Vacon X4 AC Drive Users Manual

X4 AC Drive

user's manual

Need Help?

This manual answers most installation and startup questions that may arise. However, if you have any problems, please let your first call be to us.

Vacon, Inc.

Chambersburg, PA 17202

Normal business hours:

(North America)

8:00 AM to 5:00 PM, Eastern time +1 877-Vacon06

(+1 877-822-6606) After-hours support is also available

and Vacon, Inc. are trademarks of Vacon Plc, a member of Vacon Group. All other product names are trademarks of their respective companies.

and Vacon, Inc. are trademarks of Vacon Plc, a member of Vacon Group. All other product names are trademarks of their respective companies.

Copyright 2009, Vacon, Incorporated. All rights reserved.

Summary of X4 Parameters

= cannot change in Run Bold type = Level 1 parameter

No. |

Parameter Name |

Options |

Default |

User Setting |

See Page |

001 |

Model Number |

Model Dependent |

Read-only |

|

60 |

|

|

|

|

|

|

002 |

Software Rev |

0.00-99.99 |

Read-only |

|

60 |

|

|

|

|

|

|

003 |

Rated Current |

0.0-200.0 A |

Read-only |

|

60 |

|

|

|

|

|

|

005 |

Serial No. 1 |

0-65535 |

Read-only |

|

60 |

|

|

|

|

|

|

006 |

Serial No. 2 |

0-65535 |

Read-only |

|

60 |

|

|

|

|

|

|

010 |

Last Fault |

text string |

Read-only |

|

60 |

|

|

|

|

|

|

025 |

4th Fault |

text string |

Read-only |

|

60 |

|

|

|

|

|

|

040 |

3rd Fault |

text string |

Read-only |

|

60 |

|

|

|

|

|

|

055 |

2nd Fault |

text string |

Read-only |

|

60 |

|

|

|

|

|

|

070 |

1st Fault |

text string |

Read-only |

|

60 |

|

|

|

|

|

|

102 |

Output Freq |

0.0-400.0 Hz |

Read-only |

|

61 |

|

|

|

|

|

|

103 |

Output Voltage |

0-600 V |

Read-only |

|

61 |

|

|

|

|

|

|

104 |

Output Current |

0.0-200.0 A |

Read-only |

|

61 |

|

|

|

|

|

|

105 |

Drive Load |

-200.0-200.0% |

Read-only |

|

61 |

|

|

|

|

|

|

106 |

Load Torque |

-200.0-200.0% |

Read-only |

|

61 |

|

|

|

|

|

|

107 |

Drive Temp |

-20.0-200.0 °C |

Read-only |

|

61 |

|

|

|

|

|

|

108 |

Total Run Time |

0.0-6553.5 h |

Read-only |

|

61 |

|

|

|

|

|

|

109 |

Power On Hours |

0-65535 h |

Read-only |

|

61 |

|

|

|

|

|

|

110 |

Stator Freq |

0.0-400.0 Hz |

Read-only |

|

61 |

|

|

|

|

|

|

111 |

DC Bus Voltage |

0 - 1000 Vdc |

Read-only |

|

61 |

|

|

|

|

|

|

115 |

Drive Power Out |

0.0-200.0% |

Read-only |

|

61 |

|

|

|

|

|

|

201 |

Input Mode |

text string |

Local Only |

|

62 |

202 |

Rev Enable |

text string |

Forward |

|

62 |

203 |

Stop Key Remote |

text string |

Coast |

|

62 |

204 |

Ref Select |

text string |

Vin1 |

|

63 |

|

|

|

|

|

|

205 |

Vin1 Config |

text string |

0-10V |

|

63 |

|

|

|

|

|

|

206 |

Vin1 Offset |

0.0% to 100.0 % |

0.00% |

|

63 |

|

|

|

|

|

|

207 |

Vin1 Span |

10.0% to 200.0% |

100.00% |

|

64 |

|

|

|

|

|

|

208 |

Cin Config |

text string |

0-20mA 50 |

|

64 |

|

|

|

|

|

|

209 |

Cin Offset |

0.0% to 100.0% |

0.0% |

|

64 |

|

|

|

|

|

|

210 |

Cin Span |

10.0% to 200.0% |

100.0% |

|

64 |

|

|

|

|

|

|

211 |

Vin2 Config |

text string |

0-10V |

|

64 |

|

|

|

|

|

|

212 |

Vin2 Offset |

0.0% to 100.0 % |

0.00% |

|

64 |

|

|

|

|

|

|

213 |

Vin2 Span |

10.0% to 200.0% |

100.00% |

|

64 |

|

|

|

|

|

|

214 |

Vin1 Filter Time |

0 to 1000 ms |

20 ms |

|

64 |

|

|

|

|

|

|

215 |

Cin Filter Time |

0 to 1000 ms |

20 ms |

|

64 |

|

|

|

|

|

|

216 |

Vin2 Filter Time |

0 to 1000 ms |

20 ms |

|

65 |

|

|

|

|

|

|

217 |

Trim Ref Enable |

text string |

Disabled |

|

65 |

|

|

|

|

|

|

218 |

Trim % Factor |

-100.0 - 100.0% |

0.0% |

|

65 |

|

|

|

|

|

|

222 |

Ref Loss Config |

text string |

No Fault |

|

65 |

|

|

|

|

|

|

301 |

Min Frequency |

0.0 - Max Freq. |

0.0 Hz |

|

65 |

|

|

|

|

|

|

302 |

Max Frequency |

0.0 - 400.0 Hz |

60.0 Hz |

|

65 |

|

|

|

|

|

|

303 |

Preset Freq 1 |

Min Freq-Max Freq |

5.0 Hz |

|

65 |

|

|

|

|

|

|

304 |

Preset Freq 2 |

Min Freq-Max Freq |

10.0 Hz |

|

65 |

|

|

|

|

|

|

305 |

Preset Freq 3 |

Min Freq-Max Freq |

20.0 Hz |

|

65 |

|

|

|

|

|

|

306 |

Preset Freq 4 |

Min Freq-Max Freq |

30.0 Hz |

|

65 |

|

|

|

|

|

|

307 |

Preset Freq 5 |

Min Freq-Max Freq |

40.0 Hz |

|

65 |

|

|

|

|

|

|

308 |

Preset Freq 6 |

Min Freq-Max Freq |

50.0 Hz |

|

65 |

|

|

|

|

|

|

(cont’d)

Note that all parameters can be addressed by adding 40000 to the parameter number. For example, parameter 201 (Input Mode) can be addressed by Modbus address 40201.

DPD00088A |

- iii - |

© 2009 Vacon Incorporated All Rights Reserved |

X4 AC Drive User’s Manual |

|

|

Summary of X4 Parameters |

||||||

|

|

|

|

|

|

|

= cannot change in Run |

||

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

Bold type |

= Level 1 parameter |

||

|

|

|

|

|

|

|

|

|

|

|

No. |

Parameter Name |

Options |

Default |

|

User Setting |

See Page |

|

|

|

|

|

|

|

|

|

|

|

|

309 |

Cut-Off Freq |

0.0-5.0 Hz |

0.0 Hz |

|

|

|

66 |

|

|

|

|

|

|

|

|

|

|

|

|

401 |

Ramp Select |

text string |

ART-DI |

|

|

|

66 |

|

|

|

|

|

|

|

|

|

|

|

|

402 |

Accel Time 1 |

0.1-3200.0 sec |

5.0 sec |

|

|

|

66 |

|

|

|

|

|

|

|

|

|

|

|

|

403 |

Decel Time 1 |

0.1-3200.0 sec |

5.0 sec |

|

|

|

66 |

|

|

|

|

|

|

|

|

|

|

|

|

404 |

Accel Time 2 |

0.1-3200.0 sec |

3.0 sec |

|

|

|

67 |

|

|

|

|

|

|

|

|

|

|

|

|

405 |

Decel Time 2 |

0.1-3200.0 sec |

3.0 sec |

|

|

|

67 |

|

|

|

|

|

|

|

|

|

|

|

|

406 |

DC Inject Config |

text string |

DC at Stop |

|

|

|

67 |

|

|

|

|

|

|

|

|

|

|

|

|

407 |

DC Inject Time |

0.0-5.0 sec |

0.2 sec |

|

|

|

67 |

|

|

|

|

|

|

|

|

|

|

|

|

408 |

DC Inject Level |

0.0% to 100.0% |

50.0% |

|

|

|

67 |

|

|

|

|

|

|

|

|

|

|

|

|

409 |

DC Inj Freq |

0.0 to 20.0 Hz |

0.0 Hz |

|

|

|

68 |

|

|

|

|

|

|

|

|

|

|

|

|

|

410 |

DB Config |

text string |

Internal |

|

|

|

68 |

|

|

414 |

S Ramp Rounding |

1 - 100% |

25% |

|

|

|

68 |

|

|

490 |

App Macro |

text string |

Factory |

|

|

|

50 |

|

|

491 |

Seq Appl |

text string |

Disabled |

|

|

|

50 |

|

492 |

SIO Visible |

text string |

No |

|

|

|

50 |

|

|

|

|

|

|

|

|

|

|

|

|

|

501 |

V/Hz Select |

text string |

Linear Fixed |

|

|

|

69 |

|

|

502 |

Voltage Boost |

0.0-50% |

1.0% |

|

|

|

69 |

|

|

|

|

|

|

|

|

|

|

|

|

503 |

V/Hz Knee Freq |

25.0-400.0 Hz |

60.0 Hz |

|

|

|

69 |

|

|

504 |

Skip Freq Band |

0.2-20.0 Hz |

0.2 Hz |

|

|

|

70 |

|

|

|

|

|

|

|

|

|

|

|

505 |

Skip Freq 1 |

Min Freq-Max Freq |

0.0 Hz |

|

|

|

70 |

|

|

|

|

|

|

|

|

|

|

|

|

506 |

Skip Freq 2 |

Min Freq-Max Freq |

0.0 Hz |

|

|

|

70 |

|

|

|

|

|

|

|

|

|

|

|

|

507 |

Skip Freq 3 |

Min Freq-Max Freq |

0.0 Hz |

|

|

|

70 |

|

|

|

|

|

|

|

|

|

|

|

|

508 |

Skip Freq 4 |

Min Freq-Max Freq |

0.0 Hz |

|

|

|

70 |

|

|

|

|

|

|

|

|

|

|

|

|

|

509 |

Rated Mtr Volt |

100V-690V |

Model Dependent |

|

|

|

70 |

|

|

510 |

Rated Mtr FLA |

50% - 200% of ND Rating |

ND Rating |

|

|

|

70 |

|

|

511 |

Rated Mtr RPM |

0-24000 rpm |

1750 rpm |

|

|

|

70 |

|

|

|

|

|

|

|

|

|

|

|

|

512 |

Midpoint Freq |

0.0 Hz-V/Hz Knee Freq |

60.0 Hz |

|

|

|

70 |

|

|

513 |

Midpoint Volt |

0.0-100.0% |

100.0% |

|

|

|

70 |

|

|

514 |

Motor RS |

0.0-655.35 Ohms |

Model Dependent |

|

|

|

70 |

|

|

|

|

|

|

|

|

|

|

|

515 |

Power Factor |

0.50-1.00 |

0.80 |

|

|

|

70 |

|

|

|

|

|

|

|

|

|

|

|

|

516 |

Slip Comp Enable |

text string |

No |

|

|

|

71 |

|

|

|

|

|

|

|

|

|

|

|

|

517 |

Single Phase |

text string |

No |

|

|

|

71 |

|

|

|

|

|

|

|

|

|

|

|

|

|

519 |

Find Mtr Data |

Not active / Motor RS |

Not active |

|

|

|

71 |

|

|

520 |

Filter FStator |

1 - 100 ms |

8 ms |

|

|

|

71 |

|

|

521 |

Start Field En |

Yes / No |

No |

|

|

|

71 |

|

|

522 |

Filter Time Slip |

10 - 1000 ms |

100 ms |

|

|

|

71 |

|

|

523 |

Id Percent |

0 - 200% |

Read-only |

|

|

|

72 |

|

|

524 |

Iq Percent |

0 - 200% |

Read-only |

|

|

|

72 |

|

|

525 |

Power Fail Config |

text string |

CTS No Msg |

|

|

|

72 |

|

|

|

|

|

|

|

|

|

|

|

526 |

UV Ride-Thru En |

text string |

w/ LVT |

|

|

|

72 |

|

|

|

|

|

|

|

|

|

|

|

|

600 |

Current Lim Sel |

text string |

Fixed Lvls |

|

|

|

73 |

|

|

|

|

|

|

|

|

|

|

|

|

601 |

Cur Lim Mtr Fwd |

5%-150% |

120% |

|

|

|

73 |

|

|

|

|

|

|

|

|

|

|

|

|

602 |

Cur Lim Mtr Rev |

5%-150% |

120% |

|

|

|

73 |

|

|

|

|

|

|

|

|

|

|

|

|

603 |

Cur Lim Reg Fwd |

5%-150% |

80% |

|

|

|

73 |

|

|

|

|

|

|

|

|

|

|

|

|

604 |

Cur Lim Reg Rev |

5%-150% |

80% |

|

|

|

73 |

|

|

|

|

|

|

|

|

|

|

|

|

605 |

Cur Lim Freq |

0-400 Hz |

3.0 Hz |

|

|

|

73 |

|

|

|

|

|

|

|

|

|

|

|

|

606 |

Ramp Time CL |

0.1-3200.0 sec |

1.0 sec |

|

|

|

73 |

|

|

|

|

|

|

|

|

|

|

|

|

607 |

Cur Limit Minimum |

0 - 50% |

10% |

|

|

|

73 |

|

|

|

|

|

|

|

|

|

|

|

|

608 |

Restart Number |

text string |

0 |

|

|

|

74 |

|

|

|

|

|

|

|

|

|

|

|

|

609 |

Restart Delay |

0-60 sec |

60 sec |

|

|

|

74 |

|

|

|

|

|

|

|

|

|

|

|

|

(cont’d)

Note that all parameters can be addressed by adding 40000 to the parameter number. For example, parameter 201 (Input Mode) can be addressed by Modbus address 40201.

DPD00088A |

- iv - |

© 2009 Vacon Incorporated All Rights Reserved |

X4 AC Drive User’s Manual |

|

|

Summary of X4 Parameters |

||||||

|

|

|

|

|

|

|

= cannot change in Run |

||

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

Bold type |

= Level 1 parameter |

||

|

|

|

|

|

|

|

|

|

|

|

No. |

Parameter Name |

Options |

Default |

User Setting |

See Page |

|

||

|

|

|

|

|

|

|

|

|

|

610 |

Timed OL Select |

text string |

Std Ind 60s |

|

|

|

74 |

|

|

|

|

|

|

|

|

|

|

|

|

|

613 |

Max Regen Ramp |

100 - 1000% |

300% |

|

|

|

74 |

|

|

614 |

Stability Gain |

0 - 10 |

Model Dependent |

|

|

|

75 |

|

|

|

|

|

|

|

|

|

|

|

615 |

Stability Rate |

0 - 1000 |

Model Dependent |

|

|

|

75 |

|

|

|

|

|

|

|

|

|

|

|

|

700 |

Vmet Config |

text string |

Freq Out |

|

|

|

75 |

|

|

|

|

|

|

|

|

|

|

|

|

701 |

Vmet Span |

0.0-200.0% |

100.0% |

|

|

|

75 |

|

|

|

|

|

|

|

|

|

|

|

|

702 |

Imet Config |

text string |

Drive Load |

|

|

|

75 |

|

|

|

|

|

|

|

|

|

|

|

|

703 |

Imet Span |

0.0-200.0% |

100.0% |

|

|

|

75 |

|

|

|

|

|

|

|

|

|

|

|

|

704 |

Imet Offset |

0.0-90.0-% |

0.0% |

|

|

|

75 |

|

|

|

|

|

|

|

|

|

|

|

|

705 |

Relay 1 Select |

text string |

Drv Fault |

|

|

|

76 |

|

|

|

|

|

|

|

|

|

|

|

|

706 |

Relay 2 Select |

text string |

Drive Run |

|

|

|

76 |

|

|

|

|

|

|

|

|

|

|

|

|

707 |

DO1 Select |

text string |

Drv Ready |

|

|

|

76 |

|

|

|

|

|

|

|

|

|

|

|

|

708 |

DO2 Select |

text string |

At Speed |

|

|

|

76 |

|

|

|

|

|

|

|

|

|

|

|

|

|

720 |

Active Logic |

text string |

Active High |

|

|

|

76 |

|

|

721 |

D1 Configure |

text string |

Preset 1 |

|

|

|

77 |

|

|

|

|

|

|

|

|

|

|

|

722 |

D2 Configure |

text string |

Preset 2 |

|

|

|

77 |

|

|

|

|

|

|

|

|

|

|

|

|

723 |

D3 Configure |

text string |

Preset 3 |

|

|

|

77 |

|

|

|

|

|

|

|

|

|

|

|

|

724 |

D4 Configure |

text string |

Alt Ramp |

|

|

|

77 |

|

|

|

|

|

|

|

|

|

|

|

|

725 |

D5 Configure |

text string |

Fault Reset |

|

|

|

77 |

|

|

|

|

|

|

|

|

|

|

|

|

726 |

MOL Polarity |

text string |

NO Operate |

|

|

|

77 |

|

|

|

|

|

|

|

|

|

|

|

|

727 |

MOL Configure |

text string |

MOL |

|

|

|

77 |

|

|

|

|

|

|

|

|

|

|

|

|

|

801 |

Program Number |

0-9999 |

0 |

|

|

|

77 |

|

|

802 |

Start Options |

text string |

LS Lockout |

|

|

|

78 |

|

|

803 |

PWM Frequency |

0.6-16.0 kHz |

3.0 kHz |

|

|

|

78 |

|

|

|

|

|

|

|

|

|

|

|

804 |

Display Mode |

text string |

Std Disply |

|

|

|

78 |

|

|

|

|

|

|

|

|

|

|

|

|

805 |

Display Units |

alphanumeric |

RPM:1 |

|

|

|

79 |

|

|

|

|

|

|

|

|

|

|

|

|

809 |

Display Scale |

1-65535 |

1 |

|

|

|

79 |

|

|

|

|

|

|

|

|

|

|

|

|

810 |

Language |

text string |

English |

|

|

|

79 |

|

|

|

|

|

|

|

|

|

|

|

|

811 |

Access Code |

0-9999 |

0 |

|

|

|

79 |

|

|

|

|

|

|

|

|

|

|

|

|

812 |

Freq Ref Output |

text string |

6FS |

|

|

|

79 |

|

|

|

|

|

|

|

|

|

|

|

|

813 |

Speed Ratio |

0.0-200.0% |

100.0% |

|

|

|

79 |

|

|

|

|

|

|

|

|

|

|

|

|

814 |

Display Status |

text string |

Drive load |

|

|

|

80 |

|

|

|

|

|

|

|

|

|

|

|

|

816 |

Fly Catch Mode |

Sweep FWD / REV / F/R |

Sweep FWD |

|

|

|

80 |

|

|

|

|

|

|

|

|

|

|

|

|

|

850 |

PI Configure |

text string |

No PI |

|

|

|

80 |

|

|

851 |

PI Feedback |

text string |

Vin1 |

|

|

|

80 |

|

|

|

|

|

|

|

|

|

|

|

852 |

PI Prop Gain |

0-2000 |

0 |

|

|

|

80 |

|

|

|

|

|

|

|

|

|

|

|

|

853 |

PI Int Gain |

0-10000 |

0 |

|

|

|

81 |

|

|

|

|

|

|

|

|

|

|

|

|

854 |

PI Feed Gain |

0-2000 |

1000 |

|

|

|

81 |

|

|

|

|

|

|

|

|

|

|

|

|

855 |

PI Error 1 |

0.00-100.00% |

Read-only |

|

|

|

81 |

|

|

|

|

|

|

|

|

|

|

|

|

856 |

PI Error 2 |

0.00-100.00% |

Read-only |

|

|

|

81 |

|

|

|

|

|

|

|

|

|

|

|

|

857 |

PI High Corr |

0.00-100.00% |

100.00% |

|

|

|

81 |

|

|

|

|

|

|

|

|

|

|

|

|

858 |

PI Low Corr |

0.00-100.00% |

0.00% |

|

|

|

81 |

|

|

|

|

|

|

|

|

|

|

|

|

900 |

SIO Protocol |

text string |

RTU N81 |

|

|

|

81 |

|

|

|

|

|

|

|

|

|

|

|

|

901 |

SIO Baud Rate |

text string |

9600 |

|

|

|

81 |

|

|

|

|

|

|

|

|

|

|

|

|

902 |

Comm Drop # |

1-247 |

1 |

|

|

|

81 |

|

|

|

|

|

|

|

|

|

|

|

|

903 |

SIO Timer |

0.0-60.0 sec |

1.0 sec |

|

|

|

81 |

|

|

|

|

|

|

|

|

|

|

|

|

904 |

SIO Cntl Word |

text string |

0x0000 |

|

|

|

82 |

|

|

|

|

|

|

|

|

|

|

|

|

905 |

Ext Ref Freq1 |

Min-Max Freq |

0.0 Hz |

|

|

|

82 |

|

|

|

|

|

|

|

|

|

|

|

|

906 |

Ext Ref Freq2 |

Min-Max Freq |

0.0 Hz |

|

|

|

82 |

|

|

|

|

|

|

|

|

|

|

|

|

(cont’d)

Note that all parameters can be addressed by adding 40000 to the parameter number. For example, parameter 201 (Input Mode) can be addressed by Modbus address 40201.

DPD00088A |

- v - |

© 2009 Vacon Incorporated All Rights Reserved |

X4 AC Drive User’s Manual |

Summary of X4 Parameters |

= cannot change in Run Bold type = Level 1 parameter

No. |

Parameter Name |

Options |

Default |

User Setting |

See Page |

|

|

|

|

|

|

908 |

Status Word |

text string |

Read-only |

|

82 |

|

|

|

|

|

|

909 |

DI Status |

text string |

Read-only |

|

82 |

|

|

|

|

|

|

910 |

Vin1 Status |

0.00-100.00% |

Read-only |

|

83 |

|

|

|

|

|

|

911 |

Cin Status |

0.00-100.00% |

Read-only |

|

83 |

|

|

|

|

|

|

912 |

Vin2 Status |

0.00-100.00% |

Read-only |

|

83 |

|

|

|

|

|

|

913 |

Output Status |

text string |

Read-only |

|

83 |

|

|

|

|

|

|

914 |

Vmet Status |

0.00-100.00% |

Read-only |

|

83 |

|

|

|

|

|

|

915 |

Imet Status |

0.00-100.00% |

Read-only |

|

83 |

|

|

|

|

|

|

916 |

Infrared Baud |

n/a |

9600 |

|

83 |

|

|

|

|

|

|

931 |

Seq Cntl 1 |

n/a |

00000000000 |

|

83 |

932 |

Seq Cntl 2 |

n/a |

00000000000 |

|

83 |

933 |

Seq Cntl 3 |

n/a |

00000000000 |

|

83 |

934 |

Seq Cntl 4 |

n/a |

00000000000 |

|

83 |

935 |

Seq Cntl 5 |

n/a |

00000000000 |

|

83 |

936 |

Seq Cntl 6 |

n/a |

00000000000 |

|

83 |

937 |

Seq Cntl 7 |

n/a |

00000000000 |

|

83 |

938 |

Seq Cntl 8 |

n/a |

00000000000 |

|

83 |

939 |

Seq Cntl 9 |

n/a |

00000000000 |

|

83 |

951 |

Seq Count 1 |

0-65535 |

0 |

|

84 |

|

|

|

|

|

|

952 |

Seq Count 2 |

0-65535 |

0 |

|

84 |

|

|

|

|

|

|

953 |

Seq Count 3 |

0-65535 |

0 |

|

84 |

|

|

|

|

|

|

954 |

Seq Count 4 |

0-65535 |

0 |

|

84 |

|

|

|

|

|

|

955 |

Seq Count 5 |

0-65535 |

0 |

|

84 |

|

|

|

|

|

|

956 |

Seq Count 6 |

0-65535 |

0 |

|

84 |

|

|

|

|

|

|

957 |

Seq Count 7 |

0-65535 |

0 |

|

84 |

|

|

|

|

|

|

958 |

Seq Count 8 |

0-65535 |

0 |

|

84 |

|

|

|

|

|

|

959 |

Seq Count 9 |

0-65535 |

0 |

|

84 |

|

|

|

|

|

|

Note that all parameters can be addressed by adding 40000 to the parameter number. For example, parameter 201 (Input Mode) can be addressed by Modbus address 40201.

DPD00088A |

- vi - |

© 2009 Vacon Incorporated All Rights Reserved |

X4 AC Drive User’s Manual |

Table of Contents |

CONTENTS

Summary of X4 Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iii

Chapter 1: Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.1 Product Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 1.2 Overview of This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 1.3 User’s Manual Publication History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Chapter 2: Technical Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.1 |

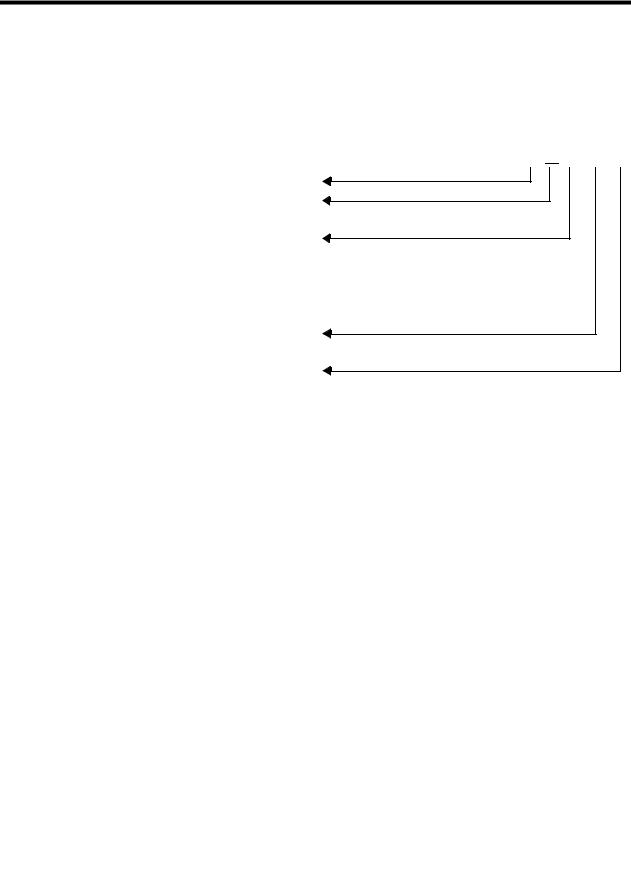

Interpreting Model Numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

11 |

2.2 |

Power and Current Ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

12 |

2.3 |

Environmental Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

13 |

2.4 |

Electrical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

14 |

2.5 |

Control Features Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

15 |

2.6 |

Dimensions and Weights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

16 |

Chapter 3: Receiving and Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3.1 Preliminary Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3.2 Installation Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3.3 Dissipation Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

3.4 Cover Assembly and Torque Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

3.5 Serial Number Label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

3.6 Conduit Usage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

3.7 Condensation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Chapter 4: Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

4.1 |

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

25 |

4.2 |

General Wiring Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

25 |

4.2.1 Wiring Practices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25 4.2.2 Considerations for Power Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25 4.2.3 Considerations for Control Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

4.3 Input Line Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

4.3.1 Line Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27 4.3.2 Line Capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27 4.3.3 Phase Imbalance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27 4.3.4 Single-phase Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28 4.3.5 Ground Fault Circuit Interrupters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28 4.3.6 Motor Lead Length . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28 4.3.7 Using Output Contactors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

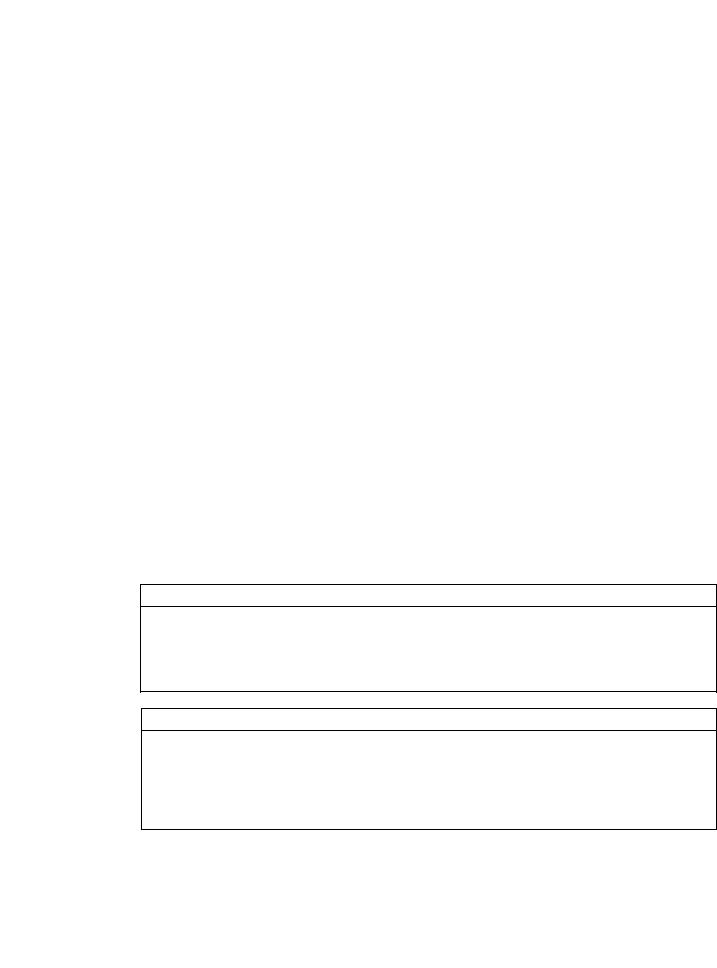

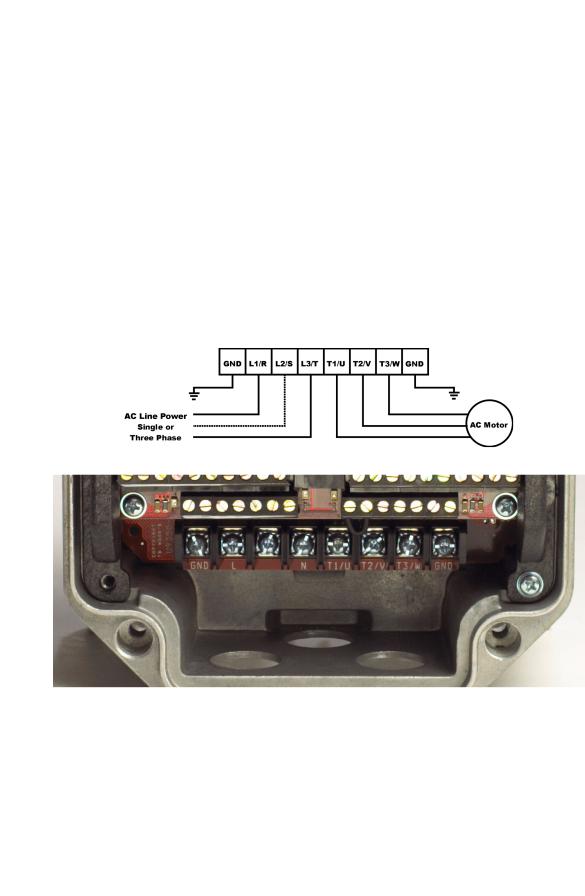

4.4 Terminals Found on the X4 Power Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

4.4.1 Description of the Terminals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29 4.4.2 Typical Power Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

4.5 Dynamic Braking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32 4.6 Terminals Found on the X4 Control Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

4.6.1 |

Description of the Control Terminals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

34 |

4.6.2 |

Typical Connection Diagrams for Digital Inputs . . . . . . . . . . . . . . . . . . . . . . . . |

37 |

DPD00088A |

- vii - |

© 2009 Vacon Incorporated All Rights Reserved |

X4 AC Drive User’s Manual |

Table of Contents |

4.6.3 Typical Connection Diagrams for Analog Inputs . . . . . . . . . . . . . . . . . . . . . . . .38 4.6.4 Typical Connection Diagrams for Analog Outputs . . . . . . . . . . . . . . . . . . . . . . .38 4.6.5 Modbus Connection Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

4.7 Reducing Current Surges and Voltage Transients . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Chapter 5: Keypad Operation and Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

40 |

|

5.1 |

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

40 |

5.2 |

Keypad Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

41 |

5.3 |

LCD Displays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

43 |

5.3.1 Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

5.3.2 X4 Keypad Status and Warning Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

5.3.3 Rights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

5.3.4 Other Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

5.4 Keypad Display Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

5.5 Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

5.5.1 Accessing Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

5.5.2 Changing the Display Scroll Rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

5.5.3 Programming Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

5.5.4 Restoring Factory Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

5.5.5 Viewing Parameters That Have Changed. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

5.5.6 Using Macro Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

5.6 Measuring Stator Resistance (RS Measurement) . . . . . . . . . . . . . . . . . . . . . . . . . . |

47 |

|

5.6.1 |

Activating Automatic RS Measurement Using the Keypad . . . . . . . . . . . . . . . |

.47 |

5.6.2 |

Activating Automatic RS Measurement via Serial Link (Modbus) . . . . . . . . . . |

48 |

Chapter 6: Using Macro Mode and Getting a Quick Start . . . . . . . . . . . . . . . . . . . . . . . . 49

6.1 Entering Macro Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49 6.2 Description of Parameters Used in Macro Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . 50 6.3 Macro Mode Applications and Included Parameters . . . . . . . . . . . . . . . . . . . . . . . . 52 6.4 Quick Start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Chapter 7: X4 Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

7.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

7.2 Level 1 Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

7.3 Description of Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

7.4 Using the X4 Program Sequencer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

7.4.1 Enabling the X4 Program Sequencer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .84

7.4.2 Controlling the X4 Program Sequencer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .84

7.4.3 Sequencer State Configuration Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .86

7.4.4 Sequencer Status Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .89

7.4.5 Sample Sequencer Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .89

Blank Worksheet to Remove and Copy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .91

Chapter 8: Troubleshooting and Fault Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93 Chapter 9: X4 AC Drive Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98 Appendix A: Parameter 201 Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

DPD00088A |

- viii - |

© 2009 Vacon Incorporated All Rights Reserved |

Chapter 1: Introduction

1.1Product Overview

Although the X4 AC drive is small in size, it is big on performance. It is an economical yet powerful solution for many industrial applications. It features remote communications capability (using Modbus® protocol), a keypad for easy configuration, and standard NEMA 4X / IP66 and NEMA 12 / IP55 enclosures that eliminate the need for mounting in a separate enclosure.

The X4 product family includes a wide variety of models to suit almost any input voltage requirement. An ‘x’ in the following table indicates what models are currently available. Refer to “Chapter 2: Technical Characteristics” on page 11 for help in interpreting model numbers.

|

|

|

Input Voltage |

|

|

Horsepower |

115 Vac |

230 Vac |

|

460 Vac |

575 Vac |

|

1 Phase |

3 Phase |

|

3 Phase |

3 Phase |

1 |

x |

x |

|

x |

x |

|

|

|

|

|

|

2 |

|

x |

|

x |

x |

|

|

|

|

|

|

3 |

|

x |

|

x |

x |

|

|

|

|

|

|

5 |

|

x |

|

x |

x |

|

|

|

|

|

|

7.5 |

|

x |

|

x |

x |

|

|

|

|

|

|

10 |

|

x |

|

x |

x |

|

|

|

|

|

|

15 |

|

x |

|

x |

x |

|

|

|

|

|

|

20 |

|

x |

|

x |

x |

|

|

|

|

|

|

25 |

|

x |

|

x |

x |

|

|

|

|

|

|

30 |

|

x |

|

x |

x |

|

|

|

|

|

|

40 |

|

|

|

x |

x |

|

|

|

|

|

|

50 |

|

|

|

x |

x |

|

|

|

|

|

|

60 |

|

|

|

x |

x |

|

|

|

|

|

|

75 |

|

|

|

x |

x |

|

|

|

|

|

|

100 |

|

|

|

x |

x |

|

|

|

|

|

|

125 |

|

|

|

x |

x |

|

|

|

|

|

|

150 |

|

|

|

x |

x |

|

|

|

|

|

|

200 |

|

|

|

x |

x |

|

|

|

|

|

|

1.2Overview of This Manual

This manual contains specifications, receiving and installation instructions, configuration, description of operation, and troubleshooting procedures for X4 AC drive devices.

For experienced users, a Quick Start section begins on page 58. A summary of parameters begins on page iii of this manual.

DPD00088A |

- 9 - |

© 2009 Vacon Incorporated All Rights Reserved |

X4 AC Drive User’s Manual Chapter 1: Introduction

1.3 User’s Manual Publication History

Date |

Form Number |

Nature of Change |

|

June 2005 |

1428 |

First release |

|

|

|

|

|

|

|

Minor corrections throughout manual. |

|

|

|

Clarification of technical information and specifications. |

|

March 2006 |

1428B |

Added X4 models for Frame Size 2. |

|

|

|

Reformatted to larger page-size document; separated appendices |

|

|

|

from manual to be available on the web site (www.vacon.com). |

|

|

|

|

|

August 2006 |

1428C |

Minor corrections and enhancements throughout manual. |

|

Added 40 and 50 HP models. |

|||

|

|

||

|

|

|

|

June 2007 |

1428D |

Added 60-200 HP models, new parameters. |

|

Minor corrections and reformatting throughout manual. |

|||

|

|

||

|

|

|

|

March 2008 |

1428E |

Minor changes to format, copyright information, and logo |

|

Minor corrections throughout manual |

|||

|

|

||

|

|

|

|

May 2008 |

1428F |

Minor corrections throughout manual; added new EU Declaration |

|

of Conformity |

|||

|

|

||

|

|

|

|

June 2008 |

1428G |

Changed corporate information for Vacon Incorporated |

|

|

|

|

|

|

DPD00088 |

Changed installation diagrams to reflect changes in product; |

|

|

changed photographs of product; added information to Chapter 2 |

||

November 2008 |

(1st release under this |

||

|

number) |

on current surges and voltage transients; deleted mention of |

|

|

Model X4C20300C; other minor changes and corrections. |

||

|

|

||

|

|

|

|

April 2009 |

DPD00088A |

Revised EU Declaration of Conformity |

|

|

|

|

DPD00088A |

- 10 - |

© 2009 Vacon Incorporated All Rights Reserved |

Chapter 2: Technical Characteristics

2.1Interpreting Model Numbers

The model number of the X4 AC drive appears on the shipping carton label and on the technical data label affixed to the model. The information provided by the model number is shown below:

X4 C 20 030 C

X4 Series

Torque:

C = Constant - Normal duty

Input Voltage:

1S |

= |

115 Vac, Single-phase |

20 |

= |

230 Vac, Three-phase |

40 |

= |

460 Vac, Three-phase |

50 |

= |

575 Vac, Three-phase |

Horsepower:

For example, 010 = 1.0 HP and 075 = 7.5 HP

Enclosure:

C= NEMA 4X / IP66, with keypad

D= NEMA 12 / IP55

DPD00088A |

- 11 - |

© 2009 Vacon Incorporated All Rights Reserved |

X4 AC Drive User’s Manual |

Chapter 2: Technical Characteristics |

2.2Power and Current Ratings

115 Vac Ratings

Model |

Normal Duty |

Input current (A) |

Output current (A) |

Heavy Duty |

Input current (A) |

Output current (A) |

||||||

number |

HP |

kW |

- |

115 Vac |

- |

230 Vac |

HP |

kW |

- |

115 Vac |

- |

230 Vac |

|

||||||||||||

X4C1S010C |

1 |

0.75 |

- |

15 |

- |

4.2 |

0.5 |

0.37 |

- |

11 |

0 |

2.2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

230 Vac Ratings |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Model |

Normal Duty |

Input current (A) |

Output current (A) |

Heavy Duty |

Input current (A) |

Output current (A) |

||||||

number |

HP |

kW |

200 Vac |

230 Vac |

200 Vac |

230 Vac |

HP |

kW |

200 Vac |

230 Vac |

200 Vac |

230 Vac |

|

||||||||||||

X4C20010C |

1 |

0.75 |

5.6 |

4.8 |

4.8 |

4.2 |

0.5 |

0.37 |

2.9 |

2.5 |

2.5 |

2.2 |

X4C20020C |

2 |

1.5 |

9 |

7.8 |

7.8 |

6.8 |

1 |

0.75 |

5.6 |

4.8 |

4.8 |

4.2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

X4C20030C |

3 |

2.2 |

12.7 |

11 |

11 |

9.6 |

2 |

1.5 |

9 |

7.8 |

7.8 |

6.8 |

X4C20050C |

5 |

4 |

20.2 |

17.5 |

17.5 |

15.2 |

3 |

2.2 |

12.7 |

11 |

11 |

9.6 |

|

|

|

|

|

|

|

|

|

|

|

|

|

X4C20075C |

7.5 |

5.5 |

29.2 |

25.3 |

25.3 |

22 |

5 |

4 |

20.2 |

17.5 |

17.5 |

15.2 |

X4C20100C |

10 |

7.5 |

37.2 |

32.2 |

37.2 |

28 |

7.5 |

5.5 |

29.2 |

25.3 |

25.3 |

22 |

|

|

|

|

|

|

|

|

|

|

|

|

|

X4C20150C |

15 |

11 |

52.1 |

46.4 |

48.3 |

42 |

10 |

7.5 |

37.2 |

32.2 |

37.2 |

28 |

|

|

|

|

|

|

|

|

|

|

|

|

|

X4C20200C |

20 |

15 |

68.3 |

57.4 |

62.1 |

54 |

15 |

11 |

52.1 |

46.4 |

48.3 |

42 |

X4C20250C |

25 |

18.5 |

82.3 |

73.8 |

78.2 |

68 |

20 |

15 |

68.3 |

57.4 |

62.1 |

54 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

NOTE: All 230 Vac models can be operated at single-phase, with 50% derating |

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

460 Vac Ratings |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Model |

Normal Duty |

Input current (A) |

Output current (A) |

Heavy Duty |

Input current (A) |

Output current (A) |

||||||

number |

HP |

kW |

380 Vac |

460 Vac |

380 Vac |

460 Vac |

HP |

kW |

380 Vac |

460 Vac |

380 Vac |

460 Vac |

|

||||||||||||

X4C40010C |

1 |

0.75 |

3 |

2.4 |

2.4 |

2.1 |

0.5 |

0.37 |

1.6 |

1.3 |

1.3 |

1.1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

X4C40020C |

2 |

1.5 |

5.2 |

3.9 |

3.8 |

3.4 |

1 |

0.75 |

3 |

2.4 |

2.4 |

2.1 |

X4C40030C |

3 |

2.2 |

7.2 |

5.6 |

5.1 |

4.8 |

2 |

1.5 |

5.2 |

3.9 |

3.8 |

3.4 |

X4C40050C |

5 |

4 |

12 |

8.8 |

8.9 |

7.6 |

3 |

2.2 |

7.2 |

5.6 |

5.1 |

4.8 |

|

|

|

|

|

|

|

|

|

|

|

|

|

X4C40075C |

7.5 |

5.5 |

15 |

12.8 |

12 |

11 |

5 |

4 |

12 |

8.8 |

8.9 |

7.6 |

X4C40100C |

10 |

7.5 |

19.7 |

16.3 |

15.6 |

14 |

7.5 |

5.5 |

15 |

12.8 |

12 |

11 |

|

|

|

|

|

|

|

|

|

|

|

|

|

X4C40150C |

15 |

11 |

30.9 |

25.8 |

23 |

21 |

10 |

7.5 |

19.7 |

16.3 |

15.6 |

14 |

|

|

|

|

|

|

|

|

|

|

|

|

|

X4C40200C |

20 |

15 |

40 |

33.3 |

31 |

27 |

15 |

11 |

30.9 |

25.8 |

23 |

21 |

|

|

|

|

|

|

|

|

|

|

|

|

|

X4C40250C |

25 |

18 |

46.3 |

40 |

37 |

34 |

20 |

15 |

40 |

33.3 |

31 |

27 |

X4C40300C |

30 |

22 |

57.5 |

47.8 |

43 |

40 |

25 |

18 |

46.3 |

40 |

37 |

34 |

|

|

|

|

|

|

|

|

|

|

|

|

|

X4C40400C |

40 |

30 |

73.2 |

62.4 |

61 |

52 |

30 |

22 |

57.5 |

47.8 |

43 |

40 |

|

|

|

|

|

|

|

|

|

|

|

|

|

X4C40500C |

50 |

37 |

82 |

78 |

71 |

65 |

40 |

30 |

73.2 |

62.4 |

61 |

52 |

X4C40600C |

60 |

45 |

94 |

80 |

86 |

77 |

50 |

37 |

82 |

78 |

71 |

65 |

|

|

|

|

|

|

|

|

|

|

|

|

|

X4C40750C |

75 |

55 |

114 |

99 |

105 |

96 |

60 |

45 |

94 |

80 |

86 |

77 |

X4C41000C |

100 |

75 |

149 |

129 |

140 |

124 |

75 |

55 |

114 |

99 |

105 |

96 |

X4C41250D |

125 |

90 |

168 |

156 |

168 |

156 |

100 |

75 |

140 |

124 |

140 |

124 |

X4C41500D |

150 |

110 |

205 |

180 |

205 |

180 |

125 |

90 |

168 |

156 |

168 |

156 |

|

|

|

|

|

|

|

|

|

|

|

|

|

X4C42000D |

200 |

132 |

240 |

240 |

240 |

240 |

150 |

110 |

205 |

180 |

205 |

180 |

|

|

|

|

|

|

|

|

|

|

|

|

|

DPD00088A |

- 12 - |

© 2009 Vacon Incorporated All Rights Reserved |

X4 AC Drive User’s Manual |

|

|

|

|

|

|

Chapter 2: Technical Characteristics |

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

575 Vac Ratings |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Model |

Normal Duty |

|

Input current (A) |

Output current (A) |

Heavy Duty |

Input current (A) |

Output current (A) |

|

||||||

|

number |

HP |

kW |

|

- |

575 Vac |

- |

575 Vac |

HP |

kW |

- |

575 Vac |

- |

575 Vac |

|

|

|

|

|||||||||||||

|

X4C50010C |

1 |

0.75 |

|

- |

2.0 |

- |

1.7 |

0.5 |

0.37 |

- |

1.2 |

- |

0.9 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

X4C50020C |

2 |

1.5 |

|

- |

3.6 |

- |

2.7 |

1 |

0.75 |

- |

2.0 |

- |

1.7 |

|

|

X4C50030C |

3 |

2.2 |

|

- |

5.0 |

- |

3.9 |

2 |

1.5 |

- |

3.6 |

- |

2.7 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

X4C50050C |

5 |

4 |

|

- |

7.6 |

- |

6.1 |

3 |

2.2 |

- |

5.0 |

- |

3.9 |

|

|

X4C50075C |

7.5 |

5.5 |

|

- |

10.4 |

- |

9.0 |

5 |

4 |

- |

7.6 |

- |

6.1 |

|

|

X4C50100C |

10 |

7.5 |

|

- |

14.1 |

- |

11.0 |

7.5 |

5.5 |

- |

10.4 |

- |

9.0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

X4C50150C |

15 |

11 |

|

- |

23 |

- |

17 |

10 |

7.5 |

- |

14.1 |

- |

11 |

|

|

X4C50200C |

20 |

15 |

|

- |

31 |

- |

22 |

15 |

11 |

- |

23 |

- |

17 |

|

|

X4C50250C |

25 |

18 |

|

- |

37 |

- |

27 |

20 |

15 |

- |

31 |

- |

22 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

X4C50300C |

30 |

22 |

|

- |

39.5 |

- |

32 |

25 |

18 |

- |

37 |

- |

27 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

X4C50400C |

40 |

30 |

|

- |

49 |

- |

41 |

30 |

22 |

- |

39.5 |

- |

32 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

X4C50500C |

50 |

37 |

|

- |

58 |

- |

52 |

40 |

30 |

- |

49 |

- |

41 |

|

|

X4C50600C |

60 |

45 |

|

- |

68 |

- |

62 |

50 |

37 |

- |

58 |

- |

52 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

X4C50750C |

75 |

55 |

|

- |

82 |

- |

77 |

60 |

45 |

- |

68 |

- |

62 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

X4C51000C |

100 |

75 |

|

- |

107 |

- |

99 |

75 |

55 |

- |

82 |

- |

77 |

|

|

X4C51250D |

125 |

90 |

|

- |

125 |

- |

125 |

100 |

75 |

- |

99 |

- |

99 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

X4C51500D |

150 |

110 |

|

- |

144 |

- |

144 |

125 |

90 |

- |

125 |

- |

125 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

X4C52000D |

200 |

132 |

|

- |

192 |

- |

192 |

150 |

110 |

- |

144 |

- |

144 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2.3Environmental Specifications

|

For 2003, 2005, 5005, 2030, 4030, and 5030 models: |

|

Operating temperature |

–10 °C to +35 °C (14 °F to 95 °F) |

|

For all other models: |

||

|

||

|

–10 °C to +40 °C (14 °F to 104 °F) |

|

|

|

|

Storage temperature |

–20 °C to +65 °C (-4 °F to 149 °F) |

|

|

|

|

Humidity |

0% to 95% non-condensing |

|

|

|

|

Altitude |

1000 m (3300 ft) without derating |

|

|

|

|

Maximum vibration |

per EN50178 (1g @ 57-150 Hz) |

|

|

|

|

Acoustic noise |

80 dba sound power at 1 m (3 ft), maximum |

|

|

|

|

|

1 to 5 HP models: Natural convection |

|

Cooling |

7.5 to 200.0 HP models: Forced air |

|

|

Note: 575Vac 5 HP model has a fan. |

|

|

|

DPD00088A |

- 13 - |

© 2009 Vacon Incorporated All Rights Reserved |

X4 AC Drive User’s Manual |

Chapter 2: Technical Characteristics |

2.4Electrical Specifications

|

X4C1Sx models: 115 Vac 1 phase, +/- 10% |

|

|

||

Input voltage |

X4C2x models: 200-230 Vac, 3 phase, +/- 15% |

|

|

||

X4C4x models: 380-460 Vac, 3 phase, +/- 15% |

|

|

|||

|

|

|

|||

|

X4C5x models: 575Vac, 3 phase, +/-15% |

|

|

||

|

|

|

|

|

|

Line frequency |

50 / 60 Hz ±2 Hz |

|

|

|

|

|

|

|

|

||

Source kVA (maximum) |

10 times the unit rated kVA (see note below) |

|

|

||

|

|

|

|

|

|

DC bus voltage for: |

115 Vac models |

230 Vac models |

460 Vac models |

575 Vac models |

|

Overvoltage trip |

406 Vdc |

406 Vdc |

814 |

Vdc |

1017 Vdc |

Dynamic brake activation |

388 Vdc |

388 Vdc |

776 |

Vdc |

970 Vdc |

Nominal undervoltage (UV) trip |

199 Vdc |

199 Vdc |

397 |

Vdc |

497 Vdc |

|

|

|

|

|

|

|

V/Hz or SVC |

|

|

|

|

Control system |

Carrier frequency = 1 - 16 kHz, programmable; 8 kHz max. for 125-200 HP |

||||

|

models |

|

|

|

|

|

|

||||

Output voltage |

3-phase: 0 to 100% of incoming line (0-230 Vac for 115 Vac models) |

||||

|

|

|

|||

Overload capacity |

120% of rated normal duty rms current for 60 seconds |

|

|||

150% of rated heavy duty rms current for 60 seconds |

|

||||

|

|

||||

|

|

|

|

|

|

Frequency range |

0.1 to 400 Hz |

|

|

|

|

|

|

|

|||

Frequency stability |

0.1 Hz (digital), 0.1% (analog) over 24 hours +/- 10 °C |

|

|||

|

|

|

|

|

|

|

By keypad or by external signal |

|

|

|

|

Frequency setting |

(Speed Pot 0 to 5 Vdc; 0 to 10 Vdc; 0 to 20 mA, or 4 to 20 mA) |

||||

|

OR by pulse train up to 100 kHz |

|

|

|

|

|

|

|

|

|

|

Note: Unit Rated kVA = rated Voltage x rated Current x 1.732

DPD00088A |

- 14 - |

© 2009 Vacon Incorporated All Rights Reserved |

X4 AC Drive User’s Manual |

Chapter 2: Technical Characteristics |

2.5Control Features Specifications

|

0-5/10 Vdc, 0/4-20 mAdc (250 Ω load) |

|

Vin1 reference input |

6FS pulse train input, 0-1/10/100 kHz pulse input, inverted function, 0-5-10 bipolar |

|

|

input, broken wire detection. Span and offset adjustment. |

|

|

|

|

Vin2 reference input |

0-5/10 Vdc, 0-5-10 bipolar input, inverted function, broken wire detection, span and |

|

offset adjustment. Programmable for frequency reference or current limit input. |

||

|

||

|

|

|

Cin reference input |

0/4-20 mAdc (50 Ω load), inverted function, span and offset adjustment. |

|

Programmable for frequency reference or current limit input. |

||

|

||

|

|

|

Reference voltage |

10 Vdc (10 mAdc maximum) |

|

|

|

|

Digital inputs - 10 |

Off=0 to 3 Vdc; On=10 to 32 Vdc (pullup logic), selectable between pullup and |

|

pulldown logic |

||

|

||

|

|

|

Digital supply voltage |

24 Vdc (150 mAdc maximum) |

|

|

|

|

Preset frequencies |

3 inputs for seven preset frequencies (selectable) |

|

|

|

|

Digital outputs |

2 SPDT relay output - 130 Vac, 1 A/250 Vac, 0.5 A |

|

2 open collector outputs 50 mA per device |

||

|

||

|

|

|

Digital pulse train output |

Open collector output pulse train proportional to output frequency |

|

|

|

|

Vmet analog output |

0 to 10 Vdc (5 mAdc maximum) |

|

|

|

|

Imet analog output |

0-20 mAdc output into a 500 Ω load (maximum) |

|

|

|

|

DC holding / injection braking |

At start, stop, by frequency with adjustable current level and time or continuous DC |

|

injection by digital input. |

||

|

|

|

Current limit |

Four quadrant adjustable from 5 to 150% |

|

|

|

|

Speed ramps |

Primary and alternate adjustable from 0.1 to 3200.0 seconds |

|

|

|

|

Voltage boost |

Fixed boost adjustable from 0 to 50%, or auto boost in Vector mode |

|

|

|

|

Voltage characteristic (V/Hz) |

Linear, pump, fan or 2-piece linear |

|

|

|

|

Timed overload |

Adjustable inverse time trip (shear pin, 30 sec, 60 sec, 5 min), standard or inverter- |

|

duty motors |

||

|

||

|

|

|

|

Overcurrent, overvoltage fault, ground fault, short circuit, dynamic brake overload, |

|

Protective features |

drive temperature, power wiring fault, drive timed overload, input voltage quality, |

|

|

overvoltage ridethrough |

|

|

|

|

Program Sequence Logic |

9-step PLC type functionality that can control speed, direction, and ramps based on |

|

Controller (PSLC) |

time, analog input, digital input, or pulse input. |

|

|

|

|

Serial communications |

Modbus Standard: RTU or ASCII |

|

|

|

DPD00088A |

- 15 - |

© 2009 Vacon Incorporated All Rights Reserved |

X4 AC Drive User’s Manual |

Chapter 2: Technical Characteristics |

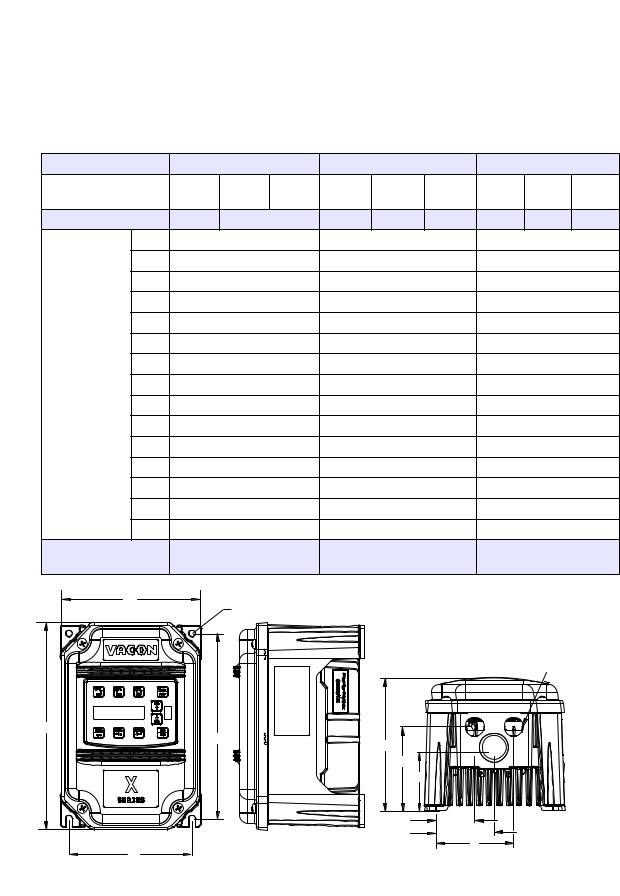

2.6Dimensions and Weights

Table 2-1 lists dimensions and weights for the X4 frame size 0, 1, 2, and 3 models. Dimensions and weights for the X4 frame size 4 and 5 models are shown in Table 2-2 on page 18.

See Figures 2-1, 2-2, 2-3, 2-4, 2-5, and 2-6 on pages 16 - 19 for locations of dimensions. Dimensions A through Q are in inches / millimeters (in/mm). Weight is in pounds / kilograms (lb/kg).

Table 2-1: Dimensions and Weights for Frame Sizes 0 - 2

Frame |

|

0 |

|

|

1 |

|

|

2 |

|

||

Voltage |

115 |

230 |

460 |

230 Vac |

460 Vac |

575 Vac |

230 |

460 |

575 |

||

Vac |

Vac |

Vac |

Vac |

Vac |

Vac |

||||||

|

|

|

|

||||||||

Horsepower |

1 |

1-3 |

|

5-7.5 |

5-10 |

1-10 |

10-15 |

15-30 15-30 |

|||

|

A |

9.47 (241) |

|

|

12.01 (306) |

|

|

17.38 |

(442) |

|

|

|

B |

6.50 (165) |

|

|

8.72 (221) |

|

|

10.75 |

(273) |

|

|

|

C |

6.08 (155) |

|

|

6.51 (166) |

|

|

7.91 (201) |

|

||

|

D |

8.45 (215) |

|

|

11.03 (280) |

|

|

16.50 |

(419) |

|

|

|

E |

5.69 (145) |

|

|

7.88 (200) |

|

|

9.76 (248) |

|

||

Dimensions |

F |

0.28 (7.11) |

|

|

0.28 (7.11) |

|

|

0.41 |

(10) |

|

|

inches (mm) |

G |

3.84 (98) |

|

|

4.05 (103) |

|

|

4.72 (120) |

|

||

(See the |

H |

2.77 (70) |

|

|

N/A |

|

|

N/A |

|

||

corresponding |

|

|

|

|

|

||||||

J |

1.93 (49) |

|

|

2.31 (59) |

|

|

2.88 |

(73) |

|

||

X4 diagrams on |

|

|

|

|

|

||||||

following pages |

K |

2.85 (72) |

|

|

3.94 (100) |

|

|

4.84 (123) |

|

||

|

|

|

|

|

|

||||||

|

L |

3.75 (95) |

|

|

5.56 (1.41) |

|

|

6.88 (175) |

|

||

|

M |

0.88 (22) |

|

|

0.88 (22) |

|

|

1.38 |

(35) |

|

|

|

N |

N/A |

|

|

N/A |

|

|

1.13 |

(29) |

|

|

|

P |

N/A |

|

|

N/A |

|

|

N/A |

|

||

|

Q |

N/A |

|

|

N/A |

|

|

N/A |

|

||

Weight |

|

8.5 (3.85) |

|

|

14.0 (6.35) |

|

|

29.5 (13.38) |

|

||

lb (kg) |

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

||

B |

|

F |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

M |

|

||

A |

|

D |

C |

|

|

|

G |

|

H |

|

J |

|

K |

E |

L |

|

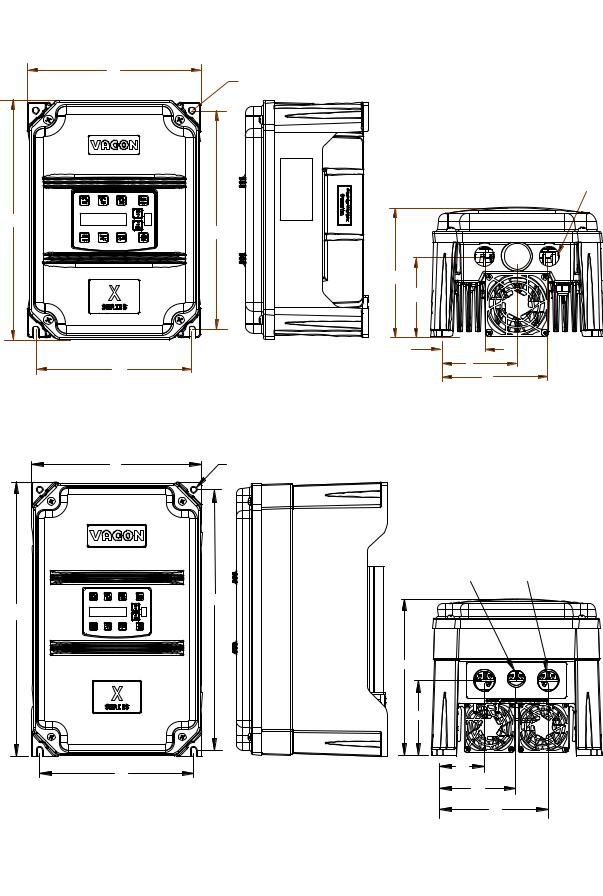

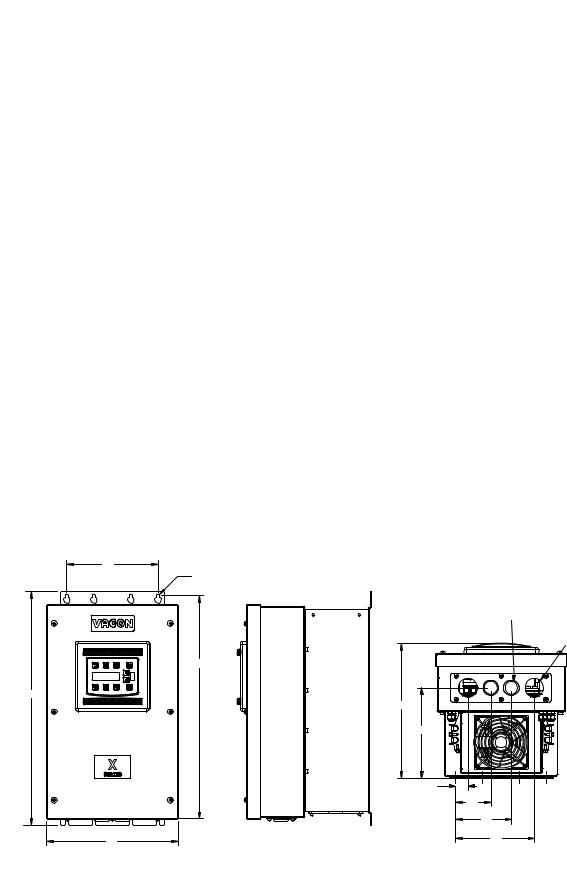

Figure 2-1: X4 Frame Size 0 Models

DPD00088A |

- 16 - |

© 2009 Vacon Incorporated All Rights Reserved |

X4 AC Drive User’s Manual |

Chapter 2: Technical Characteristics |

B

F (4 places)

M (3 places)

A

D

|

C |

|

|

G |

|

|

J |

|

E |

K |

|

L |

||

|

||

|

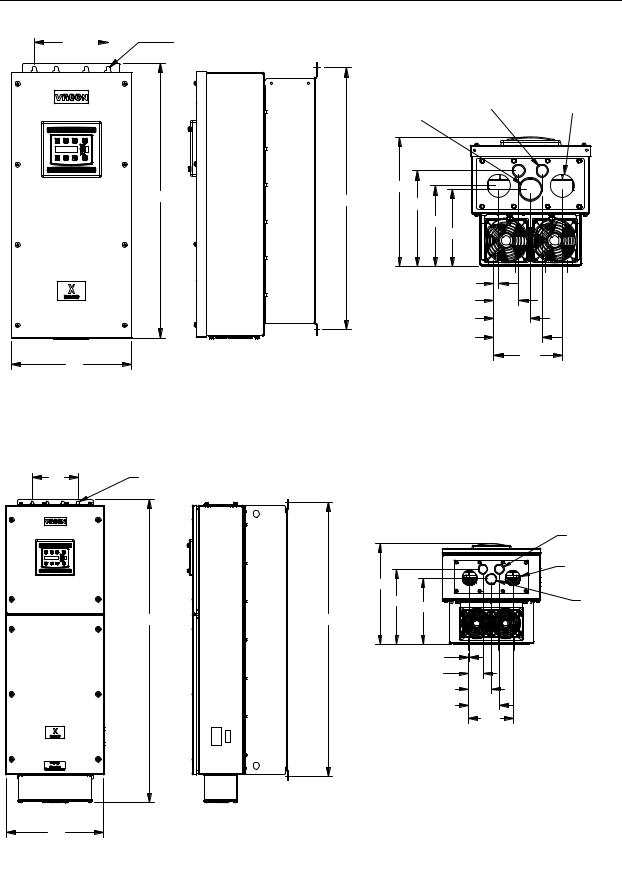

Figure 2-2: X4 Frame Size 1 Models |

|

B |

F (4 PLACES) |

N M (2 PLACES)

D

A

C

G

J

E

K

L

Figure 2-3: X4 Frame Size 2 Models

DPD00088A |

- 17 - |

© 2009 Vacon Incorporated All Rights Reserved |

X4 AC Drive User’s Manual |

Chapter 2: Technical Characteristics |

Table 2-2: Dimensions and Weights for Frame Sizes 3-5

Frame |

|

|

3 |

|

|

4 |

5 |

||||

Voltage |

|

230 Vac |

|

460 Vac |

|

575 Vac |

460 Vac |

575 Vac |

460 Vac |

575 Vac |

|

|

|

|

|

|

|

|

|

|

|

|

|

Horsepower |

|

20-30 |

|

40-50 |

|

40-50 |

60-100 |

60-100 |

125-200 |

125-200 |

|

|

|

A |

|

20.19 (513) |

|

29.35 |

(745) |

50.77 (1290) |

51.02 (1296) |

||

|

|

|

|

|

|

|

|

|

|

||

|

|

B |

|

11.25 (286) |

|

12.84 |

(326) |

16.31 |

(414) |

||

|

|

|

|

|

|

|

|

|

|

||

|

|

C |

|

11.73 (314) |

|

13.80 |

(351) |

16.88 |

(429) |

||

|

|

|

|

|

|

|

|

||||

|

|

D |

|

19.25 (489) |

|

28.00 (711) |

45.77 (1163) |

||||

|

|

|

|

|

|

|

|

|

|||