VACUUBRAND VHCpro User Manual

page 1 of 36

Technology for Vacuum Systems

Instructions for use

VHC

pro

page 2 of 36

After sales service:

Contact your local dealer or call +49 9342 808-5500.

The document ”Safety information for vacuum equipment” is

part of this manual! Read the ”Safety information for vacuum

equipment” and observe the instructions contained therein!

Trademark index:

VACUU•LAN® (US-Reg.No 3,704,401), VACUU•BUS®, VACUU•CONTROLTM,

chemistry-HYBRIDTM, Peltronic®, TURBO•MODETM, VARIO® (US-Reg.No

3,833,788), VARIO-SPTM, VACUUBRAND® (US-Reg.No 3,733,388) and also

the shown company logos are trademarks of VACUUBRAND GMBH +

CO KG in Germany and/or other countries.

page 3 of 36

Contents

Safety information! ............................................................. 4

Important information! ......................................................................... 4

General information ............................................................................. 6

Intended use........................................................................................ 6

Ambient conditions .............................................................................. 7

Operating conditions ........................................................................... 7

Safety during operation ....................................................................... 8

Maintenance and repair....................................................................... 9

Technical data ................................................................... 10

Wetted parts ..................................................................................... 10

System parts .....................................................................................11

Use and operation ............................................................ 12

Assembling the wall holder................................................................ 14

Adapters ............................................................................................ 16

Changing the adapter ........................................................................ 17

Settings ............................................................................................. 19

Handling ............................................................................................ 20

Shutdown .......................................................................................... 24

Cleaning and decontaminating ....................................... 25

Accessories and spare parts........................................... 27

Troubleshooting ............................................................... 29

Replacing the aspiration hose ........................................ 30

Notes on return to the factory ......................................... 32

Health and safety clearance form ................................... 35

page 4 of 36

Safety information!

Important information!

+ Keep this manual complete and accessible to per-

sonnel at all times!

+ Read this manual carefully before installing or op-

erating the equipment. Observe the instructions

contained in this manual.

+ Do not modify the equipment without authorization.

NOTICE

This manual is an integral part of the equipment described therein. It describes the safe and proper use

of the vacuum pump.

Make operating personnel aware of dangers arising

from the pump and the pumped substances.

VACUUBRAND disclaims any liability for inappropriate use of these pumps and for damage from failure

to follow instructions contained in this manual.

This manual is only to be used and distributed in its complete and original form. It is strictly the users’ responsibility

to check carefully the applicability of the guidance in this

manual with respect to his product.

Manual-no.: 999276 / 07/26/2013

The following signal word panels and safety

symbols are used throughout this manual:

This is the safety alert symbol. It is used to alert you to potential personal injury hazards. Obey all safety messages

that follow this symbol to avoid possible injury and death.

page 5 of 36

➨ DANGER indicates a hazardous situation which, if not

avoided, will result in death or serious injury.

+ WARNING indicates a hazardous situation which, if not

avoided, could result in death or serious injury.

• CAUTION indicates a hazardous situation which, if not

avoided, could result in minor or moderate injury.

NOTICE

NOTICE is used to address practices not related to per-

sonal injury.

Formatting used in this manual:

Note: The signal word panels in all sections of this manual always refer

to all paragraphs of the same format (➨ / + / • / plain text) following each

signal word panel.

page 6 of 36

General information

+ Read and comply with this manual before installing

or operating the equipment.

+ Before operating the equipment read and comply

with the section ”Cleaning and decontamination”!

NOTICE

Remove all packing material, remove the product from its

packing-box, remove the protective covers from the inlet

and outlet ports and keep, inspect the equipment.

If the equipment is damaged, notify the supplier and the

carrier in writing within three days; state the item number of the product together with the order number and the

supplier’s invoice number. Retain all packing material for

inspection.

Do not use the equipment if it is damaged.

Intended use

+ The device may only be used by well trained and skilled

personnel.

+ The device may not be used for in vivo applications (e.

NOTICE

NOTICE

g., not at humans or animals).

Ensure that the equipment and all components are suitable for the intended application. Use the system only for

aspiration of liquids.

Setting up

The VHC

system, e. g., VACUUBRAND BVC systems.

Comply with all applicable and relevant safety requirements (regulations and guidelines), implement the required actions and adopt suitable safety measures.

pro

is intended to be conntect to a suitable suction

page 7 of 36

Ambient conditions

• The systems are designed for ambient temperatures

during operation between +10°C and +40°C. Check the

maximum temperatures.

Operating conditions

➨ The devices are not suitable to aspirate:

- unstable substances

- substances which react explosively under impact

(mechanical stress) and/or when being exposed to

elevated temperatures without air,

- self inammable substances,

NOTICE

- substances which are inammable without air and

- explosive substance

➨ The devices have no approval for operation below

ground.

+ The pumps are not suitable for aspiration of dust.

• Take into consideration interactions and chemical

reactions of the aspirated media.

• Ensure that the materials of the wetted parts are compatible with the aspirated substances, see section

”Technical data”.

If aspirating different substances, it is recommended

that the aspiration hose be purged prior to changing the

media in order to rinse out residues and to avoid reactions

of the substances with each other and with the materials.

page 8 of 36

Safety during operation

➨ Ensure that while operating the device no persons can

be endangered.

➨ Wear personal protection equipment.

➨ Comply with requirements when using infectious liq-

uids, pathogenic germs, toxic, radioactive or aggressive substances.

➨ Prior to operation check all relevant safety and health

requirements and determine the applicability of regula-

tory limitations prior to use if necessary.

➨ Comply with material safety data sheets and notes on

safe use of the manufacturer.

➨ Comply with the biosafety level of the laboratory.

➨ Use appropriate safety work materials and methods if

necessary, e. g., steam sterilization, sterilization indicators or germicides. For notes concerning the sterilization of wetted parts, see the “Technical Data” section

and “Cleaning and decontaminating”. It is the user´s

responsibility to ensure effective sterilization.

➨ Never operate a defective or damaged device.

+ Comply with applicable regulations when disposing of

chemicals. Take into consideration that chemicals may

be polluted.

+ Use only OEM spare parts and accessories; other-

wise safety and performance of the equipment as well

as the electromagnetic compatibility of the equipment

might be reduced.

NOTICE

+ In case of leaks in the aspiration hose, aspirated sub-

stances might be released into the environment. Comply especially with notes on operation and use.

Ensure that, in case of failure, the system will always return to a safe status. Provide appropriate protective measures (i.e., precautions which allow for the requirements

of the respective application) even for the case of failure

and malfunction.

page 9 of 36

Maintenance and repair

➨ Attention: The device might be contaminated with nox-Attention: The device might be contaminated with nox-

ious or otherwise dangerous chemicals that have been

aspirated during operation. Ensure that the device is

decontaminated before maintenance.

+ Take adequate precautions to protect people from the

effects of dangerous substances if contamination has

occurred. Wear appropriate safety-clothing when you

come in contact with contaminated components.

NOTICE

Ensure that maintenance is done only by suitably trained

and supervised technicians. Ensure that the maintenance

technician is familiar with the safety procedures which relate to the products processed by the system.

In order to comply with law (occupational, health and safety regulations, safety at work law and regulations for environmental protection) vacuum pumps, components and

measuring instruments returned to the manufacturer can

be repaired only when certain procedures (see section

”Notes on return to the factory”) are followed.

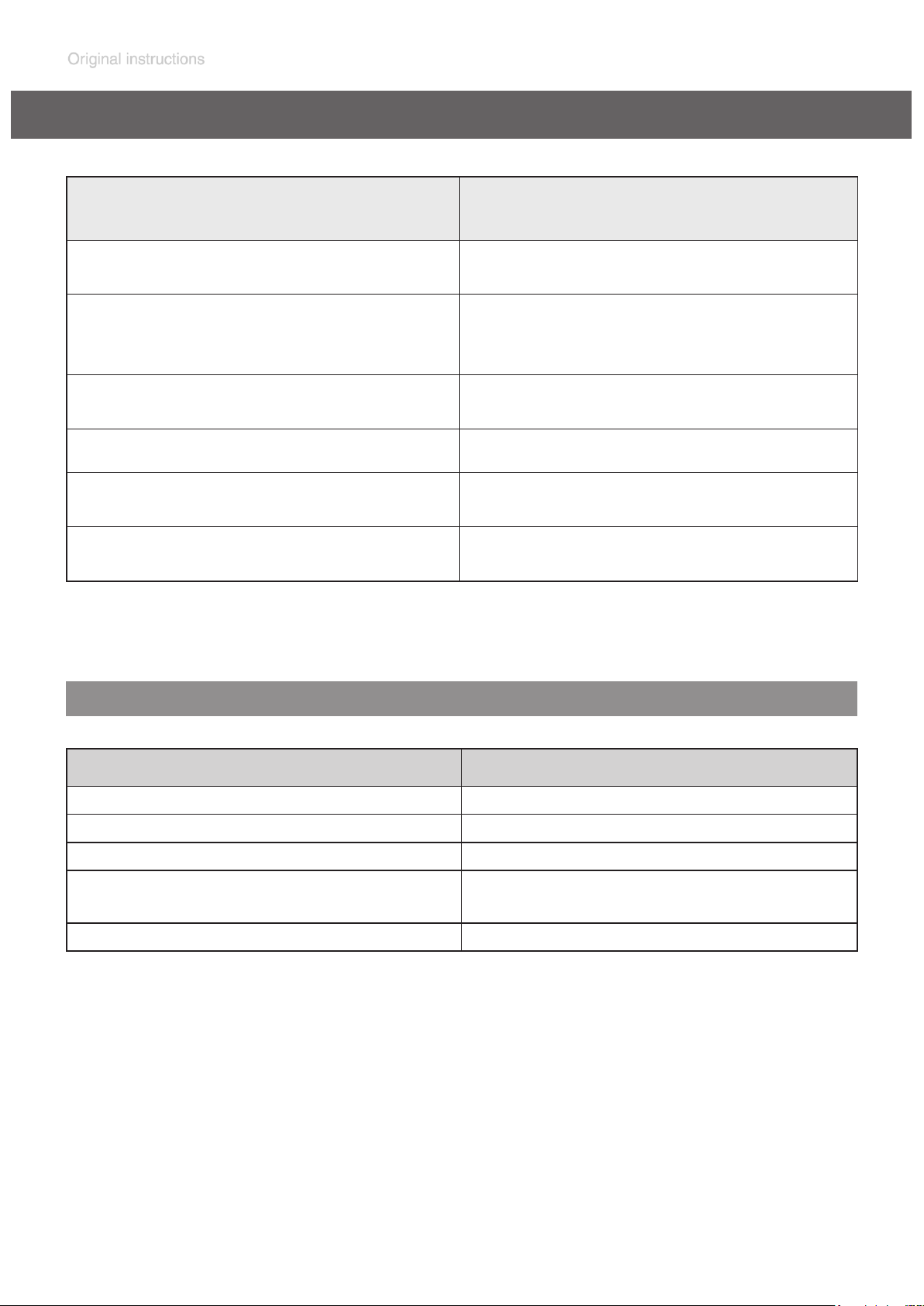

Technical data

page 10 of 36

Type VHC

Permissible ambient temperature storage / operation

Permissible relative atmospheric moisture during operation

(no condensation)

Adapters for

Length of aspiration hose m 2.5

Dimensions L x W x H approx.

(without aspiration hose)

Weight (with aspiration hose)

approx.

°F

°C

% 30 to 85

Pipettes with outer diameter 5.5 - 8 mm

Pipette tips 2 - 200 µl and 50 - 1000 µl

mm

g 125

14 to 140 / 50 to 104

(-10 to +60 / +10 to +40)

185 x 30 x 38

pro

Wetted parts

Components Wetted parts

Aspiration hose Silicone rubber

Adapter pipettes TPE / PP

Adapter pipette tips PP

Screw cap, adjusting knob, operating

lever

Housing PP, glass bre reinforced

PPS, glass bre reinforced

We reserve the right for technical modications without prior notice!

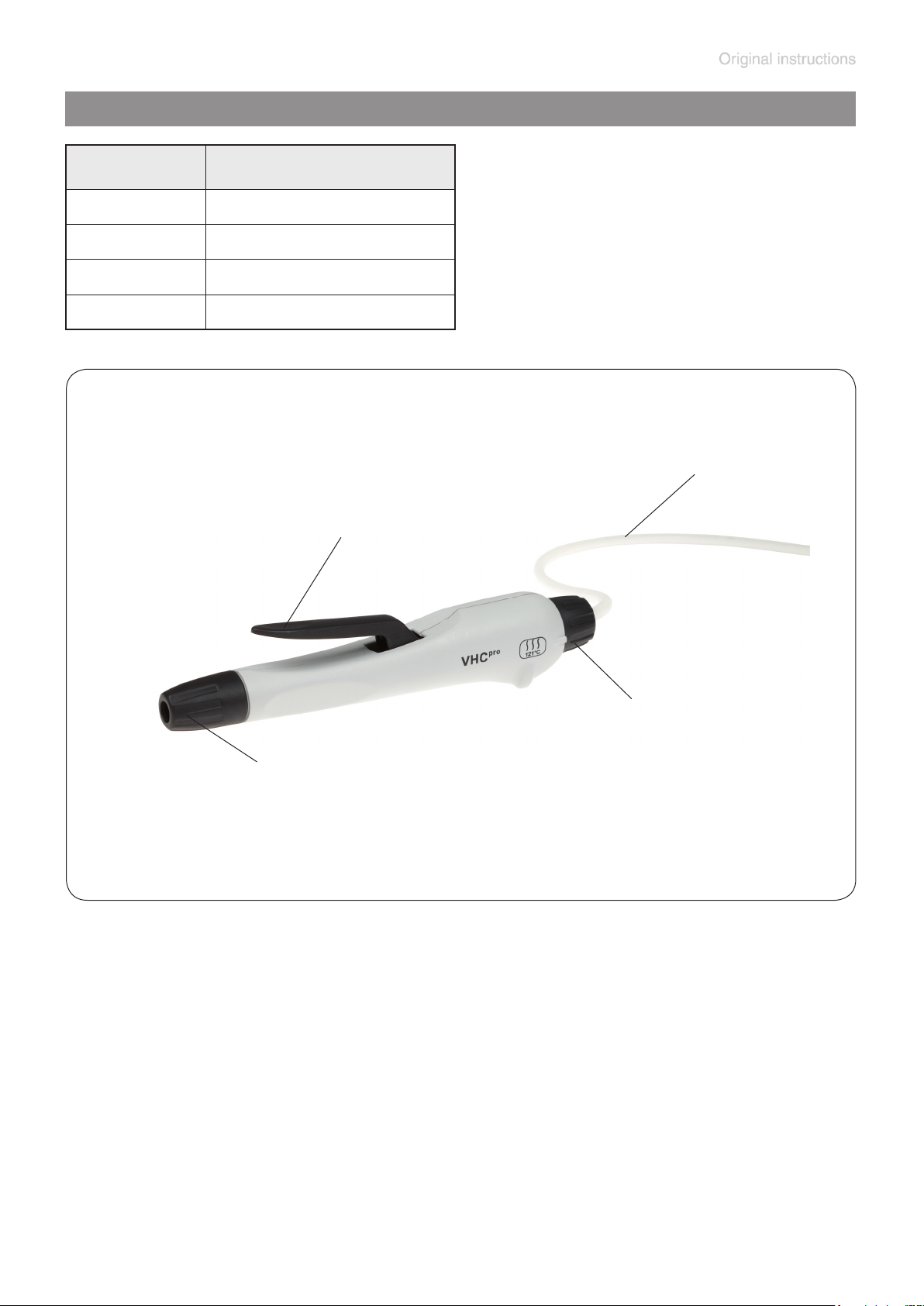

System parts

Position Designation

1 operating lever

2 aspiration hose

3 adjusting knob

4 screw cap

page 11 of 36

2

1

3

4

Loading...

Loading...