VACUUBRAND VNC 1 User Manual

page 1 of 35

Technology for Vacuum Systems

Instructions for use

VNC 1

Vacuum Controller

Documents are only to be used and distributed completely and unchanged. It is strictly the users´ responsibility to check

carefully the validity of this document with respect to his product. Manual-no.: 999118 / 16/12/2009

page 2 of 35

Dear customer,

Your VACUUBRAND vacuum controller shall support you at your work for a long time without any trouble

and with full load output. Thanks to our large practical experience we attained much information how you

could add to an efficient application and to personal safety. Please read these instructions for use prior to

the initial start-up of your controller.

VACUUBRAND vacuum controllers are the result of many years of experience in construction and practical

operation of these vacuum controllers combined with the latest results in material and manufacturing

technology.

Our quality maxim is the ”zero fault principle”:

Every delivered vacuum controller is tested extensively including an endurance run. Due to this endurance

run, also faults, which occur rarely, are reported an can be corrected. Every single vacuum controller is

tested on achievement of the specification after the endurance run.

Every VACUUBRAND controller leaving our factory achieves the specification. We feel obliged to

this high quality standard.

We are aware that the controller should not draw a part of the real work and we hope to contribute with our

products to an effective and troublefree realisation of your work.

Yours

VACUUBRAND GMBH + CO KG

After sales service: Contact your local dealer or call +49 9342 808-193.

Documents are only to be used and distributed completely and unchanged. It is strictly the users´ responsibility to check

carefully the validity of this document with respect to his product. Manual-no.: 999118 / 16/12/2009

page 3 of 35

Contents

Safety information! ....................................................................................................4

Technical data............................................................................................................ 6

Description ................................................................................................................8

Notes on operation.................................................................................................. 13

General view of factory-set modes .........................................................................14

Menu structure of controller ...................................................................................15

Working with the controller .....................................................................................18

Readjustment ..........................................................................................................24

Calibration in the factory......................................................................................... 25

Interface parameters ............................................................................................... 25

Read commands .....................................................................................................26

Write commands...................................................................................................... 28

Troubleshooting ...................................................................................................... 30

Cleaning the pressure transducer .........................................................................31

Notes on return to the factory ................................................................................ 32

Health and safety clearance form ..........................................................................33

Attention! Important notes!

Not permitted! Misuse may cause damage.

Isolate equipment from mains.

Note.

Documents are only to be used and distributed completely and unchanged. It is strictly the users´ responsibility to check

carefully the validity of this document with respect to his product. Manual-no.: 999118 / 16/12/2009

Safety information!

Remove all packing material, remove the protective covers and keep, inspect the

equipment.

If the equipment is damaged, notify the supplier and the carrier in writing within three

days; state the item number of the product together with the order number and the

supplier’s invoice number. Retain all packing material for inspection.

Do not use the equipment if it is damaged.

If the equipment is not used immediately, replace the protective covers. Store the

equipment in suitable conditions.

☞ Read and obey this manual before installing or operating the equipment.

☞ For operation valves and/or vacuum pumps are necessary.

Use the equipment for the intended use only (for generation and measurement of

vacuum).

☞ Obey notes on correct vacuum and electrical connections.

☞ Make sure that the individual components are only connected, combined and oper-

ated according to their design and as indicated in the instructions for use.

page 4 of 35

Obey national safety regulations and safety requirements concerning the use of

vacuum and electrical equipment.

☞ Equipment must be connected only to a suitable fused and protected electrical

supply and a suitable earth point. Failure to connect the pumping unit to ground

may result in deadly electrical shock.

☞ Check that mains voltage and current conform with the equipment (see rating plate).

☞ Make sure ventilation is adequate if the controller is installed in a housing or if the

ambient temperature is elevated.

To the best of our knowledge the equipment is in compliance with the requirements of

the applicable EC-directives and harmonized standards (see “Declaration of conformity”) with regard to design, type and model, especially directive IEC 1010. This directive

gives in detail conditions, under which the equipment can be operated safely (see also

IP degree of protection).

☞ Adopt suitable measures in case of differences, e. g. using the equipment outdoors,

installation in altitudes of more than 1000 m above mean sea level, conductive

pollution or dewiness.

The devices are not suitable for applications which involve dangerous or explosive

gases or explosive or flammable mixtures. Ensure that the materials of the wetted

parts are compatible with the pumped substances, see section “Technical data”.

☞ Adopt suitable measures to prevent the release of dangerous, explosive, corrosive

or polluting fluids.

☞ In case of residues, aggressive or condensable media install a gas washing bottle,

if necessary.

☞ Position the device and the vacuum line in a way that condensate can not reach the

pressure transducer.

☞ If necessary connect inert gas for venting.

Max. permitted pressure: 2 bar (absolute).

☞ At pressures higher than 1060 mbar the display flashes. Error message ”p Er-

ror” appears, four beeps.

➨ Immediate pressure relief necessary! Risk of bursting!

Attention: At pressures above 1100 mbar the device does no longer display the cor-

rect pressure values (pressure transducer saturated).

Documents are only to be used and distributed completely and unchanged. It is strictly the users´ responsibility to check

carefully the validity of this document with respect to his product. Manual-no.: 999118 / 16/12/2009

page 5 of 35

The controller is equipped with a short circuit proof wide-range power supply with

integrated overload protection.

☞ Failure of the device (e. g. by power failure) or of connected components must not

lead to a critical dangerous situation under any circumstances.

Electronic equipment is never 100% fail-safe. This may lead to an ill-defined status of

the equipment or of other connected devices. Provide protective measures against

misfunction and failure. Ensure that in case of failure the controller and the vacuum

system always will turn into a safe status.

Attention: If Auto-Start (Auto-St.) is preselected, the process starts immediately

after switching on the controller without pressing any further key. It is the user’s responsibility to ensure that no dangerous status of the system due to the automatic startup

of the pump,e.g. after a power failure, can occur and to provide appropriate safety

measures. If necessary, the user has to check prior to using the equipment if the

option ”Auto-Start” is enabled.

Use only genuine spare parts and accessories.

☞ Otherwise safety and performance of the equipment as well as the electromagnetic

compatibility of the equipment might be reduced.

Ensure that maintenance is done only by suitably trained and supervised technicians.

Ensure that the maintenance technician is familiar with the safety procedures which

relate to the product processed by the vacuum system and that the equipment, if

necessary, is appropriately decontaminated before starting maintenance.

Obey local and national safety regulations.

Before starting maintenance vent the system, isolate the vacuum controller from the

vacuum system and the electrical supply.

Wait two minutes after isolating the equipment from mains to allow the capacitors to

discharge.

Attention: Due to the operation the device might be contaminated by harmful or dangerous substances.

Interior components of the controller can only be repaired at the factory.

In order to comply with law (occupational, health and safety regulations, safety at work

law and regulations for environmental protection) vacuum pumps, components and

measuring instruments returned to the manufacturer can be repaired only when certain

procedures (see section “Notes on return to the factory“) are followed.

Documents are only to be used and distributed completely and unchanged. It is strictly the users´ responsibility to check

carefully the validity of this document with respect to his product. Manual-no.: 999118 / 16/12/2009

Technical data

rellortnoC 1CNV

page 6 of 35

recudsnarterusserP edamrecudsnarterusserpetulosbaeviticapac

yalpsiD sretcarahc8x2

)neewteb

nemerusaeM )rroT1-rroT528(rabm1-rabm0011

tneiciffeocerutarepmeT )K/rroT50,0(K/rabm70,0-/+<

n(noitarepo

esuF V052/A8T,mm02x

evlav

)etulosba(egnart

)noitasnednoco

)noitarepodaol-on(wardrewoP AV3

DNARBUUCAVhtiwwardrewoP

dehctiwsebot(noisrevnocelacscinortcelE

*)etulosba(lortnocerusserpfoegnar.xaM )rroT1-rroT597(rabm1-rabm

ylluferacrecudsnarthtiw(ytniatrecnU

)erutarepmettnatsnoctadnadetarbilac

noitarepotaerutarepmettneibmadettimreP C°04+otC°01

rotstaerutarepmettneibmadettimreP C°07+otC°01-

ega

gniruderutsiomcirehpsomtaevitalerdettimreP

ylppusegatlovfoegnardettimrep.xaM zH06/05)%01+(~V032ot)%01-(~V001

retawgniloocdnaevlavnoitalosi-C6VV

0601

<

5

cimarecedixomuinimulafo

,yalpsidDCLlaciremunahpla

aPhrorroT,rabm

tigid1-/+)rroT57,0(rabm1-/+

%58ot%03

ctiwstuohtiw(AV01.xam

)tuptuoh

:tekcosedoidfoyticapacgnikaerB

zH06/05V032-011ylppusegatlov

gatlov

seirossecca

epmettneibma

itcetorpfoeergeD

noitcennocmuucaV

noisrevgnisuoh

noisrevni-tliub

aM

ecafretnilaireS C232SR

* The actual available range of the vacuum control can be limited due to the ultimate vacuum of the pump, the developed amount of gas, etc.

** ohm resistive (inductive) load

C°03erutar

C°04erutarepmettneibma

noisrevni-tliubfoedistnorf

)etulosba(recudsnart

recudsnarterusserpta

zH06/05V011-001ylppuse

noitareposuoenatlumisehtrofdengised

lanigirogniwollofehthtiw)noitcennoclellarap(

**tekcosCEIfoyticapacgnikaerB

925CEIotgnidroccano

erusserptaerusserpdettimrep.x

aidemsuoesagfoerutarepmetdettimrep.xaM

)tekcosedoidaiv(tupnirorrelanretxE V42-5

.xam,V42

02PI

45PI

gnibut

Am004

Am043.xam,V42

C6VVevlavnoitalosi-

=V42evlavretawgnilooc-

~V521A)2,7(2,7,~V052A)4(2,7

~V521A)6(6,~V052A)4(6

sohmuucavrofelzzonesoh

.D.Imm01-6

)rroT0051(rab2

usdoireptrohsrof

htiwse

EFTProf8/01WNnoitcennocesohdewercs

C°08otp

We reserve the right for technical modifications without prior notice!

Documents are only to be used and distributed completely and unchanged. It is strictly the users´ responsibility to check

carefully the validity of this document with respect to his product. Manual-no.: 999118 / 16/12/2009

page 7 of 35

rellortnoC 1CNV

)noisrevni-tliub(elbacfohtgneL m1.xorppa

)noisrevni-tliub/noisrevgnisuoh(thgieW gk1/8,0

vtuohtiw(snoisnemiD

HxWxLnoisrevgnisuoh

)tinupotelbatylno(dordnatS 8Mdaerht

niaM

wardrewoP

ylppusrewoP

wardtnerruC

rgeD

noisrevgnisuohylppuss

noisrevni-tliub

evlavdetarepodioneloS

etunimrepselcycgnitarepO

925CEInoitcetorpfoee

hguorht-wolffonoitceridnitneidarg

)snoitcennocmuuca

HxWxL)elbactuohtiw(noisrevni-tliub

)lenaptnorfforaerdniheb(htpednoitallatsnI mm06

05.xam

W6

%01-/+=V42

A22,0.ac

56PI

erusserp,erusserpecnereffiddettimrep.xaM

rab5,1

mm27xmm09xmm441

mm76xmm09xmm441

noitanibmocCEIdetargetni

elbactatekcos/gulpCEI

stnenopmoC strapdetteW

elzzonesoh/noitcennocmuucaVSPP/leetssselniats

noitcennocesohdewercs/noitcennocmuucaVFDVP/leetssselniats

noitcennocmuucav(noitcennocesohdewercSFDVP

)

)noitcennocmuucav(gnittifwoblEEFTCE/EFTE

r-O/retpadAMPF/PP

gnisuohrecudsnarterusserPleetssselniats

slaeS remotsaleoroulftnatsiseryllacimehc

rterusserP cimarecedixomuinimula

kcolbevlaVEP

evlaVMKFF

wolloHleetssselniats

wercs

gulpdnilBPP

recudsna

evlavdetarepodioneloS remotsaleoroulf/EFTP/FDVP

)noitcennocmuucav(gni

We reserve the right for technical modifications without prior notice!

Accessoires:

Isolation valve VV 6C 24 V= ...................................................................................................... 67 40 91

Isolation valve VV 15C, 24 V=, DN 16 ......................................................................................... 67 41 10

Isolation valve VV 15C 24 V=, DN 25 ......................................................................................... 67 41 15

Isolation valve VV 25, 230 V, DN 25 ............................................................................................ 67 41 05

Cooling water valve 24 V= ........................................................................................................... 67 60 13

VARIO adapter cable .................................................................................................................. 63 71 76

Cable RS 232C nine-pole Sub-D ..................................................................................................63 78 37

Documents are only to be used and distributed completely and unchanged. It is strictly the users´ responsibility to check

carefully the validity of this document with respect to his product. Manual-no.: 999118 / 16/12/2009

Description

After the connection of components the controller can be operated in different basic

modes, see ”Basic modes and menu structure”.

When switching on the controller, the current basic mode and the number of version

are displayed for 2s.

page 8 of 35

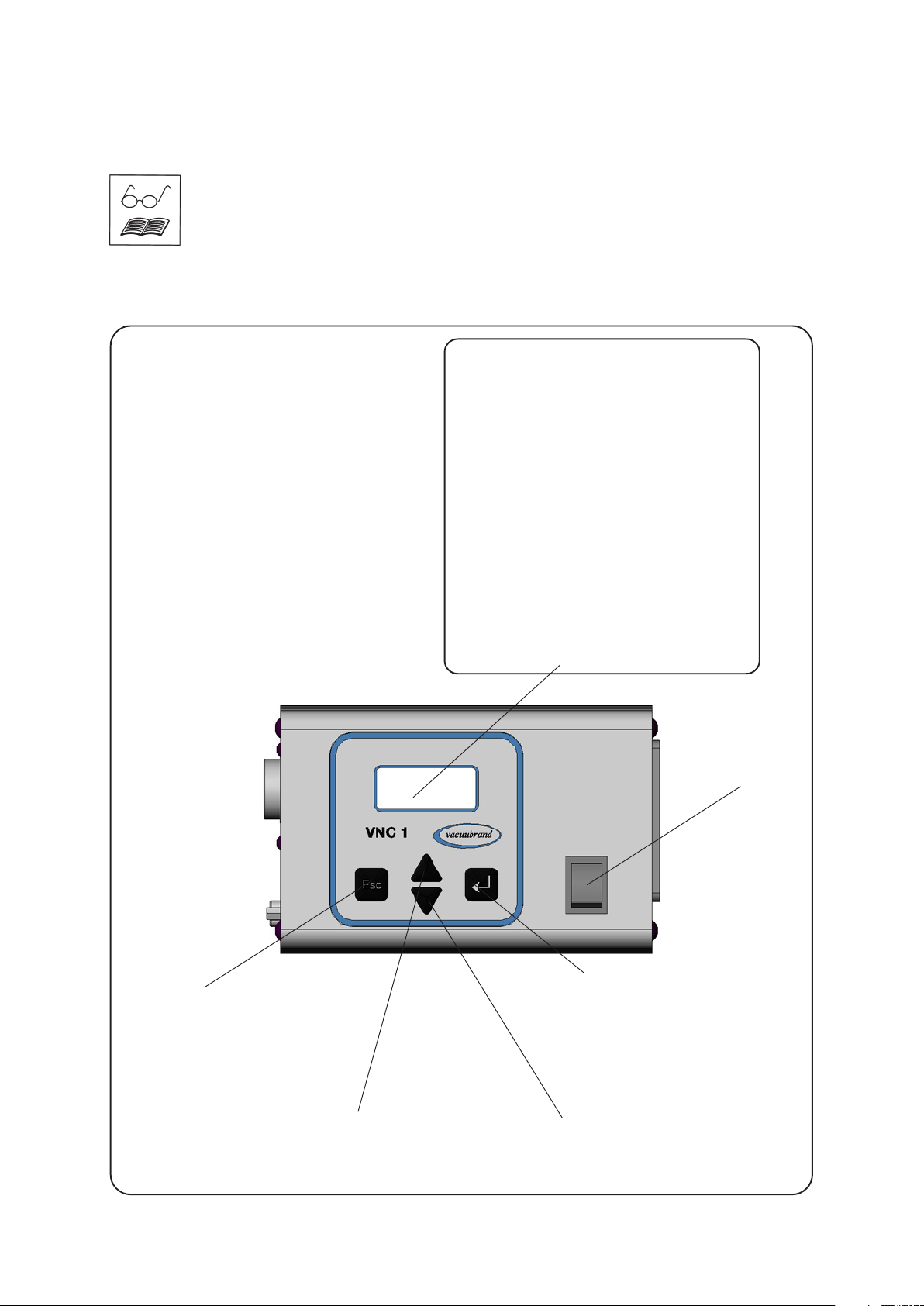

Display and keys

Display

In menus

line1: caption

line 2: menu item

In submenus (only setting of RS 232C)

line 1: menu item (RS 232)

line 2: submenu

After selection of menu item

line 1: menu item (or submenu)

line 2: value to be set

In program

line 1: pressure

line 2: status message

mains switch

key ”Esc”:

- go to previous level of program

(operation menu)

- interruption of operation (reset to

previous settings)

- stop of control

key ”up”

- select menu

- previous menu item

- increase value

Documents are only to be used and distributed completely and unchanged. It is strictly the users´ responsibility to check

carefully the validity of this document with respect to his product. Manual-no.: 999118 / 16/12/2009

key ”Enter”

- start of control

- next step in menu setting

- adopt set value and quit menu

key ”down”

- select menu

- next menu item

- decrease value

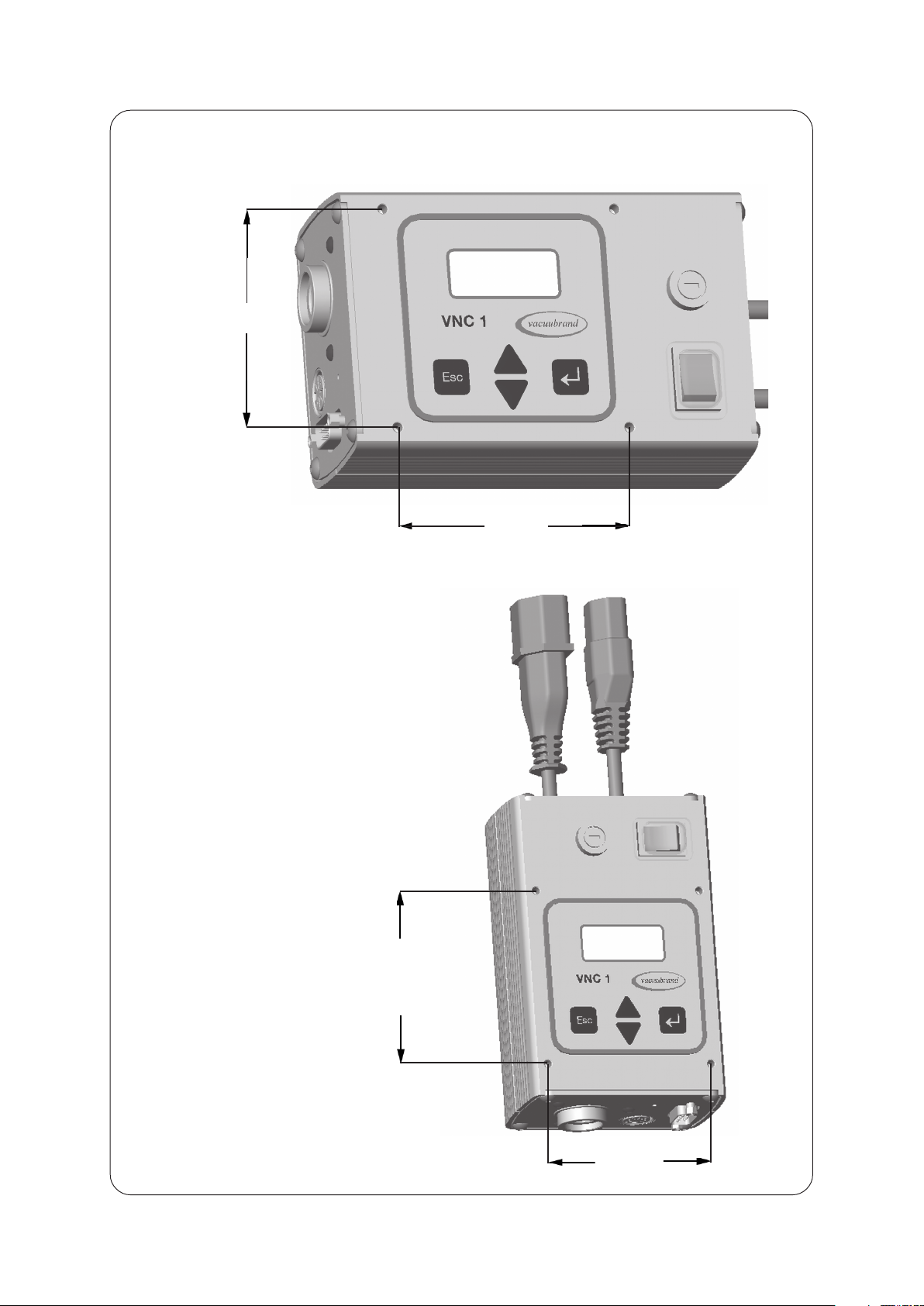

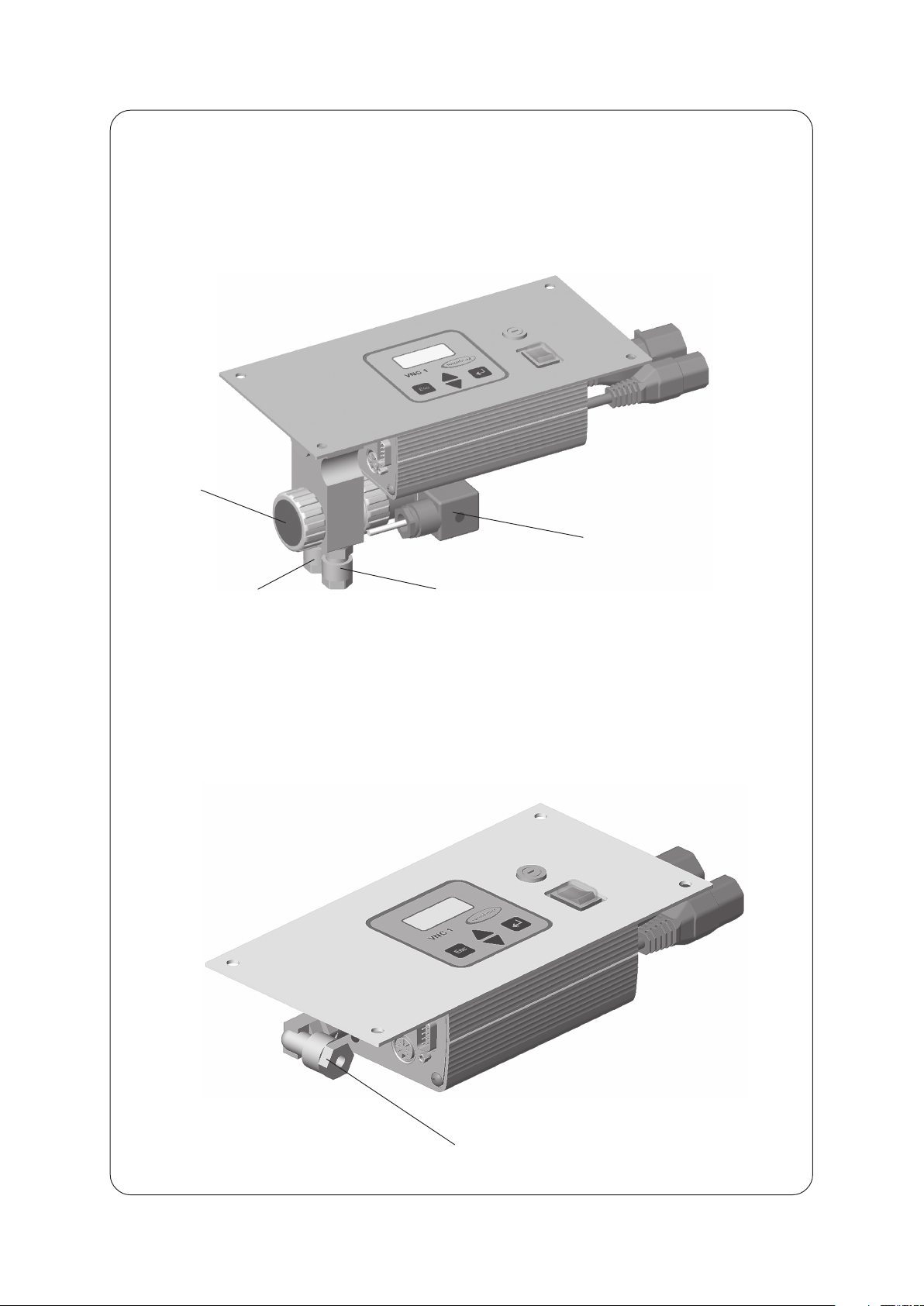

Controller VNC 1, built-in version

bores for screws M4

73,5 mm

page 9 of 35

Built-in version for vertical installation

bores for screws M4

78,0 mm

78,0 mm

73,5 mm

Documents are only to be used and distributed completely and unchanged. It is strictly the users´ responsibility to check

carefully the validity of this document with respect to his product. Manual-no.: 999118 / 16/12/2009

page 10 of 35

Built-in version with front panel (120 x 240 mm)

and solenoid operated isolation valve

The controller VNC 1 is equipped with a non return valve underneath the blind cap. If the connection to

the pump is vented, the non return valve prevents interference with the system and the pressure

transducer. Check the non return valve regularly and clean or replace if necessary (Cat.-no. 63 88 36).

blind cap

solenoid operated

isolation valve

towards vacuum application

Bores in front panel: ø 6,5 mm;

distance between bores: 100 mm and 220 mm (long side)

towards pump

Built-in version with front panel (120 x 240 mm)

and adjustable elbow fitting for hose connection NW 10/8

adjustable elbow fitting

for hose connection NW 10/8

Documents are only to be used and distributed completely and unchanged. It is strictly the users´ responsibility to check

carefully the validity of this document with respect to his product. Manual-no.: 999118 / 16/12/2009

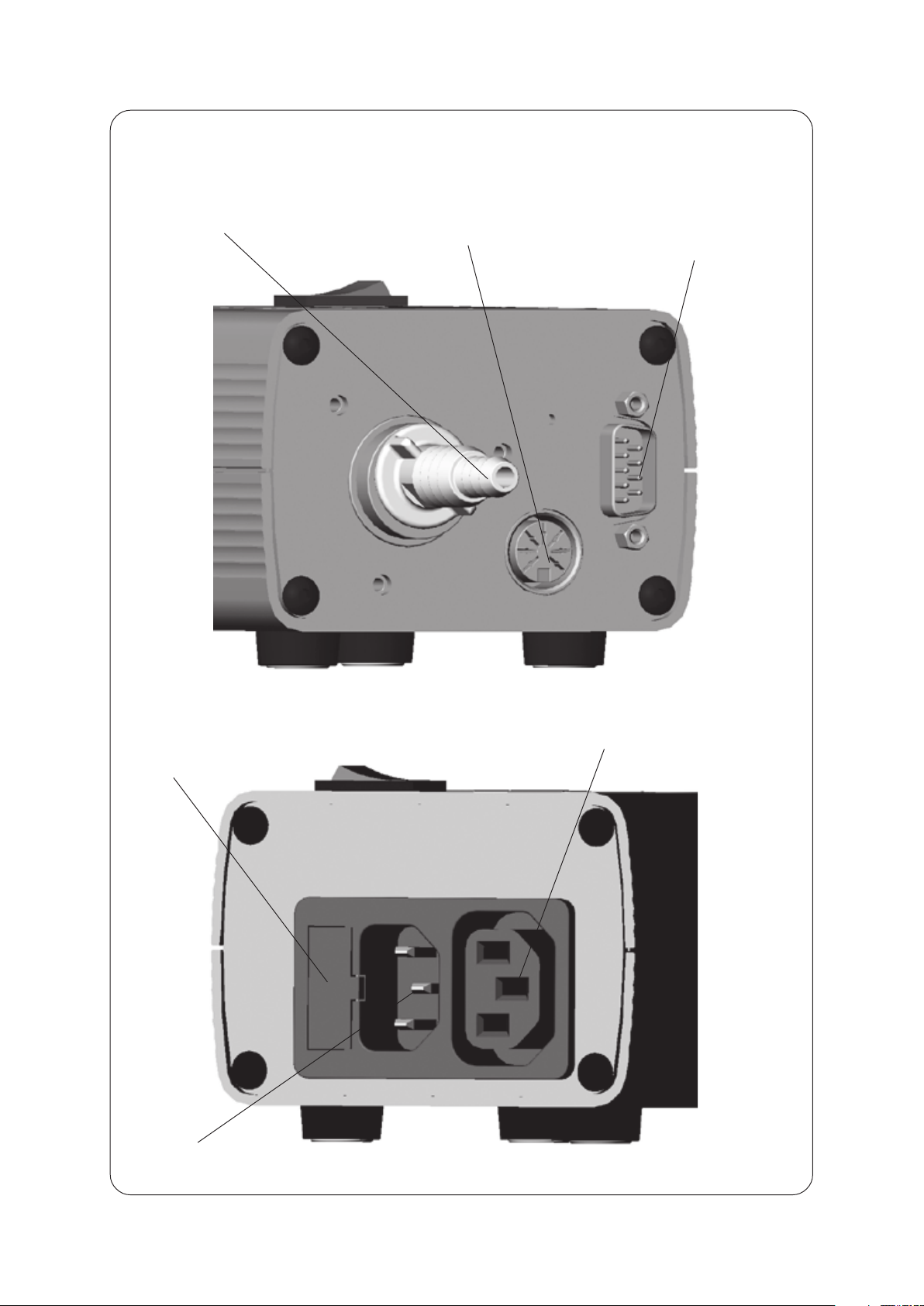

Connections

page 11 of 35

vacuum connection

hose nozzle NW 10/6

8-pin socket for connection of

cooling water valve or isolation valve

or speed control signal (PWM)

serial interface

RS 232 C

cover

fuse switch output

connection mains cable

socket for connection of

pump or valve according

to voltage supply

(switch output)

Documents are only to be used and distributed completely and unchanged. It is strictly the users´ responsibility to check

carefully the validity of this document with respect to his product. Manual-no.: 999118 / 16/12/2009

Loading...

Loading...