Page 1

Instructions for commissioning, maintenance

and troubleshooting

For the competent person

Instructions for commissioning, maintenance and troubleshooting

Solar heating system

with auroSTOR

Solar hot water system

GB, IE

Page 2

Table of contents

Table of contents

1 Notes on the documentation ................................3

1.1 Other applicable documents ...................................3

1.2 Storing documents .....................................................3

1.3 Symbols used ...............................................................3

1.4 Applicability of the instructions .............................. 3

1.5 Cylinder identification plate .....................................4

1.6 CE label .........................................................................4

1.7 Benchmark ...................................................................4

2 Safety instructions and regulations ..................4

2.1 Safety and warning information .............................4

2.1.1 Classification of action-related warnings .............4

2.1.2 Structure of warnings ................................................4

2.2 Intended use ................................................................5

2.3 General safety instructions ......................................5

2.4 Overview of EU standards ........................................6

2.4.1 General information on solar heating system .....6

2.4.2 Cylinder and cylinder assembly .............................. 7

2.5 Regulations for Great Britain ...................................7

2.5.1 Technical Guidance .....................................................7

2.5.2 Related documents.....................................................7

2.5.3 Regulations for the prevention of accidents .......8

3 System description ..................................................8

3.1 Design and function of solar heating system ......8

3.2 Electrical wiring......................................................... 10

3.3 Hot water temperature regulation ....................... 10

3.4 Heating control .......................................................... 10

4 Description of the components ............................11

4.1 auroSTOR solar cylinder ...........................................11

4.1.1 Safety devices .............................................................12

4.1.2 Cylinder operating elements ...................................12

4.2 Solar fluid ....................................................................14

4.2.1 Properties of solar fluid ...........................................14

4.2.2 Solar circuit frost and corrosion protection

system ..........................................................................14

4.2.3 Cylinder frost protection ..........................................14

4.2.4 Safety data sheet for Vaillant solar fluid .............15

4.3 System configuration ................................................17

4.3.1 Vaillant controllers and their basic functions .....17

4.3.2 Control functions .......................................................18

4.3.3 Technical data of the auroSTOR solar cylinder 20

4.3.4 Dimensions .................................................................22

5 Assembly ...................................................................23

5.1 Scope of delivery ......................................................23

5.2 Transporting the cylinder .......................................23

5.3 Requirements for installation site ........................23

6 Installation ................................................................24

6.1 Installation sequence ...............................................24

6.2 Installation of solar circuit piping .........................24

6.2.1 Piping material in the solar circuit .......................24

6.2.2 Layout of piping in the solar circuit .....................24

6.2.3 Realisation of solar circuit piping .........................25

6.2.4 Venting the solar circuit..........................................27

6.3 Pipes for the primary heating circuit ..................29

6.4 Installing hot water pipes .......................................29

6.5 Hot water thermostat mixer ..................................29

6.5.1 Installing the hot water thermostat mixer

(without secondary circulation line) ................... 30

6.5.2 Installing the hot water thermostat mixer

(with secondary circulation line) .......................... 30

6.5.3 Setting the hot water thermostat mixer ............ 30

6.6 Installation of cold mains inlet ...............................31

6.6.1 Pressure in cold mains inlet ....................................31

6.6.2 Mounting the safety assembly ...............................31

6.6.3 Mounting the expansion vessel .............................32

6.6.4 Mounting the drain valve ........................................32

6.6.5 Laying the pipes to the tundish ............................32

6.7 Installation of discharge pipe ................................32

6.7.1 Design of discharge pipe .........................................32

6.7.2 High drain ...................................................................34

6.8 Electrical installation ...............................................34

6.8.1 Options for combining control components ......34

6.8.2 Electrical connection of control components ....36

6.8.3 Connecting up the electric immersion heater ... 37

6.8.4 Connection of the solar pump ...............................38

6.8.5 Connecting up the solar yield temperature

sensor ..........................................................................38

6.8.6 Installing the control components in accordance

with the connection wiring diagrams .......................40

7 Commissioning .........................................................52

7.1 Checking leak-tightness ..........................................52

7.2 Flushing the solar circuit with solar fluid ...........53

7.3 Filling the solar circuit with solar fluid ................53

7.4 Setting the flow rate in the solar circuit ............ 54

7.5 Flushing the primary heating circuit ...................55

7.6 Water treatment ........................................................55

7.7

7.8 Filling the central heating system ........................57

7

7.10 Setting the hot water thermostat mixer ............ 58

7.11 Filling in the commissioning report ....................58

7.12 Handover to the operator ...................................... 58

Filling the cylinder ................................................... 56

.9 Commissioning the gas-fired wall-hung boiler 58

2 Instructions on commissioning, maintenance, and troubleshooting for auroSTOR 0020111119_02

Page 3

8 Inspection and maintenance ...............................59

8.1 Checking the temperature/pressure

relief valve and expansion relief valve .................61

8.2 Checking the charge pressure

of the expansion vessel ............................................61

8.3 Draining the cylinder ................................................61

9 Fault finding ..............................................................62

10 Taking the cylinder out of service ................... 65

10.1 Temporarily taking the cylinder out of service 65

10.2 Permanently taking the cylinder

out of service ............................................................ 65

11 Recycling and disposal ......................................... 65

11.1 Cylinder disposal ...................................................... 65

11.2 Disposal of packaging ............................................. 65

12 Customer service and manufacturer's

guarantee .................................................................. 66

12.1 Vaillant service ......................................................... 66

12.2 Vaillant guarantee ................................................... 66

Notes on the documentation 1

1 Notes on the documentation

The following instructions are intended to guide you

through the entire documentation.

Other documents apply in addition to these installation

instructions.

We do not accept liability for any claims or damages

resulting from failure to observe these instructions.

1.1 Other applicable documents

> When installing and maintaining the solar heating system,

you must observe all of the installation and maintenance

instructions for system components as well as those for

other accessories which are used in the system.

These installation and maintenance instructions are provided with the relevant system components and accessories.

1.2 Storing documents

> Pass these installation instructions and all other appli-

cable documents and, if necessary, any required tools to

the system operator.

The system operator will store these so that they are

available when required.

1.3 Symbols used

The symbols used in the text are explained below.

Symbol that denotes useful tips and

information

i

> Symbol for a required action

1.4 Applicability of the instructions

These instructions apply for the following only:

Unit type Cylinder volume Article number

VIH S GB 210/2 S 210 litres 0020115422

VIH S GB 260/2 S 260 litres 0020115425

VIH S GB 310/2 S 310 litres 0020115428

Table 1.1 Applicability of the instructions

> The article number of the unit is displayed

on the identification plate.

Instructions on commissioning, maintenance, and troubleshooting for auroSTOR 0020111119_02 3

Page 4

1 Notes on the documentation

2 Safety instructions and regulations

1.5 Cylinder identification plate

The identification plate is attached to the cylinder

at the factory.

1.6 CE label

CE labelling shows that, based on the type overview, the

units comply with the basic requirements of the applicable directives.

The CE declarations of conformity can be viewed at the

manufacturer's premises and can be supplied if necessary.

1.7 Benchmark

Vaillant Ltd. supports the Benchmark Initia-

tive. You will find the Benchmark Logbook on

i

the last page of this instruction manual. It is

very important that this document be filled

out properly when installing, commissioning

and handing-over to the operator of the

installation. Installers should point out also

the service record section for completion following service calls to this appliance.

Benchmark places responsibilities on both

manufacturers and installers. The purpose is

to ensure that customers are provided with

the correct equipment for their needs, that it

is installed, commissioned and serviced in

accordance with the manufacturer’s instructions by competent persons approved at the

time by the Health and Safety Executive and

that it meets the requirements of the appropriate Building Regulations.

The Benchmark Checklist can be used to demonstrate compliance with Building Regulations

and should be provided to the customer for

future reference.

Installers are required to carry out installation, commissioning and servicing work in

accordance with the Benchmark Code of Practice which is available from the Heating and

Hot water Industry Council who manage and

promote the Scheme.

Visit "www.central heating.co.uk" for more

information

.

2 Safety instructions and regulations

2.1 Safety and warning information

When conducting installation and maintenance work,

observe the general safety instructions and the warning

notes which appear before each of the actions.

2.1.1 Classification of action-related warnings

The action-related warnings are classified in accordance

with the severity of the possible danger using the following warning signs and signal words:

Warning sign Signal word Explanation

Danger!

a

Danger!

e

Warning!

a

Caution!

b

2.1.2 Structure of warnings

Warning signs are identified by an upper and lower separating line and are laid out according to the following

basic principle:

Signal word!

Type and source of danger!

a

Explanation of the type and source of danger.

> Measures for averting the danger

Imminent danger to life or

risk of severe personal injury

Risk of death from

electric shock

Risk of minor

personal injury

Risk of material or

environmental damage

4 Instructions on commissioning, maintenance, and troubleshooting for auroSTOR 0020111119_02

Page 5

Safety instructions and regulations 2

2.2 Intended use

The Vaillant solar heating system has been constructed

using state-of-the-art technology in accordance with recognised safety regulations.

Nevertheless, there is still a risk of injury or danger of

death to the operator or others or of damage to the unit

and other property in the event of improper use or use

for which the unit is not intended.

These components of the Vaillant solar heating system

are not intended to be used by persons (including children) with limited physical, sensory or mental capabilities or insufficient experience and/or knowledge, unless

they are supervised by a person who is responsible for

their safety or have been instructed by this person on

how to use the unit.

Children must be supervised to ensure that they do not

play with the unit.

The purpose of the Vaillant solar heating system is to

provide a solar-supported hot water supply.

Vaillant auroSTOR VIH S GB 210/2 S, VIH S GB 260/2 S,

and VIH S GB 310/2 S solar cylinders are unvented, indirectly heated domestic hot water cylinders for solar

heating systems designed for use with gas-fired wallhung boilers as per GB standards for hot water supply

systems. The cylinders work with the pressure of the

water supply line and do not need a cold water tank for

their supply.

They are used only to supply potable water heated up to

80 ºC by means of a solar collector array. They may only

be used for this purpose. The cylinders can be used in

combination with a downstream gas-fired wall-hung

boiler for hot water production in accordance with

GB standards.

Any other use that is not specified in these instructions,

or use beyond that specified in this document shall be

considered improper use.

Any direct commercial or industrial use is also deemed

to be improper.

The manufacturer/supplier is not liable for any claims or

damage resulting from improper use. The user alone

bears the risk.

Intended use includes the following:

– observance of accompanying operating, installation and

servicing instructions for Vaillant products as well as for

other parts and components of the system

– compliance with all inspection and maintenance condi-

tions listed in the instructions.

.

Improper use of any kind is prohibited!

At the end of these instructions there is a commissioning report which you must fill in and hand over to the

operator.

All installers should have a current ID card and registration number. The cylinder must be installed by a competent person approved at the time by the Health and

Safety Executive to the prevailing standards, installation

book and building regulations at the time of installation.

2.3 General safety instructions

Installation, commissioning, and maintenance

Installation and adjustment as well as service, maintenance and repair must be carried out by a competent

person approved at the time by the Health and Safety

Executive and be in accordance with the relevant

requirements of the Local Authority, Building Regulations, Building Regulations (Scotland), Building Regulations (Northern Ireland), and the bye-laws of the local

Water Undertaking.

All electrical wiring must be carried out by a competent

electrician and be in accordance with the current I.E.E.

Wiring Regulations.

> Make sure that the system has been planned in

accordance with technical regulations and all applicable

planning standards.

Risk of death due to lack of safety devices

A lack of safety devices (e.g. expansion relief valve,

expansion vessel) can lead to potentially fatal scalding

and other injuries, e.g. due to explosions.

The schematic drawings included in this document do

not show all safety devices required for correct installation.

> Install the necessary safety devices in the system.

> Inform the operator about the function and position of

the safety devices.

> Observe the applicable national and international laws,

standards and guidelines.

Safety information on the solar heating system

> Mount and operate the entire solar heating system in

accordance with the recognised technical regulations.

> Make sure that all valid health and safety regulations are

observed, especially for work on the roof. Always use fall

protection devices if there is a risk of falling. We recommend the use of a Vaillant safety belt. Observe the accident prevention regulations of the professional associations.

> Earth the solar circuit for potential equalisation and to

protect against overvoltage. Attach earthing pipe clamps

to the solar circuit pipes and connect the clamps to a

potential equalisation bar using 16 mm

2

Cu cable.

Instructions on commissioning, maintenance, and troubleshooting for auroSTOR 0020111119_02 5

Page 6

2 Safety instructions and regulations

Cylinder safety information

Following an inspection, it was ascertained that this

product complies with the building regulations for closed

hot water cylinder systems and must not be changed or

rebuilt in any way.

> When replacing parts, only original replacement parts

from Vaillant Ltd. may be used.

The installation must be approved in accordance with

the building regulations.

> Installation plans must be disclosed to the relevant

authorities.

Important:

As stipulated in the manual "Handling Operations Regulations 1992", the weight of the unit exceeds that which

should be lifted by one person alone.

Electric potential equalisation

If you use an electric immersion heater in the cylinder,

the external voltage may build up electrical potential in

the water which can result in the electrochemical corrosion of the electric immersion heater.

If the solar cylinder is connected with pipes made of

non-metallic materials and is not earthed, corrosion

damage can occur.

> Make sure that both the hot water and cold mains inlets

are connected to the earth line by means of

an earth cable directly on the cylinder.

> You must also make sure that the electric immersion

heater is connected to the earth line via the earthing terminal.

Risk of scalding and damage from escaping hot or cold

water.

> If you use plastic pipes for the hot or cold water connec-

tion of the unit, you must only use pipes which are temperature-resistant up to 95 °C under a pressure of 1.0

MPa (10 bar).

If the solar heating system is in stagnation, hot steam

can escape from the expansion relief valve of the solar

pump unit, causing injury to persons. Escaping solar

fluid is visible in the collection canister.

> Connect the expansion relief valve to a collecting

container via a metal pipe.

> Position an air vent or an air separator system in such a

way that persons are not endangered by escaping steam.

> Install a hot water thermostat mixer in the system

to protect against scalding.

Preventing frost damage

You should not turn the gas-fired wall-hung boiler off

completely so that you can still use all of the safety

functions for your heating system. If you want to take

the unit out of operation for a relatively long period of

time in an unheated room at risk from frost, you must

completely drain the auroSTOR.

Avoiding damage caused by leaks

If there are leaks in the pipework, close off the cold

water stop valve on the safety assembly and notify a

competent person so that they can rectify the leaks.

Preventing damage due to unauthorised changes

to the unit

Changes to the supply lines, relief valve termination,

and expansion relief valve may only be carried out by

a competent person!

2.4 Overview of EU standards

2.4.1 General information on solar heating system

EN ISO 9488

Solar heating system and components, terminology

(ISO/DIS 9488; 1995)

Improper use and/or the use of unsuitable tools may

result in damage (e.g. water leaks).

> Always use a suitable open-end wrench (spanner) to tigh-

ten or undo threaded connections. Do not use pipe wrenches, extensions, etc.

If the water does not satisfy the standards for water

quality in the UK with a maximum chloride content of

EN 12975-1

Solar heating systems and components; Collectors,

Part 1: General requirements

EN 12975-2

Solar heating systems and components; Collectors;

Part 2: Testing methods

250 mg/l, this may result in corrosion damage to the

cylinder.

> Only use the cylinder to heat potable water.

EN 1991-2-3

Eurocode 1 – Basis of design and actions on structures,

Part 2–3: Actions on structures - Snow loads

Avoiding burns and scalds

> Install and replace collectors or collector parts on very

cloudy days. Only carry out installation work

in the early morning or in the evening on sunny days or

cover the collector.

> Fill and flush the solar heating system when the collec-

tors are cold. Cover the collectors while doing so.

EN 12976-1

Solar heating systems and components;

Factory made systems - Part 1: General requirements

EN 12976-2

Solar heating systems and components;

Factory made systems - Part 2: Testing methods

6 Instructions on commissioning, maintenance, and troubleshooting for auroSTOR 0020111119_02

Page 7

Safety instructions and regulations 2

ENV 12977-1

Solar heating systems and components;

Custom built systems,

Part 1: General requirements

ENV 12977-2

Solar heating systems and components;

Factory made systems,

Part 2: Testing methods

ISO 9459-1: 1993

Solar heating – Domestic water heating systems – Part 1:

System rating procedures using indoor test methods

ISO/TR 10217

Solar energy; Water heating system; Guideline for material selection with reference to internal corrosion

2.4.2 Cylinder and cylinder assembly

Pressure equipment directive 97/23/EC

Directive of the European Parliament and Council

of 29th May 1997 for the approximation of the laws

on pressure equipment of the Member States

EN 12977-3

Solar heating systems and components;

Custom built systems,

Part 3: Performance characterisation of domestic

hot water cylinders

EN 12897:2006

Water supply - specification for indirectly heated

unvented (closed) domestic hot water cylinders

2.5 Regulations for Great Britain

2.5.1 Technical Guidance

The system must be installed in accordance with all rele-

vant and applicable national regulations, and must be

installed to suit site conditions.

Observe all national regulations, including:

– Working at Heights Regulations 2005

– Health and Safety at Work Act 1974

– Electricity at Work Regulations 1989

– IEE Wiring Regulations BS 7671

– Lightning protection requirements

– Equipotential bonding of electrical installations.

2.5.2 Related documents

The installation of the solar system must be in accord-

ance with the relevant requirements of Health and

Safety Document No. 635 (The Electricity at Work Regu-

lations 1989), BS7671 (IEE Wiring Regulations) and the

Water Supply (Water Fitting) Regulations 1999, or The

Water Bylaws 2000 (Scotland). It should also be in

accordance with the relevant requirements of the Local

Authority, Building Regulations, The Building Regulations

(Scotland), The Building Regulations (Northern Ireland)

and the relevant recommendations of the following

British Standards:

BS EN 806: Specification for installations inside build-

ings conveying water for human consumption

BS 6700: Services supplying water for domestic use

within buildings and their curtilages.

EN 806-1

Specifications for installations inside buildings conveying

water for human consumption - Part 1: General

EN 1717

Protection against pollution of potable water installations and general requirements of devices to prevent

pollution by backflow

EN 60335-2-21

Safety of household and similar electrical appliances;

Part 2: Particular requirements for storage water heaters (domestic hot water cylinders and hot water boilers)

(IEC 335-2-21: 1989 and supplements 1; 1990 and 2; 1990,

modified)

Lightning protection

ENV 61024-1

Protection of structures against lightning – Part 1:

General principles (IEC 1024-1: 1990; modified)

BS 6651: Code of practice for protection of structures

against lightning

Instructions on commissioning, maintenance, and troubleshooting for auroSTOR 0020111119_02 7

BS. 5449 Forced circulation hot water central heating

systems for domestic premises. Note: only up to 45 kW.

BS. 6880 Low temperature hot water heating systems

of output greater than 45 kW.

Part 1 Fundamental and design considerations.

Part 2 Selection of equipment.

Part 3 Installation, commissioning and maintenance.

BS 6114: Expansion vessels using an internal diaphragm

for unvented hot water supply systems

BS. 4814 Specification for: Expansion vessels using an

internal diaphragm, for sealed hot water heating sys-

tems.

Unvented hot water systems must comply with building

regulation G section 3.

Page 8

2 Safety instructions and regulations

3 System description

2.5.3 Regulations for the prevention of accidents

When carrying out works such as solar installation work

it is necessary to do so in a safe and workman like manner, taking due care of any aspects of the works that

could result in injuries to person in or about the building

as well as workers, passers by and the general public at

large. To that end these works must conform, but not be

limited to, the current regulations in force such as the

following

Health and Safety at Work act 1974

Work at Height Regulations 2005.

Electricity at Work Regulations 1989

All necessary Building Regulations.

Work should be preceded by a risk assessment covering

all aspects of health and safety risks, or training requirements that can reasonably be foreseen to be

associated with the work. All scaffolding in the UK, other

than prefabricated (zip-up) scaffold towers, must be

designed and constructed by a vetted contractor, and

have suitable kick boards, hand rails and where appropriate netting. Areas around the scaffolding should be

zoned off and marked with suitable warning signs to a

suitable distance to protect persons from falling objects.

Workers should have available and use personal protective equipment as necessary. This would include equipment such as fall protection systems, safety gloves,

goggles, dust masks as well as any specialised equipment that may be in use such as lifting and handling

equipment.

The completed works shall comply with all necessary

BS EN Standards and Codes of practice as well as Building control or planning requirements and be confirmed

where necessary by notification to building control or

the appropriate competence based notification body.

3 System description

3.1 Design and function of solar heating system

The solar heating system consists of four main compo-

nents:

– The collectors, which absorb the solar radiation and

make it useful

– The solar controller, which monitors, displays, and cont-

rols all system functions

– The solar pump unit, which is responsible for trans-

porting the solar heat

– The solar cylinder

The Vaillant solar heating system is a closed hydraulic

system in which heat is transferred to the cylinder via

the heat exchanger with the help of the system's special

heat transfer fluid.

On days when the solar radiation is not sufficient to heat

the hot water in the cylinder, the cylinder water must be

reheated using a heating system. This can take place

using a gas-fired wall-hung boiler or an electric immer-

sion heater.

8 Instructions on commissioning, maintenance, and troubleshooting for auroSTOR 0020111119_02

Page 9

System description 3

6

7

8

9

C

M

3

10

D

DHW

12

2

5

M

5

M

Fig. 3.1 System for solar hot water production

Key

1 Gas-fired wall-hung boiler

2 Cylinder

3 Two port motorised valve (230 V, supplied with cylinder)

4 Electric immersion heater

5 Two port motorised valve (230 V)

6 Collector (tube collector with top connections (example) or flat

collector with top and bottom connections)

7 Solar pump unit

8 Solar protection and expansion vessel (Combined unit)

9 Collection canister for solar fluid

4

1

BA

10 Automatic air separator system

11 Hot water expansion vessel

12 Thermostat mixer

A Primary heater flow

B Primary heater return

C Solar flow

D Solar return

DHW Hot water

11

Instructions on commissioning, maintenance, and troubleshooting for auroSTOR 0020111119_02 9

Page 10

3 System description

The collection canister for solar fluid collects

escaping solar fluid. The solar fluid must not

i

i

i

The collector(6) converts solar energy into heat and

transfers the heat energy to a frost-protected solar fluid.

Using the pipe system, the solar pump of the solar pump

unit (7) conveys the heat from the collector to the bivalent cylinder (2). The solar pump unit is controlled by

the solar controller.

The solar controller switches the solar pump on and off

as soon as the temperature difference between the collector and cylinder exceeds or falls below the preset

value. If the solar energy is not sufficient for requirements, the controller activates the gas-fired wall-hung

boiler (1) to reheat the top third of the cylinder to the

set hot water temperature value. The water in the cylinder can also be reheated using the electric immersion

heater installed at the factory.

A solar expansion vessel compensates for pressure

fluctuations in the solar circuit.

A solar protection vessel protects the expansion vessel

from excessive temperatures in the solar circuit. We recommend installing a protection vessel.

All Vaillant solar sets contain a combined solar protection and solar expansion vessel (8).

reach the drainage system.

For the supply and return lines in the solar cir-

cuit, use insulated stainless steel pipes, e.g. the

Vaillant Solar flexible pipe that is included in the

scope of delivery of a Vaillant Solar set. Alternatively, you can also use copper pipes with press

fittings and suitable insulation. Soft solder connections are not suitable for solar piping.

If a cylinder is fitted very high up in the building,

negative pressure may form in the cylinder.

Under such circumstances, the competent person must decide whether an anti-vacuum valve

is required in order to prevent damage to the

cylinder. If, as a result of draining or thermal

contraction of the drinking water, the negative

pressure in the cylinder is too high, an anti-vacuum valve ensures pressure compensation as a

result of air flowing into the cylinder.

3.2 Electrical wiring

If you use an eBUS-compatible Vaillant gas-fired wallhung boiler, you can use a Vaillant Control Centre for the

wiring.

If you are using a non-eBUS-compatible Vaillant gasfired wall-hung boiler or a third-party boiler, you can

use a standard cabling box.

Section 6.8 of these instructions describes the electrical

wiring of the system in detail.

3.3 Hot water temperature regulation

You can control the hot water temperature in the top

third of the cylinder using an auroMATIC VRS 560/2 or a

calorMATIC VRC470 with VR68/2 and VR61/2 or with a

separate hot water controller.

Danger!

Risk of burns and scalds!

a

3.4 Heating control

If you are using an eBUS-compatible Vaillant gas-fired

wall-hung boiler, you can control the heating using a

programmable Vaillant VRT room thermostat or a VRC

weather compensator.

If you are using a non-eBUS-compatible Vaillant gasfired wall-hung boiler or a third-party boiler, you can use

a Vaillant VRT30 room thermostat or one of the room

thermostats commonly available on the market.

Water at a temperature of more than 60 ºC

could be delivered to the hot water draw-off

points.

> Install a hot water thermostat mixer in

the hot water pipe to provide effective

scald protection.

> Set the hot water thermostat mixer to

less than 60 ºC and check the temperature at

a hot water draw-off point.

10 Instructions on commissioning, maintenance, and troubleshooting for auroSTOR 0020111119_02

Page 11

4 Description of the components

4.1 auroSTOR solar cylinder

26

25

Description of the components 4

1

2 3

21

22

24

23

20

3

4

2

5

1

18

19

3

17

16

15

14

13

12

11

Fig. 4.1 auroSTOR solar cylinder function elements

10

4

67

5

9

8

Key

1 Hot water draw off

2 Expansion relief valve (6.0 bar)

3 Pressure reducing valve (3.5 bar) with line strainer

4 Cold water inlet

5 Pressure-controlled cold water inlet

6 Connection for hot water expansion vessel

7 Cylinder connection

8 Hot water expansion vessel

9 Tundish

10 Cylinder drain valve

11 Solar return

12 Solar yield temperature sensor (Ertrag)

13 Cold water inlet

14 Solar circuit thermal cut-out (TCO), set to 80ºC, to be con-

nected with the solar pump in order to isolate this heat source

if there is a fault in the solar control.

15 Solar circuit cylinder dry pocket (SP2)

16 Solar flow

17 2-pole isolating switch for electric immersion heater

18 Electric immersion heater with thermostat and thermal cut-out

19 Return (gas-fired wall-hung boiler)

20 Primary heating circuit cylinder dry pocket (SP1)

21 Primary heating circuit thermal cut-out, set to 80ºC, to be con-

nected to the two port motorised valve in order to isolate the

primary heat source if a fault occurs.

22 Cylinder thermostat (20 °C to 65 °C)

23 Two port motorised valve

24 Flow line (gas-fired wall-hung boiler)

25 Secondary return

26 Temperature and pressure relief valve (90 °C, 7 bar)

Instructions on commissioning, maintenance, and troubleshooting for auroSTOR 0020111119_02 11

Page 12

4 Description of the components

The auroSTOR solar cylinder is available in three sizes:

210, 260, and 310 litres. The cylinder is made from stainless steel and is insulated with EPS with heat radiation

absorbers. The cylinder is supplied along with all

required cold and hot water control devices and a two

port motorised valve.

The cylinder works with the pressure of the water supply

line and does not need a cold water tank for its supply.

The cylinder has hot and cold water inlets with a diameter of 22 mm. To enable the cylinder to work as well as

possible, a cold water supply with a dynamic pressure

and flow rate that are appropriate for the system is

required (¬ section 6.6.1).

4.1.1 Safety devices

The cylinder is delivered with all safety and control

devices for the operation of the unvented domestic

hot water supply system:

– Temperature and pressure relief valve (90 °C, 7 bar)

– Pressure reducing valve (3.5 bar) with line strainer

– Expansion relief valve (one-way valve, 6.0 bar)

– Solar circuit thermal cut-out, set to 80 ºC, to be connec-

ted with the solar pump in order to isolate this heat

source if there is a fault in the solar control.

– Thermal cut-out for electric immersion heater

– Primary heating circuit thermal cut-out, set to 80 ºC, to

be connected to the two port motorised valve in order to

isolate the primary heat source if a cylinder thermostat

fault occurs.

The thermal cut-out and other safety devices must

always be used.

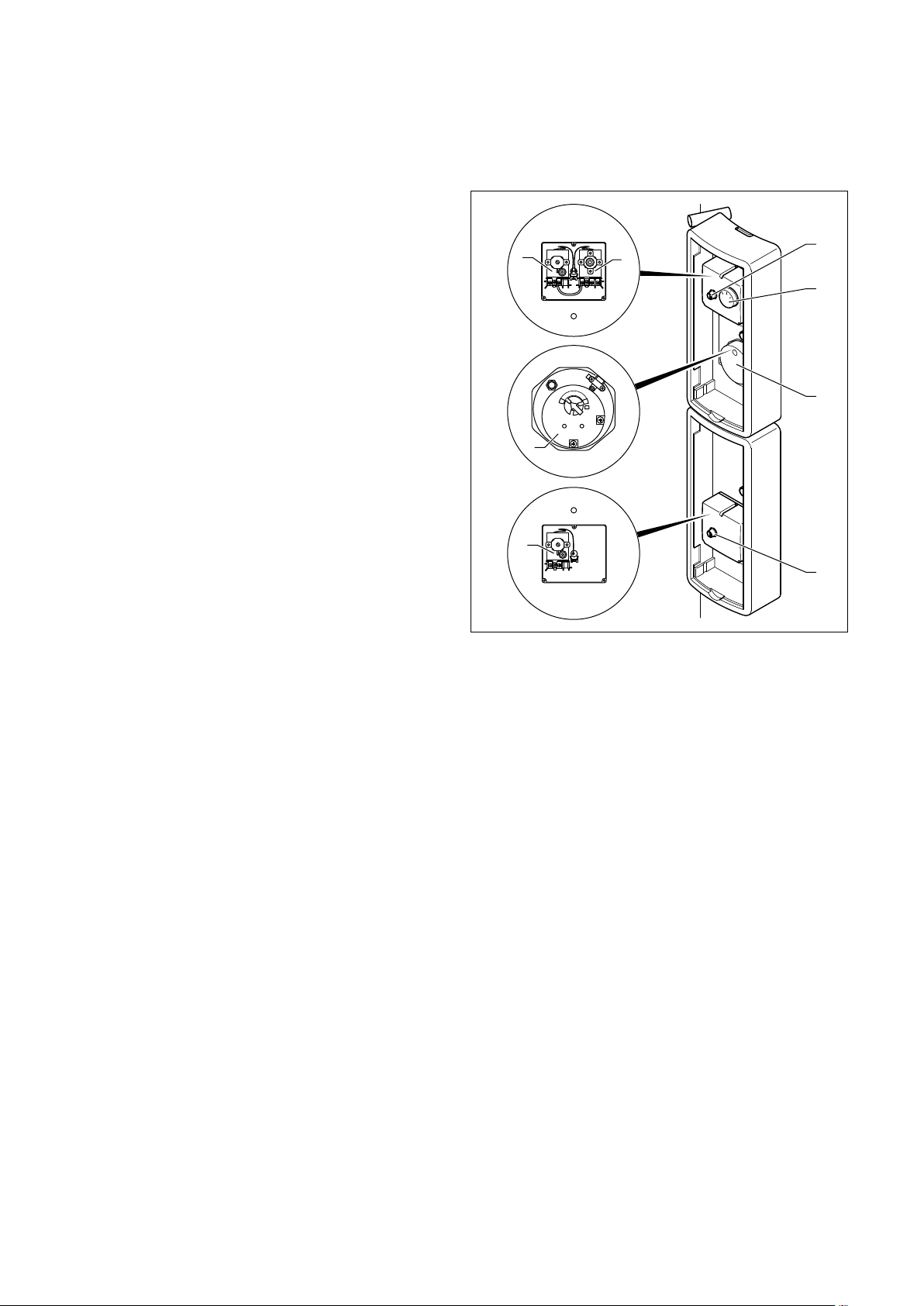

4.1.2 Cylinder operating elements

8

3

4

5

6

5

Fig. 4.2 Cylinder operating elements

Key

1 Cover cap for reset button for primary heating circuit TCO

2 Primary heating circuit temperature controller

3 Electric immersion heater cover

4 Cover cap for reset button for solar circuit TCO

5 Solar circuit thermal cut-out (TCO)

6 Electric immersion heater

7 Cylinder thermostat

8 Primary heating circuit thermal cut-out

7

2

1

1

2

3

4

The following are pre-mounted at the factory for the

auroSTOR solar cylinder:

– Cylinder thermostat (7) and primary heating circuit ther-

mal cut-out (8)

– Electric immersion heater(6) with thermal cut-out and

cylinder thermostat

– Solar circuit thermal cut-out (5)

The cylinder must be properly wired in order to comply

with G3 building regulations.

12 Instructions on commissioning, maintenance, and troubleshooting for auroSTOR 0020111119_02

Page 13

Description of the components 4

Electric immersion heater

1

1

3

2

3

2

3

4

3

Fig. 4.4 Electric immersion heater operating elements

3

4

5

2

3

1

Fig. 4.3 Connection diagram for solar pump

Key

1 Solar controller or solar module

2 Terminal strip for series circuit to solar pump via TCO solar

circuit

3 Solar pump

4 Solar circuit thermal cut-out

You must connect the solar pump to the solar

controller via the solar circuit thermal cut-out

i

(5) (¬section 6.8). The thermostat switches the

solar pump off if the hot water temperature in

the cylinder exceeds 80 ºC. Set the maximum

cylinder temperature (MAXT 1)

to 75 °C (factory setting) on the auroMATIC

VRS 560 solar controller.

Key

1 Electric immersion heater temperature controller

2 Electric immersion heater TCO reset button

3 Electric immersion heater

The cylinder is equipped with an additional electric

immersion heater (3) with a heating output of 3 kW. The

electric immersion heater is located behind the top front

cladding. The electric immersion heater is designed for

use in unvented cylinders and has a thermostat with a

temperature controller (1) and a thermal cut-out (TCO)

with a reset button (2).

If you need to make a replacement, you must

use the correct electric immersion heater with a

i

thermal cut-out for overheating protection. The

seal of the electric immersion heater must also

always be replaced. Use only original replacement parts from VaillantLtd.

Setting the hot water temperature

You can set the hot water temperature by pointing the

arrow on the temperature controller (1) of the electric

immersion heater to a number between 1 and 5. The following table contains the approximate hot water temperature for each of the five settings.

Setting Hot water temperature

1 20 °C

2 35 °C

3 45 °C

4 60 °C

5 68 °C

Table 4.1 Setting the hot water temperature

Instructions on commissioning, maintenance, and troubleshooting for auroSTOR 0020111119_02 13

Page 14

4 Description of the components

4.2 Solar fluid

4.2.1 Properties of solar fluid

This information applies to Vaillant solar fluid

(20l canister: article number 302498 and 10l canister:

article number 302363).

Vaillant solar fluid is a ready-mixed frost and

corrosion protection agent, consisting of approximately

45% propylene glycol with anti-corrosion inhibitors and

55% water.

Vaillant solar fluid is extremely temperature-resistant

and can be used in conjunction with Vaillant tube collectors and Vaillant flat collectors.

The solar fluid also has a high heat capacity.

The inhibitors provide reliable corrosion protection when

different types of metal are used (mixed installations).

Caution!

Risk of damaging the collectors and

b

i

other system parts if unsuitable solar

fluid is used.

If you mix the solar fluid with water or

another liquid, frost and corrosion protection cannot be ensured.

> Never mix the solar fluid with water

or another liquid.

Do not use any other frost protection agents or

inhibitors for the Vaillant solar heating system.

Only Vaillant's solar fluid is permitted for use

with the system.

4.2.2 Solar circuit frost and corrosion protection

system

In order to reliably protect the solar heating system

from frost in winter, you must fill the entire system with

undiluted Vaillant solar fluid.

Filling the solar heating system with Vaillant

solar fluid provides frost protection up to

i

We recommend the Vaillant refractometer for quick and

simple checking. A classic Vaillant frost protection tester

can be used for this.

See the enclosed operating instructions.

4.2.3 Cylinder frost protection

If you want to put a cylinder out of operation where it

may be at risk from frost, you must drain it completely.

It is drained at the cold water inlet with a T-piece with

tap to be provided by the installer.

Any heat exchangers not filled with solar fluid in rooms

which are at risk of frost must also be completely

drained.

approx. -28 ºC.

Even at outside temperatures of lower than

-28 ºC, frost damage does not occur straight

away since the explosive effect of the water is

distributed. Check the frost protection effect

after filling the system and then once every year.

Vaillant solar fluid is infinitely durable in hermetically

sealed containers.

It is not dangerous if it comes into contact with the skin.

Eye contact only causes minor irritations, you should

nevertheless immediately wash your eyes.

Pay attention to the safety data sheet

(¬ section 4.2.4).

14 Instructions on commissioning, maintenance, and troubleshooting for auroSTOR 0020111119_02

Page 15

Description of the components 4

4.2.4 Safety data sheet for Vaillant solar fluid

1) Name of substance/preparation and company

details:

1a) Trade name:

Vaillant ready-mixed solar fluid

1b) Use:

Heat transfer fluid for solar heating systems

1c) Company:

Vaillant GmbH

Berghauser Str. 40

42859 Remscheid, Germany

Tel. 0049 (0) 2191 18-0, Fax 0049 (0) 2191 18-2810

1d) Emergency information:

your local poison information centre

(see directory assistance or telephone directory).

2) Possible dangers:

2a) Special danger indications for people and the

environment: Not required!

3) Composition/information on ingredients:

3a) Chemical nature:

Aqueous solution of 1.2-propylene glycol

(CAS no.: 57-55-6) with corrosion inhibitors.

3b) Hazardous ingredients:

1,1’-iminodipropan-2-ol

content (w/w): > 1 % - < 3 %, CAS no.: 110-97-4

EC no.: 203-820-9, hazard symbol: Xi

INDEX no: 603-083-00-7, R phrases: 36

If hazardous ingredients are named, the wording for

the hazard symbols and R phrases will be

provided in Point 16.

4) First aid measures:

4a) General information:

Remove dirty clothes.

4b) After inhalation:

Discomfort after inhaling fumes/aerosol:

fresh air, help from a doctor.

4c) After skin contact:

Wash off with water and soap.

4d) After contact with the eyes:

Thoroughly rinse out with running water

for at least 15 minutes with the eyes open.

4e) After swallowing:

Rinse mouth and drink lots of water.

4f) Information for the doctor:

Treatment of symptoms (decontamination,

vital function), no specific antidote known.

5) Firefighting measures:

5a) The product is not flammable. Surrounding fire can be

combated with sprayed water, dry extinguishers, alcohol-resistant foam, and carbon dioxide (CO

5b) Special dangers: Fumes which are detrimental to

health. Formation of smoke/mist. The specified substances/substance groups may be released in the event

of a fire.

5c) Special protection equipment: Wear a breathing appa-

ratus which is independent of the circulating air in the

event of a fire.

5d) Further information: The dangers depend on the bur-

ning substances and the fire conditions. Polluted fire

water must be disposed of according

to local official regulations.

6) Measures in the case of accidental release:

6a) Precautions to protect persons:

No particular measures required.

6b) Measures to protect the environment:

Contaminated water/fire water must be withheld.

It must not be discharged into bodies of water without

being pre-treated first (in a biological waste water

treatment plant).

6c) Cleaning/collection procedure:

Contain any escaped material and cover with large

quantities of sand, soil, or another absorbing material;

then sweep enthusiastically to promote absorption.

Fill the mixture into containers or plastic bags and

take away for disposal.

Wash away small amounts (splashes) with large quan-

tities of water. For large quantities, pump out the product, collect it up and take it away for disposal. If larger quantities may have entered the drainage system

or water bodies, contact the responsible water authorities.

7) Handling and storage:

7a) Handling:

No particular measures required.

7b) Fire and explosion protection:

No particular measures required.

7c) Storage:

Containers must be closed so that they are airtight

and stored in a dry location.

Galvanised storage containers must not be used.

).

2

Instructions on commissioning, maintenance, and troubleshooting for auroSTOR 0020111119_02 15

Page 16

4 Description of the components

8) Exposure prevention and personal protective equipment:

8a) Personal protective equipment:

Breathing protection: Breathing protection

if vapours/aerosols are released.

Hand protection: chemical-resistant protective gloves

(EN 374).

Recommended: Nitrile rubber (NBR), protection class

6.

Owing to the large variety of types, observe the

manufacturers' operating instructions.

Eye protection: Safety glasses with lateral protection

(framed glasses) (EN 166)

8b) General protection and hygiene measures:

The usual precautions for working with chemicals

must be observed.

9) Physical and chemical properties:

Form: Liquid.

Colour: Fluorescent red.

Smell: Product-specific.

Freezing point: Approx. -25 ºC (ASTM D 1177)

Solidification point: Approx. -31 ºC (DIN 51583)

Boiling point: >100 ºC (ASTM D 1120)

Flashpoint: N/A

Lower explosion limit: 2.6 vol% (propylene glycol)

Upper explosion limit: 12.6 vol% (propylene glycol)

Ignition temperature: N/A

Vapour pressure (20° C): 20 mbar

Density (20 ºC): Approx. 1,030 g/cm

3

(DIN 51757)

Solubility in water: Completely soluble

Solubility in other solvents: Soluble in polar

solvents

pH value (20 ºC): 9.0 - 10.5 (ASTM D 1287)

2

Viscosity (kinematic at 20 ºC): Approx. 5.0 mm

/s (DIN

51562)

10) Stability and reactivity:

10a) Substances to be avoided:

Strong oxidants

10b) Hazardous reactions:

No dangerous reactions if the storage and handling

regulations/notes are observed

10c) Hazardous decomposition products:

No dangerous decomposition products if the storage

and handling regulations/notes are observed.

11) Toxicology information:

LD50/oral/rat: > 2000 mg/kg

Primary skin irritation (rabbits):

Non-irritant (OECD Directive 404).

Primary mucous membrane irritation (rabbits):

Non-irritant (OECD Directive 405).

11a) Additional information:

The product has not been checked. The statements

are derived from the properties of the individual components.

12) Ecology information:

12a) Ecotoxicity:

Fish toxicity: Leuciscus idus/LC50 (96 h):

> 100 mg/l

Aquatic invertebrates: EC50 (48 h): > 100 mg/l

Aquatic plants: EC50 (72 h): > 100 mg/l

Micro-organisms/effect on activated sludge:

DEV-L2 > 1000 mg/l. If low concentrations are properly introduced into adapted biological waste water

treatment plants, no disturbances of the degradation

activity of activated sludge are to be expected.

12b) Assessment of aquatic toxicity:

The product has not been checked. The statements

are derived from the properties of the individual components.

12c) Persistence and degradability:

Details regarding elimination:

OECD 301A test method (new version)

Analysis method: DOC acceptance

Degree of elimination: > 70 %

Assessment: easily biodegradable.

13) Information on disposal:

13a) Disposal:

When disposing of the fluid, you must observe all local

regulations, e.g. take the waste to a suitable dump or

incinerator. For quantities of less than

100 l, contact the local city cleaning department

or mobile environmental service.

13b) Contaminated packaging:

Uncontaminated packaging can be reused. Packaging

that cannot be cleaned must be disposed of in the

same way as the material.

14) Information on transport:

Not dangerous goods in terms of the transport

regulations.

(ADR RID ADNR IMDG/GGV, see ICAO/IATA)

15) Legislation:

15a) European Union legislation (labelling)/national

regulations:

EU Directive 1999/45/EC

(Dangerous Preparations Directive):

No labelling obligation

15b) Other legislation:

Water hazard class 1: Low hazard to water

(Germany, VwVwS of 17.05.1999).

16 Instructions on commissioning, maintenance, and troubleshooting for auroSTOR 0020111119_02

Page 17

Description of the components 4

16) Other information

Complete wording for hazard symbols and R phrases

if stated in "Hazardous ingredients"

in section 3: Xi: Irritant. R36: Irritates the eyes.

All information which has been changed since the last

edition is identified by means of a vertical slash on

the left-hand side of the passage in question.

In such cases, the information shown in older editions

loses its validity.

The safety data sheet is intended to communicate the

most important physical, safety-related, toxicological,

and ecological information to be observed when working with chemicals and preparations and to provide

recommendations for safe use and/or storage, handling, and transport. No liability is assumed for damage

in connection with the usage of this information or

the usage, application, adaptation or processing of the

products described here. This does not apply as long

as we, our statutory agents or assistants are liable in

the event

of intention or gross negligence. No liability is assumed for indirect damage.

This information has been compiled to the best of our

knowledge and conscience according to our current

state of knowledge. No guarantee can be made for

product properties.

17) Valid as of: 01.01.2009

Created by: Vaillant GmbH.

4.3.1 Vaillant controllers and their basic functions

VRS560/2 solar controller

The auroMATIC 560/2 solar controller is a differential

temperature-controlled control set for solar-aided hot

water production with demand-controlled primary heating for Vaillant gas-fired wall-hung boilers.

The control set is a fully equipped system for solar heating systems with a collector array and cylinder.

If a solar yield temperature sensor (VR 10, supplied with

controller) is connected, the solar yield can be recorded.

Control Centre

A Vaillant Control Centre provides a system solution

which allows the Vaillant dual-channel eBUS controller

(low-voltage) to be used in the English market with

valves and domestic hot water cylinders with conventional 230 V cylinder thermostats.

The Control Centre sends the information on the heat

requirement of the cylinder to the Vaillant ecoTEC gasfired wall-hung boiler. The gas-fired wall-hung boiler

decides whether a hot water requirement needs to be

met and sends a signal to control the 230 V valves via

the Control Centre.

The gas-fired wall-hung boiler can thus hold different set

temperature values for heating mode and for hot water

handling.

A Control Centre can be used to integrate commonly

available 230 V S plan or Y plan components into the

Vaillant eBUS system.

4.3 System configuration

The Vaillant solar heating system enables various system configurations and control types in accordance with

the connection wiring diagrams 1 to 6 (¬section 6.8).

Single-channel eBUS controllers are not suitable

for this system configuration.

i

Wiring

If you use an eBUS-compatible Vaillant gas-fired wallhung boiler, you can use one of the Vaillant Control Centres to wire the system.

For all other gas-fired wall-hung boilers, you can use a

standard cabling box.

VRC weather compensator

(VRC430, VRC430f, VRC470, VRC470f)

A VRC controller controls the solar heating system in a

weather-compensated and time-dependent manner with

or without hot water production/a circulation pump in

conjunction with a Vaillant gas-fired wall-hung boiler

with an eBUS interface and the Vaillant VR68/2 solar

module.

Solar module VR 68/2

The VR68/2 solar module integrates a solar heating system into the control concept of a VRC controller. In conjunction with a VRC controller , various solar heating

system configurations can be implemented and the solar

yield recorded. You can combine the VR68/2 solar module with a VR61/2 mixer module in a solar heating system.

VR 61/2 mixer module

The VR61/2 mixer module is a system component which

controls a cylinder charging circuit or circulation pump

in conjunction with a VRC controller.

You can use the VR 61/2 mixer module to control a solar

heating system for the heating of potable water in conjunction with a VRC controller and the VR68/2 solar module.

Instructions on commissioning, maintenance, and troubleshooting for auroSTOR 0020111119_02 17

Page 18

4 Description of the components

4.3.2 Control functions

Hot water temperature control

The hot water temperature in the top half of the cylinder

can be controlled in one of the following ways:

– Vaillant auroMATIC VRS 560/2 solar controller or

– using one of the Vaillant Control Centre‘s with the Vail-

lant dual-channel eBUS controller

– Vaillant VRC weather compensator with VR 61/2 mixer

module and VR68/2 solar module or

– using the cylinder thermostat in conjunction with a timer.

If you are using a controller by a third-party manufacturer, you use this controller to adjust the hot water

temperature. In this case, the Vaillant controller (e.g.

auroMATIC 560/2) acts only as a solar controller and

only controls the temperatures for solar water heating.

Solar circuit control system

The solar circuit can be controlled in one of the following ways:

VRS560/2

(connection wiring diagrams 1, 2, 3, 4, and 6,

¬section6.8)

The lower cylinder sensor (SP 2) and the solar yield

temperature sensor are connected up to the VRS 560/2.

The solar pump is controlled via the VRS560/2.

VRC with VR 68/2

(connection wiring diagram 5, ¬ section 6.8)

The lower cylinder sensor (SP 2) and the solar yield

temperature sensor are connected up to the VR68/2.

The solar pump is controlled via a VRC.

Kol 1

230 V~

7

6

C

D

Fig. 4.5 Temperature differential control of solar pump

Key

1 Solar controller or solar module

2 Gas-fired wall-hung boiler

3 Solar cylinder

4 Solar circuit thermal cut-out

5 Solar yield temperature sensor

6 Solar pump

7 Solar pump unit

Kol 1 Collector sensor for flow line collector temperature

SP1 Cylinder sensor for upper cylinder temperature

(primary heating circuit/standby section)

SP2 Cylinder sensor for lower cylinder temperature (solar circuit)

A Primary heater flow

B Primary heater return

C Solar flow

D Solar return

5

3

SP 1

4

SP 2

A

1

2

B

Temperature differences, not absolute temperature values, are important for the operation of solar heating

systems. For this reason, solar heating systems are controlled via temperature differential controllers.

Integrated temperature sensors record the temperature

difference between the collector and the cylinder.

If the temperature difference (Kol 1–SP2) is larger than

7K, the solar heating system's solar pump is switched on.

If the temperature difference (Kol 1–SP2) is smaller

than 3K, the solar heating system's solar pump is

switched off.

18 Instructions on commissioning, maintenance, and troubleshooting for auroSTOR 0020111119_02

Page 19

Description of the components 4

Primary heating circuit control system

The primary heating circuit can be controlled in one

of the following ways:

Vaillant dual-channel eBUS controller with Vaillant

Control Centre (connection wiring diagrams 1 and 2,

¬section 6.8)

Important:

Terminals NTC and CYL. of the Vaillant Control Centre

may not be connected at the same time.

– Option 1: The upper cylinder sensor NTC is connected to

terminal NTC of the Vaillant Control Centre.

The recharging of the cylinder is controlled via the eBUS

controller. Here, the cylinder temperature is measured

using the cylinder sensor NTC. The temperature is compared with the target value programmed in the eBUS

controller and the cylinder is reheated if necessary.

– Option 2: The cylinder thermostat is connected

up to terminal CYL. of the Vaillant Control Centre.

The recharging of the cylinder is triggered via the cylinder thermostat. If the actual value falls below the target

temperature set on the cylinder thermostat, the cylinder

thermostat is shut. The closing of the cylinder thermostat is registered by the Vaillant Control Centre and

passed onto the eBUS controller.

The eBUS controller releases the recharging of the

cylinder for the programmed primary heating times:

The primary heating device activates and the Vaillant

Control Centre switches the zone valves into the correct

position for the recharging of the cylinder.

The required zone valve position differs depending

on whether the S plan is being used:

– S plan: Valve CH closed, valve DHW open.

VRS560/2

(connection wiring diagrams 3 and 4, ¬section6.8)

The upper cylinder sensor is connected to the terminal

SP1 of the VRS560/2.

The output EP of the VRS 560/2 is connected to the

input CYL. of the Vaillant Control Centre.

The recharging of the cylinder is controlled via the

VRS 560/2. Here, the sensor SP1 measures the cylinder

temperature. The temperature is compared with the programmed target value in the VRS560/2.

Within the primary heating times programmed in the

VRS560/2, the contact EP is closed if the actual value

falls below the target temperature for the cylinder.

The closing of the contact EP is registered by the

Vaillant Control Centre and the recharging of the cylinder is triggered: The primary heating device activates

and the Vaillant Control Centre switches the zone valves

into the correct position for the recharging of the cylinder.

The required zone valve position differs depending

on whether the S plan is being used:

– S plan: Valve CH closed, valve DHW open.

Vaillant dual-channel eBUS controller with VR68/2

(connection wiring diagram 5, ¬section 6.8)

The upper cylinder sensor is connected to the terminal

SP1 of the VR68/2.

The recharging of the cylinder is controlled via the eBUS

controller, which is connected with the VR68/2 and

VR61/2 via eBUS. The zone valves are switched via the

VR61/2 (valve DHW open, heating circuit valve closed).

VRS560/2 in conjunction with non-eBUS-compatible

controllers (connection wiring diagram 6, ¬section6.8)

The upper cylinder sensor is connected to the terminal

SP1 of the VRS560/2.

The output EP of the VRS560/2 is connected to the

wiring of the S plan via the cylinder thermostat.

Important:

The target temperature on the cylinder thermostat must

be set to the maximum temperature!

The recharging of the cylinder is controlled via the

VRS 560/2. Here, the sensor SP1 measures the cylinder

temperature. The temperature is compared with the programmed target value in the VRS560/2.

Within the primary heating times programmed in the

VRS560/2, the contact EP is closed if the actual value

falls below the target temperature for the cylinder.

The switching signal is coupled into an S plan and the

recharging of the cylinder is triggered.

Room heating control

The room heating can be controlled in one of the following ways:

Vaillant dual-channel eBUS controller with Vaillant

Control Centre (connection wiring diagrams 1, 2, 3,

and 4, ¬section 6.8)

The room heating is controlled by the Vaillant

eBUS controller.

The actuation of the valves (S plan plan)

is controlled by the Vaillant Control Centre.

Vaillant dual-channel eBUS controller with VR61/2

(connection wiring diagram 5, ¬section 6.8)

The room heating is controlled by the Vaillant eBUS

controller.

The actuation of the valves (S plan plan) is controlled by

the VR61/2.

Programmable timer and room thermostat

(connection wiring diagram 6, ¬section6.8)

The room heating is controlled using a programmable

timer and a room thermostat.

The actuation of the valves (S plan) is realised

via the programmable timer and DHW timer.

Instructions on commissioning, maintenance, and troubleshooting for auroSTOR 0020111119_02 19

Page 20

4 Description of the components

4.3.3 Technical data of the auroSTOR solar cylinder

Unit VIH S GB 210/2 S VIH S GB 260/2 S VIH S GB 310/2 S

Total capacity litres 210 260 310

Actual capacity litres 209,4 254,4 297,2

Hot water capacity (upper coil) litres 104,8 142,0 144,2

Hot water capacity (solar coil) litres 203,3 246,1 271,1

Dedicated solar volume litres 104,6 112,4 153,0

Maximum supply pressure to pressure reducing valve MPA (bar) 1,2 (12)

Rated pressure of cylinder MPA (bar) 0,7 (7)

Maximum operating pressure of heating coil MPA (bar) 0,35 (3,5)

Maximum operating pressure of solar coil MPA (bar) 0,6 (6)

Operating pressure MPA (bar) 0,35 (3,5)

Pressure limiting valve MPA (bar) 0,35 (3,5)

Expansion relief valve MPA (bar) 0,6 (6)

Temperature and pressure relief valve °C,

Charge pressure of hot water expansion vessel MPA (bar) 0,4 (4)

Maximum temperature of heating circuit °C 85

Maximum temperature of potable hot water °C 85

Maximum temperature of solar fluid °C 85

Standing heat loss kW/24 h 1,98 2,15 2,35

Heat up time according to EN 12897 mins 20 27 28

Recovery time (70% capacity) mins 15 20 21

Primary heat exchanger performance kW 16,7 16,5 16,0

Flow rate for primary heat exchanger performance l/min 23,3

Primary heat exchanger pressure drop mbar 79 78 79

Primary heat exchanger volume Liter 2,37

Primary heat exchanger surface area m

Heat up time according to EN 12897 (solar) min 32 40 49

Solar heat exchanger performance kW 19,7 19,5 17,2

Flow rate for solar heat exchanger output l/min 23,3

Solar heat exchanger pressure drop mbar 97 95 98

Solar heat exchanger volume Liter 2,94

Solar heat exchanger surface area m

Dimensions

Height mm 1593 1843 2153

Height with hot water draw off mm 1625 1875 2185

Topple measure mm 1680 1918 2217

Diameter mm 554,5

Depth mm 633

Net weight kg 40 43 50

Weight (full) kg 249 298 347

Connections

Cold water inlet 22 mm unprofiled pipe (crimp joints)

Hot water draw off 22 mm unprofiled pipe (crimp joints)

Balanced pressure cold water outlet 22 mm unprofiled pipe (crimp joints)

Secondary return 15 mm unprofiled pipe (crimp joints)

Primary heater flow 22 mm unprofiled pipe (crimp joints)

Primary heater return 22 mm unprofiled pipe (crimp joints)

Solar flow 22 mm unprofiled pipe (crimp joints)

Solar return 22 mm unprofiled pipe (crimp joints)

Primary heating circuit cylinder dry pocket size mm 8

Solar circuit cylinder dry pocket size mm 8

MPA (bar)

2

2

90,

0,7 (7)

0,5

0,62

Tab. 4.2 Technical data for auroSTOR solar cylinder

20 Instructions on commissioning, maintenance, and troubleshooting for auroSTOR 0020111119_02

Page 21

Description of the components 4

Unit VIH S GB 210/2 S VIH S GB 260/2 S VIH S GB 310/2 S

Electrical connections

Immersion heater (according to EN BS 60335) 2.7 kW, 230 V, 50 Hz

Length of immersion heater inch 14

Two port motorised valve 230/240 V, 50 Hz

Cylinder thermostat 230/240 V, 50 Hz

Thermal cut-out solar 230/240 V, 50 Hz

Material data

Cylinder body material Stainless steel (1.4521)

Cylinder jacket material Polypropylene

Insulation material EPS with infrared absorber

Insulation thickness mm 50

Corrosion protection Stainless steel

Blowing agent for insulation material Pentane (GWP < 5)

ODP 0

Tab. 4.2 Technical data for auroSTOR solar cylinder (continued)

The heat up time is based on a flow rate

of 1400l/h at 80 ºC.

i

Temperature rise from 15 ºC to 60 ºC.

Instructions on commissioning, maintenance, and troubleshooting for auroSTOR 0020111119_02 21

Page 22

4 Description of the components

4.3.4 Dimensions

a

b

c

d

1

2

3

4

5

6

7

8

9

10

11

e

f

g

h

633

Ø 554,5

i

j

k

l

Fig. 4.6 Dimensions of the auroSTOR solar cylinder

Key

1 Hot water draw off

2 Temperature and pressure relief valve connection

3 Secondary return

4 Primary heater flow

5 Primary heating circuit cylinder dry pocket (SP 1)

Unit type a b c d e f g h i j k l

VIH S GB 210/2 S 1625 1593 1341 1158 1052 912 822 802 534 506 259 51

VIH S GB 260/2 S 1875 1843 1591 1346 1102 962 872 852 534 506 259 51

VIH S GB 310/2 S 2185 2153 1901 1578 1377 1237 1147 1127 534 506 259 51

Tab. 4.3 Dimensions

6 Primary heater return

7 Electric immersion heater

8 Solar flow

9 Solar circuit cylinder dry pocket (SP 2)

10 Cold mains inlet connection

11 Solar return

25°

45°

22 Instructions on commissioning, maintenance, and troubleshooting for auroSTOR 0020111119_02

Page 23

Assembly 5

5 Assembly

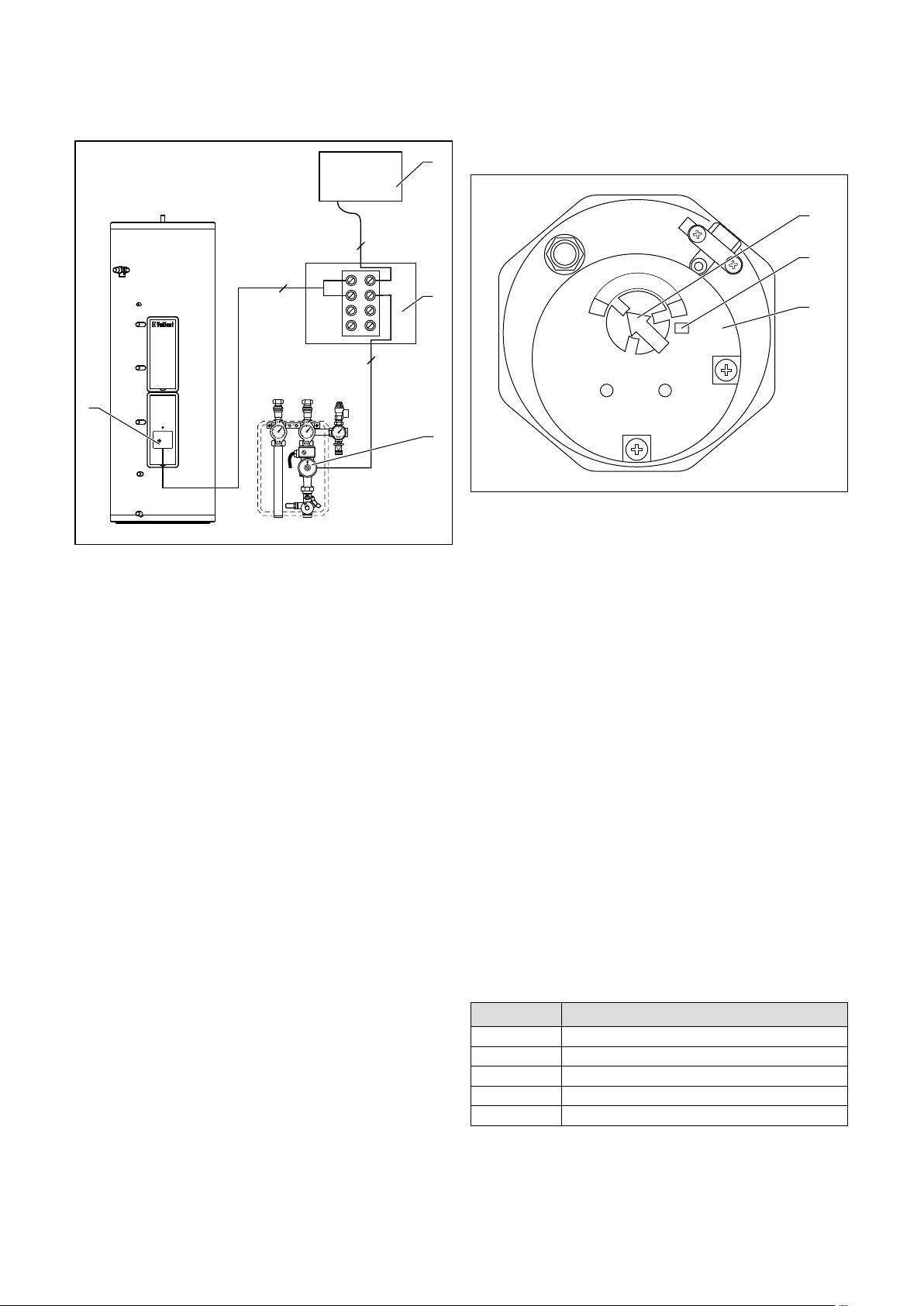

5.1 Scope of delivery

8

7

6

5

4

3

Fig. 5.1 Scope of delivery

Item Quantity Component

11

22

In separate packaging:

31

4 1 Two port motorised valve

5 1 15mm compression cap for secondary return

6 1 Tundish

7 1 Assembly set for hot water expansion vessel

81

Table 5.1 Scope of delivery

Domestic hot water cylinder with insulation

in separate packaging

Instructions on commissioning, maintenance,

and troubleshooting and operating instructions (packaged with the cylinder)

Safety assembly (pressure reducing valve,

expansion relief valve, connections for pressure-controlled cold water inlet and hot water

expansion vessel)

Hot water expansion vessel:

12 l for VIH GB 120/2 S and VIH GB 155/2 S

18 l for VIH GB 180/2 S and VIH GB 210/2 S

25 l for VIH GB 260/2 S and VIH GB 310/2 S

5.2 Transporting the cylinder

Danger!

Risk of injury due to heavy load!

a

Heavy load can cause injuries.

> At least two people should lift the cylin-

der to prevent injuries.

> Use a suitable transportation aid

(sack truck or similar).

1

> Transport the packaged cylinder to the installation site.

> Only remove the cylinder from its packaging once

it reaches the installation site.

5.3 Requirements for installation site

Position the domestic hot water cylinder as near as

possible to the heater to prevent unnecessary heat loss.

2

Place the cylinder in a suitable location in the building,

paying attention to the following:

– The tundish discharge pipe must be installed with a mini-

mum slope of 1:200 and must end in a safe and visible

place (¬section6.7).

– The installation surface must be flat and capable

of bearing the weight of the entire cylinder

(¬section5.3).

– The installation site must not be at risk of frost.

If necessary, install a frost protection thermostat.

– The control system for the installed cylinder thermostat

beneath the front plate must be easily accessible to the

operator.

– There must be sufficient space for the assembly, check,

and pressure build-up of the expansion vessel.

– There must be sufficient space for mounting, maintai-

ning and replacing the electric immersion heater.

– The floor must be even.

> Choose a cylinder installation site that allows the potable

water and heating lines to be laid in an appropriate man-

ner.

> To prevent energy losses in accordance with the Heating

Equipment Ordinance, provide all system pipes with ther-

mal insulation.

> Check the scope of delivery for completeness.

> Make sure the cylinder is stored in an upright position in

a dry environment prior to its installation.

Instructions on commissioning, maintenance, and troubleshooting for auroSTOR 0020111119_02 23

Page 24

6 Installation

6 Installation

6.1 Installation sequence

Install the solar heating system in the following order:

– Solar collectors and solar pump unit

– Cylinder

– Solar circuit piping

– Primary heating circuit piping

– Hot water piping, with secondary circulation line if requi-

red

– Cold water piping

– Discharge pipes

– Electrical installation

> Assemble the collectors in accordance with the assembly

instructions supplied with the collector assembly set.

> Install the solar pump unit in accordance with the instal-

lation instructions supplied with the solar pump unit.

> For the rest of the installation process, proceed

as described in the sections below.

6.2 Installation of solar circuit piping

6.2.1 Piping material in the solar circuit

All Vaillant solar sets are supplied with pipes made from

stainless steel with DN fittings.

Caution!

Risk of damage to the system if the

b

wrong piping material is used in the solar

circuit!

The solar fluid can reach high temperatures

and leaks can occur if the wrong piping

material is used (e.g. PE pipes and Teflon

band).

> You should preferably use copper pipes

in the solar circuit.

> Use brazing solder to solder the piping

in the solar circuit.

> Only use press fittings if the manufactu-

rer has stated that they can be used up

to

a temperature of 200 ºC.

6.2.2 Layout of piping in the solar circuit

The correct choice of pipe diameter is vital to ensure

the optimum efficiency of the solar heating system.

To keep the pressure loss in the solar circuit as low as

possible, the flow velocity in the pipe must not be more

than 1.5m/s.

At the same time, the flow velocity must be at least

0.4 m/s to transport air bubbles from the collectors

downwards to the air vents (¬ section 6.2.4).

A nominal flow rate of 0.66 l/min is required for the flat

collectors and a nominal flow rate of 0.4 l/min per m

net collector area is required for the vacuum tube collectors in order to achieve optimum heat transfer (¬ table

6.1 and 6.2).

A further decisive factor to ensure that your solar heating system works as well as possible is the correct solar

pump design. It must be possible for the solar pump to

convey more than the nominal flow rate at the specified

operating pressure. The selection of the required pump

speed depends on the installed system. For a reference

value for the selection of a solar pump, see section 7.4.

2

of

24 Instructions on commissioning, maintenance, and troubleshooting for auroSTOR 0020111119_02

Page 25

6.2.3 Realisation of solar circuit piping

Danger!

Risk of death from electric shock!

a

b

Incorrect installation or a faulty power

cable can result in a supply voltage on the

pipes, which can cause personal injury.

> Attach earthing pipe clamps to the pipes

and connect the earthing pipe clamps to

a potential equalisation bar using 16 mm

cable.

Caution!

Risk of damage to electronics resulting

from lightning strikes!

Without potential equalisation, lightning

can destroy the electronics in the solar

heating system, heating system, or building.

> Earth the solar circuit in accordance with

the requirements of "BS7671 IEE Wiring

Regulations". Attach earthing pipe

clamps to the solar circuit pipes, for

instance, and connect the earthing pipe

clamps to a potential equalisation bar

using 16 mm

> Connect the collectors to an existing buil-

ding lightning protection system.

2

cable.

Installation 6

2

Caution!

Risk of damage to the collectors due

b

Observe the following points to ensure perfect operation

with maximum energy utilisation:

> Ensure that the piping diameter is not too large, since

this could result in low flow velocities in the solar hea-

ting system; this makes the system less efficient.

> Design all system components to ensure an even flow