Vaillant auroSTOR VIH S GB 300/3 BES, auroSTOR VIH S GB 250/3 BES, auroSTOR VIH S GB 200/3 BES Installation And Maintenance Instructions Manual

For the competent person

Installation and maintenance instructions

auroSTOR

VIH S GB .../3 BES

GB, IE

Installation and maintenance instructions

Publisher/manufacturer

Vaillant GmbH

Berghauser Str. 40 D-42859 Remscheid

Tel. +49 21 91 18‑0 Fax +49 21 91 18‑2810

info@vaillant.de www.vaillant.de

Contents

2 Installation and maintenance instructions auroSTOR 0020221298_02

Contents

1 Safety .................................................................... 3

1.1 Action-related warnings ......................................... 3

1.2 Risk caused by inadequate qualifications.............. 3

1.3 Intended use.......................................................... 3

1.4 General safety information .................................... 3

1.5 Regulations (directives, laws, standards) .............. 4

2 Notes on the documentation .............................. 5

2.1 Observing other applicable documents ................. 5

2.2 Storing documents................................................. 5

2.3 Applicability of the instructions .............................. 5

2.4 Benchmark............................................................. 5

3 Product description............................................. 5

3.1 Serial number ........................................................ 5

3.2 Information on the identification plate.................... 5

3.3 CE label ................................................................. 5

4 Installation............................................................ 6

4.1 Observing the requirements for the product's

installation site ....................................................... 6

4.2 Transport ............................................................... 6

4.3 Unpacking the product........................................... 6

4.4 Checking the scope of delivery.............................. 7

4.5 Product dimensions ............................................... 7

5 Installation............................................................ 7

5.1 Setting up the unit horizontally .............................. 7

5.2 Hydraulic connection ............................................. 7

5.3 Electrical installation ............................................ 11

6 Start-up ............................................................... 14

6.1 Checking and treating the heating water/filling

and supplementary water .................................... 14

6.2 Setting the immersion heater thermostat............. 15

6.3 Cold water inlet pressure..................................... 15

6.4 Setting the thermostatic mixer ............................. 15

6.5 Filling and purging the product ............................ 15

6.6 Filling and purging the heating circuit .................. 15

6.7 Filling and purging the solar circuit ...................... 15

7 Handing the product over to the operator ...... 15

8 Troubleshooting ................................................ 16

8.1 Detecting and rectifying faults ............................. 16

8.2 Procuring spare parts .......................................... 16

9 Inspection and maintenance ............................ 16

9.1 Observing inspection and maintenance

intervals ............................................................... 16

9.2 Draining the product ............................................ 16

9.3 Checking the safety group's expansion relief

valve and the cylinder's expansion relief valve .... 16

9.4 Checking the pre-charge pressure of the

expansion vessel ................................................. 16

10 Decommissioning the product ......................... 16

11 Customer service............................................... 16

Appendix ............................................................................ 17

A Detecting and rectifying faults ......................... 17

B Inspection and maintenance work –

Overview............................................................. 17

C Technical data.................................................... 17

D Commissioning Checklist ................................. 20

Index ................................................................................... 23

Safety 1

0020221298_02 auroSTOR Installation and maintenance instructions 3

1 Safety

1.1 Action-related warnings

Classification of action-related warnings

The action-related warnings are classified in

accordance with the severity of the possible

danger using the following warning signs and

signal words:

Warning symbols and signal words

Danger!

Imminent danger to life or risk of

severe personal injury

Danger!

Risk of death from electric shock

Warning.

Risk of minor personal injury

Caution.

Risk of material or environmental

damage

1.2 Risk caused by inadequate

qualifications

The following work must only be carried out

by competent persons who are sufficiently

qualified to do so:

– Installation

– Disassembly

– Installation

– Start-up

– Maintenance

– Repair

– Decommissioning

▶ Observe all instructions that are included

with the product.

▶ Proceed in accordance with the current

state of technology.

▶ Observe all applicable directives, stand-

ards, laws and other regulations.

1.3 Intended use

There is a risk of injury or death to the user or

others, or of damage to the product and other

property in the event of improper use or use

for which it is not intended.

The product is intended as a system component for hot water generation and storage for

closed central heating installations.

Intended use includes the following:

– observance of accompanying operating,

installation and servicing instructions for

the product and any other system components

– installing and fitting the product in accord-

ance with the product and system approval

– compliance with all inspection and main-

tenance conditions listed in the instructions.

Intended use also covers installation in accordance with the IP class.

Any other use that is not specified in these

instructions, or use beyond that specified in

this document shall be considered improper

use. Any direct commercial or industrial use

is also deemed to be improper.

Caution.

Improper use of any kind is prohibited.

1.4 General safety information

1.4.1 Risk of death due to lack of safety

devices

The schematic drawings included in this document do not show all safety devices required for correct installation.

▶ Install the necessary safety devices in the

system.

▶ Observe the applicable national and inter-

national laws, standards and guidelines.

1.4.2 Risk of death from electric shock

There is a risk of death from electric shock if

you touch live components.

Before commencing work on the product:

▶ Disconnect the product from the power

supply by switching off all power supplies

at all poles (electrical partition with a con-

1 Safety

4 Installation and maintenance instructions auroSTOR 0020221298_02

tact opening of at least 3 mm, e.g. fuse or

line protection switch).

▶ Secure against being switched back on

again.

▶ Check that there is no voltage.

1.4.3 Risk of being burned or scalded by

hot components

▶ Only carry out work on these components

once they have cooled down.

1.4.4 Risk of material damage caused by

using an unsuitable tool

▶ Use the correct tool to tighten or loosen

screw connections.

1.4.5 Risk of material damage caused by

frost

▶ Do not install the product in rooms prone

to frost.

1.4.6 Risk of injury during transport due

to a high product weight

▶ Make sure that the product is transported

by at least two people.

1.5 Regulations (directives, laws,

standards)

▶ Observe the national regulations, stand-

ards, guidelines and laws.

Notes on the documentation 2

0020221298_02 auroSTOR Installation and maintenance instructions 5

2 Notes on the documentation

2.1 Observing other applicable documents

▶ You must observe all the operating and installation in-

structions included with the system components.

2.2 Storing documents

▶ Pass these instructions and all other applicable docu-

ments on to the system operator.

2.3 Applicability of the instructions

These instructions apply only to:

Product article number

VIH S GB 200/3 BES

0010019221

VIH S GB 250/3 BES

0010019222

VIH S GB 300/3 BES

0010019223

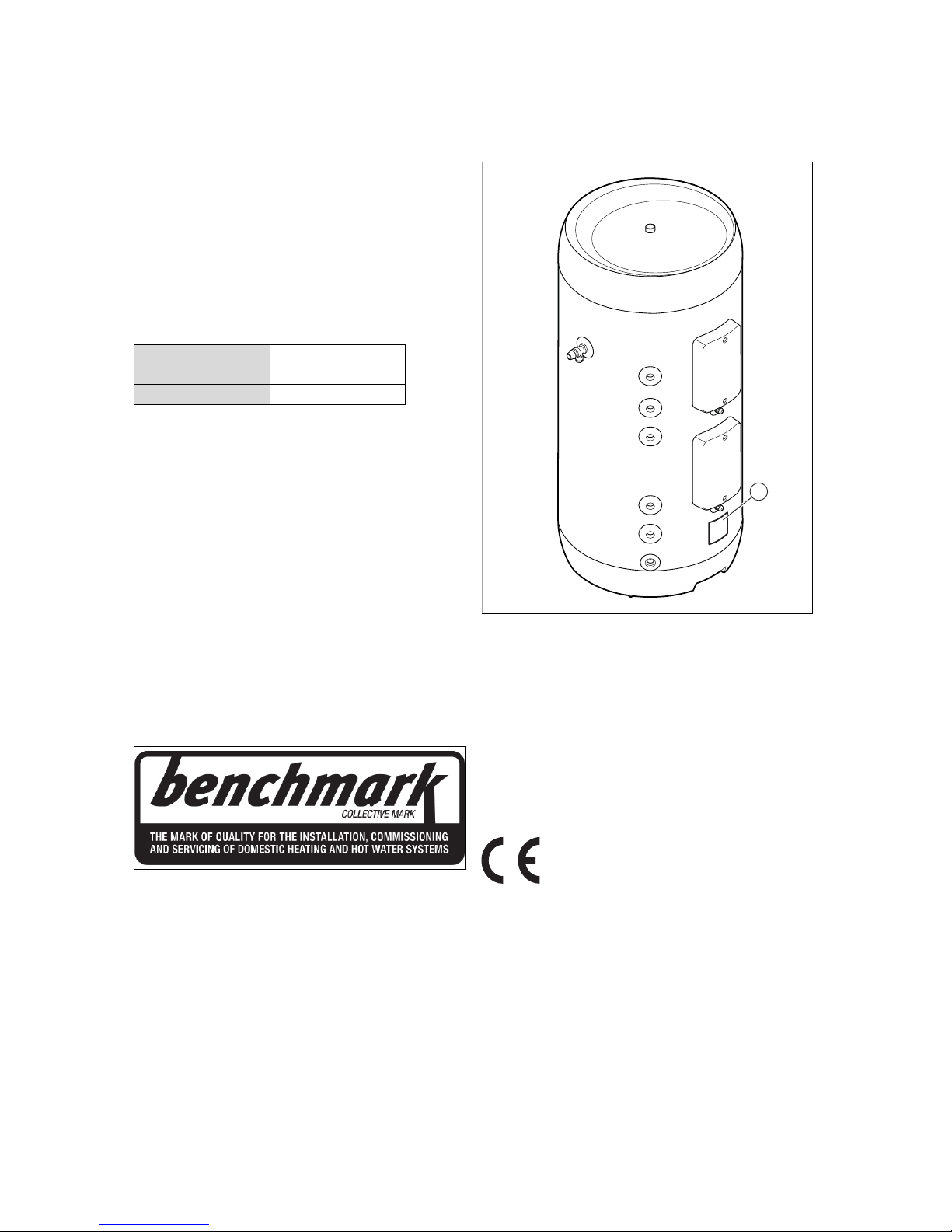

2.4 Benchmark

Vaillant is a licensed member of the Benchmark Scheme.

Benchmark places responsibilities on both manufacturers

and installers. The purpose is to ensure that customers are

provided with the correct equipment for their needs, that it is

installed, commissioned and serviced in accordance with the

manufacturer’s instructions by a competent person approved

at the time by the Health and Safety Executive and that it

meets the requirements of the appropriate Building Regulations. The Benchmark Checklist can be used to demonstrate compliance with Building Regulations and should be

provided to the customer for future reference.

Installers are required to carry out installation, commissioning and servicing work in accordance with the Benchmark

Code of Practice which is available from the Heating and

Hotwater Industry Council who manage and promote the

Scheme.

Benchmark is managed and promoted by the Heating and

Hotwater Industry Council.

For more information visit www.centralheating.co.uk

3 Product description

3.1 Serial number

1

You can find the serial number on the identification plate (1),

which is located on the cylinder below the electronics box.

3.2 Information on the identification plate

The identification plate is attached to the product at the factory.

The identification plate keeps record of the country in which

the product is to be installed.

This product meets the requirements of standard EN

12897:2006.

3.3 CE label

The CE label shows that the products comply with the basic

requirements of the applicable directives as stated on the

identification plate.

The declaration of conformity can be viewed at the manufacturer's site.

4 Installation

6 Installation and maintenance instructions auroSTOR 0020221298_02

4 Installation

4.1 Observing the requirements for the

product's installation site

Caution.

Material damage due to frost

If the water in the system freezes, there is

a risk of damage to the domestic hot water

cylinder.

▶ Install the cylinder in a dry, permanently

frost-free room.

Caution.

Material damage due to escaping water

In the event of damage, water may escape

from the cylinder.

▶ Select the installation location so that, in

the event of damage, large volumes of

water can be drained safely (e.g. into a

floor drain).

Caution.

Material damage due to high load

When filled, the cylinder may damage the

ground on which it stands due to its weight.

▶ Take into consideration the weight of the

filled cylinder and the weight-bearing capacity of the floor.

▶ If required, reinforce the installation area.

Select a sensible installation site and take into consideration

the routing of the lines.

Install the cylinder as close as possible to the heat generator

in order to minimise heat losses.

Set up the product in a suitable location in a room and, when

doing so, pay attention to the following points:

– Plan the installation of the tundish (→ Page 9).

– The installation surface must be even and have sufficient

load-bearing capacity to support the operating weight of

the product.

– The installation site must be frost-free.

– Install the product in such a way that the thermostat and

immersion heater can be accessed easily.

– Leave sufficient space around the product for installing,

maintaining and replacing the expansion vessel.

To prevent energy losses, the lines must be provided with

thermal insulation that complies with the applicable thermal

insulation regulations.

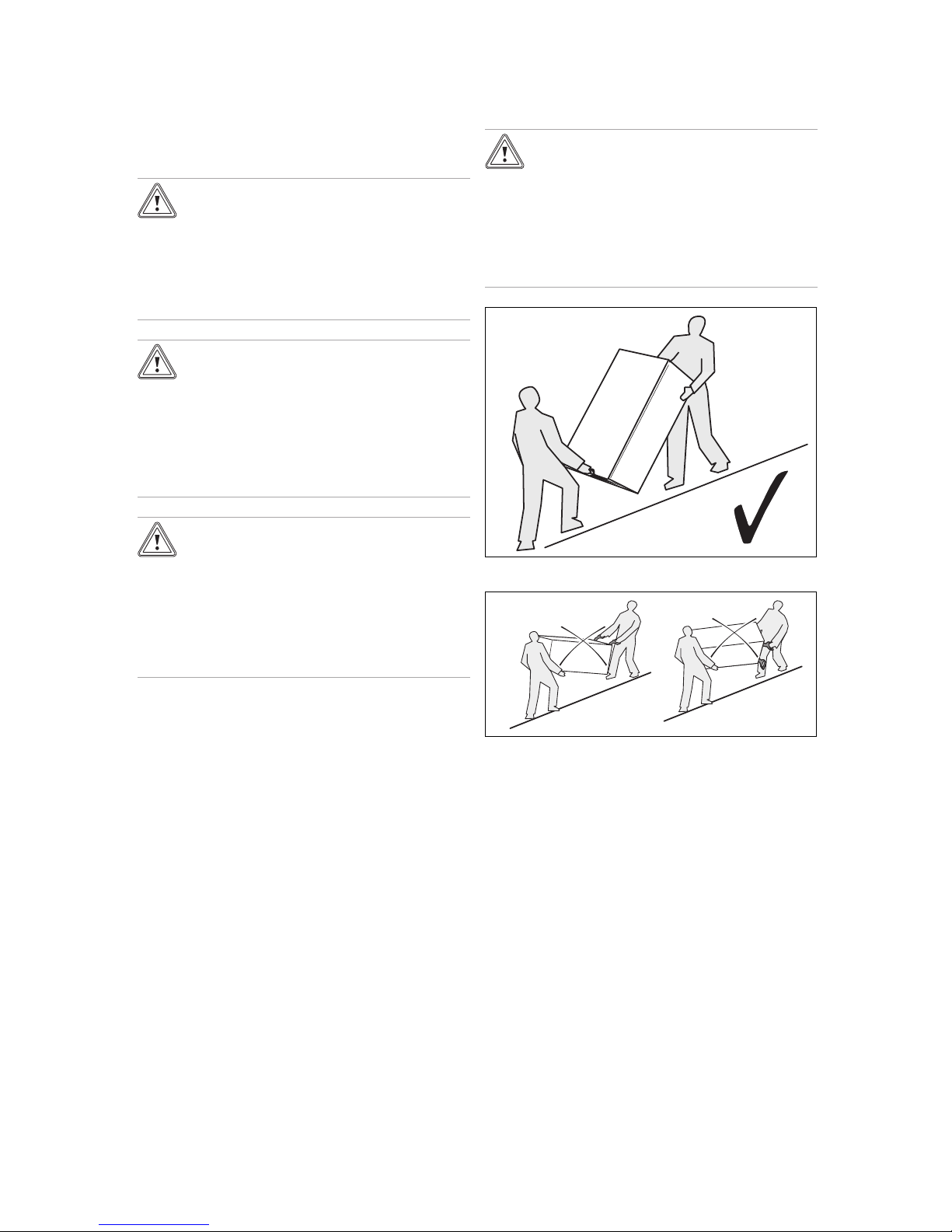

4.2 Transport

Caution.

Risk of material damage caused by incor-

rect transport.

The components must not be used to transport the cylinder. Otherwise there is a risk

that the cylinder could malfunction.

▶ Do not use the cylinder's components to

transport it.

Always transport the unit as illustrated above.

Never transport the unit while it is horizontal.

4.3 Unpacking the product

1. Remove the product from its box.

2. Remove the protective film from all of the product's

components.

Installation 5

0020221298_02 auroSTOR Installation and maintenance instructions 7

4.4 Checking the scope of delivery

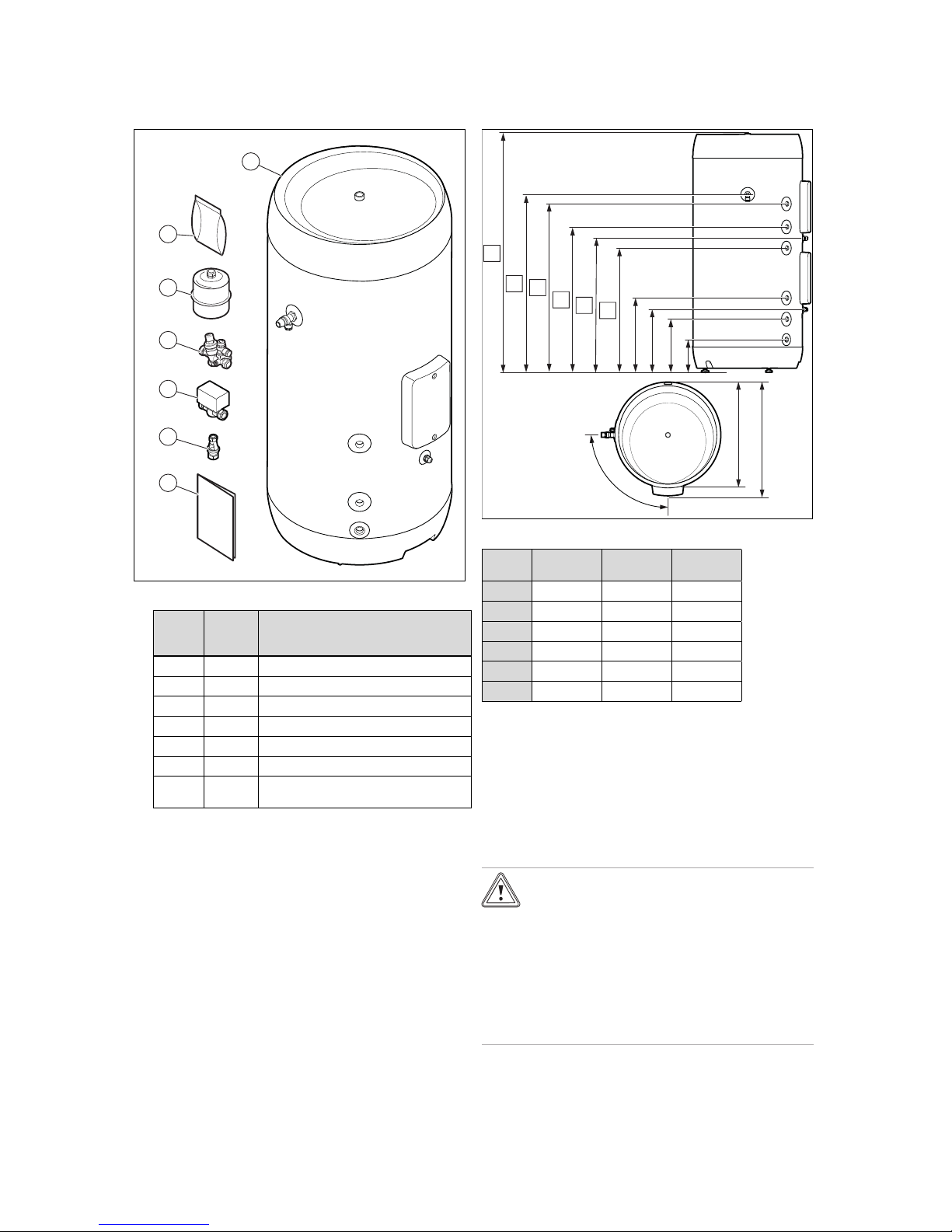

1

2

3

4

5

6

7

▶ Check that the scope of delivery is complete.

Reference

point

Quantity

Description

1 1 Enclosed documentation

2 1 Tundish with retainer

3 1 2-way motorised valve

4 1 Safety group

5 1 Expansion vessel

6 1 Bag with accessories

7 1 Domestic hot water cylinder and temper-

ature and pressure relief valve

4.5 Product dimensions

Ø 595

638

90°

379

317

265

154

B

A

D

C

E

F

Dimensions (mm)

VIH S GB

200/3 BES

VIH S GB

250/3 BES

VIH S GB

300/3 BES

A

1,265 1,535 1,745

B

940 1,210 1,421

C

890 1,090 1,271

D

764 914 995

E

702 852 933

F

650 800 881

5 Installation

5.1 Setting up the unit horizontally

▶ Align the product vertically by adjusting the adjustable

feet.

5.2 Hydraulic connection

Caution.

Risk of damage caused by heat transfer

when welding.

The heat that is transferred during welding

may damage the cylinder and its components

as well as the connection seals.

▶ Protect the product and its components.

▶ Do not weld the connection pieces if these

have been screwed into the pipe fittings.

5 Installation

8 Installation and maintenance instructions auroSTOR 0020221298_02

Caution.

Risk of material damage by drilling

through the product.

The product may be damaged by drilling

work.

▶ Do not drill through the product.

Caution.

Risk of material damage to the cylinder.

If the cylinder is fitted high up in the building,

negative pressure may form in the cylinder.

▶ Install a pressure relief valve to prevent

damage to the cylinder.

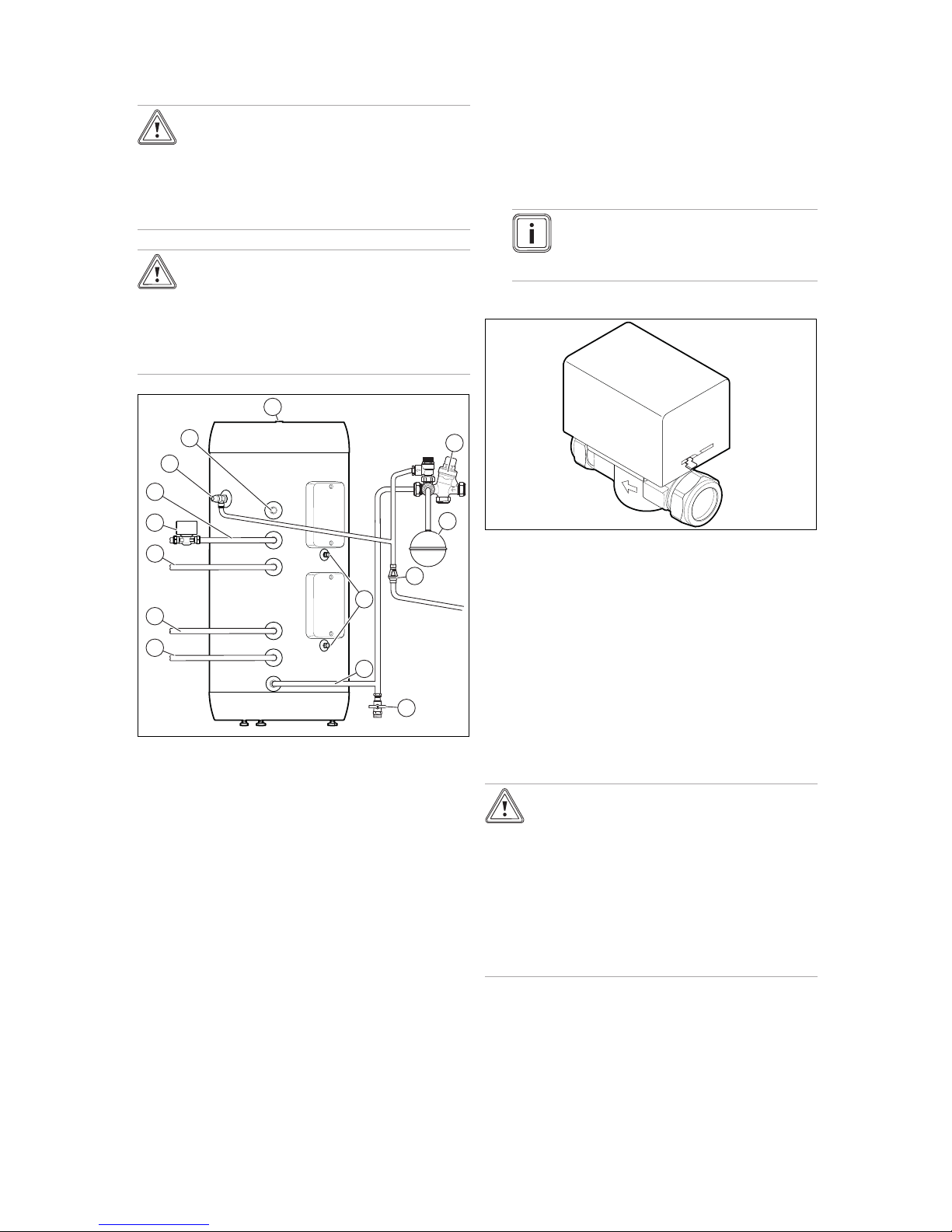

6

7

8

11

10

12

13

1

2

4

3

5

9

14

1 Solar circuit return

2 Solar circuit flow

3 Heat generator heating

return

4 2-way motorised valve

5 Heat generator heating

flow

6 Temperature and pres-

sure expansion relief

valve

7 Secondary circuit return

8 Hot water outlet

9 Safety group

10 Expansion vessel

11 Tundish

12 Cylinder dry pocket

for the solar circuit

temperature sensor

13 Cold water inlet

14 Drain valve

5.2.1 Connecting the solar circuit

1. Connect the solar circuit to the inlet (1) and the outlet

(2).

Installing the solar yield sensor

2. Install the yield sensor on the solar coil outlet close to

the cylinder.

5.2.2 Connecting the product to the heating

circuit

1. Connect the heating circuit to the inlet (5) and the outlet

(3).

– Minimum diameter of the copper pipe: ≥ 22 mm

Note

Ensure that the distance between the heat

generator and the product is as small as possible in order to prevent heat losses.

Installing the 2-way motorised valve

AUTO

M

AIN

OPEN

2. Install the 2-way motorised valve at the pipe coil's inlet

or outlet.

3. For the 2-way motorised valve, follow the installation

direction that is marked by an arrow.

4. The 2-way motorised valve can be installed vertically or

horizontally. For horizontal installation, align the valve

head so that it is facing upwards.

5.2.3 Installing the drain valve

The drain valve must be supplied by the customer.

Install the drain valve at the height of the cold water supply

or further below this level.

5.2.4 Installing the safety group

Caution.

Excessive pressure in the domestic hot

water cylinder

Excessive pressure in the domestic hot water

cylinder may cause the cylinder to burst.

▶ Ensure that the expansion relief valves

are not blocked.

▶ Ensure that there is no stop valve

between the safety group and the

cylinder.

Loading...

Loading...