Page 1

INSTRUCTION

MANUAL

PREP SA

4509, 4510, 4512

I

g

g,

i

I

i

Persons under age 18 are not permitted to operate or

have accessibility to operate this equipment per

U.S. Dept. of Labor Employment Standards

Administration Fact Sheet No. ESA91-3.

univex

4509/10/12 1104

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

ED7

Page 2

4509/4510/4512

TO INSU RE BOTH SAFE AND

TROUBLE-FREE PERFORMANCE WE STRESS

THAT ALL PERSONNEL THAT WILL BE

INVOLVED WITH YOUR NEW UNIVEX SLICER

MUST, READ AND UNDERSTAND THESE

INSTRUCTIONS BEFORE ATTEMPTING TO

OPERATE THIS UNIT.

WE APPRECIATE YOUR COOPERATION AND

YOUR BUSINESS. SHOULD THERE BE A

QUESTION OR IF WE CAN BE OF FURTHER

ASSISTANCE, PLEASE CALL US,

1-603-893-6191.

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 3

TABLE QE CONTENTS

DESCRIPTION

Table of Contents

List of Illustrations

Introduction

Installation Instruction

Safety Warnings

Operating Instructions

Sharpening Instructions

Operator's Care of Slicer

Cleaning and Lubrication

Mechanics Maintenance

Trouble Shooting Guide

Repair Instructions including Disassembly, Replacement, and Reassembly

Replacement Parts Lists Keyed to Figure Drawings

Wiring Diagram

Warranty Information

4509/4510,4312

PAGE

1

1

3

3

3 - 4

4

5

6 - 7

8

9

10

12

13 - 19

20

Back Cover

LIST OF ILLUSTRATIONS

ILLUSTRATION

Figure 1

Figure 2

Figure 3

Figure 4

Figure 5

Figure 6

Figure 7

Figure 8

Figure 9

Overall View of Meat Slicer Model 4509/4510/4512

Lubrication Diagram and Instructions

Housing, Knife, and Fence Assembly

Carriage Arm Assembly

Carriage Assembly

Slice Adjustment Knob Assembly

Motor and Electrical Assembly

Sharpener Assembly

Wiring Diagram 115V, 60Hz, 1 PH, 230v, 60HZ, 1PH,

230V, 50HZ, 1PHV

Page 1

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

PAGE

2

7

13 - 14

is

16

17

is

19

20

Page 4

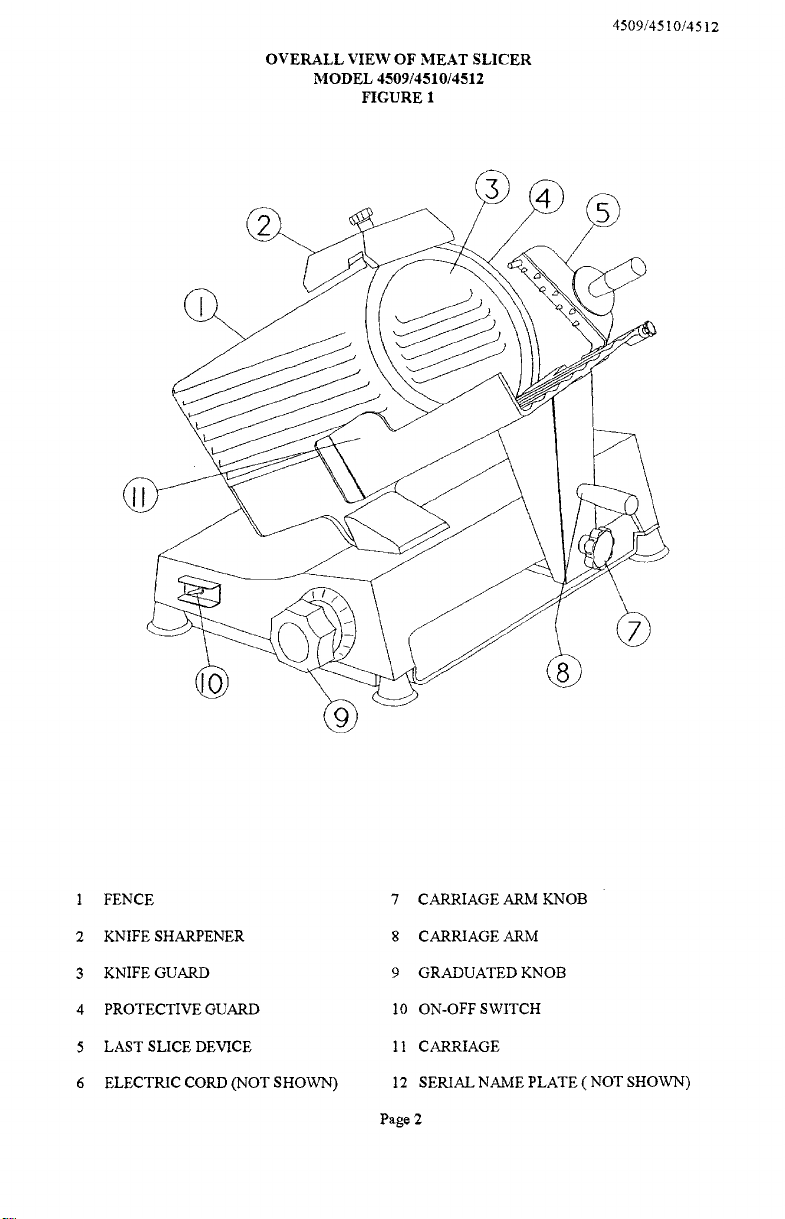

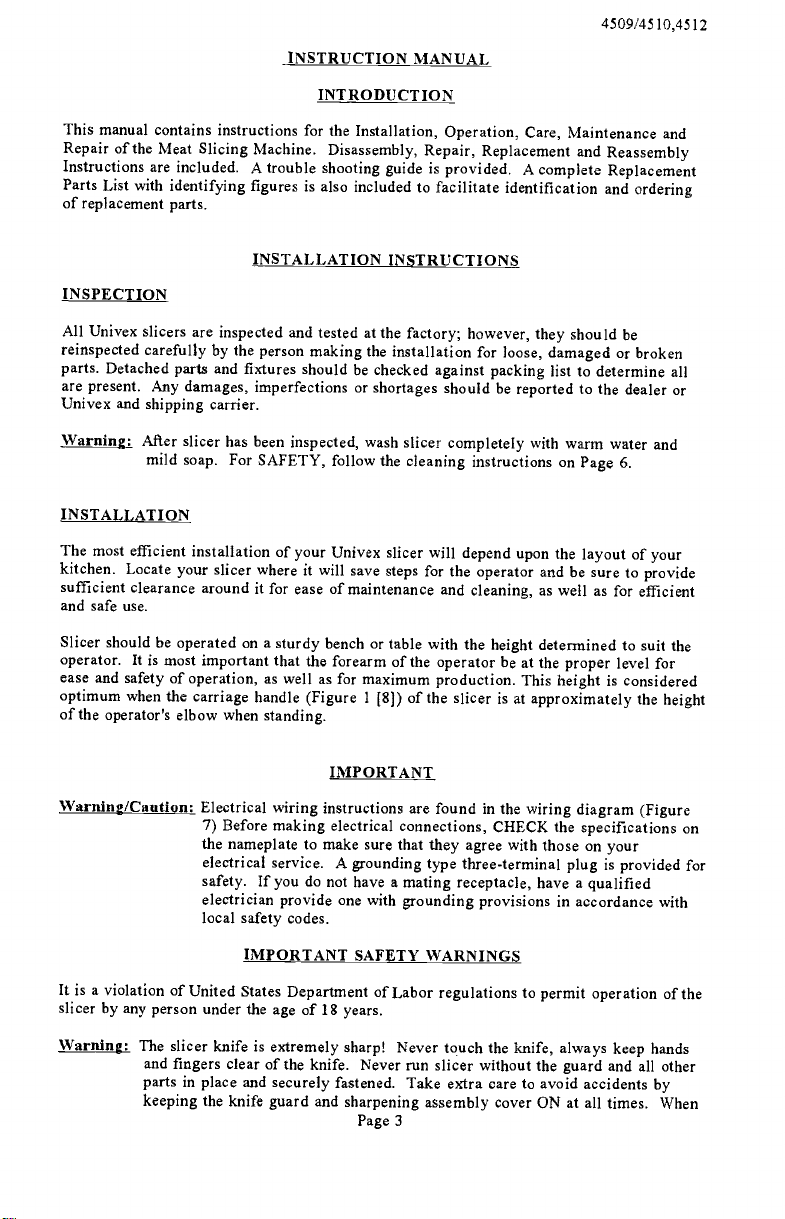

OVERALL VIEW OF MEAT SLICER

MODEL 4509/4510/4512

FIGURE 1

4509/4510/4512

FENCE

1

KNIFE SHARPENER

2

KNIFE GUARD

3

PROTECTIVE GUARD

4

LAST SLICE DEVICE

5

6 ELECTRIC CORD (NOT SHOWN)

7 CARRIAGE ARM KNOB

8 CARRIAGE ARM

GRADUATED KNOB

9

10 ON-OFF SWITCH

11 CARRIAGE

12 SERIAL NAME PLATE (NOT SHOWN)

Page 2

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 5

4509/4510,4512

INSTRUCTION MANUAL

INTRODUCTION

This manual contains instructions for the Installation, Operation, Care, Maintenance and

Repair of the Meat Slicing Machine. Disassembly, Repair, Replacement and Reassembly

Instructions are included. A trouble shooting guide is provided. A complete Replacement

Parts List with identifying figures is also included to facilitate identification and ordering

of replacement parts.

INSTALLATION INSTRUCTIONS

INSPECTION

All Univex slicers are inspected and tested at the factory; however, they should be

reinspected carefully by the person making the installation for loose, damaged

or broken

parts. Detached parts and fixtures should be checked against packing list to determine all

are present. Any damages, imperfections or shortages should be reported to the dealer or

Univex and shipping carrier.

Warning: After slicer has been inspected, wash slicer completely with warm water and

mild soap. For SAFETY, follow the cleaning instructions on Page 6.

INSTALLATION

The most efficient installation of your Univex slicer will depend upon the layout of your

kitchen. Locate your slicer where it will save steps for the operator and be sure to provide

sufficient clearance around it for ease of maintenance and cleaning, as well as for efficient

and safe use.

Slicer should be operated on a sturdy bench or table with the height determined to suit the

operator.

It is most important that the forearm of the operator be at the proper level for

ease and safety of operation, as well as for maximum production. This height is considered

optimum when the carriage handle (Figure 1 [8]) of the slicer is at approximately the height

of the operator's elbow when standing.

IMPORTANT

Warning/CautIon: Electrical wiring instructions are found in the wiring diagram (Figure

7) Before making electrical connections, CHECK the specifications on

the nameplate to make sure that they agree with those on your

electrical service. A grounding type three-terminal plug is provided for

safety. If you do not have a mating receptacle, have a qualified

electrician provide one with grounding provisions in accordance with

local safety codes.

IMPORTANT SAFETY WARNINGS

It is a violation of United States Department of Labor regulations to permit operation of the

slicer by any person under the age of 18 years.

Warning: The slicer knife is extremely sharp! Never touch the knife, always keep hands

and fingers clear of the knife. Never run slicer without the guard and all other

parts in place and securely fastened. Take extra care to avoid accidents by

keeping the knife guard and sharpening assembly cover ON at all times. When

Page 3

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 6

4509/45 10/45 12

the machine is not in use, the slice adjustment knob should be turned fully back

to the closed position (beyond "0") so that the knife edge is not exposed.

Observe the cleaning instruction on Page 6 for best results and for safety. Also

remember to always turn off the slicer and disconnect the electrical supply cord

before cleaning.

When slicing, always work the carriage using only the carriage arm handle

(Figure 1 [8]). Do not hold or push the carriage from any other place.

OPERATION INSTRUCTIONS

The Univex slicer is designed to meet the cook's demand for an efficient, sturdy slicer. The

Univex slicer will give unfailing performance over a period of years, when operated and

maintained according to instructions contained herein.

START/STOP SWITCH

The slicer is started by toggling the ON/OFF switch (Figure 1 [10]) to the ON position.

SLICE ADJUSTMENT

Warning: Dial-type knob adjustment (Figure 1 [9]) allows for slice thicknesses ranging

from paper thin up to 1/2". Dial graduations allow you to precisely set up

specific slice thicknesses for various needs. When not in use, always return

knob back to its fully closed position (beyond "0") so that the knife edge is not

exposed.

POSITIVE HOLD CARRIAGE

Caution: A last slice gravity feed grip (Figure 1 [5]) is provided. Do not use this last slice

device to work the carriage back and forth. Use only the carriage arm handle

(Figure 1 [8]).

Always make sure the carriage is positively secured to the slicer by checking to

see that the carriage arm knob (Figure 1 [7]) is fully tightened. Failure to do

this could result in the carriage striking and damaging the knife edge.

PROTECTIVE GUARD

Warning: The protective guard (Figure 1 [4]) covers the knife edge completely except

under the sharpener cover and the forward edge where slicing will be performed.

This forward edge is covered by the edge of the fence, but only when the slice

adjustment is completely closed.

The knife guard (Figure 1 [3]) can be removed for cleaning by unscrewing the

knife guard knob (Figure 3 [11]). For safety, keep the knife guard on at all

times except when cleaning. Never operate the slicer with the knife guard

removed.

Page 4

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 7

SHARPENING INSTRUCTIONS

4509/4510,4512

This slicer is equipped with a kmfe having a concave

or hollowed surface for superior

slicing quality. Of course, any knife, however superior, must be sharpened regularly and

properly in order to produce not only the highest quality slices, but also to allow it to

maintain its productivity. The knife sharpener (Figure 1 [2])

on this machine is a top

mounted built-in mechanism, designed for simplicity and ease of use.

Warning: The following sharpening procedure will provide high quality sharpening results

and should also be followed for safety considerations:

WarnIng: Keep away from the knife edge.

Completely close the slice adjustment (beyond '0") so that the knife edge is

not exposed.

The knife cutting area should be clean and free from food, especially

Grease will ruin the ability of a grinding stone to sharpen an edge. The stone

simply will not cut. If cleaning is necessary, follow the procedure outlined

Page 6.

grease.

on

Loosen sharpener knob assembly (Figure 8 [4]) which bears against sharpener

post, then lift sharpener assembly (Figure 1 [2]) and rotate it 1/2 turn (180°).

Then force it down over the knife.

Tighten sharpener knob assembly (Figure 8 [4]). As the knob assembly is

tightened, it bears on the sharpener post and automatically aligns the grinding

and deburring stones to the precise orientations which are preset at

factory.

Turn slicer

This will start the grinding process. Run until the beveled

our

cutting surface (back side of blade) cleans up. This can take from 30 seconds

to several minutes depending on how dull the blade was allowed to become.

Turn slicer OFF.

Check for the formation of a very slight burr on the side of knife opposite the

bevel (front side of blade) which indicates complete grinding of the bevel.

This slight burr can be detected either visually or by picking with a small

piece of stiff paper.

Turn slicer ON. Lightly press deburring (honing) button (Figure 8 [15]) of

the sharpener assembly and hold for 1 to 2 seconds while you turn OFF the

slicer. Blade should now be completely sharpened and honed.

Caution: It is important for best slicing results not to deburr the knife too

long or the keen edge will be destroyed due to the formation of

an undesirable second bevel on the opposite side. This

condition tends to be the primary cause of unsatisfactory slicing

results.

Turn slicer OFF. Loosen knob assembly, (Figure 8 [4]) then lift and return

sharpener to its storage position. Tighten knob assembly.

Clean slicer and knife according to the cleaning procedure on Page 6 in order

to thoroughly remove grinding debris.

Page 5

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 8

CLEANING

4509/451014512

OPERATORS CARE OF SLICER

Warning:

Warning:

Caution:

Warning

Warning:

Never touch the knife edge. Always keep your hands, fingers and

1.

arms clear of knife.

Turn off slicer and DISCONNECT ELECTRICAL CORD before

2.

cleaning. Leave protective guard (Fig. 1 [4]) in place,

Turn slice adjustment knob (Figure 1 [9]) to the fully closed position

3.

(beyond "O") so that the knife edge is not exposed.

Remove carriage assembly (Figure 1 [5, 8, 11]) by loosening carriage

4.

knob (Figure 1 [7]) and lifting off. Carriage may be washed in a

sink. Use care in washing the sharply pointed prongs on the last slice

device, (Figure 1 [5]). Wash this area thoroughly. A small bristle

brush is recommended. Use only warm water and mild soap. Rinse

carriage assembly with warm water and dry thoroughly using a clean

soft cloth.

Never use detergents or wash the slicer or any of its parts in a dish

washing machine or the clear protective finish will be damaged.

Wash body of slicer using warm water and mild soap using a clean

5.

soft cloth. Under no circumstances should the slicer be hose rinsed.

It is recommended that the cloth be folded over a thin wooden stick

when cleaning between the fence and the knife.

Remove knife guard (Figure 1 [3]) by loosening knife guard knob

(Figure 3 [11]) and pushing the long stud upward to lift knife guard

above surface of knife. Then carefully lift and remove guard.

Remove knife deflector (Fig. 3 [6]) by unscrewing screw (Fig. 3 [7]).

8. CAREFULLY wash the front and rear of the knife with a cloth using

warm water and mild soap.

It is recommended that the cloth be

folded over a thin wooden stick as a further caution to avoid

accidental contact with the knife edge. CAREFULLY wash between

the knife edge and protective guard (Figure 1 [4]) using a soft cloth

inserted between knife edge and guard on both front and rear of knife

using extreme caution to never touch the knife edge. Rinse with

warm water applied with a cloth. Dry thoroughly with a clean soft

cloth.

Caution:

Following cleaning, a commercial nontoxic sanitizer may be wiped on

9.

the clean surfaces with a soft clean cloth or sprayed as recommended

on the container labeling.

It is important that the sanitizer be

compatible with anodized aluminum or the clear protective finish on

the slicer will be damaged. Surface should be wetted completely, but

not to the point of running or puddling.

Replace the knife guard. Never leave the slicer without its knife

Warning:

10.

guard installed!

Replace knife deflector.

11.

Page 6

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 9

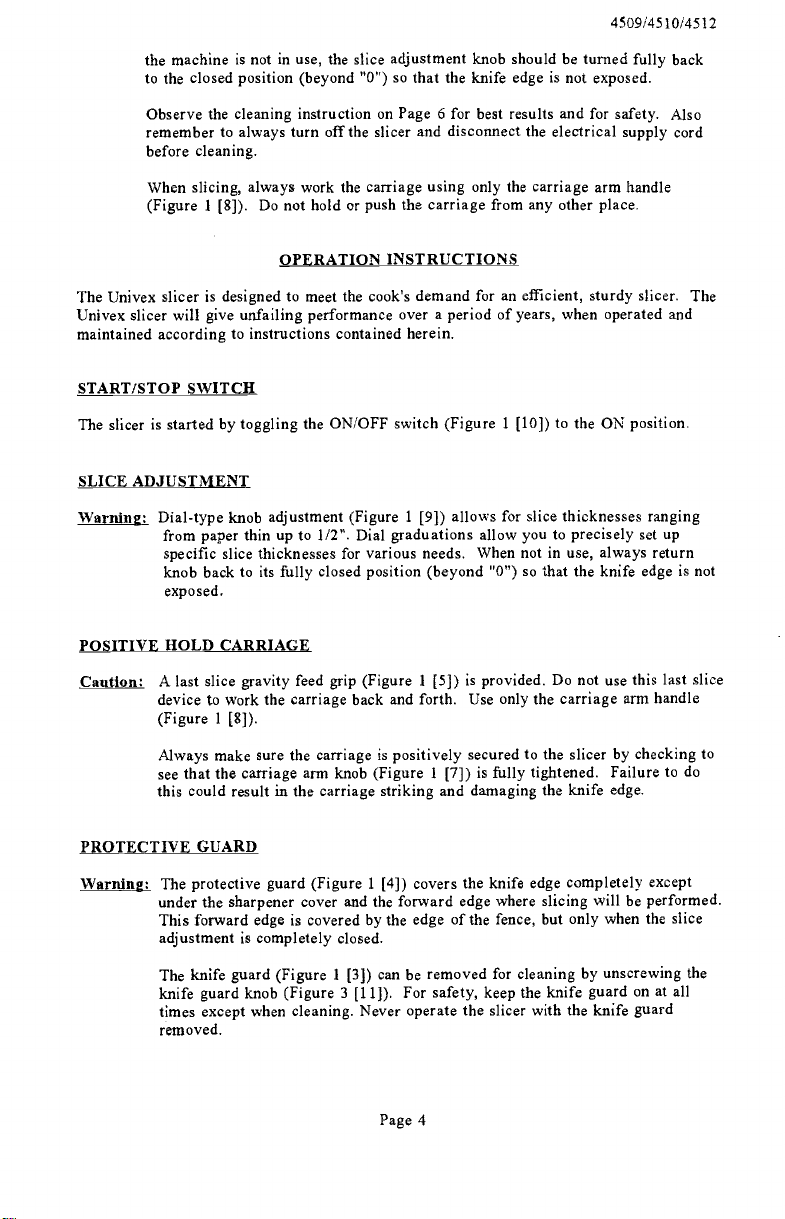

LUBRICATION & FUNCTION ChECK

4509/4510,4512

Warning:

Turn oft' slicer and DISCONNECT ELECTRICAL CORD before

lubricating. Leave protective guard (Fig. i [4]) in place.

General lubrication should be performed in accordance with the lubrication instructions in

Fig. 2. During this lubrication sequence, be sure to check for free operation and movement

of related parts as well as for excessive wear and looseness of various parts. Be sure to

check all handles and knobs for tightness.

LUBRICATION

FIGURE 2

A -Apply Petro-Gel (4400408) often as required to maintain light film.

B - Clean and apply mineral oil weekly

Page 7

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 10

450914510/4512

MECHANICS MAINTENANCE

Every year a mechanic or service technician should perform the following inspection and

carry out the respective maintenance as required:

Warning

FOR SAFETY, TURN OFF SLICER AND DISCONNECT ELECTRICAL

CORD.

BELT DRIVE This drive features a multi-ribbed high performance belt for

long trouble-free service. Inspect belt for proper tension.

If worn, replace. If

tension requires adjustment, it may be obtained by loosening nut (Fig. 7 [2))

and turning screw (Fig. 7 [3)) clockwise until desired tension is achieved.

Holding screw (Fig. 7 [3)) stationary, tighten nut (Fig. 7 [2]) against motor

casing.

CARRIAGE - Check for free smooth operation of last slice device and for

smooth travel of carriage arm (Fig. 4 [2)). Check for excess backlash between

slide bearing (Fig. 4 [10)) and carriage slide bar (Fig. 4 [8]). The correct lash

(clearance) required for smooth carriage operation is obtained when a very

slight lash or movement can be detected. Too much lash can result in the

carriage striking and damaging the knife edge. Too little lash results in

binding and a loss of smoothness in carriage travel. Lash is adjusted by

loosening locknut (Fig. 4 [14]) and turning set screw (Fig. 4 [15)) clockwise

to reduce lash and counterclockwise to increase lash, Tighten locknut while

holding nylon tipped stud stationary with a screwdriver so it does not move.

Grease only the side of the carriage slide (Fig. 4 [8]) on which this set screw

slides. General guidelines: tighten screw until snug and then loosen 1/8 turn

and tighten locknut as described above

LUBRICATION & FUNCTION CHECK - General lubrication should be

performed in accordance with the lubrication instructions in Fig. 2. During

this lubrication sequence, be sure to check for free operation and movement of

related parts as well as for excessive wear and looseness of various parts. Be

sure to check all handles and knobs for tightness.

KNIFE - Check knife edge to see that it has been properly sharpened. If there

is any evidence of incorrect sharpening procedure, such as excessive honing,

alert owner and operator.

Page 8

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 11

TROUBLESHOOTING GUIDE 4509/4510/4512

4509/4510,4512

TROUBLE

L Slicer will not

operate.

2. Motor straining

but will not turn

(humming sound).

3. Slippage of knife

during slicing.

4. Motor stalls

during slicing,

POSSIBLE CAUSE REMEDY

1.1 Electrical service

down.

1.1 Check electrical service.

Replace fuse or reset circuit

breaker as necessary.

1.2 Burned switch

contacts.

1.3 Motor capacitor

defective.

1.4 Burned out motor.

2.1 Belt tension too tight.

1.2 Replace switch.

1.3 Replace

1,4 Remove, test, repair or replace.

2.1 Readjust belt tension.

NOTE: Often after a long period

of no use, such as in storage, the

belt flows and takes a set in the

pulley ribs. A slight urging of the

knife with a wooden stick will

get the slicer turning with no

further problems. Do not use

hands to turn the knife.

3.1 Loose belt.

3.2 Grease or oil on belt.

3.1 Tighten belt tension.

3.2 Clean pulleys with safety

approved cleaning solvent on

soft clean rag. Replace belt.

4.1 Knife cutting edge dull

or improperly

sharpened

4.2 Product such as cheese

old and dried out.

4.3 Low voltage service

4.4 Belt tension excessive.

4.1 Sharpen using the procedure

specified. Use care not to use

honing stone longer than the 1

to 2 seconds.

4.2 Reduce thickness of slice.

4,3 Have electrician check service

voltage.

4.4 Readjust belt tension.

5. Excessive noise.

6. Smearing or

tearing when

slicing soft

cheese.

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

5.1 Knife contacting the

knife guard.

5.2 Badly worn or frayed

drive belt.

5.3 Motor pulley and belt

misaligned.

5.4 Loose set screw in

motor pulley.

5.5 Knife contacting

deflector.

5.6 Knife contacting

sharpener.

5.7 Carriage contacting

fence or knife.

6.1 Soft cheese is at room

temperature.

6.2 Knife dirty with hard

dried-on product.

Page 9

5.1 Tighten knob which secures

guard.

5.2 Replace belt.

53. Realign motor pulley.

5.4 Tighten set screw.

5.5 Adjust deflector.

5.6 Adjust sharpener.

5.7 Tighten knob which secures

carriage.

6.1 ChilI soft cheese for best slicing

results.

6.2 Clean knife thoroughly.

Page 12

Including disassembly, replacement, and reassembly.

REPAIR INSTRUCTiONS

4509/4510/4512

Warning: Always turn off slicer and disconnect electrical cord before doing any

maintenance or repair on the slicer. Keep guards on at all times. Keep slice

adjustment fully closed so knife edge is not exposed. Keep sharpener assembly

also in place so top of knife edge is not exposed.

KNIFE REPLACEMENT (Figure 3)

Warning: Disconnect electrical power cord.

Remove carriage assembly (Figure 1 [8, 11])

Loosen sharpener knob assembly (Figure 8 [4] ), then lift and remove sharpening

unit.

Set aside.

Remove knife guard knob (Figure 3 [11]) and carefully remove knife guard

(Figure 3 [21] ).

Warning: Using caution to avoid the sharp knife edge, remove the three screws

(Figure 3 [20] ) that secure knife (Figure 3 [23] ).

Carefully remove knife and set aside with its flat side down flush on a bench so

the edge is not exposed.

Reinstall new knife in the reverse procedures outlined above.

Even though a new knife is very sharp, the sharpening procedure specified on

page 5 should be performed to true the new knife's bevel to the slicer.

Warning: Worn knife should be disposed of in a safe responsible way, showing concern

for others who may handle it.

It is recommended that the edge of the knife be

wrapped several times with heavy tape and that a caution (CAUTION: SHARP

EDGE) be written on both sides of the knife.

SHARPENING STONES

Warning: Disconnect electrical cord.

Unscrew sharpener knob assembly (Figure 8 [4] ).

Lift up sharpening assembly (Figure 1 [2] ) and remove from slicer.

Using an open end wrench, unscrew cover knob (Figure 8 [8]).

It is

recommended that a piece of tape or paper be temporarily wrapped around knob

prior to unscrewing it so as to protect its finish. Remove cover (Figure 8 [9]) off

of mount assembly.

Unscrew nut (Figure 8 [21] ) and remove along with washer and sharpening

stone (Figure 8 [23] ).

Install new sharpening stone. Hollowed side should be toward the outside.

Page 10

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 13

4509/4510,4512

Honing (deburring) stone (Figure 8 [18)

screw (Figure 8 [14] ) from button (Figure 8

Gently remove button taking care to not lose the

(Figure 8 [16 & 17] ) which are inside.

Unscrew nut (Figure 8 [13] ) and

(Figure 8 [18] ).

Install new honing stone with the hollowed side

Reattach cover and reinstall in the reverse procedures

DRIVE BELT REPLACEMENT

WarnIng: Disconnect electrical power cord.

Remove knife per knife replacement instructions.

Remove four rubber suction feet (Figure 3 [4]

3 [29] ) to slicer. Remove cover.

Loosen nut (Figure 7 [2) ) on motor adjustment

motor adjustment screw

Loosen set screws (Figure 7 [15 & 17]). Slide

the right (towards the blade) until left end of rod

) is removed by first unscrewing lock

El 5]).

small ball bearing and spring

remove along with washer and honing stone

toward the inside.

(4. through 1.).

) that secure bottom cover (Figure

screw (Figure 7 [1] ). Loosen

motor pivot rod (Figure 7 [16)) to

disengages with base casting.

Page 11

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 14

Pivot motor to unwrap belt from motor pulley shaft.

Remove drive belt through the knife pulley opening in base casting.

4509/4510,4512

Install replacement belt on knife pulley and on motor pulley shaft. DO

reinstall knife at this time.

Reinstall motor pivot rod. Tighten set screw (Figure 7 [15]).

Position the pivot rod collar (End of motor shaft should be 1/16

from base casting. If not slide motor along rod accordingly.) Tighten

- 1/8" away

screw (Figure 7 [17]),.

Align belt on motor shaft and knife pulley.

Tighten motor adjustment screw (Figure 7 [3]) until adequate belt

acquired. DO NOT over tighten. Tighten jam nut (Figure 7 [2]).

Connect electrical power cord and operate slicer to check that belt and

are running true.

tension is

Turn off slicer and disconnect electrical power cord.

Reinstall bottom cover and secure with the four suction feet.

Using caution, reinstall knife and secure wìth three

screws.

Reinstall knife guard and secure with knife guard knob.

Reinstall sharpener and secure with knob assembly.

NOT

collar set

pulley

Page 12

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 15

HOUSING. KNIFE & FENCE ASSEMBLY

FIGURE 3

4509/4510/4512

ILLUS.

1

PART NO.

4509020

4512020 BASE CASTING (4512)

2

4509021

4512021

3

4512032 PLUG (4512 ONLY)

4

6509093

5

4512031

6

4509022

4512022

7

6509024 SCREW

8

4509066

9

10

6509081

4509023

4510023

4512023

11

4509024

4512024

12

13

14

15

16

17

18

6509080

4509058

6509089

4509085

4509059

4509027

4509086

4509026

19

4509028

4510028

4512025

20

8512229

8512229

21

4509029

4510029

4512026

22

4509030

4512027

23

6509013

6510013

4512028

24

25

4512030

4512029

26 7510008

27

28

4509088

4509087

29 4509034

DESCRIPTION

QTY

BASE. CASTING (4509, 4510)

SUPPORT (4509, 4510)

SUPPORT (4512)

FOOT

SHIELD (4512 ONLY)

DEFLECTOR (4509, 4510)

DEFLECTOR (4512)

WASHER

NUT, ACORN

FENCE, 9 IN.

FENCE, 10 IN.

FENCE, 12 IN.

KNOB, KNIFE GUARD (4509, 4510)

KNOB, KNIFE GUARD (4512)

STUD

PIN (4509, 4510 ONLY)

SET SCREW, M6-1.0 X 14 CUP POINT

BLADE SUPPORT

RETAINING RING

BEARING

PULLEY

PULLEY ASSEMBLY (INCLUDES 15, 17, 18, 26, 28)

GUARD, PROTECTIVE, 9 IN.

GUARD, PROTECTIVE, 10 IN.

GUARD, PROTECTIVE, 12 IN.

SCREW, (4509,4510)

SCREW, (4512)

GUARD, KNIFE, 9 IN.

GUARD, KNIFE, 10 IN.

GUARD, KNIFE, 12 IN. 1

ROD, KNIFE GUARD (4509, 4510)

ROD, KNIFE GUARD (4512)

KNIFE, 9 IN. 1

KNIFE, IO IN.

KNIFE, 12 IN.

SPACER (4512 ONLY)

SCREW (4512 ONLY)

INSERT, PULLEY 1

BELT

SPACER, BEARING

COVER, BOTTOM

1

1

1

2

4

1

1

1

2

1

1

1

1

1

1

2

1

2

1

1

1

7

5

1

1

1

1

1

2

2

1

Page 13

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 16

450914510,4512

HOUSING, KNIFE & FENCE ASSEMBLY

FIGURE 3

Page 14

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 17

4509/4510/4512

CARRIAGE A1M ASSEMBLY

ILLUS.

PART NO. DESCRIPTION QTY

6509017

1

2 4509053 ARM, CARRIAGE 4509

KNOB, CARRIAGE ARM

4510053 ARM, CARRIAGE 4510

4512033

6509080 SCREW, ARM ATTACHMENT

3

7510035 SCREW

4

4509065 SPRING

5

4509054

6

7 4509089 SPACER

4509055

8

1204004

9

10 4509069 BEARING

11

12

13

14

15

16

17

1200076 WASHER

4509056

4509057 BUSHING

6509074 NUT

6509073

8512308

6509054

ARM. CARRIAGE 4512

ROD, ARM

BAR, FRAME

SCREW, M5-0,8 X 16

BUSHING, ARM

SET SCREW

SCREW, HX HD M8-1.25 X 28

HANDLE

FIGURE 4

I

1

1

4

3

1

2

1

1

2

5

1

2

1

1

1

1

Page 15

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 18

CARRIAGE ASSEMBLY

FIGURE 5

4509/4510,4512

ILLUS.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

PART NO.

4400410

4512046

8512439

6509059

4509048

6512035

4509063

6509160

4509051

4512034

4509075

4512035

6509153

4509052

6509049

6509080

4512036

7120129

4512037

4512038

4512051

4512052

4512953

4512054

DESCRIPTION

NUT, M8 (4509,4510)

NUT, MiO (4512)

RESERVED

WASHER (4509, 4510)

WASHER (4512)

CARRIAGE (4509, 4510)

CARRIAGE (4512)

NYLON TIP (4509, 4510)

NYLON TIP (4512)

LAST SLICE DEVICE (4509, 4510)

LAST SLICE DEVICE (4512)

HANDLE (4509, 4510)

HANDLE (4512)

KNOB (4512 ONLY)

SHAFT, LAST SLICE DEVICE (4509, 4510)

SHAFT, LAST SLICE DEVICE (4512)

STUD, M8-L25 X 30 (MODIFIED) (4509, 4510)

STUD (4512)

STUD, M6-1.0 X20 (4509, 4510)

STUD, (4512)

SCREW, M6-1.0 X 12 (4512 only)

CAM STOP (4512 only)

SCREW FLAT HD SS M6 X 1MM (4512 ONLY)

SLEEVE PLASTIC (4512 ONLY)

PIN (4512 ONLY)

QTY

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

2

1

Page 16

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 19

4509/4510/4512

ILLUS.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

PART NO.

4509090

6509059

4509044

4509045

1204001

6509074

1204043

4509046

1204005

6509040

4509061

7510021

6509072

4400116

6509098

4512042

6509061

4509068

4509070

4509062

4509047

4512039

6509041

4512041

4512040

SLICE ADJUSTMENT KNOB ASSEMBLY

FIGURE 6

DESCRIPTION

KNOB, SLICE ADJ

WASHER, SLICE ADJ

SPRING, SLICE ADJ

GUIDE

SCREW SOC HD CAP M6-l.0 X 12

NUT, M6-1.0

STUD, M6-1.0 X 11

SHAFT

SCREW, SOC HD CAP M6-1.0 X 20

SCREW, M6-1.0 X 30

STUD (4509, 4510 ONLY)

WASHER (4509, 4510 ONLY)

NUT, M8-1.25 (4509, 4510 ONLY)

ROLLPIN (4509, 4510 ONLY)

SET SCREW

SCREW M6-1.0 X 8 NYLON SLOTTED SS FLAT PT

(4512 ONLY)

SPRING

WASHER

CAM

PIN (4509, 4510 ONLY)

SUPPORT, FENCE HOLDER (4509, 4510)

SUPPORT, FENCE HOLDER (4512)

WASHER

STUD, (4512 ONLY)

PIN (4512 ONLY)

QTY

I

1

1

3

2

I

1

I

3

1

1

1

1

2

1

1

1

1

1

1

1

1

1

1

REPLACES

LLUS. 20

FOR 4512 ONLY

Page 17

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 20

4509/4310,4512

MOTOR & ELECTRICAL ASSEMBLY

ILLUS.

PART NO.

1 4509073

4512043

4509077

4509078

2 6509115

DESCRIPTION QTY

MOTOR, 115V, 60HZ, 1PH (4509, 4510)

MOTOR, 115V, 60HZ, 1PH (4512)

MOTOR, 230V, 60HZ, IPH (4509, 4510)

MOTOR, 230V, 50HZ, 1PH (4509, 4510)

NUT, M5-0.8 (4509, 4510)

6509074 NUT, (4512)

3

1204002

4512044

4 4509041 CLAMP, CAPACITOR

5

1204042 STUD, M6-1.0 X 30, CAPACITOR BRACKET

6

6509074

7

4509072

SCREW, SLOT PAN HD M5-0.8 X 45(4509, 4510)

SCREW, M6-1.0 X 70 (4512)

NUT, M6-1,0 4

CAPACITOR 115V/60/1

4509076 CAPACITOR 220V/50-60/1

8 1204020 LOCK WASHER, M6

9

10 7120009 SWITCH

11

12

13 4400053

14

15

4509074 WIRE, MOTOR GROUND

7129011 GUARD, SWITCH

4400081

PIN, SWITCH GUARD 2

CORD, POWER

8800210

CORD, POWER

1012042 STAIN RELIEF

6509089 SET SCREW

16

4509060

17

6509098

18 4509091 COLLAR

ROD, MOTOR

SET ,SCREW

CANADA ONLY

19

20

4400237

4400227 LABEL, RESET (NOT SHOWN)

CIRCUIT BREAKER (NOT SHOWN)

FIGURE 7

1

1

1

1

1

1

1

I

2

2

1

1

1

1

1

1

1

2

2

Page 18

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 21

SHARPENER ASSEMBLY

FIGURE 8

4509/4510/4512

ILLUS. NO. PART NO.

1

2 6509041

3

4

5

6

7

8 4509036

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

4509065

8512852

4509035

6509124

6509125

6509137

4509037

6509150

4509038

6509132

6509131

6509136

6509135

6509133

6509134

4509092

6509129

6509128

6509143

8512516

4509093

4509039

6509127

6509147

6509126

4509040

4510040

4512045

29

4509066

DESCRIPTION

STUD, SHARPENER SUPPORT

WASHER

NUT, ACORN

KNOB, ASSEMBLY

PIN, SET

WASHER, PIN, SET

SCREW

KNOB

COVER

NUT

SPACER

WASHER

NUT

SCREW

BUTTON, STONE DEPRESS

BALL

SPRING

STONE, HONING

STUD, HONING

BUSHING

NUT

WASHER

STONE, SHARPENING

STUD, SHARPENING

SPRING

STUD MOUNTING

MOUNT

SUPPORT, SHARPENER 4509 1

SUPPORT, SHARPENER 4510

SUPPORT, SHARPENER 4512 1

WASHER

QTY

1

1

1

1

1

i

2

1

1

1

1

1

1

1

1

1

1

1

1

I

1

1

2

1

1

1

Page 19

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

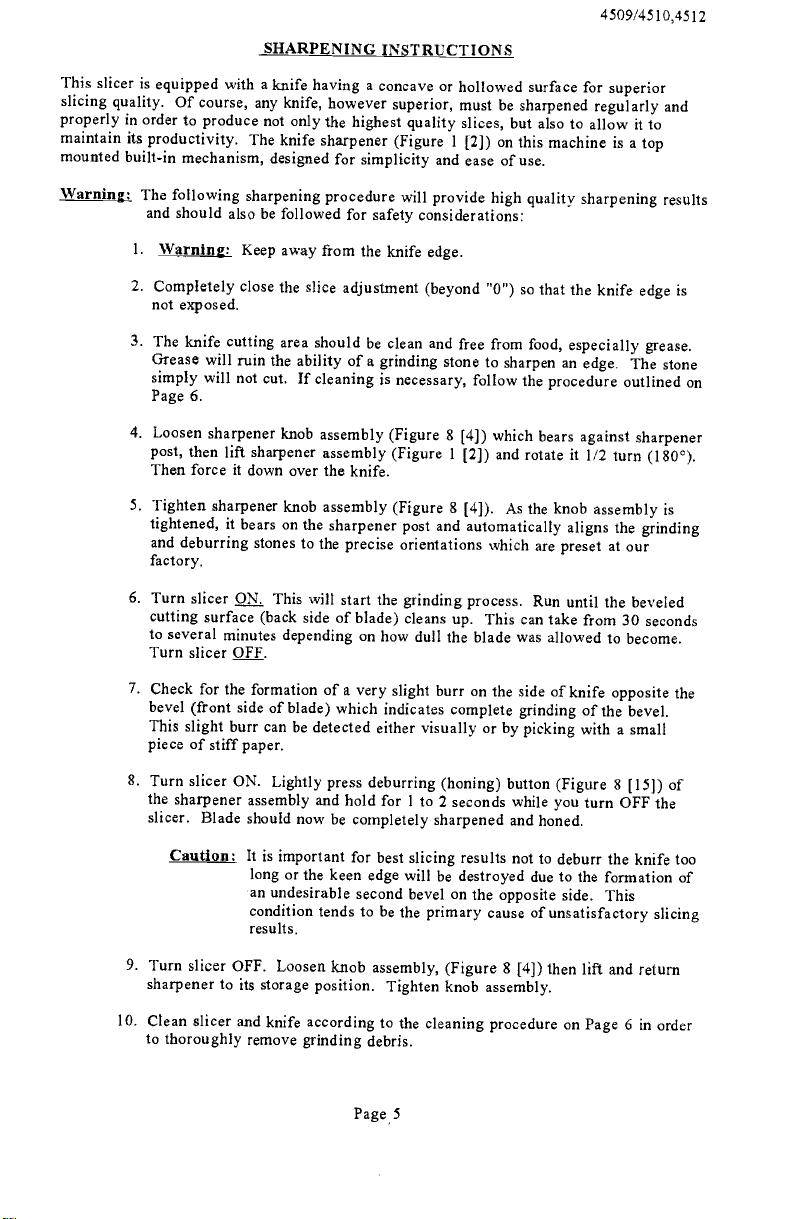

Page 22

450914510,4512

WIRING DIAGRAM MODEL 4509/4510/4512

POWER IN

/ CAPACITOR

BLACKE T-

115V, 60HZ, 1PH

23QV, 60HZ, 1PH

230V, 50HZ, 1PH

SWITCH

FIGURE 9

-1

BLACK

WHITE

OHO

WHITE

POWER IN

/

WHITE

GREEN

i

\

ÇT1

WHITE

L J

GREEN

o

CANADA ONLY

115V, 60HZ, 1PH

SWITCH

o

BLACK

BLACK

CIRCUI T

BREAKET

2

WHITE

BLACK

GREEN/YELLOW

CAPACI TOR

WHITE

MOTOR

GREEN/YELLOw

IMPORTANT

Warning: Before making electrical connections, check the specifications on the data plate

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

to assure they agree with those of your electrical service.

Whenever cleaning or maintenance is being performed, DISCONNECT

electrical cord.

Page 20

Loading...

Loading...