Page 1

INSTRUCTION

MANUAL

Persons under age 18 are not permitted to operate or

have accessibility to operate this equipment per

U.S. Dept. of Labor Employment Standards

Administration Fact Sheet No. ESA91-3.

univex

8512/0804

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

ED 12

Page 2

TO

INSURE

BOTH

SAFE

AND

TROUBLE-FREE PERFORMANCE WE STRESS

THAT

ALL PERSONNEL

THAT

WILL

BE

INVOLVED WITH YOUR NEW UNIVEX SLICER

MUST READ

INSTRUCTIONS

OPERATE THIS UNIT.

WE APPRECIATE YOUR COOPERATION AND

YOUR BUSINESS.

AND

BEFORE

SHOULD THERE BE A

UNDERSTAND THESE

ATTEMPTING

TO

QUESTION OR IF WE CAN BE OF FURTHER

ASSISTANCE,

PLEASE

CALL

US,

1403-893-6191,

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 3

TABLE OF CONTENTS

8512

DESCRIPTION

Table of Contonts

List of Illustrations

Introduction

Installation Instructions

Safy Warnings

Operating Instructions

Sharponing Instructions

Operator's Care of Slicer - Cleaning Instructions

Lubrication Instructions

Trouble Shooting Guide

Repair Instructions Including Disassembly, Replacemontand Reassembly

Replacemmt Parts

Warranty Information

LIST OF ILLUSTRATIONS

ILLUSTRATIONS

Figure

Figure 2

Figure

Figure 3A

Figure 4

Figure

Figure

Figure 7

Figure

Figure

Figure

1

Overall View of Meat Slicer

Base Assembly

3

Casting and Blade Assembly

Meat Deflector

Arm Assembly

5

Slice Control Assembly

6

Carriage assembly

Sharpmer Assembly

8

Electrical Assembly

9

Sthematic 115V, 60HZ, 1PH, 100V, 50/60HZ, 1PH

10

Sthematic 220V, 50hz, iph

PAGE

3

3

3

4

4-5

s -6

7

S

9-Il

12-23

Back Cover

PAGE

2

12- 13

14 - 15

16

17

18

19

20 -21

22 - 23

24

25

Page 1

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 4

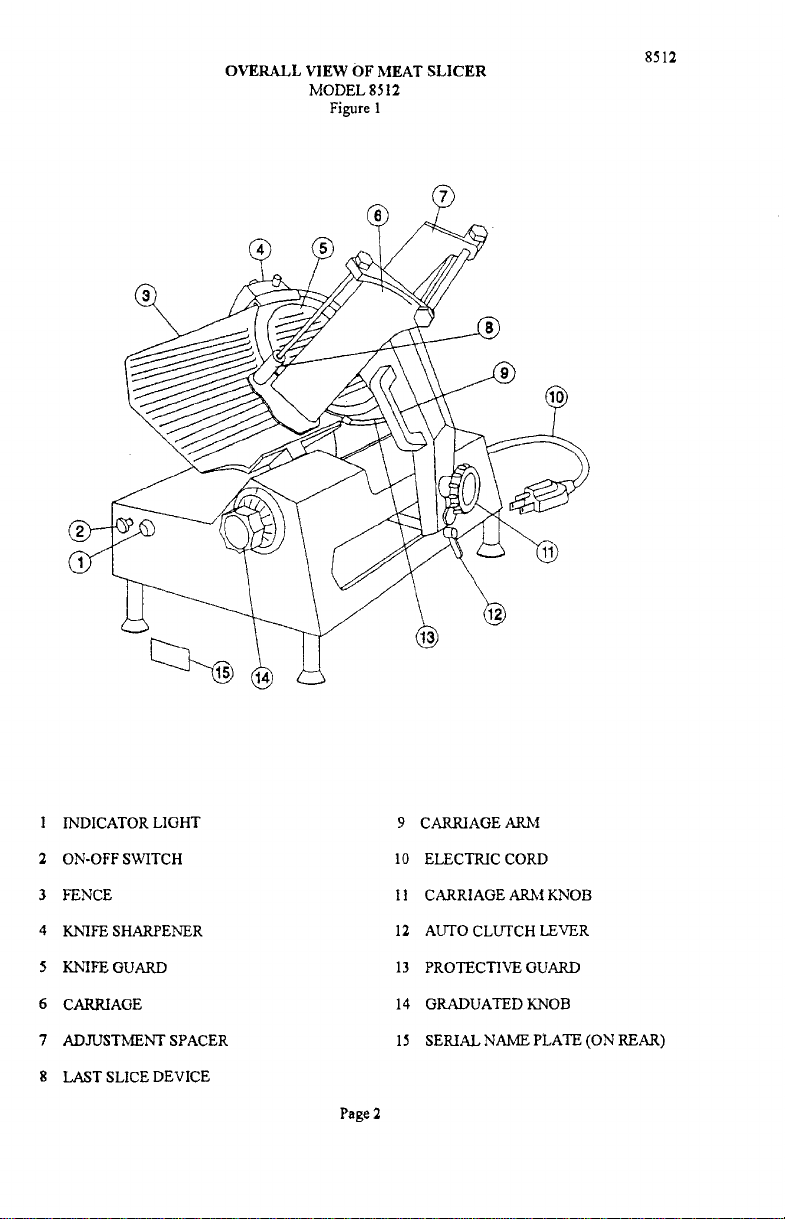

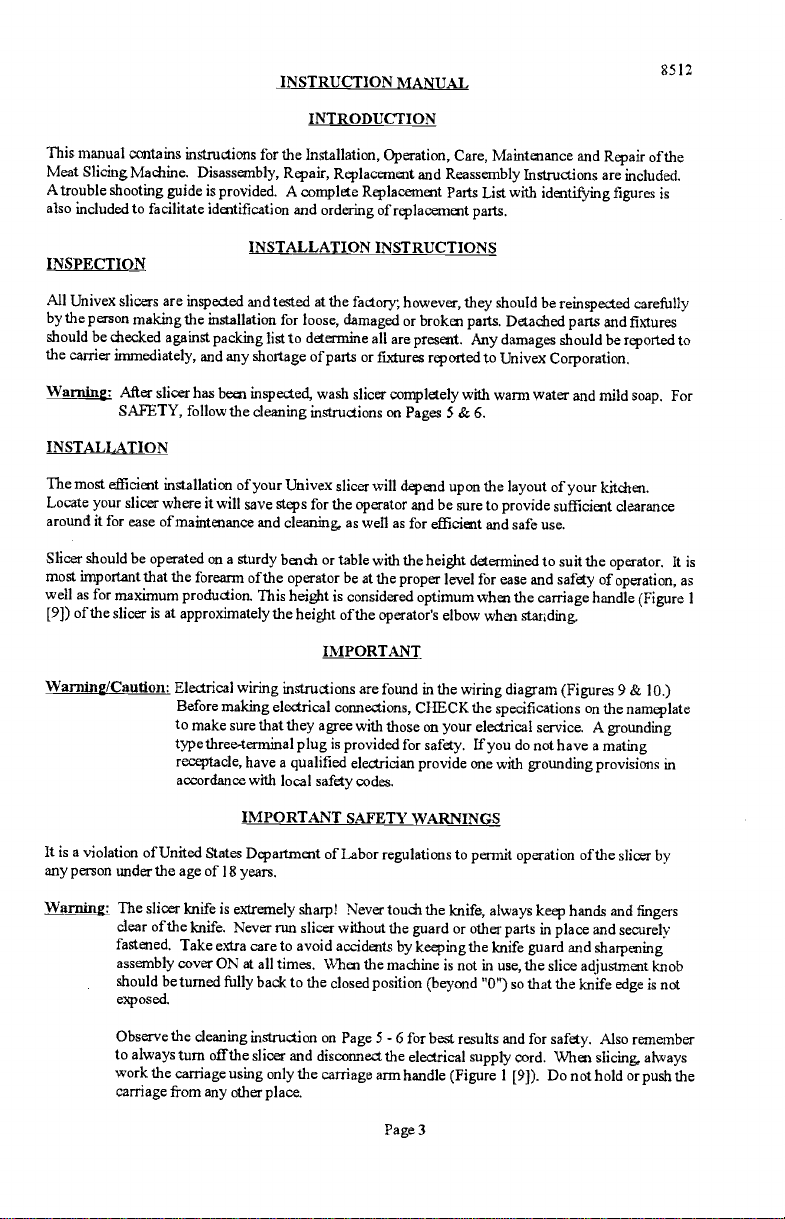

OVERALL VIEW OF MEAT SLICER

MODEL 8512

Figure 1

8512

I

INDICATOR LIGHT

2

ON-OFF SWITCH

3 FENCE li CARRIAGEARMKNOB

4

KNiFE SHARPENER

5

KNIFE GUARD

6 CARRIAGE

7 ADJUSTMENT SPACER 15

8

LAST SLICE DEVICE

9 CARRIAGE ARM

10 ELECTRIC CORD

ALTFO CLUTCH LEVER

12

13 PROTECTIVE GUARD

14 GRADUATED KNOB

SERIAL NAME PLATE (ON REAR)

Page 2

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 5

INSTRUCTION MANUAL

8512

INTRODUCTION

This manual contains instructions f'or the Installation, Operation, Care, Maintenance and Repair of the

Meat Slicing Machine. Disassembly, Repair, Replacement and Reassembly Instructions are included.

Atrouble shooting guide is provided. A complete Replacement Parts List with identifying figures is

also included to facilitate identification and ordering of replacement parts.

INSPECTION

INSTALLATION INSTRUCTIONS

All Univex slicers are inspected and tested at the factoiy; however, they should be reinspected carefully

by the person makingthe installation for loose, damaged or broken parts. Detached parts and fixtures

should be checked against packing list to determine all are present. Any damages should be reported to

the canier immediately, and any shortage ofparts or fixtures reported to Univex Corporation.

Warning: After slicer has been inspected, wash slicer completely with warm water and mild soap. For

SAFETY, follow the cleaning instructions on Pages 5 & 6.

INSTALLATION

The most eflicient installation of your Univex slicer will depend upon the layout of your kitchen.

Locate your slicer where it will save steps for the operator and be sure to provide sufficient clearance

around it for ease of maintenance and cleaning, as well as for efficient and safe use.

Slicer should be operated on a sturdy bench or table with the height determined to suit the operator. It is

most important that the forearm ofthe operator be at the proper level for ease and safety of operation, as

well as for maximum production. This height is considered optimum when the carriage handle (Figure 1

ofthe slicer is at approximately the height of the operator's elbow when standing.

[p1)

IMPORTANT

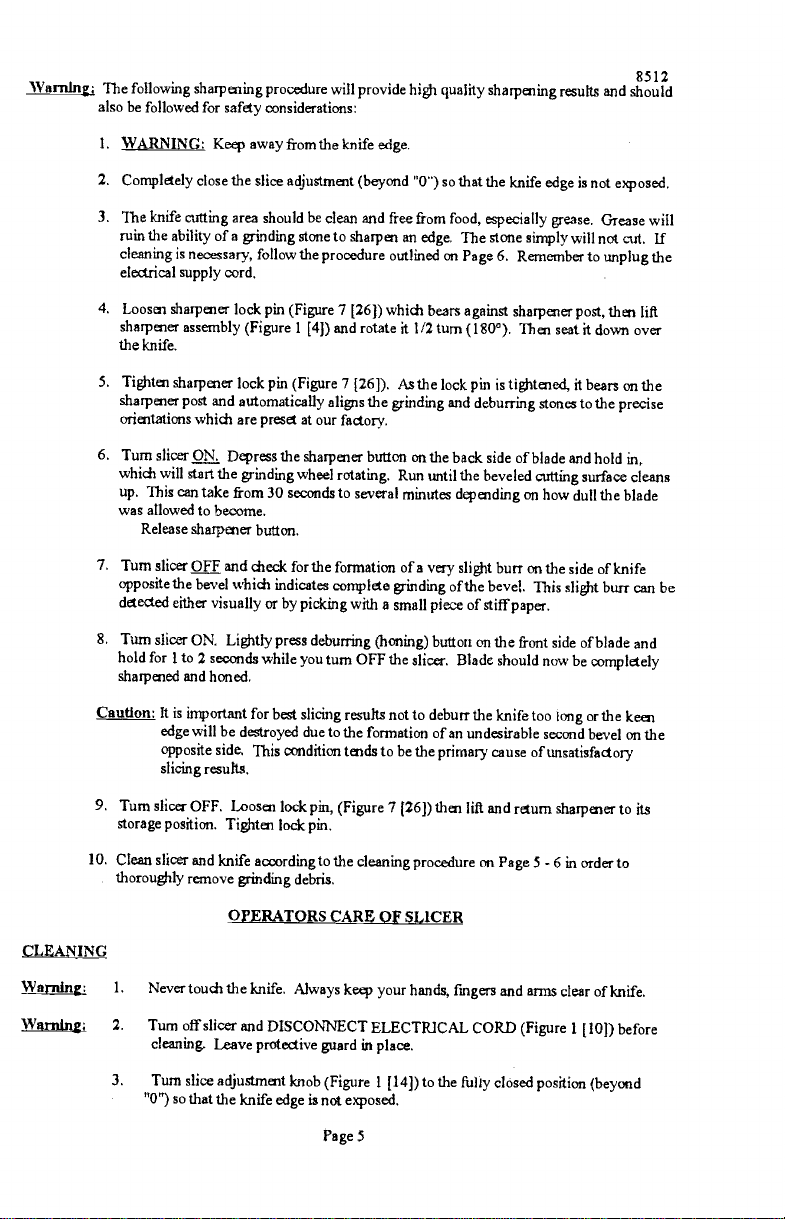

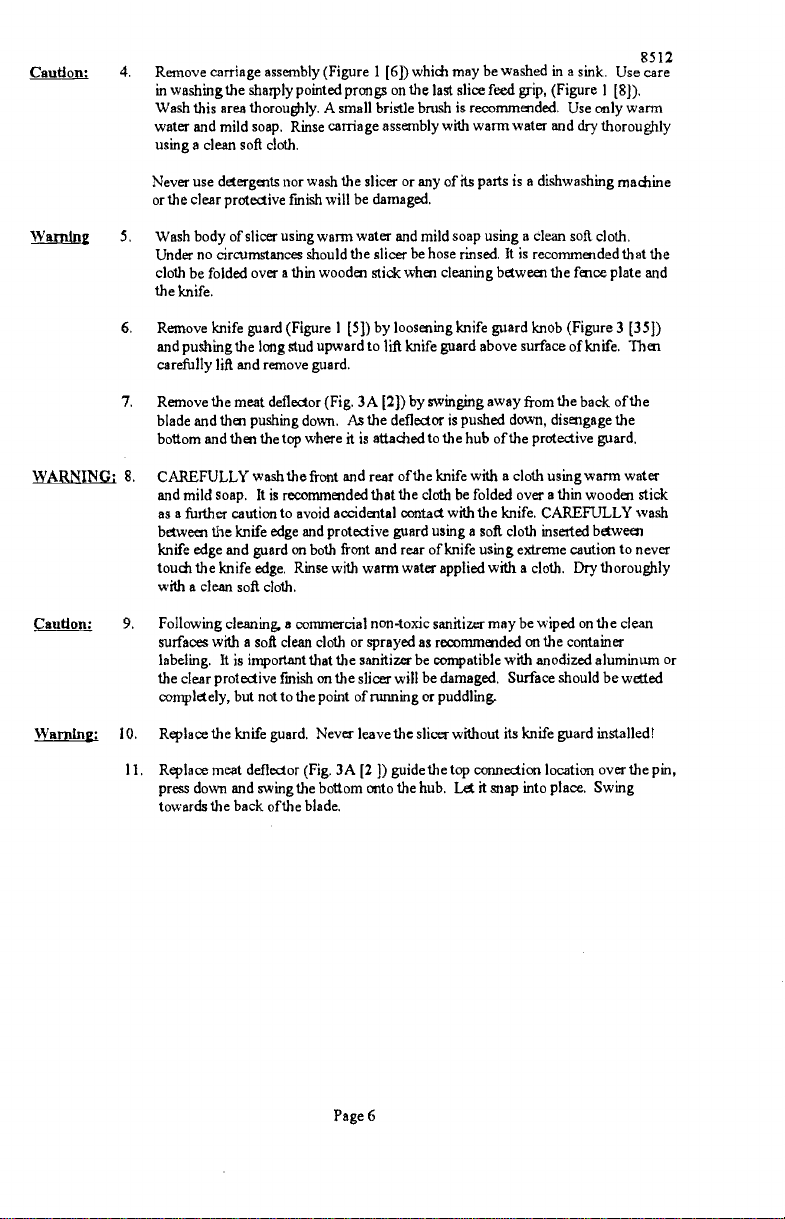

Warning/Caution: Electrical wiring instructions are found inthe wiring diagram (Figures 9 & IO.)

Before making electrical connections, CHECK the specifications on the nameplate

to make sure that they agree with those on your electrical service. A grounding

type three-terminal plug is provided for safety. If you do not have a mating

receptacle, have a qualified electrician provide one with grounding provisions in

accordance with local safety codes.

IMPORTANT SAFETY WARNINGS

It is a violation of United States Department of Labor regulations to permit operation ofthe slicer by

any person under the age of 18 years.

Warning: The slicer knife is extremely sharp! Never touch the knife, always keep hands and fingers

clear ofthe knife. Never run slicer without the guard or other parts in place and securely

fastened. Take extra careto avoid accidents by keeping the knife guard and sharpening

assembly cover ON at all times. When the machine is not in use, the slice adjustment knob

should be turned fully back to the closed position (beyond 'O') so that the knife edge is not

exposed.

Observe the cleaning instruction on Page 5 -6 for best results and for safety. Also remember

to always turn offthe slicer and disconnect the electrical supply cord. When slicing, always

work the carriage using only the carriage arm handle (Figure 1 [9]). Do not hold or push the

carriage from any other place.

Page 3

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 6

OPERATION INSTRUCTIONS

8512

The Univex slicer is desigueci to me the cook's demand for an efliciont, sturdy slicer.

slicer will give unfinling performance over a period of years, whon operated and maintained

to instrurtions contained herein.

The Univex

START/STOP SWITCH

The slicer is started by pulling the ON/OFF switth (Figure 1 [2)) out to the ON position.

(Figure I [1)) is provided to indicate what the slicer is turned

on.

SLiCE ADJUTMENT

WarnIng: Dial-type knob adjustmrnt (Figure 1 [14)) allows for slicethicknesses ranging

thin up to i 3/16". Dial graduations allow you to precisely sd

for various needs, Whon not in use, always raum knob back to its fully closed

(beyond "O") so that the knife edge is not exposed.

up specific slice thicknesses

POSITIVE HOLD CARRIAGE

Caution: A last slice gravity feed grip (Figure 1 [8)) is provided whith

whon not required, Do not use this last slice device to work the carriage back

only the carriage arm handle (Figure 1 [9]).

Always make sure the carriage is positively secured to the slicer by thecking

can be locked out of the way

carriage arm knob (Figure I [Il]) is fully tightmed. Failure to do this could result in

carriage striking and damagingthe knife edge.

MEAT DEFLECTOR

Be sure Meat Deflector is snapped into position towards the back ofthe blade. It

contact the blade, but follow the blade contour closely. If necessary adjust the location of

deflector by loosoning screw (Fig 3A [4 J) and sliding the spring clip (Fig.

correct adjustruont and tightasing the screw again.

3A [3]) for the

according

A pilot light

from paper

position

and forth. Use

to see that the

the

should not

the

PROTECT IVE GUARD

WARNING: The protective guard (Figure 1 [13]) covers the knife edge complctely

sharponer cover and the forward edge where slicing will be performed. This forward

edge is covered by the edge ofthe fonce, but only whon the slice adjustmont is complctely

closed.

The knife guard (Figure 1 [5])can be removed for cleaning by unscrewingthe knife

guard knob (Figure 3 E2]). For safdy, keep the knife guard

cleaning. Never operate the slicer with the knife guard removed.

excopt under the

on at all times except whon

SHARPENING NSTRUCTIONS

This slicer is equipped with a knife having a concave or hollowed

quality. Of course, any knife, howev

produce not only the highest quality slices, but also to allow it to maintain its

sharpener (Figure 1 [4]) on this macfiine is atop mounted built-in desigu simplicity

even has an automatic aligning feature.

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

superior, must be shaiponed regularly and properly in order to

Page 4

rear surface for superior slicing

productivity. The knife

and ease of use. It

Page 7

Warning; The following sharpening procedure wilt provide high quality sharpening results and should

also be followed for safoty considerations:

8512

L WARNING: Keep away from the knife edge.

Complotely close the slice adjustment (beyond "0") so that the knife edge is not exposed.

The knife cutting area should be clean and free from food, especially grease. Grease will

ruin the ability of a grinding stone to sharpen an edge. The stone simply will not cut. If

cleaning is necessary, follow the procedure outlined on Page 6, Remember to unplug the

electrical supply cord.

Loosen sharpener lock pin (Figure 7 [261) whith bears against sharpener post, then lift

sharpener assembly (Figure 1 [41) and rotate it 1/2 turn (1800). Then seat it down over

the knife

Tighten sharpener lock pin (Figure 7 [26]). As the lock pin is tightened, it bears on the

sharpener post and automatically aligus the grinding and deburring stones to the precise

orientations whith are presst at our factory.

Turn slicer ON. Depress the sharpener button on the back side of blade and hold in,

whith will stasi the grinding wheel rotating. Run until the beveled cutting surface cleans

up. This can take from 30 seconds to several minutes depending on how dull the blade

was allowed to become.

Release sharpener button.

Turn slicer OFF and deck for the formation of a very slight burr on the side of knife

opposite the bevel whith indicates coniple grinding ofthe bevel. This slight burr can be

dctected either visually or by picking with a small piece of stiff paper.

Turn slicer ON. Lightly press deburring (honing) button on the front side of blade and

hold for Ito 2 seconds while you turn OFF the slicer. Blade should now be complotely

sharpened and honed,

Caution: It is impoitant for best slicing results not to deburr the knife too long or the keen

edge will be destroyed dueto the formation of an undesirable second bevel on the

opposite sìde This condition tends to be the primary cause of unsatisfactory

slicing results.

Turn slicer OFF. Loosen lock pin, (Figure 7 [26 J) then lift and rdum sharpener to its

storage position. Tighten lock pin.

Clean slicer and knife according to the cleaning procedure on Page 5 -6 in order to

thoroughly remove grinding debris.

OPERATORS CARE OF SLiCER

CLEANING

Warning:

WarnIng;

1.

Never touth the knife. Always keep your hands, fingers and arms clear of knife.

2.

Turn off slicer and DISCONNECT ELECTRICAL CORD (Figure 1 [l0j) before

cleaning. Leave protective guard in place.

3.

Turn slice adjustment knob (Figure 1 [14]) to the fully closed position (beyond

"0") so that the knifè edge is not exposed.

PageS

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 8

CautIon;

Remove carriage assembly (Figure 1 [6])whith may be washed in a sink. Use care

4.

in washing the sharply pointed prongs on the last slice feed grip, (Figure 1 [8J).

Wash this area thoroughly. A small bristle brush is recommended. Use only warm

water and mild soap. Rinse carriage assembly with warm water and dry thoroughly

using a clean soft cloth.

Never use dotergents nor wash the slicer or any of its parts is a dishwashing mathine

or the clear protective finish will be damaged.

8512

Warning

WARNING: 8.

CautIon:

Warning;

5. Wash body of slicer using warm water and mild soap using a clean soft cloth.

Under no circumstances should the slicer be hose rinsed. lt is recommended that the

cloth be folded over a thin wooden stick when cleaning botween the fence plate and

the knife.

Remove knife guard (Figure 1 [5]) by loosening knife guard knob (Figure 3 [35])

and pushingthe long stud upward to lift knife guard above surface of knife. Then

carefully lift and remove guard.

Remove the meat deflector (Fig. 3A [2])by swinging away from the back of the

blade and then pushing down. As the deflector is pushed down, disengage the

bottom and then the top where it is attathed to the hub ofthe protective guard.

CAREFULLY wash the front and rear of the knife with a cloth using warm water

and mild soap. It is recommended that the cloth be folded over a thin wooden stick

as a farther caution to avoid accidental contact with the knife. CAREFULLY wash

botween the knife edge and protective guard using a soft cloth inserted bstween

knife edge and guard on both front and rear of knife using extreme caution to never

toucfi the knife edge. Rinse with warm water applied with a cloth. Dry thoroughly

with a clean soft cloth.

9, Following cleaning, a commercial non-toxic sanitizer may be wiped on the clean

surfaces with a soft clean cloth or sprayed as recommended on the container

labeling. lt is important that the sanitizer be compatible with anodized aluminum or

the clear protective finish on the slicer will be damaged. Surface should bewotted

complotely, but not to the point of running or puddling.

Replace the knife guard. Never leave the slicer without its knife guard installed!

IO.

11. Replace meat deflector (Fig. 3A [2 ))guidethetop connection location overthe pin,

press down and swing the bottom onto the hub, 14 it snap into place. Swing

towards the back of the blade,

Page 6

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 9

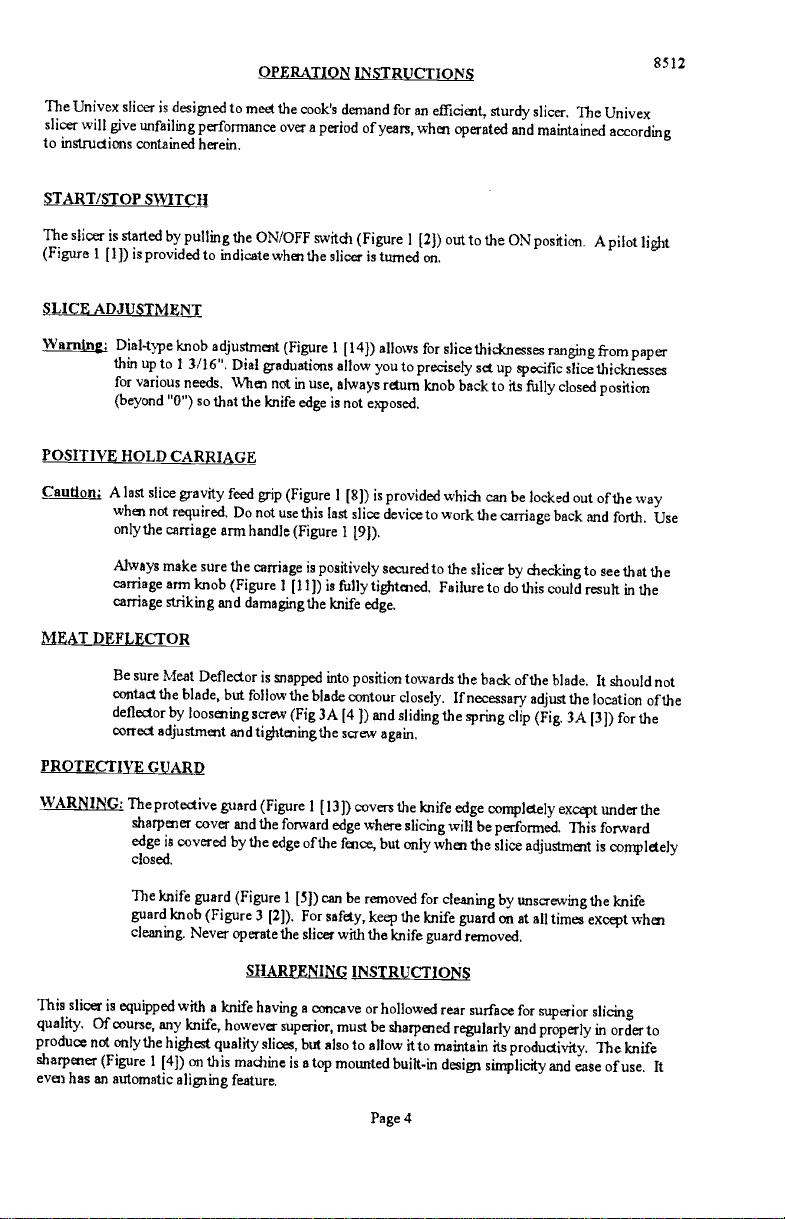

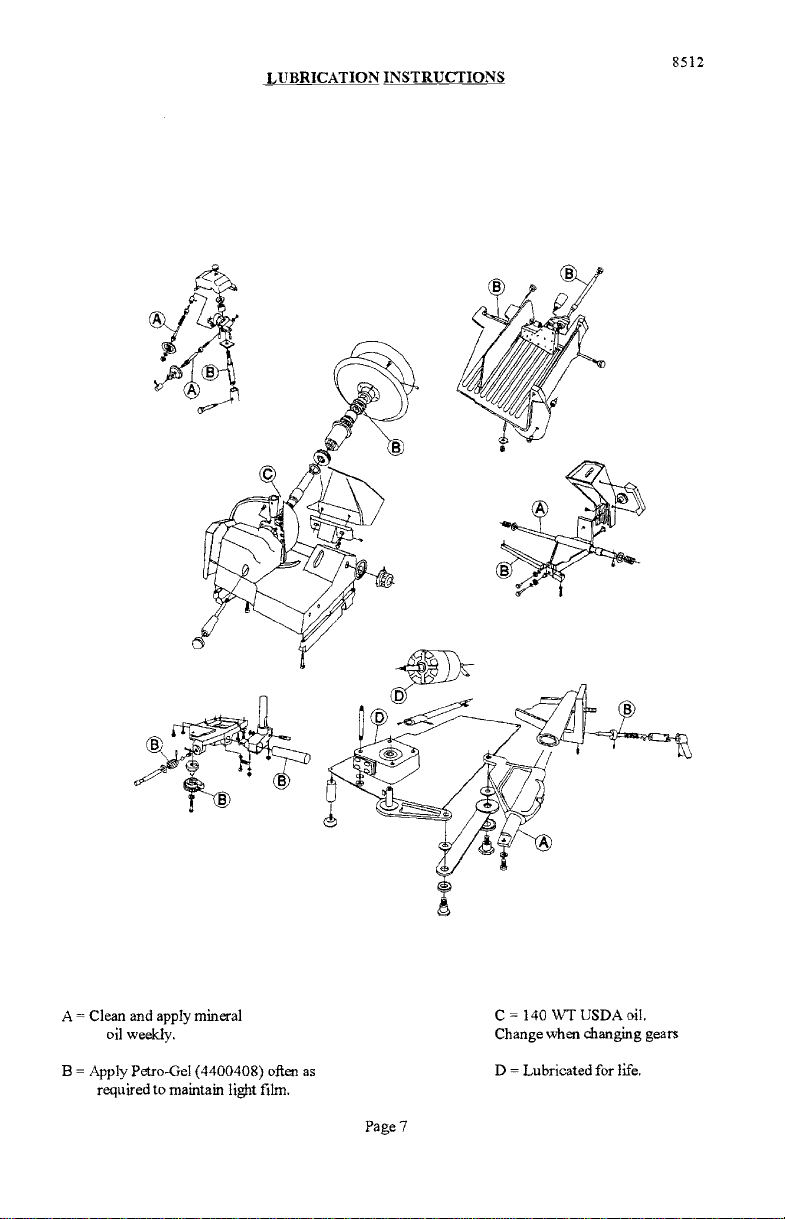

LUBRICATION INSTRUCTIONS

8512

A = Clean and apply mineral

oil weekly.

B = Apply Petro-Gel (4400408) often as

required to maintain light film.

Page 7

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

C= 140 WTUSDAoìI.

Change when changing gears

D = Lubricated for life.

Page 10

TROUBLESHOOTING GUIDE

8512

TROUBLE

1. Slicer will not operate.

2. Motor running, blade

not turning, (carriage)

still

operating).

3 Carriage not operating

(blade is operating).

4. Excessive noise.

POSSIBLE CAUSE

1.1 Electrical service down.

1.2 Burned switch contacts.

1.3 Motor capacitor defective.

1.4 Burned out motor.

1.1 Check electrical service.

1.2 Clean or replace.

1.3 Replace

1.4 Remove, test, repair or replace.

REMEDY

Replace fuse or react circuit

breaker as necessary.

2.1 Broken gear 2.1 Replace gear

3.1 Loose or broken belt

3.2 Cone clutch assembly not

engaging.

3.3 Connecting rod support

jammed.

4.1 Blade contacting knife

guard.

4.2 Deflector contacting blade.

4.3 Sharpener contacting blade

3.1 Adjust belt tension or

replace belt.

3.2 Adjust spring bushing.

3.3 Check for foreign objects in

mechanism.

4.1 Check for loose knife guard

knob. Shim tapered bushing.

4.2 Adjust deflector.

4.3 Adjust cover from hitting

blade.

5. Not cutting properly.

4.4 Connecting rod support

hitting bottom cover,

4.5 Fan hitting motor cover.

4.6 Damaged belt hitting

against motor cover.

4.7 Reduction gearbox.

5.1 Dull blade.

5.2 Soft cheese.

Page 8

4.4 Pull bottom cover from

support.

4.5 Remove cover and adjust fan.

4.6 Replace belt.

4.7 Replace.

5.1 Sharpen blade following

outlined procedures.

5.2 Chill for best slicing results.

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 11

(including disassembly, replacement and reassembly)

REPAIR INSTRUCTIONS

KNIFE (Removal) (Figure 3)

I. WARNING Disconnect electrical power cord.

Remove carriage assembly (Fig. 6).

Remove knife guard knob (Fig. 3 [35]) and carefully remove knife guard.

Loosen sharpener lock pin (Fig. 7 [26]), lift and relock in up position.

WARNING Using caution to avoid the sharp knife edge, remove the four screws (Fig. 3 [15]).

Carefully remove knife and set aside with its flat side down flush on a bench so the edge is not

exposed.

Reinstall new knife in the reverse procedures outlined above.

Even though a new knife is very sharp, the sharpening procedure specified on pages 6 and 7 should

be performed to true the new knife's bevel to the slicer.

8512

WARNING: Worn knife should be disposed of in a safe responsible way, showing concern for others

who may handle it.

with heavy tape and that a caution (CAUTION, SHARP EDGE) be written on both sides

It recommended that the edge ofthe knife be wrapped several times

ofthe knife.

KNIFE SEAL (Figure 3)

Remove knife per above instructions.

Unscrew and remove tapered bushing (Fig. 3 [12]). Maintain shims that may have been used in

assenthly.

Using a small screwdriver, carefully pry and remove the knife seal (Fig. 3 [13]) from knife support

(Fig. 3 [81).

Apply light film of mineral oil on outer diameter and lip of rubber seal.

KNIFE SUPPORT Figure

1. KNIFE SUPPORT ASSEMBLY

Remove knife per above instructions.

Loosen lama (Fig. 3 [36]) by holding tapered bushing (Fig. 3 [12]) while turning lama with

allen wrench.

Elevate left side or lama side of machine 3-1/2" to prevent oil from spilling.

Remove oil.

Page 9

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 12

Remove lama by turning counter-clockwise,

Push knife support assembly from bottom and remove.

2, GEAR REPLACEMENT

A. With knìfe support assembly removed, theck gear (Fig. 3 [7)) for wear. If worn, replace.

B. Remove snap ring (Fig. 3 [6)).

C. Pry gear off of shaft.

D. Replace gear in reverse procedures.

3. BEARING REPLACEMENT

Remove tapered bushing (Fig. 3 [12)).

Press shaft (Fig. 3 [5)) from top of blade support assembly.

C, Remove shim washers (7120040) if presont.

D. Using a small screwdriver, carefully pry and remove the knife seal (Fig. 3 [13)).

E. Reznoverainingring(Fig. 3 [lfl).

F. Invt assembly on bmd and drive bearings and spacer from back side.

G. Put new bearing in by reversing above procedure.

8512

MOTOR REPLACEMENT/OR BELT REPLACEMENT

Follow procedure for removing blade support assembly.

Remove acorn nuts (Fig. 2 [47)).

Remove motor cover (Fig. 2 [45)).

Looson and pull fan (Fig. 2 [48)).

Pivot idler arm (Fig. 2 [43])to ease tmsion on belt.

Remove belt (Fig. 2 [50)).

a. If only replacing belt, put on new belt at this point and reassemble in reverse procedure.

For motor replacemont, continue disassembly by removing pulley (Fig. 2 [49)).

Removetworemainingnuts(Fig. 8 [5).

Pull motor (Fig. 8 [1)) from housing.

Connect all wiring to new motor following wiring diagram on page 24 or 25.

Reverse above procedures to complcte installation of new motor.

Page 10

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 13

ELECTRICAL ASSEMBLY

I. WARNING DISCONNECT ELECTRICAL SUPPLY

Remove four rubber feet (Fig. 2 [241) and 4 extonsion legs (Fig. 2 [52 J).

Remove bottom cover (Fig. 2 [19)).

Remove casing cover (fig. 8 [22)).

Distharge capacitors by jumping across terminals with electrically protected screwdriver.

Remove reduction gear rod (Fig. 2 [34)) by removing two bolts (Fig. 2 [38)) and removing set

screw at reduction gear md.

Remove switth shaft (Fig. 8 [16)) by loosming nut (Fig. 8 [iS)) near switth md.

Remove capacitor on left to access ground screw holding electrical equipmmt casing.

Remove electrical equipmmt casing by removing three screws (Fig. 8 [21)).

Replace capacitors (Fig. 8 [24)) if found to be defective.

il. Relay (Fig. 8 [7)) and switth (Fig. 8 [20)) can also be thecked from this procedure.

12. Replace any defective electrical componont and reverse procedures to reassemble.

8512

Page 11

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 14

ILLUS.NO. PART NO,

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

16.

17.

18.

19.

20.

21.

22.

23.

24.

25.

8512300A

6509098

8512823

8512826

8512827

8512828

8512824

8512829

8512818

8512819

6509028

6509040

8512817

1012167

8512814'

8512812

8512811

8512813

8512853

8512816

8512805

8512808

8512855

8512803A

26.

27.

28.

29.

8512516

8512803

6509143

30.

31.

32.

33.

34.

35.

36.

37.

38.

39.

40.

41.

42.

43.

44.

45.

46.

8512846

8512862

8512831

8512830

8512836

8512834

8512832

8512833

6509131

1204044

8512863

1204045

8512864

8512870

8512201

8512851

47.

48.

8512868

BASE ASSEMBLY

Figure 2

DESCRIPTION

SUPPORT, CARRIAGE, ALSO FIG.4 [6)

SET SCREW, M6-I.0 X 8MM

BOLT, CONE CLUTCH

BUSHING, SPRING

SET SCREW, M5-0.8 X 5MM

SPRING

CAM

KNOB, CONE CLUTCH

BUSHING, AUTOMATIC

ROD, ROUNDGUIDE

WASHER,M8

SCREW, SOC HD CAP M8-1.25 X 25MM

SCREW, CRANK ATTACHMENT

BALL BEARING

SCREW, CRANK ATTACHMENT

BALLBEARING

CRANK

SPACER

COVER, BOTTOM

SPACER

RESERVED

SUPPORT, CONNECTION ROD

KEY

FOOT

GEAR, REDUCTION

RESERVED

WASHER, M6

STUD

NUT M61.0

RESERVED

KEY

PULLEY, MOTOR

KEY, REDUCTION GEAR

ROD, REDUCTION GEAR

KEY

BALLBEARING

FLANGE, BEARING

SCREW,M6-1.OX20MJvI

NUT,JAMM8-l.25

SCREW M8-1.25 X 50MM

BEARING, IDLER

SCREW, M6-1.OX2OMM

ARM, IDLER

AXLE, IDLER BEARING

COVER, MOTOR

STUD/SCREWM6-1.o

RESERVED

FAN

8512

QTY.

1

4

2

I

1

1

2

2

1

1

1

1

1

I

1

1

4

1

4

4

4

4

1

1

1

1

1

2

2

2-

1

2

1

2

1

Page 12

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 15

ILLUS.NO. PARTNO.

49.

50.

51.

52

53

54

55

8512865

8512867

8512637

8512248

8512866

8512869

8512871

BASE ASSEMBLY

Figure 2 (CONT.)

DESCRIPTION

PULLEY

VBELT

VENT, PLASTIC

LEG, EXTENSION

SPRING, EXTENSION

POST, SPRING

PIN

8512

QTY.

4

Page 13

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 16

ILLUS.NO. PART NO.

8512736

8512203

8512215

8512216

8512729

8512218

8512220

8512730

8512731

Il.

1030019

8512225

8512226

8512227

86 12009*

8512229

8512228

is:

8512234

8512861

8512237

6509080

6509081

8512214

7510084

8512209

8512208

34,

35..

38

39

40

41

42

43

44

45

46

7510067

8512233

8512232

8612011

8512928

8512930

8512929

8512030

6509082

4400339

7510012

8512735

8512871

CASTING and BLADE ASSEMBLY

Figure 3

DESCRIPTION

CASTING

PIN

SEAL

SEAL, O-RING

ROD, CUTTER SUPPORT

RETAINING RING

GEAR

SUPPORT, BLADE, INCLUDES 4 THRU 13

SPACER, BEARING

BEARING

RETAINING RING

BUSHING, TAPERED

SEAL

GUARD, KNIFE

SCREW, FLAT HD M5-0.8 X 12MM

BLADE

RESERVED

RESERVED

FENCE

SUPPORT. FENCE

SET SCREW

STUD, FENCE ADJUSTING

ACORN NUT, M8

RESERVED

SET SCREW, M6-1.0 X I6MMB

KNOB, GRADUATED

RESERVED

RESERVED

Rl VET

GRADUATED KNOB BUSH

RESERVED

RESERVED

RESERVED

SCREW, SOC HD CAP M6-1.0 X 20MM

KNOB, KNIFE GUARD

LAMA

ROD, KNIFE GUARD

RIGHT SUPPORT

SCREW M8-l.0 X 45MM

LEFT SUPPORT

PROTECTIVE GUARD (SEE FIG. 3A)

WASHER

LABEL. MAX (NOT SHOWN)

SPACER, .81 ID X 1.18 OD X

. I2THK

SCREW, SOC HD M5-0.8 X 25MM

PIN

8512

QTY.

2

2

3

2

2

2

2

4

4

4

* ILLUS NO. 14 INCLUDES ILLUS

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

NO.46

Page 14

Page 17

CASTING and BLADE ASSEMBLY

Figure 3

8512

Page 15

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 18

MEAT DEFLECTOR

Figure 3A

8512

ILLUSNO. PART NO.

1. 8512030

2

3

4

5

6

7

8

7512156

7510342

7510346

7510343

7510344

7510345 PLUNGER

7510347

DESCRIPTION

PROTECTIVE GUARD

DEFLECTOR

CLIP. SPRING

SCREW PAN HD MS X 10MM

POST

SPRING

POST, HEADED

QTY.

I

1

1

I

I

1

Page 16

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 19

ARM ASSEMBLY

Figure 4

8512

ILLUS.NO. PART NO.

7510038

2.

3.

4.

5 *

6. 8512300

7.

8.

9.

lo.

11. 1053510

12. 8512308

13. 6509031

14. 6509028

15.

16. 8512319

17.

18. 6509045

19. 6509046

8512314

8512313

8512312 ROD, ROUND GUIDE

8512301 BUSHING

8512316

8512318

8512317

9512299

6509042

6509044

20. 8512325

21. 8512326

DESCRIPTION

RUBBER SHOCK ABSORBER

SPRING, DAMPER

SCREW, SOC HD CAP M8-1.25 X 30MM

ARM SU000RT

BAR, FRAME

WASHER, EXTERNAL TOOTH

SCREW

BUSHING, ECCENTRIC

SCREW, CAP M6-1.0 X 25MM HEX HD

BOLT, BEARING LOCKING

BEARING

WASHER, M8

STUD, ARM ATTACHMENT

CARRIAGE ARM

KNOB, CARRIAGE ARM

HANDLE, CARRIAGE ARM

SCREW, HEX HD WASHER M6-1.OX15MM

CARRIAGE ANCHOR

STUD, CARRIAGE ANCHOR

* 8512301 PART OF ILLUS NO.6, CANNOT BE PURCHASED

QTY.

2

2

2

2

2

2

2

Page 17

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 20

SLICE CONTROL ASSEMBLY

Figure 5

8512

ILLUS.NO. PART NO.

1.

2. 8512527

3.

4.

5.

6.

7. 8512839

8. 6509028

9. 6509071

10. 8512511

11.

12.

13. 8512326

14.

15. 7510061

16. 8512518

17.

18.

19.

7510067

8512526 JIB

8512525

7510065

7512076

8512512

7510073

6509131

6509046

* 8512501

8512502 GEAR

20. 8512503

21.

22.

23.

8512504

8512510

6509086

24. 8512507

25. 8512506

26.

27.

28. 8512529

29.

8512508

8512505

8512530

30. 8512500

DESCRIPTION

QTY.

BOLT, SOC HD CAP M6-1.0 X 20MM

BOLT, HEX HD M8-1,25 X 30MM

WASHER, EXTERNAL TOOTH M6

SCREW, HEX HD M6-1.0 X 20MM

SUPPORT, TAPER

NUT, M8-1.25

WASHER, M8

STUD, CRANK

BLOCK, SLICE CONTROL MOVING

SHAFT, SLICE CONTROL

STUD, JIB ATTACHMENT

SETSCREW, M8-1 25 X 20MM

NUT, THIN M8-l.25 2

SPRING

SCREW, HEX HD M6-1.0 X 10MM

WASHER. M6

ECCENTRIC PIN

WASHER, SPECIAL

BOLT, HEX HD ME-1.25 X 5OMMT

SHAFT, GRADUATED KNOB

FLEXIBLE WASHER

WORM GEAR

BALL

ROLL PIN

BALL STUD

SCREW, PAN HD M5-0.8 X 25MM

NUT, M5-0,8

SLICE CONTROL GUIDE UNIT

2

2

2

2

*

Illus 18 (8512501) can not be purchased separately; included in IlIus 19(8512502)

Page 18

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 21

CARRIAGE ASSEMBLY

Figure 6

8512

ILLUS NO. PART NO,

8512432

2

3

4

5

6 8512924

7 8512926

8

9

10"

11

12 8512438 NYLON PIP, ADJUSTMENT SPACER

13

14

15

16

17

18

19

20

8512437 STUD & KNOB, ADJUSTMENT SPACER

8512448 STUD

8512433 BUSHING, ADJUSTMENT SPACER

8512925

6509153

8512428

8512427

8512425

8512434

RESERVED

8512431

8512927 STUD, LAST SLICE DEVICE 1

6509038

6509058

6509059

8512439 STUD, CARRIAGE 1

DESCRIPTION

SPACER, ADJUSTMENT

SUPPORT, LAST SLICE DEVICE

HANDLE, LAST SLICE DEViCE

LAST SLICE DEVICE

KNOB, LAST SLICE DEVICE SHAFT 3

SHAFT, LAST SLICE DEVICE

BUSHING, LAST SLICE DEVICE

CARRIAGE

SHAFT, ADJUSTMENT SPACER

NYLON PIP, LAST SLICE DEVICE

SCREW, FLAT HEAD

BOXNUT,M10-1.5

WASHER, SPECIAL

* = PART OF ILLUS i (8512432), CANNOT BE PURCHASED SEPARATELY.

** = PART OF ILLUS 5(8512925), CANNOT BE PURCHASED SEPARATELY.

QTY.

I

1

I

1

1

S

I

Page 19

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 22

ILLUS NO. PART NO.

7510151

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

6509153

6509151

6509150

6509149

6509125

6509137

6509138

7510120

8512728

6509147

6509127

6509128

6509129

6509130

6509131

6509134

6509133

6509135

6509136

6509132

6509143

6509144

6509142

6509141

6509128

6509 126A

7510150

SHARPENER ASSEMBLY

Figure 7

DESCRIPTION

SHARPENER ASSEMBLY WITH COVER

KNOB, COVER

COVER, SHARPENER

NUT, COVER SPACER

SPACER. COVER

WASHER, SETPIN

SCREW

WASHER

SETPIN, SHARPENER

PIN, SHARPENER CASTING

BOLT, SHARPENERGIJIDE

SPRING

BUSHING

STUD, HONING STONE

STONE, HONING

NUT

SPRING

BALL

BUTTON, DEPRESS

SET SCREW, DEPRESS BUTTON

WASHER, HORNiNG STONE

NUT, SHARPENINGSTONE

WASHER, SHARPENJNG STONE

STONE, SHARPENING

STUD, SHARPENING STONE

BUSHING

MOUNT, SHARPENER STONE

LOCKING PIN, SHARPENER

8512

QTY.

I

1

1

1

2

2

1

1

2

2

2

2

1

1

1

1

Page 20

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 23

SHARPENER ASSEMBLY

Figure 7

8512

PART OF ILLUS

IN FIG. 3

Page 21

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

41\

Page 24

ELECTRICAL ASSEMBLY

115v,60hz iph

220v, 50hz, iph

Figure 8

8512

ILLUS.NO.

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14,

15.

16.

17.

18.

19.

20.

21.

22.

23.

24.

25.

26.

27.

28

29

PART NO.

8512844

8512844A

8512601

8512602

8512932

8512934

8512620

8512622

8512621

8512606

1814069

1814069A

8512624

8512627

8512615

8512614

8512613

4400053

4400053A

8512612

8512611

7120009

8512609

8512626

8512608

8512616

8512618

6509028

8512617

8512643

8512935

8512933

DESCRiPTION

MOTOR, 115V, 60Hz, 1PH, 1/2HP, 100V,50/60HZ, IPH

MOTOR, 220V, 50HZ, 1PH, 1/2HP

KEY

RUBBER SHOCK ABSORBER

WORM GEAR

SPACER

RESERVED

RELAY, 11SVONLY

NUT, M4-0.7

SCREW, PAN HD M4-0.7 X 10MM

BOLT, MOTOR SHORT

LAMP, WARNING, 1 1SV/100V

LAMP, WARNING, 220V

FASTENER, CABLE

SCREW, PHIL HD SHEET METAL

KNOB, SWITCH

NUT, M6-1.0

SHAFT, SWITCH

CORDANDPLUG,115V/100V

CORD AND PLUG, 220V

JOINT

NUT

SWITCH

SCREW,M5-0.8X12MM

COVER, CASING

ELECTRICAL EQUIPMENT CASING

CAPACITOR, 3OMFD, 450V,(115V/100V)

CAPACITOR, 1OMFD, 500V,(220V)

WASHER, MS

NUT, M8-1.25

WASHER

BUSHING/NUT

SPRING

QTY.

I

1

1

1

1

4

1

1

I

3

2

1

1

1

i

3

1

1

2

1

2

6

Page 22

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 25

ELECTRICAL ASSEMBLY

Figure 8

8512

Page 23

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 26

SCHEMATIC

115V, 60HZ, 1PH

100V. 50/60HZ, IPH

Figure 9

8512

RELAY

ISV

BLACK

PILOT

LIGHT

OREEN / YELLOW

SWITCH

CAPAC TOR

3OMO. 450V

II

GREEN

WH I TE

BLACK

CAPAC I TOR

3OMFO. 450V

o

o

I

TO 115V. 50HZ.

POWER SUPPLY

o

I)

IPH

Page 24

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 27

BLACK

P LOT

L GHT

SCHEMATIC

220V, 50HZ, 1PH

FIGURE 10

CARAO TOR

IOMFD, 500V

o

GREEN / YELLOW

SWITCH

BLACK WHITE

ORE EN

BLACK

o

H

I

TO 220V. 50HZ.

POWER SUPPLY

-

8512

PH

Page 25

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Loading...

Loading...