Page 1

9514 MAX SLICER

nivex

Exacting Standards, Just Like Yours, sirce 1948

EExxaaccttiinngg SSttaannddaarrddss,, JJuusstt LLiikkee YYoouurrss,, ssiinnccee 11994488

9514

99551144

Manual Gravity Feed Slicer

MMaannuuaall GGrraavviittyy FFeeeedd SSlliicceerr

9514 MAX SLICER

99551144 M

Operations & Parts Manual

Operations & Parts Manual

Persons under the age of 18 are not permitted to operate or have

Persons under the age of 18 are not permitted to operate or have

accessibility to operate this equipment per U.S. Dept. of Labor Employment

accessibility to operate this equipment per U.S. Dept. of Labor Employment

Standards Administration Fact Sheet No. ESA91-3.

Standards Administration Fact Sheet No. ESA91-3.

M

AXX SSLLII

A

CEE

C

R

R

UNIVEX CORPORATION - 3 Old Rockingham Road - Salem, NH 03079-2140 - Tel (800) 258-6358 - Fax (800) 356-5614

UNIVEX CORPORATION - 3 Old Rockingham Road - Salem, NH 03079-2140 – Tel (800) 258-6358 – Fax (800) 356-5614

Int'l Tel 603-893-6191 - Int'l Fax 603-893-1249 - Website www.univexcorp.com - E-mail Univex@univexcorp.com

Printed in USA

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Int’l Tel 603-893-6191 – Int’l Fax 603-893-1249 – Website www.univexcorp.com - E-mail Univex@univexcorp.com

Printed in USA

Page 2

TO INSURE BOTH SAFE AND

TROUBLE-FREE PERFORMANCE WE STRESS

THAT ALL PERSONNEL THAT WILL BE

INVOLVED WITH YOUR NEW UNIVEX SLICER

MUST READ AND UNDERSTAND THESE

INSTRUCTIONS BEFORE ATTEMPTING TO

OPERATE THIS UNIT.

WE APPRECIATE YOUR

COOPERATION AND YOUR BUSINESS.

SHOULD THERE BE A QUESTION OR IF

WE CAN BE OF FURTHER ASSISTANCE,

PLEASE CALL US, 1-603-893-6191.

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 3

TABLE OF CONTENTS

9514

DESCRIPTION

Table of Contents

List of Illustrations

Introduction

Installation Instructions

Safety Warnings

Operating Instructions

Sharpening Instructions

Operator's Care of Slicer - Cleaning Instructions

Lubrication Instructions

Trouble Shooting Guide

Repair Instructions Including Disassembly, Replacement and

Replacement Parts

Warranty Information

LIST OF ILLUSTRATIONS

ILLUSTRATIONS

Overall View of Meat Slicer

1

Figure

Figure 2

Top Casting and Blade Assembly

Figure 2A Meat Deflector

Figure 3

Figure 4

Figure 5

Figure 6

Figure 7

Figure 8

Figure 9

Arm Assembly

Slice Control Assembly

Carriage assembly

Sharpener Assembly

Electrical Assembly

Schematic 115V, 60HZ, IPH, 100V, 50-60HZ, 1PH

Schematic 220V, 50HZ, 1PH; 100V, 50-60HZ, 1PH

Reassembly

PAGE

3

3

3-4

4

5

6

7

8

9-11

12-21

Back Cover

PAGE

2

12-13

14

.15

16

17

18-19

20-21

22

23

Page 1

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 4

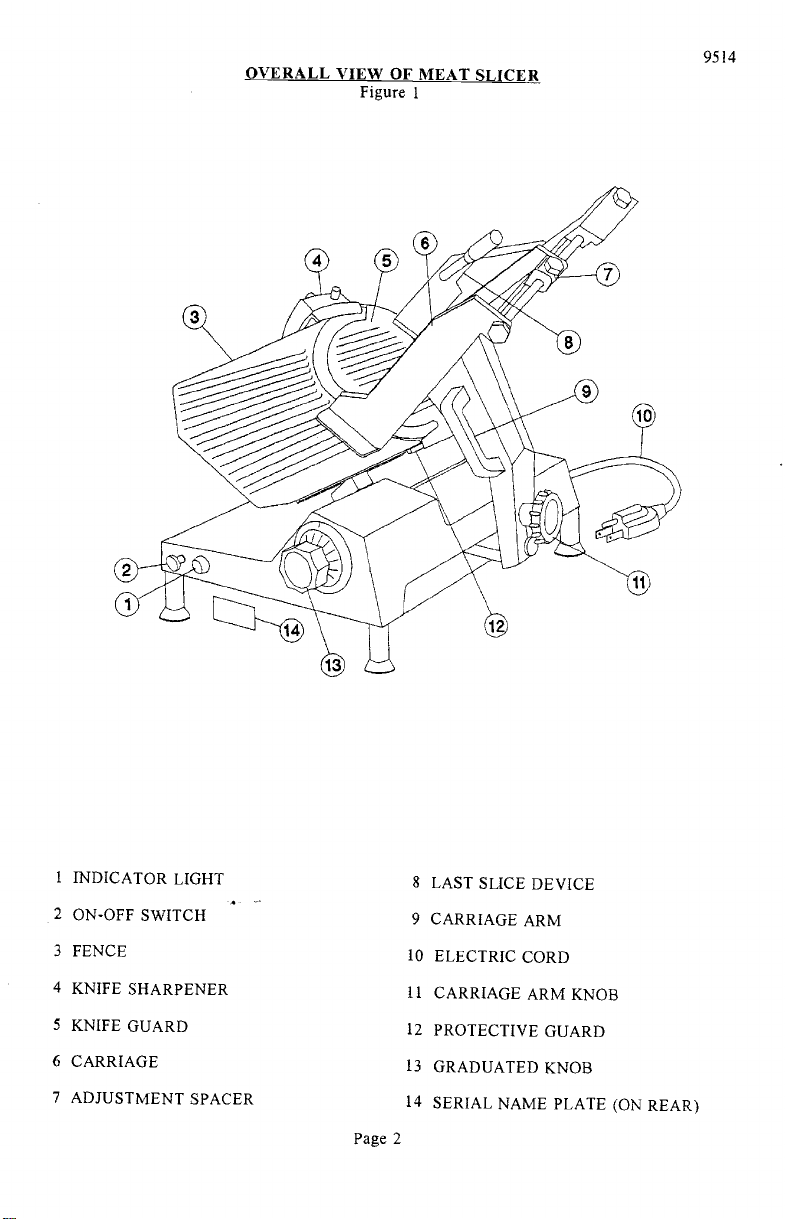

OVERALL VIEW OF MEAT SLICER

Figure 1

9514

i INDICATOR LIGHT

2 ON-OFF SWITCH

3 FENCE

4 KNIFE SHARPENER

5 KNIFE GUARD

6 CARRIAGE

7 ADJUSTMENT SPACER

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

8 LAST SLICE DEVICE

9 CARRIAGE ARM

10 ELECTRIC CORD

II CARRIAGE ARM KNOB

12 PROTECTIVE GUARD

13 GRADUATED KNOB

14 SERIAL NAME PLATE (ON REAR)

Page 2

Page 5

INSTRUCTION MANUAL

INTRODUCTION

This manual contains instructions for the Installation,

Repair of the Meat Slicing Machine. Disassembly, Repair,

Instructions are included. A trouble shooting guide is

Parts List with identifying figures is also included to

of replacement parts.

Operation, Care, Maintenance and

Replacement and Reassembly

provided. A complete Replacement

facilitate identification and ordering

INSTALLATION INSTRUCTIONS

INSPECTION

All Univex slicers are inspected and tested at the factory;

reinspected carefully by the person making the installation

parts. Detached parts and fixtures should be

are present. Any damages, imperfections or

checked against packing list to determine all

shortages should be reported to the dealer or

however, they should be

for loose, damaged or broken

Univex and shipping carrier.

Warning: After slicer has been inspected, wash slicer

completely with warm water and

mild soap. For SAFETY, follow the cleaning instructions on

INSTALLATION

The most efficient installation of your Univex slicer will

kitchen. Locate your slicer where it will save steps for

sufficient clearance around it for ease of maintenance and

and safe use.

Slicer should be operated on a sturdy bench or table

operator.

ease and safety of operation, as well as for

It is most important that the forearm of the operator

maximum production. This height is considered

depend upon the layout of your

the operator and be sure to provide

cleaning, as well as for efficient

with the height determined to suit the

optimum when the carriage handle (Figure 1 [9]) of the slicer

of the operator's elbow when standing.

IMPORTANT

Warning/Caution: Electrical wiring instructions are found in the

8 & 9.) Before making electrical connections,

specifications on the nameplate to make sure that they agree

on your electrical service. A grounding type

provided for safety.

If you do not have a mating receptacle, have a

qualified electrician provide one with grounding provisions

accordance with local safety codes.

9514

Page 6.

be at the proper level for

is at approximately the height

wiring diagram (Figures

CHECK the

with those

three-terminal plug is

in

IMPORTANT SAFETY WARNINGS

It is a violation of United States Department of Labor regulations to

any person under the age of 18 years.

Warning: The slicer knife is extremely sharp! Never touch the

and fingers clear of the knife. Never run slicer without

parts in place and securely fastened. Take extra care to

keeping the knife guard and sharpening assembly cover ON at

the machine is not in use, the slice adjustment knob should

to the closed position (beyond "O") so that the knife

Page 3

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

permit operation of the slicer by

knife, always keep hands

the guard and all other

avoid accidents by

all times. When

be turned fully back

edge is not exposed.

Page 6

Observe the cleaning instruction

remember to always turn off the slicer and

before cleaning.

on Page 6 for best results and for safety.

9514

Also

disconnect the electrical supply cord

When slicing, always work the carriage

(Figure 1 [9]). Do not hold or push the

OPERATION INSTRUCTIONS

The Univex slicer is designed to

Univex slicer will give unfailing

maintained according to instructions

meet the cook's demand for an efficient,

performance over a period of

contained herein.

START/STOP SWITCH

The slicer is started by pulling the ON/OFF

indicator light (Figure 1 [1]) is provided

SLICE ADJUSTMENT

Warning: Dial-type graduated knob

ranging from paper thin up to 1 3/16'.

adjustment (Figure 1 [13]) allows for

set up specific slice thickness for various

return knob back to its fully closed position

is not exposed.

POSITIVE HOLD CARRIAGE

Caution: A last slice gravity feed grip

of the way when not required. Do

(Figure i [8]) is provided which

carriage back and forth. Use only the

Always make sure the carriage is

see that the carriage arm knob (Figure 1 [11])

this could result in the carriage striking

using only the carriage

arm handle

carriage from any other place.

sturdy slicer. The

years, when operated and

switch (Figure 1 [2]) out to the ON

to indicate when the slicer is turned

Dial graduations allow you to

on.

slice thickness

needs. When not in use, always

(beyond "O") so that the knife edge

not use this last slice device to work the

can be locked out

carriage arm handle (Figure 1 [9]).

positively secured to the slicer by checking

is fully tightened. Failure

and damaging the knife edge.

position A

precisely

to

to do

PROTECTIVE GUARD

Warning; The protective guard (Figure

the forward edge where slicing will

by the edge of the fence, but only

closed.

The knife guard (Figure 1 [5])

knife guard knob (Figure 2 [46]).

times except when cleaning. Never

removed.

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

1 [12]) covers the knife edge

be performed. This forward edge

when the slice adjustment is

completely except

completely

can be removed for cleaning by unscrewing

For safety, keep the knife guard

operate the slicer with the knife guard

Page 4

on at all

is covered

the

Page 7

SHARPENING INSTRUCTIONS

9514

This slicer is equipped with a knife having a concave or hollowed surface for superior

slicing quality. Of course, any knife, however superior, must be sharpened regularly and

properly in order to produce not only the highest quality slices, but also to allow it to

maintain its productivity. The knife sharpener (Figure 1 [4]) on this machine is a top

mounted built-in design simplicity and ease of use.

feature.

lt even has an automatic aligning

Warning: The following sharpening procedure will provide high quality sharpening results

and should also be followed for safety considerations:

Warning: Keep away from the knife edge.

Completely close the slice adjustment (beyond "0") so that the knife edge is

not exposed.

The knife cutting area should be clean and free from food, especially grease.

Grease will ruin the ability of a grinding stone to sharpen an edge. The stone

simply will not cut, If cleaning is necessary, follow the procedure outlined on

Page 6. Remember to unplug the electrical supply cord.

Loosen sharpener lock pin knob (Figure 6 [30]) which bears against sharpener

post, then lift sharpener assembly (Figure 1 [4]) and rotate it 1/2 turn (1800).

Then seat it down over the knife.

Tighten sharpener lock pin knob (Figure 6 [30]). As the lock pin is tightened,

it bears on the sharpener post and automatically aligns the grinding and

deburring stones to the precise orientations which are preset at our factory.

Turn slicer Qj. Depress the sharpener button on the right side of the

sharpener assembly and hold in, which will start the grinding wheel rotating.

Run until the beveled cutting surface cleans up. This can take from 30

seconds to several minutes depending on how dull the blade was allowed to

become. Release sharpener button.

Turn slicer Q]E.E and check for the formation of a very slight burr on the side

of knife opposite the bevel which indicates complete grinding of the bevel.

This slight burr can be detected either visually or by picking with a small

piece of stiff paper.

Turn slicer ON. Lightly press deburring (honing) button on the left side of the

sharpener assembly and hold for 1 to 2 seconds while you turn OFF the slicer.

Blade should now be completely sharpened and honed.

Caution: It is important for best slicing results not to deburr the knife too

long or the keen edge will be destroyed due to the formation of an

undesirable second bevel on the opposite side. This condition tends

to be the primary cause of unsatisfactory slicing results.

Turn slicer OFF. Loosen lock pin, knob (Figure 6 [30]) then lift and return

sharpener to its storage position. Tighten lock pin.

Clean slicer and knife according to the cleaning procedure on Page 6 in order

to thoröughly remove grinding debris.

Page 5

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 8

CLEANING

OPERATORS CARE OF SLICER

9514

Warning:

Warning:

Caution:

Warning

Warning; 8.

1.

Never touch the knife edge. Always keep

arms clear of knife.

2.

Turn off slicer and DISCONNECT

[10]) before cleaning. Leave

3.

Turn slice adjustment knob (Figure 1 [13])

protective guard (Fig. 2 [7]) in place.

position (beyond "0") so that the knife

4.

Remove carriage assembly (Figure 1 [6])

sink. Use care in washing the sharply

feed grip, (Figure I [8]). Wash this

brush is recommended. Use only

carriage assembly with warm water and

soft cloth.

Never use detergents or wash the slicer

dishwashing machine or the clear protective

5.

Wash body of slicer using warm

soft cloth. Under no circumstances should

water and mild soap using a clean

It is recommended that the cloth be folded

when cleaning between the fence plate

6.

Remove knife guard (Figure 1

(Figure 2 [46]) and pushing the long

[5]) by loosening knife guard knob

above surface of knife. Then carefully

7.

Remove the meat deflector (Fig. 2A [2])

the blade and then pushing down. As the

the bottom and then the top where it is

guard.

CAREFULLY wash the front and

warm water and mild soap.

folded over a thin wooden stick

accidental contact with the knife edge.

rear of the knife with a cloth using

It is recommended that the cloth be

as a further caution to avoid

the knife edge and protective guard

inserted between knife edge and guard

using extreme caution to

warm water applied with a cloth, Dry thoroughly

cloth.

never touch the knife edge. Rinse with

your hands, fingers and

ELECTRICAL CORD (Figure 1

to the fully closed

edge is not exposed.

which may be washed in

pointed prongs on the last slice

area thoroughly. A small bristle

warm water and mild soap

Rinse

dry thoroughly using a clean

or any of its parts in a

finish will be damaged.

the slicer be hose rinsed.

over a thin wooden stick

and the knife.

stud upward to lift knife guard

lift and remove guard.

by swinging away from the back of

deflector is pushed down, disengage

attached to the hub of the protective

CAREFULLY wash between

(Figure 1 [12]) using a soft cloth

on both front and rear of knife

with a clean soft

a

Caution:

Warning: lo.

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

9.

Following cleaning, a commercial

on the clean surfaces with a soft clean cloth

non-toxic sanitizer may be wiped

recommended on the container labeling.

sanitizer be compatible with anodized

protective finish on the slicer will be

wetted completely, but not to the point

Replace the knife guard. Never leave

guard installed!

Page 6

aluminum or the clear

damaged. Surface should be

of running or puddling.

the slicer without its knife

or sprayed as

It is important that the

Page 9

Il.

Replace meat deflector (Fig. 2A [2 ]) guide the top

press down and swing the bottom onto the hub. Let it

towards the back of the blade.

LUBRICATION & FUNCTION CHECK

connection location over the pin.

9514

snap into place. Swing

Warning:

Turn off slicer and DISCONNECT ELECTRICAL

before lubricating. Leave protective guard (Fig.

General lubrication should be performed in accordance

below. During this lubrication sequence, be

of related parts as well as for excessive

check all handles and knobs for tightness.

sure to check for free operation and

wear and looseness of various parts. Be

LUBRICATION INSTRUCTIONS

CORD (Figure i [10])

i [12]) in place,

with the lubrication instructions

movement

sure to

A = Clean and apply mineral

oil weekly.

B = Apply Petro-Gel (4400408) often

required to maintain light film.

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

as

Page 7

C = 140 WT USDA oil.

Change when changing gears

D = Lubricated for life.

Page 10

TROUBLESHOOTiNG GUIDE

9514

TROUBLE

1. Slicer will not

operate.

2. Motor running,

blade not turning.

3. Excessive noise.

POSSIBLE CAUSE

1.1 Electrical service down.

1.2 Burned switch contacts.

1.3 Motor capacitor defective,

1.4 Burned out motor,

2.1 Broken gear

3.1 Blade contacting knife

guard.

3.2 Deflector contacting

blade.

3.3 Sharpener contacting

blade

3.5 Fan hitting motor cover,

REMEDY

1.1 Check electrical service.

Replace fuse or reset circuit

breaker as necessary.

1.2 Clean or replace.

1.3 Replace

1.4 Remove, test, repair or

replace.

2.1 Replace gear

3.1 Check for loose knife guard

knob. Shim tapered bushing.

3.2 Adjust deflector,

3.3 Adjust cover from hitting

blade.

3.5 Remove cover and adjust fan.

4. Not cutting

properly,

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

4.1 Dull blade or improperly

sharpened blade,

4.2 Soft cheese.

4.3 Knife dirty with hard,

dried-on product.

Page 8

4.1 Sharpen blade following

outlined procedures.

4.2 Chill for best slicing results.

4.3 Clean knife thoroughly

Page 11

(including disassembly, replacement and reassembly)

REPAIR INSTRUCTIONS

KNIFE (Removal) (Figure 2)

Warning Disconnect electrical power cord.

Remove carriage assembly (Fig. 5).

Remove knife guard knob (Fig. 2 [46]) and carefully remove knife guard.

Loosen sharpener lock pin knob (Fig. 6 [30]), lift and relock in up position.

9514

Warning Using caution to avoid the sharp knife edge, remove the four screws (Fig. 2

[10]).

Carefully remove knife and set aside with its flat side down flush on a bench so the

edge is not exposed.

Reinstall knife in the reverse procedures outlined above.

Even though a new knife is very sharp, the sharpening procedure specified on pages 6

and 7 should be performed to true the new knife's bevel to the slicer.

Warning; Worn knife should be disposed of in a safe responsible way, showing concern

for others who may handle it.

It recommended that the edge of the knife be

wrapped several times with heavy tape and that a caution (CAUTION,

SHARP EDGE) be written on both sides of the knife.

KNIFE SEAL (Figure 2)

Remove knife per above instructions,

Unscrew and remove tapered bushing (Fig. 2 [18]). Maintain shims that may have

been used in assembly.

Using a small screwdriver, carefully pry and remove the knife seal (Fig. 2 [19]) from

knife support (Fig. 2 [14]).

Apply light film of mineral oil on outer diameter and lip of rubber seal.

KNIFE SUPPORT (Figure 2)

1. KNIFE SUPPORT ASSEMBLY

Remove knife per above instructions.

Loosen lama (Fig. 2 [45]) by holding tapered bushing (Fig. 2 [18]) while turning

lama with allen wrench.

Elevate left side or lama side of machine 3-1/2" to prevent oil from spilling.

Remove oil.

Page 9

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 12

Remove lama by turning counter-clockwise.

Push knife support assembly from bottom and remove.

2. GEAR REPLACEMENT

9514

With knife support assembly removed, check gear (Fig. 2 [13]) for

worn, replace.

Remove snap ring (Fig. 2 [12]).

Pry gear off of shaft.

Replace gear in reverse procedures.

3. BEARING REPLACEMENT

A. Remove tapered bushing (Fig. 2 [18]).

B, Press shaft (Fig. 2 [11]) from top of blade support assembly.

Remove shim washers (7120040) if present.

Using a small screwdriver, carefully pry and remove the knife seal (Fig. 2 [19]).

Remove retaining ring (Fig, 2 [17]).

Invert assembly on bench and drive bearings and spacer from back side.

Put new bearing in by reversing above procedure.

MOTOR REPLACEIENT

Follow procedu

Remove acorn NUts (Fig. 2 [4]).

for removing blade support assembly.

wear. If

Remove motor hover (Fig. 2 [5]).

Remove collar (Fig 7 [11]) and pull fan (Fig. 7 [10]).

Remove two remaining nuts (Fig. 7 [5]).

Pull motor (Fig. 7 [1]) from housing.

Connect all wiring to new motor following wiring diagram

Reverse above procedures to complete installation of new motor.

Page 10

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

on page 22 or 23.

Page 13

ELECTRICAL ASSEMBLY

Warning DISCONNECT ELECTRICAL SUPPLY

Remove two legs (Fig. 2 [40]).

Remove two screws (Fig. 3 [9]).

Remove bottom cover (fig. 2 [42]).

Replace two screws (Fig 3 [9]) securing square bar temporarily.

Discharge capacitors by jumping across terminals with electrically protected

screwdriver.

Remove switch shaft (Fig. 7 [16]) by loosening nut (Fig. 7 [15]) near switch end.

Remove electrical equipment casing by removing three screws (Fig. 7 [20] & [23]).

Replace capacitors (Fig. 7 [18]) if found to be defective.

Relay (Fig. 7 [21]) and switch (Fig. 7 [22]) can also be checked from this procedure.

Il. Replace any defective electrical component and reverse procedures to reassemble.

9514

Page 11

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 14

CASTING and BLADE ASSEMBLY

Figure 2

9514

ILLUS.NO.

1.

2.

3.

4.

5. 9512105

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

16. 1030019

17.

18.

19.

20.

21.

22.

23.

24.

25.

26.

27.

28.

29.

30.

31.

32.

33.

34.

35.

36.

37.

38.

39.

40.

41.

42.

43.

44.

45.

46.'

47

48

49

PART NO.

9514009

8512203

8512851

8512852

8512859

9514010

8512215

8512216

8512229

8512729

8512218

8512220

8512220A

9514045

8512731

8512225

9514012

9514042

9514013

9514014

9514015

8512732

8512237

6509080

6509081

8512214

7510084

8512208

8512209

9514016

8512855

9514017

7510067

8612011

8512232

8512233

7510012

8512735

4400339

DESCRIPTION

CASTING

PIN

STUD

NUT, ACONE M6-l.0

COVER, MOTOR

VENT

PROTECTIVE GUARD (SEE FIG. 2A)

SEAL

SEAL, O-RING

SCREW, FLAT HD M5-0.8 X 12MM

ROD, CUTTER SUPPORT

RETAINING RING

GEAR (For 115V)

GEAR (For 220V)

SUPPORT, BLADE, INCLUDES 9 THRU 19

SPACER, BEARING

BEARING

RETAINING RING

BUSHING, TAPERED

SEAL

GUARD, KNIFE

RESERVED

BLADE

FENCE

SUPPORT, FENCE

SET SCREW

STUD, FENCE ADJUSTING

ACORNNUT,M8

RESERVED

SET SCREW, M6-l.0 X I6MMB

KNOB, GRADUATED

GRADUATED KNOB BUSH

RIVET

RESERVED

RESERVED

RESERVED

RESERVED

RESERVED

RESERVED

RESERVED

EXTENSION FOOT

FOOT

COVER, BOTTOM

SCREW, SOC HD CAP M6-l.0 X 20MM

ROD, KNIFE GUARD

LAMA

KNOB, KNIFE GUARD

SPACER .81 ID X 118 OD X 12MM

SCREW, SOC HD M5-O.8 X 25MM

LABEL, MAX (NOT SHOWN)

QTY.

2

2

2

1

3

1

1

1

1

2

1

1

1

1

1

2

2

2

1

1

1

2

4

4

4

1

4

1

Page 12

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 15

CASTING and BLADE ASSEMBLY

Figure 2

9514

Page 13

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 16

MEAT DEFLECTOR

Figure 2A

9514

ILLUS.NO. PART NO.

2

3

4

5

6

7

8

9

10

Ii

12

13

14

iS

16

9514010

9514011

7510342

7510346

7510343 POST

7510344

7510345

7610037

9514041

7610023

6509074 NUT

9514038

9514039 WASHER

9514040

7610024

7510347

DESCRIPTION

PROTECTIVE GUARD

DEFLECTOR

CLIP, SPRING

SCREW,SSPANHDM5X1O

SPRING

PLUNGER

ROD THREADED

STANDOFF

SKIRT

POST

PIN

STANDOFF

POST, HEADED

QTY.

2

2

Page 14

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 17

ARM ASSEMBLY

Figure 3

9514

ILLUS.NO. PART NO.

1.

2.

3,

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

16.

17.

18.

19.

20.

21.

*

Illus 5 (8512301) can not be purchased separately; included in Illus 6 (9512300).

7510038

8512313

9514018

* 8512301

9512300

9514019

8512318

8512317

9512299

1053510

8512308

6509031

6509028

6509042

9514020

6509044

6509045

6509046

8512325

8512326

DESCRIPTION

RUBBER SHOCK ABSORBER

RESERVED

SCREW, SOC HD CAP M8-1.25 X 30MM

ROD, ROUND GUIDE

BUSHING

ARM BUSHING

BAR, FRAME

WASHER, EXTERNAL TOOTH

SCREW

BUSHING, ECCENTRIC

SCREW, CAP, M6.1.0 X 25MM HXHD

BOLT, BEARING LOCKING

BEARING

WASHER, M8

STUD, ARM ATTACHMENT

CARRIAGE ARM

KNOB, CARRIAGE ARM

HANDLE, CARRIAGE ARM

SCREW, HEX HD WASHER M6-1.0 X 15MM

CARRIAGE ANCHOR

STUD, CARRIAGE ANCHOR

*

QTY.

2

2

2

2

2

2

2

2

Page 15

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 18

ILLUS.NO.

PART NO.

9514046

7510067

8512527

8512526

8512525

7510065

7512076

8512839

6509028

6509071

8512511

12,

8512512

7510073

8512326

6509131

7510061

8512518

6509046

*

8512501

8512502

8512503

8512504

8512510

6509086

8512507

8512506

8512508

8512505

8512529

8512530

* Illus 18 (8512501)

8512500

SLICE CONTROL ASSEMBLY

Figure 4

DESCRIPTION

SLICE CONTROL ASSEMBLY (NOT SHOWN)

(INCLUDES ITEMS 1

BOLT, SOC HD CAP M6-l.0 X 20MM

BOLT, HEXHDM8-1.25X30MM

JIB

- 30, EXCEPT ITEM 6)

WASHER, EXTERNAL TOOTH M6

SCREW, HEX HD M6-1.0 X 20MM

SUPPORT, TAPER

NUT, M8-1.25

WASHER, M8

STUD, CRANK

BLOCK, SLICE CONTROL MOVING

SHAFT, SLICE CONTROL

STUD, JIB ATTACHMENT

SET SCREW, M8-1.25 X 20MM

NUT, THEN M8-1.25

SPRING

SCREW, HEX HD M6-1.0 X 10MM

WASHER. M6

ECCENTRIC PIN

GEAR

WASHER, SPECIAL

BOLT, HEX HD M8-1.25 X 50MM

SHAFT, GRADUATED KNOB

FLEXIBLE WASHER

WORM GEAR

BALL

ROLL PIN

BALL STUD

SCREW, PAN HD M5-0.8 X 25MM

NUT, M5-0.8

SLICE CONTROL GUIDE UNIT

can not be purchased separately; included in Illus 19 (8512502)

9514

QTY.

2

2

2

2

1

I

1

1

1

2

1

1

1

1

1

1

1

1

1

1

1

1

1

Page 16

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 19

CARRIAGE ASSEMBLY

Figure 5

9514

ILLUS NO.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

PART NO.

9514043

9514021

9514022

DESCRIPTION

LAST SLICE DEVICE (Item 4,5,10,13,14)

CARRIAGE

SHAFT, ADJUSTMENT SPACER

6509153 KNOB

9514023

9514024

9514025

6509058

8512439

8512431

9514026

9514027

8512436

8512924

9514028

NYLON SCREW

STUD

PLATE, WASHER

BOX NUT

STUD CARRIAGE

NYLON PIP

LAST SLICE DEVICE

SHAFT, LAST SLICE DEVICE

STUD

HANDLE, LAST SLICE DEVICE

ROD, LAST SLICE DEVICE

9514051 PIN

9514052

4512051

9514052

SCREW, FLAT HD SS M6 X 48MM

CAM STOP

SPACER

QTY.

SUB ASSY

3

1

1

2

2

I

1

1

1

1

2

I

2

Page 17

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 20

SHARPENER ASSEMBLY

9514

ILLUS NO.

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

PART NO.

9514029

6509153

8512617

9514030

6509150

6509137

DESCRIPTION

SHARPENER ASSEMBLY WITH COVER

KNOB

NUT

COVER, SHARPENER

NUT, COVER SPACER

SCREW

RESERVED

Figure 6

9514031

MOUNT, SHARPENER STONE

6509041 WASHER

9514032

6509127

SCREW

SPRING

6509128 BUSHING

6509129

6509132

6509130

6509131

6509136

6509134

6509135

6509133

6509143

6509144

9514033

6509141

STUD, HONING STONE

WASHER, HORNING STONE

STONE, HONING

NUT

SET SCREW, DEPRESS BUTTON

SPRING

BUTTON, DEPRESS

BALL

NUT, SHARPENING STONE

WASHER, SHARPENING STONE

STONE, SHARPENING

STUD, SHARPENING STONE

RESERVED

9514034

SET PIN, SHARPENER

RESERVED

9514035

9514036

9514037

COVER, BOTTOM

NUT, KNURLED

LOCKING PIN

QTY.

2

1

2

1

1

2

2

2

2

1

I

1

1

1

I

1

Page 18

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 21

SHARPENER ASSEMBLY

Figure 6

9514

PART OF LLUS 7

N FIG. 2

Page 19

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 22

ELECTRICAL ASSEMBLY

115V, 60HZ, 1PH

100V, 50160HZ, 1PH

220V, 50HZ, 1PH

Figure 7

9514

ILLUS,NO.

1.

2,

3.

4. 8512932

5.

6.

7. 8512644

8.

9.

10. 8512848

11. 8512931

12,

13.

14. 8512611

15.

16.

17.

18.

19.

20. 9512103

21.

22. 7120009

23.

24. 9512104

25.

26.

27.

28 8512935

29

PART NO.

8512844

8512844A

8512601

8512602

DESCRIPTION

MOTOR, 115v, 60Hz, 1PH, II2HP,

MOTOR, 220V, 50HZ, 1PH, 1/2HP

KEY

RUBBER SHOCK ABSORBER

WORM GEAR

8512934 SPACER

8512605

BOLT, MOTOR

CORK WASHER

6509028

8512617

WASHER, M8 2

NUT, M8-1.25

FAN

COLLAR, FAN

8512643

8512612

CORK WASHER

JOINT

NUT

8512614

8512613

8512615

8512616

8512618

9512101

NUT, M6-1.0

SHAFT, SWITCH

KNOB, SWITCH

CAPACITOR, 3OMFD, 450V, (100/115V)

CAPACITOR, IOMFD, 500V, (220V)

SCREW, PAN HD M5-0.8 X 10MM

SCREW, PAN HD M5-0.8 X 30MM

8512620

RELAY, 1LSVONLY

SWITCH

9512102

SCREW, PAN HD M5-0.8 X 20MM

ELECTRICAL EQUIPMENT CASING

1814069

1814069A

8512624

4400053

8800210

LAMP, WARNING, 100/115V (NOT SHOWN)

LAMP, WARNING, 220V (NOT SHOWN)

FASTENER, CABLE (NOT SHOWN)

CORD AND PLUG, 100/115V (NOT SHOWN)

CORD AND PLUG, 220V (NOT SHOWN)

BUSHING/NUT

8512933

SPRING

QTY.

100V, 50/60HZ, 1PH

I

1

2

1

1

4

4

6

1

1

1

1

2

2

1

1

2

1

2

1

1

3

1

1

1

i

1

1

FOR CANADA ONLY

30

31 4400227

1814105

CIRCUIT BREAKER 6 AMP (CANADA ONLY)

LABEL, RESET (CANADA ONLY)

Page 20

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 23

ELECTRICAL ASSEMBLY

Figure 7

o

9514

o

Page 21

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 24

115v, 60Hz, 1PH, 100V, 50/60HZ, 1PH

SCHEMATIC

Figure 8

9514

BROWN

RELAY

r-

RED

RELAY I SV

r-

BLACK

I

I SV

4

O

3

BLACK

P I LOT

L I 01-IT

MOTOR

H5V. 60HZ

PH

BL

OREEN / YELLOW

SWITCH

CAPACI TOR

3OMFD. 450V

GREEN

WH I TE

B LACK

CAPACI TOR

3OMFD. 450V

o o

I

TO 115V. 60HZ.

POWER SUPPLY

o

IPH

FOR CANADA ONLY

BLACK

CAPAC TOR

3OMFD. 450V

o

CAPACI TOR

3OMFD. 450V

O

o

2

L.. -

B ROWN

REO

SWITCH

GREEN

WH I TE

B LACK

TO 115V. 50HZ.

POWER SUPPLY

IPH

r--T_1

CIRCUIT

BREAKER

CANADA ONLY

2

L

IMPORTANT: Before making electrical connections, check the specifications

plate to assure they agree with those of your electrical service.

WARNING: Whenever maintenance is being performed DISCONNECT electrical cord.

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

J

on the data

Page 22

Page 25

SCHEMATIC

220V, 50HZ, 1PH

FIGURE 9

9514

BLACK

P LOT

L OkT

MO TO R

220V. 50HZ

B LACK

PH

SWI TCH

OREEN /

CAPAC TOR

OMFD, 500V

O

'ELL0W

PEEN

Pik TE

B LACK

O

TO 220V. 50HZ. 0H

POWER SUPPLY

IMPORTANT: Before making electrical

plate to assure they agree with those of

WARNING: Whenever maintenance is being

connections, check the specifications on the data

your electrical service.

performed DISCONNECT electrical cord.

Page 23

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Loading...

Loading...