Page 1

TTeecchhnniiccaall BBuulllleettiinn

1/16” Allen

Wrench

TTBB--110011

Transilluminator Selector Switch Replacement

Overview

The purpose of this Technical Bulletin is to explain the process of uninstalling a faulty selector

switch and installing a replacement switch on a UVP transilluminator. This instruction applies to

transilluminator selector switches used either for wavelength or intensity selection.

To complete this procedure, the following tools will be required:

• Phillips-head screwdriver

• 1/16" Allen wrench

• Pliers

• Flat-head screwdriver

Caution: This procedure requires a moderate level of technical competence. If you are not

comfortable working with electronics, tools and/or related components, contact UVP for

information on returning your transilluminator for repair or replacement.

Note: For information on replacing the transilluminator power switch, see TB-100, “Power Switch

Replacement Instructions”.

Removal Procedure

When performing the following procedure, place all components (screws, nuts, etc.) in a secure

location as they will be reused for installation.

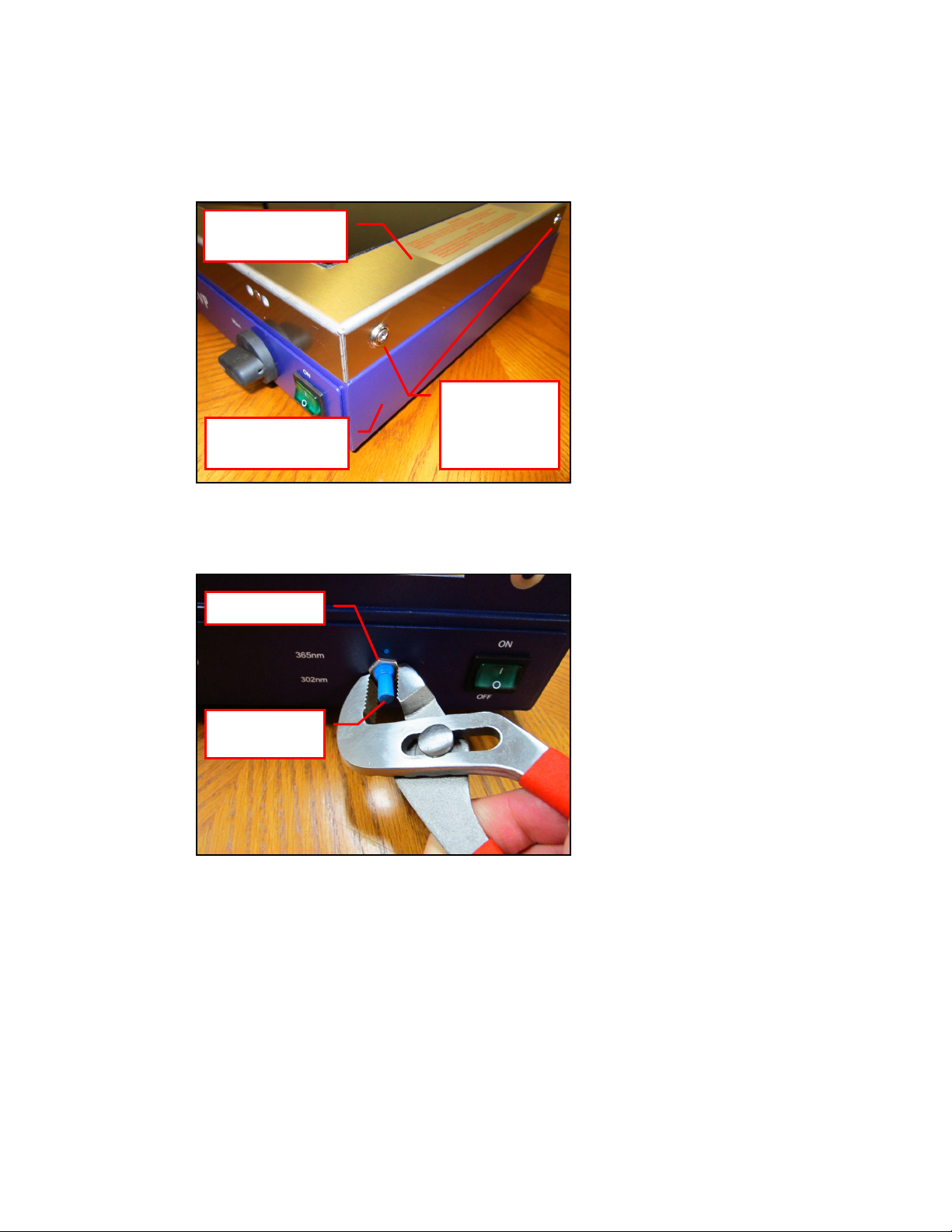

1. Turn off the transilluminator by placing the power switch on the front of the unit in the OFF

position. Then, unplug the unit from the wall power.

2. Using a 1/16” Allen wrench, loosen the set screw securing the selector switch knob to the

selector switch shank.

3. While firmly holding the transilluminator housing, pull forward on the knob to remove it from

the selector switch shank. Note: This process may require a fair amount of force as the knob

fits snugly over the shank.

TB-101 Rev STD

Page 2

Two of Four

Securing Nut

Selector

Switch Shank

Transilluminator

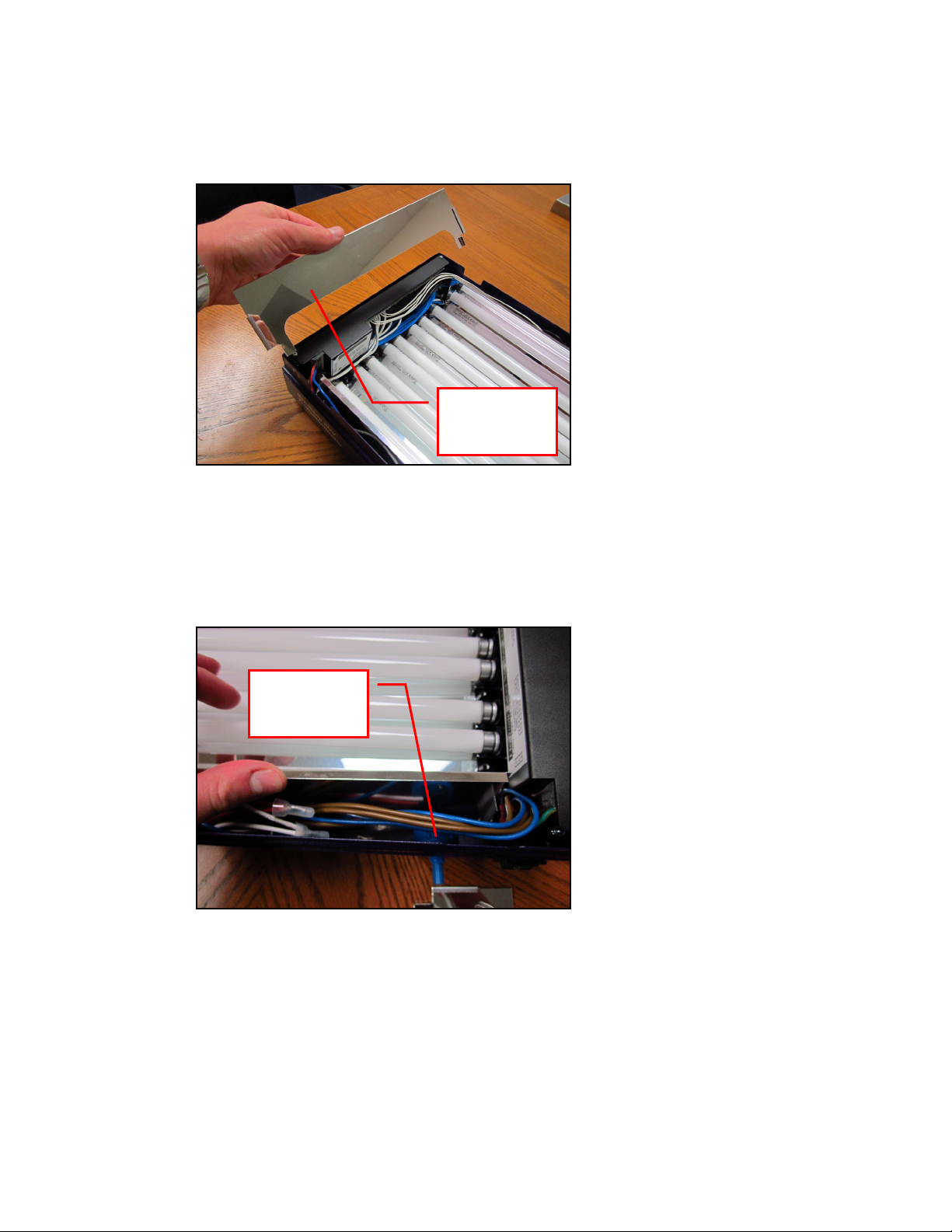

4. Remove the four Phillips-head screws and washers securing the transilluminator filter

frame to the body of the transilluminator. Lifting up, remove the transilluminator filter frame

from the transilluminator body. Place the filter frame aside.

Filter Frame

Phillips-Head

Transilluminator

Body

Screws and

Washers

5. Using the pliers, remove the securing nut securing the selector switch to the transilluminator

body.

Page 3

6. Inside the unit, locate the side reflector panels which are two reflective metal panels located

Side

Panel

Back Side of

Switch

at each end of the transilluminator light tubes. Note how these panels are installed prior to

removal, as this will aid with reinstallation later on.

Reflector

7. Pulling straight up, remove the two side reflector panels from inside the transilluminator.

8. Looking inside the front panel of the transilluminator body, locate the back side of the

transilluminator selector switch. Trace the wires from the back of the switch to the gray

wiring junction block located at the front-left corner of the unit. Note which wires are

connected from the switch to the junction block.

Selector

Page 4

9. Note: Prior to completing this step, make a note of the location of the transilluminator selector

Pull on Wire

Gray Wiring

Built-In

Lock Washer

switch wiring on the gray wiring junction block.

The gray wiring junction block contains a number of spring-loaded gray squares with

diagonal hash marks. The spring-loaded action of these squares holds the corresponding

wire in place. Using a flat-head screwdriver and while pulling on the appropriate wire, press in

on the gray square and pull the wire out. Repeat this process until all wires leading from the

selector switch to the junction block are removed.

Spring-

Loaded Gray

Square

Junction

Block

10. Locate the portion of the built-in reflector panel directly behind the selector switch. Flexing

the reflective panel toward the rear of the transilluminator, remove the selector switch from

the inside of the transilluminator.

Note: There is a metal lock washer located between the selector switch body and the

transilluminator body. When removing the switch, be careful not to lose this washer in the

base of the transilluminator under the reflector panel as it will be used during installation of

the replacement switch.

Reflector

Panel

Page 5

Installation Procedure

Alignment

Flex

Lock Washer

1. Looking at the front of the replacement selector switch, note the position of the alignment

tab. When installing the new switch, this tab should be aligned with the alignment hole in the

body of the transilluminator (see illustration).

Hole

Alignment

Tab

2. Place the lock washer over the shank of the replacement selector switch.

3. Flexing the front of the reflective panel toward the rear of the transilluminator, insert the

selector switch into the opening in the body of the transilluminator so that the alignment tab

and selector switch shank fit through the correct holes.

Note: Ensure that the alignment tab is inserted into the small hole above the opening for the

selector switch shank. Also, ensure that the lock washer is in place between the body of the

selector switch and the body of the transilluminator.

Reflective

Panel Back

Page 6

4. Thread the securing nut onto the shank of the selector switch. Hand tighten the nut, and

Securing Nut

Tab

Manually

Shank

then use the pliers to tighten the nut snugly. Again, verify that the alignment tab is inserted

in the small hole above the shank of the switch.

Alignment

5. Without the selector switch knob installed, use your fingers to rotate the selector switch shank

to the lowest position (in this case, to the “302nm” position).

Rotate

Selector

Switch Shank

Page 7

6. The selector switch knob does not have a groove or flat surface to align on the selector

Wrench

switch shank, so it is necessary to visually align the white indicator line on the knob with the

desired indicator position on the face of the transilluminator.

Once the position of the knob has been aligned, firmly press the selector switch knob into

place on the switch shank. Gently rotate the knob to ensure correct alignment. If the knob is

not aligned, remove the knob and repeat the process until properly aligned.

7. Using the 1/16” Allen wrench, tighten the set screw securing the selector switch knob to the

selector switch shank.

1/16” Allen

Page 8

8. Route the wiring from the selector switch to the gray wiring junction block. Using a flat-

Gray Wiring

head screwdriver, press in on the gray square while pushing the metal portion of the wire into

the corresponding hole (refer to the notes from Step 9 in the “Removal Procedure” to

determine where each wire should be installed). Repeat this process until all wires leading

from the selector switch to the junction block are installed.

Note: When a wire is fully installed, the gray square will remain in the “pushed in” position

and the wire will stay snugly in place.

Junction

Block

9. Using a soft cloth, clean any fingerprints or other dirt off of the surface of the side reflector

panels prior to reinstallation.

Side

Reflector

Panel

Page 9

10. The side reflector panels must be aligned with the main reflector panel during reinstallation.

180° Metal

Tab (b)

90° Small

Metal Tab (a)

Back Side of

Transilluminator

Panel

a. A small metal tab (a) protrudes from the side reflector panel at a 90° angle. This tab

must slide on the inside (the bulb side) of the main reflective panel.

b. Another portion of the side reflector panel is bent at a tight 180° angle to create a

180° angle tab (b). This must be aligned with a metal tab protruding from the outside

(non-bulb side) of the main reflective panel.

Main

Reflector

11. As the edges of the side reflector panels are sharp, ensure that all wiring is moved out of the

way during installation of the side reflector panels to avoid cutting into the sheathing of the

wiring. Slide the side reflector panels into place until the top edges of the reflector panels are

flush with the top edges of the main reflector panel.

Page 10

12. With the two sets of two small holes on the filter frame facing toward the front of the unit,

Two Sets of

Holes

Transilluminator

Transilluminator

replace the transilluminator filter frame on top of the body of the transilluminator.

Two Small

13. Reinstall the four Phillips-head screws and washers on the sides of the transilluminator to

secure the transilluminator filter frame to the transilluminator body.

Filter Frame

Body

Technical Support

Contact UVP Technical Support for additional assistance:

If you are in North America, South America,

East Asia or Australia:

Two of Four

Phillips-Head

Screws and

Washers

If you are in Europe, Africa,

the Middle East or Western Asia:

Technical Support during regular business days, between

Call (800) 452-6788 or (909) 946-3197, and ask for

7:00 am and 5:00 pm, PST.

E-mail your message to: info@uvp.com or

techsupport@uvp.com

Fax Technical Support at (909) 946-3597

Call +44(0) 1223-42002, and ask for Customer Service

during regular business days between 8:30 am and 5:30

pm.

E-mail your message to: uvp@uvp.co.uk

Fax Customer Service at

+44(0) 1223-420561

Loading...

Loading...