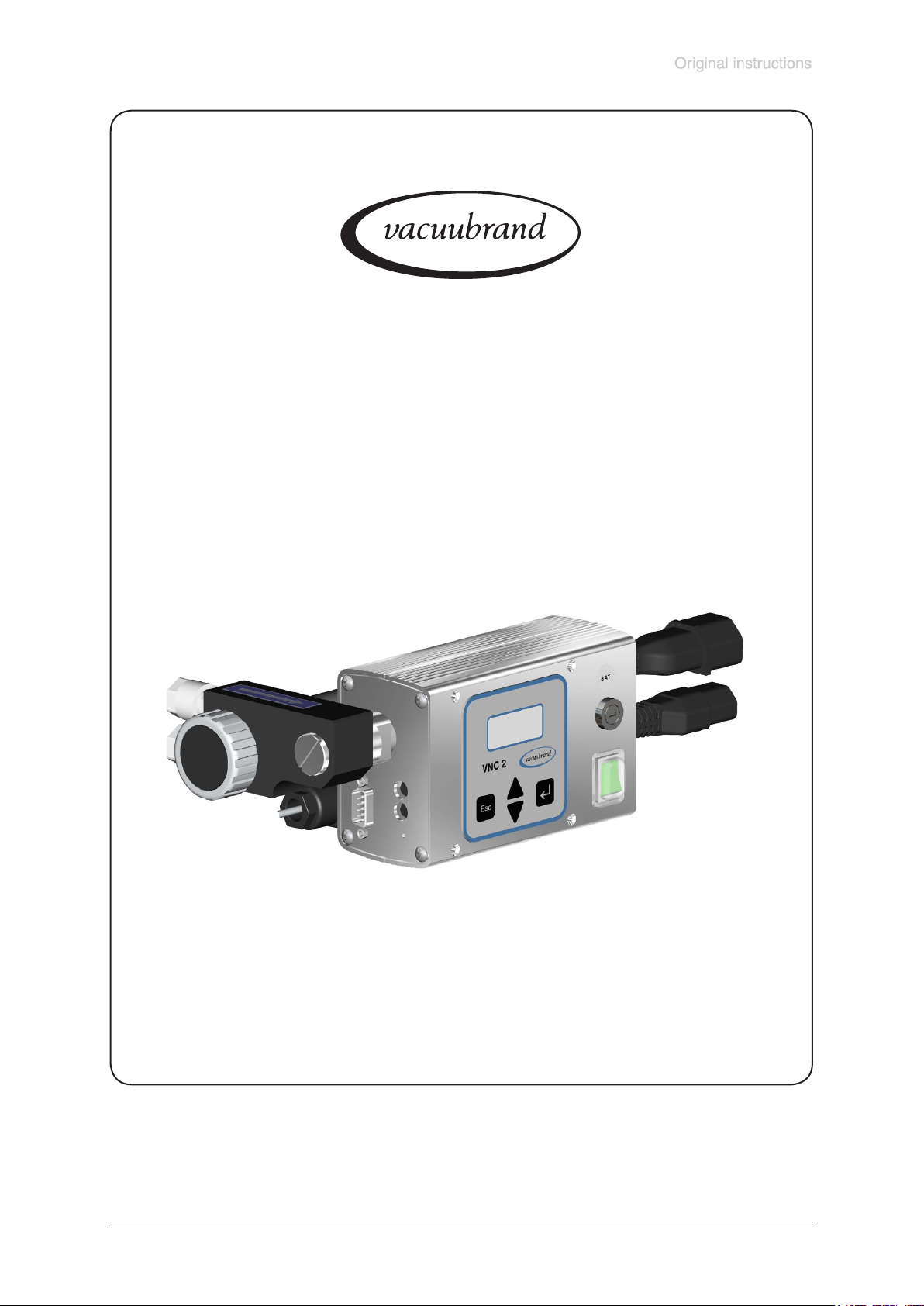

VACUUBRAND VNC 2 E User Manual

page 1 of 41

Technology for Vacuum Systems

Instructions for use

VNC 2 E

Vacuum Controller

Documents are only to be used and distributed completely and unchanged. It is strictly the users´ responsibility to check carefully

the validity of this document with respect to his product. Manual-no.: 999199 / 28/11/2012

page 2 of 41

Dear customer,

Your VACUUBRAND vacuum controller shall support you at your work for a long time without any trouble

and with full load output. Thanks to our large practical experience we attained much information how you

could add to an efcient application and to personal safety. Please read these instructions for use prior

to the initial start-up of your controller.

VACUUBRAND vacuum controllers are the result of many years of experience in construction and practical operation of these vacuum controllers combined with the latest results in material and manufacturing technology.

Our quality maxim is the ”zero fault principle”:

Every delivered vacuum controller is tested extensively including an endurance run. Due to this endurance run, also faults, which occur rarely, are reported an can be corrected. Every single vacuum control-

ler is tested on achievement of the specication after the endurance run.

Every VACUUBRAND controller leaving our factory achieves the specication. We feel obliged

to this high quality standard.

We are aware that the controller should not draw a part of the real work and we hope to contribute with

our products to an effective and trouble-free realisation of your work.

Yours

VACUUBRAND GMBH + CO KG

After sales service:

Contact your local dealer or call +49 9342 808-5500.

The document ”Safety information for vacuum equipment” is part of this

manual! Read the ”Safety information for vacuum equipment” and observe

the instructions contained therein!

Trademark index:

VACUU•LAN® (US-Reg.No 3,704,401), VACUU•BUS®, VACUU•CONTROLTM, chemistry-HYBRIDTM, Peltronic®,

TURBO•MODETM, VARIO® (US-Reg.No 3,833,788), VARIO-SPTM, VACUUBRAND® (US-Reg.No 3,733,388) and

also the shown company logos are trademarks of VACUUBRAND GMBH + CO KG in Germany and/or

other countries.

Documents are only to be used and distributed completely and unchanged. It is strictly the users´ responsibility to check carefully

the validity of this document with respect to his product. Manual-no.: 999199 / 28/11/2012

page 3 of 41

DE

Achtung: Die vorliegende Betriebsanleitung ist nicht in allen EU-Sprachen verfügbar. Der Anwender darf

die beschriebenen Geräte nur dann in Betrieb nehmen, wenn er die vorliegende Anleitung versteht oder

eine fachlich korrekte Übersetzung der vollständigen Anleitung vorliegen hat. Die Betriebsanleitung muss

vor Inbetriebnahme der Geräte vollständig gelesen und verstanden werden, und alle geforderten Maßnahmen müssen eingehalten werden. ”Sicherheitshinweise für Vakuumgeräte”

EN

Attention: This manual is not available in all languages of the EU. The user must not operate the device

if he does not understand this manual. In this case a technically correct translation of the complete

manual has to be available. The manual must be completely read and understood before operation of

the device and all required measures must be applied. ”Safety instructions for vacuum equipment”

FR

Attention: Le mode d’emploi présent n’est pas disponible dans toutes les langues d’Union Européenne.

L’utilisateur ne doit mettre le dispositif en marche que s’il comprend le mode d’emploi présent ou si une

traduction complète et correcte du mode d’emploi est sous ses yeux. Le dispositif ne doit pas être mis en

marche avant que le mode d’emploi ait été lu et compris complètement et seulement si le mode d’emploi

est observé et tous les mesures demandées sont prises. «Avis de sécurité pour des dispositifs à

vide»

BG

Внимание: Тези инструкции не са преведени на всички езици от ЕО. Потребителят не бива да

работи с уреда, ако не разбира инструкциите за ползване. В този случай е необходимо да бъде

предоставен пълен технически превод на инструкциите за ползване. Преди работа с уреда е

задължително потребителят да прочете изцяло инструкциите за работа. ”Указания за безопасност за вакуумни уреди”

CN

注意:该操作手册不提供所有的语言版本。操作者在没有理解手册之前,不能操作该设备。在这种情况

下,需要有一个整个操作手册技术上正确的翻译。在操作该设备前,必须完全阅读并理解该操作手册,

必须实施所有需要的测量。 真空设备的安全信息

CZ

Upozornění :Tento návod k použití není k dispozici ve všech jazycích Evropské unie. Uživatel není

oprávněn požít přístroj pokud nerozumí tomuto návodu. V takovém případě je nutno zajistit technicky

korektní překlad manuálu do češtiny. Návod musí být uživatelem prostudován a uživatel mu musí plně

porozumět před tím než začne přístroj používat. Uživatel musí dodržet všechna příslušná a požadovaná

opatření. ”Bezpečnostní upozornění pro vakuové přístroje”.

DA

Bemærk: Denne manual foreligger ikke på alle EU sprog. Brugeren må ikke betjene apparatet hvis

manualen ikke er forstået. I det tilfælde skal en teknisk korrekt oversættelse af hele manual stilles til rådighed. Manual skal være gennemlæst og forstået før apparatet betjenes og alle nødvendige forholdsregler skal tages. »Sikkerhedsregler for vakuumudstyr«

EE

Tähelepanu! Käesolev kasutusjuhend ei ole kõigis EL keeltes saadaval. Kasutaja ei tohi seadet käsitseda, kui ta ei saa kasutusjuhendist aru. Sel juhul peab saadaval olema kogu kasutusjuhendi tehniliselt

korrektne tõlge. Enne seadme kasutamist tuleb kogu juhend läbi lugeda, see peab olema arusaadav

ning kõik nõutud meetmed peavad olema rakendatud. ”Ohutusnõuded vaakumseadmetele”

ES

Atención: Este manual no está disponible en todos los idiomas de UE. El usuario no debe manejar el

instrumento si no entiende este manual. En este caso se debe disponer de una traducción técnicamen-

te correcta del manual completo. El manual debe ser leído y entendido completamente y deben aplicarse todas las medidas de seguridad antes de manejar el instrumento. ”Notas sobre la seguridad

para equipos de vacío”

Documents are only to be used and distributed completely and unchanged. It is strictly the users´ responsibility to check carefully

the validity of this document with respect to his product. Manual-no.: 999199 / 28/11/2012

page 4 of 41

FI

Huomio: Tämä käyttöohje ei ole saatavilla kaikilla EU: n kielillä. Käyttäjä ei saa käyttää laitetta, jos hän

ei ymmärrä tätä ohjekirjaa. Tässä tapauksessa on saatavilla oltava teknisesti oikein tehty ja täydellinen

ohjekirjan käännös. Ennen laitteen käyttöä on ohjekirja luettava ja ymmärrettävä kokonaan sekä suoritettava kaikki tarvittavat valmistelut ja muut toimenpiteet. ”Vakuumilaitteen turvallisuustiedot”

GR

Προσοχή! : Οι οδηγίες αυτές δεν είναι διαθέσιµες σε όλες τις γλώσσες της Ευρωπαϊκής Ένωσης. Ο χρήστης δεν πρέπει να θέσει σε λειτουργία την συσκευή αν δεν κατανοήσει πλήρως τις οδηγίες αυτές. Σε

τέτοια περίπτωση ο χρήστης πρέπει να προµηθευτεί ακριßή µετάφραση του ßιßλίου οδηγιών. Ο χρήστης

πρέπει να διαßάσει και να κατανοήσει πλήρως τις οδηγίες χρήσης και να λάßει όλα τα απαραίτητα µέτρα

πριν θέσει σε λειτουργία την συσκευή. ”Υποδείξεις ασφάλειας για αντλίες κενού”

HR

Pažnja:ove upute ne postoje na svim jezicima Europske Unije. Korisnik nemora raditi sa aparatom ako

ne razumije ove upute.U tom slucaju tehnicki ispravni prijevod cijelih uputstava mora biti na raspolaganju. Uputstva moraju biti cijela procitana i razumljiva prije rada sa aparatom i sve zahtijevane mjere

moraju biti primjenjene. ”Sigurnosne napomene za vakuumske uređaje”

HU

Figyelem! Ez a kezelési utasítás nem áll rendelkezésre az EU összes nyelvén. Ha a felhasználó nem

érti jelen használati utasítás szövegét, nem üzemeltetheti a készüléket. Ez esetben a teljes gépkönyv

fordításáról gondoskodni kell. Üzembe helyezés előtt a kezelőnek végig kell olvasnia, meg kell értenie

azt, továbbá az üzemeltetéshez szükséges összes mérést el kell végeznie. ”A vákuum-készülékekkel kapcsolatos biztonsági tudnivalók”

IT

Attenzione: Questo manuale non è disponibile in tutte le lingue della Comunità Europea (CE). L‘utilizzatore non deve operare con lo strumento se non comprende questo manuale. In questo caso deve

essere resa disponibile una traduzione tecnicamente corretta del manuale completo. Il manuale deve

essere completamente letto e compreso prima di operare con lo strumento e devono essere applicati

tutti gli accorgimenti richiesti. ”Istruzioni di sicurezza per apparecchi a vuoto”

JP

注意:この取扱説明書はすべての言語で利用可能ではありません。 もしこの取扱説明書を理解できな

いならば、ユーザーは装置を操作してはなりません。 この場合、技術的に正しい翻訳がなされた完全

なマニュアルを用意しなければなりません。 装置を作動する前にマニュアルを完全に読み、そして理

解されなくてはなりません。そして、すべての要求される対策を講じなければなりません。

真空装置を安全に取り扱うために

KR

주의 : 이 매뉴얼은 모든 언어로 번역되지는 않습니다. 만약 이 매뉴얼의 내용을 충분히 인지하지 못했다

면 기기를 작동하지 마십시오. 매뉴얼의 내용을 기술적으로 정확하게 번역한 경우에 이용하십시오. 기기

를 사용하기 전에 이 매뉴얼을 충분히 읽고 이해하고 모든 요구되는 사항들을 적용해야 합니다.

진공 장비에 대한 안전 정보

LT

Dėmesio: šis vadovas nėra pateikiamas visomis ES kalbomis. Naudotojui draudžiama eksploatuoti įtaisą, jeigu jis nesupranta šio vadovo. Tokiu atveju reikia turėti viso vadovo techniškai taisyklingą vertimą.

Vadovą būtina visą perskaityti ir suprasti pateikiamas instrukcijas prieš pradedant eksploatuoti įtaisą, bei

imtis visų reikiamų priemonių. ”Vakuuminės įrangos saugos informacija”

LV

Uzmanību: Lietotāja instrukcija nav pieejama visās ES valodās. Lietotājs nedrīkst lietot iekārtu, ja viņš

nesaprot lietotāja instrukcijā rakstīto. Šādā gadījumā, ir nepieciešams nodrošināt tehniski pareizu visas

lietotāja instrukcijas tulkojumu. Pirms sākt lietot iekārtu, un, lai izpildītu visas nepieciešamās prasības,

iekārtas lietotāja instrukcija ir pilnībā jāizlasa un jāsaprot. ”Vakuuma iekārtu drošības noteikumi”

Documents are only to be used and distributed completely and unchanged. It is strictly the users´ responsibility to check carefully

the validity of this document with respect to his product. Manual-no.: 999199 / 28/11/2012

page 5 of 41

NL

Attentie: Deze gebruiksaanwijzing is niet in alle talen van de EU verkrijgbaar. De gebruiker moet niet

met dit apparaat gaan werken als voor hem/haar de gebruiksaanwijzing niet voldoende duidelijk is. Bij

gebruik van deze apparatuur is het noodzakelijk een technisch correcte vertaling van de complete gebruiksaanwijzing te hebben. Voor het in gebruik nemen van het apparaat moet de gebruiksaanwijzing

volledig gelezen en duidelijk zijn en dienen alle benodigde maatregelen te zijn genomen. ”Veilig-

heidsvoorschriften voor vacuümapparaten”

PL

Uwaga!! Ta instrukcja nie jest dostępna we wszystkich językach Unii Europejskiej. Użytkownik nie może

rozpocząć pracy z urządzeniem dopóki nie przeczytał instrukcji i nie jest pewien wszystkich informacji

w niej zawartych. Instrukcja musi byc w całości przeczytana i zrozumiana przed podjęciem pracy z

urządzeniem oraz należy podjąć wszystkie niezbędne kroki związane z prawidłowym uzytkowaniem.

”Wskazówki bezpieczeństwa do urządzeń próżniowych”

PT

Atenção: Este manual não está disponível em todas as línguas da UE. O usuário não deve utilizar o

dispositivo, se não entender este manual. Neste caso, uma tradução tecnicamente correta do manual

completo tem de estar disponível. O manual deve ser lido e entendido completamente antes da utilização do equipamento e todas as medidas necessárias devem ser aplicadas. ”Informação de Segurança para Equipamento que funciona a Vácuo”

RO

Atentie: Acest manual nu este disponibil in toate limbile EU. Utilizatorul nu trebuie sa lucreze cu aparatul

daca daca nu intelege manualul. Astfel, va disponibile o traducere corecta si completa a manualului.

Manualul trebuie citit si inteles in intregime inainte de a lucra cu aparatul si a luat toate masurile care se

impun. ”Instrucţiuni de siguranţă pentru aparatele de vidare”

RU

Внимание: Эта инструкция по эксплуатации не имеется на всех языках. Потребителю не дозволенно эксплуатировать данный прибор, если он не понимает эту инструкцию. В этом случае нужен технически правильный перевод полной инструкции. Прежде чем использовать этот прибор,

необходимо полностью прочитать и понять эту инструкцию и принять все необходимые меры.

”Указания по технике безопасности при работе с вакуумными устройствами”

SE

Varning: Denna instruktion är inte tillgänglig på alla språk inom EU. Användaren får inte starta utrust-

ningen om hon/han inte förstår denna instruktion. Om så är fallet måste en tekniskt korrekt instruktion

göras tillgänglig. Instruktionen måste läsas och förstås helt före utrustningen tas i drift och nödvändiga

åtgärder göres. ”Säkerhetsinformation för vakuumutrustning”

SI

Pozor: Ta navodila niso na voljo v vseh jezikih EU. Uporabnik ne sme upravljati z napravo, če ne razume

teh navodil. V primeru nerazumljivosti mora biti na voljo tehnično pravilen prevod. Navodila se morajo

prebrati in razumeti pred uporaba naprave, opravljene pa moraja biti tudi vse potrebne meritve.

”Varnostni nasveti za vakuumske naprave”

SK

Upozornenie: Tento manuál nie je k dispozícii vo všetkých jazykoch EÚ. Užívateľ nesmie obsluhovať

zariadenie, pokiaľ nerozumie tomuto manuálu. V takomto prípade musí byť k dispozícii technicky správny preklad celého manuálu. Pred obsluhou zariadenia je potrebné si prečítať celý manuál a porozumieť

mu, a musia byť prijaté všetky opatrenia. ”Bezpečnostné pokyny pre vákuové zariadenia”

TR

Dikkat : Bu kullanım kitabı, tüm dillerde mevcut değildir. Kullanıcı, bu kullanım kitabını anlayamadıysa

cihazı çalıştırmamalıdır. Bu durumda, komple kullanım kitabının, teknik olarak düzgün çevirisinin bulunması gerekir. Cihazın çalıştırılmasından önce kullanım kitabının komple okunması ve anlaşılması ve

tüm gerekli ölçümlerin uygulanması gerekir. ”Vakumlu cihazlar için güvenlik uyarıları”

Documents are only to be used and distributed completely and unchanged. It is strictly the users´ responsibility to check carefully

the validity of this document with respect to his product. Manual-no.: 999199 / 28/11/2012

page 6 of 41

Contents

Safety information ......................................................................................................7

General information ............................................................................................................................7

Intended use .......................................................................................................................................7

Connecting the controller ...................................................................................................................7

Ambient conditions .............................................................................................................................8

Operating conditions .........................................................................................................................8

Safety during operation .....................................................................................................................9

Maintenance and repair ......................................................................................................................9

` Important information: Equipment marking (ATEX) ................................................................... 11

Technical data ...........................................................................................................12

Wetted parts ....................................................................................................................................13

Description ................................................................................................................14

Notes on operation ...................................................................................................17

Menu structure of controller ....................................................................................18

Working with the controller .....................................................................................21

Readjustment ............................................................................................................25

Calibration in the factory .........................................................................................26

Interface parameters ................................................................................................26

Setting of the interface ....................................................................................................................26

Read commands compatible to ”CVC 2000” ...................................................................................27

Write commands compatible to ”CVC 2000” ...................................................................................29

Read commands compatible to ”CVC 3000” ...................................................................................30

Write commands compatible to ”CVC 3000” ...................................................................................33

Troubleshooting .......................................................................................................34

Cleaning the pressure transducer ..........................................................................36

Accessories ..............................................................................................................37

Notes on return to the factory .................................................................................38

Health and safety clearance form ...........................................................................39

EC Declaration of Conformity .................................................................................40

➨ DANGER indicates a hazardous situation which, if not avoided, will re-

☞ WARNING indicates a hazardous situation which, if not avoided, could

• CAUTION indicates a hazardous situation which, if not avoided, could

NOTICE

NOTICE is used to address practices not related to personal injury.

Isolate equipment from mains.

sult in death or serious injury.

result in death or serious injury.

result in minor or moderate injury.

Documents are only to be used and distributed completely and unchanged. It is strictly the users´ responsibility to check carefully

the validity of this document with respect to his product. Manual-no.: 999199 / 28/11/2012

Safety information

General information

☞ Read and comply with this manual before installing or operating the equip-

ment.

☞ Do not use the equipment if it is damaged.

To operate the vacuum controller, valves and/or vacuum pumps are necessary. Oth-

NOTICE

erwise the controller works as measuring device.

Remove all packing material, remove the product from its packing-box, remove the

protective covers and keep, inspect the equipment.

If the equipment is damaged, notify the supplier and the carrier in writing within three

days; state the item number of the product together with the order number and the

supplier’s invoice number. Retain all packing material for inspection.

If the equipment is not used immediately, replace the protective covers. Store the

equipment in suitable conditions.

page 7 of 41

NOTICE

Intended use

☞ Ensure that the individual components are only connected, combined and oper-

ated according to their design, or with OEM parts, and as indicated in the instructions for use.

☞ Comply with notes on correct vacuum and electrical connections, see section

„Description“, pg. 14.

☞ The equipment is designed for ambient and gas temperatures at continuous

operation between +10°C and +40°C and up to 80°C for short periods at the

vacuum connection. Check the maximum temperatures, especially if installing

the equipment in a cabinet or a housing and make sure ventilation is adequate.

Ensure that the maximum permitted gas temperature at the pressure transducer

(see „Technical data“, pg. 12) is not exceeded.

Use the equipment and all system parts for the intended use only, i.e. for control

and measurement of vacuum in vessels designed for that purpose.

Connecting the controller

☞ Do not permit any uncontrolled pressurizing (e.g., make sure that pipelines

cannot become blocked) to avoid a risk of bursting!

☞ Check the maximum ambient and gas temperatures (see „Technical data“, pg.

12, especially if installing the equipment in a cabinet or a housing or in case of

elevated ambient temperatures.

• Comply with max. permitted pressure at the pressure transducer, see section

„Technical data“, pg. 12.

• Connect hoses gas tight at the vacuum connection of the pressure transducer.

• Ensure the stability of hose connections.

Documents are only to be used and distributed completely and unchanged. It is strictly the users´ responsibility to check carefully

the validity of this document with respect to his product. Manual-no.: 999199 / 28/11/2012

NOTICE

page 8 of 41

• Check the power source and the equipment’s rating plate to be sure that the

power source and the equipment match in voltage, phase, and frequency.

• In case of residues or aggressive or condensable media install a gas washing

bottle if necessary.

• Use inert gas for venting if necessary. Avoid overpressure of more than 0.2 bar in

case inert gas is connected.

The VNC 2E is equipped with a short circuit proof wide range power supply with

an integrated overload protection. The VNC 2E is equipped with a fuse T8A.

Avoid high heat supply (e. g. due to hot process gases).

Connect the equipment to the vacuum application.

Position the controller and its vacuum connection lines in such a way that condensate cannot ow towards the pressure transducer.

Allow the equipment to equilibrate to ambient temperature if you bring it from cold

environment into a room prior to operation. Notice if there is water condensation on

cold surfaces.

Comply with national safety regulations and safety requirements concerning the

use of vacuum and electrical equipment. Comply with all applicable and relevant

safety requirements (regulations and guidelines), implement the required ac-

tions and adopt suitable safety measures.

NOTICE

Do not connect to a VACUUBRAND NT VARIO pump or pumping unit.

Ambient conditions

☞ Pay attention to the permissible maximum ambient and gas temperatures

(see „Technical data“, pg. 12).

• Adopt suitable measures in case of differences from recommended conditions,

e.g., using the equipment outdoors, conductive pollution or external condensation.

To the best of our knowledge the equipment is in compliance with the requirements

of the applicable EC-directives and harmonized standards (see ”Declaration of conformity”) with regard to design, type and model. Directive EN 61010-1 gives in detail

conditions under which the equipment can be operated safely (see also IP degree of

protection, pg. 12).

Operating conditions

➨ This device is not approved for operation in potentially explosive atmospheres.

Do not operate the device in potentially explosive atmospheres.

➨ Controllers without the ”`” mark on the rating plate are not approved for opera-

tion with dangerous or explosive gases or with potentially explosive or inammable substances. Do not operate the controller with dangerous or explosive gases

or with potentially explosive or inammable substances.

➨ Controllers bearing the ”`” mark on their rating plates are approved for op-

eration with potentially explosive atmospheres according to their classication

II 3G IIC T3 X according to ATEX, but they are not approved for operation in potentially explosive atmospheres (see section „` Important information: Equipment marking (ATEX)“, pg. 11.

Documents are only to be used and distributed completely and unchanged. It is strictly the users´ responsibility to check carefully

the validity of this document with respect to his product. Manual-no.: 999199 / 28/11/2012

page 9 of 41

• Ensure that the materials of the controller’s wetted parts are compatible with the

substances in the vacuum system, see section „Technical data“, pg. 12.

Safety during operation

➨ Adopt suitable measures to prevent the release of dangerous, toxic, explosive,

corrosive, noxious or polluting uids, vapours and gases.

☞ Prevent any part of the human body from coming into contact with vacuum.

☞ Attention: At pressures above approximately 1100 mbar the pressure reading

becomes incorrect due to saturation of the pressure transducer.

Release pressure immediately! Risk of bursting!

At pressures above 1060 mbar the display ashes.

”p Error” is displayed and the controller sounds ve blips.

☞ Use only original manufacturer’s spare parts and accessories. Otherwise the

safety and performance of the equipment, as well as the electromagnetic compatibility of the equipment might be reduced.

The CE mark or the cTÜVus mark may be voided if not using original manufac-

turer’s spare parts.

NOTICE

• Switching of an in-line valve or a vacuum pump, or opening of a venting valve by

the controller must not lead to a critical dangerous situation under any circumstances.

• Attention: If Auto-Start ”Auto-St.” is preselected, the process starts immedi-

ately after a power failure without pressing any further key. It is the user’s responsibility to ensure that no dangerous status of the system due to the automatic

start-up can occur and to provide appropriate safety measures. If necessary, the

user has to check prior to starting process control, whether the option ”AutoStart” is enabled.

Electronic equipment is never 100% fail-safe. This may lead to an ill-dened status of the equipment or of other connected devices. Provide appropriate protective

measures to allow for the possibility of failure and malfunction. The protective measures must also allow for the requirements of the respective application.

Maintenance and repair

➨ Switch off the vacuum controller.

➨ Disconnect the power supply and wait two minutes before starting maintenance

to allow the capacitors to discharge.

➨ Note: The equipment may be contaminated with chemicals, which have been

processed during operation. Ensure that the equipment is completely decontaminated before maintenance commences. Take adequate precautions to protect

people from the effects of dangerous substances if contamination has occurred.

Use appropriate protective clothing, safety goggles and protective gloves.

☞ Before starting maintenance vent the vacuum controller and isolate it from the

vacuum system.

Documents are only to be used and distributed completely and unchanged. It is strictly the users´ responsibility to check carefully

the validity of this document with respect to his product. Manual-no.: 999199 / 28/11/2012

NOTICE

page 10 of 41

Ensure that maintenance is done only by suitably trained and supervised technicians. Ensure that the maintenance technician is familiar with the safety procedures

which relate to the products processed in the vacuum system.

Interior components of the controller can only be repaired at the factory.

In order to comply with law (occupational, health and safety regulations, safety at

work law and regulations for environmental protection) vacuum pumps, components

and measuring instruments returned to the manufacturer can be repaired only when

certain procedures (see section „Notes on return to the factory“, pg. 38) are followed.

Documents are only to be used and distributed completely and unchanged. It is strictly the users´ responsibility to check carefully

the validity of this document with respect to his product. Manual-no.: 999199 / 28/11/2012

page 11 of 41

` Important information: Equipment marking (ATEX)

VACUUBRAND equipment bearing mark (see rating plate)

II 3G IIC T3 X

Internal Atm. only

Tech. File Ref.: VAC-EX01

and

VACUUBRAND equipment bearing mark (see rating plate)

X see manual

For equipment labelled with „ X see manual“ the following classication according to Directive 94/9/EC (ATEX) is

valid:

The classication II 3G IIC T3 X according to ATEX is only valid for the inner part (wetted part, pumped gas or vapor)

of the equipment. The equipment is not suitable for use in external, potentially explosive atmospheres (environment).

II 3G IIC T3 X, Internal Atm. only, Tech. File Ref.: VAC-EX01.

The overall category of the equipment depends on the connected components. If the connected components do not

comply with the classication of the VACUUBRAND equipment, the specied category of the VACUUBRAND equipment is no longer valid.

Vacuum pumps and vacuum gauges in category 3 are intended for connection to equipment in which during normal

operation explosive atmospheres caused by gases, vapors or mists normally don’t occur or, if they do occur, are likely

to do so only infrequently and for a short period only.

Equipment in this category ensures the requisite level of protection during normal operation.

The use of gas ballast or the operation of venting valves is only permitted if thereby explosive atmospheres normally

don’t occur in the interior of the equipment or, if they do occur, are likely to do so only infrequently and for a short

period.

The pumps are marked with ”X” (according to EN 13463-1), i.e., restrictions of the operation conditions:

• The equipment is designated for a low degree of mechanical stress and has to be installed in a way so that it cannot be damaged from outside.

Pumping units have to be installed protected against shocks from the outside and against glass splinters in the

event of breaking (implosion).

• The equipment is designated for an ambient and gas inlet temperature during operation of +10 to +40°C. Never

exceed these ambient and gas inlet temperatures. If pumping / measuring gases which are not potentially explosive, extended gas inlet temperatures are valid, see instructions for use, section “Gas inlet temperatures” or

“Technical data”.

After any intervention at the equipment (e.g., repair / maintenance) the ultimate vacuum of the pump has to be

checked. Only if the pump achieves its specied ultimate vacuum, the pump’s leak rate is low enough to ensure that

no explosive atmospheres will occur in the interior of the equipment.

After any intervention at the vacuum sensor the leak rate of the equipment has to be checked.

Attention: This manual is not available in all languages of the EU. The

user must not operate the device if he does not understand this manual.

In this case a technically correct translation of the complete manual has

to be available. The manual must be completely read and understood before operation of the device and all required measures must be applied.

Documents are only to be used and distributed completely and unchanged. It is strictly the users´ responsibility to check carefully

the validity of this document with respect to his product. Manual-no.: 999199 / 28/11/2012

page 12 of 41

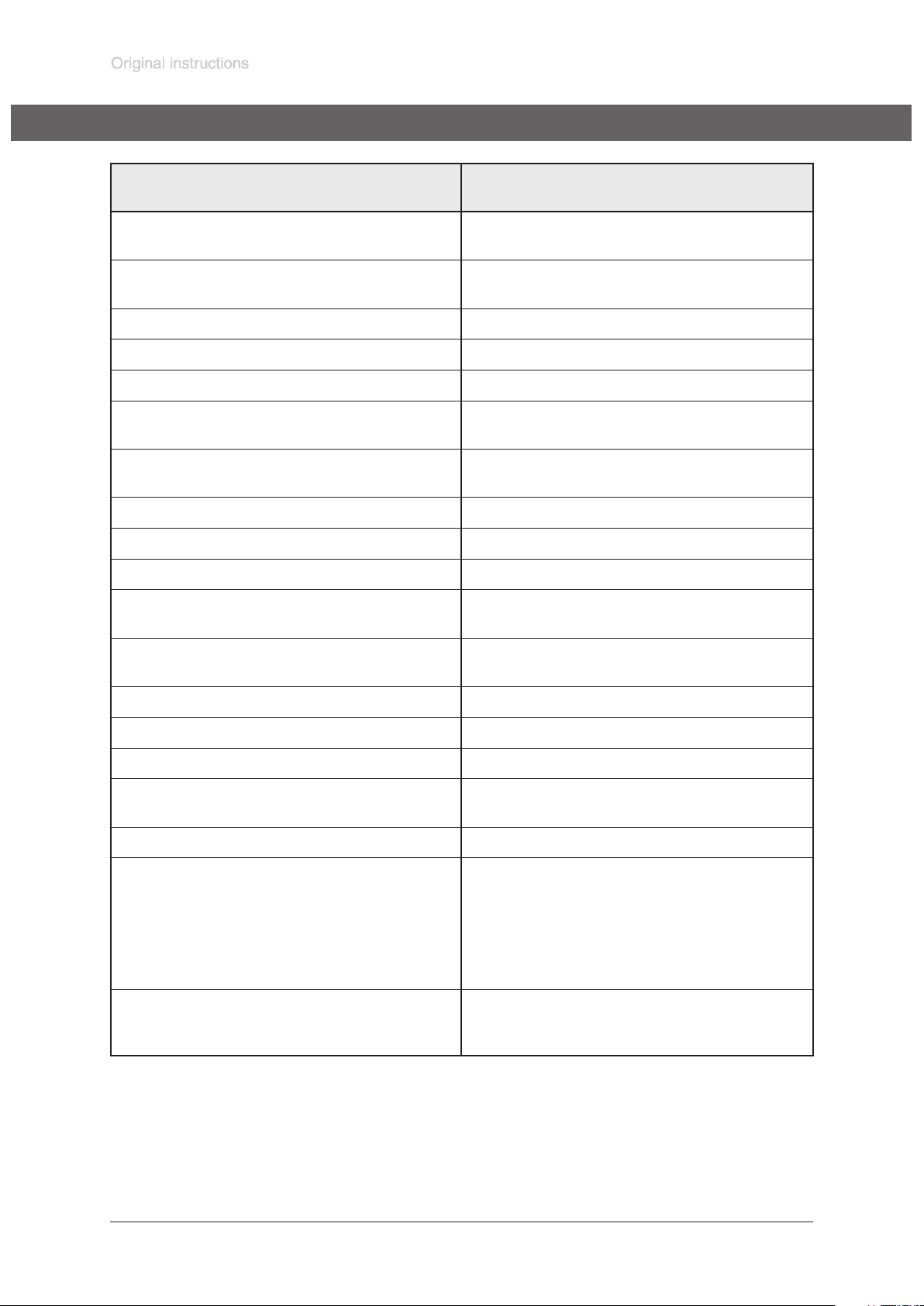

Technical data

Controller VNC 2 E

Pressure transducer

Display

Pressure units / scale (selectable) mbar, Torr or hPa

Measuring range (absolute) 1100 mbar - 1 mbar (825 Torr - 1 Torr)

Maximum range of pressure control (absolute)* 1060 mbar – 1 mbar (795 Torr – 1 Torr)

Maximum permissible pressure at pressure

transducer (absolute)

Measurement uncertainty (absolute) after careful

adjustment and at constant temperature

Temperature coefcient <± 0.07 mbar/K (0.05 Torr/K)

Ambient temperature range (operation) 10°C to +40°C

Ambient temperature range (storage) -10°C to +70°C

Permissible relative atmospheric moisture during

operation (no condensation)

Maximum permissible temperature of gaseous

media at pressure transducer

capacitive, absolute pressure transducer made of

aluminium oxide ceramics, independent of gas type

alphanumeric LCD display, illuminated

2 x 8 characters

1.5 bar (1125 Torr)

<±1 mbar (0.75 Torr) ±1 digit

30% to 85%

continuous operation: 40°C**

for short periods up to 80°C**

Max. permissible range of supply voltage 100 V~ (-10%) to 230 V~ (+10%) 50/60 Hz

Fuse (IEC connection) 5x20 mm, T 8 A / 250 V

Power draw (no-load operation) 3 VA

Power draw with VACUUBRAND VV-B 6C in-line

valve and coolant valve VKW-B

Serial interface RS 232 C

Supply line VACU•UBUS

voltage supply 110-230 V 50/60 Hz

voltage supply 100-110 V 50/60 Hz

designed for the simultaneous operation (parallel

connection) with the following original accessories:

Breaking capacity of IEC socket***

ambient temperature 30°C

ambient temperature 40°C

* The actual available range of the vacuum control can be limited due to the ultimate vacuum of the

pump, the developed amount of gas, etc.

** if pumping potentially explosive atmospheres: +10°C to +40°C

*** ohm resistive (inductive) load

max. 10 VA (without switch output)

24 V, max. 400 mA

24 V, max. 340 mA

one in-line valve VV-B 6C 24V=

one coolant valve VKW-B 24 V=

one venting valve VB M-B 24 V=

7.2(4) A 250 V~ / 7.2(7.2) A 125 V~

6(4) A 250 V~ / 6(6) A 125 V~

We reserve the right for technical modications without prior notice!

Documents are only to be used and distributed completely and unchanged. It is strictly the users´ responsibility to check carefully

the validity of this document with respect to his product. Manual-no.: 999199 / 28/11/2012

page 13 of 41

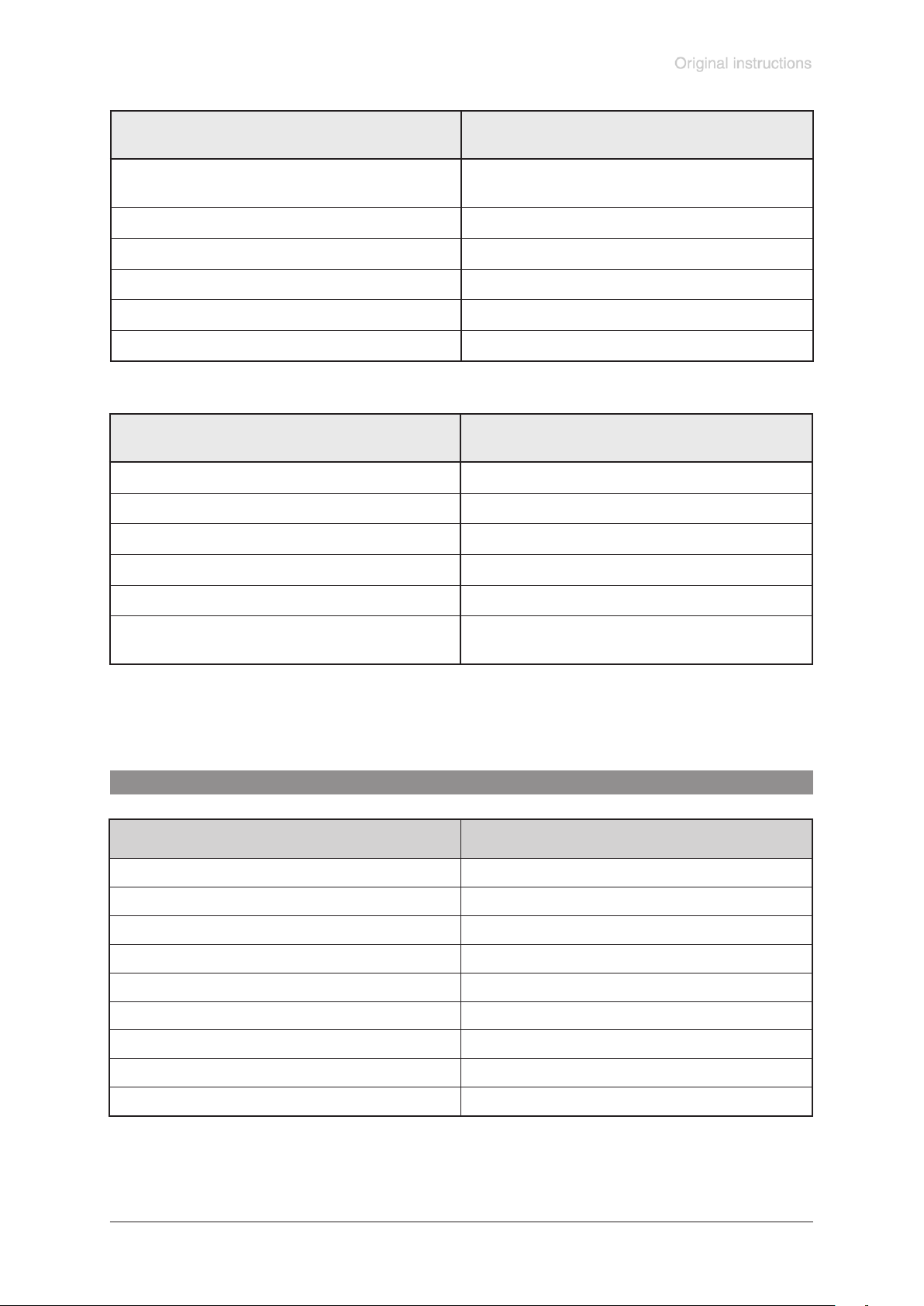

Controller VNC 2 E

Degree of protection according to IEC 529

Vacuum connection hose connection for PTFE tubing 8/10mm

Weight 1.4 kg

Dimensions (without cable) L x W x H 203 x 90 x 130 mm

Installation depth behind rear of front panel 130 mm

Mains connection IEC plug / socket at cable 1m

IP 20 (rear)

IP 54 (front)

Solenoid operated valve

Operating cycles per minute max. 50

Power draw 6 W

Power supply

Current draw approx. 0.22 A

Degree of protection according to IEC 529 IP 65

24 V= ±10%

Max. permitted difference pressure, pressure

gradient in direction of ow-through

➨ The VACUUBRAND controller VNC 2 E can only be operated with components compatible to the

VACUUBRAND VACUU•BUS system, see accessories.

1.5 bar

Wetted parts

Components Wetted materials

Sensor aluminium oxide ceramics

Sensor housing PPS / glass bre

Sensor seal chemically resistant uoroelastomer

Valve block PP

O-rings FPM

Housing of isolation valve PVDF

Non return valve FFKM

Diaphragm / seal ring PTFE

Screw-in ttings PVDF

We reserve the right for technical modications without prior notice!

Documents are only to be used and distributed completely and unchanged. It is strictly the users´ responsibility to check carefully

the validity of this document with respect to his product. Manual-no.: 999199 / 28/11/2012

Loading...

Loading...