Page 1

For the operator

Instructions for use

Instructions for use

Publisher/manufacturer

Vaillant GmbH

Berghauser Str. 40 D-42859 Remscheid

Telefon 021 91 18‑0 Telefax 021 91 18‑28 10

info@vaillant.de www.vaillant.de

auroFLOW plus

Solar system

GB, IE

Page 2

Contents

Contents

1 Safety .................................................................... 3

1.1 Action-related warnings ......................................... 3

1.2 General safety information .................................... 3

1.3 CE label ................................................................. 3

1.4 Intended use.......................................................... 3

2 Notes on the documentation .............................. 4

2.1 Original instructions for use ................................... 4

2.2 Observing other applicable documents ................. 4

2.3 Storing documents................................................. 4

2.4 Applicability of the instructions .............................. 4

3 System.................................................................. 4

3.1 System characteristics........................................... 4

3.2 Control functions of the system ............................. 6

4 Operation.............................................................. 7

4.1 Digital Information and Analysis System (DIA)...... 7

4.2 Operating concept ................................................. 7

4.3 Basic display.......................................................... 8

4.4 Operating levels..................................................... 8

4.5 Reading the solar yield .......................................... 8

5 Troubleshooting .................................................. 9

5.1 Reading fault messages ........................................ 9

6 Auxiliary functions .............................................. 9

6.1 Operation in the menu ........................................... 9

6.2 Live Monitor ......................................................... 12

6.3 Displaying contact data........................................ 12

6.4 Displaying the serial number and article

number................................................................. 12

6.5 Displaying operating hours .................................. 12

6.6 Setting the language............................................ 12

6.7 Setting the date/time and summer time............... 12

6.8 Setting the display contrast ................................. 12

7 Maintenance....................................................... 12

7.1 Servicing the solar system................................... 12

7.2 Caring for the product .......................................... 12

8 Decommissioning.............................................. 13

8.1 Switching off the solar charger ............................ 13

8.2 Decommissioning the solar system

permanently......................................................... 13

8.3 Recycling and disposal........................................ 13

9 Customer service and guarantee..................... 13

9.1 Customer service................................................. 13

9.2 Guarantee............................................................ 13

Index ................................................................................... 14

2 Instructions for use auroFLOW plus 0020160592_00

Page 3

Safety 1

1 Safety

1.1 Action-related warnings

Classification of action-related warnings

The action-related warnings are classified in accordance

with the severity of the possible danger using the following

warning signs and signal words:

Warning symbols and signal words

Danger!

Imminent danger to life or risk of severe personal

injury

Danger!

Risk of death from electric shock

Warning.

Risk of minor personal injury

Caution.

Risk of material or environmental damage

1.2 General safety information

1.2.1 Installation by competent persons only

Only an approved competent person is permitted to carry out

installation, inspection, maintenance and repair work on the

product.

1.2.2 Danger due to incorrect handling

▶ Read through these instructions carefully.

▶ Observe the general safety information and warnings for

all tasks that involve the Vaillant product.

▶ Perform all tasks only as described in this manual.

1.2.3 Risk of burns from components through

which solar fluid flows and heating water

pipes

In solar mode, components through which solar fluid flows,

such as collectors and solar lines, as well as the heating

water pipes, reach extremely high temperatures. Touching

these components may result in serious personal injury.

▶ Only touch these components if you have first checked

the temperature.

1.2.4 Danger due to changes in the product

environment

There is a risk of injury or death to the operator or others, or

of damage to the product and other property, in the event of

changes to the product environment. Changes must not be

made to the following:

– the product,

– the product environment,

– the solar fluid, heating water and power supply lines,

– the discharge line and the collecting container for the

solar fluid,

– the drain line and expansion relief valve for the heating

water,

– the structural conditions that may affect the operational

safety of the product.

▶ Never shut down the safety devices.

▶ Do not tamper with any of the safety devices.

1.2.5 Damage to the building as a result of

leaking water

Leaking water may cause damage to the building structure.

▶ If there is a possibility of leaks in the pipework, close the

service valves immediately.

▶ Have any leaks remedied by a heating specialist com-

pany.

1.3 CE label

The CE label shows that the products comply

with the basic requirements of the applicable guidelines as

stated on the identification plate.

1.4 Intended use

There is a risk of injury or death to the user or others, or of

damage to the product and other property in the event of

improper use or use for which it is not intended.

The product is designed for use in solar systems. The

Vaillant solar system is used for solar heating support or

hot water generation. The product must only be operated

in the solar circuit with Vaillant ready-mixed solar fluid. The

product has been specially developed for the Vaillant solar

collectors auroTHERM (VFK 135 VD and VFK 140 VD). The

components in the solar circuit have been developed for use

with Vaillant solar fluid.

Intended use includes the following:

– observing the included operating, installation and servi-

cing instructions for the Vaillant product and any other

system components

– compliance with all inspection and maintenance condi-

tions listed in the instructions.

This product is not designed to be used by persons (including children) with limited physical, mental or sensory capabilities or by persons who do not have enough experience

and/or knowledge, unless they are supervised by a person

who is responsible for their safety or have been instructed by

him/her about how to use the product.

Children must be supervised to ensure that they do not play

with the product.

The use of the product in vehicles, such as mobile homes

and caravans, is not classed as intended use. Units that are

not classed as vehicles are those that are installed in a fixed

and permanent location (known as "fixed installation").

Installing and using the product in locations where there is

a risk of exposure to damp or splashed water constitutes

improper use.

Any other use that is not specified in these instructions, or

use beyond that specified in this document shall be considered improper use. Any direct commercial or industrial

use is also deemed to be improper.

Caution.

Improper use of any kind is prohibited.

0020160592_00 auroFLOW plus Instructions for use 3

Page 4

2 Notes on the documentation

1

2

3

1

2

3

2 Notes on the documentation

2.1 Original instructions for use

These instructions are the original instructions for use within

the context of the machine directive.

2.2 Observing other applicable documents

▶ You must observe all operating instructions enclosed with

the system components.

2.3 Storing documents

▶ Keep this manual and all other applicable documents

safe for future use.

2.4 Applicability of the instructions

These instructions apply for the following only:

Product types and article numbers

VPM 15 D basic module

VPM 30 D expansion module

The 10-digit article number of the product is the seventh to

sixteenth number of the serial number (→ Page 12).

The article number can also be found on the identification

plate, which is fitted in the factory on the underside of the

product.

0020133195

0020133196

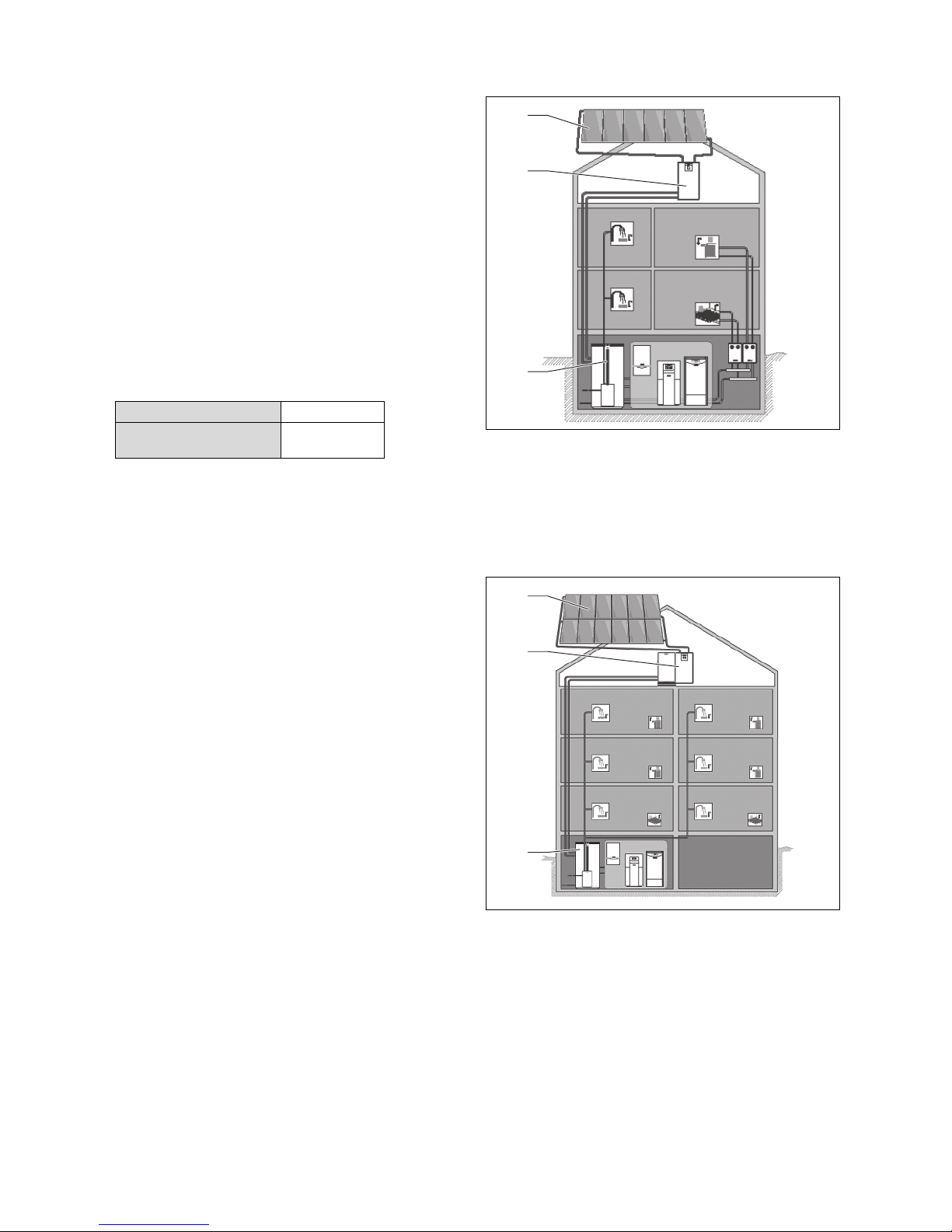

3.1.2 Design of coordinated system examples

1 Collector field with max-

imum six collectors (VFK

135 VD or VFK 140 VD)

A typical example for the use of the basic module of the

auroFLOW plus solar charger is solar-supported heating

in a single-occupancy house. Cylinder cascades and swimming pool heating are possible.

2 auroFLOW plus basic

module

3 Buffer cylinder

3 System

3.1 System characteristics

3.1.1 Basic principles of the system

The auroFLOW plus solar system acts as a heat generator

in a hot water heating installation with a buffer cylinder. In order to cover the basic load and potential peak loads of the

heat demand, various heat generators are used in solar-supported heating installations, e.g. heat pumps, block heating

and generating plants and gas boilers. The hot water generation can be combined with the buffer cylinder.

The auroFLOW plus solar system comprises:

– Collector field

– auroFLOW plus solar charger

– Buffer cylinder

– Solar lines

– Heating water pipes

In addition, a system controller can be used to control all

components of the heating installation, e.g. the auroMATIC

VRS 620.

1 Collector field with max-

imum 12 collectors (VFK

135 VD or VFK 140 VD)

A typical example for the use of the basic module and expansion module of the auroFLOW plus solar charger is

solar-supported production of hot water in multiple-occupancy houses. Cylinder cascades and swimming pool heating are possible.

For even larger applications, up to four solar chargers (basic

module and expansion module) can be cascaded. The collector field can then be made up of up to 48 collectors.

2 Basic module and expan-

sion module auroFLOW

plus

3 Buffer cylinder

4 Instructions for use auroFLOW plus 0020160592_00

Page 5

System 3

1

2

T5

T1

T3

T2

T4

T6

P3

P2

P1

STW1

STW2

3

9

8

7

4

6

5

Flowsensor

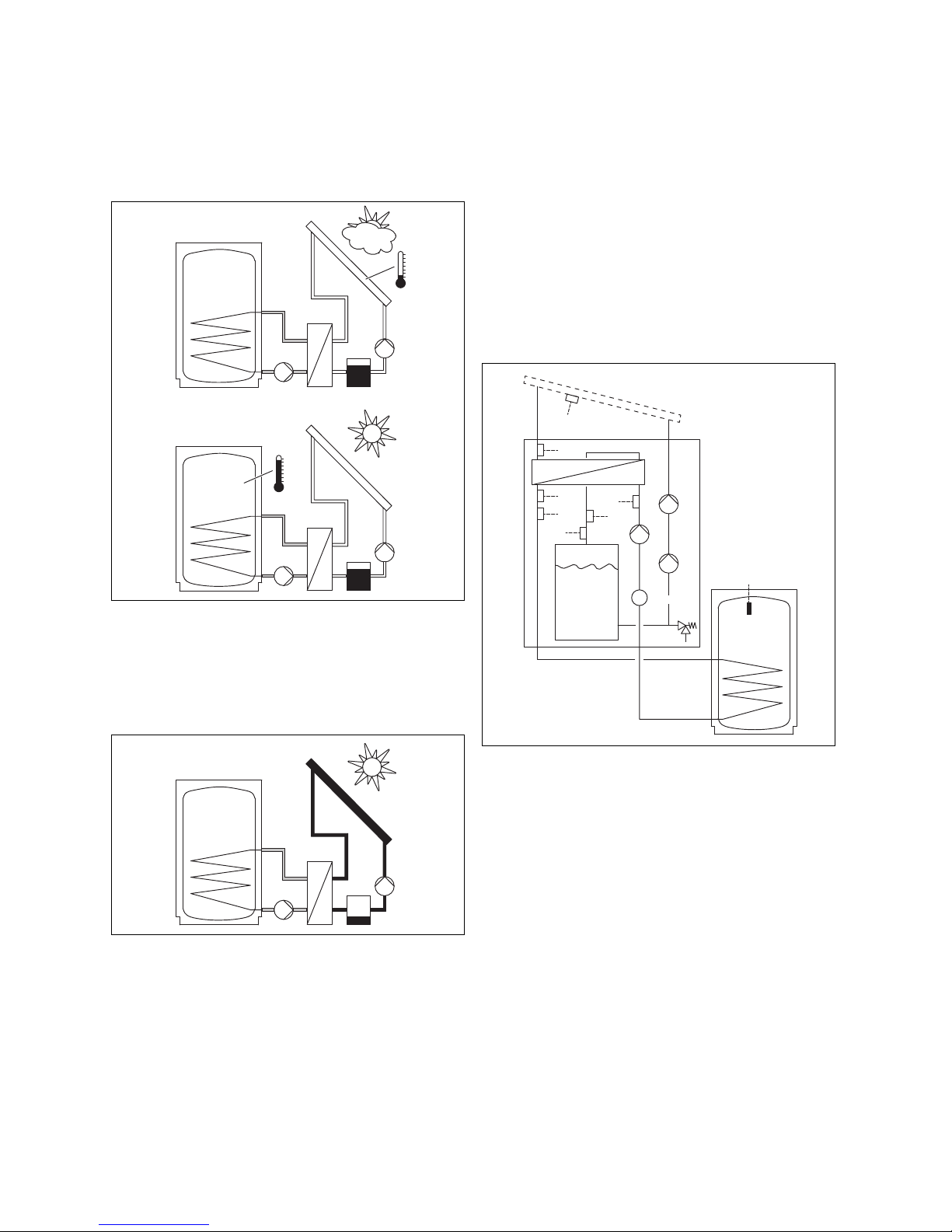

3.1.3 Functionality

The way the auroFLOW plus solar system operates is different to many other solar systems. The auroFLOW plus

solar system is not completely filled with solar fluid and it is

not under pressure. For this reason, some of the otherwise

standard components for solar systems, such as the expansion vessel, pressure gauge and air vent, are not fitted.

– The fluid capacity of the collector field and the solar lines

is precisely designed with the solar system in mind.

– The minimum length and the maximum length of the

solar lines must be observed

– All solar lines have defined diameters in relation to

the number of collectors

– The use of corrugated hoses impairs the functionality

of the solar system

– The design and number of collectors must not be

changed

– The physical properties of the solar fluid are also an im-

portant contributing factor to the fault-free operation of

the system. Therefore, only original Vaillant solar fluid

without additives may be added to the system.

3.1.4 Product function

When the solar pump is idle, the solar fluid is collected in

the storage tank. The collector field and all solar lines are

installed with downward gradients, to ensure that the solar

fluid flows back to the solar charger. The solar lines and the

collector field are then filled with air. The solar fluid is a special ready-mixed water/glycol fluid that is added to the solar

system during installation by the competent person.

The way the basic module of the solar charger operates is

described below.

If the expansion module is also installed,

– the solar fluid volume is doubled by a separate storage

tank connected in parallel

When the solar control activates the solar pump, the solar

pump pumps the solar fluid from the storage tank through

the solar return into the collector field. The solar fluid is

heated at this point, before flowing back to the solar charger

via the solar flow pipe.

– When the solar pump is idle, there is air in the collectors

and solar lines. Frost protection measures are therefore

only required for the installation site of the solar charger.

– The collector field and solar lines, and especially the

downward gradient of the lines, must be installed as specified to ensure that the solar system functions correctly.

– the pump output is higher as a result of two solar pumps

connected in series

The way the solar charger operates remains the same, however.

When the solar pump is idle, only the storage tank (8) contains solar fluid. The collectors (1) and solar lines (2) and (9)

are then filled with air.

The solar control in the solar charger activates the solar

pump whenever

– the temperature difference between the collector temper-

ature sensor (T5) and cylinder temperature sensor (T6) is

at least 15 K (if a system controller is connected, the cylinder temperature is transmitted to the solar control via

the eBUS line)

– the cylinder temperature is lower than the set maximum

cylinder temperature

0020160592_00 auroFLOW plus Instructions for use 5

Page 6

3 System

– the anti-cycling time of ten minutes after the last cylinder

charging has expired

– the safety temperature limit of 110 °C in the solar circuit

is not exceeded (STW2)

– the safety temperature limit in the buffer cylinder (4) is

not exceeded (STW1)

– the temperature has fallen by at least 15 K following ac-

tivation of a safety cut-out

– there are no faults (e.g. sensor faults, activated safety

temperature monitor)

– activation of the solar pump is enabled (only if a system

controller is connected)

The solar control in the solar charger deactivates the solar

pump whenever

– the maximum cylinder temperature is reached

– current solar radiation is < 250 W

– there is a fault, see fault message (→ Page 9)

Every time the solar pump is switched on, a filling phase is

started. The solar pump ((P1) and/or (P2)) is now working

at maximum power and pumps the solar fluid via the solar

return (2) into the collector field. The solar fluid then forces

the air out of the solar return and the collector field into the

solar flow pipe and the storage tank.

In the collector field, the solar fluid is heated up, some of

which can then evaporate. The vapour mixes with the air that

is still present.

The continued flow of the solar fluid is supported by the

downward gradient of the solar flow pipe (9). The air and

solar fluid mixture passes through the solar flow pipe to the

heat exchanger (3) in the solar charger. The heat exchanger

transfers the heat energy of the solar fluid to the heating

water in the buffer cylinder charging circuit. After a specified

filling time, the solar control reduces the output of the solar

pump. The filling phase is then completed.

If (T1) measures a temperature > 50 °C and > activation

temperature (default setting: 15 K), the solar control activates the cylinder charging pump (P3) in the solar charger.

The heating water then circulates from the heat exchanger to

the buffer cylinder.

The temperature sensors (T3) and (T4) in the flow (5) and

return (6) of the buffer cylinder charging circuit as well as a

flow sensor (Flowsensor) enable the solar control to measure the solar yield.

The solar fluid flows back from the heat exchanger into the

storage tank. The tank volume dimensions are such that the

air bubbles from the solar fluid are separated out before the

solar fluid is pumped further by the solar pump.

When the solar system heats up, the solar fluid and the air

expand. The pressure of the air enclosed in the solar system increases slightly as a result. The enclosed air in the

system therefore fulfils the role of an expansion vessel. The

increased pressure is necessary and must not be discharged

in any way. For this reason, an air vent must not be fitted in

the solar system.

If there is a fault, an expansion relief valve (7) protects the

solar plant from prohibited overpressure.

3.2 Control functions of the system

With the help of the solar control integrated in the solar charger, the solar charger can charge a buffer cylinder. Whether

or not the buffer cylinder is charged depends on the cylinder

temperature and the current solar radiation.

If coordination with other heat generators of the heating installation is required, a system controller is needed.

3.2.1 Range of available functions for the

integrated controller

The auroFLOW plus solar system is regulated by the integrated, microprocessor-controlled solar control.

3.2.1.1 Differential temperature control system

The solar control works according to the differential temperature control principle. When the temperature difference

(temperature of collector - temperature of cylinder) is greater

than the switch-on differential, the solar control switches on

the solar pump. The internal sensors in the solar charger determine the power through the collector field. When power is

no longer available from the collector field, the solar control

switches off the solar pump.

3.2.1.2 Annual calendar

The solar control is fitted with an annual calendar that enables automatic adjustment between summer and winter

time. During installation, the competent person enters the

current date to activate the annual calendar.

Note

Note that, in the event of a power failure, the solar

control is equipped with a reserve power supply

of 30 minutes. The internal clock stops after 30

minutes. The calendar does not continue running once the voltage supply is restored. In this

instance, the time must be reset. Check the current date.

Note

If a system controller is connected, it is not necessary to set the date, time or summer time.

3.2.2 Combination with system controller

The product can be combined with the auroMATIC VRS 620

system controller or the controller of the geoTHERM heat

pumps.

If the product is combined with the auroMATIC VRS 620

system controller, we recommend the installation of a VPM

W drinking water station.

6 Instructions for use auroFLOW plus 0020160592_00

Page 7

Operation 4

4

3

6

5

1

2

F. X X

Previous day

0 kWh

Solar yield

Back

Next

4 Operation

4.1 Digital Information and Analysis System

(DIA)

The product is equipped with a digital information and analysis system (DIA system). The DIA system consists of a

display that shows symbols and plain text, along with 5 operating buttons. The DIA system provides information on the

operating condition of the product and helps you deal with

problems.

The display lights up when one of the DIA system buttons

is pressed. At first, pressing the button does not trigger any

other function.

The light automatically switches off after one minute if no

further buttons are pressed.

DIA system control elements

Symbol Meaning Explanation

Solar pump(s) active Flashes: Solar circuit is

starting up (filling of the

field)

Permanently on: solar

circuit running, cylinder

charging pump active

Fault in the solar system Appears instead of the

basic display.

A plain text display

explains the displayed

fault code.

4.2 Operating concept

The product is operated using the selection buttons and the

plus/minus buttons.

Both selection buttons have a soft key function. This means

that the function of the selection buttons changes.

1 Display of the current

assignment of the righthand selection button

2 Minus and plus button

3 Fault clearance key

4 Left and right-hand selec-

tion buttons

5 Display of the current

assignment of the lefthand selection button

6 Display

4.1.1 Displayed symbols

Symbol Meaning Explanation

Display of the current

solar output (bar display)

Collector temperature Temperature at the

Power transmitted to the

cylinder

collector temperature

sensor (T5)

If, for example, the left-hand selection button is pressed

in the basic display, the current function of (solar yield)

switches to Back.

Press :

– to switch directly from the basic display to the yield

display

– to cancel the change to a set value

– to go one selection level higher in the menu.

Press :

– to go to the next yield display, for example

– to confirm a set value

– to go one selection level lower in the menu.

Press + simultaneously:

– to call up a menu with additional functions.

Press or :

– to go back and forth between the individual points of the

entry list in the menu

– to increase or decrease a selected set value.

Configurable values are always displayed flashing.

You must always confirm any change to a value. Only then

does the product save the new setting.

0020160592_00 auroFLOW plus Instructions for use 7

Page 8

4 Operation

Menu

Live Monitor

Information

Basic settings

SelectBack

0

25°C

Previous day

0 kWh

Solar yield

Back

Next

Note

You always have the option to cancel the change

to a setting or the reading of a value by pressing

the left-hand selection button.

A highlighted object is indicated in the display inversely (light

text on dark background).

Note

If you do not press any buttons for more than 15

minutes, the display returns to the basic display.

Any unconfirmed changes are then cancelled by

the product.

4.4 Operating levels

The product has two operating levels.

4.4.1 Operating level

The standard operating level offers you the most frequently

used setting options that do not require any special prior

knowledge and displays the most important information.

You can access additional information using a menu.

4.4.2 Installer level

The installer level must only be operated by a competent

person. The installer level is therefore protected with a code.

The competent person uses this level to calibrate the parameters of the solar charger with the solar system.

4.5 Reading the solar yield

4.3 Basic display

In the normal operating condition, the basic display is shown.

The basic display shows the current condition of the solar

system. When the left-hand selection button is pressed, the

display shows the solar yield. If the display is dimmed, the

first button push switches on the display illumination. In this

case, to trigger the button function, you must press the button again.

You can switch back to the basic display by:

–

pressing to exit the selection levels

– not pressing any button for longer than 15 minutes.

The product does not save any unconfirmed changes in this

case.

If there is a fault message, the basic display switches to a

plain text display of the fault message.

The solar yield can be displayed in the basic display in kilowatt hours as follows:

▶

Press .

◁ The display shows the solar yield from the previous

day.

▶

Press .

◁ The display shows the solar yield from the current

month.

▶

Press .

◁ The display shows the solar yield from the current

year.

▶

Press .

◁ The display shows the total solar yield.

8 Instructions for use auroFLOW plus 0020160592_00

Page 9

Troubleshooting 5

Menu

Live Monitor

Information

Basic settings

SelectBack

1

4

2

3

5 Troubleshooting

5.1 Reading fault messages

Fault messages have priority over all other displays. If a fault

occurs in the solar system, the solar system switches itself

off. The display of the solar charger displays a fault code in

place of the basic display. A plain text display explains the

displayed fault code.

If multiple faults occur at the same time, the display shows

the corresponding fault codes for two seconds each in sequence.

▶ If the solar charger displays a fault message, contact

your approved competent person.

Note

Status messages about the condition of the

solar system can be called up using the Live

Monitor (→ Page 12) function.

5.1.1 Fault message

Fault messages appear on the display approx. 20 seconds

after a fault has occurred. If a fault is present for at least

three minutes, a fault message is recorded in the fault

memory of the solar control.

Note

Only a competent person can eliminate the cause

of the faults described below and delete the fault

memory.

Fault code Fault text

20 Shut-down of temperature limiter

1272 Electronics fault in cylinder charge pump

1273 Electronics fault in solar pump

1274 Electronics fault in solar pump 2

1275 Cylinder charge pump blocked

1276 Solar pump blocked

1277 Solar pump 2 blocked

1278 T5 collector sensor fault

1279 T6 cylinder temperature sensor fault

1281 T1 temperature sensor fault

1282 T2 temperature sensor fault

1283 T3 temperature sensor fault

1284 T4 temperature sensor fault

1355 Volume flow sensor cylinder circuit fault

6.1 Operation in the menu

Press and ("i") at the same time to access the menu.

6.1.1 Design of the menu

1 Scroll bar

(only appears if there are

more list entries than can

be shown at once on the

display)

The Digital Information and Analysis System has a menu

containing up to two selection levels (sub-menus).

The selection levels are used to navigate to the setting level

required to read or change settings.

Note

Path details at the start of an instruction specify

how this function can be accessed, e.g. Menu →

Information → Contact data.

2 Current functions of the

right and left selection

buttons

(Soft key functions)

3 Selection level list entries

4 Name of the selection

level

6 Auxiliary functions

The digital information and analysis system provides auxiliary functions via the menu.

0020160592_00 auroFLOW plus Instructions for use 9

Page 10

6 Auxiliary functions

21 10 43

0001000033NO

0010011621

0219118

90

25°C

Menu

Solar yield

Live Monitor

Information

SelectBack

Menu

Solar yield

Live Monitor

Information

SelectBack

Live Monitor

Back

Information

Contact data

Serial number

Operating hours

SelectBack

Information

Contact data

Serial number

Operating hours

SelectBack

Information

Contact data

Serial number

Operating hours

SelectBack

Contact data

Back

Serial number

Back

Operating hours:

Back

Cylinder charge

pump

S.xx

Next

Collector temperature

Back

20 °C

Next

Cylinder temperature

Back

40 °C

Next

Power

Back

Cylinder circuit

0 kW

50

Menu

Solar yield

Live Monitor

Information

SelectBack

Solar yield

Back

Previous day

Next

Solar yield

Back

Month

Next

Solar yield

Back

Year

Next

Solar yield

Back

Total

0 kWh0 kWh0 kWh0 kWh

6.1.2 Overview of the menu structure

10 Instructions for use auroFLOW plus 0020160592_00

Page 11

Auxiliary functions 6

Menu

Live Monitor

Information

Basic settings

SelectBack

Menu

Information

Basic settings

Resets

SelectBack

Menu

Basic settings

Resets

Installer level

SelectBack

Basic settings

Language

Display contrast

Date

SelectBack

Language

Back

02 English

Language

Cancel

02 English

OK

Cancel

English ?

OK

Basic settings

Language

Display contrast

Date

SelectBack

Basic settings

Language

Display contrast

Date

SelectBack

Basic settings

Display contrast

Date

Time

SelectBack

Basic settings

Date

Time

Summer/winter time

SelectBack

Display contrast

Back

255

Date

Back

05.05.12

Time

Back

10:00

Summer/winter time

Back

Automatic

clock change

Off

Summer/winter time

Cancel OK

Automatic

clock change

On

0020160592_00 auroFLOW plus Instructions for use 11

Page 12

7 Maintenance

6.2 Live Monitor

Menu → Live Monitor

– This function allows you to display the current product

status of the solar system. The display also shows the

meaning in plain text.

– The display is automatically updated if the product status

changes.

Status code Meaning

400 Module in standby

401 Solar circuit being filled

403 Cylinder completely charged

405 Heating zone being charged

406 Process water zone being charged

407 Pool or second cylinder being charged

408 Frost protection active

410 Module shut down

411 Cylinder charging starting

413 Cylinder being charged

6.3 Displaying contact data

Menu → Information → Contact details

– If the competent person has entered their telephone

number during the installation, you can read the data under Contact data.

6.4 Displaying the serial number and article

number

Menu → Information → Serial number

– Serial number shows the serial number of the product,

which the competent person may require you to tell him.

– The article number is found in the second line of the

serial number (seventh to sixteenth digits).

6.5 Displaying operating hours

Menu → Information → Operating hours

– Under Operating hours, you can display the number

of operating hours of the cylinder charging pump since

start-up.

6.6 Setting the language

Menu → Basic setting → Language

– During installation, the competent person has set the de-

sired language for you. If you want to set a different language, you can do this using the menu point mentioned

above.

6.7 Setting the date/time and summer time

Note

The date, time and automatic summer/winter adjustment can only be set if there is no system controller connected.

Menu → Basic setting → Date

– You can use this menu point to set the date.

Menu → Basic setting → Time

– You can use this menu point to set the time.

Menu → Basic setting → Summer/winter time

– You can use this menu point to set the DIA to switch

automatically between summer time and winter time.

6.8 Setting the display contrast

Menu → Basic setting → Display contrast

– This function is used to adjust the display contrast to

ensure that the display can be read easily.

7 Maintenance

7.1 Servicing the solar system

Danger!

Risk of injury and material damage due to

incorrect maintenance and repairs.

Failure to carry out maintenance, or incorrectly completed maintenance, may

adversely affect the operational reliability of

the solar system.

▶ Never attempt to carry out maintenance

work or repairs on the solar system yourself.

▶ Always employ a competent person.

Permanent operational readiness and safety, reliability and

a long working life require inspections and maintenance

work to be carried out annually on the solar system by an

approved competent person.

Regular maintenance ensures maximum efficiency and economical operation of the solar system

We recommend signing up to a maintenance contract.

7.2 Caring for the product

Caution.

Risk of material damage caused by un-

suitable cleaning agents.

Unsuitable cleaning agents can damage the

casing, the fittings or the operator control

elements.

▶ Do not use sprays, scouring agents, de-

tergents, solvents or cleaning agents that

contain chlorine.

12 Instructions for use auroFLOW plus 0020160592_00

Page 13

Decommissioning 8

▶ Clean the casing with a damp cloth and a little solvent-

free soap.

8 Decommissioning

8.1 Switching off the solar charger

▶ Disconnect the product by de-energising it using a parti-

tion with a contact opening of at least 3 mm (e.g. fuses or

power switches).

8.2 Decommissioning the solar system

permanently

▶ Contact a competent person to decommission the solar

system permanently.

8.3 Recycling and disposal

Disposing of the packaging

▶ The competent person who installed your product is re-

sponsible for the disposal of the packaging.

Disposing of the product and accessories

▶ Do not dispose of the product or the accessories with

household waste.

▶ Ensure that the product and all accessories are disposed

of properly.

▶ Observe all relevant regulations.

Disposing of solar fluid

The solar fluid must not be disposed of with normal household waste.

▶ Dispose of the solar fluid in compliance with local regula-

tions through an appropriate disposal company.

▶ Dispose of packaging that cannot be cleaned in the same

way as solar fluid.

Uncontaminated packaging can be reused.

guarantee (this does not affect the customer’s statutory

rights).

9 Customer service and guarantee

9.1 Customer service

To ensure regular servicing, it is strongly recommended

that arrangements are made for a Maintenance Agreement.

Please contact Vaillant Service Solutions (0870 6060 777)

for further details.

9.2 Guarantee

Vaillant provides a full parts and labour guarantee for this

appliance. The appliance and all associated pipe work and

controls must be installed by suitably competent persons

in accordance with all current and relevant safety, building

control and planning regulations and in full compliance with

the manufacturer’s instructions. All unvented domestic hot

water cylinders must be installed by a competent person to

the prevailing building regulations at the time of installation

(G3).

Terms and conditions apply to the guarantee, details of

which can be found on the guarantee registration card

included with this appliance.

Failure to install and commission this appliance in compliance with the manufacturer’s instructions will invalidate the

0020160592_00 auroFLOW plus Instructions for use 13

Page 14

Index

Index

A

Accessories

Disposal.........................................................................13

Article number ................................................................. 4, 12

B

Basic display .........................................................................8

C

Care.....................................................................................12

CE label.................................................................................3

Cleaning ..............................................................................12

Contact details..................................................................... 12

Cylinder charging pump

Operating hours............................................................. 12

D

Decommissioning

Permanently...................................................................13

Solar charger .................................................................13

DIA system ............................................................................ 7

Display................................................................................. 7

Basic display.................................................................... 8

Displayed symbols........................................................... 7

Disposal

Accessories ................................................................... 13

Packaging......................................................................13

Product .......................................................................... 13

Solar fluid....................................................................... 13

Documents ............................................................................4

F

Fault ...................................................................................... 9

Fault message.......................................................................9

H

Heating installation

Leaking ............................................................................3

I

Inspection .............................................................................. 3

Installation .............................................................................3

Instructions

Applicability...................................................................... 4

L

Live Monitor.........................................................................12

M

Maintenance.................................................................... 3, 12

Menu

Design..............................................................................9

Overview........................................................................ 10

O

Operating hours

Cylinder charging pump................................................. 12

Operating level

Competent person ........................................................... 8

Operator...........................................................................8

Operator control elements..................................................... 7

P

Packaging

Disposal.........................................................................13

Product status .....................................................................12

R

Repair....................................................................................3

S

Serial number ...................................................................... 12

Setting the display contrast ................................................. 12

Setting the language ...........................................................12

Solar fluid

Disposal.........................................................................13

Solar system

Servicing........................................................................12

Solar yield

Month............................................................................... 8

Previous day.................................................................... 8

Year .................................................................................8

Symbols.................................................................................7

System

Leaking ............................................................................3

14 Instructions for use auroFLOW plus 0020160592_00

Page 15

Page 16

0020160592_00 30.11.2012

Vaillant Ltd

Nottingham Road Belper Derbyshire DE56 1JT

Telephone 08 45 602 29 22 Vaillant Service Solutions 080 70 606 07 77

info@vaillant.co.uk www.vaillant.co.uk

© Vaillant GmbH 2012

These instructions, or extracts thereof, may only be printed with the written consent of Vaillant GmbH.

All designations of products in these instructions are brand names/trade marks of the companies in question.

We reserve the right to make technical changes.

Loading...

Loading...