base.

▶ Only use suitable load weights.

▶ Observe the required ballast load of the

load weights.

1. Determine the required number of racks.

– For the first collector: Two racks

– For each additional collector: One additional rack

Flat roof fitting and installation 5

4. Push the locking button (1) on the telescopic rail.

5. Pull the telescopic rail (2) into the desired installation

angle and allow the locking button to engage again.

2. Fold out the first rack.

3. Select the required installation angle.

– Installation angle:

– 30°

– 45°

– 60°

6. Position the crossbeams (1) such that their fastening

holes lie between the corresponding threaded holes in

the telescopic rail.

7. To secure the rack, insert the fixing screw (2) through

all rails.

8. Secure the fixing screw (2) with the self-locking nuts (3).

9. Tighten the nuts.