Page 1

MODEL 5100-02-IT

IT Series

COMBUSTIBLE GAS SENSOR MODULE

Version 2.00a

APPLICABILITY & EFFECTIVITY

Effective for all Model 5100-02-IT Modules manufactured after February 15, 2008.

Instruction Manual Part Number T12019

Rev. B1

Page 2

Model 5100-02-IT Combustible Gas Sensor Module

FM APPROVAL

ONLY THE FOLLOWING ITEMS, FUNCTIONS AND OPTIONS ARE FM* APPROVED

Model 5100-02-IT Combustible Gas Sensor Module

Sensor Module

Model 5100-02-IT Combustible Gas Sensor Module

Model 5100-02-IT-SS Combustible Gas Sensor Module, 316SS

Calibration Equipment

Model 1200-26 Calibration Gas Delivery System

Model 1290-02 Combustible Gas Cylinder

Model 5358-01 Calibration Head, Standard

Model 5360-00 Calibration Gas Delivery Fitting

Model 1260-02 Combustible 50% LEL Gas Cylinder

Model 1260-42 Cylinder H2 50% LEL Type A

Model 1250-01 Gas Sensor Calibrator Kit, Type A

Model 1256-01 Regulator Type A Calibrator

Model 5394-61 Auxiliary Connection Option

Model 5394-62 Auxiliary Relay Option

Model 5394-64 RS-485 Multidrop Option

Model 5394-51 Remote Sensor Option – 5100-02-IT

Notes:

1) FM Approval applies only to conventional (one cable run per sensor

module) or multiplexed (multiple sensor modules per cable) installations.

Apparatus must be installed in accordance with National Electrical Code.

2) FM Comments

*FM Approvals, a subsidiary of FM Global

Project# 3021050

Page 3

Model 5100-02-IT Combustible Gas Sensor Module

TABLE OF CONTENTS

PRODUCT DESCRIPTION .............................................................................................................................3

1.

1.1 GENERAL........................................................................................................................................................3

1.2 PRODUCT CONFIGURATION........................................................................................................................3

1.3 THEORY OF OPERATION..............................................................................................................................3

1.4 MODES OF OPERATION................................................................................................................................3

1.4.1 SENTRY INTERFACE..............................................................................................................................3

1.4.2 MODBUS OPERATION............................................................................................................................5

1.4.3 ANALOG OPERATION ............................................................................................................................5

1.4.4 AUXILIARY RELAY OPERATION (Appendix E)......................................................................................5

1.4.5 ENHANCED CONNECTION (Appendix F) ..............................................................................................5

1.4.6 AUXILIARY RS-485 MULTIDROP (Appendix G).....................................................................................5

1.4.7 REMOTE SENSOR (Appendix D)............................................................................................................5

1.4.8 REMOTE ALARM RESET........................................................................................................................5

1.5 MECHANICAL .................................................................................................................................................5

1.5.1 ENCLOSURE ...........................................................................................................................................5

1.5.2 TRANSMITTER ELECTRONICS .............................................................................................................5

1.5.3 SENSOR ASSEMBLY ..............................................................................................................................5

1.6 INTERCONNECT WIRING..............................................................................................................................6

1.7 POWER REQUIREMENTS .............................................................................................................................6

2. CAUTIONS & WARNINGS .............................................................................................................................7

2.1 INTRODUCTION .............................................................................................................................................7

2.2 IT MODULES - GENERAL ..............................................................................................................................7

2.3 WIRING............................................................................................................................................................7

2.3.1 CATALYTIC BEAD SENSOR MODULES................................................................................................8

3. INSTALLATION ..............................................................................................................................................9

3.1 SENSOR MODULE LOCATIONS...................................................................................................................9

3.2 WIRING............................................................................................................................................................9

3.2.1 ANALOG 4-20 mA OPERATION..............................................................................................................9

3.2.2 MODBUS OPERATION USING RS-485 CONNECTION ........................................................................9

3.2.3 SENTRY OPERATION USING SMC SENTRY CONNECTION ..............................................................9

3.2.4 GENERAL ................................................................................................................................................9

3.3 ENCLOSURE INSTALLATION......................................................................................................................10

3.4 TRANSMITTER AND SENSOR INSTALLATION ..........................................................................................10

3.5 INSTALLATION CONFIGURATION ..............................................................................................................12

4. INTRODUCTION – HUMAN-MACHINE INTERFACE SYSTEM..................................................................15

4.1 HUMAN-MACHINE INTERFACE ..................................................................................................................15

4.2 MAIN MENU...................................................................................................................................................16

4.3 CONFIGURE SET-POINTS...........................................................................................................................17

4.4 MAINTENANCE FUNCTIONS.......................................................................................................................20

5. CALIBRATION..............................................................................................................................................21

5.1 CALIBRATION FREQUENCY .......................................................................................................................21

5.2 CALIBRATION PREPARATION ....................................................................................................................21

5.2.1 CALIBRATION GAS DELIVERY METHODS.........................................................................................21

5.2.2 CALIBRATION PROCEDURE ...............................................................................................................21

5.2.3 SENSOR EXPOSURE TO GAS.............................................................................................................21

6. SERVICE........................................................................................................................ ...............................23

6.1 SENSOR MODULE CONFIGURATION ........................................................................................................23

Contents

Page 4

Model 5100-02-IT Combustible Gas Sensor Module

6.2 ENCLOSURE REPLACEMENT ....................................................................................................................23

6.3 TRANSMITTER REPLACEMENT .................................................................................................................24

6.4 SENSOR REPLACEMENT............................................................................................................................24

6.5 INSTALLATION INSPECTION ......................................................................................................................24

CONTROLLER INSTALLATION ............................................................................................................24

CABLING INSTALLATION .....................................................................................................................24

SENSOR MODULE INSTALLATION .....................................................................................................24

MOISTURE TRAPS AND RAINSHIELDS..............................................................................................25

STANDARD VOLTAGES .......................................................................................................................25

INSPECTION AND TROUBLESHOOTING GUIDE ...............................................................................25

IF MODULE DOES NOT RESPOND TO GAS ......................................................................................25

IF THE MODULE DOES NOT COME OUT OF WARM UP...................................................................25

If the module does not display the correct %LEL...................................................................................25

If the display shows ‘NO SENSR’ –Sensor Failing ................................................................................25

IF THE MODULE SHOWS “***Calibration Required***” ........................................................................25

IF THE MODULE SHOWS “***UNCALIB***” .........................................................................................25

If the display shows ‘H’ (OR l) THEN THE LOCAL HIGH OR LOW ALARM IS ACTIVE ......................25

If the display shows ‘w’ – radio freQuency INTERFERENCE................................................................25

If the display shows “C” – calibration mode ...........................................................................................25

other error messages – call factory........................................................................................................25

7. APPENDICES ...............................................................................................................................................26

7.1 APPENDIX A: SPECIFICATIONS..................................................................................................................26

7.2 APPENDIX B: MODEL NUMBERS & PARTS LIST .......................................................................................27

7.3 APPENDIX C: LIMITED WARRANTY............................................................................................................28

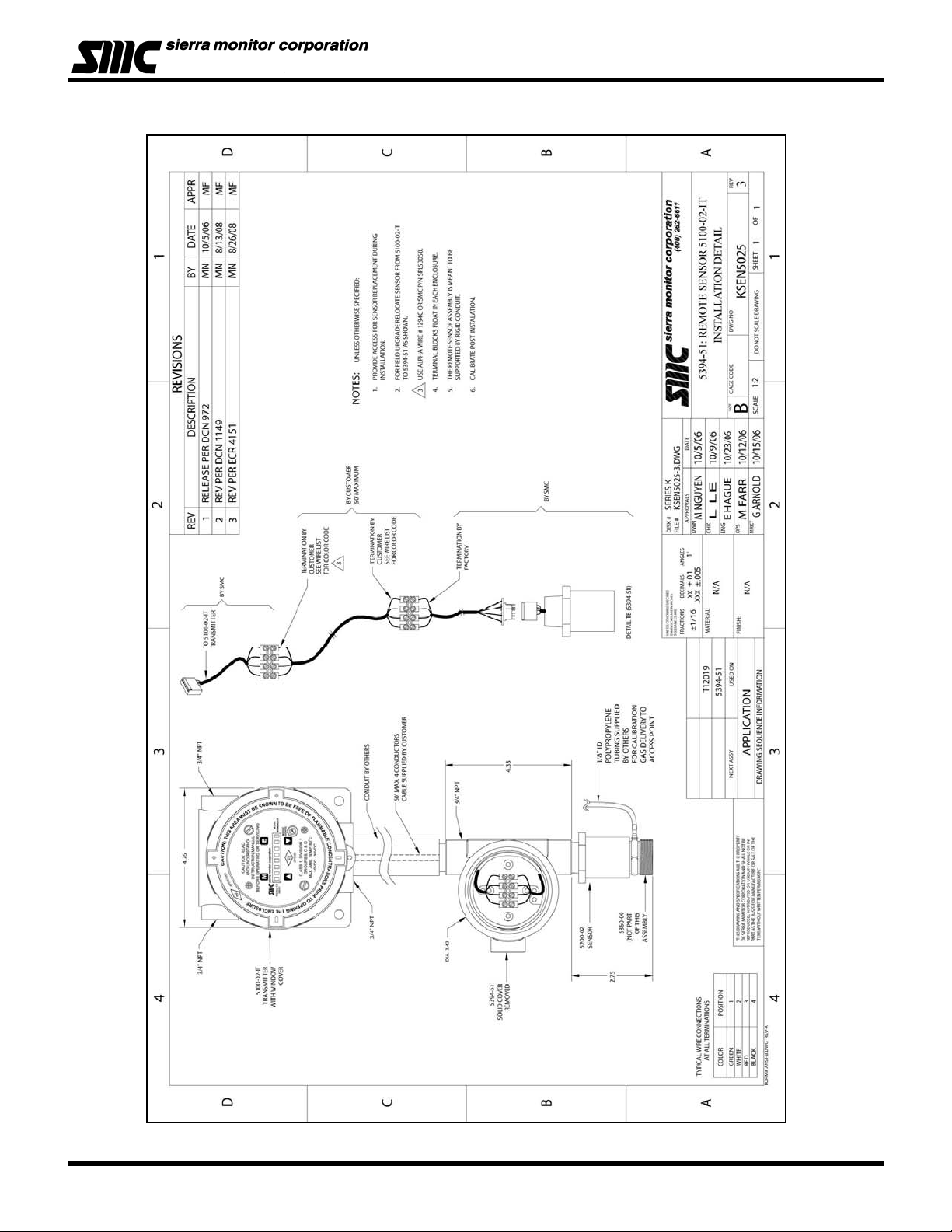

7.4 APPENDIX D: REMOTE SENSOR/DISPLAY DRAWING 5394-50 ...............................................................29

7.5 APPENDIX E: AUXILIARY RELAY ASSEMBLY 5394-62..............................................................................30

7.6 APPENDIX F: AUXILIARY CONNECTION ASSEMBLY 5394-61 .................................................................31

7.7 APPENDIX G: AUXILIARY RS-485 MULTIDROP ASSEMBLY 5394-64 ……………………………………..32

7.8

APPENDIX H: MODBUS MEMORY MAP......................................................................................................34

7.9 APPENDIX I: COMBUSTIBLE GAS SCALING FACTORS............................................................................35

7.10 APPENDIX J: MENU KEY FOR 5100-02-IT GAS SENSOR MODULE …………………………….…….......36

Contents

Page 5

Model 5100-02-IT Combustible Gas Sensor Module

®

1. PRODUCT DESCRIPTION

1.1 GENERAL

The Model 5100-02-IT Catalytic Bead Combustible Gas Sensor Module

is a member of the Sentry Information Technology ”IT” family of gas

sensor transmitter modules. IT modules offer a broad array of features

including:

• Integral Alphanumeric display

• 180 day calibration frequency

• Integral alarm relays (3)

• 4-20 mA output

• Modbus

• SMC Sentry interface

• 316 Stainless steel enclosure option

• Remote alarm reset

®

RTU interface

• Auxiliary relay option

• Remote sensor option

• Auxiliary connector option

IT modules are designed, and approved for installation and operation in hazardous locations.

1.2 PRODUCT CONFIGURATION

Various module configuration options are available. Where applicable, these options are factory configured

prior to shipment.

1.3 THEORY OF OPERATION

Catalytic bead gas sensors detect gas by comparing the resistance of two heated elements. One element is

catalytic to enhance the burning of combustible gases, the other element is passive. Electronic circuits are

used to compare the change in the catalytic bead resistance relative to the passive bead. The relative change

is calibrated to determine the concentration of the gas of interest.

1.4 MODES OF OPERATION

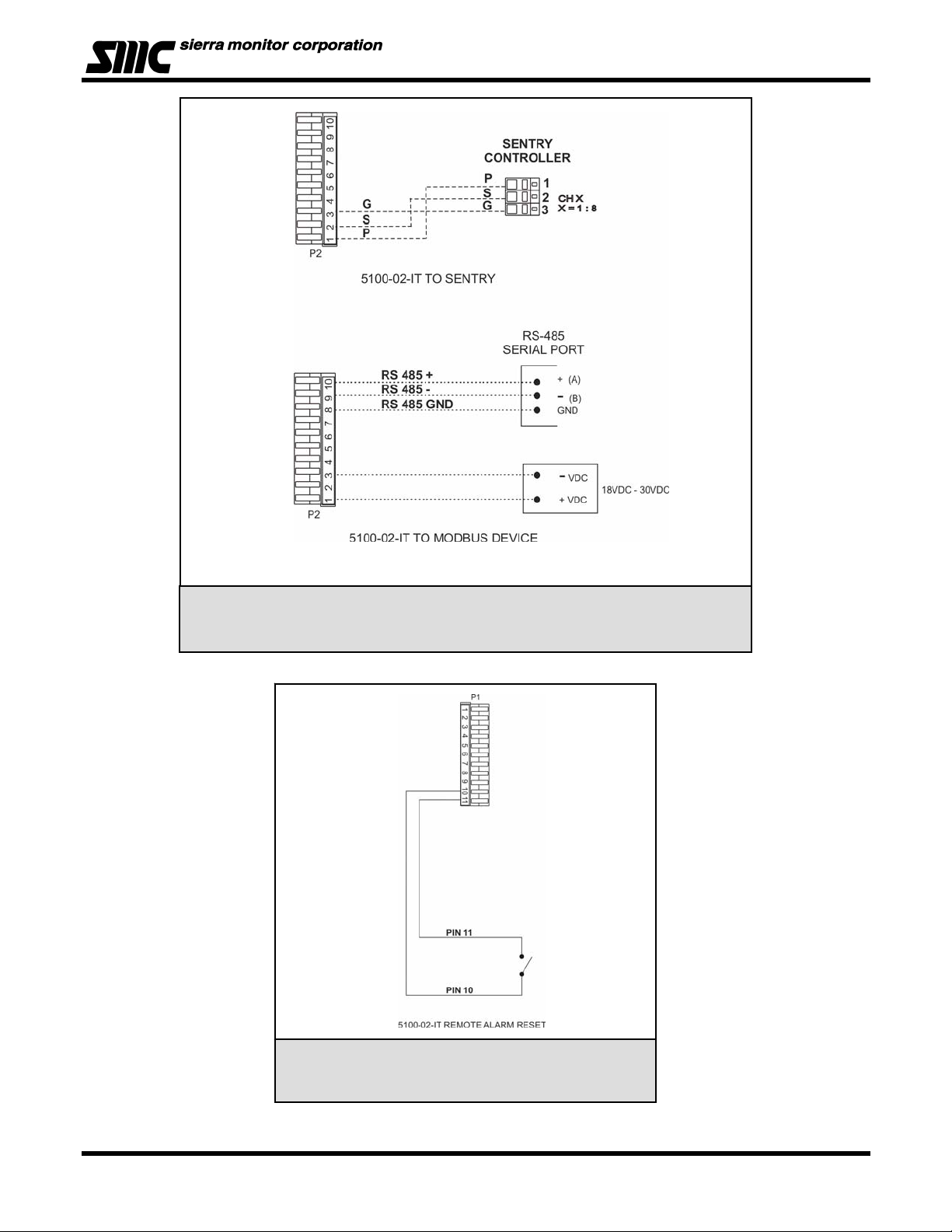

1.4.1 SENTRY INTERFACE

All IT gas sensor modules can be installed on Sierra Monitor Sentry Model 5000 controllers. Catalytic bead

modules communicate as a combustible gas sensor module (Type 2 communication) and are automatically

detected by the Sentry controller. When it is installed in a Sentry system the IT module must have a unique

address which can be established by setting an address between 1 and 8 on the rotary switch accessible

from the cover plate as illustrated in Figure 3-1. Figure 3-4 in this manual provides the wiring terminations

for connections to the Sentry controller.

When the module is operated in conjunction with a Sentry controller, the alarm relay setup (See section

4.3) should be set to “Sentry”, allowing the Sentry controller to manage alarm relay action rather than the

5100-02-IT Gas Sensor Module.

An available option, applicable only to Sentry installations, is a connector card which allows daisy chain

installation using the Sentry multiplex capability. Use of the connector card reduces costs by avoiding the

requirement for wiring junction boxes. The connector card has two sets of connections, allowing for a

continuous run to the next module.

Registered trademark of Schneider Electric.

Page: 3

Page 6

Model 5100-02-IT Combustible Gas Sensor Module

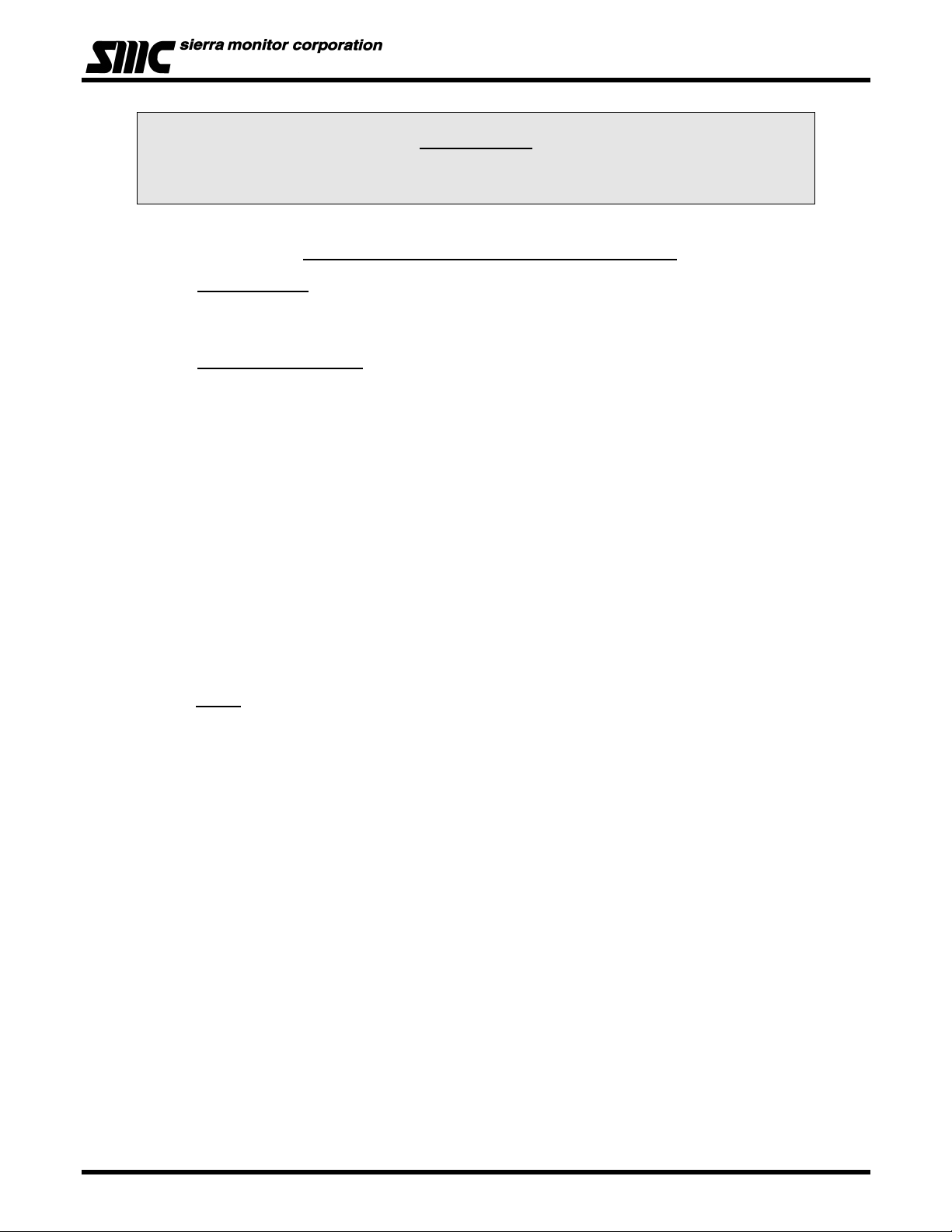

Figure 1-1

Model 5100-02-IT Combustible Gas Sensor Module Stainless Steel – Dimensions

Figure 1-2

Model 5100-02-IT Combustible Gas Sensor Module Aluminum – Dimensions

Page: 4

Page 7

Model 5100-02-IT Combustible Gas Sensor Module

1.4.2 MODBUS OPERATION

All IT gas sensor modules have a Modbus RTU RS-485 serial interface to allow direct connection to any

standard PLC or DCS. The Module Address Switch (section 3.5) allows the user to select Modbus

addresses 1 thru 15. Switch position “0” allows the user to set addresses up to 254 using the s Menu (See

Table 4-3). Figure 3-4 provides the wiring terminations for Modbus connections.

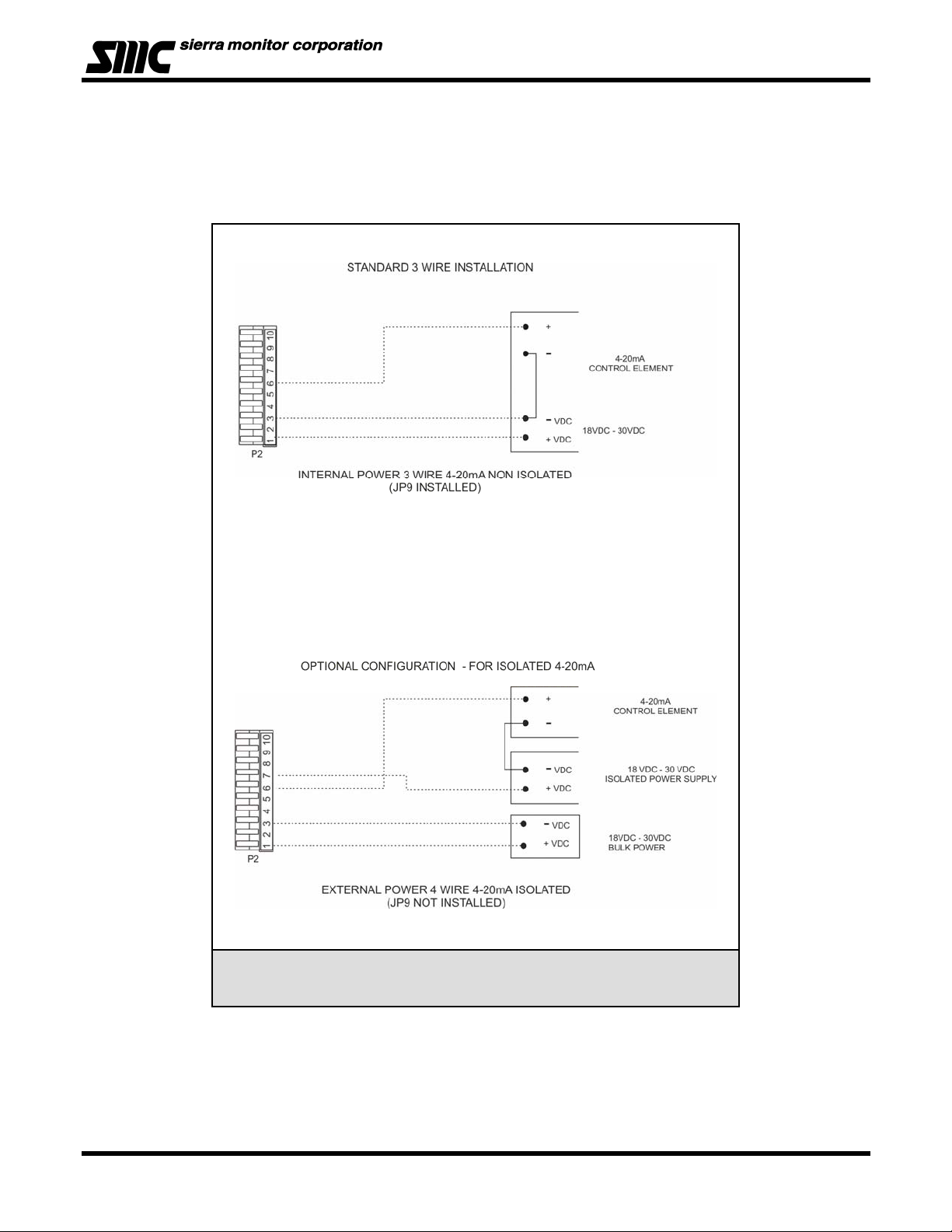

1.4.3 ANALOG OPERATION

All IT gas sensor modules have a 4-20 mA interface to allow direct connection to standard analog

indicators or PLCs. The standard Model 5100-02-IT provides a 4-20 mA analog interface which allows

power and loop connections. When IT modules are to be operated with analog interface, each module

requires individual home run wiring and no unique address is required. Figure 3-3 provides the wiring

terminations for 4-20 mA connections.

1.4.4 AUXILIARY RELAY OPERATION (APPENDIX E)

While the 5100-02-IT has three internal 0.25 amp relays (high alarm, low alarm and trouble) as standard,

an available option is an Auxiliary Relay Assembly, Part Number 5394-62, which provides 8 amp alarm

relays for each of the two conditions, low alarm and high alarm.

1.4.5 ENHANCED CONNECTION (APPENDIX F)

An Auxiliary Connection Assembly, Part Number 5394-61, applicable to Sentry and RS-485 installations

only, provides connections capable of accepting 12 AWG wire. Additionally, the enhancement acts as a

junction box providing connections for the next module in the run, when utilizing the Sentry multiplexing

capability.

1.4.6 AUXILIARY RS-485 MULTIDROP (APPENDIX G)

The Auxiliary RS-485 Multidrop Connection Assembly, Part Number 5394-64, provides the additional

terminal connectors to enable the user to connect the In/Out terminations of a RS-485 connection.

1.4.7 REMOTE SENSOR (APPENDIX D)

Extension kit 5394-51 can be used to remotely mount the sensor up to 50’ from the transmitter.

1.4.8 REMOTE ALARM RESET

An input is available for connection of remote alarm reset/acknowledge. Figure 3-5 provides the wiring

termination for connecting the remote alarm reset.

1.5 MECHANICAL

The sensor module is comprised of the following three primary components:

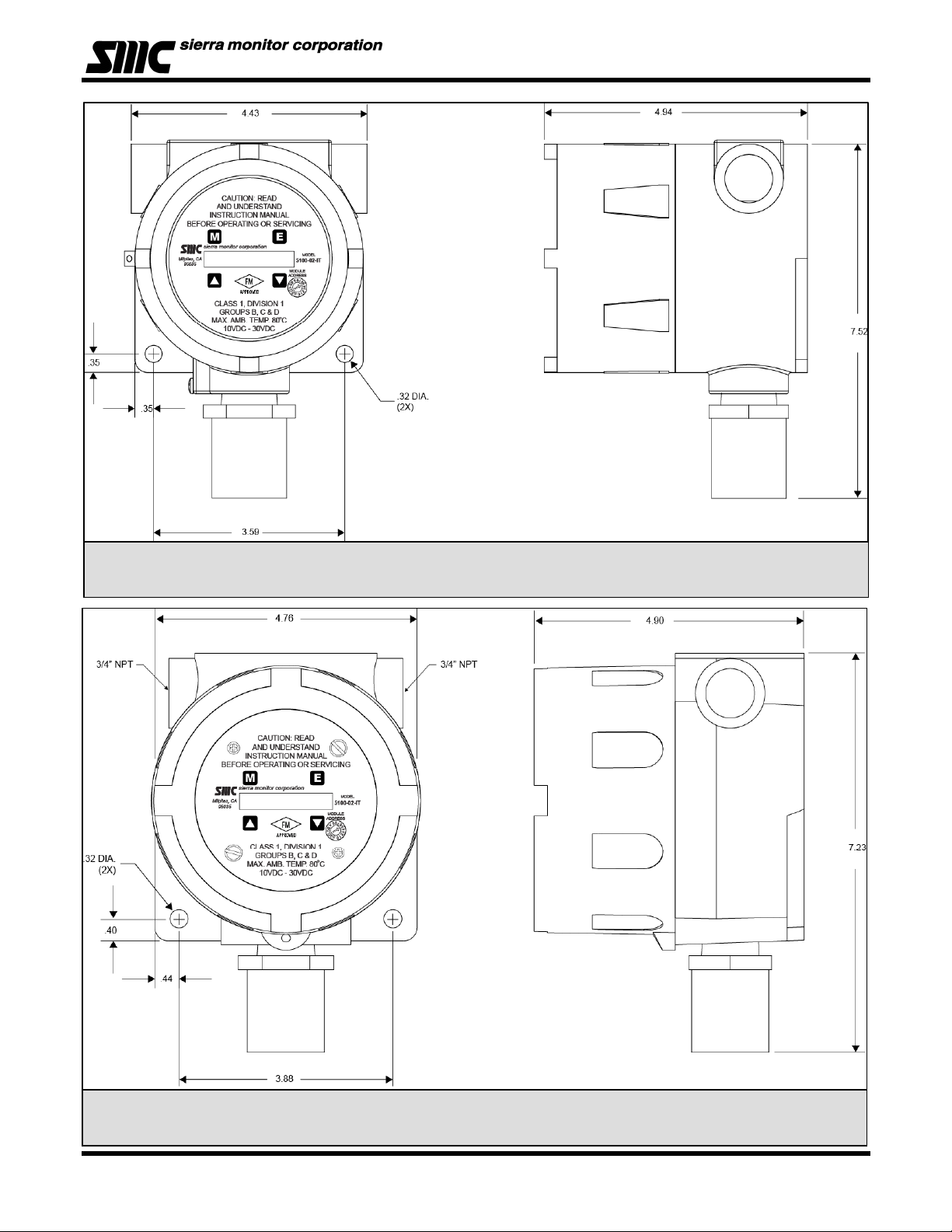

1.5.1 ENCLOSURE

Standard on the 5100-02-IT is an explosion-proof, rain-tight cast aluminum electrical housing with three ¾”

FNPT conduit hubs. The 5100-02-IT-SS has a 316 Stainless Steel enclosure. Both enclosure covers have

a viewing window. The design of the enclosure allows 3-way mounting choices as shown in figure 1-3. .

1.5.2 TRANSMITTER ELECTRONICS

Electronic Assembly consisting of one printed circuit board assembly mounted under a cover plate. Wiring

connections for power, signal interface and alarm relays are located on the back side of the display.

1.5.3 SENSOR ASSEMBLY

The sensor assembly includes an explosion proof housing containing the gas sensor and a wiring harness

for connection to the transmitter. The sensor assembly threads into one hub of the enclosure. The

exposed end of the sensor assembly is threaded to allow connection of a rain-shield or calibration gas

delivery fitting.

Page: 5

Page 8

Model 5100-02-IT Combustible Gas Sensor Module

1.6 INTERCONNECT WIRING

Not supplied with the sensor module, but necessary to the installation and operation is the multi conductor

wiring which connects the module to its power source and controller. Before this wiring is installed it is

important to read and understand the control system installation instructions to determine wiring requirements

and alternatives.

1.7 POWER REQUIREMENTS

IT modules operate on DC power between 10 VDC and 30 VDC. Regulated DC power must be supplied from

a separate source, or from an approved Sentry or IT Controller.

Page: 6

Page 9

Model 5100-02-IT Combustible Gas Sensor Module

2. CAUTIONS & WARNINGS

2.1 INTRODUCTION

Although IT Transmitter Modules are designed and constructed for installation and operation in industrial

applications including "hostile" environments, caution should be taken to insure that the installation is made in

compliance with this instruction manual and that certain procedures and conditions are avoided. This chapter

discusses the necessary cautions. Read the entire chapter prior to installation of the equipment.

2.2 IT MODULES - GENERAL

Avoid installing sensor modules where they will be unnecessarily exposed to wind, dust, water (i.e. direct hose

down), shock, or vibration. Observe temperature range limitations.

Sensors may be adversely affected by prolonged exposure to certain materials. Loss of sensitivity, or

corrosion, may be gradual if such materials are present in low concentrations. These materials include:

Halides (compounds containing chlorine, fluorine, bromine, iodine), acid vapors, caustic liquids or mists.

Care has been taken by the manufacturer to ship modules in protective packaging to avoid contamination prior

to installation. It is recommended that the modules remain protected during installation and that the covering

be removed immediately prior to system start-up.

During normal use the sensor is protected from dirt and oil contamination by a sintered metal cover. If this

cover becomes clogged, the response of the sensor will be reduced. Protect the sensor from contamination

by careful placement, or by use of rain and dust shields.

Sensor modules must not be painted. Paint may contain compounds which will contaminate the sensor. Paint

will cause clogging of the sintered metal cover and will cause difficulties during attachment of the calibration

head or other maintenance activity. It is recommended that the module be tagged

"DO NOT PAINT".

2.3 WIRING

The manufacturer recommends that extra caution be taken where the installation is near any sources of

electromagnetic or radio frequency interference. Precautions include:

• Avoid running sensor module cable close to high power cables, radio transmission lines, or cables

subject to pulses of high current.

• Avoid running cables near large electric motors or generators.

• When the sensor module is to be operated in analog (4-20mA output) mode shielded cable is required.

• When the risk of interference is present use shielded cables. In conduit installations the shield should

be connected to the conduit. In cable applications the shield should be connected to instrument

ground.

• All splices must be via either a termination hardware system or soldered. Improperly spliced cable can

result in corrosion, resistance changes and system errors.

Installation and wiring must be in accordance with the National Electrical Code.

Voltage AC conductors are not to be run in the same conduit as voltage DC

NOTE

conductors.

Page: 7

Page 10

Model 5100-02-IT Combustible Gas Sensor Module

2.3.1 CATALYTIC BEAD SENSOR MODULES

Model 5100-02-IT Gas Sensor Modules are FM performance approved for detection of Combustible gas

(methane and hydrogen). The sensor is cross sensitive to the combustible gases indicated in Table 2-1.

Risk management planning should take into consideration the potential for the presence of other gases in

the monitored area.

Note that the 5100-02-IT has a gas factor scaling feature in which a calibration standard of Methane or

Propane may be used in conjunction with scaling factors to cause alarm function in %LEL scale of another

gas. See Appendix I.

Acetaldehyde

Acetic Acid

Acetic Anhydride

Acetone

Acetylene

Alkyl Alcohol

Ammonia

n-Amyl Alcohol

Aniline

Benzene

Biphenyl

1,3-Butadiene

n-Butane

iso-Butane

Butene-1

cis-Butene-2

trans-Butene-2

n-Butyl Alcohol

iso-Butyl Alcohol

tert-Butyl-Alcohol

n-Butyl Benzene

iso-Butyl Benzene

n-Butyric Acid

Carbon Disulfide

Carbon Monoxide

Carbon Oxysulphide

Chlorobenzene

Cyanogen

Cyclohexane

Cyclopropane

n-Decane

Diethylamine

Dimethylamine

2,3-Dimethylpentane

2,3-Dimethylpropane

Dimethylsulphide

1,4-Dioxane

Epichlorohydrin

Ethane

Ethyl Acetate

Ethyl Alcohol

Ethylamine

Ethyl Benzene

Ethyl Bromide

Ethyl Chloride

Ethylcyclopentane

Ethylene

Ethylenedichloride

Ethyleneoxide

Diethyl Ether

Dimethoxyethane

Dimethyl Ether

Dimethylformamide

Ethyl Formate

Ethylmercaptan

n-Heptane

n-Hexane

Hydrazine

Hydrogencyanide

Hydrogen

Hydrogen Sulfide

Methane

Methyl Actetate

Methyl Alcohol

Methylamine

Methyl Bromide

Methyl Chloride

Methylcyclohexane

Methylenedichloride

Methylethylether

Methylethylketone

Methyl Formate

Methylmercaptan

Methylpropionate

Methyl n-propylketone

Napthalene

Nitromethane

n-Nonane

n-Octane

n-Pentane

i-Pentane

Propane

n-Propyl Alcohol

n-Propylamine

n-Propylchloride

Propylene

Propyleneoxide

iso-Propylether

Propyne

Toluene

Triethylamine

Trimethylamine

Vinylethylether

o-Xylene

m-Xylene

p-Xylene

JP-4 (Jet Fuel)

Table 2-1

Combustible gases detected by Model 5100-02-IT Combustible Gas Sensor Module

Page: 8

Page 11

Model 5100-02-IT Combustible Gas Sensor Module

3. INSTALLATION

All modules are tagged to indicate the configuration including the sensor module number.

All IT modules are factory pre-configured and calibrated.

Identify all components during unpacking and install using the factory configuration.

NOTE

3.1 SENSOR MODULE LOCATIONS

Select locations for each sensor module based on the following:

• Modules should be placed close to the potential source of gas.

• Modules should be placed in areas accessible for calibration.

• Sensors should be pointed down and the conduit should include an inverse trap to reduce moisture

(condensation) from accumulating in the electronics enclosure.

• Remote calibration fitting (5360-00) can be used to facilitate calibration gas delivery. Run polyurethane

tubing (1/4” O.D. x 1/8” I.D.) from fitting to an accessible location.

3.2 WIRING

3.2.1 ANALOG 4-20 MA OPERATION

The 4-20 mA output for the 5100-02-IT can be either 3-wire (using the 5394-61 Connector Board) or 4-wire

operation. If using 3-wire operation, use a minimum of 18 AWG, shielded, 3-conductor cable up to 2000’.

For 4-wire operation, use a minimum of 2 each, 18 AWG, twisted, shielded, pair up to 2000’.

3.2.2 MODBUS OPERATION USING RS-485 CONNECTION

Use a minimum of 18 AWG, 2 conductor for DC power connection. No shield required. In addition use a

minimum of 24 AWG, low capacitance, shielded data cable for RS-485 half duplex communication. The

installation may be planned in a manner which provides up to 32 sensor modules on a single home run.

3.2.3 SENTRY OPERATION USING SMC SENTRY CONNECTION

Use a minimum of 18 AWG, 3-conductor cable up to 2000’. The cable may or may not be shielded. We

recommend shielded cable in circumstances that there could be RF or EM interference present. Shield to

be terminated and grounded only at the Sentry controller. Shield must be cut and dressed at the module

end so that no part of it comes in contact with the conduit or ground.

Be sure to follow all local electric code and safety requirements when installing the 5100-02-IT Gas Sensor Module

3.2.4 GENERAL

NOTE:

Install conduit as required by local code or construction specifications. When sensor modules are to be

multiplexed for Sentry or RS-485 communication two alternatives may be planned:

• Install splice boxes above each sensor module. Use multi-position positive contact terminals to

connect daisy chain wiring and provide a pigtail to connect to the sensor module transmitter board.

• Use Auxiliary Connection Assembly, Model 5394-61. The Auxiliary Connection Assembly plugs into

the sensor module transmitter and provides daisy chain wiring.

Installation and wiring must be in accordance with the National Electrical Code. Temperature

The drain wire of shielded cable must NOT be used as one of the conductors.

rating of cable wire must be at least 75oC. If cable runs through higher temperature

environments, it must be specified for that environment.

NOTE

Page: 9

Page 12

Model 5100-02-IT Combustible Gas Sensor Module

3.3 ENCLOSURE INSTALLATION

To protect the transmitter and sensor assembly they should be removed from the enclosure and preserved

until final installation and wiring termination.

Prior to installation and wiring.

1. Remove the transmitter from the module housing by:

• Unscrew the two captive panel screws on the face plate.

• Lift the transmitter out of the housing.

• Unplug the sensor cable from transmitter connector J2.

• Remove the sensor assembly from the enclosure hub.

2. Install the module housing onto the end of the supply conduit and/or bolt into position as required.

When housing earth grounding is required for the installation a grounding lug is located in the

NOTE

base of the enclosure. Install the earth ground to under the green ground lug.

3.4 TRANSMITTER AND SENSOR INSTALLATION

When all pre-wire is complete:

1. Install sensor assembly in the open hub on the module enclosure. The sensor assembly thread

must be fully seated into the hub and tightened to maintain explosion proof assembly.

2. Connect the wires which return to the controller to transmitter connectors P1 and P2 (Figure 3-2)

according to Figures 3-3 (Analog Output), 3-4 (Digital Interface), 3-5 (Remote Alarm Reset).

3. Connect the sensor assembly cable to transmitter connector J2.

4. Reconnect any required auxiliary wiring to the applicable terminals according to project

requirements and Table 3-2.

5. Connectors P1 and P2 are removable to facilitate wiring termination. When reinstalling the

connectors pay attention to the connector orientation. See Figures 3-2, 3-3, 3-4, 3-5, etc.

Connectors P1 and P2 are removable for easy wiring termination.

NOTE

Page: 10

Page 13

Model 5100-02-IT Combustible Gas Sensor Module

6. Carefully return the transmitter to the enclosure installing it over the two standoffs. Tighten the

retaining screws into the standoffs.

P1 FUNCTION P2 FUNCTION

1 High Alarm Relay NC 1 Power

2 High Alarm Relay NO 2 Signal

3 High Alarm Relay COM 3 Ground

4 Low Alarm Relay NC 4 N/A

5 Low Alarm Relay NO 5 N/A

6 Low Alarm Relay COM 6 4-20 mA output -

7 Trouble Relay NC* 7 4-20 mA output +

8 Trouble Relay NO* 8 RS-485 Ground

9 Trouble Relay COM 9 RS-485 (-) (B)

10 Digital Input SW+ 10 RS-485 (+) (A)

11 Digital Input SW-

*Trouble relay is fail safe so it is energized for normal operation. Functions

are labeled for normal operation.

Table 3-1

Sensor Module External Interfaces

7. Establish the module address according to section 3.5.

The warm-up period is 3 minutes from power on.

NOTE

Page: 11

Page 14

Model 5100-02-IT Combustible Gas Sensor Module

3.5 INSTALLATION CONFIGURATION

Table 3-3 and Figures 3-1 through 3-4 provide location and installation details.

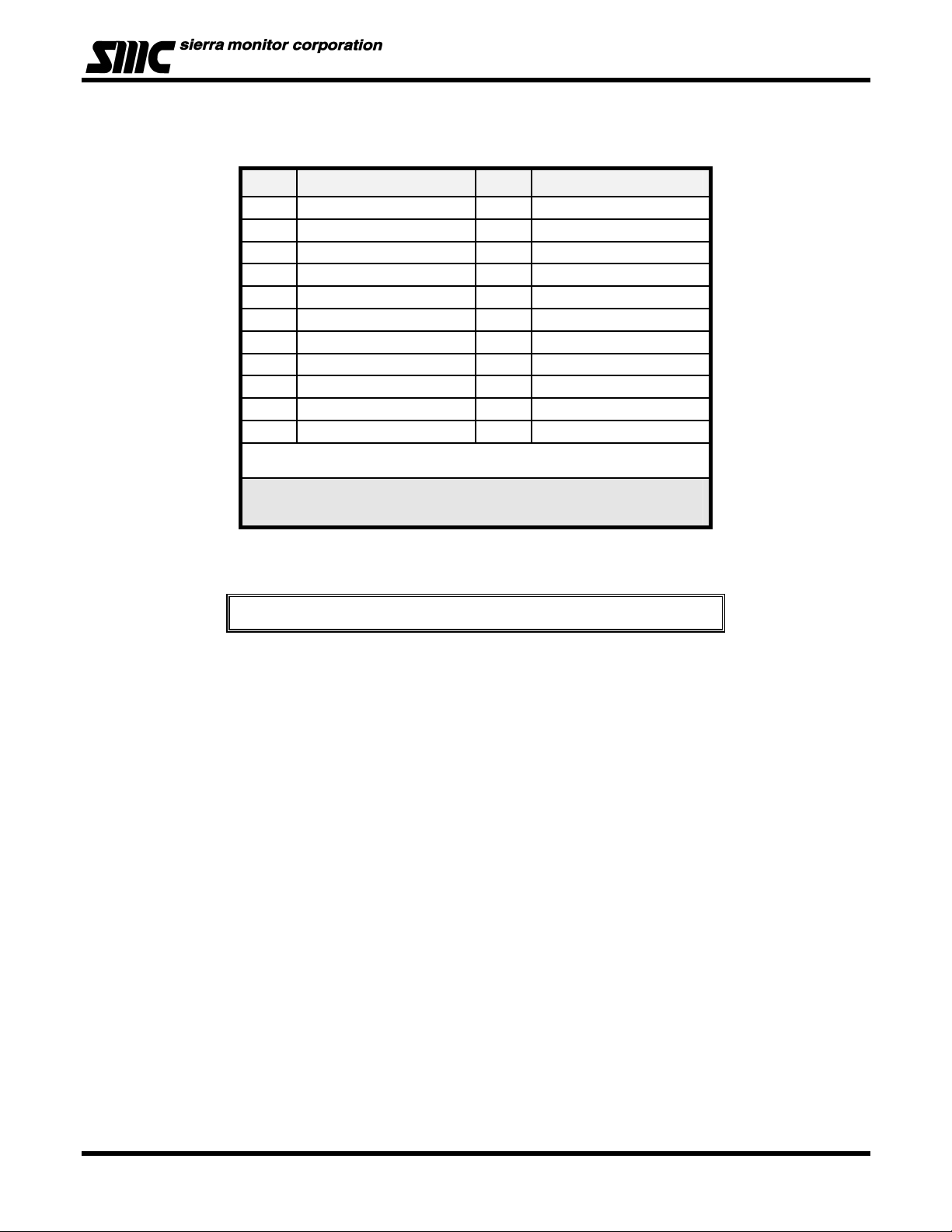

POSITION ADDRESS POSITION ADDRESS

1 Sensor 1 9 Sensor 09

2 Sensor 2 A Sensor 10

3 Sensor 3 B Sensor 11

4 Sensor 4 C Sensor 12

5 Sensor 5 D Sensor 13

6 Sensor 6 E Sensor 14

7 Sensor 7 F Sensor 15

8 Sensor 8 0 Select

Table 3-2

Sensor Module Rotary Switch Positions

Figure 3-1

Module Address Rotary Switch

For Sentry applications only sensor addresses 1-8 are allowed. If using Modbus output

sensor addresses 1-15 are available. Position 0 allows the Modbus or Sentry address to be

set by software menu, in the range 16-254.

NOTE

Figure 3-2

Connector Locations

Page: 12

Page 15

Model 5100-02-IT Combustible Gas Sensor Module

Figure 3-3

4-20 mA Connection

Page: 13

Page 16

Model 5100-02-IT Combustible Gas Sensor Module

Figure 3-4

Digital Interface Connections

Figure 3-5

Remote Alarm Reset

Page: 14

Page 17

Model 5100-02-IT Combustible Gas Sensor Module

r

4. INTRODUCTION – HUMAN-MACHINE INTERFACE SYSTEM

The Combustible Gas Sensor utilizes a visual menu system operated by means of a magnet. A magnet stick is

supplied for this purpose. The menu system is used to configure alarm set-points, calibrate the sensor

module, and for maintenance procedures and alarms acknowledge.

4.1 HUMAN-MACHINE INTERFACE

The module menu system is operated by means of directing the magnet stick toward each of four independent

hall-effect magnetic switches. Each switch functions as if it is a manually activated panel key. The keys are

located above and below the faceplate display and are labeled

• Key M : MODE

• Key E : ENTER

• Key ▲: UP (+)

M , E , ▲, and ▼as shown in Figure 4-6.

• Key ▼: DOWN (-)

Mode

Ente

Up

Down

Figure 4-6

HMI Switch Locations

Page: 15

Page 18

Model 5100-02-IT Combustible Gas Sensor Module

4.2 MAIN MENU

Table 4-1 describes the primary human-machine interface operation.

Function Display Description Reference

Key

M E

ST

M E

ST

ME

S T

ME

S T

M E

ST

M E

ST

M E

ST

M E

ST

M E

ST

M E

ST

M E

ST

Mode Switch [M]

Enter Switch [E]

Up Switch [▲] Previous Menu

Down Switch [▼] Next Menu

5100-02 First screen at power up-model

1.Xxa VX.Xxx Second screen at power up-version

Warm.XXX Third screen at start up-warm up

0%LEL Normal condition - default display

Mode ALMRSET: Mode Function -Alarms Acknowledge

SSSSSSSS

Banner: Use <M> switch for different menu items. Select <E> to

enter menu item.

0%LEL Default Display

Mode ALMRSET: Mode Function - Alarms Reset

Mode CALIB: Mode Function - Calibrate Table 5-1

Mode SETUP: Mode Function - Set Point Adjustments Table 4-3

Mode MAINT: Mode Function - Maintenance Table 4-4

Mode EXIT-? Exit Mode

Enter 0%LEL Apply Selected Mode (Exit)

0%LEL Default Display

Table 4-1

Master Menu

Table 4-2 describes the operational display values of the human-machine interface system.

Display Description

STARTING Warm-up at start-up

##%LEL Concent ration

L ##%LEL Low Alarm

H ##%LEL High Alarm

HIGH >100% Full Scale

NO SENSR Sensor Failure

C ##%LEL Calibration Mode

ACK Acknowledged Function

Table 4-2

Operation Display Values

ID THE DISPLAY SHOWS “START” INSTEAD OF “STARTING, THE MODULE MUST BE CALIBRATED BEFORE USING IT.

Page: 16

Page 19

Model 5100-02-IT Combustible Gas Sensor Module

4.3 CONFIGURE SET-POINTS

The sensor module set-points menu is used to initially set-up the alarm set points, relay actions, gas type and

range, 4-20 mA action and RS-485/Sentry address and baud rates (See Menu Key in Appendix J).

• Alarm Set-points: Once the Set-up menu is selected, press [E] to activate the Alarm Set-point

screen. Use the [▲] or [▼] keys to select Low Alarm or High Alarm menu. Key [▲] will adjust the

setpoint upwards and Key [▼] will adjust the value downwards. Once it reaches the desired

setpoint, Key [E] will accept it and ACK will appear. Set-points can be configured using this menu to

values between 0 and 60.

• Alarm Relay Set-up: Once the Set-up menu is selected, press key [▼] once and press [E] to

activate the Relay Set-up menu. Use the [▲] or [▼] keys to select High Alarm or Low Alarm relay

menu and press [E]. Use the [▲] or [▼] keys to select the correct alarm relay action for the

application, Latch, Sentry or Non-Latch. Selecting “Sentry” enables the Sentry controller to make all

alarm action decisions. * indicates the current selection.

• Gas Factor: A calibration standard of Methane or Propane may be used in conjunction with scaling

factors to cause alarm function in %LEL scale of another gas. See Appendix I for a list of the scaling

factors. Note that if the 5100-02-IT is interfaced to a Sentry controller that the gas factor can be set in

the Sentry or the Gas Sensor Module but NOT IN BOTH. It is recommended that the gas factor be

adjusted in the Gas Sensor Module so that the display values on both the Gas Sensor Module and

the Sentry are matched. Note that gas factors are not applicable during calibration.

• 4-20mA: Once the Set-up menu is selected, press key [▼] three times and press [E] to activate the

4-20mA Set-up menu. Use the [▲] or [▼] keys to select Calib, or CalibOut TblOut menu and press

[E]. The “Calib” section of the menu allows the user to calibrate the 4 mA and 20 mA outputs. To

calibrate the 4 mA and 20 mA outputs it is necessary to have an amp meter connected to the 510028-IT and upon selecting the 4 mA output calibration then the [▲] or [▼] keys can be used to adjust

the 4 mA reading on the amp meter until it reads 4 mA. Similar steps can then be performed for the

20 mA output. The CalibOut section allows the user to select the 4-20 mA output action desired

during calibration. * indicates the current selected value. Available selections include:

Track – the 4-20mA value tracks the calibration gas exposed to the gas sensor module

Zero – the 4-20mA value is held at 0mA during calibration

C1.50mA – the 4-20mA value is held at 1.50mA during calibration

C4.00mA – the 4-20mA value is held at 4.0mA during calibration.

The Tbl Out menu enables the user to select the mA output value for the Trouble Alarm. Select

“T2.5mA” to choose the 2.5mA default valve. Or select “User mA” and use the [▲] or [▼] keys to

select any valve between 0.5mA and 3.7mA.

• RS-485 - Once the Set-up menu is selected, press key [▼] four times and press [E] to activate the

RS-485/Sentry Set-up menu. Use the [▲] or [▼] keys to select Address or Baud rate menu and

press [E]. Note that the 5100-28-IT has a rotary switch on the faceplate and it is used to select

addresses 1-15. When connected to Sentry the user can select 1-8 and using Modbus RS-485 the

user can select addresses 1-15. For Modbus addresses above 15, set the rotary switch to 0 and

then use the “Address” menu to select any address between 16 and 254. The Baud rate menu

allows the user to select a baud rate of 38400, 19200, 9600, 4800 or 2400. * indicates current

selection.

Page: 17

Page 20

Model 5100-02-IT Combustible Gas Sensor Module

Function Display Description Reference

Key

--0%LEL- Default Display

M E

ST

M E

ST

M E

ST

M E

ST

ME

S T

ME

S T

ME

S T

ME

S T

M E

ST

M E

ST

ME

S T

M E

ST

Mode ALMRSET: Mode Function - Alarm Reset

Mode CALIB:-- Mode Function - Calibrate

Mode SETUP:--- Mode Function - Set Point Adjustments

Enter Alarms S.P. Function - Alarm Adjust * A Below

Down Relays S.P. Function - Relays Adjust * B Below

Down GasFactr S.P. Function - Gas Factor Adjust * C pg. 19

Down 4-20mA S.P. Function - 4-20 mA Adjust * D pg. 19

Down RS-485 S.P. Function - RS-485/Sentry Output Adjust * E pg. 19

High Alarm Set Point Adjustment Example

Enter H.Alarm S.P. Function - High Alarm Adjust *A

Enter HASP:60- High Alarm Set Point: current = 60

Use S or T keys to adjust to new set point

Down (x5) HASP:55- High Alarm Set Point: new = 55

Enter ACK Momentary Acknowledge of new Set Point

H.Alarm S.P. Function - High Alarm Adjust

M E

ST

ME

S T

M E

ST

ME

S T

ME

S T

Relays Set Point A djustment Example

Enter H. Relay S.P. Function - High Alarm Relay Adjust *B

Down L.Relay S.P. Function - Low Alarm Relay Adjust

Enter Latch

Down Sentry

Use S or T keys to adjust to new relay action

(Latch, Sentry, NonLatc) * indicates current

NOTE: Sentry indicates that Sentry controls relay

action and not the IT Sensor Module

Down *Sentry High Alarm Relay set to Sentry

Table 4-3A Set-Up Configuration

Page: 18

Page 21

M E

ST

M E

ST

M E

ST

M E

ST

M E

ST

M E

ST

M E

ST

M E

ST

ME

S T

M E

ST

M E

ST

M E

ST

M E

ST

M E

ST

M E

ST

M E

ST

M E

ST

M E

ST

M E

ST

M E

ST

M E

ST

ME

S T

M E

ST

Model 5100-02-IT Combustible Gas Sensor Module

Gas Factor Example

Enter GasFactr S.P. Function - Gas Factor Adjust *C

Enter Factr100

Enter ACK Acknowledgement of new Gas Factor Value

Enter Calib S.P. Function - Calib Adjust *D

Enter Out: 4mA Use S or T keys to select 4 mA or 20mA

Enter 4mA Selects 4 mA

Enter ACK Momentary Acknowledge of new Set Point

Mode Calib S.P. Function - Calib Adjust

Down CalibOut S.P. Function - Output during Calibration Adjust

Enter Track Use S or T keys to select Track, Zero, C1.50mA, C4.00mA

Enter *Track * = Current selection

Mode

Calib S.P. Function - Calib Adjust

Down Tbl Out S.P. Function - output during Trouble Alarm

Enter *T2.50mA Current Valve 2.5mA for Trouble

Down User mA S.P. Function - User Selectable mA Valve

Enter *T2.50mA

Enter *T1.75mA Selctd 1.75mA for volume during trouble

Enter Address S.P. Function - RS-485 Address Adjust *E

Enter Addr:016 Use S or T keys to enter new address

Enter ACK New address selected

Enter Address S.P. Function - RS-485 Address Adjust

Down Baud S.P. Function - RS-485 Baud Rate Adjust

Enter *38400 Press [E] to select or [S] or [T] to select another

Select [E] to select or S or T to adjust factor

number and press [E]

4-20 mA Adjustment Example

Track = Output during calibration tracks the calibration gas,

Zero = Output is Zero during calibration,

C1.50mA = Output during calibration is 1.50 mA, C4.00mA =

Output during calibration is 4.0 mA

Use S or T keys to select mA Valve between 0.5

and 0.7mA

RS-485 Adjustment Example

Table 4-3B

Set-Up Configuration

Page: 19

Page 22

Model 5100-02-IT Combustible Gas Sensor Module

4.4 MAINTENANCE FUNCTIONS

The maintenance menu allows the operator to monitor certain Sensor values, and select the required analog or

digital communication interface. The maintenance menu operation is described in Table 4-4.

Function Display

Key

M E

ST

M E

ST

M E

ST

M E

ST

M E

ST

Mode ALMRSET: Mode Function - Alarm Reset

Mode CALIB: Mode Function - Calibration

Mode SETUP: Mode Function - Set Point Adjustments

Mode MAINT: Mode Function - Maintenance

Enter V2.00aA Module Version

0%LEL Default Display

Description

Table 4-4

Maintenance Menu

Reference

Page: 20

Page 23

Model 5100-02-IT Combustible Gas Sensor Module

5. CALIBRATION

5.1 CALIBRATION FREQUENCY

The manufacturer specifies that sensor modules must be calibrated every 180 days. Periodic functional tests are

advisable for critical applications and hostile environments.

The sensor module microprocessor software includes high level self checking algorithms which provide continuous

sensor diagnostic and self adjustment. Users may elect to increase calibration periods based on low drift

experience during the first two calibration periods.

CALIBRATION PREPARATION

5.2

Calibration of the sensor is accomplished by simple menu based steps and application of span gas.

If an error is made during any stage of the calibration process, hold the magnet stick at the

Switch 1 for 10 seconds. A scrolling display will indicate “Operate Mode” and the sensor module

will exit the calibration activity and return to normal operating mode. The calibration procedure

NOTE

can then be restarted.

Calibration must be performed only when the area is known to be clear of combustible gas. If necessary, use a

portable instrument to confirm that there is no background combustible gas.

For compliance with Factory Mutual (FM) Approvals, the Sierra Monitor Model 1200-26, 1250-01, 1256-01, 1260 02 and 1260-42 are the FM Approved calibration gas delivery devices. Use Model 5358-01 Calibration Adapter or

Model 5360-00 Gas Delivery Fitting.

5.2.1 CALIBRATION GAS DELIVERY METHODS

Calibration gas can be delivered to the sensors via the following delivery devices:

Model 5358-01: Calibration Adapter - use with portable calibrators. See Fig 5-1.

Model 5360-00: Calibration Gas Delivery fitting - permanently installed fitting

which allows tubing to be run to a convenient delivery location.

5.2.2 CALIBRATION PROCEDURE

Table 5-1 shows the step by step process of the calibration procedure.

The procedures requires that the menu “keys” be activated using the magnet

stick. Each key press steps through the process of setting the zero value for

clean air and then setting the span value.

At each of these steps, apply calibration gas of the value corresponding to the

setting accepted on the sensor module display.

Model 5358-01 Calibration Adapter

Figure 5-1

5.2.3 SENSOR EXPOSURE TO GAS

Calibration gas must be delivered to the sensor using the flow rate and duration listed in below:

Model Gas Flow Period

5100-02-IT Combustible 100-300 cc/min Until Stable (minimum 3 minutes.)

Following calibration, the module counts down for 300 seconds. During this time the module is updating its internal memory and it

is very important that its power not be interrupted

NOTE:

Page: 21

Page 24

Key

M E

ST

M E

ST

M E

ST

M E

ST

M E

ST

Model 5100-02-IT Combustible Gas Sensor Module

FunctionDisplay Description Reference

0%LEL Default Display

Mode ALMRSET: Mode Function - Alarms Reset

Mode CALIB: Mode Function - Calibrate or Sub Routine A

Enter CAL-0%

Enter ACK Zero gas setting acknowledged

50%-SPAN

Enter CAL-50%

C 0%LEL

Banner: Apply zero gas, enter <E> when done

Operation: Confirm area clear of gas, or apply zero air to sensor.

Banner: Select span, enter <E> when done

Banner: Apply 50% gas, then enter <E> to calibrate gas sensor

Operation: Apply calibration gas.

use Sub Routine B

M E

ST

M E

ST

ME

S T

ME

S T

M E

ST

ME

S T

M E

ST

Enter CAL-OK Calibration Passed - now remove gas

Mode (Any)

Down 25%-SPAN

Down Adj-SPAN

Enter 25%-SPAN

Up (x5) 30%-SPAN

Enter CAL-FAIL

CXX%LEL

WAIT-300

Operation: As gas is applied the reading will increase - wait 3 minutes

Operation: Five minute time out before sensor is returned to service.

Sub-Routine A - Abort Calibration

Operation: Hold magnet over Mode <SW1> for ten sec onds to abort

calibration

Banner: Operate mode

0%LEL Default Display

50%-SPAN

Banner: Select span, enter <E> when done

Operation: Change Span Gas Value to 25%

Operation: User adjustable value

Operation: Ready for user adjustment

Operation: User adjustment to new val ue 30%

Sub-Routine C - Calibration Fail

Operation: No calibration gas applied, or sensor did not respond

correctly.

WAIT-300

Operation: Five minute time out before sensor is returned to service.

Sub-Routine B - Select Span

Table 5-1

Calibration

use Sub Routine C

Page: 22

Page 25

Model 5100-02-IT Combustible Gas Sensor Module

6. SERVICE

6.1

SENSOR MODULE CONFIGURATION

The gas sensor module is comprised of the following sub-assemblies (Figure 6-1):

5100-02-IT Gas Sensor Module

SPL21810 Alluminum Enclosure (SPL32178 316SS Enclosure)

SPL21813 Transmitter Assembly

5200-02 Sensor Assembly

There are no field serviceable components below the sub assembly level.

6.2

ENCLOSURE REPLACEMENT

The enclosure should be replaced if the cover threads or conduit threads have been damaged, or if the enclosure

has been damaged sufficiently that it no longer meets the required NEMA classification.

To replace the enclosure follow the transmitter and sensor

assembly removal instructions, remove the damaged

enclosure from its conduit, install a new enclosure and

continue the transmitter and sensor assembly replacement

instructions.

Page: 23

Figure 5-1

Module Components

Page 26

Model 5100-02-IT Combustible Gas Sensor Module

TRANSMITTER REPLACEMENT

6.3

The transmitter assembly should be replaced when it is determined that it is unreliable, noisy or cannot be

calibrated. This may occur due to age, corrosion or failed components.

To replace the transmitter assembly:

a. Remove the cover of the main enclosure

b. Unscrew the two thumb screws in the top of the cover plate, lift the assembly and rotate 90

wiring service loop

c. Unplug the sensor connector from the transmitter

d. Plug connector into new transmitter (be sure to match numbers between connector and socket).

e. Restore power and allow a minimum of 3 hours for stabilization before re-calibration

6.4

SENSOR REPLACEMENT

The gas sensor which is located inside the sensor assembly housing can be replaced without replacement of the

housing. The gas sensor needs replacement when:

The “CAL-FAIL” message appears after calibration

The sensor output signal is noisy, causing erroneous gas level readings

To replace the sensor:

a. Confirm that system power has been removed

b. Remove the gas sensor module enclosure cover,

c. Unscrew the two thumb screws in the top of the faceplate, lift the transmitter assembly and rotate 90

relieve the wiring service loop.

d. Unplug the sensor connector from the transmitter

e. Unscrew the old sensor assembly from the enclosure conduit hub. Remove the sensor assembly with its

harness

f. Unscrew sensor housing cover from the sensor (be sure to loosen the set screw first)

g. Carefully pull the old sensor straight up from the socket

h. Press the new sensor into the socket.

i. Reverse the preceding steps to install the sensor assembly.

j. Allow the new sensor to stabilize for a minimum of 3 hours and then calibrate using the procedure in Section

5.

6.5

INSTALLATION INSPECTION

o

to relieve the

o

to

Prior to system start-up or trouble shooting, the entire system should be visually inspected. The following are

guidelines for that inspection:

6.5.1 CONTROLLER INSTALLATION

• Controller installed in conformance to instruction manual recommendations.

• AC power is correctly grounded.

• Hot AC and relay connections have safety covers installed.

6.5.2 CABLING INSTALLATION

• All splices are soldered or via terminal block.

• Cabling is away from sources of electrical noise where possible.

• Connector P2, terminals P2 1, 2, 3 on sensor module are connected to Sentry controller as Power, Signal,

Ground, respectively.

6.5.3 SENSOR MODULE INSTALLATION

• Module installation in conformance with this manual.

• Modules accessible for calibration.

Page: 24

Page 27

Model 5100-02-IT Combustible Gas Sensor Module

• Wiring terminations clean and correct.

6.5.4 MOISTURE TRAPS AND RAINSHIELDS

• Conduit seals and drains installed to avoid moisture build up in electronics enclosure. Water accumulation in

sensor module enclosures is a major cause of damage and system failures - take precautions to seal

electrical conduits and provide moisture traps and drains to avoid water damage

• Rain-shields installed where applicable.

6.5.5 STANDARD VOLTAGES

• Regulated DC Voltage to be applied to the sensor module must be between 10 VDC and 30 VDC.

6.5.6 INSPECTION AND TROUBLESHOOTING GUIDE

The inspection and troubleshooting guide can be used to step through the system start-up and to determine the

corrective action if a fault occurs.

6.5.7 IF MODULE DOES NOT RESPOND TO GAS

1. Repeat calibration procedure.

2. Remove the gas and wait for the timer to completely count down.

3. Apply 50%LEL and verify that the sensor sees 50% LEL gas after calibration.

4. If the sensor still does not see gas, power cycle the unit and repeat calibration.

6.5.8 IF THE MODULE DOES NOT COME OUT OF WARM UP

1. Make sure the sensor is placed in an ambient room temperature environment.

2. Power cycle the sensor.

3. Ensure that the sensor is not exposed to combustible gas during warm-up.

6.5.9 IF THE MODULE DOES NOT DISPLAY THE CORRECT %LEL

1. Power cycle the unit.

2. Recalibrate the sensor.

6.5.10 IF THE DISPLAY SHOWS ‘NO SENSR’ –SENSOR FAILING

1. Power down the unit

2. Open the enclosure and unplug the sensor from the transmitter board.

3. Plug the sensor back into the transmitter board carefully and ensure a secure fit.

4. Power up the unit.

6.5.11 IF THE MODULE SHOWS “***CALIBRATION REQUIRED***”

1. Calibrate the module

6.5.12 IF THE MODULE SHOWS “***UNCALIB***”

1. Hold magnet to any key to acknowledge message

2. Calibrate the module

6.5.13 IF THE DISPLAY SHOWS ‘H’ (OR L) THEN THE LOCAL HIGH OR LOW ALARM IS ACTIVE

6.5.14 IF THE DISPLAY SHOWS ‘W’ – RADIO FREQUENCY INTERFERENCE

1. Remove source of interference.

6.5.15 IF THE DISPLAY SHOWS “C” – CALIBRATION MODE

1. Complete calibration or exit to operating mode.

6.5.16 OTHER ERROR MESSAGES – CALL FACTORY

1. E: OSC F1 Oscillator Fail

Page: 25

Page 28

Model 5100-02-IT Combustible Gas Sensor Module

7. APPENDICES

7.1 APPENDIX A: SPECIFICATIONS

Specifications:

Sensor:

Type: Catalytic Bead

Range: 0-100% LEL Combustible

Repeatability: +/-1% LEL

Response time: < 12 sec to 60% full scale

Accuracy: +/- 1% for 0-50% LEL range

+/- 2% for 51-100% LEL range

Sensor Life: Typically >3 years

Output:

Display: Fixed and Scrolling LED

Relays (Standard): High Alarm, Low Alarm, Trouble (SPDT Form C, 0.25 Amp@ 250VAC)

Signal Output: Sentry Digital Bus

Relays (Option): High Alarm, Low Alarm (8 Amp, 250VAC)

420 mA: 3-wire sensor powered analog 4-20 mA or optically isolated (Calibration: 4.0

mA (default) or 1.5 mA. or Normal)

RS485: Serial RS-485 Modbus RTU

Input:

Remote Alarm Reset: Normally open digital input

Electrical Data:

Power consumption: 3 watts

Connection type: 3 wire

Input voltage: 24 VDC nominal: 10-30VDC

RFI/EMI Protection: EN50081-2, EN50082-2

Operating Range:

Ambient Temperature Range: -40o to 176 oF(-40o to 80oC)

Relative Humidity: 0-99%

Enclosure:

Dimensions: 7.5 x 5.0 x 4.8 inches (H x W x D)

(21.6 x 12.7 x 12.2 cm)

Weight: 2.7 lb. (1.3 Kg)

Housing: NEMA 4X

Electrical Classification:

Performance: Explosion proof, Class 1, Div. I, Groups B, C, D

Class 1, Zone 1, Group IIB+H2 IP66

Approvals:

FM Approved: Approval Standards: 6320, 3600

Modbus:

Baud: 38400 (Adjustable 2400 to 38400 baud)

Parity: None

Stop bit: 1

Data bits: 8

Flow Control: None

Memory map: Available upon request

Warranty:

Limited warranty: 2 years

Specifications subject to change without notice

Page: 26

Page 29

7.2 APPENDIX B: MODEL NUMBERS & PARTS LIST

Sensor Module

5100-02-IT-AL Sensor Module, Combustible, Aluminum housing

5100-02-IT-SS Sensor Module, Combustible, 316SS housing

Model 5100-02-IT Combustible Gas Sensor Module

Options

5311-00 Rainshield

5394-51 Remote Sensor/Display Option

5394-61 Auxiliary Connection Assembly

5394-62 Auxiliary Relay Assembly

Calibration Items

1200-26 Gas Sensor Calibrator w/2 Gas Cylinders

1250-01 Gas Sensor Calibrator Kit

1256-01 Regulator Type A Calibrator

1260-00 Gas Cylinder – Air (Type A), 105 liters

1260-02 Gas Cylinder – Methane 50% LEL, (type A), 105 liters

1260-42 Gas Cylinder - Hydrogen, 50% LEL, (Type A), 105 liters

1290-02 Gas Cylinder - Combustible, CH4, 50% L.E.L.

5358-01 Calibration Adapter - Direct, Standard

5358-50 Calibration/Configuration Magnetic Tool

Spare Parts

SPL21813 Transmitter for 5100-02-IT

5200-02-IT Sensor Assy for 5100-02-IT

Page: 27

Page 30

Model 5100-02-IT Combustible Gas Sensor Module

7.3 APPENDIX C: LIMITED WARRANTY

SIERRA MONITOR CORPORATION warrants its products to be free from defects in workmanship or material

under normal use and service for two years after date of shipment. SMC will repair or replace without charge any

equipment found to be defective during the warranty period. Final determination of the nature and responsibility

for defective or damaged equipment will be made by SMC personnel.

All warranties hereunder are contingent upon proper use in the application for which the product was intended and

do not cover products which have been modified or repaired without SMC approval or which have been subjected

to accident, improper maintenance, installation or application, or on which original identification marks have been

removed or altered. This Limited Warranty also will not apply to interconnecting cables or wires, consumables (i.e.

calibration gases, batteries, sensors), nor to any damage resulting from battery leakage.

In all cases SMC’s responsibility and liability under this warranty shall be limited to the cost of the equipment. The

purchaser must obtain shipping instructions for the prepaid return of any item under this warranty provision and

compliance with such instruction shall be a condition of this warranty.

Except for the express warranty stated above, SMC disclaims all warranties with regard to the products sold

hereunder including all implied warranties of merchantability and fitness and the express warranties stated herein

are in lieu of all obligations or liabilities on the part of SMC for damages including, but not limited to, consequential

damages arising out of/or in connection with the use or performance of the product.

Page: 28

Page 31

Model 5100-02-IT Combustible Gas Sensor Module

7.4 APPENDIX D: REMOTE SENSOR DRAWING 5394-50

Page: 29

Page 32

Model 5100-02-IT Combustible Gas Sensor Module

7.5 APPENDIX E: AUXILIARY RELAY ASSEMBLY 5394-62

Page: 30

Page 33

Model 5100-02-IT Combustible Gas Sensor Module

7.6 APPENDIX F: AUXILIARY CONNECTION ASSEMBLY 5394-61

Page: 31

Page 34

Model 5100-02-IT Combustible Gas Sensor Module

7.7 APPENDIX G: AUXILIARY RS-485 MULTIDROP ASSEMBLY 5394-64

Page: 32

Page 35

Model 5100-02-IT Combustible Gas Sensor Module

Page: 33

Page 36

Model 5100-02-IT Combustible Gas Sensor Module

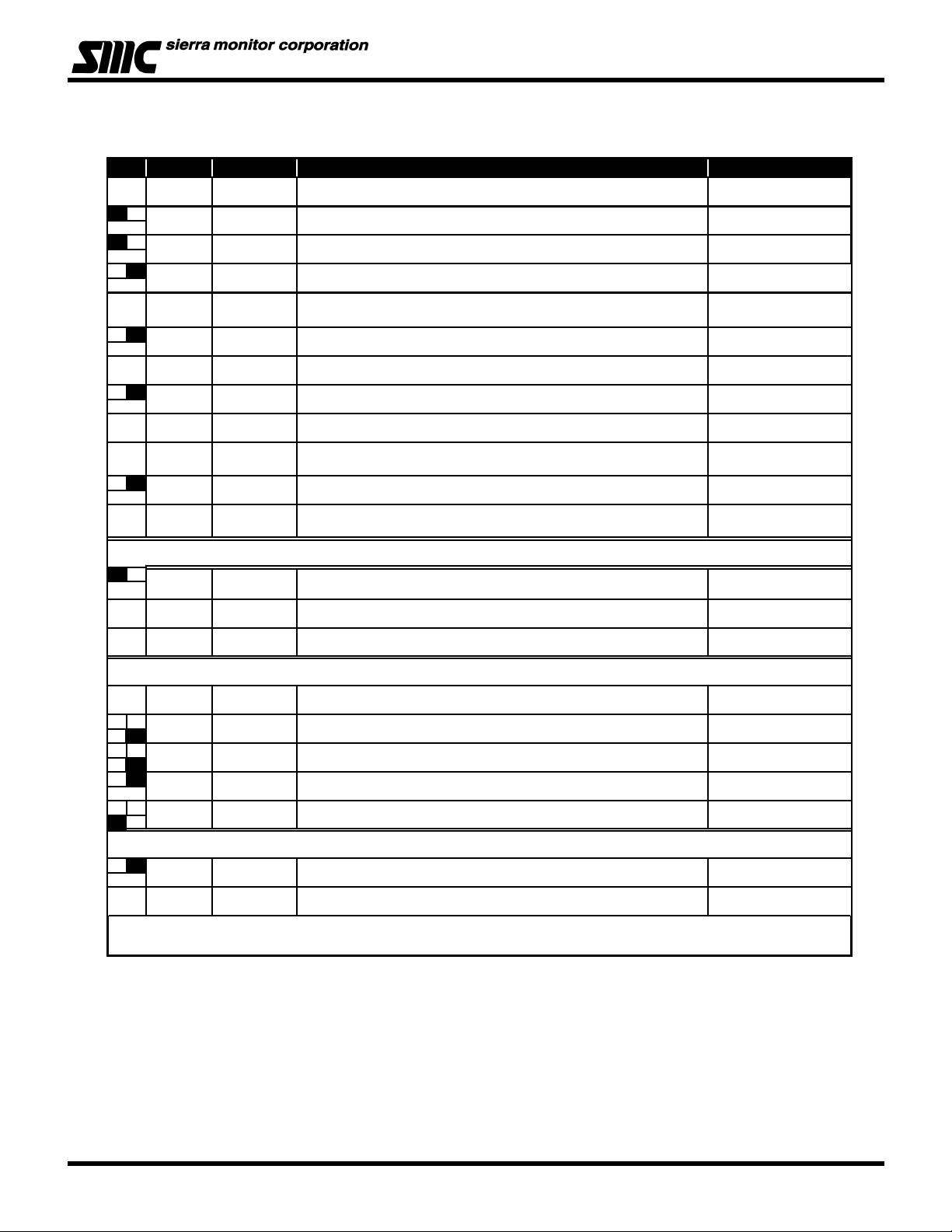

7.8 APPENDIX H: MODBUS MEMORY MAP

Read Register Table

Register Description Comments

40001 Concentration Gas Concentration multiplied by 100

40002 Temperature Temperature in degrees Celsius scalled by a factor of 100

40003 High Alarm Relay Boolean indicating the High Alarm Status, 0 No Alarm, 1 High Alarm

40004 Low Alarm Relay Boolean indicating the Low Alarm Status, 0 No Alarm, 1 Low Alarm

40005 Low Alarm Value Low alarm set point, used for activating Alarms

40006 High Alarm Value High alarm set point, used for activating High Alarms

40007 Reserved

40008 Reserved

40009 Reserved

40010 Reserved

40011 Trouble Bits 0 for no trouble

40012 Trouble 1 for any trouble, 0 for no trouble

40013 High Alarm Immediate Like 40003. but never latched

40014 Low Alarm Immediate Like 40004, but never latched

40015 Random ID Randomly generated permanent ID of sensor

40016 Restart Count

40017 Run time – high In minutes

40018 Run time – low In minutes

40019 Max. gas value *scale ((see 40024)

40020 Model 51002

40021 Range *scale (see 40024)

40022 Units 1 is %LEL

40023 Temperature Units 0 is C, 1 is F

40024 Gas Scale Value like 1 or 100

40025 Temperature Scale Value like 1 or 100

Page: 34

Page 37

Model 5100-02-IT Combustible Gas Sensor Module

7.9 APPENDIX I: COMBUSTIBLE GAS SCALING FACTORS

For combustible gas monitoring, a calibration standard of Methane may be used in conjunction with scaling

factors to cause Sentry concentration display and alarm function in %LEL scale of another gas as follows:

GAS METHANE

FACTOR

Acetaldehyde 60

Acetic Acid 54

Acetic Anhydride 46

Acetone 52

Acetylene 57

Alkyl Alcohol 51

Ammonia 126

n-Amyl Alcohol 33

Aniline 39

Benzene 41

Biphenyl 25

1,3-Butadiene 56

n-Butane 58

iso-Butane 52

Butene-1 45

cis-Butene-2 48

trans-Butene-2 51

n-Butyl Alcohol 34

iso-Butyl Alcohol 53

tert-Butyl-Alcohol 74

n-Butyl Benzene 31

iso-Butyl Benzene 32

n-Butyric Acid 38

Carbon Disulfide 18

Carbon Monoxide 75

Carbon Oxysulphide 93

Chlorobenzene 34

Cyanogen 89

Cyclohexane 41

Cyclopropane 62

n-Decane 33

Diethylamine 49

Dimethylamine 58

2,3-Dimethylpentane 40

2,3-Dimethylpropane 40

Dimethylsulphide 43

1,4-Dioxane 45

Epichlorohydrin 45

Ethane 68

Ethyl Acetate 51

Ethyl Alcohol 73

Ethylamine 53

Ethyl Benzene 36

Ethyl Bromide 91

Ethyl Chloride 57

Ethylcyclopentane 40

Ethylene 71

Ethylenedichloride 66

Ethyleneoxide 52

NOTES:

Diethyl Ether 46

Dimethoxyethane 42

Dimethyl Ether 63

Dimethylformamide 46

Ethyl Formate 44

Ethylmercaptan 56

n-Heptane 39

n-Hexane 37

Hydrazine 45

Hydrogencyanide 48

Hydrogen 77

Hydrogen Sulfide 41

Methane 100

Methyl Actetate 50

Methyl Alcohol 86

Methylamine 77

Methyl Bromide 90

Methyl Chloride 102

Methylcyclohexane 44

Methylenedichloride 93

Methylethylether 44

Methylethylketone 41

Methyl Formate 67

Methylmercaptan 61

Methylpropionate 51

Methyl n-propylketone 40

Napthalene 34

Nitromethane 34

n-Nonane 31

n-Octane 37

n-Pentane 46

i-Pentane 46

Propane 55

n-Propyl Alcohol 47

n-Propylamine 48

n-Propylchloride 50

Propylene 52

Propyleneoxide 46

iso-Propylether 44

Propyne 42

Toluene 40

Triethylamine 40

Trimethylamine 48

Vinylethylether 42

o-Xylene 36

m-Xylene 39

p-Xylene 39

JP-4 (Jet Fuel) 41

GAS METHANE

FACTOR

1. Scaling factors are not FMRC approved.

2. Base data source: EEV sensor specification catalog. (EEV claims some data is the result of specific

tests, other data is empirically derived).

Page: 35

Page 38

Model 5100-02-IT Combustible Gas Sensor Module

7.10 APPENDIX J: Menu Key for 5100-02-IT Gas Sensor Module

• Key M : MODE

• Key E : ENTER

• Key ▲ UP (+)

• Key ▼ DOWN (-)

MAIN MENU

Use the M key to access each of the 4 main sections of the menu.

M M M M M

| | | | |

|- ALMRSET: |- CALIB: |- SETUP: |- MAINT: |- EXIT?

ALARM RESET MENU

ALMRSET:

|

E– RESET (Resets current alarm)

CALIB MENU

CALIB:

|

E – CAL-0% (Calibrate Zero)

|

E – Ack (Acknowledges Zero)

|

*50%-SPAN (Last span gas used – initially set at 50%)

| |

| ▲ 25%-SPAN

| ▲ 50%-SPAN (Select Span gas value from below)

| ▲ 75%-SPAN

| ▲ Adj-SPAN (To select an alternate span gas value)

| |

| E 50%-SPAN

| |

| ▲ 51%-SPAN (Change span value to desired, once completed E starts calibration)

|

E C XX%LEL (Reading the value of the calibration gas being applied)

|

|- CAL-OK (if successful) or CAL-FAIL (if unsuccessful)

Page: 36

Page 39

Model 5100-02-IT Combustible Gas Sensor Module

SETUP MENU

Once in the SETUP menu use the ▲ or ▼ keys to access each of the 5 main sections of the SETUP menu.

▼ ▼ ▼ ▼ ▼

| | | | |

|- Alarms: |- Relays: |- GasFactr: |- 4-20mA: |- RS-485

SETUP:

|

E – Alarms (Alarms Set-Point Adjustment)

| |

| E – H.Alarm (High Alarm Setup)

| |

| E --------------------------- OR---------------------------------------▼

| | |

| |- HASP: 60 (Current Hi Alarm set-point |- L. ALARM (Low Alarm Setup)

| | |

| ▲ or ▼ (To adjust to desired set-point) E LASP:20 (Current Lo Alarm Set-point)

| | |

| E – Ack (Accepts set-point) ▲ or ▼ (To adjust to desired set-point)

| |

| E – Ack (Accepts set-point)

|

|

|----▼ Relays (Relay Set Point Adjustment)

| |

| E ----------------------------- OR-----------------------------------------▼:

| | |

| |- H. Relay (High Relay Setup) |- L. Relay (Low Relay Setup)

| | |

| E – Latch E – Latch

| | |

| ▲ or ▼ (To adjust to desired condition) ▲ or ▼ (To adjust to desired condition)

| (Selections are Latch, NonLatc, or Senty)

| (* indicates current status, Sentry = Sentry controller controls alarm relay action)

|

|----▼ Gas Factr (Gas Factor Adjustment)

| |

| E *Factr100 (* = current selection)

| |

| ▲ or ▼ (To adjust to desired factor)

| If USER is selected use the ▲ or ▼ keys to change to desired value

|

Page: 37

Page 40

Model 5100-02-IT Combustible Gas Sensor Module

|

|----▼ 4-20mA (Verifies 4mA or 20mA output and selects condition of output during calibration)

| |

| ▼ -------or--------------- E Calib

| | |

| | |- Out: 4mA

| | |

| | ▼ --or—E (To calibrate analog output 4mA, |▲ or ▼ to adjust level,

| | | then E t o accept)

| | |- Out: 20mA

| | ▼ --or--E (To calibrate analog output 20mA, |▲ or ▼ to adjust level,

| | | then E to accept)

| | |- In: 4mA

| | ▼ --or—E (To calibrate analog input 4mA, |▲ or ▼ to adjust level,

| | | then E to accept)

| | |- In: 20mA

| | ▼--or--E (To calibrate analog input 20mA, |▲ or ▼ to adjust level,

| | then E to accept)

| |

| ▼ -------or--------------- E CalibOut (Adjust 4-20mA output during Calibration)

| | |

| | |- Track: (▲ or ▼ (To adjust action/mA value during calibration

| | Track = mA value tracks Gas value

| | Hold = holds mA value existing prior to calibration

| | C1.50mA = 1.50 mA during calibration

| | C4.00 mA = 4.00 mA during calibration

| | User mA = |▲ or ▼ to adjust to desired mA value

| |

| ▼ -------or--------------- E Tbl Out (Adjust 4-20mA output during Trouble condition)

| | |

| | |- T2.50mA: (▲ or ▼ (To select 2.50mA or User mA, * = current value)

| | User mA = |▲ or ▼ to adjust to desired mA value

| |

| |

|----▼ RS-485 (Select RS-485 address and baud rate)

| |

| | - Address

| |

| ▼ | -------or--------------- E Addr:016 (Use (▲ or ▼ and E to select module address – 016 to 254)

| |

| |- Baud --------------- E *38400 (Use |▲ or ▼ and E to select baud rate, * = current selection)

MAINT MENU

MAINT::

|

E – V2.00aB (Software version installed on module)

|

E – CCC001 (Configuration number)

Page: 38

Page 41

Model 5100-02-IT Combustible Gas Sensor Module

THIS PAGE INTENTIONALLY LEFT BLANK

Page: 39

Loading...

Loading...