Vaillant aurotherm classic VFK 135/2 VD, aurotherm classic VFK 140/2 VD Installation Manual

For the competent person

Installation manual

Installation manual

Publisher/manufacturer

Vaillant GmbH

Berghauser Str. 40 D-42859 Remscheid

Telefon 021 91 18‑0 Telefax 021 91 18‑28 10

info@vaillant.de www.vaillant.de

auroTHERM classic

VFK 135/2 VD, VFK 140/2 VD

GB, IE

Contents

Contents

1 Safety .................................................................... 3

1.1 Action-related warnings ......................................... 3

1.2 General safety information .................................... 3

1.3 Intended use.......................................................... 4

1.4 Regulations (directives, laws, standards) .............. 5

1.5 CE label ................................................................. 6

2 Notes on the documentation .............................. 7

2.1 Observing other applicable documents ................. 7

2.2 Storing documents................................................. 7

2.3 Applicability of the instructions .............................. 7

2.4 Name ..................................................................... 7

3 Description of the unit......................................... 7

3.1 Type overview........................................................ 7

3.2 Information on the identification plate.................... 7

3.3 Purpose of the unit................................................. 7

4 On-roof fitting and installation ........................... 7

4.1 Preparing for fitting and installation ....................... 7

4.2 Carrying out the installation ................................. 10

4.3 Completing and checking the installation ............ 17

5 Flat roof fitting and installation ........................ 18

5.1 Preparing for fitting and installation ..................... 18

5.2 Carrying out the installation ................................. 27

5.3 Completing and checking the installation ............ 34

6 Inspection and maintenance ............................ 35

6.1 Maintenance plan ................................................ 35

6.2 Observing inspection and maintenance

intervals ............................................................... 35

6.3 General inspection and maintenance

instructions........................................................... 35

6.4 Preparing for inspection and maintenance .......... 35

6.5 Checking collectors and connections for

damage, dirt and lack of tightness ....................... 35

6.6 Cleaning collectors .............................................. 35

6.7 Checking brackets and collector components

for firm seating ..................................................... 36

6.8 Check the pipe insulations for damage ............... 36

6.9 Replacing damaged pipe insulations................... 36

6.10 Disposing of damaged pipe insulations ............... 36

7 Troubleshooting ................................................ 36

7.1 Procuring spare parts .......................................... 36

7.2 Carrying out repairs ............................................. 36

8 Decommissioning.............................................. 37

8.1 Temporary decommissioning .............................. 37

8.2 Permanently decommissioning............................ 37

9 Customer service............................................... 38

10 Technical data.................................................... 38

10.1 Technical data table............................................. 38

10.2 Dimensions.......................................................... 39

Index ................................................................................... 40

2 Installation manual auroTHERM classic 0020159946_01

Safety 1

1 Safety

1.1 Action-related warnings

Classification of action-related warnings

The action-related warnings are classified in

accordance with the severity of the possible

danger using the following warning signs and

signal words:

Warning symbols and signal words

Danger!

Imminent danger to life or risk of

severe personal injury

Danger!

Risk of death from electric shock

Warning.

Risk of minor personal injury

Caution.

Risk of material or environmental

damage

1.2.3 Risk of death due to falling parts

Unsecured collectors can fall from the roof

and create a possible danger to people.

▶ Block off the areas in the fall area below

the place of work to a sufficient extent so

that people cannot be injured by falling

objects.

▶ Indicate the working area, e.g. with inform-

ation signs, in accordance with the applicable regulations.

1.2.4 Risk of injury and material damage

due to incorrect maintenance and

repairs

If maintenance or repair work is not carried

out, or is carried out incorrectly, this may result in injuries or in damage to the solar plant.

▶ Ensure that only an approved competent

person carries out maintenance and repair

work.

1.2 General safety information

1.2.1 Risk of death due to improper

fastening systems

The collectors may fall if fastening systems

are incorrectly fitted.

Only the combination of Vailllant collectors

and Vaillant fastening systems has been

tested. This combination can withstand the

forces caused by additional wind and snow

loads.

▶ Only use the collector fastening systems

that are approved by Vaillant.

1.2.2 Risk of death due to inadequate

load-bearing capacity of the roof

A roof with an insufficient load-bearing capacity may collapse due to the additional load of

the collectors.

Above all, additional wind and snow loads

may result in higher forces which could cause

the roof to collapse.

▶ Ensure that a structural engineer has con-

firmed the roof as suitable for collector installation.

▶ Only install the collectors on a roof that

has adequate load-bearing capacity.

1.2.5 Risk of death due to inadequate

fastening of the collectors

Collectors can fall from their anchors if they

are not properly fastened on the roof. Collectors falling from the roof could cause lifethreatening accidents.

▶ Perform all work steps as described in this

manual.

▶ Observe all safety precautions described

in this manual.

▶ In addition, comply with all safety regula-

tions that specifically apply in your region.

1.2.6 Risk of burns due to hot collector

surfaces

In the event of solar radiation inside the units,

collectors can reach 200 °C. If you touch the

collectors without protection, you could burn

yourself.

▶ If a sun protection film has been attached

to the collectors in the factory, remove it

only after the solar plant has been started

up.

▶ Avoid performing installation and mainten-

ance work under direct sunlight.

▶ Cover the collectors before starting work.

▶ You should preferably perform the work in

the morning.

0020159946_01 auroTHERM classic Installation manual 3

1 Safety

▶ Wear suitable safety gloves.

1.2.7 Risk of injury due to breaking glass

The glass of the collectors may break due to

mechanical destruction or torsion.

▶ Wear suitable safety gloves.

▶ Wear suitable protective goggles.

1.2.8 Material damage caused by a highpressure cleaner

High-pressure cleaners may damage the

collectors due to the extremely high pressure.

▶ Never clean the collectors with a high-

pressure cleaner.

1.2.9 Material damage due to lightning

Lightning can damage the collector system.

▶ Connect the collector system to a lightning

protection device in accordance with applicable regulations.

▶ In particular, only use the tool specified in

the work steps of this manual.

1.2.13 Risk of death from electric shock

Incorrect installation or a faulty power cable

can result in a supply voltage on the pipes,

which can cause life-threatening injuries.

▶ Secure earthing pipe clamps to the pipes.

▶ Connect the earthing pipe clamps to a

busbar using 16 mm² copper cable.

1.2.14 Material damage due to overvoltage

Overvoltage may damage the solar plant.

▶ Earth the solar circuit to provide equipoten-

tial bonding and overvoltage protection.

▶ Secure earthing pipe clamps to the pipes.

▶ Bond the earthing pipe clamps to a busbar

using 16 mm² copper cable.

1.2.15 Risk of death and material damage

due to contact corrosion

1.2.10 Frost damage due to water in the

solar circuit

Water residue in the collector may freeze in

frosty conditions and damage the collector.

▶ Never fill or flush the collector with water.

▶ Only fill and flush the collector with Vaillant

ready-mixed solar fluid.

▶ Check the solar fluid regularly with an anti-

freeze tester.

1.2.11 Material damage due to frost

Frost may damage the collectors.

▶ Ensure that the system can be drained

completely.

The system can be drained completely if the

bottom edges of the collectors are aligned

precisely in a horizontal plane and the

pipeline has a steady downward gradient.

▶ During the installation, ensure that the bot-

tom edges of the collectors are positioned

above the cylinder connection.

1.2.12 Material damage due to an

unsuitable tool

An unsuitable tool may damage the solar

plant.

▶ Only use a suitable tool.

For roofs or façade sections made of metals

more precious than aluminium (e.g. copper

roof), contact corrosion may occur on the

brackets. Collectors could fall and put persons at risk.

▶ Use suitable underlays to separate the

metals.

1.2.16 Material damage due to snow falling

from roofs

If the collector field is installed below a sloping roof, then snow falling from the roof may

damage the collectors.

▶ Install snow fences above the collectors as

protection against falling snow.

1.3 Intended use

There is a risk of injury or death to the user or

others, or of damage to the product and other

property in the event of improper use or use

for which it is not intended.

The Vaillant VFK VD flat collector is used for

solar heating support and for solar-supported

hot water generation.

The collectors must only be operated with

Vaillant ready-mixed solar fluid. Passing

heating water or hot water directly through

the collectors constitutes improper use.

4 Installation manual auroTHERM classic 0020159946_01

Safety 1

The Vaillant VFK VD flat collector must

only be combined with Vaillant components

(fastenings, connections, etc.) and parts of

the auroFLOW plus system from Vaillant.

The use of other components or system parts

shall be considered as improper use.

Intended use includes the following:

– observing the included operating, install-

ation and servicing instructions for the

Vaillant product and any other system

components

– compliance with all inspection and main-

tenance conditions listed in the instructions.

Installation of the collector in or on a vehicle

is not permissible and is considered improper. Units that are not classed as vehicles

are those that are installed in a fixed and

permanent location (known as "fixed

installation").

Any other use that is not specified in these

instructions, or use beyond that specified in

this document shall be considered improper

use. Any direct commercial or industrial use

is also deemed to be improper.

Caution.

Improper use of any kind is prohibited.

ments of Health and Safety Document No.

635 (The Electricity at Work Regulations

1989), BS7671 (IEE Wiring Regulations) and

the Water Supply (Water Fitting) Regulations

1999, or The Water Bylaws 2000 (Scotland).

It should also be in accordance with the relevant requirements of the Local Authority,

Building Regulations, The Building Regulations (Scotland), The Building Regulations

(Northern Ireland) and the relevant recommendations of the following British Standards:

– BS EN 806: Specification for installations

inside buildings conveying water for human consumption

– BS 6700: Services supplying water for

domestic use within buildings and their

curtilages

– BS 5449 Forced circulation hot water cent-

ral heating systems for domestic premises.

Note: only up to 45 kW

– BS. 6880 Low temperature hot water heat-

ing systems of output greater than 45 kW

– Part 1 Fundamental and design consid-

erations.

– Part 2 Selection of equipment

– Part 3 Installation, commissioning and

maintenance

1.4 Regulations (directives, laws,

standards)

1.4.1 Regulations (directives, laws,

standards)

Technical Guidance

The system must be installed in accordance

with all relevant and applicable national regulations, and must be installed to suit site conditions. Observe all national regulations, including:

– Working at Heights Regulations 2005

– Health and Safety at Work Act 1974

– Electricity at Work Regulations 1989

– IEE Wiring Regulations BS 7671

– Lightning protection requirements

– Equipotential bonding of electrical installa-

tions.

Related documents

The installation of the solar system must

be in accordance with the relevant require-

– BS 6114: Expansion vessels using an in-

ternal diaphragm for unvented hot water

supply systems

– BS. 4814 Specification for: Expansion

vessels using an internal diaphragm, for

sealed hot water heating systems

– Unvented hot water systems must comply

with building regulation G section 3

1.4.2 Regulations for the prevention of

accidents

When carrying out works such as solar installation work it is necessary to do so in a

safe and workman like manner, taking due

care of any aspects of the works that could

result in injuries to person in or about the

building as well as workers, passers by and

the general public at large. To that end these

works must conform, but not be limited to, the

current regulations in force such as the following:

– Health and Safety at Work act 1974

0020159946_01 auroTHERM classic Installation manual 5

1 Safety

– Work at Height Regulations 2005

– Electricity at Work Regulations 1989

– All necessary Building Regulations

Work should be preceded by a risk assessment covering all aspects of health and

safety risks, or training requirements that can

reasonably be foreseen to be associated with

the work. All scaffolding in the UK, other than

prefabricated (zip-up) scaffold towers, must

be designed and constructed by a vetted contractor, and have suitable kick boards, hand

rails and where appropriate netting. Areas

around the scaffolding should be zoned off

and marked with suitable warning signs to

a suitable distance to protect persons from

falling objects. Workers should have available

and use personal protective equipment as

necessary. This would include equipment

such as fall protection systems, safety gloves,

goggles, dust masks as well as any specialised equipment that may be in use such as

lifting and handling equipment.

The completed works shall comply with all

necessary BS EN Standards and Codes of

practice as well as Building control or planning requirements and be confirmed where

necessary by notification to building control or

the appropriate competence based notification body.

1.5 CE label

The CE label shows that the products comply

with the basic requirements of the applicable

directives as stated on the identification plate.

The declaration of conformity can be viewed

at the manufacturer's site.

6 Installation manual auroTHERM classic 0020159946_01

Notes on the documentation 2

Serial-No.

2 Notes on the documentation

2.1 Observing other applicable documents

▶ You must observe all the operating and installation in-

structions included with the system components.

2.2 Storing documents

Document handover

▶ Pass this installation manual and all other applicable

documents and, if necessary, any required tools to the

system operator.

Availability of documents

The system operator is responsible for storing the documents so that they are available whenever required.

2.3 Applicability of the instructions

These instructions apply for the following only:

Collector types and article numbers

VFK 135/2 VD

VFK 140/2 VD

2.4 Name

In this manual, flat collectors are referred to as collectors.

0010010204, 0010010206

0010013172

Information on the identification plate

V Vertical design

D Drainback

Flat plate collector Flat collector

A

G

V

F

m Weight

A Dimensions

Q

max

tstgf Stagnation temperature

Pmax Max. permissible operating

Meaning

Gross area

Liquid volume

Max. output

pressure

Bar code with serial number

The 7th to 16th digits of the

serial number form the article

number

3.3 Purpose of the unit

The collectors are used for solar heating support as well as

for solar-supported hot water generation.

4 On-roof fitting and installation

3 Description of the unit

3.1 Type overview

– VFK 135/2 VD

– VFK 140/2 VD

3.2 Information on the identification plate

Information on the identification plate

Meaning

CE label:

The collectors comply with

the relevant product-specific

European guidelines.

Solar Keymark:

The collectors have been

successfully tested according

to the rules and requirements

for the Solar Keymark.

MCS certificate:

The collectors comply with

the relevant product-specific

requirements set out in the

Microgeneration Certification

Scheme (MCS).

Read the installation manual.

▶ When fitting and installing the collectors, you must ob-

serve the chapter "Safety".

4.1 Preparing for fitting and installation

4.1.1 Delivery, transport and positioning

4.1.1.1 Storing collectors

▶ To prevent moisture from penetrating into the collector,

always store the collectors dry and in a weatherproof

area.

VFK 135/2 VD

VFK 140/2 VD

VFK Vaillant flat collector

135, (140) Collector output

/2 Unit generation

0020159946_01 auroTHERM classic Installation manual 7

Type designation

4 On-roof fitting and installation

1

2

7

5

2

9

1

11

10

9

6

3

8

8

4

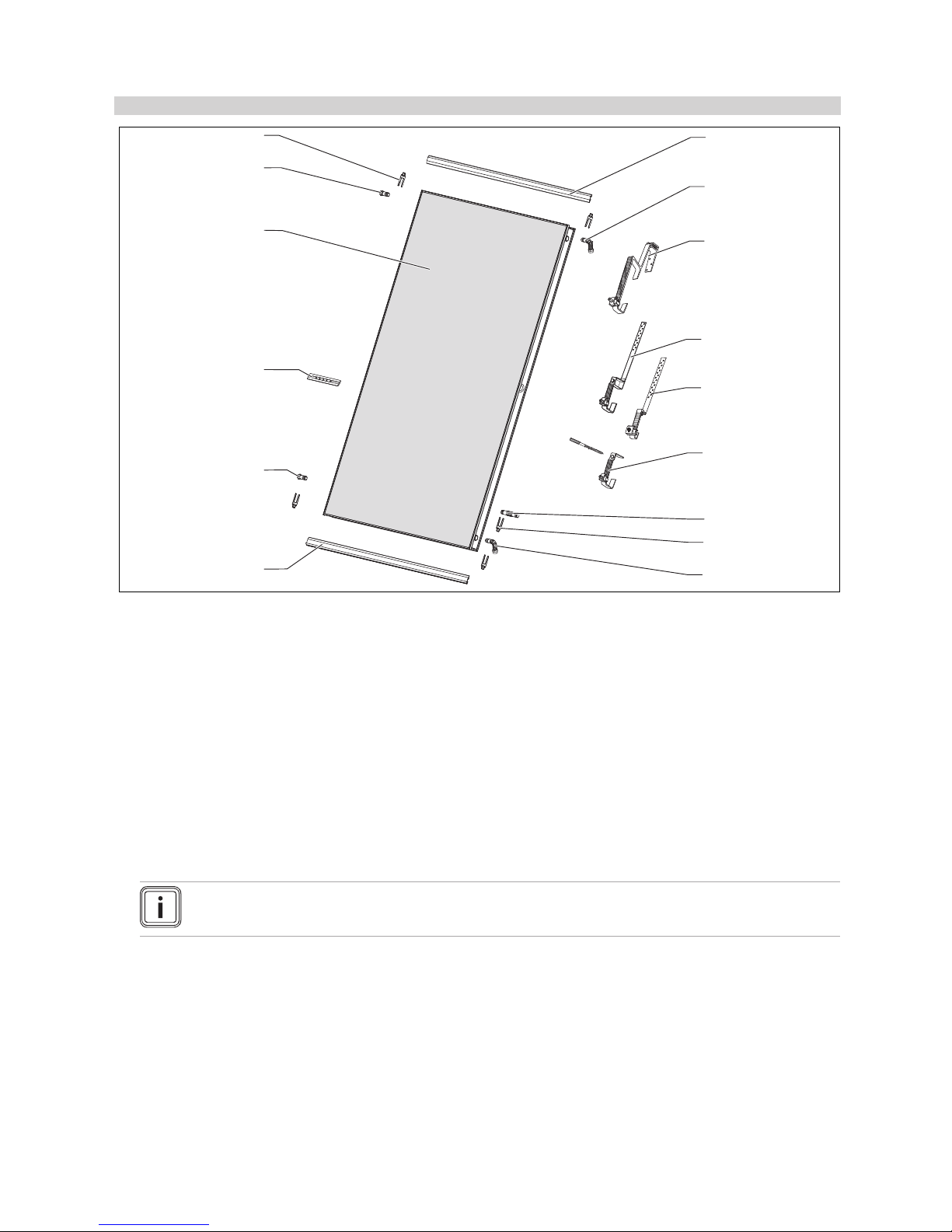

4.1.1.2 Checking the scope of delivery

Conditions: Collector position: Vertical

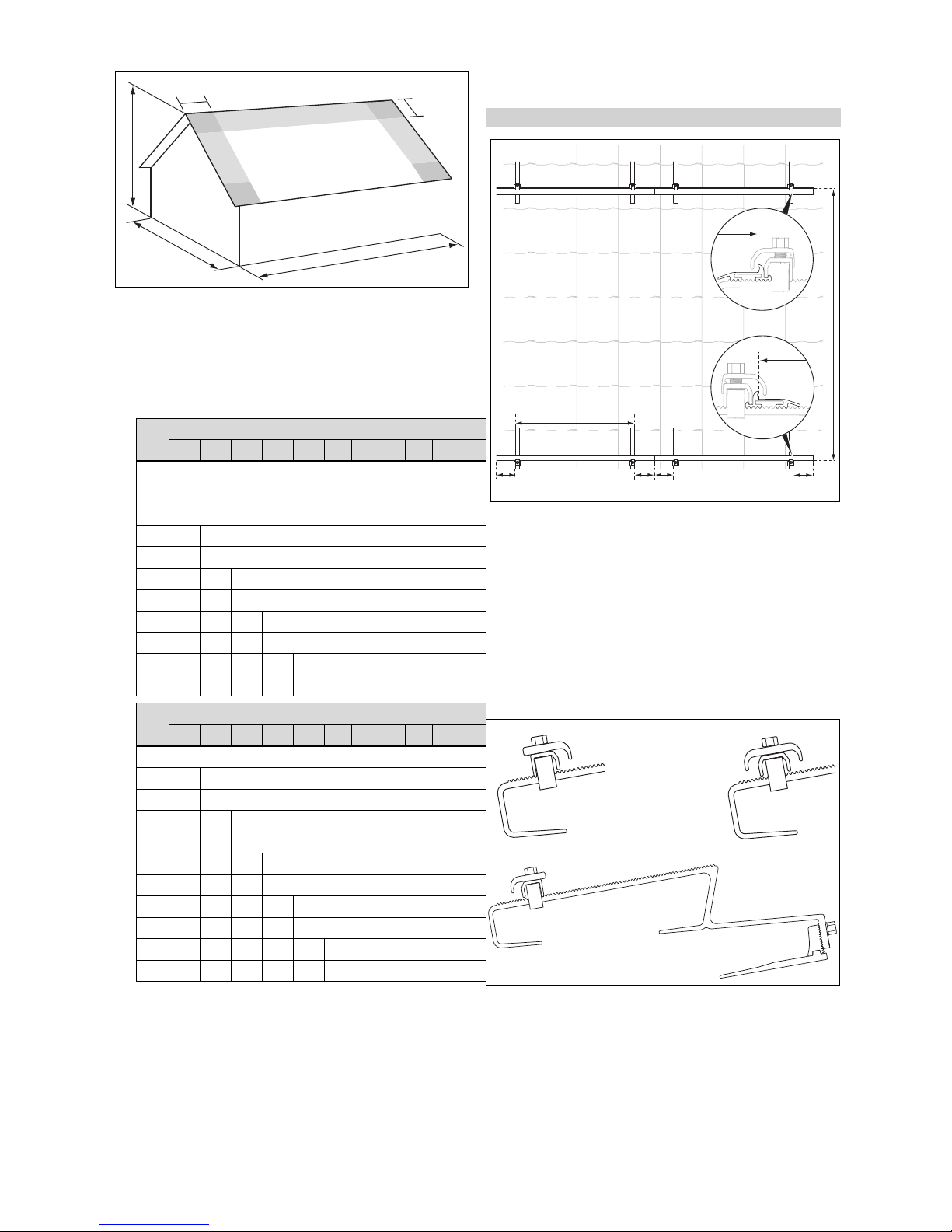

List of materials for on-roof installation for 4/5/6 vertical collectors

1 Rail mounting set, vertical

4/5/6 pc

2 Hydraulic connections from the sensor set

2/2/2 pc

3 Roof bracket type P (for pantile) from the basic set

16/20/24 pc

4 Roof bracket type S (for beaver tail, etc.) from the basic

set

16/20/24 pc

5 Roof bracket type S, flat, (for beaver tail, etc.) from the

basic set

16/20/24 pc

6 Hanger bolt fastening set from the basic set

16/20/24 pc

▶ Use the image to check that the installation sets are complete.

Note

Not all roof bracket types are available in all countries.

7 Hydraulic inter-connector from the sensor set

6/8/10 pc

8 Clamp from the sensor set

16/20/24 pc

9 Plug from the sensor set

2/2/2 pc

10 Rail connector from the sensor set

6/8/10 pc

11 auroTHERM VFK 135/2 VD collector

4/5/6 pc

auroTHERM VFK 140/2 VD collector

4/5/6 pc

8 Installation manual auroTHERM classic 0020159946_01

4.1.1.3 Transporting collectors

1. To protect the collectors against damage, always transport them horizontally.

2. Transport the collectors to the roof using suitable aids.

4.1.2 Complying with clearances and installation

clearances

In order to fit the collectors correctly, the specified clearances and installation clearances must be observed.

▶ For the necessary edge clearances, see chapter "Defin-

ing edge clearances of the roof brackets".

4.1.3 Selecting suitable connection

▶ When installing the collectors, observe the installation

instructions for the auroFLOW plus system.

▶ Select the appropriate connection for the collectors.

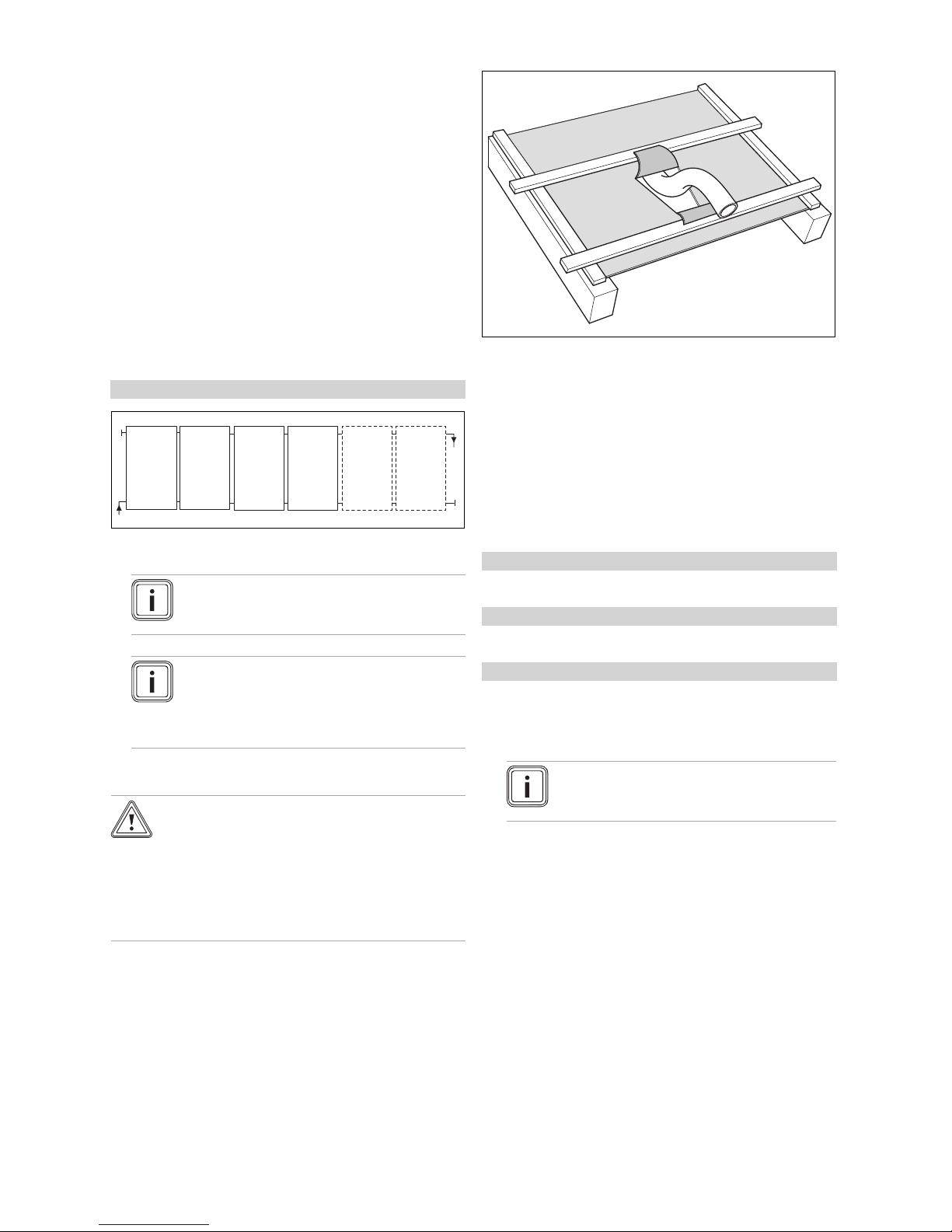

Conditions: Array configuration: Adjacent

▶ Install a maximum of six collectors next to each other.

Note

Collector fields with 4-6 collectors must be

connected on opposite sides.

Note

If the collector field is connected on opposite

sides, the mounting rails must have an incline

to the lower connection (collector return) of

approx. 1%.

On-roof fitting and installation 4

1. Make a v-shaped cut in the roofing felt membrane.

2. Fold the upper, wider flap onto the roof batten above,

and fold the lower, narrower flap onto the roof batten

below.

3. Fix the roofing felt membrane tight to the roof batten, so

that any moisture runs off to the side.

4.1.5 Determining the number of required roof

brackets

1. Ask the local building authority for the regional maximum snow load sk.

Conditions: Maximum snow load: ≤ 3 kN/m²

▶ Install 4 roof brackets per collector.

Conditions: Maximum snow load: 3 … 4.5 kN/m²

▶ Install 6 roof brackets per collector.

Conditions: Maximum snow load: > 4.5 kN/m²

▶ Compile statistics for the individual case.

▶ Ensure that the maximum permissible snow load per

collector is 5.4 kN/m².

4.1.4 Preparing the roof duct

Caution.

Building damage due to penetrating wa-

ter.

If the roof duct is not prepared properly, water

may penetrate the building interior.

▶ Ensure that the roof duct is prepared prop-

erly.

0020159946_01 auroTHERM classic Installation manual 9

Note

The maximum permissible load per roof

bracket type S/type P is: F

2. If you are using extension sets, ensure that the roof

bracket is positioned centrally with equal clearances.

= 1.875 kN.

max

4.1.6 Defining the edge clearances of the roof

brackets

Maximum lift points caused by wind loads can occur at

the cut-away edges of wall and roof areas (e.g. verge and

eaves). These maximum lift points result in high loads on the

collectors and installation systems.

Areas in which lift points occur are called edge areas. Corner

areas are zones in which edge areas overlap and especially

high pull forces occur.

Edge and corner areas must not be used as installation

areas.

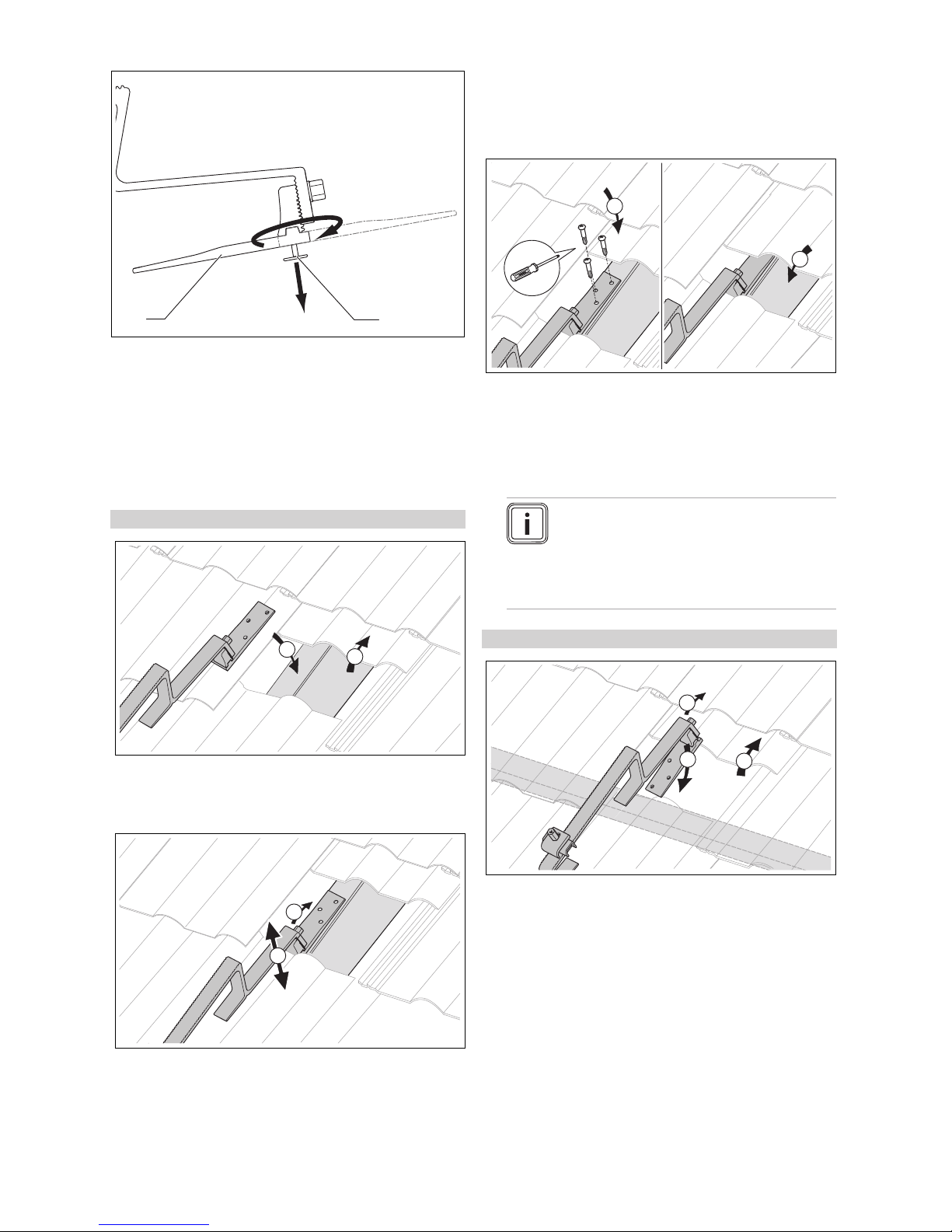

4 On-roof fitting and installation

e

lang

e

kurz

h

b

l

n

2045 * / 2020 **

200 - 300

200 - 300200 - 300

200 - 300

660 - 860

1

3

2

b Building width

h Building height

4.1.7.1

Conditions: Collector position: Vertical

l Building length

Adjacent array configuration

▶ Calculate the building width w, building height h and

building length l.

▶ The values for the edge clearances to be observed, e

and e

▶ When installing the roof brackets, observe the calculated

edge clearances.

4.1.7 Defining the roof bracket clearances

The text that follows describes the clearances of the roof

brackets for the vertical collector position in the case of "adjacent" array configuration.

can be found in the following tables.

long

b

[m]

5 6 7 8 9 10 11 12 13 14 15

8 1.0

9 1.0

10 1.0

11 1.0 1.1

12 1.0 1.2

13 1.0 1.2 1.3

14 1.0 1.2 1.4

15 1.0 1.2 1.4 1.5

16 1.0 1.2 1.4 1.6

17 1.0 1.2 1.4 1.6 1.7

18 1.0 1.2 1.4 1.6 1.8

l

[m]

5 6 7 8 9 10 11 12 13 14 15

10 1.0

11 1.0 1.1

12 1.0 1.2

13 1.0 1.2 1.3

14 1.0 1.2 1.4

15 1.0 1.2 1.4 1.5

16 1.0 1.2 1.4 1.6

17 1.0 1.2 1.4 1.6 1.7

18 1.0 1.2 1.4 1.6 1.8

19 1.0 1.2 1.4 1.6 1.8 1.9

20 1.0 1.2 1.4 1.6 1.8 2.0

h [m]

h [m]

short

▶ Define the clearances of the roof brackets.

– Pre-installation dimension (*): = Finished installation

dimension (**) + 20-25 mm

4.2 Carrying out the installation

The installation steps and notes in these instructions apply

for the vertical collector position in the case of "adjacent"

array configuration.

4.2.1 Installing roof brackets

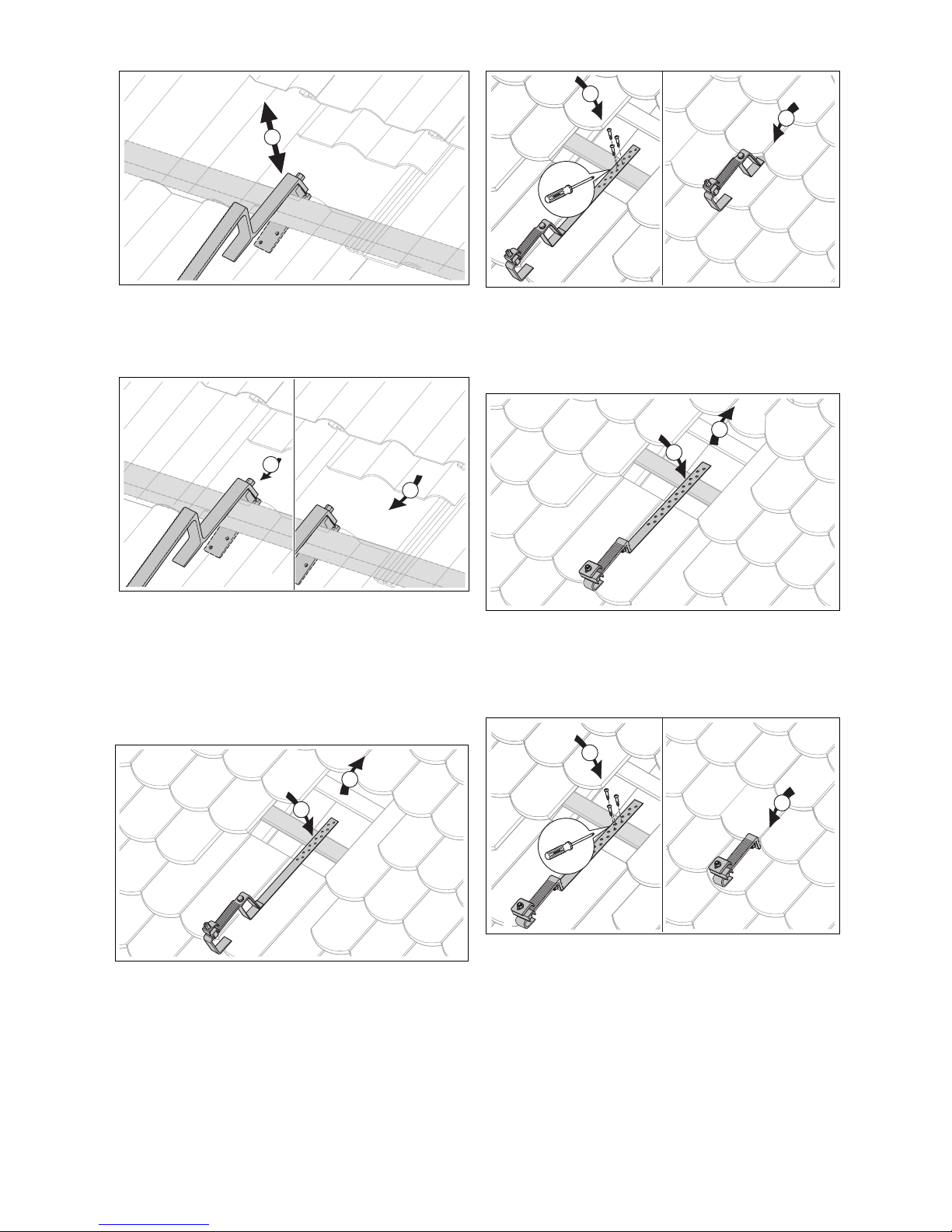

4.2.1.1 Installing type P (for pantile)

1 Lower roof bracket

2 Top roof bracket

1. Use the top, middle and lower type P roof brackets

shown.

3 Middle roof bracket

10 Installation manual auroTHERM classic 0020159946_01

A

2

1

B

5 mm

2. Secure the type P roof bracket either to the rafters (A)

1

2

3

4

5

6

A

B

1

3

2

or to the roof batten (B).

3. To do this, loosen the bolt (1) on the base of the roof

bracket with the enclosed bit and unscrew the bolt by

approx. 5 mm.

4. If you wish to secure the roof bracket onto the rafters,

turn the base (2) outwards (A).

5. If you wish to secure the roof bracket onto the roof batten, turn the base (2) inwards (B).

Conditions: Fastening type: To rafters

On-roof fitting and installation 4

▶ Adjust the roof bracket to the height of the pantiles, so

that the top part of the roof bracket lies on the roofing

(4).

▶ Tighten the top bolt.

– Working materials: SW 13 spanner

▶ Screw the roof bracket onto the rafters using the three

bolts supplied (5).

▶ Slide the pantiles into their original position again (6).

▶ To ensure that the tiles lie tightly together, notch gut-

tering onto the underside (A) or the top side (B) of the

pantile using a hammer, if necessary.

Note

For some roof types, it may be necessary to

offset the roof bracket laterally opposite the

rafters.

To do this, use the "long base" accessory,

article number 0020080177.

▶ Define the clearances of the roof brackets. (→ Page 10)

▶ Expose the rafters at the corresponding position (1).

▶ Position the roof bracket (2). Ensure the correct position

of the top, middle and lower roof brackets.

▶ Undo the top bolt until the height of the roof bracket can

be adjusted (3).

– Working materials: SW 13 spanner

0020159946_01 auroTHERM classic Installation manual 11

Conditions: Fastening type: To roof batten

▶ Define the clearances of the roof brackets. (→ Page 10)

▶ Slide one to two pantiles upwards at the corresponding

position above the roof batten (1).

▶ Undo the top bolt until the height of the roof bracket can

be adjusted (2).

– Working materials: SW 13 spanner

▶ Hang the roof bracket on the roof batten (3). Ensure that

the top, middle and lower roof brackets are positioned

correctly.

4 On-roof fitting and installation

4

5

6

A

2

1

4

3

2

1

4

3

▶ Adjust the roof bracket to the height of the pantiles, so

that the top part lies on the roofing and the bottom part is

pushed tight against the roof batten from the bottom (4).

▶ Ensure that the roof bracket fits securely around the roof

batten and that it is slightly pre-tensioned.

▶ Tighten the top bolt (5).

– Working materials: SW 13 spanner

▶ Slide the pantiles into their original position again (6).

▶ To ensure that the tiles lie tightly together, notch gutter-

ing onto the underside of the pantiles (A) using a hammer, if necessary.

4.2.1.2 Installing type S (for slate)

4. Screw the roof bracket onto the roof batten or rafters

using the three screws supplied (3).

5. Slide the pantiles into their original position again (4).

4.2.1.3 Installing type S flat (for slate)

1. Define the clearances of the roof brackets. (→ Page 10)

2. At the appropriate position, expose the rafters or roof

batten (1).

3. Position the roof bracket. Ensure that the top, middle

and lower roof brackets (2) are positioned correctly.

1. Define the clearances of the roof brackets. (→ Page 10)

2. At the appropriate position, expose the rafters or roof

batten (1).

3. Position the roof bracket. Ensure the correct position of

the top, middle and lower roof brackets (2).

12 Installation manual auroTHERM classic 0020159946_01

4. Screw the roof bracket onto the roof batten or rafters

using the three screws supplied (3).

5. Slide the pantiles into their original position again (4).

On-roof fitting and installation 4

1

2

3

6

4

5

n

1

2

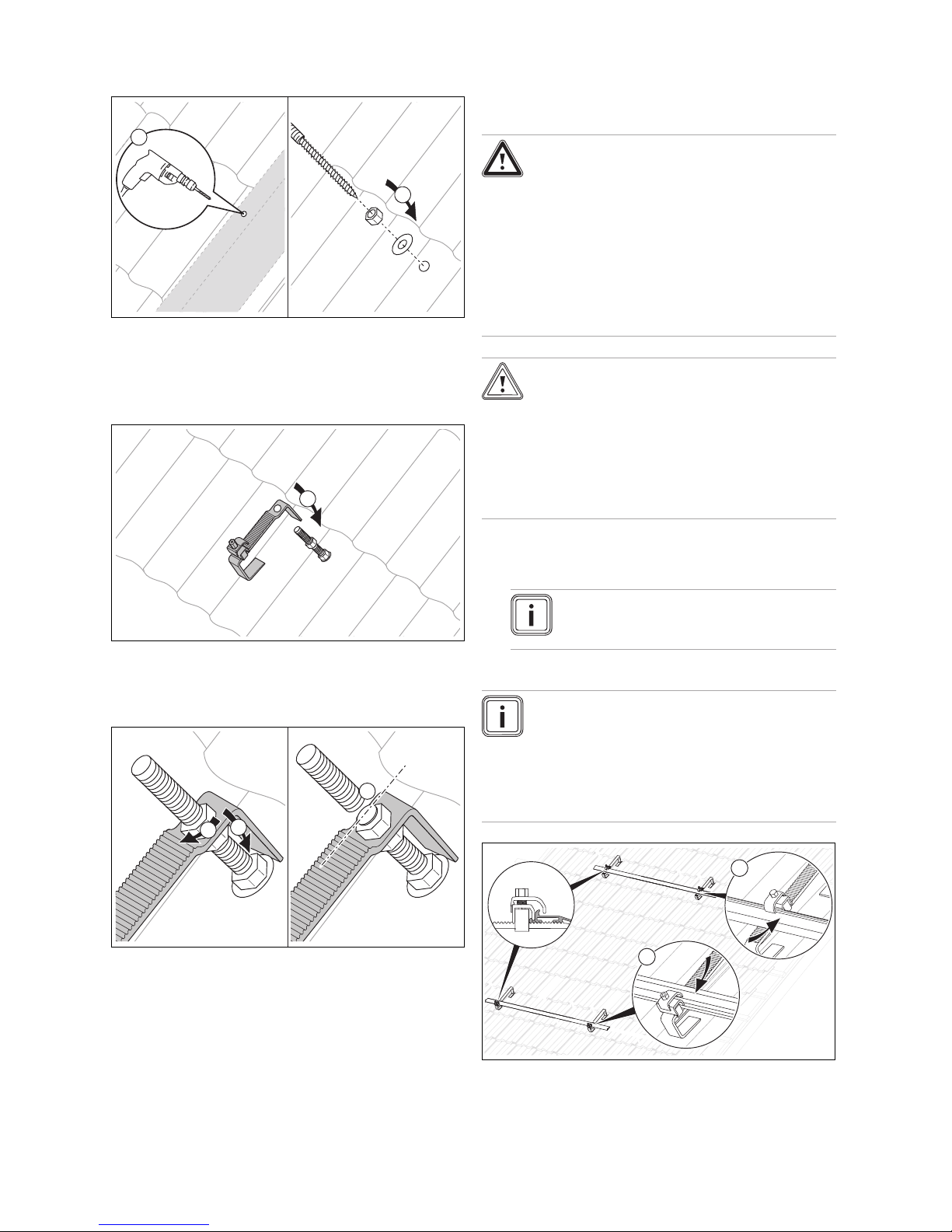

4.2.1.4 Installing the hanger bolt type

1. Define the clearances of the roof brackets. (→ Page 10)

2. At the corresponding position, drill a hole in the pantile

(1).

3. Tighten the hanger bolt onto the rafters through the

pantile(2).

4.2.2 Installing collectors

4.2.2.1

Adjacent array configuration

Danger!

Personal injury and material damage due

to a falling collector.

Improper fastening may cause a collector to

fall.

▶ Tighten the clamping elements.

▶ Check for proper tensioning by shaking

the clamping blocks.

▶ If a clamping block moves, tighten the nut

again.

Caution.

Damage to internal components.

The interior of the collector is ventilated

through a ventilation opening in the pipe

opening.

▶ Ensure that the ventilation opening is

clear so that the air can flow through it unimpeded.

1. Install the collectors on the roof as specified in the following sections.

Note

Mounting rails and clamping elements cannot

be moved at the same time.

4. Position the central nut so that, after inserting the upper

part of the roof bracket, the front contact area lies on

the roofing (3). Ensure the correct positioning of the top,

middle and lower roof brackets.

5. Position the roof bracket on the central nut (4).

6. Screw the second nut on and tighten (5).

– Working materials: SW 17 spanner

7. Disconnect the threaded rod directly above the nut (6).

8. Deburr the interface.

Installing mounting rails

Note

System malfunction.

In the case of diagonal connection, to ensure that

the auroFLOW plus system functions correctly,

the lower mounting rail must be at an incline of

1% aligned to the lower connection (collector return).

2. Secure the mounting rail depending on the field connection.

3. Secure the mounting rail so that there is a 1% incline to

the lower connection (collector return).

0020159946_01 auroTHERM classic Installation manual 13

4 On-roof fitting and installation

2

1

1

A

B

1

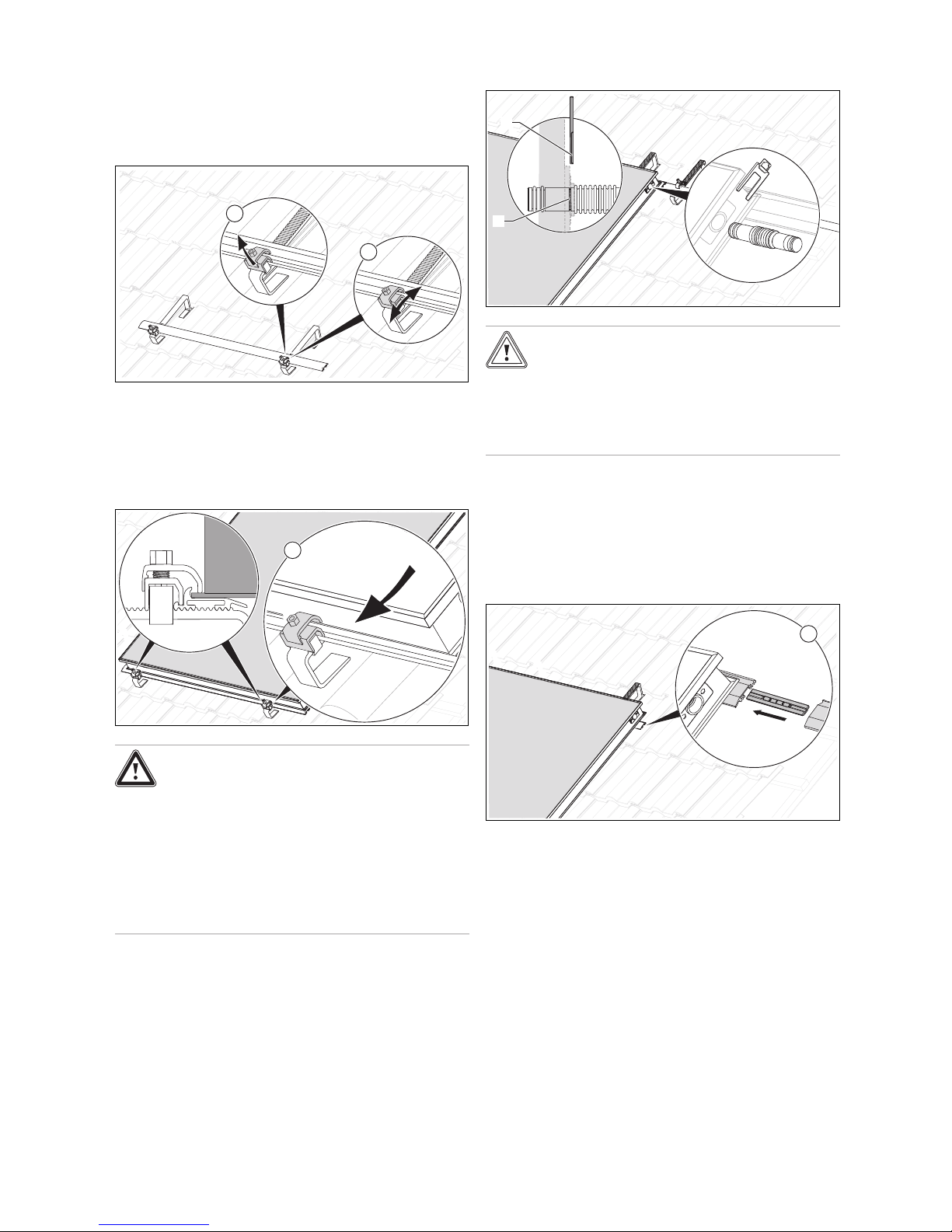

4. Secure the mounting rails with the clamping elements to

the roof anchors ((1) and (2)).

5. Position the lower rail as far as possible downwards on

the roof bracket.

Taring mounting rails

6. Secure the mounting rails horizontally.

7. Compensate for any height differences by moving the

clamping elements.

8. To do this, pull the clamping element upwards (1),

move it (2) and release it so that it engages.

Laying and hooking collectors

Fitting connectors

Caution.

Risk of damage to the collector.

Improper installation of the pipe connectors

may damage the collector.

▶ Ensure that the clamps (A) slide into the

grooves of the pipe connector (B).

12. Insert the hydraulic connectors into the provided mounting openings at the side of the previously installed collector until they reach the stop position.

13. Secure the connectors with the clamps, slide the clamp

into the guide from the top for the top connection and

from the bottom for the lower connection.

Connecting mounting rails

Danger!

Risk of burns and scalding!

In the event of solar radiation inside the units,

collectors can reach 200 °C.

▶ Avoid working in direct sunlight.

▶ Cover the collectors before starting work.

▶ You should preferably perform the work in

the morning.

▶ Wear suitable safety gloves.

9. Lay the lower edge of the first collector in the lower

mounting rail and hook it in at the clamping elements

(1).

10. Ensure that the top clamping block of the clamping ele-

ment is positioned above the edge of the collector.

11. Tighten the clamping elements of the lower mounting

rail.

– Working materials: SW 13 spanner

14 Installation manual auroTHERM classic 0020159946_01

14. Insert the connecting elements laterally into the mounting rails until you feel them engage (1).

15. Slide the mounting rails of the next collector onto the

mounting rails of the previously installed collector (1).

16. Secure the mounting rails for the next collector onto the

roof brackets using the clamping elements.

17. Tare the mounting rails. (→ Page 14)

Loading...

Loading...