Vacon 100 X ac drives Installation Manual

vacon®100 x

ac drives

Installation, Technical and Maintenance

Manual

vacon • 0

NDEX

I

Document code (Original Instructions): DPD00534G

Order code: DOC-INS03985+DLUK

Rev. G

Revision release date: 11.7.14

1. Safety................................................................................................................2

1.1 Signs....................................................................................................................................2

1.2 Units ....................................................................................................................................2

1.3 Danger.................................................................................................................................3

1.4 Warnings .............................................................................................................................4

1.5 Earthing and earth fault protection ....................................................................................5

1.6 Insulation system................................................................................................................8

1.7 Compatibility with RCDs .....................................................................................................9

1.8 Extended temperature range .............................................................................................9

1.9 Electro-magnetic compatibility (EMC)................................................................................9

1.10 Declaration of conformity .................................................................................................10

2. Receipt of delivery ..........................................................................................14

2.1 Type designation code.......................................................................................................15

2.2 Unpacking and lifting the AC drive ...................................................................................16

2.3 Accessories .......................................................................................................................16

2.3.1 Frame MM4 .......................................................................................................................16

2.3.2 Frame MM5 .......................................................................................................................17

2.3.3 Frame MM6 .......................................................................................................................17

2.3.4 STO terminal connector....................................................................................................18

2.3.5 ‘Product modified’ sticker.................................................................................................18

2.3.6 Disposal.............................................................................................................................18

3. Mounting......................................................................................................... 20

3.1 Dimensions .......................................................................................................................20

3.2 Introduction of modules....................................................................................................23

3.3 Mounting ...........................................................................................................................24

3.3.1 Wall-mounting ..................................................................................................................25

3.3.2 Motor-mounting................................................................................................................25

3.3.3 Segregated modules.........................................................................................................25

3.4 Cooling ..............................................................................................................................26

4. Power cabling .................................................................................................28

4.1 Circuit breaker ..................................................................................................................29

4.2 UL standards on cabling ...................................................................................................30

4.3 Description of the terminals .............................................................................................31

4.4 Cable dimensioning and selection....................................................................................34

4.4.1 Cable and fuse sizes, frames MM4 to MM6......................................................................34

4.4.2 Cable and fuse sizes, frames MM4 to MM6, North America............................................35

4.4.3 Brake resistor cables........................................................................................................36

4.4.4 Control cables ...................................................................................................................36

4.5 Cable installation ..............................................................................................................37

5. Control unit.....................................................................................................44

5.1 Control unit cabling...........................................................................................................45

5.1.1 Control cable sizing ..........................................................................................................45

5.1.2 Standard I/O terminals .....................................................................................................46

5.1.3 Relay and thermistor input terminals ..............................................................................47

5.1.4 Safe Torque off (STO) terminals .......................................................................................47

5.1.5 Selection of terminal functions with dip switches ...........................................................48

5.1.6 Isolating digital inputs from ground .................................................................................48

5.1.7 Bus termination of the RS485 connection........................................................................49

vacon • 1

5.2 I/O cabling and Fieldbus connection ................................................................................50

5.2.1 Prepare for use through Ethernet....................................................................................50

5.2.2 Prepare for use through RS485........................................................................................51

5.2.3 RS485 cable data...............................................................................................................52

5.3 Battery installation for Real Time Clock (RTC) ................................................................53

6. Commissioning ...............................................................................................56

6.1 Commissioning of the drive ..............................................................................................57

6.2 Changing EMC protection class........................................................................................58

6.3 Running the motor ............................................................................................................60

6.3.1 Cable and motor insulation checks ..................................................................................60

6.4 Maintenance......................................................................................................................61

7. Technical data.................................................................................................62

7.1 AC drive power ratings......................................................................................................62

7.1.1 Mains voltage 3AC 208-240V.............................................................................................62

7.1.2 Mains voltage 3AC 380-480V.............................................................................................63

7.1.3 Definitions of overloadability ............................................................................................64

7.2 Brake resistor ratings.......................................................................................................65

7.3 VACON® 100 X - technical data........................................................................................66

7.3.1 Technical information on control connections.................................................................69

8. Options............................................................................................................72

8.1 Mains switch......................................................................................................................72

8.1.1 Installation ........................................................................................................................72

8.2 Control Keypad..................................................................................................................76

8.2.1 Mounting onto the drive ....................................................................................................76

8.2.2 Installation ........................................................................................................................77

8.2.3 Wall-mounting ..................................................................................................................79

8.2.4 Graphical and Text keypad................................................................................................81

8.2.5 VACON® keypad with graphical display...........................................................................82

8.2.6 VACON® keypad with text segment display.....................................................................89

8.2.7 Fault Tracing .....................................................................................................................93

8.3 Heater (arctic option) ......................................................................................................101

8.3.1 Safety...............................................................................................................................101

8.3.2 Dangers ...........................................................................................................................101

8.3.3 Technical data .................................................................................................................101

8.3.4 Mounting instructions: MM4 Example............................................................................102

8.4 Option boards..................................................................................................................105

8.5 Flange adapter ................................................................................................................106

8.5.1 Mounting instructions: MM4 Example............................................................................109

9. Safe Torque Off .............................................................................................112

9.1 General description.........................................................................................................112

9.2 Warnings .........................................................................................................................112

9.3 Standards ........................................................................................................................113

9.4 The principle of STO........................................................................................................114

9.4.1 Technical details .............................................................................................................115

9.5 Connections.....................................................................................................................116

9.5.1 Safety Capability Cat. 4 / PL e / SIL 3 .............................................................................117

9.5.2 Safety Capability Cat. 3 / PL e / SIL 3 .............................................................................119

9.5.3 Safety Capability Cat. 2 / PL d / SIL 2 .............................................................................119

9.5.4 Safety Capability Cat. 1 / PL c / SIL 1..............................................................................120

9.6 Commissioning ...............................................................................................................121

9.6.1 General wiring instructions ............................................................................................121

9.6.2 Checklist for commissioning ..........................................................................................121

9.7 Parameters and fault tracing .........................................................................................122

9.8 Maintenance and diagnostics .........................................................................................123

Safety vacon • 2

1. S

This manual contains clearly marked warning information which is intended for your personal safety and to avoid any unintentional damage to the product or connected appliances.

Please read the warning information carefully.

VACON

motors. The product is intended to be installed in a restricted access location and for a general

purpose use.

Only VACON

maintain the drive.

®

AFETY

100 X is a drive designed to control asynchronous AC motors and permanent magnet

®

authorized, trained and qualified personnel are allowed to install, operate and

1.1 Signs

The cautions and warnings are marked as follows:

= DANGEROUS VOLTAGE!

= HOT SURFACE

= WARNING or CAUTION

Table 1. Warning signs.

1.2 Units

The dimensions used in this manual conform to International Metric System units, otherwise known

as SI (Système International d’Unités) units. For the purpose of the equipment's UL certification,

some of these dimensions are accompanied by their imperial equivalents.

Physical

dimension

length 1 mm 0.0394 inch 25.4 inch

Weight 1 kg 2.205 lb 0.4536 pound

Speed

Temperature 1 °C (T1) 33.8 °F (T2) T2 = T1 x 9/5 + 32 Fahrenheit

Torque 1 Nm 8.851 lbf in 0.113

Power 1 kW 1.341 HP 0.7457 horsepower

SI value US value Conversion factor US designation

1 min

-1

1 rpm 1

revolution per

minute

pound-force

inches

Table 2. Unit conversion table.

1

vacon • 3 Safety

1.3 Danger

The components of the power unit of VACON® 100 X drives are live when the drive is connected to mains potential. Coming into contact with this voltage is extremely dangerous and

may cause death or severe injury.

The motor terminals (U, V, W), the brake resistor terminals and the DC-terminals are live

when VACON® 100 X Drive is connected to the mains, even if the motor is not running.

After disconnecting the AC drive from the mains, wait until the indicators on the keypad go out

(if no keypad is connected, see the indicators on the cover). Wait an additional 30 seconds

®

before doing any work on the connections of VACON

this time has expired. After expiration of this time, use measuring equipment to absolutely

ensure that no

trical work!

The control I/O-terminals are isolated from the mains potential. However, the relay outputs

and other I/O-terminals may have a dangerous control voltage present even when VACON

100 X drive is disconnected from the mains.

voltage is present.

Always ensure absence of voltage before starting any elec-

100 X Drive. Do not open the unit before

®

Before connecting the AC drive to mains make sure that the powerhead of VACON

Drive is mounted firmly on the terminal box.

During a coast stop (see the Application Manual), the motor is still generating voltage to the

drive. Therefore, do not touch the components of the AC drive before the motor has completely

stopped and wait until the indicators on the keypad go out (if no keypad is connected, see the

indicators on the cover). Wait an additional 30 seconds before starting any work on the drive.

®

100 X

1

Safety vacon • 4

1.4 Warnings

VACON® 100 X AC drive is meant for fixed installations (on the motor or on the wall)

only.

Only DVC A circuits (Decisive Voltage Class A, according to IEC 61800-5-1) are

allowed to be connected to the control unit. This advice aims to protect both the drive

®

and the client-application. VACON

damages resulting from unsafe connections of external circuits to the drive. See paragraph 1.6 for more details.

Do not perform any measurements when the AC drive is connected to the mains.

®

The touch current of VACON

dard EN61800-5-1, a reinforced protective ground connection must be ensured. See

paragraph 1.5 for more details.

If the AC drive is used as a part of a machine, the machine manufacturer is responsi-

ble for providing the machine with a supply disconnecting device (EN 60204-1). See

paragraph 4.1 for more details.

100 X AC drives exceeds 3.5mA AC. According to stan-

is not responsible for direct or consequential

Only spare parts delivered by VACON® can be used.

At power-up or fault reset, the motor will start immediately if the start signal is

active, unless the pulse control for

are ready to be used (normal operation). The I/O functionalities (including start inputs)

may change if parameters, applications or software are changed. Disconnect, therefore, the motor if an unexpected start can cause danger. This is valid only if STO inputs

are energized. For prevention on unexpected restart, use appropriate safety relay connected to the STO inputs.

The motor starts automatically after automatic fault reset if the autoreset function is

activated. See the Application Manual for more detailed information. This is valid only

if STO inputs are energized. For prevention on unexpected restart, use appropriate

safety relay connected to the STO inputs.

Before performing any measurement on the motor or on the motor cable, disconnect the motor cable from the AC drive.

Do not perform any voltage withstand test on any part of VACON® 100 X. The tests

shall be performed according to a specific procedure. Ignoring this procedure may

damage the product.

Do not touch the components on the circuit boards. Static voltage discharge may

damage the components.

Start/Stop logic has been selected

) and the STO inputs

Check that the EMC level of the AC drive corresponds to the requirements of your

supply network. See paragraph 6.2 for more details.

In a domestic environment, this product may cause radio interference in which case

supplementary mitigation measures may be required.

1

vacon • 5 Safety

1.5 Earthing and earth fault protection

CAUTION!

The VACON® 100 X AC drive must always be earthed with an earthing conductor connected to the

earthing terminal marked with .

See Table 12 and Table 13 for the required cross-section of phase conductor and protective earthing conductor (both made of copper).

Since the touch current exceeds 3.5 mA AC, according to EN61800-5-1, the MM4 and MM5 shall

have a fixed connection and provision of an additional terminal for a second protective earthing

conductor of the same cross-sectional area as the original protective earthing conductor. MM6

shall have a fixed installation and a cross-section of the protective earthing conductor of at least 10

2

mm

Cu.

On the terminal-box, three screws (for MM4 and MM5) and two screws (for MM6)are provided for

ORIGINAL and MOTOR protective earthing conductors: the customer can choose the screw for each

one.

The cross-sectional area of every protective earthing conductor which does not form a part of the

supply cable or cable enclosure shall, in any case, be not less than:

•2.5 mm

•4 mm

shall be made so that the protective earthing conductor in the cord shall, in the case of failure of the strain-relief mechanism, be the last conductor to be interrupted.

The power-head is earthed through metal aglets, located on the terminal-box, which fit into spring

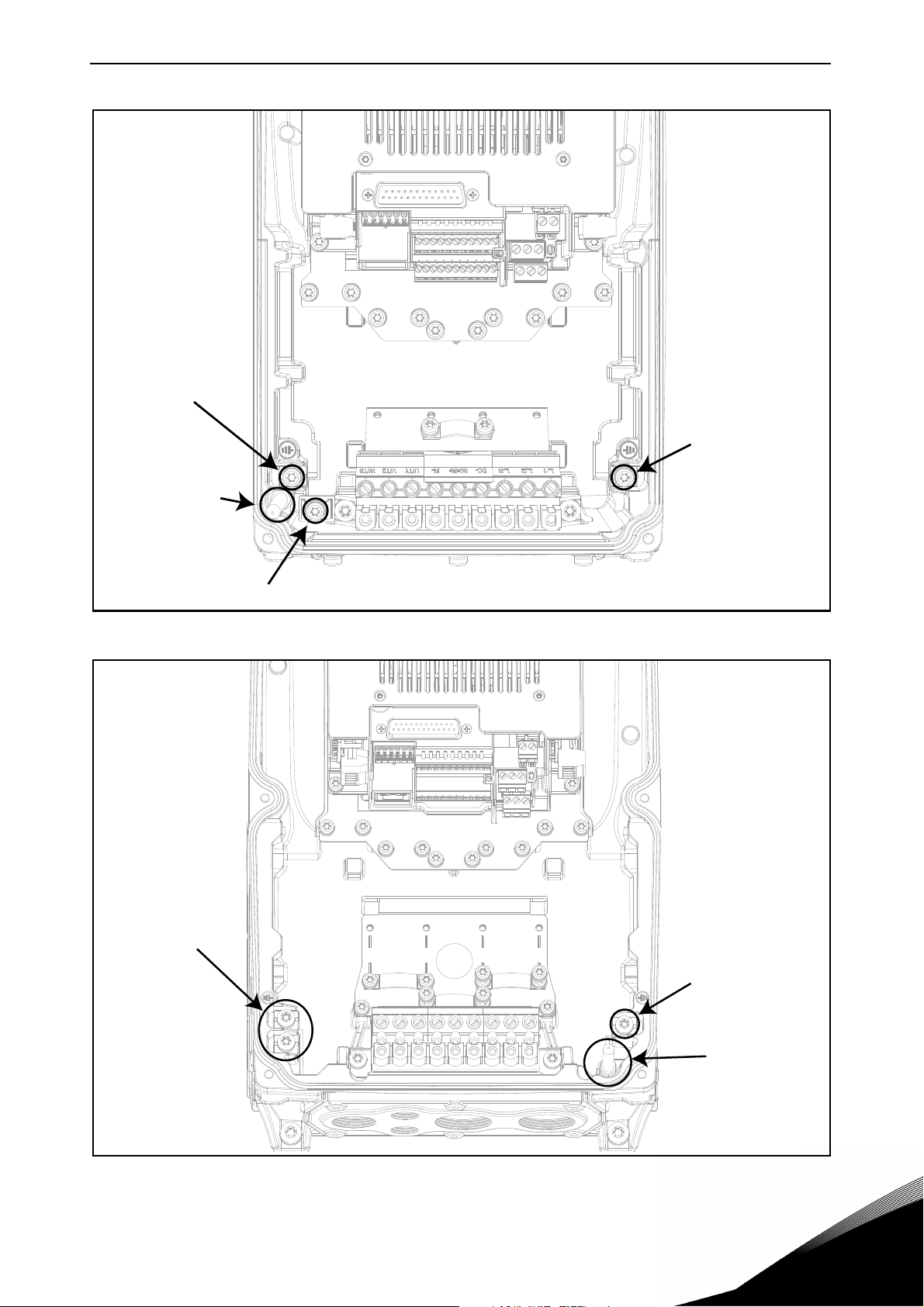

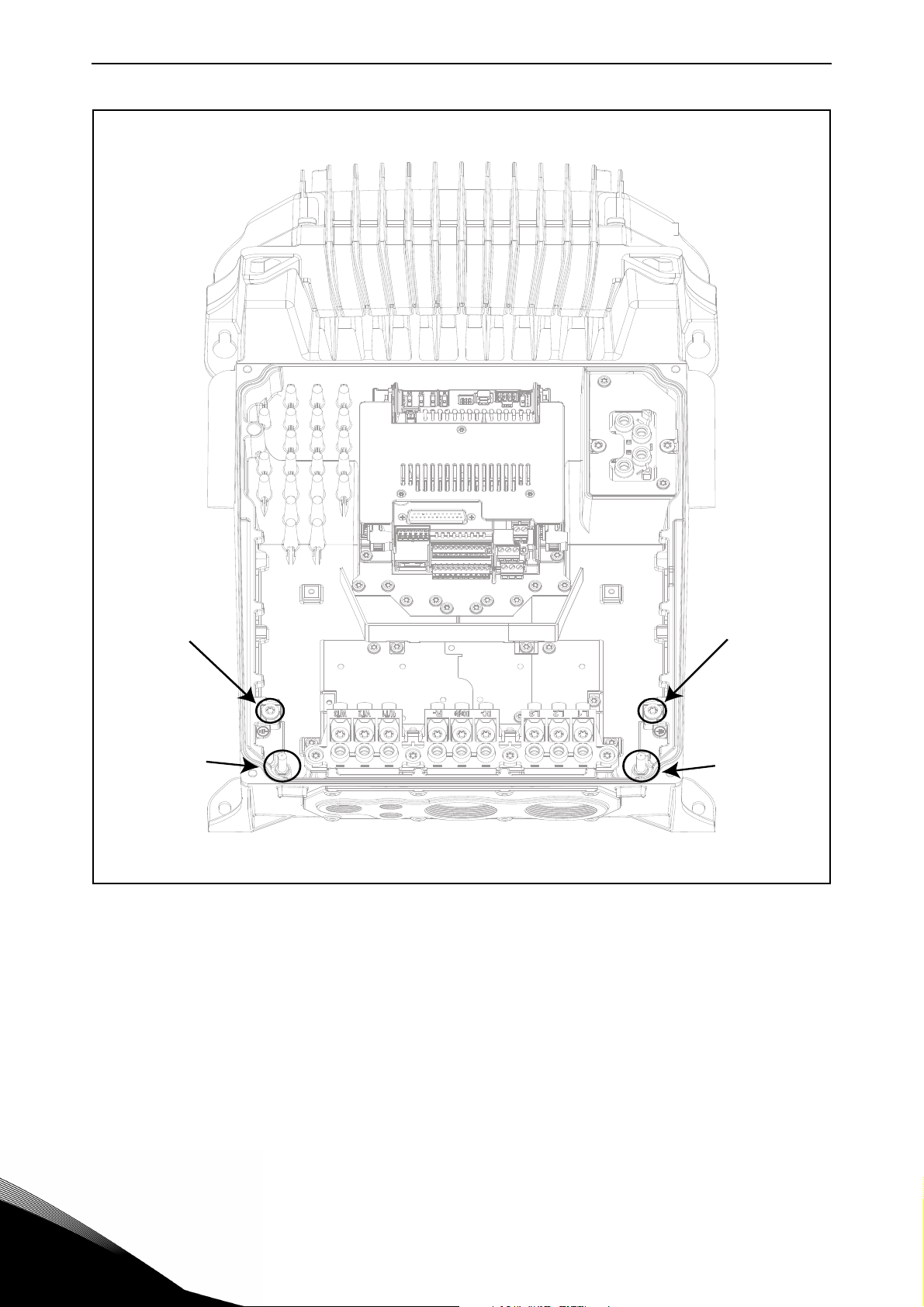

baskets on the powerhead. See Figure 1, Figure 2 and Figure 3 for the location of the screws (three

for MM4 and MM5, two for MM6) and the metal aglets (one for MM4 and MM5, two for MM6). Please,

pay attention not to damage or remove these aglets.

2

if mechanical protection is provided or

2

if mechanical protection is not provided. For cord-connected equipment, provisions

1

Safety vacon • 6

Earth connection

Metal aglet

Earth connection

Earth connection

Earth connections

Metal aglet

Earth connection

Figure 1. Earth connections and metal aglet in MM4.

Figure 2. Earth connections and metal aglet in MM5.

1

vacon • 7 Safety

Earth connection Earth connection

Metal aglet

Metal aglet

Figure 3. Earth connections and metal aglet in MM6.

However, always follow the local regulations for the minimum size of the protective earthing

conductor.

NOTE: Due to the high capacitive currents present in the AC drive, fault current protective switches

may not function properly.

1

Safety vacon • 8

POWER UNIT

L1

L2

L3

U

V

W

R01 __

R02 __

DC- DC+/R+ R-

10Vref __

Analog Inputs __

Digital Inputs__

Digital Outputs__

24V __

Ethernet __

RS485 __

STO __

___Thermistor

Keypad

CONTROL UNIT

Reinforced

Mains

Mains

DVC A

DVC A or

Mains

(*)

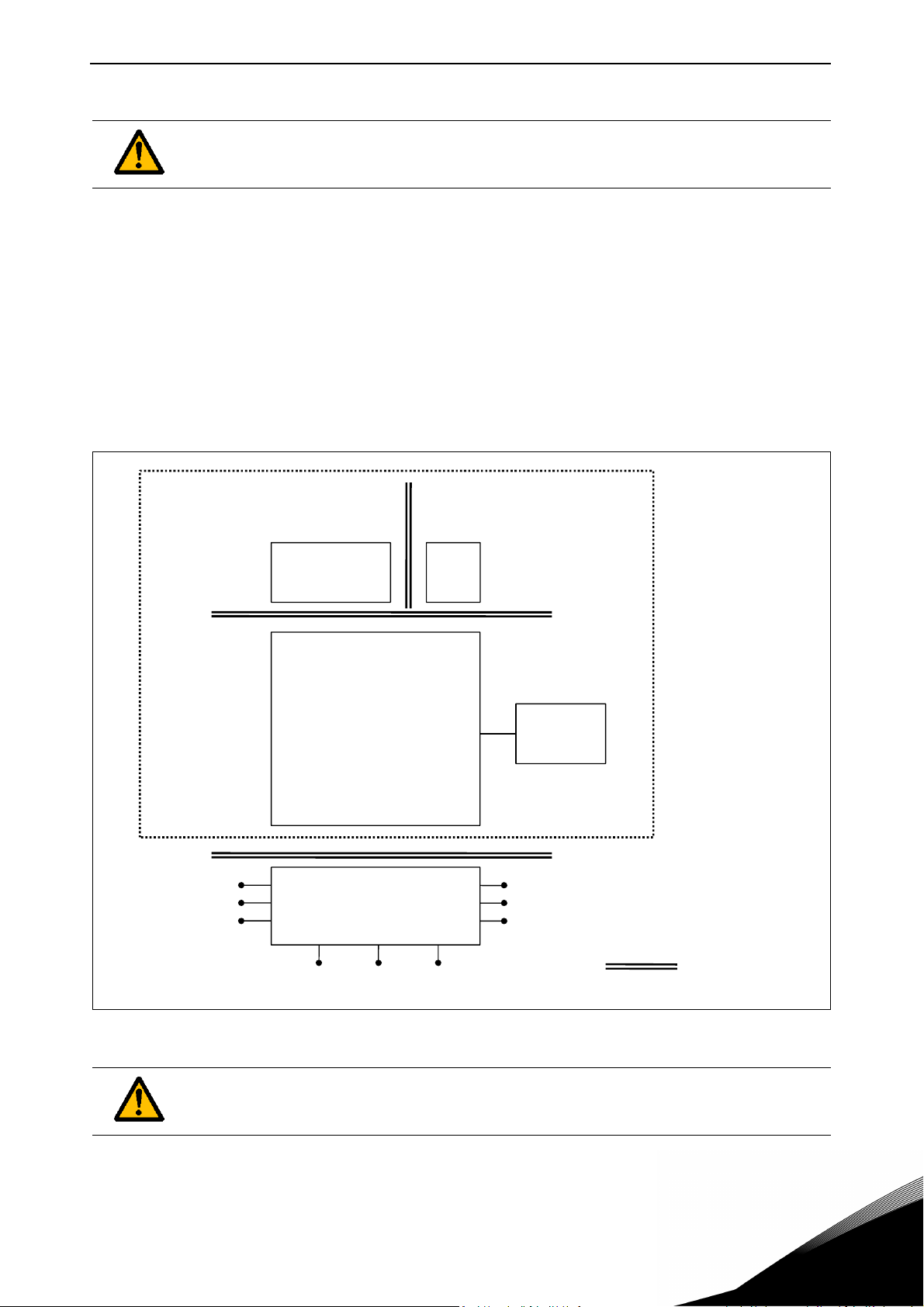

1.6 Insulation system

Please, consider carefully the insulation system depicted in Figure 4 before connecting any circuit to the unit.

A distinction has to be made for the following three groups of terminals, according the insulation

system of VACON® 100 X:

• Mains and motor connections (L1, L2, L3, U, V, W)

• Relays (R01, R02)

• Thermistor-input

• Control terminals (I/Os, RS485, Ethernet, STO)

The Control terminals (I/Os, RS485, Ethernet, STO) are isolated from the Mains (the insulation is reinforced, according to IEC 61800-5-1) and the GND terminals are referred to PE.

(*)

This is important when you need to connect other circuits to the drive and test the complete assem-

®

bly. Should you have any doubt or question, please contact your local VACON

distributor.

(*)

The relays may be used also with DVC A circuits. This is possible only if both relays

Figure 4. Insulation system.

are used with DVC A circuit: to mix Mains and DVC A is not allowed.

1

vacon • 9 Safety

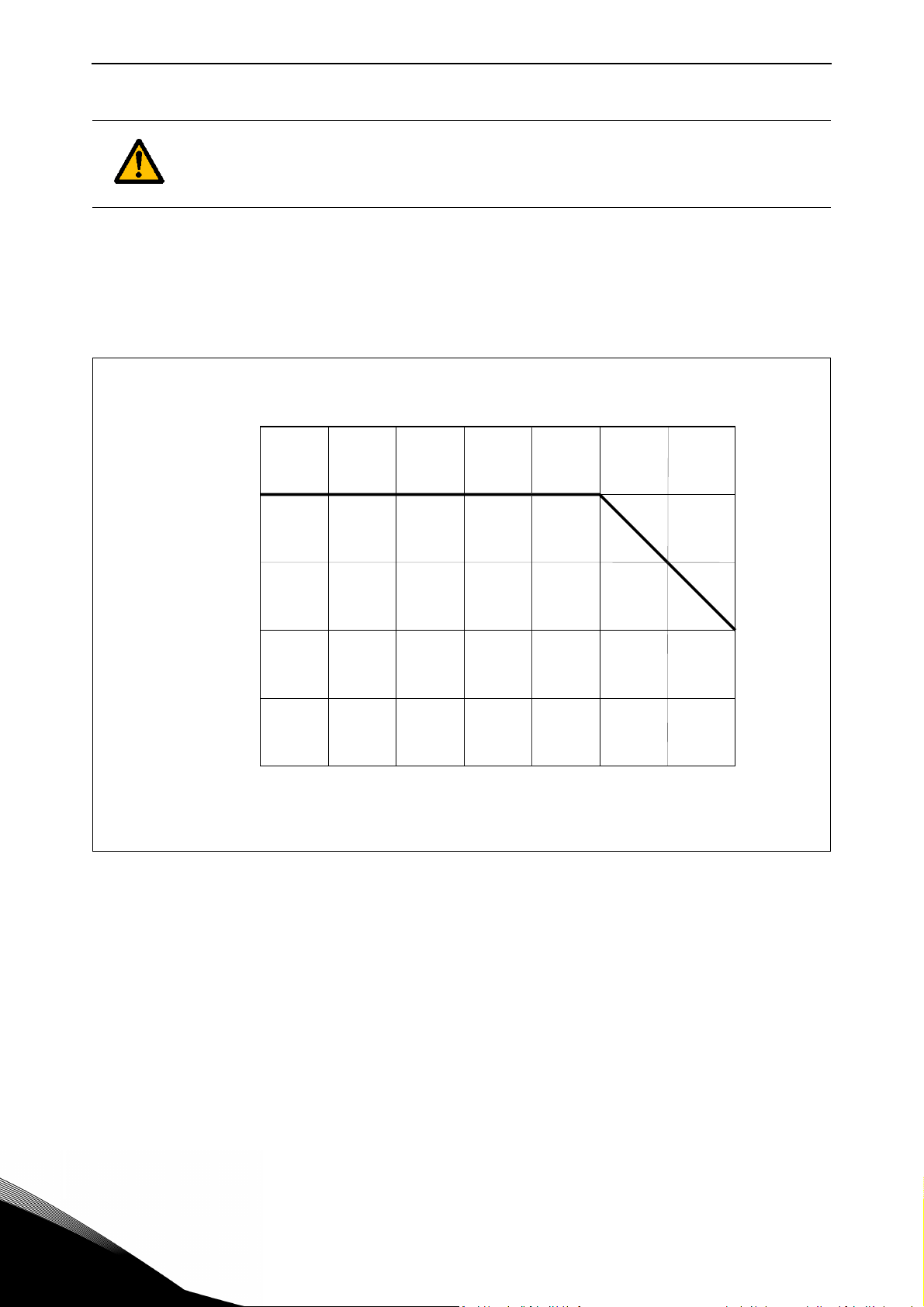

Ambient temperature (°C)

Percent rated output current (% I

N

)

10 20 30 40 50

100

75

50

25

0-10

150

60

Temperature - Output Current Derating Curve

1.7 Compatibility with RCDs

This product can cause a d.c. current in the protective earthing conductor. Where a residual current-operated protective (RCD) or monitoring (RCM) device is used for protection in case of direct or indirect contact, only an RCD or RCM of Type B is allowed

on the supply side of this product.

1.8 Extended temperature range

VACON® 100 X has an integrated cooling system, independent from the motor fan. Under maximum operating conditions, the ambient temperature cannot exceed 40 °C. See Table 24 and

Table 25 for the output rated current. Higher temperatures are allowed only with derating of the

output current. With derating the unit can operate up to 60°C. See the Figure 5.

Figure 5. Temperature-output current derating curve.

NOTE: the maximum allowed switching frequency above 50°C is 1.5 kHz.

The AC drive is cooled down by air-ventilation. Therefore, make sure that enough free space is left

around the AC drive to ensure sufficient air circulation (see for more details the mounting instructions on chapter 3).

1.9 Electro-magnetic compatibility (EMC)

The VACON® 100 X complies with IEC 61000-3-12, provided that the short circuit power (SSC) is

greater than or equal to 120 at the interface point between the user's supply and the public system.

It is the responsibility of the installer or user of the equipment to ensure, by consultation with the

distribution network operator if necessary, that the equipment is connected only to a supply with a

short-circuit power SSC greater than or equal to 120.

1

Safety vacon • 10

1.10 Declaration of conformity

Figure 6. Declaration of conformity.

1

vacon • 11 Safety

1

Figure 7. STO certificate.

1

vacon • 13 Safety

1

Receipt of delivery vacon • 14

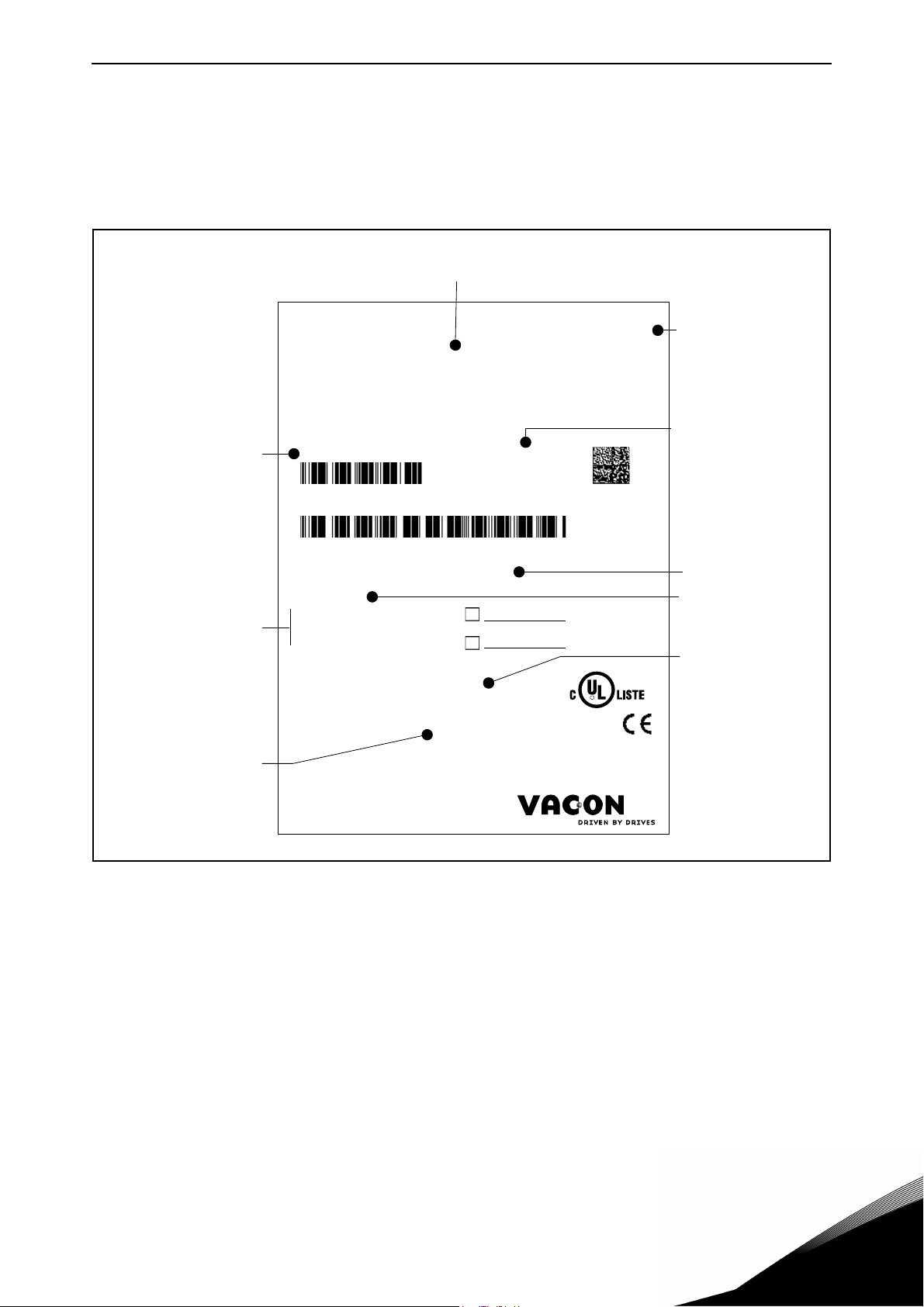

Marks:

3234500378

Cust. Ord. No:

Application:

FW0065V008

Firmware:

EMC level C2

380-480 V

IP66 / Type 4X

31 A

Rated current:

122245

B.ID:

V0789012245

S/N:

223456789012345678901234567 29012345

20-AB3L00315A02B5H1MB1C-12345678

Code:

VACON0100-3L-0031-4-X

Type:

0022345628AC DRIVE

223456789012245

Vacon type code

Rated

current

Supply

voltage

Application

code

IP class

EMC level

Serial number

CUSTOMER NAME

Customer’s

order number

Vacon order

number

Batch ID

2. R

ECEIPT OF DELIVERY

Check the correctness of delivery by comparing your order data to the drive information found on

the package label. If the delivery does not correspond to your order, contact the supplier immediately. See chapter 2.3.

Figure 8. VACON® package label.

2

vacon • 15 Receipt of delivery

VACON

This segment is common for all products.

0100

Product range:

0100 = VACON

®

100

3L

Input/Function:

3L = Three-phase input

0061

Drive rating in ampere; e.g. 0061 = 61 A

See Table 24 and Table 25 for all the drive rat-

ings.

4

Supply voltage:

2 = 208-240 V

4 = 380-480 V

X

-IP66/ Type 4X

-EMC-level C2

-Two relay outputs

-One thermistor input

+xxxx +yyyy

Additional codes (Several options possible).

Examples of additional codes:

+HMGR

Graphical keypad IP66

+F0065

HVAC Application installed

+F0159

FLOW application installed

+SRBT

Integrated battery for real time clock

+FBIE

Onboard fieldbus protocols activated

2.1 Type designation code

VACON® type designation code is formed of a nine-segment code and optional +codes. Each segment of the type designation code uniquely corresponds to the product and options you have ordered. The code is of the following format:

VACON0100-3L-0061-4-X +xxxx +yyyy

2

Receipt of delivery vacon • 16

2.2 Unpacking and lifting the AC drive

The weights of the AC drives vary according to frame size. You may need to use a piece of special

lifting equipment to move the converter from its package. Note the weights of each individual frame

size in Table 3 below.

Weight

Frame

[kg] [lb]

MM4 8.8 19.4

MM5 14.9 32.8

MM6 31.5 69.4

Table 3. Frame weights.

VACON® 100 X drives have undergone scrupulous tests and quality checks at the factory before they

are delivered to the customer. However, after unpacking the product, check that no signs of transport damage are to be found on the product and that the delivery is complete.

Should the drive have been damaged during shipping, please contact the cargo insurance company

or the carrier in the first instance.

2.3 Accessories

After having opened the transport package and lifted the drive out, check immediately that these

various accessories were included in the delivery. The contents of the accessories bag differ by

drive size:

2.3.1 Frame MM4

Item Quantity Purpose

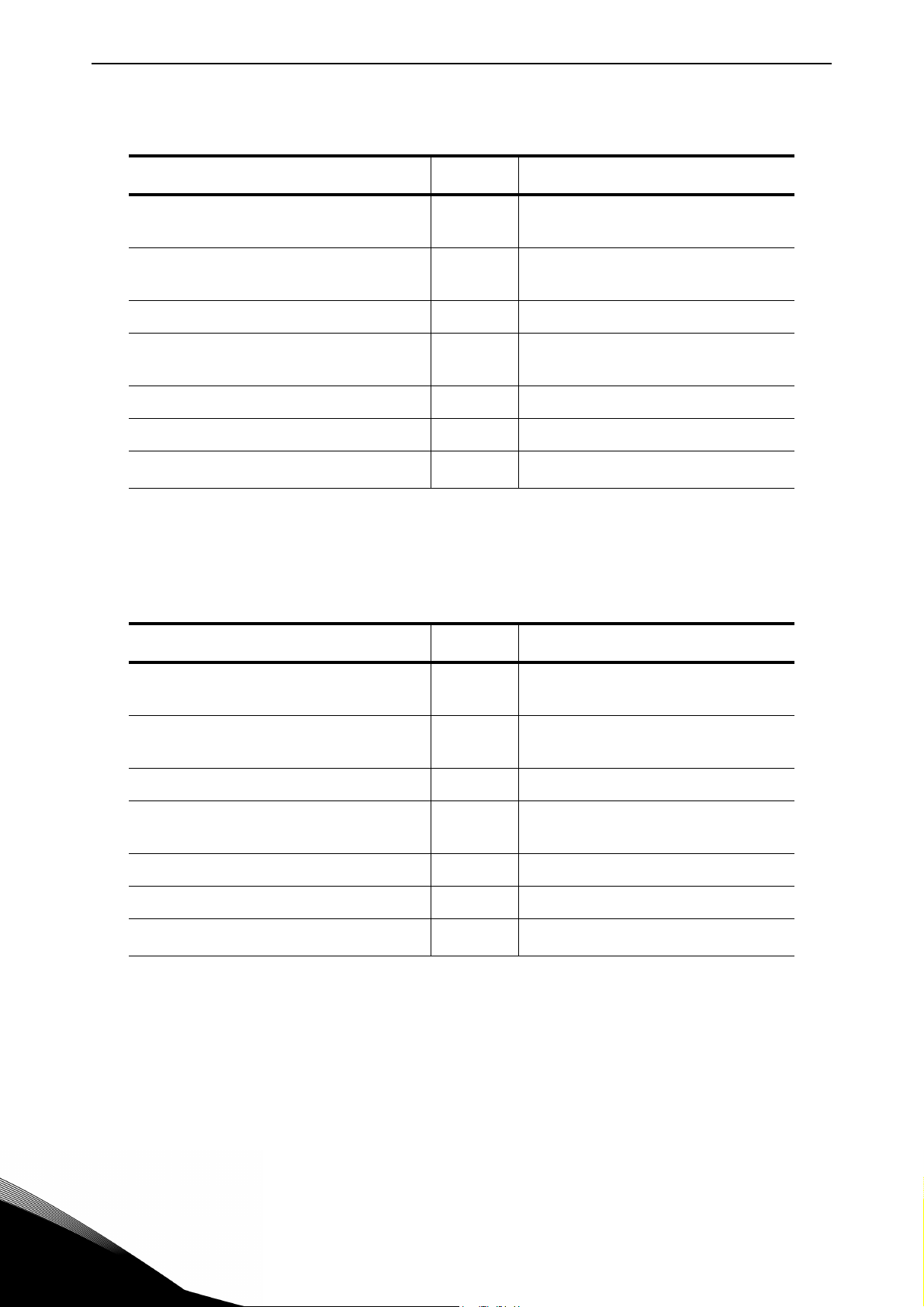

STO terminal connector 1

M4 x 12 DIN6900-3-Combi-Delta-Tx

screw

M1-3 Cable clamp 5 Clamping control cables

M4 x 12 DIN6900-3-Combi-Delta-Tx

screw

M25 Cable clamp 3 Clamping power cables

‘Product modified’ sticker 1 Information about modifications

10 Screws for control cable clamps

6 Screws for power cable clamps

Six pin black connector (see

Figure 9) to use STO function

HMI cap

*. Provided only if the drive is delivered with the keypad.

*

Table 4. Content of accessory bag, MM4.

1 Closing cap for the HMI connector

2

vacon • 17 Receipt of delivery

2.3.2 Frame MM5

Item Quantity Purpose

STO terminal connector 1

M4 x 12 DIN6900-3-Combi-Delta-Tx

screw

M1-3 Cable clamp 5 Clamping control cables

M4 x 12 DIN6900-3-Combi-Delta-Tx

screw

M32 Cable clamp 3 Clamping power cables

‘Product modified’ sticker 1 Information about modifications

HMI cap

*. Provided only if the drive is delivered with the keypad.

2.3.3 Frame MM6

*

Table 5. Content of accessory bag, MM5.

Item Quantity Purpose

10 Screws for control cable clamps

6 Screws for power cable clamps

1 Closing cap for the HMI connector

Six pin black connector (see

Figure 9) to use STO function

STO terminal connector 1

M4 x 12 DIN6900-3-Combi-Delta-Tx

screw

M1-3 Cable clamp 5 Clamping control cables

M4 x 25 DIN6900-3-Combi-Delta-Tx

screw

M40 Cable clamp 3 Clamping power cables

‘Product modified’ sticker 1 Information about modifications

HMI cap

*. Provided only if the drive is delivered with the keypad mounted.

*

Table 6. Content of accessory bag, MM6.

10 Screws for control cable clamps

6 Screws for power cable clamps

1 Closing cap for the HMI connector

Six pin black connector (see

Figure 9) to use STO function

2

Receipt of delivery vacon • 18

Product modified

Date:

Date:

Date:

13064.emf

2.3.4 STO terminal connector

Figure 9. STO connector.

2.3.5 ‘Product modified’ sticker

In the small plastic bag included in the delivery you will find a silver

Product modified

sticker. The

purpose of the sticker is to notify the service personnel about the modifications made in the AC

drive. Attach the sticker on the side of the AC drive to avoid losing it. Should the AC drive be later

modified mark the change on the sticker.

Figure 10. ‘Product modified’ sticker.

2.3.6 Disposal

When the device reaches the end of its operating life do not dispose

of it as a part of standard household garbage. Main components of

the product can be recycled, but some need to be fragmented to

separate different types of materials and components that need to

be treated as special waste from electrical and electronic

components. To ensure environmentally sound and safe recycling

treatment, the product can be taken to appropriate recycling center

or returned to the manufacturer.

Observe local and other applicable laws as they may mandate

special treatment for specific components or special treatment may

be ecologically sensible.

2

vacon • 19 Receipt of delivery

2

Mounting vacon • 20

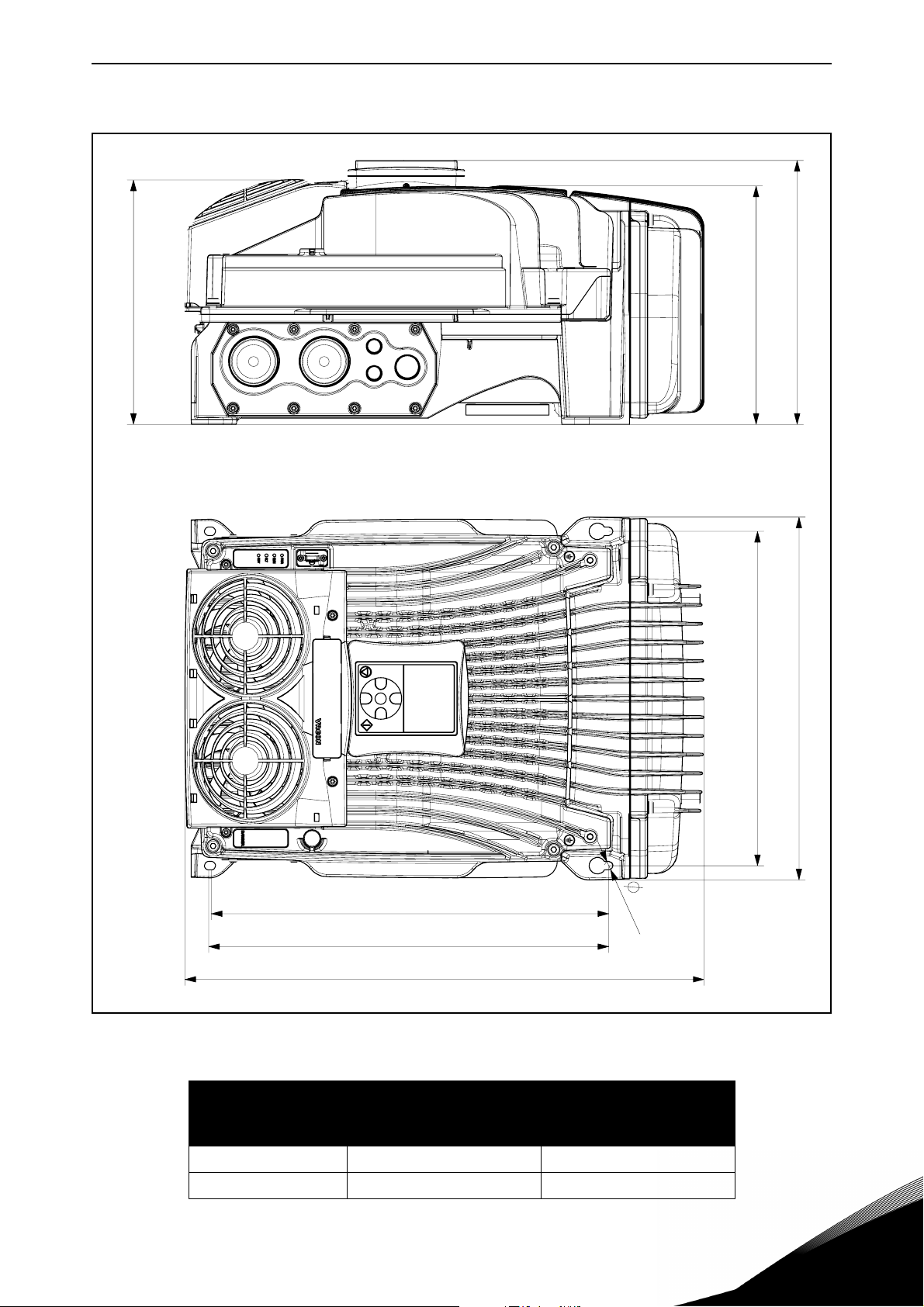

315,3

190,7

187,8

213,8

293,0

296,5

5

,

9

143,5

196,4

3. M

OUNTING

VACON® 100 X is the ideal solution for a decentralised installation. It is conceived to be mounted on

a wall or directly on the motor, saving space and reducing the cabling complexity. In both of the cases, it must be ensured that the mounting plane is even.

3.1 Dimensions

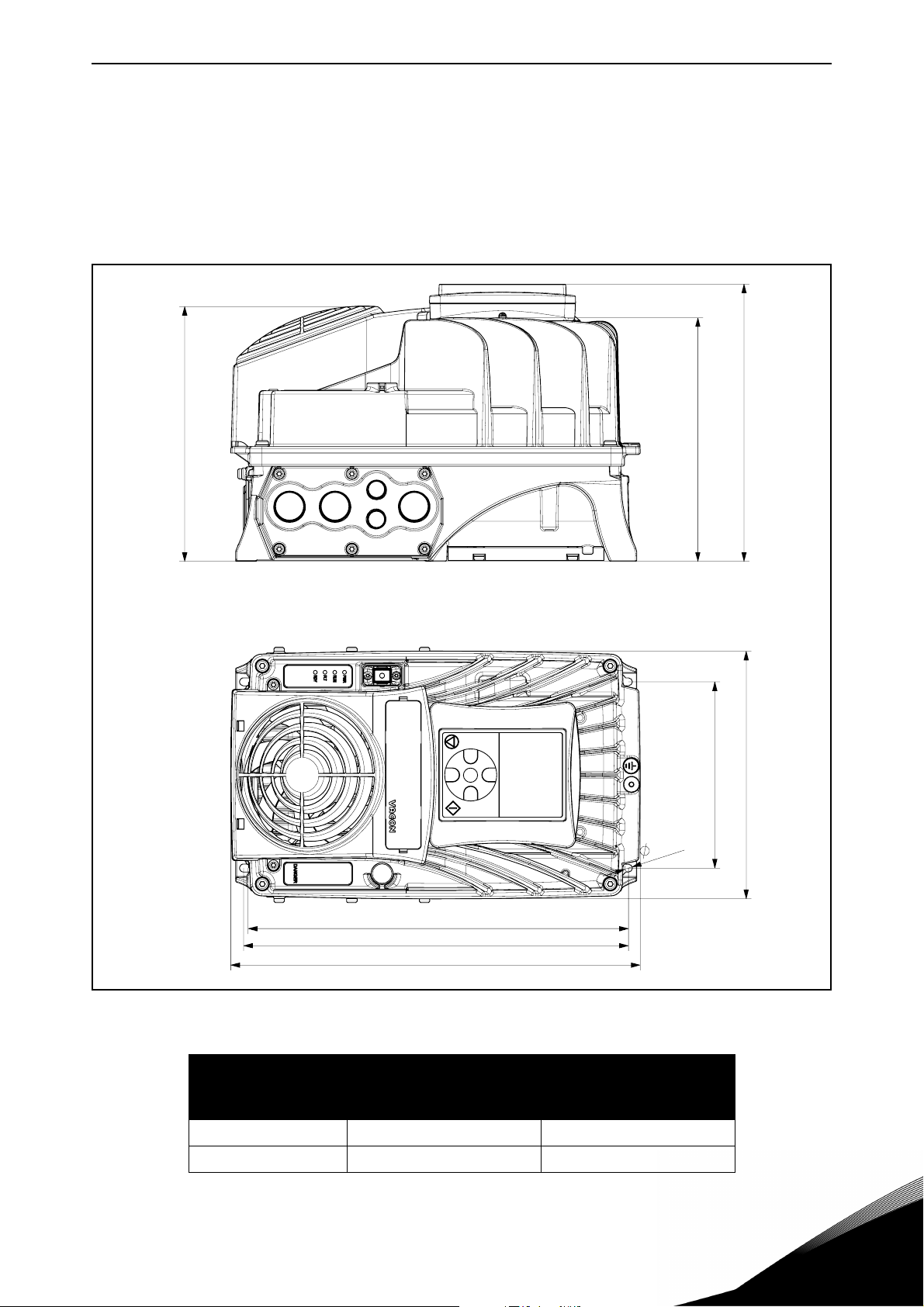

Figure 11. VACON® 100 X drive dimensions, MM4.

Dimensions W x H x D

Frame

[mm] [in]

MM4 190.7 x 315.3 x 196.4 7.51 x 12.41 x 7.73

MM4 +HMGR 190.7 x 315.3 x 213.8 7.51 x 12.41 x 8.42

3

vacon • 21 Mounting

367,4

203,7

230,8

180,0

345,2

349,2

6

,

1

232,6

213,5

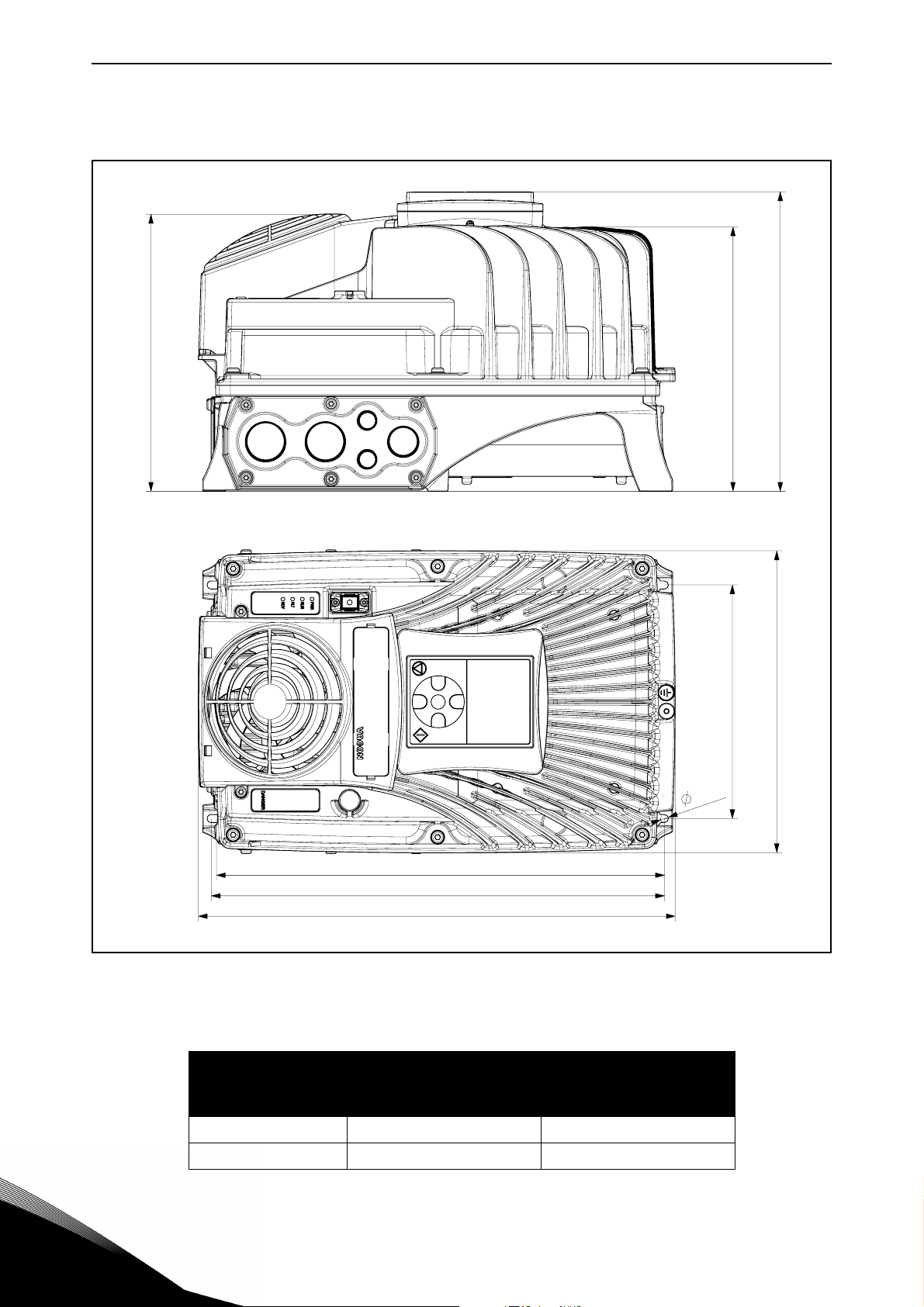

Figure 12. VACON® 100 X drive dimensions, MM5.

Dimensions W x H x D

Frame

[mm] [in]

MM5 232.6 x 367.4 x 213.5 9.16 x 14.46 x 8.41

MM5 +HMGR 232.6 x 367.4 x 230.8 9.16 x 14.46 x 9.08

3

Mounting vacon • 22

229,6

254,2

322,0

349,5

382,8

385,3

499,8

8

,

2

235,4

Figure 13. VACON® 100 X drive dimensions, MM6.

Dimensions W x H x D

Frame

[mm] [in]

MM6 349.5 x 499.8 x 235.4 13.76 x 19.68 x 9.27

MM6 +HMGR 349.5 x 499.8 x 254.2 13.76 x 19.68 x 10.00

3

vacon • 23 Mounting

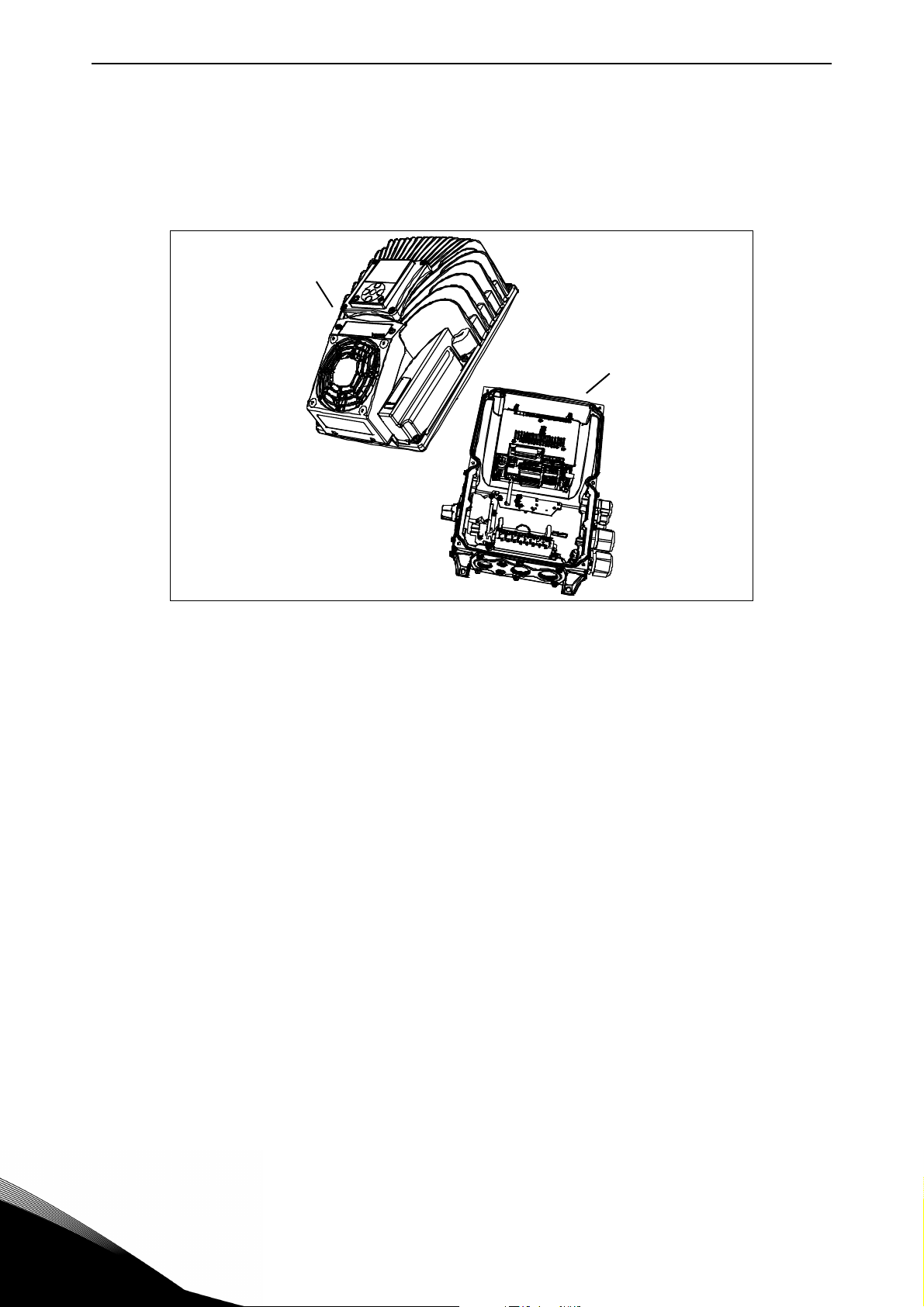

Powerhead

Terminal box

3.2 Introduction of modules

The mechanical concept of VACON® 100 X drive is based on two segregated parts, power and control, connected to each other by pluggable terminals. The power unit, called powerhead, includes

all the power electronics such as the EMC-filter, IGBTs, capacitors, choke or power boards while

the control board and the control terminals are located in the terminal box.

Figure 14. VACON® 100 X drive modules.

3

Mounting vacon • 24

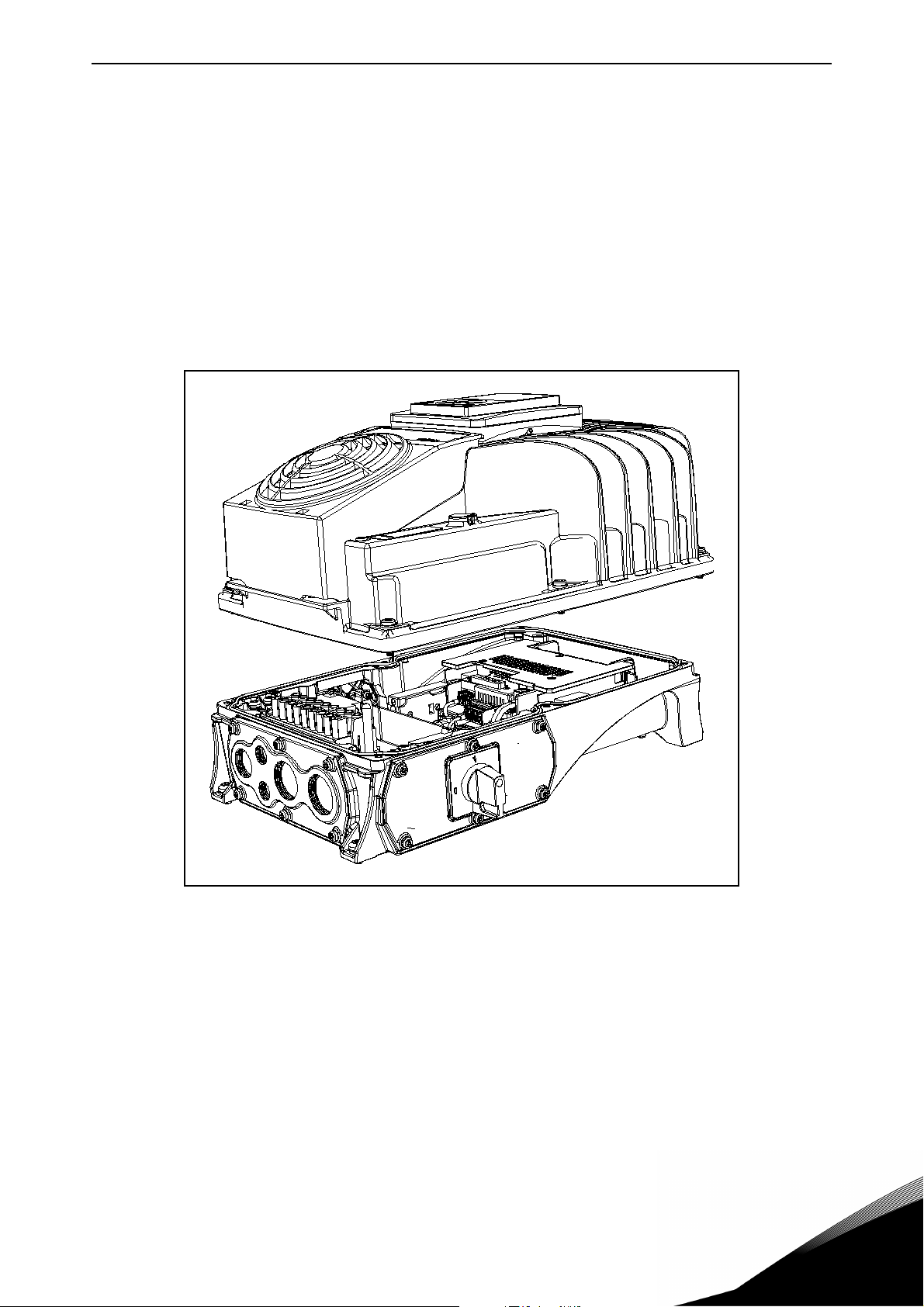

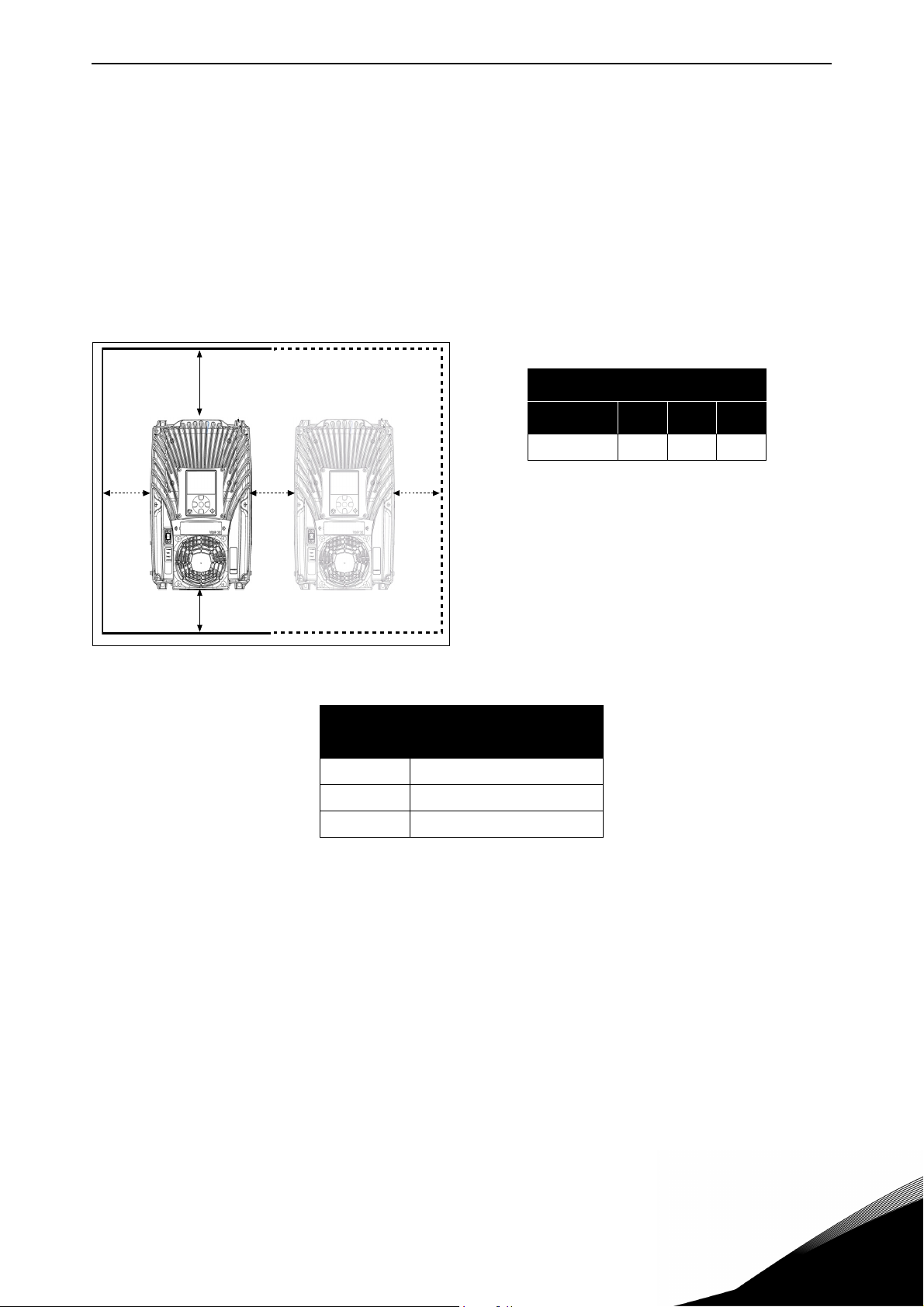

3.3 Mounting

The drive consists of two main elements:

1. The terminal box that includes the power terminals and control board with the control terminals

and

2. The powerhead containing all the power electronics.

To install the drive, both parts need to be separated. The terminal box must be fixed first and all

cabling done. After this, the powerhead will be plugged on the terminal box and fixed with 4 (MM4

and MM6) or 6 (MM5) dedicated screws located on top side of the powerhead (see Figure 15.). In order to guarantee specified IP protection, recommended fastening torque is 2-3 Nm. The screws

should be tightened crosswise.

Figure 15. Separation of modules(MM5 example).

3

vacon • 25 Mounting

3.3.1 Wall-mounting

The drive can be mounted in vertical or horizontal position on the wall or any other relatively even

mounting plane or machine frame and fixed with the screws recommended in Table 7.

Recommended screw or bolt size for MM4 is M5, for MM5 M6 and MM6 is M8.

Frame Screw number Screw size

MM4 4 M5

MM5 4 M6

MM6 4 M8

Table 7. Screws for wall mounting.

3.3.2 Motor-mounting

The drive can also be mounted on a motor (on top or on any side of the motor). The drive is equipped

with a cooling system independent of the motor. Motor-mounting requires special adapting components. Contact your local VACON

®

distributor for additional information.

3.3.3 Segregated modules

In order to ease replacements in case of failure, the power and the control sub-systems are enclosed in two segregated parts, connected together through pluggable terminals:

• Power-head: heat-sink enclosing all power electronics

• Terminal-box: block containing unit control and power terminals

Firstly, the terminal-box has to be fixed and the cabling has to be done. Secondly, the power-head

has to be plugged and fixed to the terminal-box with dedicated screws (see Table 8). In order to preserve the specified IP protection class, the recommended fastening torque is 2-3 Nm.

Frame Screw number Screw size

MM4 4 M5

MM5 6 M5

MM6 4 M6

Table 8. Screws for fixing the powerhead to the terminal box.

3

Mounting vacon • 26

B

C

AAA

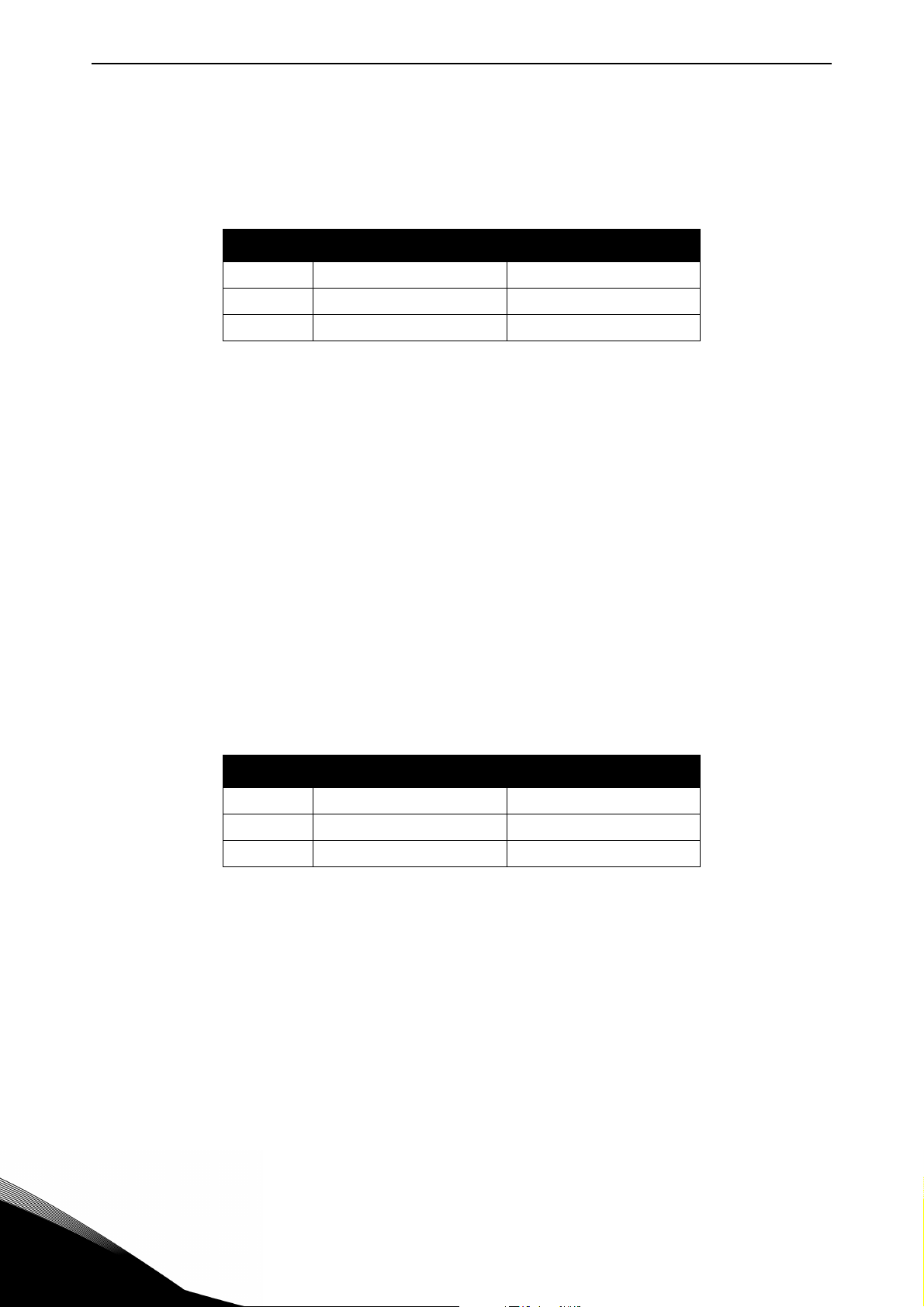

3.4 Cooling

The AC drive produces heat in operation and is cooled down by air circulated by a fan. The cooling

concept is independent of the motor fan.

Enough free space shall be left around the AC drive to ensure sufficient air circulation and cooling.

Different acts of maintenance may also require a certain amount of free space.

The minimum clearances given in Table 9 must not be exceeded. It is also important to ensure that

the temperature of the cooling air does not exceed the maximum ambient temperature of the converter.

Contact local VACON

lations.

®

distributor for more information on required clearances in different instal-

Min clearance [mm]

Type A B C

All types 80 160 60

Table 9. Min. clearances around AC drive.

A = Clearance left and right from the drive

B = Clearance above the drive

C = Clearance underneath the AC drive

Figure 16. Installation space.

Type

Cooling air required

[m3/h]

MM4 140

MM5 140

MM6 280

Table 10. Required cooling air.

Should you need further details on the cooling system of the VACON® 100 X, please contact your

local VACON® distributor.

3

vacon • 27 Mounting

3

Loading...

Loading...