Vacon optea, opte9 Installation Manual

vacon

ac drives

advanced dual port ethernet board, optea

dual port ethernet board, opte9

®

installation manual

vacon • 3

TABLE OF CONTENTS

Document: DPD01583G

Release date : 17/8/18

1. Safety...............................................................................................................6

1.1 Danger................................................................................................................................6

1.2 Warnings ............................................................................................................................7

1.3 Grounding and earth fault protection ................................................................................8

2. General information.........................................................................................9

2.1 New features - OPTEA .....................................................................................................11

2.2 New features - OPTE9......................................................................................................11

3. OPTEA/OPTE9 Ethernet board technical data ................................................12

3.1 General.............................................................................................................................12

3.2 Cables...............................................................................................................................12

4. Layout and connections..................................................................................13

4.1 Layout and connections ...................................................................................................13

4.2 LED Indications ................................................................................................................14

4.2.1 Profinet IO ........................................................................................................................15

4.3 Ethernet devices ..............................................................................................................16

4.3.1 Human to machine...........................................................................................................16

4.3.2 Machine to machine .........................................................................................................17

4.4 Connections and wiring....................................................................................................17

4.4.1 Topology: Star ..................................................................................................................18

4.4.2 Topology: Daisy Chain ......................................................................................................18

4.4.3 Topology: Ring..................................................................................................................19

4.5 ACD (Address Conflict Detection) ....................................................................................25

4.6 Time synchronization .......................................................................................................26

4.6.1 Using ID 2551 ...................................................................................................................26

4.6.2 SNTP (Simple Network Time Protocol) ...........................................................................26

5. Installation.....................................................................................................27

5.1 VACON® OPTEA Advanced Dual port Ethernet drive support........................................27

5.2 VACON® OPTE9 Dual Port Ethernet drive support.........................................................28

5.3 Installation in VACON® NX..............................................................................................29

5.4 Installation in VACON® 20...............................................................................................31

5.4.1 Enclosures MI1, MI2, MI3.................................................................................................31

5.4.2 Enclosures MI4, MI5.........................................................................................................34

5.5 Installation in VACON® 20 X and 20 CP ..........................................................................37

5.6 Installation in VACON® 100 family..................................................................................39

5.7 installation in VACON® 100 X..........................................................................................42

5.8 PC Tools ...........................................................................................................................45

5.8.1 PC tool support ................................................................................................................45

5.8.2 Updating the OPTEA and OPTE9 option board firmware with VACON® Loader ............46

5.8.3 PC Tools for VACON® NX / NCIPConfig ..........................................................................49

5.8.4 PC Tools for VACON® NX / NCDrive ...............................................................................51

5.8.5 PC Tools for VACON® 100 family and VACON® 20 / VACON® Live...............................54

6. Commissioning ..............................................................................................57

6.1 Option board menu...........................................................................................................57

6.1.1 Option board parameters.................................................................................................57

6.1.2 Option board monitoring values ......................................................................................60

6.1.3 Communication protocol .................................................................................................61

6.1.4 IP Mode and IP settings ...................................................................................................62

6.1.5 Speed and duplex.............................................................................................................62

6.1.6 Communication timeout ..................................................................................................63

6.1.7 Profinet IO - Name of Station ..........................................................................................64

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

vacon • 4

6.1.8 EIP Input and Output instance .........................................................................................64

6.1.9 EIP Product code offset ...................................................................................................64

6.1.10 Mode.................................................................................................................................64

6.1.11 MAC Address....................................................................................................................65

6.1.12 Modbus Unit Identifier .....................................................................................................65

6.1.13 Media Redundancy...........................................................................................................66

6.1.14 SNTP settings...................................................................................................................66

6.1.15 SNTP monitoring values ..................................................................................................68

6.1.16 System Redundancy.........................................................................................................68

6.2 Internal communication modes.......................................................................................68

6.3 Safety parameters............................................................................................................69

6.4 Control and status word monitoring values ....................................................................69

6.5 OPTCx emulation mode ...................................................................................................69

6.5.1 Modbus in emulation mode .............................................................................................70

6.5.2 EtherNet/IP in emulation mode.......................................................................................70

6.5.3 PROFINET in emulation mode .........................................................................................71

7. Modbus TCP / Modbus UDP ............................................................................72

7.1 Modbus UDP vs TCP.........................................................................................................73

7.2 Modbus communications.................................................................................................75

7.3 Data addresses in Modbus messages .............................................................................76

7.3.1 Modbus memory map ......................................................................................................76

7.3.2 Modbus data mapping......................................................................................................76

7.4 Modbus communication and connection timeout ...........................................................88

7.5 Quick setup.......................................................................................................................89

7.6 Modbus - example messages ..........................................................................................90

7.6.1 Example 1 - Write process data.......................................................................................90

7.6.2 Example 2 - Read process data .......................................................................................91

7.6.3 Example 3 - Exception response .....................................................................................92

8. PROFINET IO ..................................................................................................93

8.1 PROFIdrive 4.1 profile ......................................................................................................93

8.2 PROFIdrive 4.1 state machine..........................................................................................94

8.3 PROFINET IO process communication ............................................................................95

8.3.1 Choosing telegram type ...................................................................................................95

8.3.2 Telegram types ................................................................................................................96

8.3.3 Telegram building blocks ..............................................................................................104

8.3.4 Quick setup.....................................................................................................................108

8.4 PROFIdrive IO parameters.............................................................................................109

8.4.1 Parameters of the PROFIdrive.......................................................................................109

8.4.2 Vendor-specific PROFIdrive parameters.......................................................................111

8.4.3 PROFIdrive signal numbers...........................................................................................112

8.4.4 User specific record data...............................................................................................115

8.4.5 Base Mode Parameter Access Model............................................................................116

8.4.6 Parameter responses ....................................................................................................120

8.4.7 Drive parameter access using application ID................................................................124

8.4.8 Parameter channel examples .......................................................................................124

8.5 PROFINET IO communications and connection timeout...............................................131

8.6 System Redundancy.......................................................................................................132

8.7 Alarm system .................................................................................................................133

8.8 PROFIsafe.......................................................................................................................135

8.8.1 Overview .........................................................................................................................135

8.8.2 PROFIdrive on PROFIsafe ..............................................................................................136

9. EtherNet/IP..................................................................................................137

9.1 General information.......................................................................................................137

9.1.1 Overview .........................................................................................................................137

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

vacon • 5

9.1.2 AC/DC Drive Profile........................................................................................................137

9.1.3 EDS file ...........................................................................................................................137

9.1.4 LED functionality ............................................................................................................138

9.1.5 Explicit Messaging .........................................................................................................140

9.1.6 EtherNet/IP communication and connection timeout...................................................144

9.2 Common Industrial Objects implemented by OPTE9 ....................................................146

9.2.1 CIP Objects .....................................................................................................................146

9.2.2 Vendor Specific Objects .................................................................................................171

9.3 Supported assembly instances......................................................................................179

9.3.1 CIP I/O Assembly instances for AC/DC Drive ................................................................179

9.3.2 Vendor-specific I/O Assembly Instances.......................................................................185

9.3.3 Mapping of Standard Output Assemblies onto VACON® data......................................197

9.3.4 Mapping of VACON® data onto Standard Input Assemblies ........................................198

9.3.5 Special assembly instances...........................................................................................200

9.4 EtherNet/IP connection example ..................................................................................200

10. Fault tracing.................................................................................................202

10.1 Typical fault conditions ..................................................................................................202

10.2 Other fault conditions ....................................................................................................203

10.3 Fieldbus fault codes.......................................................................................................204

11. APPENDIX 1 - VACON® IO DATA DESCRIPTION............................................205

11.1 VACON® Control Word - FBFixedControlWord ............................................................205

11.2 Control Word bit support in VACON® AC drives ...........................................................207

11.3 Vacon® Status Word - FBFixedStatusWord..................................................................208

11.4 Status Word bit support in VACON® AC drives.............................................................209

11.5 Monitoring of Control & Status words in VACON® AC drives.......................................209

11.6 VACON® Speed reference and actual speed - FBSpeedReference

and FBActualSpeed ......................................................................................................210

11.7 Process data...................................................................................................................210

11.8 FIELDBUS PROCESS DATA MAPPING AND SCALING ..................................................211

12. APPENDIX 2 - EXAMPLE WITH SIEMENS PLC .............................................. 214

12.1 Siemens STEP 7 .............................................................................................................214

12.2 Siemens TIA Portal ........................................................................................................223

13. APPENDIX 3 - EXAMPLE WITH SIEMENS SIMATIC PDM ...............................234

14. APPENDIX 4 - FIELDBUS PARAMETRISATION..............................................242

14.1 Fieldbus control and basic reference selection ............................................................242

14.2 Controlling Fieldbus Parameter....................................................................................243

14.3 Torque control parametrization ....................................................................................244

15. APPENDIX 5 - LWIP LICENCE .......................................................................245

16. Appendix 6 - Fieldbus option board communication ....................................246

16.1 Requirements for communication modes.....................................................................246

16.2 Fieldbus communication mode features and limitations .............................................247

16.3 Normal fieldbus communication ...................................................................................248

16.4 Fast fieldbus communication ........................................................................................249

16.5 Normal Extended Mode .................................................................................................249

16.6 Fast safety fieldbus communication..............................................................................250

16.7 Fast PROFIBUS fieldbus communication......................................................................250

17. APPENDIX 7 - parameters for application developers ................................. 251

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

vacon • 6 Safety

9000.emf

13006.emf

9001.emf

9000.emf

9000.emf

9000.emf

9000.emf

9000.emf

9000.emf

1. SAFETY

This manual contains clearly marked cautions and warnings that are intended for your personal

safety and to avoid any unintentional damage to the product or connected appliances.

Read the information included in cautions and warnings carefully.

The cautions and warnings are marked as follows:

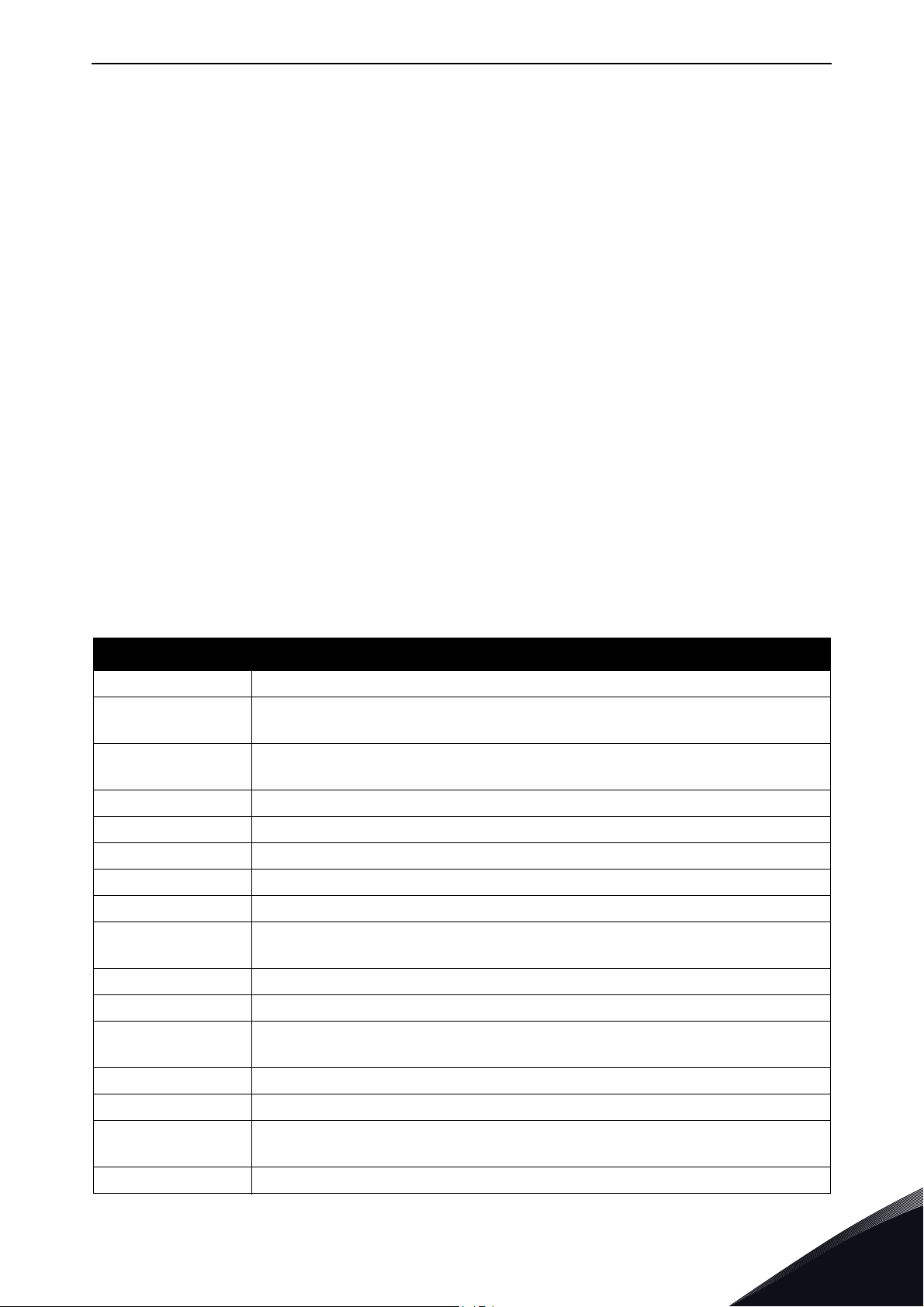

Table 1. Warning signs

= DANGER! Dangerous voltage

= WARNING or CAUTION

= Caution! Hot surface

1.1 Danger

The components of the power unit are live when the drive is connected to mains

potential. Coming into contact with this voltage is extremely dangerous and may

cause death or severe injury.

The motor terminals U, V, W and the brake resistor terminals are live when the

AC drive is connected to mains, even if the motor is not running.

After disconnecting the AC drive from the mains, wait until the indicators on the

keypad go out (if no keypad is attached, see the indicators on the cover). Wait 5

more minutes before doing any work on the connections of the drive. Do not open

the cover before this time has expired. After expiration of this time, use a

measuring equipment to absolutely ensure that no

ensure absence of voltage before starting any electrical work!

The control I/O-terminals are isolated from the mains potential. However, the

relay outputs and other I/O-terminals may have a dangerous control voltage

present even when the AC drive is disconnected from mains.

voltage is present.

Always

Before connecting the AC drive to mains make sure that the front and cable

covers of the drive are closed.

During a ramp stop (see the Application Manual), the motor is still generating

voltage to the drive. Therefore, do not touch the components of the AC drive

before the motor has completely stopped. Wait until the indicators on the keypad

go out (if no keypad is attached, see the indicators on the cover). Wait additional 5

minutes before starting any work on the drive.

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

1

Safety vacon • 7

13006.emf

13006.emf

13006.emf

13006.emf

13006.emf

13006.emf

13006.emf

13006.emf

13006.emf

13006.emf

1.2 Warnings

The AC drive is meant for fixed installations only.

Do not perform any measurements when the AC drive is connected to the mains.

The earth leakage current of the AC drives exceeds 3.5mA AC. According to

standard EN61800-5-1, a reinforced protective ground connection must be

ensured. See Chapter 1.3.

If the AC drive is used as a part of a machine, the machine manufacturer is

responsible for providing the machine with a supply disconnecting device (EN

60204-1).

Only spare parts delivered by VACON

®

can be used.

At power-up, power break or fault reset the motor will start immediately if the

start signal is active, unless the pulse control for

Start/Stop logic has been selected

Furthermore, the I/O functionalities (including start inputs) may change if

parameters, applications or software are changed. Disconnect, therefore, the

motor if an unexpected start can cause danger.

The motor starts automatically after automatic fault reset if the auto restart

function is activated. See the Application Manual for more detailed information.

Prior to measurements on the motor or the motor cable, disconnect the motor

cable from the AC drive.

Do not touch the components on the circuit boards. Static voltage discharge may

damage the components.

Check that the EMC level of the AC drive corresponds to the requirements of your

supply network.

.

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

1

vacon • 8 Safety

13006.emf 13006.emf

1.3 Grounding and earth fault protection

CAUTION!

The AC drive must always be earthed with an grounding conductor connected to the grounding

terminal marked with .

The earth leakage current of the drive exceeds 3.5mA AC. According to EN61800-5-1, one or more

of the following conditions for the associated protective circuit must be satisfied:

a) The protective conductor must have a cross-sectional area of at least 10 mm2 Cu or 16

mm2 Al, through its total run.

b) Where the protective conductor has a cross-sectional area of less than 10 mm2 Cu or 16

mm2 Al, a second protective conductor of at least the same cross-sectional area must be

provided up to a point where the protective conductor has a cross-sectional area not less

than 10 mm2 Cu or 16 mm2 Al.

c) Automatic disconnection of the supply in case of loss of continuity of the protective

conductor.

The cross-sectional area of every protective grounding conductor which does not form part of the

supply cable or cable enclosure must, in any case, be not less than:

-2.5mm

-4mm

2

if mechanical protection is provided or

2

if mechanical protection is not provided.

The earth fault protection inside the AC drive protects only the drive itself against earth faults in the

motor or the motor cable. It is not intended for personal safety.

Due to the high capacitive currents present in the AC drive, fault current protective switches may

not function properly.

Do not perform any voltage withstand tests on any part of the AC drive. There is

a certain procedure according to which the tests must be performed. Ignoring

this procedure can cause damage to the product.

NOTE! You can download the English and French product manuals with applicable safety,

warning and caution information from https://www.danfoss.com/en/service-and-support/.

REMARQUE Vous pouvez télécharger les versions anglaise et française des manuels produit

contenant l’ensemble des informations de sécurité, avertissements et mises en garde

applicables sur le site https://www.danfoss.com/en/service-and-support/.

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

1

General information vacon • 9

2. GENERAL INFORMATION

The VACON® AC drives can be connected to the Ethernet networks using the VACON® OPTEA

Advanced Dual Port Ethernet fieldbus option board (OPTEA) and the VACON

Ethernet fieldbus option board (OPTE9). The drives can be daisy chained by utilizing two Ethernet

ports. The option boards support PROFINET IO, Ethernet/IP, Modbus TCP and Modbus UDP fieldbus

protocols. The Advanced Dual Port Ethernet board (OPTEA) also supports PROFINET IO with

PROFIsafe in combination with OPTBL/OPTBM/OPTBN option board. In addition, OPTEA also

supports advanced features such as PROFINET System Redundancy "S2". OPTEA can be used alone

as PROFINET IO device, but PROFIsafe always requires OPTBL/OPTBM/OPTBN option board and

VACON

Chapter 4.4 "Connections and wiring".

Every appliance connected to an Ethernet network has two identifiers: a MAC address and an IP

address. The MAC address (Address format: xx:xx:xx:xx:xx:xx) is unique for each appliance and

cannot be changed.The Ethernet board’s MAC address can be found on the sticker attached to the

board. “EtherNet/IP

In a local network, IP addresses can be defined by the user as long as all the units connected to the

network are given the same network portion of the address. Overlapping IP addresses cause

conflicts between appliances. For more information about setting IP addresses, see Chapter 6

"Commissioning".

®

NXP control too. The following network topologies are supported. See details in

•Star

•Daisy chain

•Ring

TM

is a trademark of ODVA, Inc.

®

OPTE9 Dual Port

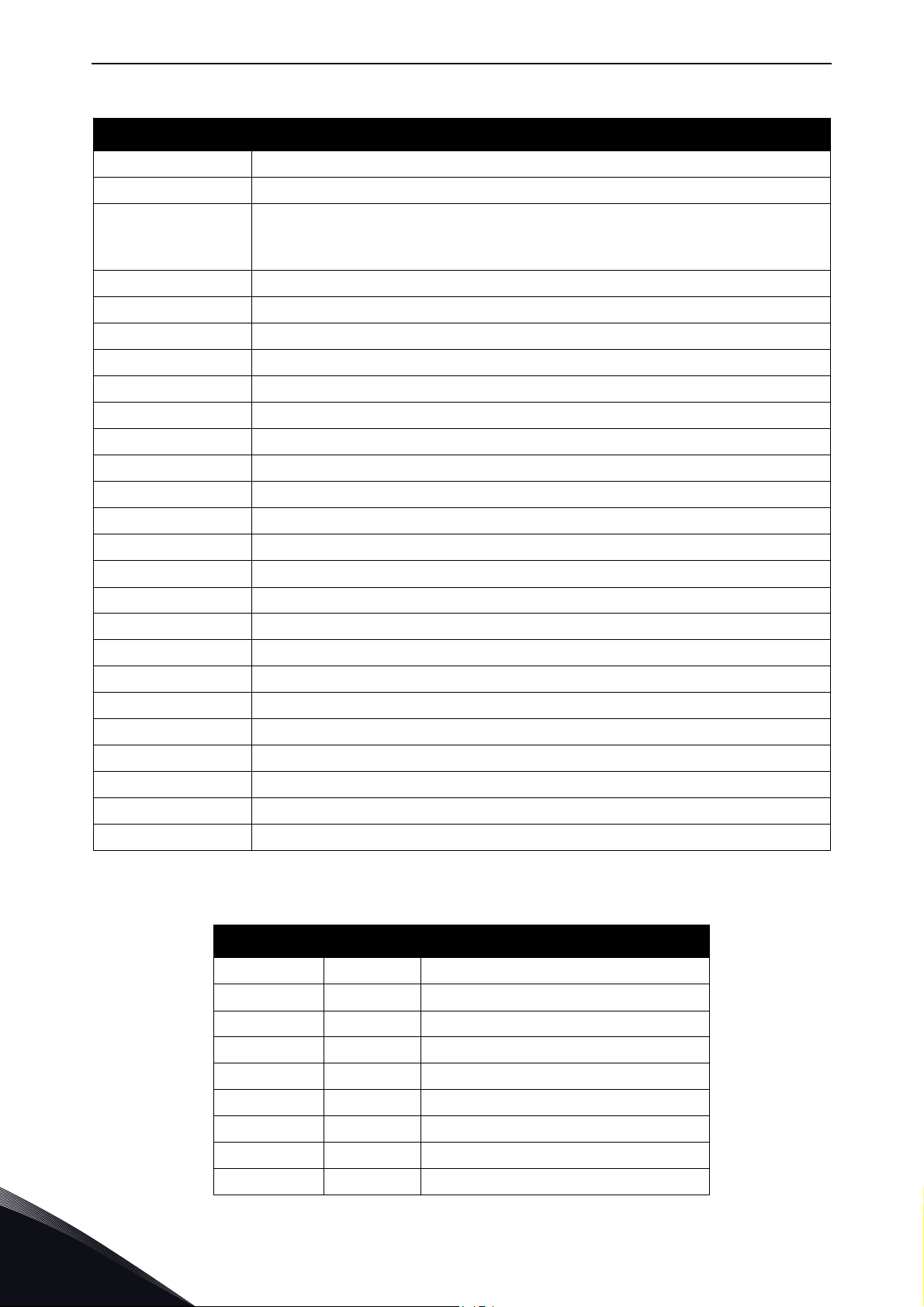

Table 2. List of abbreviations used in this document

Abbreviation Explanation

ACD Address Conflict Detection

CRC

DHCP

FB Fieldbus

GW Gateway

HI Upper 8/16 bits in a 16/32 bit value.

LO Lower 8/16 bits in a 16/32 bit value.

LWIP Light weight TCP/IP protocol stack for embedded systems.

Modbus TCP /

Modbus UDP

PDI Process data in (Profinet IO)

PDO Process data out (Profinet IO)

PHY(X)

Cyclic Redundancy Check is an error-detecting code commonly used in

fieldbusses to detect accidental changes to raw data.

Dynamic Host Configuration Protocol is used for dynamical resolving of network configuration parameters like an IP address.

Simple and vendor-neutral communication protocol intended for monitoring

and controlling of field devices.

Ethernet physical interface X, where X represents the number

of interface

PLC Programmable Logic Controller

PNU Parameter number (Profinet IO)

Profinet IO

RPM Revolutions per minute

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

Profinet is a standard for industrial automation in Ethernet network. Profi-

net IO describes the exchange of data between controllers and field devices.

2

vacon • 10 General information

Table 2. List of abbreviations used in this document

Abbreviation Explanation

RSTP Rapid Spanning Tree Protocol

SNTP Simple Network Time Protocol

Transmission Control Layer provides reliable, ordered and error-checked

TCP

UTC Coordinated Universal Time

SNMP Simple Network Management Protocol

MIB Management Information Base

DLR Device Level Ring

CIP Common Industrial Protocol

RDHT Redundancy Data Hold Time

LLDP Link Layer Discovery Protocol

LED Light-Emitting Diode

MRP Media Ring Protocol

delivery of data streams between computers that are connected to a local

area network.

MRM Media Ring Master

MRC Media Ring Client

ARP Address Resolution Protocol

DCP Discovery and Basic Configuration Protocol

HD Half Duplex

FD Full Duplex

STW1 Steuerwort 1 (German for control word 1)

ZSW1 Zustandwort 1 (German for status word 1)

NSOLL Sollwert (German for reference value)

NIST Istwert (German for actual value)

EDD Electronic Device Description

EDS Electronic Data Sheet

GSDML General Station Description Markup Language

Table 3. List of data types used in this document

Type name Bit size Explanation

INT8 8 Signed short integer

2

UINT8 8 Unsigned short integer

INT16 16 Signed integer

UINT16 16 Unsigned integer

INT32 32 Signed long integer

UINT32 32 Unsigned long integer

FLOAT32 32 32-bit floating point

STRING3 24 Three byte string

STRING5 40 Five byte string

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

General information vacon • 11

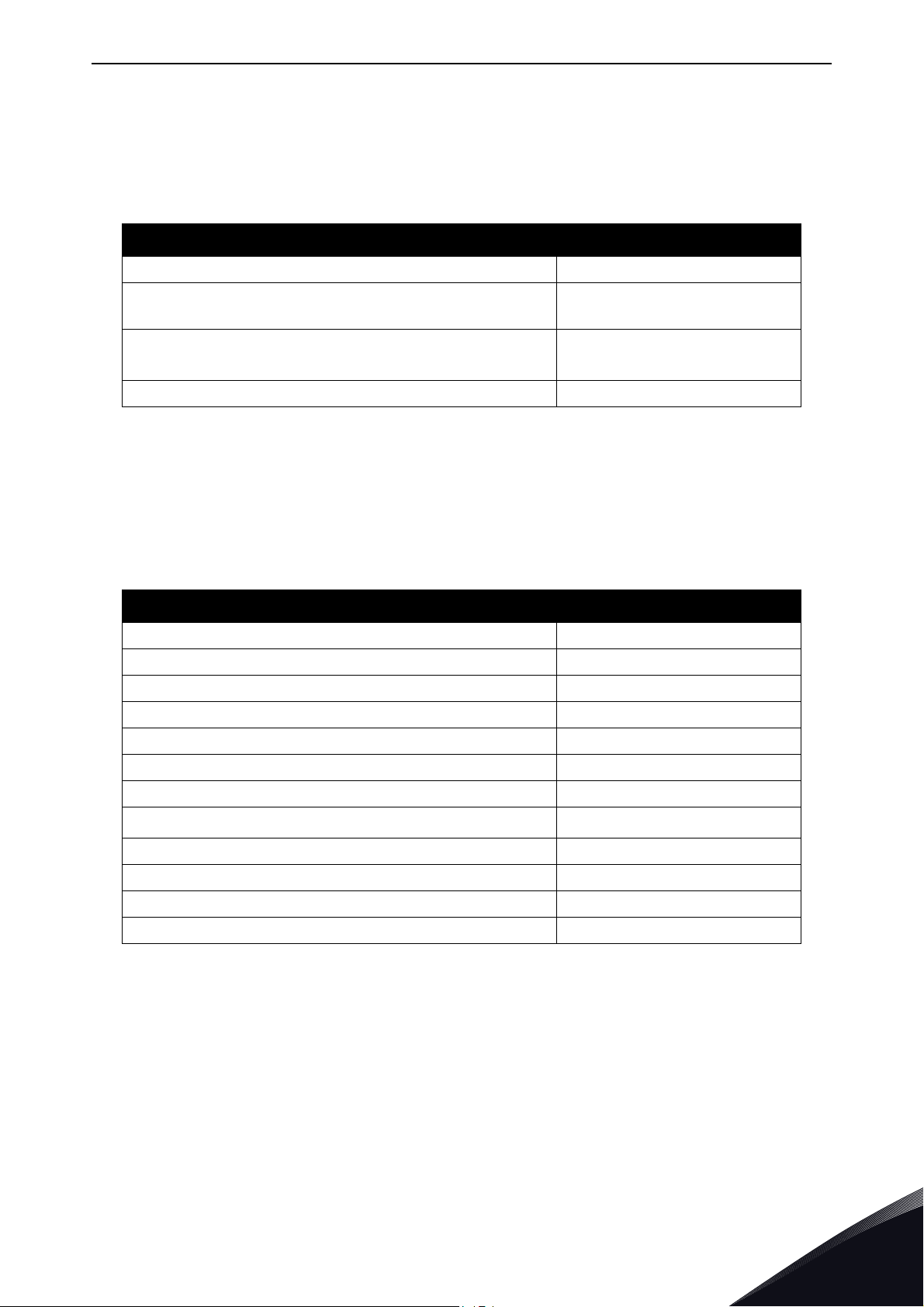

2.1 New features - OPTEA

The following table shows the new features that are added in the OPTEA Advanced Dual Port

Ethernet's firmware version.

Table 4. New features - OPTEA

New feature Firmware version

PROFINET IO + PROFIsafe V001

Support for all features supported by OPTE9 board

including EtherNet/IP and Modbus TCP/UDP protocols

Improved emulation mode with OPTCP, OPTCQ and

®

OPTCI boards when installed to VACON

PROFINET IO System Redundancy "S2" V002

PROFISAFE is supported in NXP only when OPTBL/M/N is also installed.

NXP

V002

V002

2.2 New features - OPTE9

The following table shows the new features that are added in the OPTE9 Dual Port Ethernet's

firmware versions.

Table 5. New features - OPTE9

New feature Firmware version

EtherNet/IP protocol V004

Ethernet ring support (RSTP) V004

Address Conflict Detection (ACD) V004

Media Redundancy Protocol (MRP) V006

Simple Network Management Protocol (SNMP) V006

LLDP-MIB, LLDP-EXT-DOT3-MIB, LLDP-EXT-PNO-MIB V006

EDD files SIMATIC PDM V006

Fast communication modes in VACON

PROFINET IO Alarms V007

Simple Network Time Protocol (SNTP) V008

Fast MRP support verified V008

Device Level Ring (DLR) V009

®

NXP

V007

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

2

vacon • 12 OPTEA/OPTE9 Ethernet board technical

3. OPTEA/OPTE9 ETHERNET BOARD TECHNICAL DATA

3.1 General

Table 6. Technical da ta

General Board name OPTEA/OPTE9

Ethernet connections

Communications

Protocol Modbus TCP, Modbus UDP, Profinet I/O, EtherNet/IP

Environment

Safety Fulfills EN50178 standard

Interface Two RJ-45 connectors

Transfer cable Shielded Twisted Pair (STP) CAT5e

Speed 10 / 100 Mb

Duplex half / full

Default IP-address By default the board is in DHCP mode

Ambient operating temperature

Storing temperature -40°C…70°C

Humidity <95%, no condensation allowed

Altitude Max. 1000 m

Vibration 0.5 G at 9...200 Hz

-10°C…50°C

3.2 Cables

For connecting the fieldbus Ethernet boards, use only Ethernet cables that meet at least the

requirements of category 5 (CAT5) according to EN 50173 or ISO/IEC 11801.

3

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

Layout and connections vacon • 13

RN ER BS

A

B C

1

2

11592_00

4. LAYOUT AND CONNECTIONS

The VACON® Ethernet option boards are connected to the Ethernet bus using the standard RJ45

connectors (1 and 2). The communication between the control board and the AC drive takes place

through a standard VACON

layout and connections.

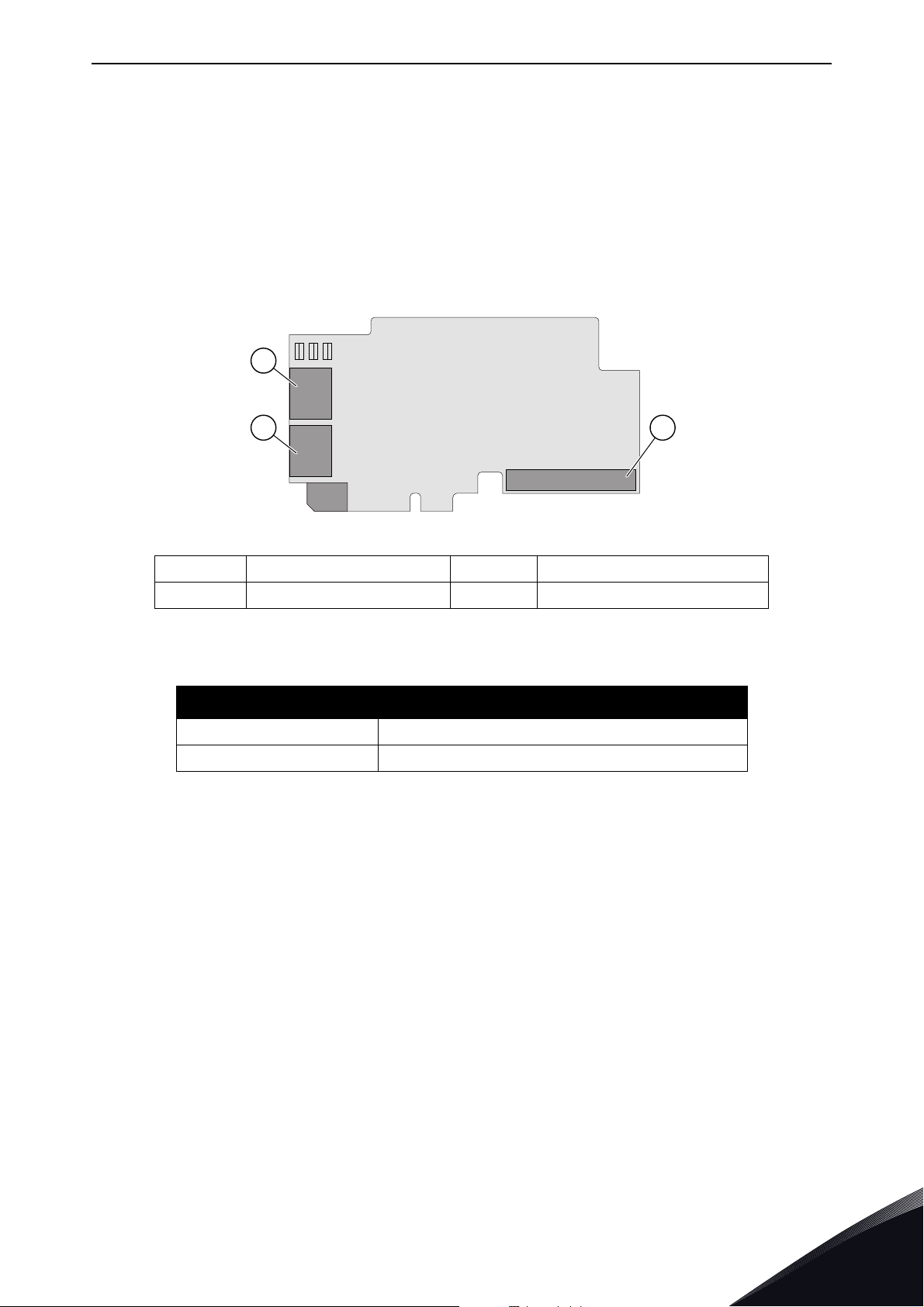

4.1 Layout and connections

®

Interface Board Connector. OPTEA and OPTE9 boards have identical

A Ethernet connector C Interface Board connector

B Ethernet connector

Figure 1. Option board layout

Table 7. Ethernet ports

Ethernet port Description

1 Ethernet port 1 (PHY1)

2 Ethernet port 2 (PHY2)

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

4

vacon • 14 Layout and connections

RN ER BS

A

1

2

11593_00

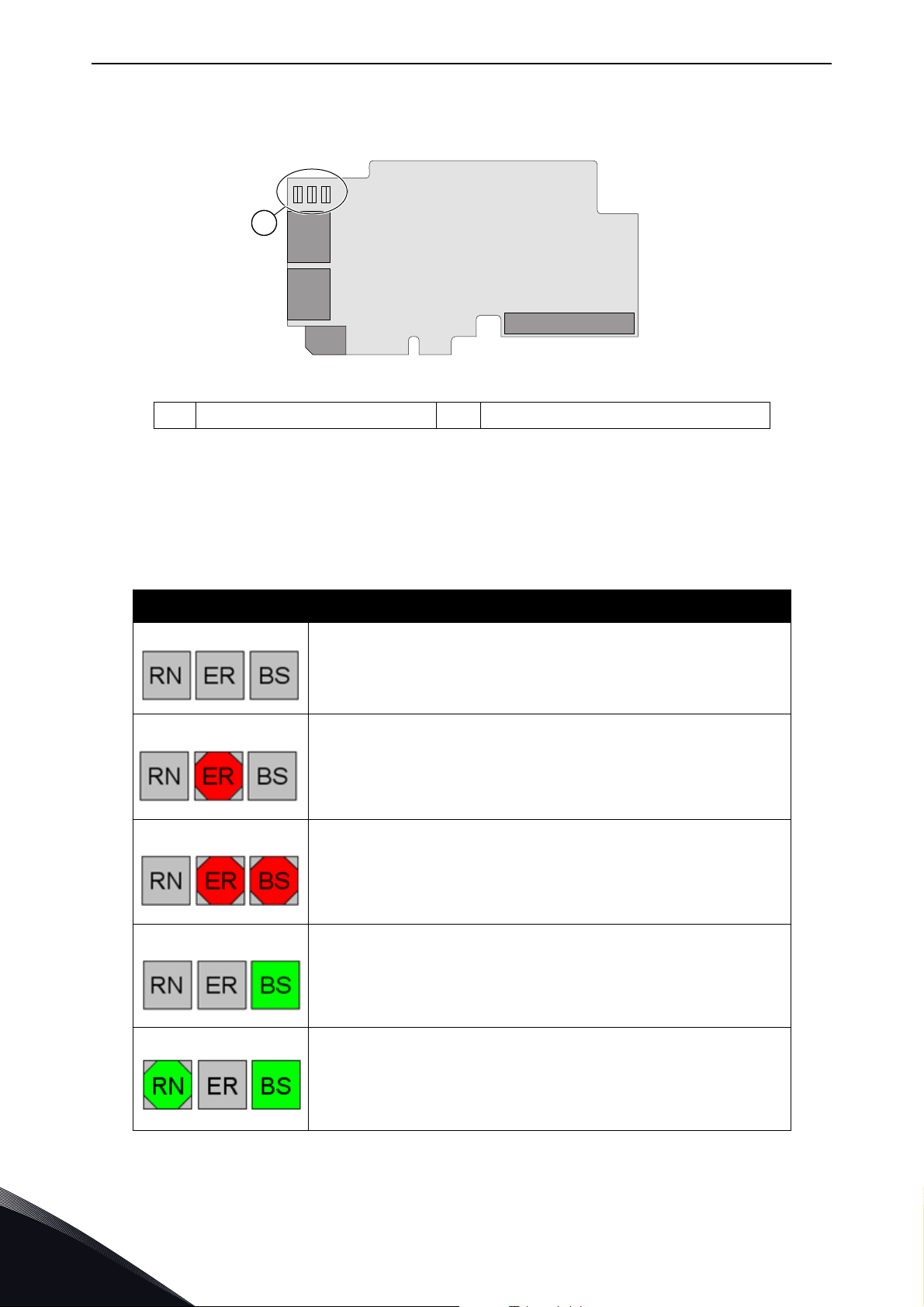

4.2 LED Indications

ALED indications

Figure 2. Option board LED indicators

The table below lists possible LED combinations and their meanings. When the EtherNet/IP is

active, the option board follows CIP standard for LED indications. Therefore, the indications

described in Table 8 do not apply. See Chapter 9.1.4 "LED functionality".

Table 8. List of possible LED combinations

LED combinations Description

No power. All LEDs are OFF.

Option board firmware is corrupted or its software is missing.

ER is blinking (0.25s ON / 0.25s OFF)

Option board failure. Option board is not operational. BS is red

and ER is possibly blinking (2.5s ON / 2.5s OFF)

Option board is operational.

Protocol is ready for communications. RN is blinking (2.5s ON /

2.5s OFF).

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

4

Layout and connections vacon • 15

LED combinations Description

Protocol is communicating.

Protocol communication fault. ER is blinking to indicate a fault.

RN is blinking to indicate that protocol is again ready for

communications.

Protocol is communicating with an active fault. ER is blinking.

Duplicate IP address detected. RN is blinking.

Profinet IO only! In node flashing test all three LEDs are

blinking.

If option board detects hardware failure or some other nonrecoverable fault situation, it will generate a slot fault (F54) and

all three LEDs are red. Try to update option board firmware. If

situation is not resolved with the update, you may need to

replace the option board.

4.2.1 Profinet IO

When using the "Node Flashing Test" function, you can determine to which device you are directly

connected. For example, in Siemens S7, by using the menu command "PLC > Diagnostics/Setting >

Node Flashing Test..." you can identify the station directly connected to the PG/PC if all three LEDs

are flashing green.

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

4

vacon • 16 Layout and connections

Power

12345678

11594_uk

Vacon PC tools interface

- Parameters

- Slow rate actual

Values:

- Trends

- Fault history

Ethernet switch

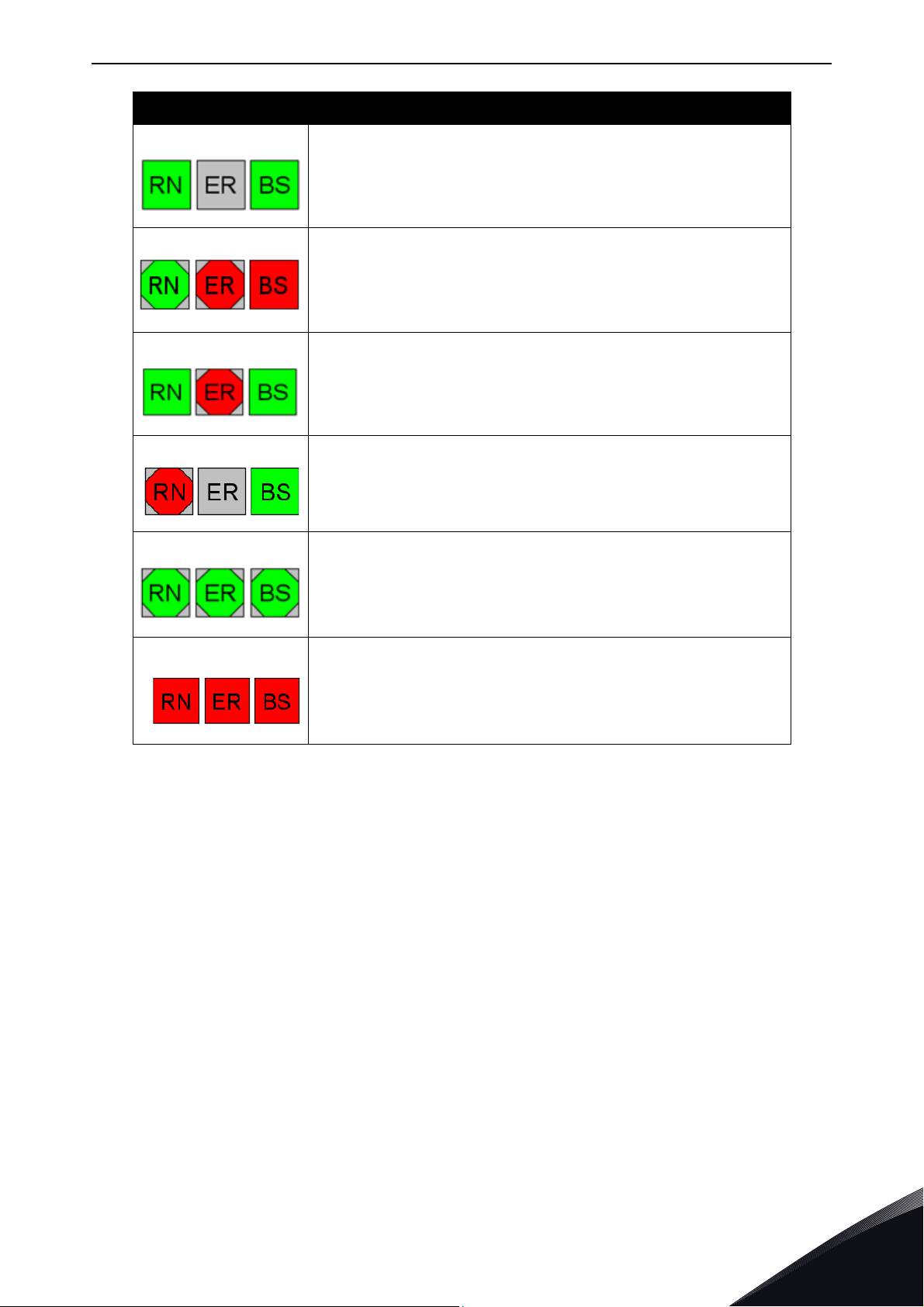

4.3 Ethernet devices

The common-use cases of Ethernet devices are 'human to machine' and 'machine to machine'. The

basic features of these two cases are presented in the pictures below.

4.3.1 Human to machine

Requirements:

- Graphical User Interface

- Relatively slow communication in use

NOTE! NCDrive can be used in VACON

with VACON

®

100 family.

NOTE! The Ethernet connection to VACON

Port Ethernet is not supported. OPTEA Advanced Dual Port Ethernet board does not support

VACON

®

20, VACON® 20 X or VACON® 20 CP.

Figure 3. Ethernet , Human to Machine

®

NXS and NXP drives via Ethernet. VACON® Live can be used

®

20, VACON® 20 X and VACON® 20 CP via the OPTE9 Dual

4

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

Layout and connections vacon • 17

Power

12345678

11595_uk

MASTER

Real-Time Control

- Start/Stop, Direction,...

- Reference

- Feedback

Ethernet switch

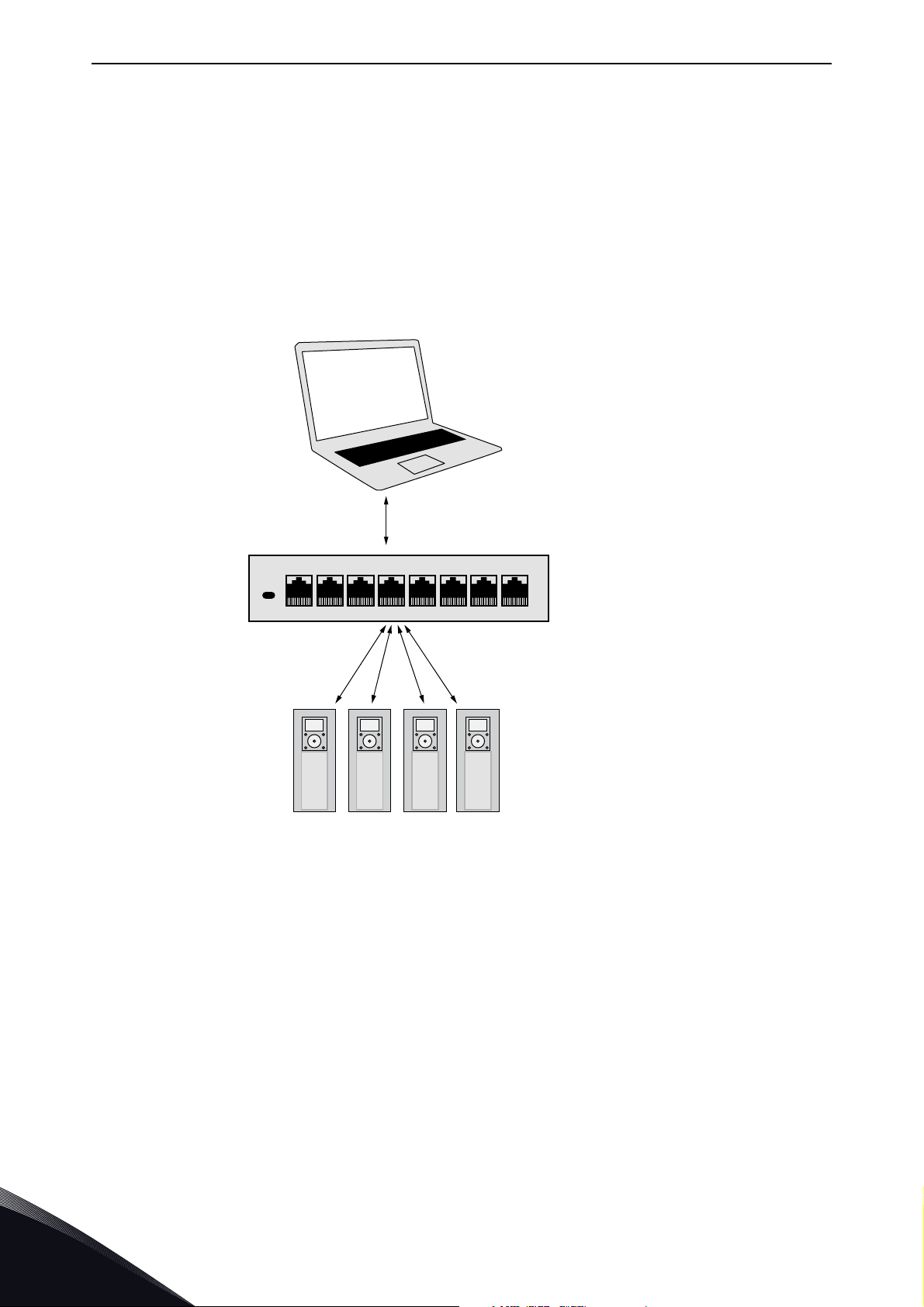

4.3.2 Machine to machine

Requirements:

- Industrial environment

- Fast communication in use

4.4 Connections and wiring

The option boards have two Ethernet ports and an embedded switch. An option board is seen in

network as a single device as it has only one MAC and IP address. This configuration enables three

different topologies:

• Star (see Chapter 4.4.1 "Topology: Star")

• Daisy chain (see Chapter 4.4.2 "Topology: Daisy Chain")

• Ring (see Chapter 4.4.3 "Topology: Ring")

Each of these topologies has their own advantages and disadvantages. When designing the network

you must carefully consider the risks and benefits against the cost of the selected topology.

Both boards support 10/100 Mb speeds in both Full- and Half-duplex modes. However, real-time

process control requires the Full-duplex mode and the 100-megabit speed. The boards must be

connected to the Ethernet network with a Shielded Twisted Pair (STP) CAT-5e cable (or better).

Use only industrial standard components in the network and avoid complex structures to minimize

the length of response time and the amount of incorrect dispatches. Both option boards have an

internal switch, so it does not matter in which port of the option board the Ethernet cables are

connected to.

Figure 4. Ethernet, Machine to Machine

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

4

vacon • 18 Layout and connections

k

PLC

DRIVE

OPTE9-1

DRIVE

...

OPTE9-2

DRIVE

OPTE9-3

DRIVE

OPTE9-8

11597A_uk

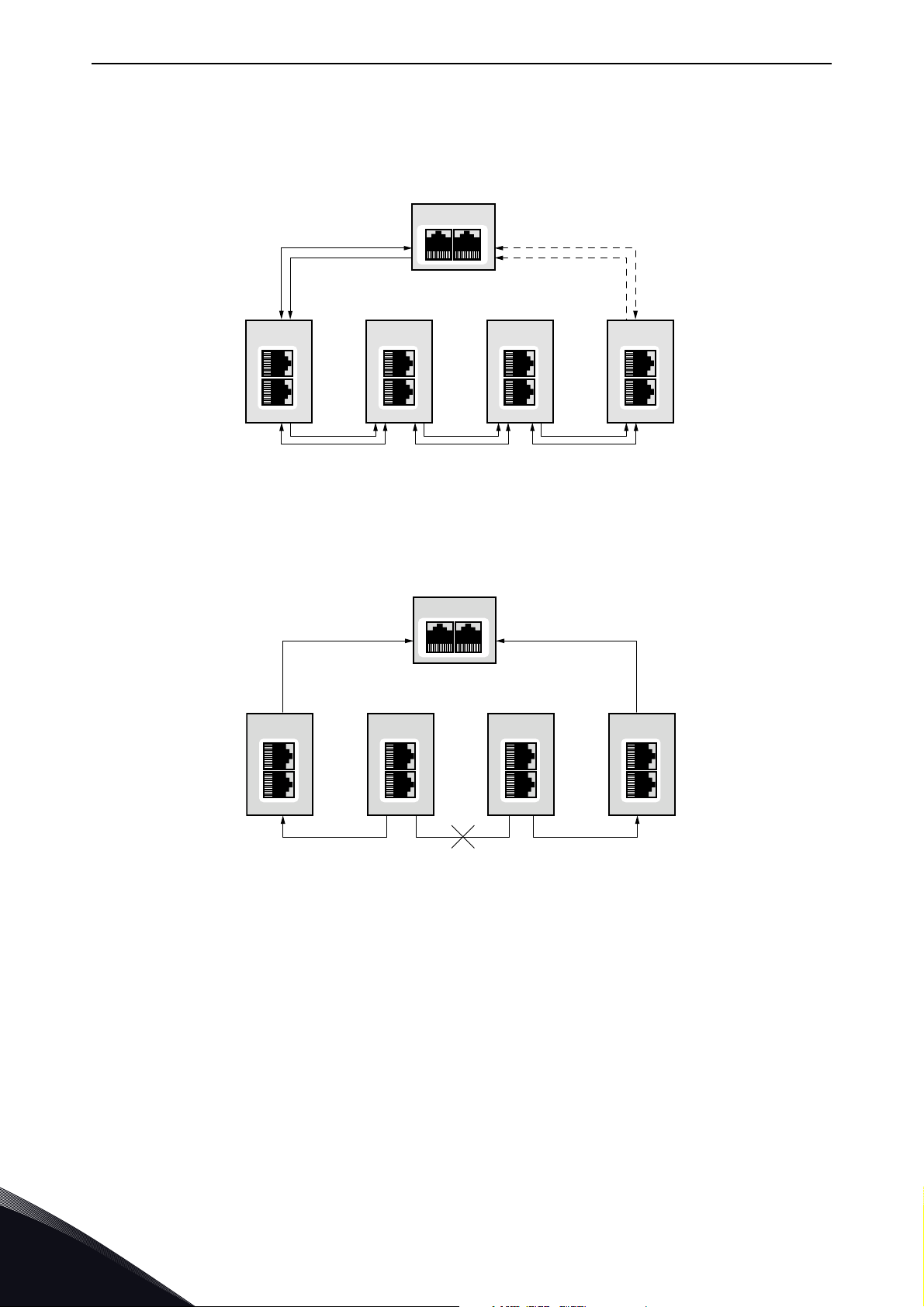

4.4.1 Topology: Star

In star network, all the devices are connected to the same switch(es). This topology reduces the

damage caused by single cable failure. It would affect only to a single drive instead of them all. In

this setup, a drive will receive only broadcast/multicast messages and messages directed to this

drive.

Only one port from the option board can be connected to a switch in the star topology. Connecting

both ports to switch(es) will cause an involuntary Ethernet ring which, in this setup, will break the

network.

1PLC

2345678

Power

DRIVE

OPTE9-1

DRIVE

OPTE9-2

DRIVE

OPTE9-3

DRIVE

...

OPTE9-8

11660_u

Figure 5. Star Topology

4.4.2 Topology: Daisy Chain

The daisy-chaining allows you to reduce the costs for cabling and networking equipment such as

switches. The maximum number of daisy-chained boards is 32. This restriction comes from the

average latency (20 to 40 microseconds) per Ethernet switch. The drawback in the daisy chain

topology is that it increases traffic in all except the last drive. The first drive in the daisy chain sees

all the traffic in the chain. Also damage to a single cable will drop all drives behind it from the

network.

Both in daisy chain topology and in star topology, the last drive's port must not be connected back

to the same line. This would cause an involuntary Ethernet ring which will break the network.

4

Figure 6. Daisy chain topology

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

Layout and connections vacon • 19

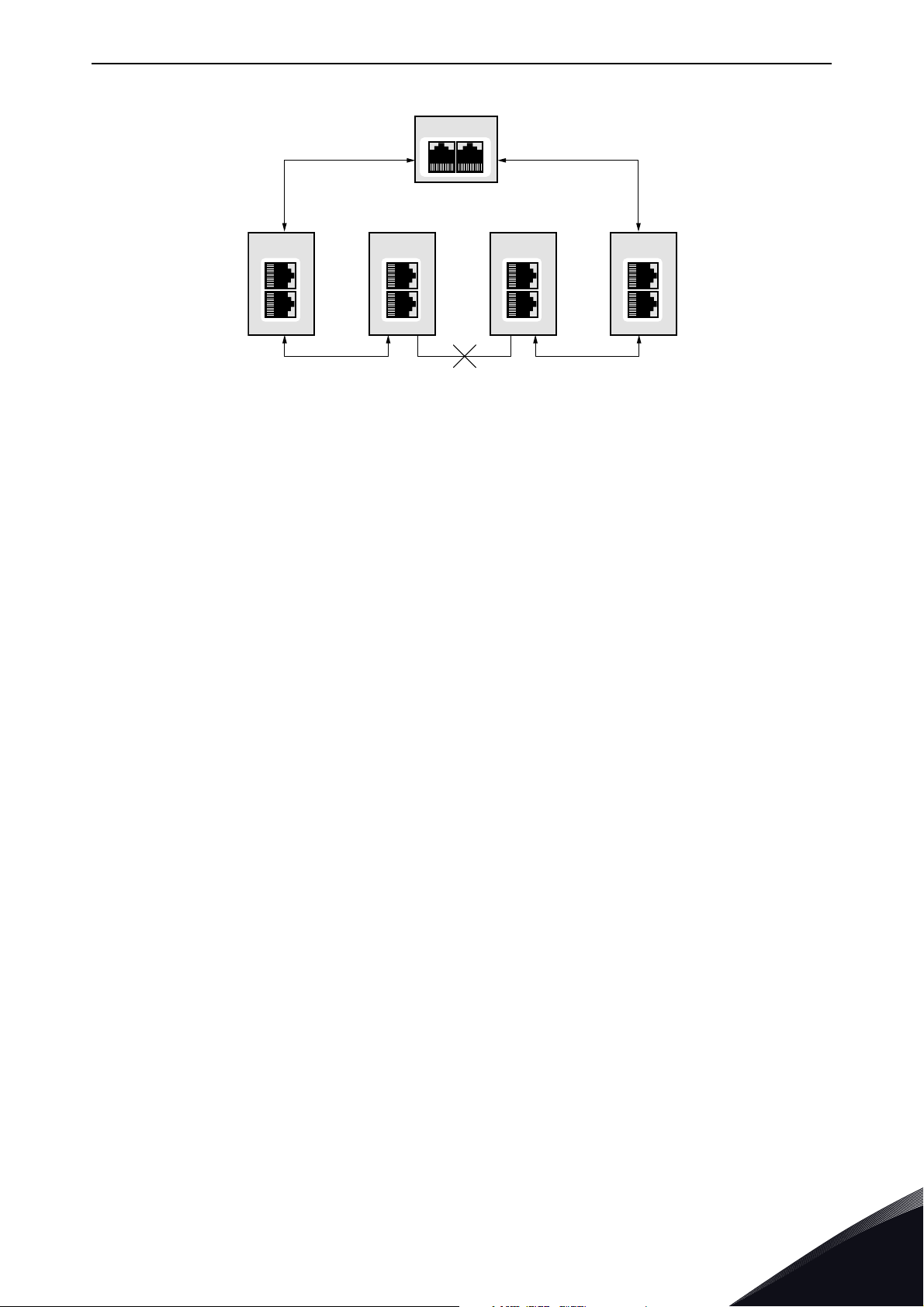

4.4.3 Topology: Ring

In some cases it is possible to use a ring topology. The ring topology gains the same reduced cabling

cost as the daisy chain topology, but decreases the damage caused by a single cable failure.

Both Ethernet boards can be used with the following media redundancy protocols:

Table 9. Supported media redundancy protocols

Protocol Active fieldbus protocol Recovery time

RSTP Any Seconds

MRP PROFINET

DLR EtherNet/IP ~4 ms

NOTE! Ring network sizes should be limited from what is specified in the media redundancy

protocols (usually up to 50 nodes) depending on the network load. When low I/O data intervals are

used, we recommend that ring networks should be limited to fewer than 32 devices. High load on

network can cause recovery times to increase and in worst cases to trigger a watchdog failure.

< 50 or < 10 ms with Fast-MRP

< 200 ms (typical)

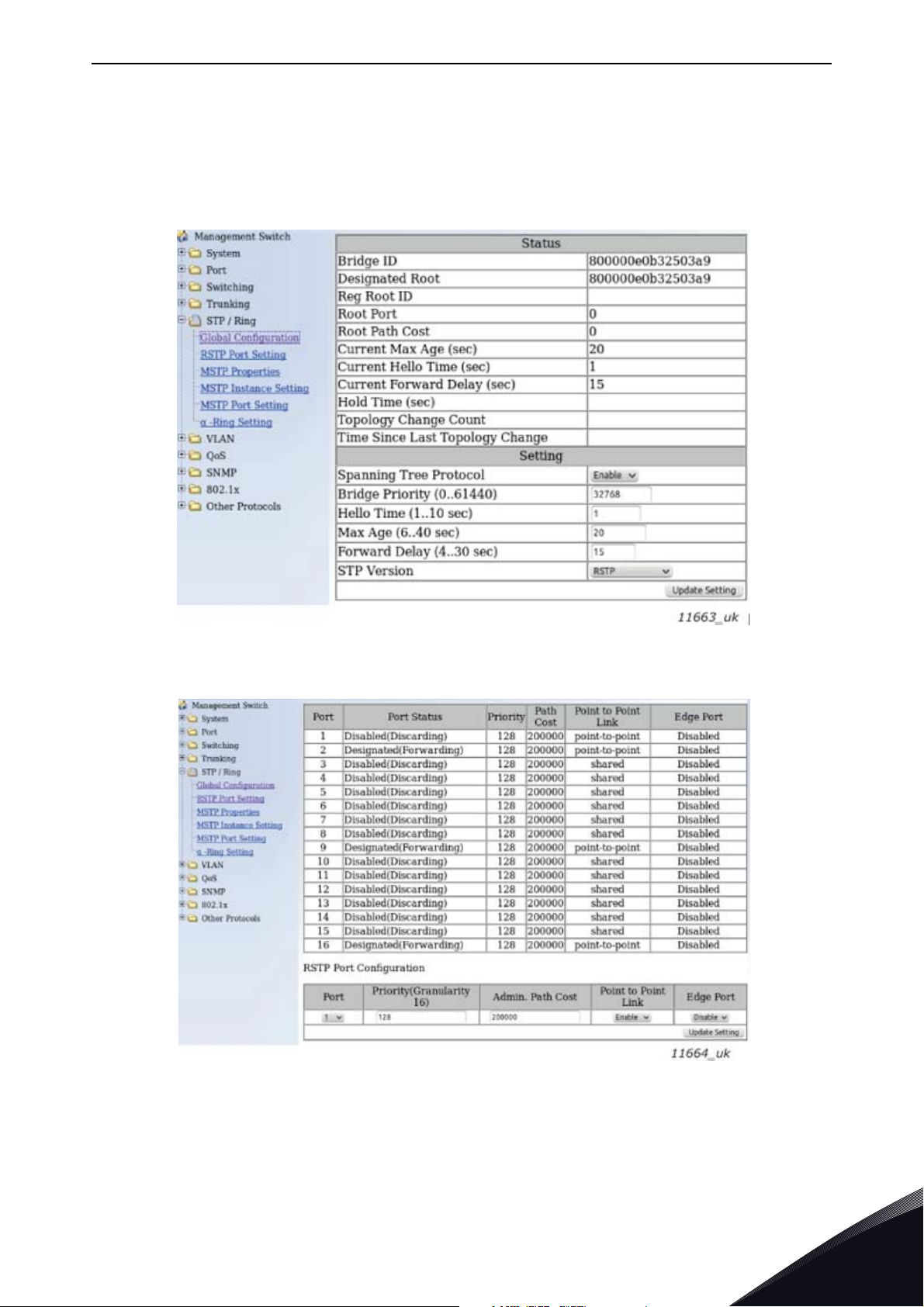

4.4.3.1

To use the RSTP protocol, add a managed Ethernet switch that supports the RSTP protocol. If a

single link is broken, the RSTP switch will notice this and start sending data from the PLC to both

directions effectively creating two daisy chains. When the link has been repaired, the switch will

notice this too and reverts back to normal operating mode. Compared to the star topology, the ring

topology adds more network traffic to almost all drives. Damage to two cables will always create an

isolated subnetwork.

In the RSTP configuration, one of the ports in the switch is "Designated Port" (DP) and the other

"Alternative Port" (AP). When the network is functioning properly, the traffic flows through the

designated port. Only the BPDU (Bridge Protocol Data Unit) packets are transferred through the AP

port. The BPDU packets are used by the switch to determine if the network is working properly. If it

detects that the BPDU packets do not go through the ring, it will change the alternative port to a

second designated port. Now the switch will send packets to both directions in the broken ring (see

Figure 8).

Each designated port has a list of MAC addresses which are behind that port. Only frames directed

to the device in the MAC list are forwarded into that designated port. The broadcast and multicast

frames are sent to all designated ports.

Rapid Spanning Tree Protocol (RSTP)

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

4

vacon • 20 Layout and connections

PLC

Managed switch with RSTP support

DRIVE

OPTE9-1

DRIVE

...

OPTE9-2

DRIVE

OPTE9-3

DRIVE

11661_uk

OPTE9-8

Power

12

DP AP

345678

PLC

Managed switch with RSTP support

DRIVE

OPTE9-1

DRIVE

...

OPTE9-2

DRIVE

OPTE9-3

DRIVE

11662_uk

OPTE9-8

Power

12

DP DP

345678

Figure 7. Ring topology

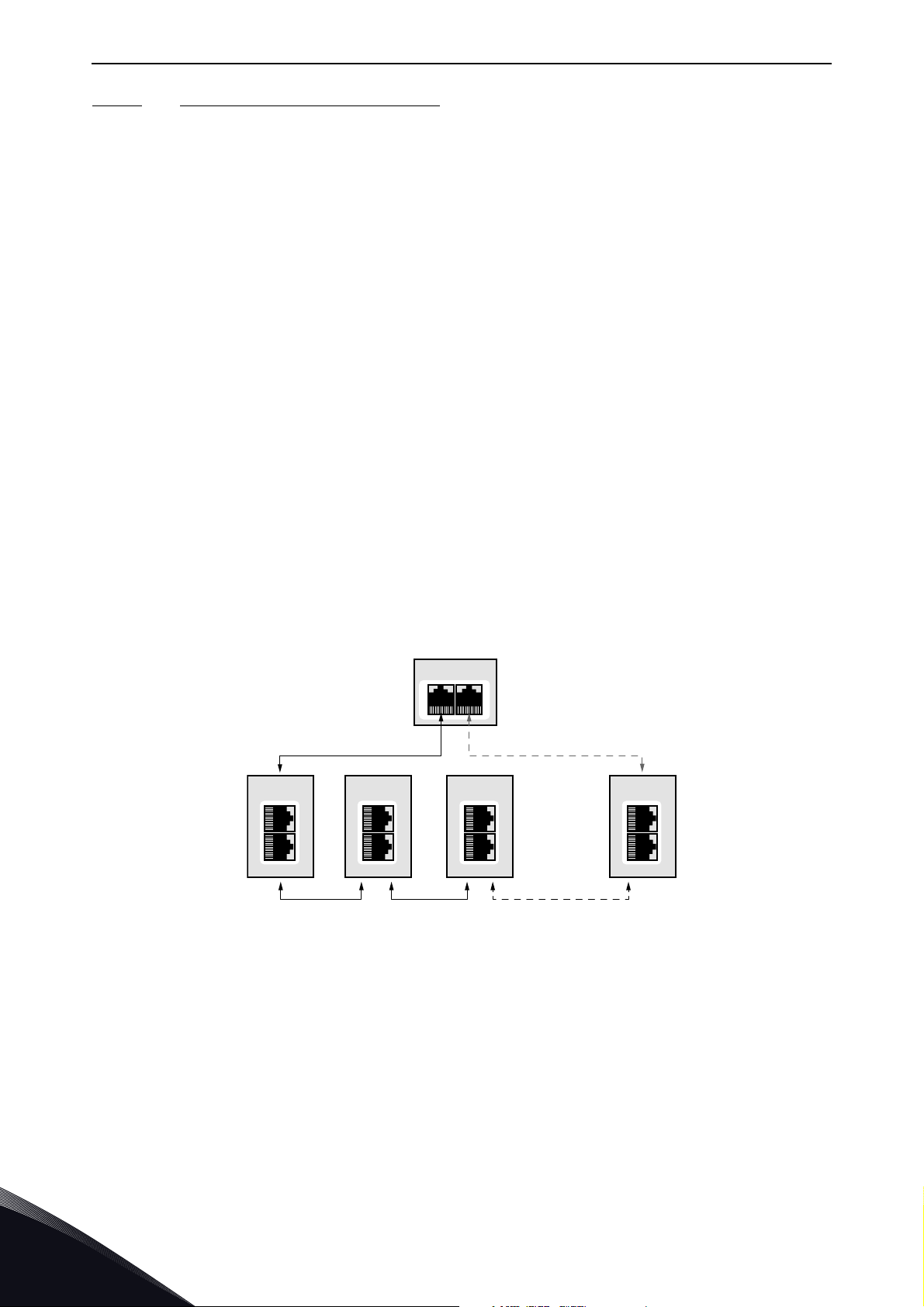

In the example below, the Ethernet communication will be interrupted to device number three and

other devices after that when the link is broken. The Fieldbus communication maybe faulted when

the link is broken, but when the switch enables the second designated port, the connections can be

reopened. In the RSTP protocol, it generally takes few seconds before the second designated port

will be activated. This depends on the BPDU exchange cycle, which is 2 seconds by default.

4

Figure 8. Ring topology: Error in network

NOTE! The switch in Ethernet boards itself does not implement the RSTP protocol, so the network

will always need a third party switch to support it.

NOTE! Do not use RSTP together with PROFIsafe. Recovery time in RSTP network can be several

seconds, and recovery time in STP network can be several tens of seconds. To compensate this, the

PROFIsafe watchdog time must be set long enough so that slow recovery time of RSTP network can

be tolerated. However, for example, in Siemens TIA portal, the longest PROFIsafe watchdog time

setting is 1920 ms, and this is too short for RSTP.

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

Layout and connections vacon • 21

Configuration example

The screenshots below (Figure 9, Figure 10) show one example of configuring the RSTP in the switch

(in this case an EtherWAN switch). Port two is the designated port and port one is the alternative

port. The PLC was connected to port nine (the laptop taking the screenshots was in port 16). When

configuring your switch, refer to the switch manufacturer's manual.

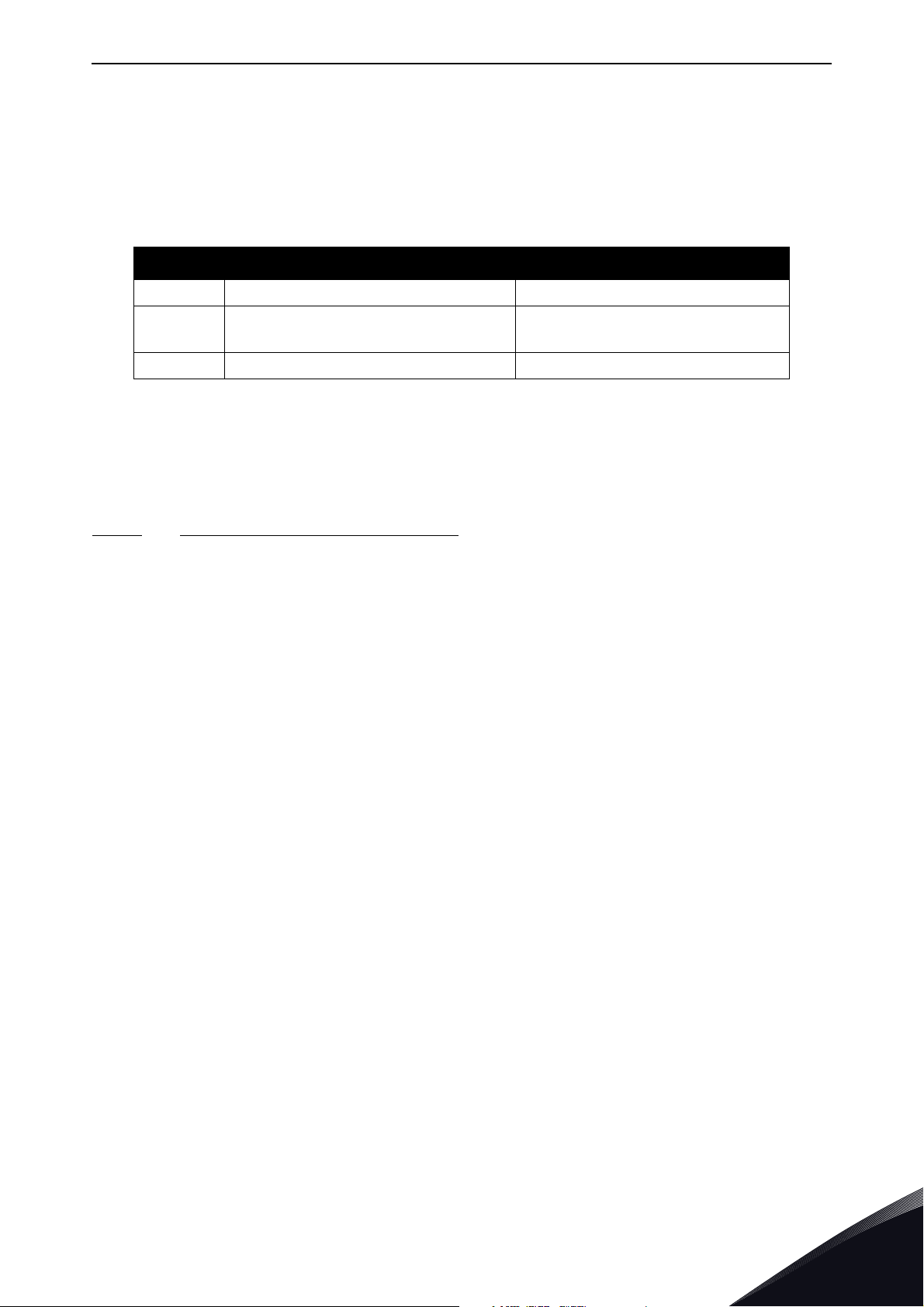

Figure 9. EtherWAN Switch RSTP Configuration example

Figure 10. EtherWAN Switch RSTP Configuration example - Port Settings

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

4

vacon • 22 Layout and connections

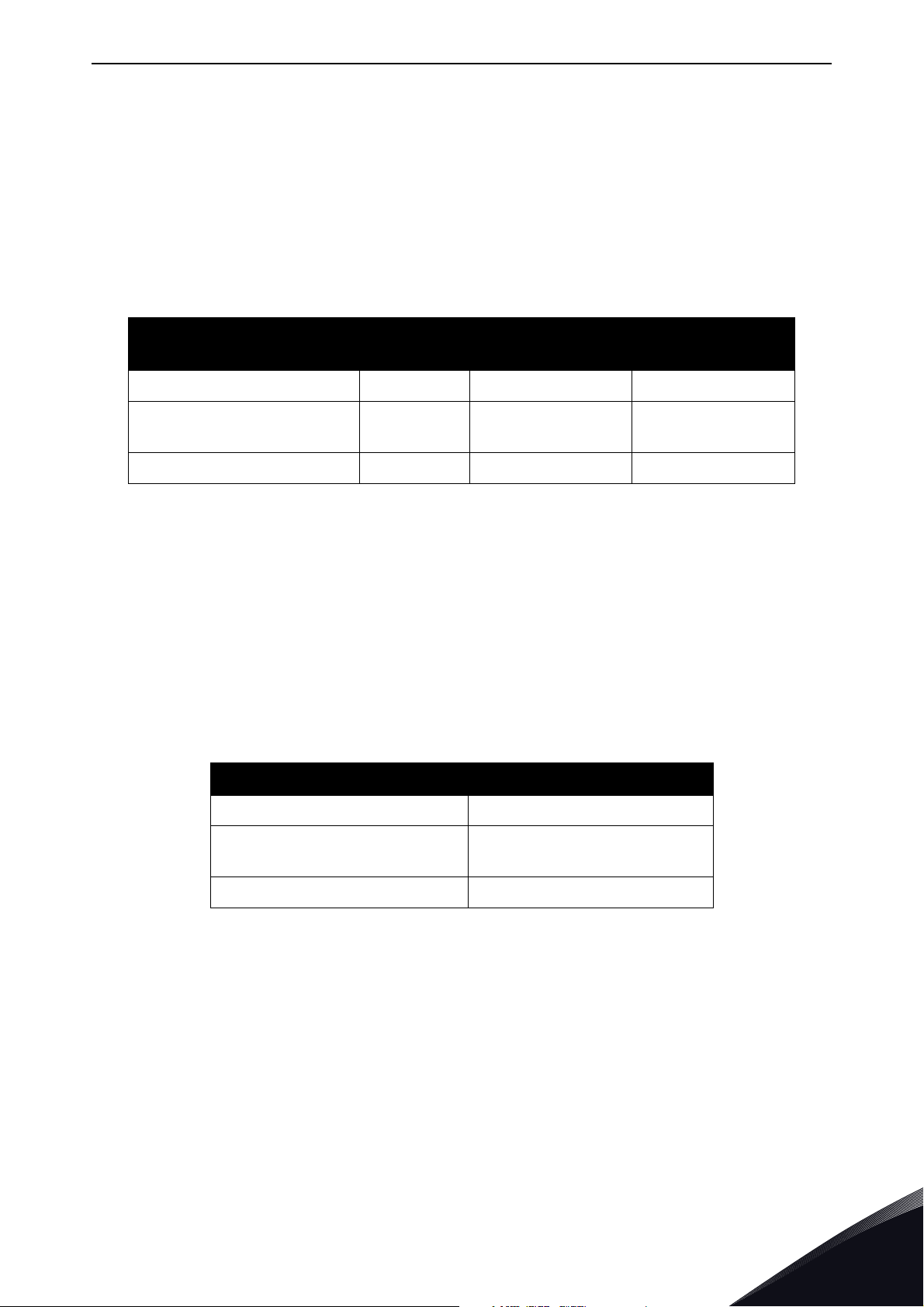

4.4.3.2 Media Redundancy Protocol (MRP)

The MRP is designed to react deterministically on a cable failure. This makes it suitable to be used

in process automation. One of the nodes in the network has the role of Media Redundancy Master

(MRM), which observes and controls the ring topology in order to react to network faults. Usually

this device is PLC or network switch.

The other nodes in the network are called Media Redundancy Clients (MRC), and they react on

received configuration frames from the MRM and can detect link changes on its ring ports. OPTEA

and OPTE9 boards support only MRC functionality.

The MRM and MRC have two ring ports, which take one of the following states:

•DISABLED

- All frames are dropped

•BLOCKING

- All frames are dropped, except the following frames:

a) MRP frames (e.g. MRP_test and MRP_TopologyChange)

b) Frames specified to pass ports in "Discarding" state, e.g. LLDP frames

•FORWARDING

- All frames are forwarded according to normal behaviour

The MRM sends MRP_Test frames in a configured time period to monitor the state of the ring

topology. If the MRM receives its own MRP_Test frames (network is closed), one of the ring ports is

set to FORWARDING state and the other to BLOCKED state (see Figure 11). If the MRP_Test frames

are not received by the MRM (network is open), it sets both of its ring ports to FORWARDING state

(see Figure 12).

The following figure shows an example of a MRP network, where the PLC acts as a MRM.

PLC

MRM

Forwarding Blocked

DRIVE

MRC

OPTE9-1

DRIVE

MRC

OPTE9-2 OPTE9-3

DRIVE

MRC

...

DRIVE

MRC

OPTE9-8

11713_uk

Figure 11. MRP ring: Closed network

4

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

Layout and connections vacon • 23

In the example below, the Ethernet communication will be interrupted to device number three and

other devices after that when the link is broken.

PLC

MRM

Forwarding Forwarding

DRIVE

MRC

OPTE9-1

DRIVE

MRC

OPTE9-2 OPTE9-3

DRIVE

MRC

...

DRIVE

MRC

OPTE9-8

11714_uk

Figure 12. MRP ring: Error in network

NOTE! MRP (as MRC) can only be used when PROFINET IO is the selected protocol. MRP is available

in all versions of OPTEA board and in OPTE9 since V006 firmware.

MRP Recovery Times and Fast MRP

MRP can be configured to send test frames with different time periods, depending on the maximum

allowed recovery time for the network. These times are set as the guaranteed time for a network of

50 nodes to recover from a ring error.

Typically, in PROFINET IO systems the recovery time is defined as 200 ms. However, the MRP

specification allows for recovery times of 500, 200, 30 and 10 ms. OPTEA and OPTE9 boards can be

used in systems with the lowest recovery time of 10 ms. This is often called “Fast MRP”.

When you use MRP in a PROFINET IO network, we suggest that you set the watchdog time of each

device in the ring to the maximum recovery time, usually 200 ms. This guarantees that a cable

failure does not interrupt the fieldbus connection.

4.4.3.3

Device Level Ring (DLR)

Device Level Ring (DLR) protocol provides a means for detecting, managing and recovering from

faults in a ring-based network. It supports a single-ring topology. Multiple or overlapping rings are

not supported. Other features include "Sign on process" used to identify all ring participants and

"Neighbor check process" which allows nodes to check the health of their adjacent nodes.

One device acts as a ring supervisor, monitoring the state of the ring while other devices act as DLR

nodes. Only one device can act as an active supervisor, although backup supervisors are possible.

Nodes can be divided into Beacon- and Announce-based nodes depending on which frames the

nodes process. OPTEA and OPTE9 boards support Announce-based functionality.

DLR nodes have three states:

• IDLE_STATE: indicating linear topology for non-supervisor nodes

• FAULT_STATE: initial state for enabled ring supervisor, or when ring fault has been detected

• NORMAL_STATE: normal function in ring topology mode

The active ring supervisor sends Beacon frames from both its ring ports once per beacon interval

(400 μs by default) to monitor the state of the ring and an Announce frame once per second. If the

Beacon frames are received back at the supervisor, one of its ports is set to blocking and the other

to forwarding state (Figure 13).

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

4

vacon • 24 Layout and connections

DLR

NODE

OPTE9-1

DLR

NODE

OPTE9-2

DLR

NODE

OPTE9-3

11858_uk

DLR

NODE

OPTE9-4

ACTIVE RING

SUPERVISOR

Link Status Link Status

• Only the following packets are processed from the blocked port:

• Beacon frames from self and other supervisors

• Link_Status/Neighbor_Status frames

• Neighbor_Check request or response and Sign_On frames

RING

SUPERVISOR

Beacon

Beacon

DLR

NODE

OPTE9-1

Announce

DLR

NODE

OPTE9-2

DLR

NODE

OPTE9-3

Announce

DLR

NODE

OPTE9-4

11857_uk

Figure 13. DLR ring: Network configuration when ring is closed (NORMAL_STATE)

If a network error occurs to DLR capable nodes, Link_Status frames are sent by nodes to inform the

ring supervisor immediately which port(s) have a failure (Figure 14).

4

Figure 14. DLR ring: Failure in network

A Link_Status frame triggers an error response in active ring supervisor, which unblocks traffic on

its previously blocked port (Figure 15). In case of an uncommon failure (for example, if cable breaks

between two non-DLR capable devices), the error is noticed from Beacon timeout value, and not

from Link_Status frames. Therefore, a recovery in a network with non-DLR capable devices can take

longer.

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

Layout and connections vacon • 25

ACTIVE RING

SUPERVISOR

DLR

NODE

OPTE9-1

DLR

NODE

OPTE9-2

DLR

NODE

OPTE9-3

DLR

NODE

OPTE9-4

11859_uk

Figure 15. DLR ring: Network configuration after failure (FAULT_STATE)

The ring recovers after Beacon frames again are received from both of the active ring supervisors

ring ports. Ring recovers back to its original state (Figure 13).

NOTE! DLR is active only when EtherNet/IP is the selected protocol. DLR is available since V002

fimware for OPTEA and since V009 firmware for OPTE9 board.

DLR Recovery Times

DLR allows setting of the beacon interval and the beacon timeout values, with lower beacon interval

providing faster ring recovery performance. With default values (400 μs interval and 1960 μs

timeout), DLR can reach much faster ring recovery times than e.g. Media Redundancy Protocol.

Typically, these times are around 3 ms for Beacon-based and 4 ms for Announce-based nodes.

When using DLR, we recommend that the watchdog time is set to a value greater than 4 ms. This

will ensure that a properly configured ring network will recover from a network failure within the

watchdog time.

4.5 ACD (Address Conflict Detection)

The OPTEA and OPTE9 option boards implement ACD algorithm (IETF RFC 5227). The

implementation includes requirements from the EtherNet/IP protocol.

The ACD algorithm tries to actively detect if the IP address configured to this device is been used by

another device in the same network. To accomplish this, ACD sends four ARP request packets when

the device's Ethernet interface goes up or when its IP address changes. ACD prevents the use of the

Ethernet interface until the ARP probing finishes. This delays the startup of fieldbus protocols about

one second. During the delay or after it, the ACD passively checks incoming ARP messages for use

of the device's IP address. If another device with the same IP address is detected, the ACD will try

to defend its IP address with a single ARP message. If the other device with the same IP address

also supports ACD, it should stop using the address. If not, the ACD will close the Ethernet

connection and indicate the situation with LEDs. This is done according the "DefendWithPolicyB".

Other policies are not supported. If the fieldbus protocol has been active, a fieldbus fault may be

activated (depends on the fieldbus and drive application configuration).

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

4

vacon • 26 Layout and connections

4.6 Time synchronization

4.6.1 Using ID 2551

System time in VACON

bit unsigned value to ID 2551. This value is seconds since 1.1.1970 (Unix time). In VACON

family, the default timezone is UTC. Local time can be configured by changing the timezone and

setting the daylight saving mode. VACON

written to this ID must be local time.

4.6.2 SNTP (Simple Network Time Protocol)

Simple Network Time Protocol enables usage of network time servers. Date and time information

is requested from the time server and set as system time. With SNTP, you can keep all devices in

your network in same time. This device acts as SNTP client. One use case for SNTP is that fault

history time stamps can now be compared between drives, enabling better fault tracing, for

example, detecting, in which order the drives were faulted. Synchronized date and time also enables

drives to automatically do programmed operations based on time information.

SNTP has two modes: Poll and Listen Only. Both also have modes where failure to update time will

generate fieldbus fault. In Poll mode, option board will request new time information periodically.

Default interval is 200 seconds. Lowest possible value is 30 seconds. This time can be adjusted from

SNTP parameters. In Listen only mode, time broadcast from server is expected every interval. You

can set two SNTP server addresses. For Poll mode, you have to define at least one SNTP server

address. You do not have to set server address in Listen Only mode, but in that case, the time

broadcasts are accepted from anyone who sends them.

When the SNTP client fails to receive time update from server within the time interval, it will first

wait (or request, depending on mode) the interval time again for the update. If it again does not

receive time update, it will change server and request (or wait for broadcast) from the second server.

If it receives the response from the second server, this server will be used until it fails. After device

restart, the SNTP will always first try the server number 1 (if its address has been defined). If the

second server also fails twice, the SNTP moves back to the server number one. If the selected mode

is Poll Fault or Listen Only Fault, a fieldbus fault is generated at this point.

®

100 family and VACON® NXP/NXS AC drives can be updated by writing 32

®

NXP/NXS AC drive does not have time settings, so value

®

100

SNTP also has port setting. By default, the SNTP port is 123, but you can change it. In Poll mode,

the requests are sent to this port on the time server. In Listen Only mode, the broadcasts are

listened in this port.

The SNTP monitoring values show the currently used SNTP server and the time since the last

received update. The SNTP status value tells status of the time synchronization. For example, if the

SNTP mode is Poll and you have not defined any SNTP server addresses, the SNTP status will be

"Invalid configuration (3)".

4

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

Installation vacon • 27

5. INSTALLATION

5.1 VACON

®

OPTEA Advanced Dual port Ethernet drive support

The VACON® OPTEA Advanced Dual Port Ethernet option board can be used with the following

VACON

®

AC drives. Option board can be used for PROFINET IO with PROFIsafe communication in

slot E, when OPTBL/OPTBM/OPTBN is installed to slot D. If PROFIsafe is not used, then OPTEA can

be installed to slot D too.

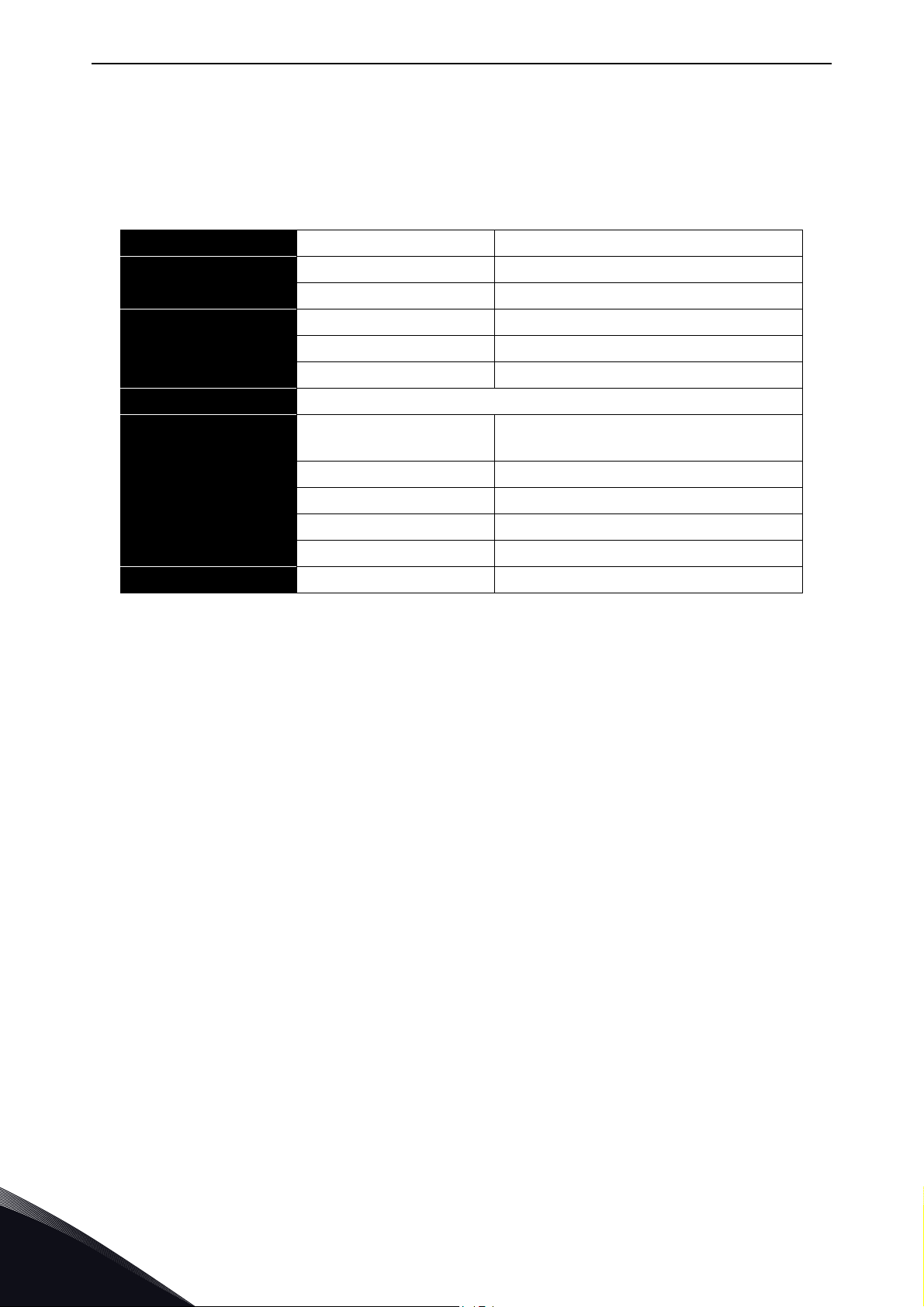

Table 10. OPTEA supported AC drives and slots

AC drive Slots

®

100 INDUSTRIAL

VACON

VACON

®

and 100 X

VACON® 100 FLOW

®

VACON

The VACON

100 family support

®

100 family AC drives are supported from the OPTEA firmware version V002. The

process data in VACON

From AC drive SW

version on

NXP

D, E NXP00002V196 V001

D, E FW0072V028 V002

D, E FW0159V018 V002

®

100 family AC drives is 32 bit. The 32-bit process data support is planned

From OPTEA SW

version on

for later firmware release. Only 16-bit process data is supported. PROFIsafe features are supported

®

only in VACON

NXP drives.

EtherNet/IP and Modbus TCP/UDP support

Support for EtherNet/IP, Modbus TCP/UDP and other features which were in OPTE9, were added to

OPTEA firmware V002. Table below shows required minimum AC drive firmware version.

Table 11. Required minimum AC drive firmware versions

AC Drive From AC drive SW version on

VACON

®

VACON

100 INDUSTRIAL and

VACON® 100 FLOW

®

100 X

NXP

NXP00002V197

FW0072V028

FW0159V018

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

5

vacon • 28 Installation

5.2 VACON® OPTE9 Dual Port Ethernet drive support

The VACON® OPTE9 Dual Port Ethernet option board can be used with the following VACON® AC

drives.

Table 12. OPTE9 supported AC drives and slots

AC drive Slots

®

®

100 INDUSTRIAL

VACON

VACON

VACON

®

and 100 X

VACON® 100 FLOW

VACON

®

20 X and CP

®

100 family AC drives are supported from the OPTE9 firmware version V003. The

VACON

®

100 family support

The VACON

VACON

process data in VACON

From AC drive SW

version on

NXP

NXS

D, E NXP00002V188 V001

D, E NXS00002V179 V001

D, E FW0072V018 V003

D, E FW0159V012 V003

®

20

- FW0107V011 V002

- FW0117V007 V002

®

100 family AC drives is 32 bit. The 32-bit process data support is planned

From OPTE9 SW

version on

for later firmware release. Only 16-bit process data is supported.

EtherNet/IP support

EtherNet/IP protocol was added to OPTE9 firmware version V004. The table below shows required

minimum AC drive firmware version .

Table 13. Required minimum AC drive firmware versions

AC Drive From AC drive SW version on

VACON® NXP

VACON

®

VACON

100 INDUSTRIAL and

VACON® 100 FLOW

VACON

VACON

®

NXS

100 X

®

20

®

20 X and CP

NXP00002V191

NXS00002V181

FW0072V018

FW0159V012

FW0107V012

FW0117V009

5

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

Installation vacon • 29

13006.emf

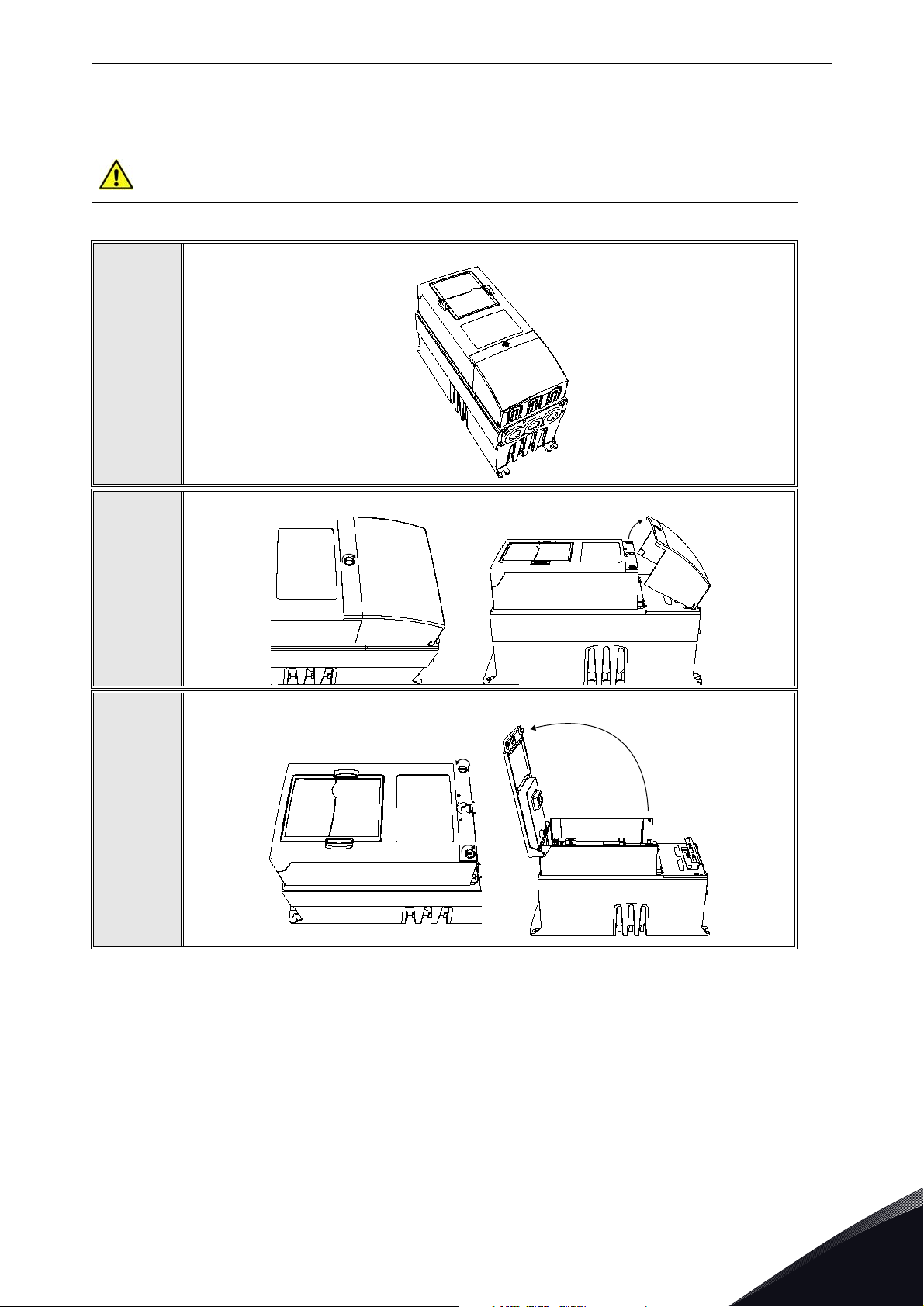

5.3 Installation in VACON® NX

Make sure that the AC drive is switched off before an option or fieldbus board is

changed or added!

VACON® NX AC drive.

1

Remove the cable cover.

2

3

Open the cover of the control unit.

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

5

vacon • 30 Installation

Install the option board in slot D or E on the control board of the AC drive. Make

sure that the grounding plate fits tightly in the clamp.

4

Make a sufficiently wide opening for your cable by cutting the grid as wide as

necessary.

5

6

Close the cover of the control unit and the cable cover.

5

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

Loading...

Loading...