Page 1

INSTRUCTION

ÑIANUAL

BCIB

BOWL CUTTER

rA

Persons under age 18 are not permitted to operate or have

accessibility to operate this equipment per U.S. Dept. of Labor

Employment Standards Administration Fact Sheet No. ESA9I-3.

QJTvex

BC1810506

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

EDI

Page 2

BC 18

WELCOME TO UNI VEX

Thank you for purchasing this Univex product.

Your new Univex BC 18 is a commercial countertop appliance designed to volume cut

and mix a long and growing list of food, as well as support and power the UNI VEX

ALMFC 12 Meat & food Chopper, VS9 Vegetable Slicer, and the VS9H Shredder and

Grater food processing attachments.

If you have any questions concerning the operation of this unit, or if we can be of

further assistance, please call our Customer Service Department.

Univex Customer Service:

USA and Canada - 800-258-6358

International - 603-893-6191

SAFETY IS OUR TOP PRIORITY

It is a violation of United States Department of Labor regulations to

permit operation of the 8C18 by any person under the age of 18 years.

Read and make sure that you understand the instructions and safety warning in this

booklet and attachment instructions before attempting to opeinte.

Choose a location which provides a level, stable working surface with safe operating

clearance around the machine.

NEYER put fingers, hands, or foreign objects under the cover while the Bowl Cutter is

operating, or serious injury could result. Shut off the power, unlock and raise the cover

to remove a food jam. ONLY FOOD IS TO GO THROUGH THE BLADE

CUTTING ZONE.

NEVER attempt to clean or service your Bowl Cutter without first shutting off the

power, and then disconnecting the electrical plug from the outlet, or shutting off the

circuit breaker at the electrical panel. To safely power down, switch the machine off

and then disconnect the electrical supply.

Be sure the attachment is properly cleaned, assembled and installed; tighten

thumbscrew before connecting to power source.

Page 1

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 3

TABLE 0F CONTENTS:

BC 18

Page

Welcome

Safety

Assembly ofBCl8

Choosing the right location

Bowl cutter operation

Operating Tips

PTO operation

PTO Safety notes

Cleaning

Maintenance

Illustrations

Bowl Cutter, Figure 1

P.T.O. Assembly., Figure 2

Main Housing, Figure3

Blade Shaft Assembly, Figure 4

Motor & Bowl Drive Assembly, Figure 5

Electrical Component Assembly, Figure 6

Cover Lock Assembly, Figure 7

Electrical Schematics

i

i

3

4

4

4

4

4

5

5

3

6

7-8

9-10

11-12

13-14

15

16-18

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 4

BC 18

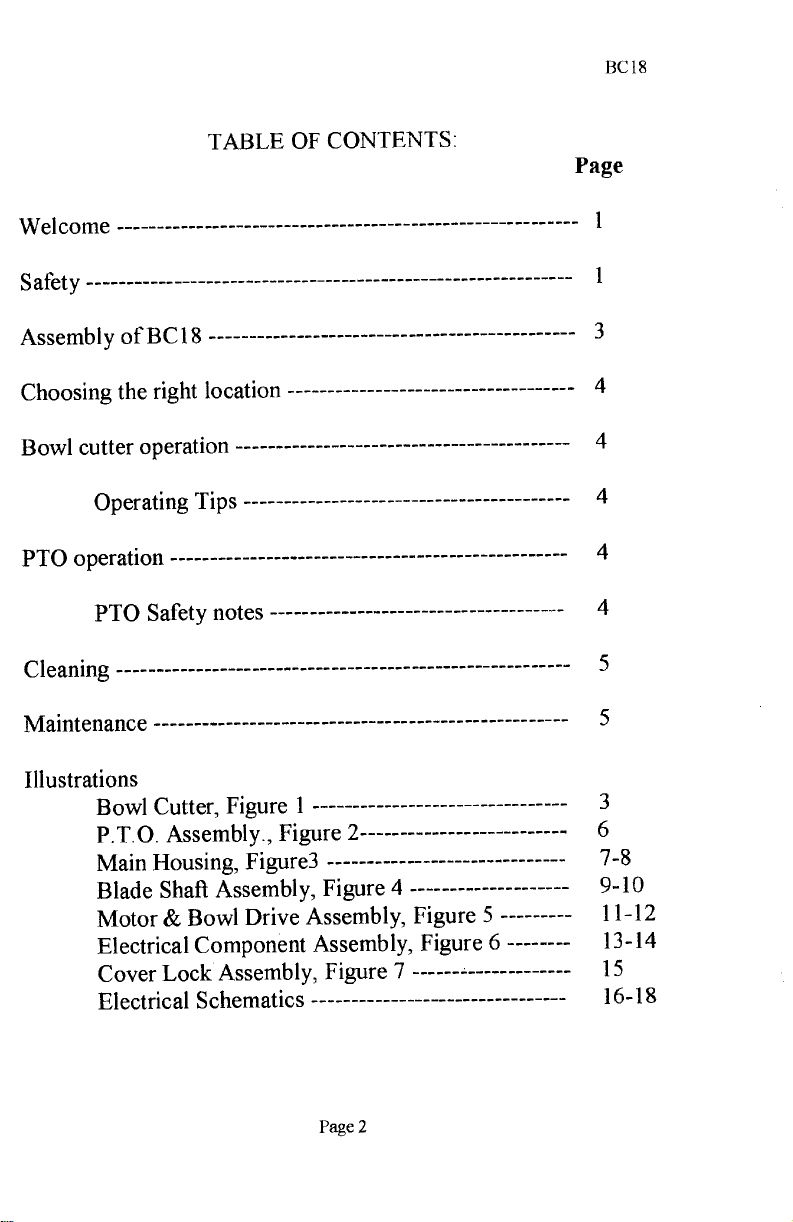

ASSEMBLY OF NEW UNIT:

Caution: Before making electrical connections, check that the specifications on the

data plate located on the BC 18 agree with those of your electrical service.

The Bowl Cutter (Page 3 Fig. i) is shipped fully assembled except for the 2 round

legs. The legs are packed separately for safe shipping and will easily thread into the

underside of your machine.

FIGURE 1 BOWL CUTTER

ON/OFF Switch

Legs

PTO

Page 3

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

4. Bowl Cover Latch

5. Bowl Cover

6. Bowl

Page 5

BC 18

CHOOSING THE RIGhT LOCATIONS

Please make certain this countertop unit is located at a safé and secure position (on a

stable, level surface) with easy access to the power supply. It is also desirable to have a

prep sink close by for easy cleaning.

BOWL CUTTER OPERATION

Clean the BCI 8 Bowl Cutter before using, carefully following the cleaning instructions

on page 5.

Operating Tips:

All products should be clean and prepared for cutting beforehand.

Product should he cut small enough to fit into the opening between the bowl cover

and the bowl.

For coarse cut, allow product to pass by the blades only once.

For finer cut, allow product to pass by the blades until desired cut is obtained.

Your stainless bowl (Fig. I, Item 6) twist locks into place over our Univex safety

sensor (Fig. 5, item 16). The safety sensor is to assure that the machine will flot

operate without the bowl correctly located in place.

Locate the bowl cover latch (Fig. 1, Item 4) at the rear of the bowl. This safety latch is

to assure that the bowl cover is in the full down and locked position before the BCI 8

will function. Rotate the latch clockwise 90° until it can rotate no longer to lock the

cover in place. If either of these special safety features appear tobe malfunctioning,

STOP and call for assistance.

The bowl cover conceals the BC 18 blades and is designed to insure that only food can

go through the cutting zone while the machine is in operation. Do not attempt either

with hands or a foreign object to reach under this cover. Should an item be too

large and jam, shut off the machine, unlock and raise the cover to remove this item. In

addition, there is an indicator light in the START/STOP switch which when lit

indicates the machine is running.

PTO OPERATION

The power-take-off hub (Fig. 2, Item 3) accommodates / 12 tapered attachments such as

a Vegetable Slicer & Shredder, or a Meat & Food Chopper. Before installing

attachments, tarit the BC 18 off. Remove the PTO cap (Fig.2, Item 1) and loosen the

thumbscrew on the PTO hub(Fig.2, Item 14). Insure adaptor (Fig. 2, Item 2) isproperly

installed on the drive shaft. Insert the attachment with a slight twist until firmly in place.

Tighten the thumbscrew. Be sure to read and follow any safety instructions for

attachments that you operate on the PTO.

SAFETY NOTES

Always turn off the BC 18 to install or remove attachments. Cover the PTO hub with

PTO cap wiìen not in use.

Page 4

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 6

BC 18

CLEANING

Before initiai cleaning and each cleaning thereafter, make certain your BC 18 is not

connected to the power source, and the switch is in the STOP position.

Rotate the bowl cover locking knob (Fig. 7, Item 11) counterclockwise 900 to the

UNLOCK position which will allow the bowl cover to be raised to an OPEN

position. This cover can be removed by lifting it off its mounting shaft.

Slowly turn the knife shaft to (a) confirm it moves freely; (b) make certain there is

clearance between the knives and the bowl; (e) locate the rear blade slightly above

bowl lip for removal.

Unscrew the knife shall knob (Fig. 4, Item 18).

Carefully remove knife assembly.

5,

Carefully twist the bowl clockwise (or unlocked position) and lift off.

Remove comb (Fig. 7, Item 5) from the housing.

These items should be hand washed, rinsed and sanitized initially before and after

each operation. Do not rinse with a hose. Do not use abrasive pads.

After the pieces have dried, safely set the bowl back over safety sensor. Twist the

bowl counterclockwise locking it back into place.

Carefully reposition the knife assembly into the notch and secure with the knife

shaft knob (Fig. 4, item ¡8). Confirm its proper position by mannally turning the

shaft (Fig. 4, Item 13) to make certain there is proper clearance in full rotation.

Insert the comb (Fig. 7, Item 5) into the housing. Slide the bowl cover back onto its

mounting shaft. Confirm that by rotating the bowl-locking knob clockwise into the

locked position, the cover (Fig. 1, Item 5) cannot be raised.

You are now ready to connect your Bowl Cutter to the power source and enjoy many

years of trouble free, labor saving performance!

MAINTENANCE

Knives: Eventual wear will cause blades (Fig. 4, Items 15) to become dull.

Sharpening can be done, but only by an experienced professional. Knife replacement

blades are available only as a set. Blade sets are precision matched and should be

initially installed by a professional service agent.

DRIVE SYSTEM IROUBLESHOOT1NG GUIDE

TROIJBLE

Bowl, knife, and PTO all have rotation

J)roblems

Bowl rotation only problem

PTO problem

Check & replace (if required) the belt,

motor, or electrical components.

Check and replace the gearbox.

Check and replace (if required) the

gearbox and flexible coupling.

REMEDY

Insure PTO adaptor is inserted.

If bowl or knife rotation problems should occur, it is most likely a belt problem.

The following is a complete Parts List, Wiring and Detailed Assembly Diagrams for

your BCI8.

PAGE 5

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 7

PTO. ASSEMBLY

FiGli RE 2

BC 18

ILLUS. NO.

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

* 11.

*12.

13.

14.

15.

16.

PART NO.

8800033

8800012

1818015

1200025H

4400005

1200075

1030019

1200117

4400230

1818016

4400006

4400016

1200119

8700019

4400210

8900019

* Part of Shaft # 10 ( not sold separately)

DESCRIPTION

Cover, PTO

Adaptor

Housing, PTO (BCIS)

Screw, hxhd, /4-20x314

Washer, Jock V4

Washer, V4

Bearing, 6204LL

Retaining ring, internal

Key, 3/16 sq. x 1 '/2

Shaft, PTO

Spring, Vi od, compression

Ball, steel '/, dia.

Retaining ring, ext.

Knob Assy., PTO

Washer, PTO

Screw, sfhd 6-32 x 3/8

QTY.

I

4

4

4

2

1

I

1

2

1

2

Page 6

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 8

MAIN HOUSING

FIGURE 3

BC 18

ILLUS. NO.

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

li.

12.

13.

14.

15.

16. 1200075

17.

18.

F7001347

4400517

F405AC30

4400409

8512855

F7000333

4400355

*F3040165

F3040400

F3040407

F3040408

19.

20.

21.

22.

23.

4400517

4400326

F4020127

181801!

1818014

PART NO.

F4020134

F4101274

F406AB24

F3030824

F7001757

F4020152

F3031282

F4710128

1814118

DESCRiPTION

Housmg, top

Axle

Collar

Bushing

Setscrew

Blade cover

Spring, cover

Anchor, cover spring

Screw, M6

X 20

Label, start/stop

Bottom cover

Label danger

rubber foot

Leg

Screw,M6x16

Washer

Label, person under age

Switch, start/ stop

Lamp 120 volt

Lamp 24 volt

(460V. machine)

Lamp 240 volt

Label, start/stop

Label, Univex

Housing, base

Cutting board

Pin, cutting board

QTY.

2

2

2

1

4

4

9

9

1

I

1

1

1

* When ordering switch please specifíy which pilot lamp is required.

Page 7

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 9

MAIN HOUSING

FIGURE 3

13C18

Page 8

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 10

BLADE SHAFT ASSEMBLY

FIGURE 4

BC 18

ILLUS. NO.

1.

2.

3.

4.

5.

6.

7.

8.

9.

lO.

11.

12.

13.

14.

15.

16.

17.

18.

19.

20.

21.

22.

23.

24.

25.

26.

27.

28.

29. F700300A

30.

31.

32.

33. F7003349

PART NO.

F4080307

F4101271

14101272

F3030311

F7000557

F41 (10012

F7Ò00547

8512227

1814016

6509041

1204005

1814018

F4100012

1814019

F3031102

1814021

1814023

1814024

F7001640 Key

F7001735

F7001745

F700334H

F3030133

14100542

F3030302

F4101292

F4101283

F7001347

F7003808

F7004008

F7001724

DESCRIPTION

Bracket, gearbox mounting

Coupling

Housïng, bearing support

Bearing,

Retaining ring, external

Pulley, blade/Pro drive

Retaining ring, internal

Seal

Bearing housing, plastic

Washer,M6

Screw, M6x2Onun

Cover, beariiïg housing

Shaft, blade

Arbor, blade assy.

Blade set

Spacer, blade assy.

Nut, blade assy.

Knob, blade assy.

Set screw, MS x 20mm

SetScrew,M6xlOmm

Screw, M8 X

Spring,idler

Shaft, idler bearing

Bearing

Spacer

Idler arm

70mm

Screw, M6x20

Stud, M8 X 115mm

Washer

Nut

Set Screw

Screw, M8 x 25mm

QTY.

I

2

I

3

3

I

1

2

1

1

1

3

I

4

4

4

2

4

Page 9

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 11

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 12

MOTOR & BOWL DRIVE ASSEMBLY

FIGURE 5

ILLUS. NO. PART NO. DESCRIPTION QTY.

1. F3030133 Belt

2. F406AB23

3. F405FC44

4.

5.

6. F4020375 Plater, bowl drive 1

7. F4100369 Pin, bowl stop

8.

9. F4100259 Shaft, plunger 1

10. F3031333

11. F4100303 Shaft, gearbox output

12.

13. F4101286 Bracket, bowl switch

14. 1818017

15. F700302A

16. F700303A

17. F7003808

18. F7004008

19.

F7900028

F4O5FCOI Washer, bayonet 3

F4080306

F4100130

F7004316 Key, gearbox output

Post, actuator, bowl

Bowl, 18"

Screw, M6 x 10mm

Gearbox assy., bowl drive

Spring,compression

Nut,output shaft 1

Switch, interlock 1

Stud, M8 x 90mm

Stud, M8 x 75mm

Washer, M8

Nut, MS

1

3

1

2

2

10

10

I

20. F7001630 Key, gearbox mput

21. F4101282

Bearing housing, bowl drive I

22. F700014N Stud, MSx6Omm 4

23.

24.

25. F700354A

F4100130

F7000547

Bearing 1

Retaining ring mt.

Set screw, M6 x 18mm 1

26. F4101281 Pulley, bowl drive 1

27. 1200476

28. 1200075

Eyebolt, ¼-20 x 1

Washer, ¼" 1

1

29. 4400141 Nut,¼-20 2

30. 1200063 Nut, kep, 5/16-18

31.

32.

1200078

1030308

1818022

Washer, 5/16"

Motor, i l5/208-240V./6OHZ/1PH

Motor, 220-240V./SOHZJ1PH

4

4

I

1818023 Motor, 208-240/460V./6OHZ/3PH I

33. 1818010 Plate, motor mountmg

34. F3040167 Cap 4

35. F7003057 Screw, M8x2Omm 4

36. 1200039 Screw, 5/16-18 x3/4" 4

37.

38.

1200412

F4101280

SetScrew,1/4-20x1/4" 2

Pulley, motor

1

BC 18

Page 11

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 13

MOTOR & BOWL DRIVE ASSEMJ3LY

FIGURE 5

BC 18

Page 12

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 14

ELECTRICAL COÌvWONENT ASSEvLY

FIGURE 6

BCI S

ILLUS. NO.

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

16.

17.

18.

19.

PART NO.

8800200

8800201

7100131

7100132

7100107

6509161

1818012

7100017

1200471

4400065

1200076

1053784

6509115

1033324

7100041

7100110

1033325

7100111

1033326

8800203

1200012

4400101

4400213

1818024

8800239

4400398

DESCRIPTION

Power cord, 115V., 1 PH

Power cord, 230V., 1 PH

Power cord, 230v., 3 PH

Power cord, 460V., 3PH

Strain relief

Stud, M5 x 25mm

PIate,electiical mounting

Mount, contactor

Screw,SCHD1O-32xY2

(on 460V. machines)

Washer, lock, #10

(on 460V. machines)

Washer, flat, #10

(on 460V. machines)

Washer,M5

Nut,M5

Starter, 115V.,6OHZ, IPH

Starter, 230V.,6OHZ, IPH

Starter, 230V.,5OHZ, 1PH

Starter, 208-240V.,6OHZ, 3PH

Starter, 480V.,6OHZ, 3PH

rrfoner(46ov. only)

Cord, motor

Screw,#10-32xY2(notshown)

Clamp, cable

Wire mounting pad ( not shown)

Screw, M3 x 8mm (not shown)

Wiring package(not shown)

ire ( not shown)

Tie,

QTY.

1

1

1

1

1

3

3

7

3

7

1

5

3

3

1

2

5

Page 13

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 15

BC I 8

ELEC1RICAL COMPONENT

FIGURE 6

ASSEMBLY

Page 14

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 16

COVER LOCK ASSEMBLY

FIGURE 7

BC 18

ILLUS. NO.

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14

15.

16.

17.

18.

19.

20.

PART NO.

1818017

F4100062

F4020136

F4100775

F4O6ABIO

F7001750

14101293

F4100060

F4100068

F700263F

14101233

4400518

F7001734

F7001760

F7001745

F406AB22

F4100070

F3031223

F7003338

F7003328

DESCRiPTION

Switch, interlock

Switch plate

Base extension

Pin, comb

Comb

Set screw M6 x 20mm

Shaft, switch actuating

Housing, lock shaft

T shaft, lock assy.

Spring washer

Knob,coverlock

Label, open/close

Set screw, M5 x 8mm

Stud, Ml2 x 30mm

Setscrew,M6xlOmm

Extension

Sleeve

Spring, compression

Screw, socket bd. M6 x 20mm

Screw, M5 x 20mm

(ii)

QTY.

2

1

i

2

1

1

3

¡

4

2

Page 15

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 17

BOWL

SWITCH

COVER

SWITCH

STOP

SWITCH

[2

r

W2

W3

11 [X

LIGHT

Wi

o

iH1

n

-J

STARTER

n

J

START

SWITCH

FIGURE S

BC1B SCHEMATIC

115V,6OHZ. 1PH,

220-240V, 50HZ, 1 PH

230V, 50HZ, 1PH

W6

n

L

/

Ti

POWER IN

LI

L2

T2 9 T3

T2

BC 18

GND

L2

13

L3

4

9

96

T3

MOTOR

W4

W5

WII

W7

Page 16

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 18

BOWL

SWITCH

COVER

SWITCH

W3

L-

W2

BC 18

FIGURE 9

8C18 SCHEMATIC

208-240V., 50HZ, 3PH.

POWER IN

/

Ll

L3

L2

GND

I

WI

-T

r

j

STARTER

r-

-i

J

Al

A2

L

T2

TI

T3

95

S1O

SWITCH

r

1x2 iH-I

2

W5

1L

H..

LIGHT

-. JL

W4

ir

START

SWITCH

-T

_T

Wi

Pagel 7

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 19

FIGURE 10

BC18 SCHEMATIC

460V., 60HZ., 3PH

380V, 50Hz., 3PH

BC 18

BOWL

SWITCH o

W2

COVER

SWITCH

L - J

W3

STOP

SWITCH

r ir-

2 lHx2

LcHp o

II

L L

LIGHT

W4

Wi

J

STARTER

START

SWITCH

-ir- -i

W6

/

L

Ti

POWER IN

LI

12

I

L2

L3

T3 C) 9

GND

MOTOR

CONTROL

TRANSFORMER

£

HI

o

H2

H3

W5

We

WZ

Page 18

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 20

WARRANTY

The Univex BC 18 Bowl Cutter carries a one-year on-

site parts and labor warranty against any defects in

materials or workmanship. The one-year period begins

on the date of purchase by the end user and remains in

effect provided the unit

full

accordance with our instructions.

performed under this warranty must be performed

between the hours of 8:00 am and 5:00 pn local time,

Monday through Frida.

overtime charges of any kind.

Warrant r

report warranty claims before arranging repair or

attempting to return the unit Io Univex Corporation,

Damages incurred in transit or incurred because of

installation error, accident, alteration, or misuse are not

covered. Transit damages should be reported to the

carrier immediately.

Service Department at 800-258-6358 to

Univex will not be liable for any consequential.

compensatory, incidental or special damages.

is used properly in

Any work to be

Univex will not cover

Please call the Univex

nTvex

3 Old Pockinghani Road, Salem, !41-1 03079-2140 Th1ephne 1-603-893-6191 Fax 1-603-893-1249

TOLL FREE ORDERING FAX 1-800-356.5614

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Loading...

Loading...