Page 1

State – Premier

®

Hybrid Electric

Heat Pump Water Heater

Installation

Instructions and

Use & Care Guide

To obtain technical, warranty or service assistance during or after

the installation of this water heater, call toll free

1-800-365-0024

When calling for assistance, please have the following

information ready:

1. Model number

2. 7 Digit product number

3. Serial number

4. Date of installation

5. Place of Purchase

Table of Contents Page

Water Heater Safety ............................................................................... 2

Installing Your Water Heater .................................................................3-9

Consumer Information ................................................................ 3

Consumer Responsibilities ......................................................... 3

Unpacking Instructions ............................................................3-4

Location Requirements ............................................................... 4

Water System Piping ................................................................ 5-6

Temperature & Pressure Relief Valve .......................................7-8

Electrical Requirements ...........................................................8-9

Installation Checklist .............................................................................. 10

Operating Your Water Heater ........................................................... 11-13

Before Using ............................................................................. 11

Water Temperature Regulation ................................................. 11

Adjusting the User Interface Module/ Operational Mode .......... 12

Operational Conditions ............................................................. 13

Maintenance of Your Water Heater ..................................................14-15

Temperature and Pressure Relief Valve .................................... 14

Draining and Flushing ................................................................ 14

Heating Element Replacement ............................................. 14-15

Cleaning the Heat Pump ........................................................... 15

Diagnostic Codes ..................................................................................16

Troubleshooting Chart ........................................................................... 17

Repair Parts Illustration ......................................................................... 18

Notes... .............................................................................................. 19-20

318258-000

February 2010

1

Page 2

WATER HEATER SAFETY

Your safety and the safety of others are very important.

We have provided many important safety messages in this manual and on your appliance. Always read and obey all

safety messages.

This is the safety alert symbol.

This symbol alerts you to potential hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol and either the word “DANGER” or

“WARNING.” These words mean:

You can be killed or seriously injured if you don’t

immediately follow instructions.

You can be killed or seriously injured if you don’t

follow instructions.

All safety messages will tell you what the potential hazard is, tell you how to reduce the chance of injury, and tell you

what can happen if the instructions are not followed.

Important Safety Instructions

CAUTION: Hydrogen gas is produced in a hot water system served by this heater that has not been used for a long

period of time (2 weeks or more). Hydrogen gas is extremely fl ammable. To reduce the risk of injury under these

conditions, it is recommended that the hot water faucet be opened for several minutes at the kitchen sink before

using any electrical appliance connected to the hot water system. When hydrogen is present, there will probably be

an unusual sound such as air escaping through the pipe as the water begins to fl ow. There should be no smoking or

open fl ame near the faucet at the time it is open.

The California Safe Drinking Water and Toxic Enforcement Act requires the Governor of California to publish a list of

substances known to the State of California to cause cancer, birth defects, or other reproductive harm, and requires

businesses to warn of potential exposure to such substances.

WARNING: This product contains a chemical known to the State of California to cause cancer, birth defects, or other

reproductive harm.

This appliance can cause low-level exposure to some of the substances included in the Act.

IMPORTANT: The heat pump portion of this water heater uses R-134a refrigerant. See the data plate on the heat pump

compressor for charge level.

2

Page 3

INSTALLING YOUR WATER HEATER

Consumer Information

This water heater should be installed in accordance with

the local code authority having jurisdiction, the power

company or electric utility, and this installation manual.

In the absence of local code requirements, follow the

regulations set forth in the latest edition of The National

Electric Code, NFPA 70. This is available from the

following:

National Fire Protection Association

1 Batterymarch Park

Quincy, MA 02269

American National Standards Institute

1430 Broadway

New York, NY 10018

Check your phone listings for the local authorities having

jurisdiction over your installation.

Consumer Responsibilities

This manual has been prepared to acquaint you with the

installation, operation and maintenance of your electric heat

pump water heater and to provide important safety information

in these areas.

We urge you to read all of the instructions thoroughly before

attempting the installation or operation of this water heater.

This manual should be kept for future reference.

The manufacturer of this water heater will not be liable for any

damages caused by failure to comply with the installation and

operating instructions outlined in this manual.

If you lack the necessary skills required to properly install this

water heater or you have diffi culty following the directions, you

should not proceed but have a qualifi ed person perform the

installation of this water heater.

Examples of a qualified person include: licensed plumbers,

authorized electric company personnel, and authorized

service personnel.

Massachusetts code requires this water heater to be installed

in accordance with Massachusetts 248-CMR 2.00: State

Plumbing Code and 248-CMR 5.00.

A data plate identifying your water heater can be found

adjacent to the upper element door. When referring to your

water heater always have the information listed on the data

plate readily available, to include the model and serial number.

Retain your original receipt as proof of purchase.

the water while the electric elements only function during

high demand periods. (See “Adjusting the User Interface

Module/ Operational Mode” section). The more often

the unit operates using the heat pump, rather than the

elements, the more effi cient the unit will be.

The 80-gallon tank capacity of this water heater is intended

to take optimal advantage of the heat pump’s capability to

heat water for large families or those having higher than

normal hot water requirements. This high capacity will

enable the unit to operate in the maximum effi ciency mode

more often than other models having lower capacity.

The HPWH uses about half the electricity of a comparably

sized conventional electric water heater when operating

in the Effi ciency Mode, and provides up to ½ ton cooling

capacity and dehumidifi cation. It is designed for indoor,

residential applications for installation in a basement,

garage or utility room (See “Location Requirements”

section).

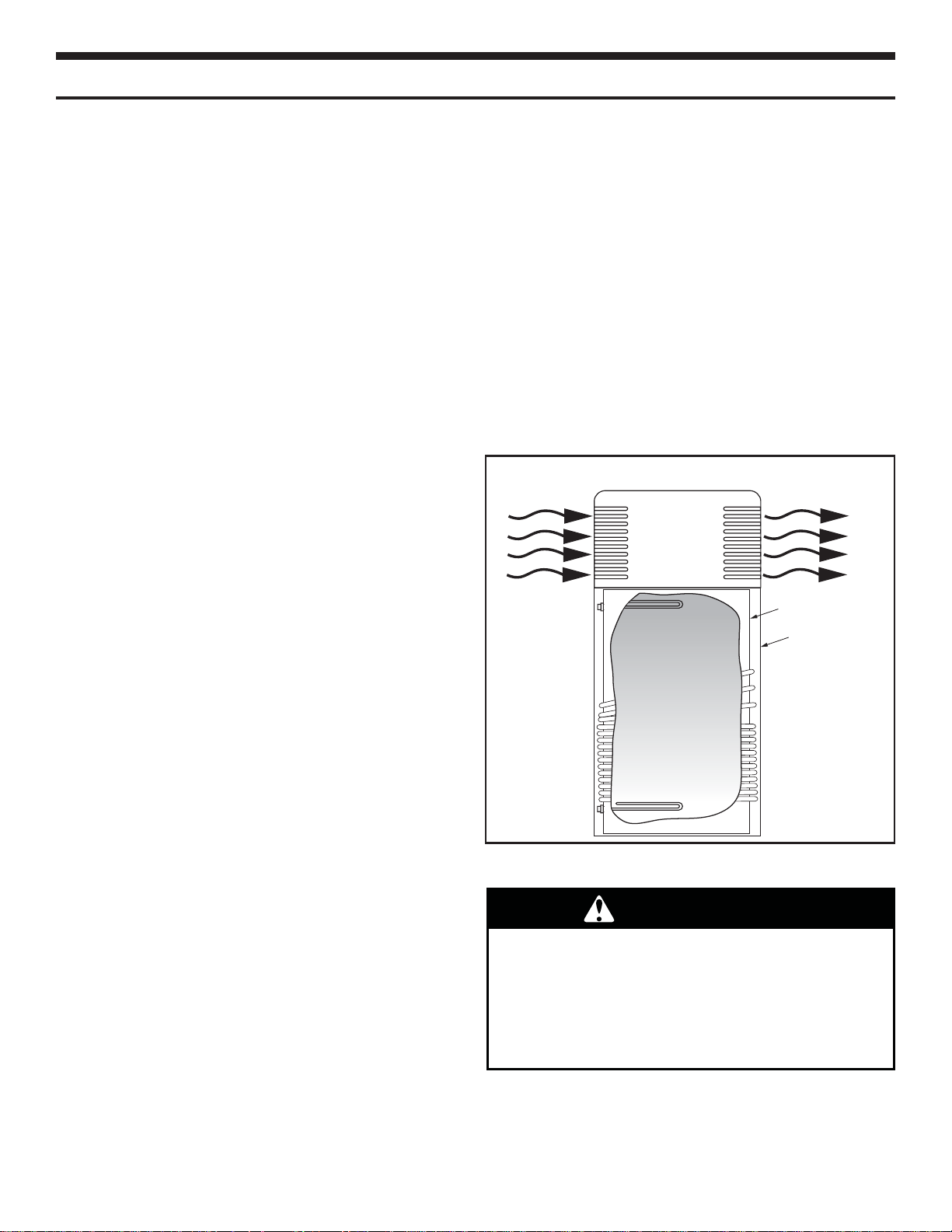

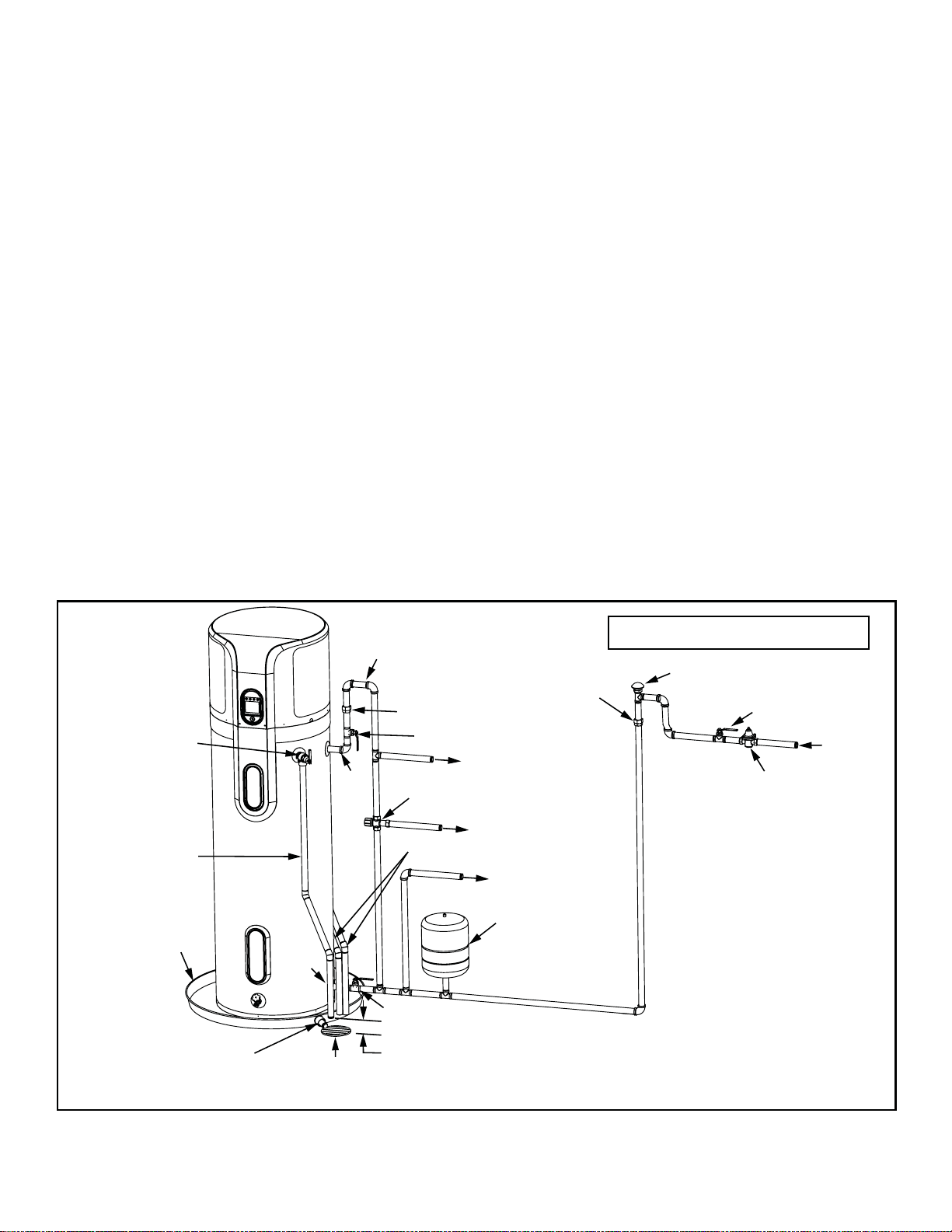

Figure 1

Heat Pump Water Heater Basic Operation

Ambient Air

Heat Pump

(Transfers heat

from ambient

air to Heat

Exchanger)

Upper Element

(4500 Watt)

Lower Element

(2000 Watt)

Unpacking the Water Heater

WARNING

Excessive Weight Hazard

Cool/Dehumidified Air

Water Tank

Jacket

Heat Exchanger

(Heat Transfer Coils)

Basic Operation Fundamentals

The Heat Pump Water Heater (HPWH) is an integrated

heat pump water heater unit, having an 850 watt

compressor and external coil heat exchanger with backup

electric elements (See Figure 1). When in Effi ciency Mode

the heat pump draws heat from the ambient air in the room

and transfers it to the water in the tank through the coil

heat exchanger. While in Electric Mode the water heater

functions like a standard electric water heater, relying on

the electric elements to heat the water. A Hybrid Mode is

available that relies primarily on the heat pump to heat

Use two or more people to move and install

water heater.

Failure to do so can result in back or

other injury.

Removing Packaging Materials

IMPORTANT: Do not remove, cover or deface any

permanent instructions, labels, or the data label from either

the outside of the water heater or on the inside of water

heater panels.

3

Page 4

The water heater must NOT be placed on its side. It •

should be transported and stored in an upright position.

Remove exterior packaging and place installation •

components aside.

Inspect all parts for damage prior to installation and •

start-up.

Completely read all instructions before attempting to •

assemble and install this product.

After installation, dispose of/recycle all packaging •

materials.

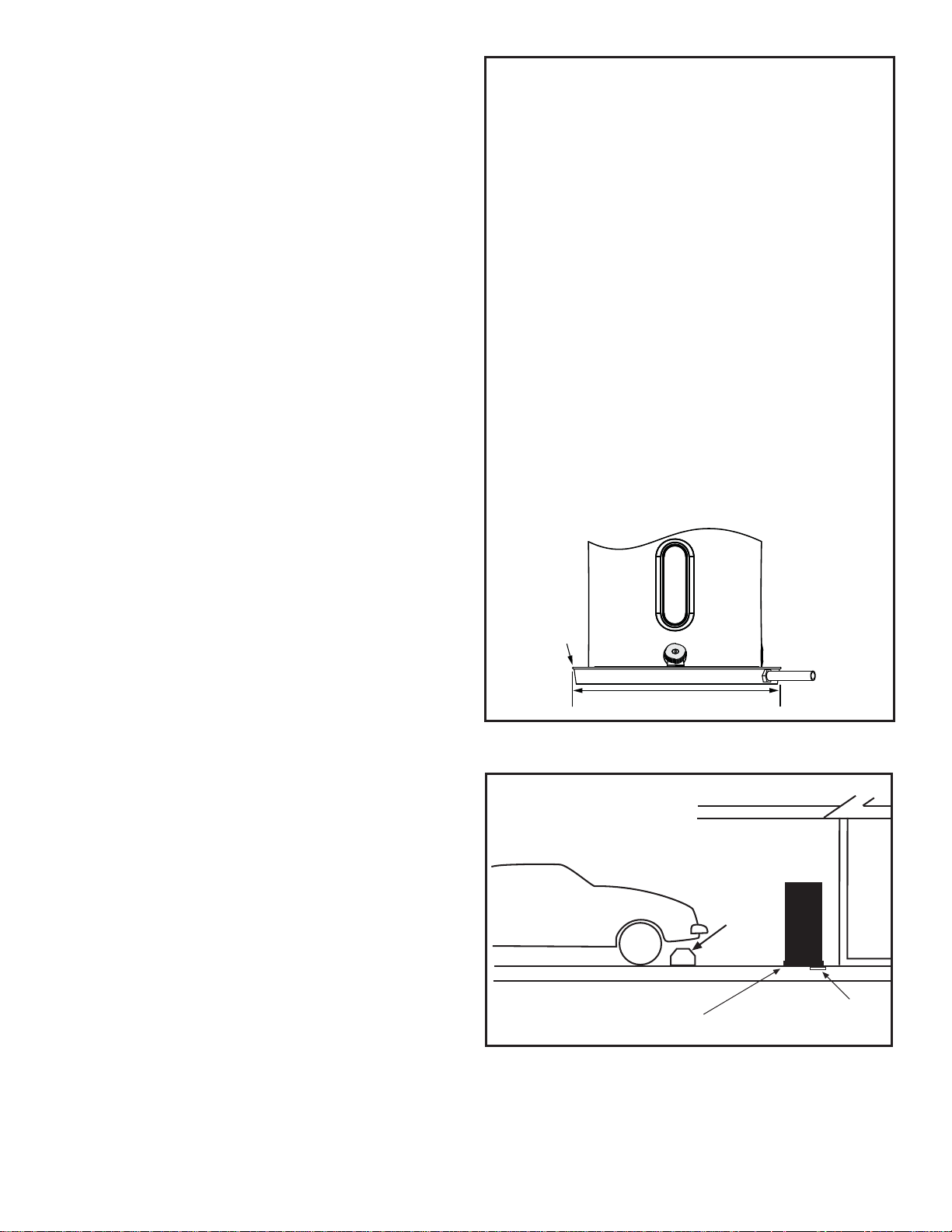

Location Requirements

Site location

Select a location near the center of the water piping system.

The unit must be installed indoors and in a vertical position

on a level surface. The fl ooring beneath the water heater

must be able to support the weight of the water heater when

fi lled with water (967 lbs. full).

IMPORTANT: The water heater must be located in a space

750 cubic feet or larger, and must have unrestricted airfl ow.

As an example, a room that has an 8 foot tall ceiling and is

10 feet long by 9-1/2 feet wide would contain 760 cubic feet.

NOTE: For optimal effi ciency and serviceability, the

following clearances should be maintained: 3 feet on the air

inlet side, 5 feet. on the air outlet side, 6 inches in the back,

and 2 feet in the front.

The water heater should be located in an area not

subject to freezing temperatures. Water heaters located

in unconditioned spaces (i.e., garages, basements, etc.)

may require the water piping, condensate piping, and drain

piping to be insulated to shelter against freezing. The drain

and controls must be easily accessible for operation and

service.

The site location must be free from any corrosive elements

in the atmosphere such as sulfur, fl uorine, and chlorine.

These elements are found in aerosol sprays, detergents,

bleaches, cleaning solvents, air fresheners, paint, and

varnish removers, refrigerants, and many other commercial

and household products. In addition, excessive dust and

lint may affect the operation of the unit (See “Cleaning the

Filter” section).

The ambient air temperature must also be considered

when installing this unit. In Effi ciency Mode the ambient air

temperature must be above 45°F and below 109°F. If the

ambient air temperature falls outside these upper and lower

limits the electrical elements will activate to meet the hot

water demand and the heat pump does not operate.

IMPORTANT: The water heater should be located in an

area where leakage of the tank, connections, condensate

lines or condensate will not result in damage to the area

adjacent to the water heater or to lower floors of the

structure. Due to the normal corrosive action of the water,

the tank will eventually leak after an extended period of

time. Also, any external plumbing leak, including those

from improper installation, may cause early failure of the

tank due to corrosion if not repaired. If the homeowner is

uncomfortable with making the repair a qualified person

should be contacted. A suitable metal drain pan should be

installed under the water heater as shown below, to help

protect the property from damage which may occur from

condensate formation or leaks in the piping connections

or tank.

The pan must limit the water level to a maximum

depth of 2-1/2 inches and be two inches wider than the

heater and piped to an adequate drain. Locate the water

heater near a suitable indoor drain. Outside drains are

subject to freezing temperatures which can obstruct

the drain line. The piping should be at least 3/4” ID and

sloped for proper drainage. Under no circumstance will the

manufacturer or seller of this water heater be held liable

for any water damage which is caused by your failure to

follow these instructions.

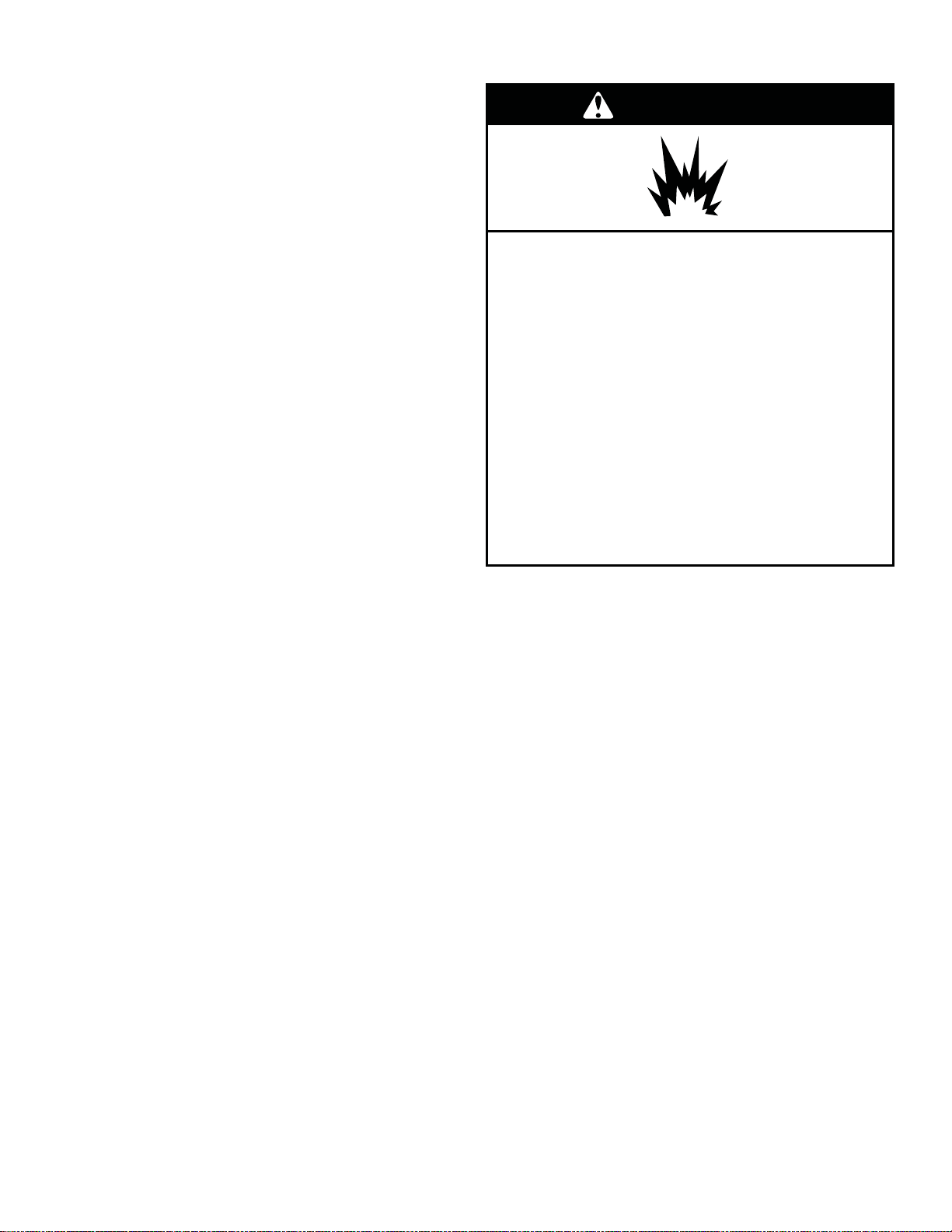

Figure 2

Metal Drain Pan

Installation

METAL

DRAIN

PAN

AT LEAST 2” GREATER THAN THE

DIAMETER OF THE WATER HEATER.

PIPED TO AN

ADEQUATE DRAIN

NOTE: The water heater shall be located so it is not subject

to physical damage by moving vehicles or area fl ooding.

Figure 3

Residential Garage

Installation

Vehicle

Stop

NOTE: Local codes and requirements in your area may

require the installation of your water heater be accomplished

in a way that the bottom element is elevated from the

fl oor at least 18 inches. Ensure that a platform capable of

supporting the combined weight of the water heater and

water (967-pounds) is used.

4

Drain

Pan

Drain

State of California

NOTE: The water heater must be braced, anchored, or

strapped to avoid moving during an earthquake. Contact

local utilities for code requirements in your area, visit

http://www.dsa.dgs.ca.gov, or call 1-916-445-8100 and

request instructions.

Page 5

Water System Piping

Piping, fi ttings, and valves should be installed according to

the installation drawing (Figure 4). If the indoor installation

area is subject to freezing temperatures, the water piping

must be properly insulated.

Water supply pressure should be 50-60 PSIG and not

exceed the maximum 80 PSIG. If the supply line pressure

exceeds 80 PSIG, a pressure reducing valve (PRV) with

a bypass should be installed in the cold water supply line.

This should be placed on the supply to the entire house in

order to maintain equal hot and cold water pressures.

IMPORTANT:

•

Heat must not be applied to the water fittings on

the heater as they may contain nonmetallic parts. If

solder connections are used, solder the pipe to the

adapter before attaching the adapter to the hot and

cold water fittings.

• Always use a good grade of joint compound and be

certain that all fittings are tight.

IMPORTANT: DO NOT over apply joint compound.

Piping Installation

Install the water piping and fittings as shown in Figure 1.

4. Connect the cold water supply (3/4” NPT) to the

fitting marked “Cold”. Connect the hot water supply

(3/4” NPT) to the fitting marked “Hot”.

The installation of unions in both the hot and cold 2.

water supply lines are recommended for ease of

removing the water heater for service or replacement.

Figure 4

Water Piping Installation

with Mixing Valve

Temperature and

Pressure Relief Valve

Discharge Pipe

(Do Not Cap or Plug)

Heat Trap - The top of the heat trap

must be higher than the storage tank

of the water heater.

Union

Shut-off Valve (Hot)

Hot

(Outlet)

Mixing Valve (Optional) - Follow the

Mixing Valve’s Manufacturer’s Installation

Instructions. (Set to 120° F)

Condensate Drain Lines*

Some local codes may require, and the manufacturer 3.

of this water heater recommends, installing a mixing

valve or an anti-scald device in the domestic hot water

line as shown in Figure 4. These valves reduce the

point-of-use temperature of the hot water by mixing

cold and hot water and are readily available. Contact

a licensed plumber or the local plumbing authority for

more information.

Some local codes may require, and the manufacturer 4.

of this water heater recommends, installing a pressure

reducing valve (PRV) in the cold water inlet line where

it enters the residence as shown in Figure 4.

If installing the water heater in a closed water system, 5.

install an expansion tank in the cold water line as

specified under “Closed System/Thermal Expansion.”

Install a shut off valve in the cold water inlet line. It 6.

should be located close to the water heater and be

easily accessible. Know the location of this valve and

how to shut off the water to the heater.

Install a discharge line from the temperature and 7.

pressure relief valve in the opening marked “T & P

RELIEF VALVE”. See Figure 5 and the “Temperature

and Pressure Relief Valve” section.)

After piping has been properly connected to the water 8.

heater, open the nearest hot water faucet. Then open

the cold water shut off valve and allow the tank to

completely fill with water. To purge the lines of any

excess air and sediment, keep the hot water faucet

open for 3 minutes after a constant flow of water is

obtained. Close the faucet and check all connections

for leaks.

Union

Untempered Water Outlet

Tempered Water to Fixtures

Massachusetts: Install a vacuum relief in cold

water line per section 19 MGL 142.

Vacuum Relief Valve

Cold Water

Inlet Valve

Cold Water

Inlet

Whole House Pressure Reducing

Valve (PRV) should be installed

where the water supply enters

the residence.

Cold Water Outlet

Metal Drain Pan 2 1/2”

Depth Maximum and

2 Inches wider than

the water heater.

Drain Line 3/4”

ID Minimum

* If an adequate drain is not available for the condensate drain lines then a condensate pump should be used. DO NOT discharge the condensate drain

lines into the metal drain pan.

Cold

(Inlet)

Drain

Shut-off Valve

(Cold)

6” Maximum

Air Gap

In a closed system, use a

thermal expansion tank.

See “Closed System/

Thermal Expansion”

section.

5

Page 6

Please note the following:

• The system should be installed only with piping that is

suitable for potable (drinkable) water such as copper,

CPVC, or polybutylene. This water heater must not be

installed using iron piping or PVC water piping.

• Use only pumps, valves, or fittings that are compatible

with potable water.

• Use only full flow ball or gate valves. The use of valves

that may cause excessive restriction to water flow is

not recommended.

• Use only 95/5 tin-antimony or other equivalent solder.

Any lead based solder must not be used.

• Piping that has been treated with chromates, boiler

seal, or other chemicals must not be used.

• Chemicals that may contaminate the potable water

supply must not be added to the piping system.

Condensate Drain Line Installation

Install two 1/2” PVC discharge lines from the condensate

drains (located on the right side near the back). The lines

should terminate a maximum of six inches above an

adequate drain. Do not discharge the condensate drain

lines into the metal drain pan. If no floor drain is available

or the drain is above the level of the condensate line, a

condensate pump should be installed. These pumps are

available from local distributors.

When installing the drain line, note the following:

Plastic pipe or tubing must be used to connect the •

condensate drain to a suitable drain or condensate

pump.

Condensate drain lines should be installed in •

conditioned areas only. Install approved insulation on

the condensate drain lines to prevent condensation

from forming on the outside of the drain lines.

Condensation drain lines installed in areas that are

subject to freezing temperatures should be wrapped

with a nationally recognized/listed heat tape. Install per

manufacturer’s instructions.

Do not connect condensate drain lines with other drain •

or discharge lines into a single (common) pipe or line.

Each line (condensate drain line, temperature and

pressure relief valve discharge pipe, etc) should be

independently run to an adequate drain.

Slope the condensate drain lines toward the inside •

floor drain or condensate pump.

The condensate drain lines and connections to the •

drain piping must comply with all local codes.

Use appropriate primer and glue to cement the •

condensate drain lines to the heat pump drain pan.

NOTE: The heat pump drain pan is ABS and the two

condensate drain pipes should be PVC.

If a condensate pump is installed it should shut off •

the heat pump in the event the condensate pump

fails or the float switch in the pump activates (See

“Condensate Pump Installation” section.)

Closed System/Thermal Expansion

WARNING

Explosion Hazard

If the temperature and pressure relief valve

is dripping or leaking, have a qualified

person replace it.

Examples of a qualified person include:

licensed plumbers, authorized electric

company personnel, and authorized service

personnel.

Do not plug valve.

Do not remove valve.

Failure to follow these instructions can

result in death or explosion.

Most public water systems in North America are required

to prevent water flowing from points of use (residences,

businesses, etc.) back into the supply system in order

to maintain water quality. To accomplish this, back flow

preventers such as check valves, are installed in the water

line going to each point of use. Typically the back flow

preventer will be installed at the water meter or inside a

building where the supply line enters the building. This

device allows water to flow into the residence but does

not allow it to flow back into the water supply. This creates

what is known as a “Closed System”. As water is heated

by the water heater, the water in the system attempts to

expand, but has nowhere to go resulting in an increase

in pressure. This increase in pressure in the system may

cause the temperature-pressure relief valve to open to

relieve the pressure. Water will drip from the temperature

and pressure relief valve. Premature tank failure will result

if this condition is not corrected. To prevent this condition, a

properly-sized thermal expansion tank should be installed

in the cold water supply to the water heater as shown in

Figure 4. Failure to install a properly sized expansion tank

in a closed system will void the warranty on the water

heater in the event of tank failure. It is important to follow

the thermal expansion tank manufacturers’ installation

instructions and to adjust the expansion tank pressure

to match the water supply pressure. Contact a plumbing

service agency or your retail supplier regarding the

installation of a thermal expansion tank.

6

Page 7

Temperature and Pressure

Relief Valve

WARNING

Explosion Hazard

If the temperature and pressure relief valve

is dripping or leaking, have a qualified

person replace it.

Examples of a qualified person include:

licensed plumbers, authorized electric

company personnel, and authorized service

personnel.

Do not plug valve.

Do not remove valve.

Failure to follow these instructions can

result in death or explosion.

Figure 5

Temperature and Pressure

Relief Valve Installation

Temperature and

Pressure Relief Valve

Discharge Pipe

(Do Not Plug or Cap)

Drain Pan 2 1/2”

Depth Maximum and

2 Inches wider than

the water heater.

Drain Line 3/4”

ID Minimum

For protection against excessive pressures and

temperatures, a temperature and pressure relief valve must

be installed in the opening marked “T & P RELIEF VALVE”

(See Figure 5).

Drain

6” Maximum

Air Gap

To reduce the risk of excessive pressures and temperatures

in this water heater, install temperature and pressure relief

protective equipment required by local codes, but no less

than a combination temperature and pressure relief valve

certifi ed by a nationally recognized testing laboratory that

maintains periodic inspection of the production of listed

equipment or materials, as meeting the requirements for

Relief Valves and Automatic Shutoff Devices for Hot Water

Supply Systems, ANSI Z21.22 - latest edition. This valve

must be marked with the maximum set pressure not to

exceed the marked maximum working pressure of the

water heater. Install the valve into an opening provided

and marked for this purpose in the water heater, and orient

it or provide tubing so that any discharge from the valve

exits only within 6 inches above drain, or at any distance

below, the structural fl oor, and does not contact any live

electrical part. The discharge opening must not be blocked

or reduced in size under any circumstance.

IMPORTANT: Only a new temperature and pressure relief

valve should be used with your water heater. Do not use an

old or existing valve as it may be damaged or not adequate

for the working pressure of the new water heater. Do not

place any valve between the relief valve and the tank.

The Temperature & Pressure Relief Valve:

• Shall not be in contact with any electrical part.

• Shall be connected to an adequate discharge line.

• Shall not be rated higher than the working pressure

shown on the data plate of the water heater.

The Discharge Line:

• Shall not be smaller than the pipe size of the relief

valve or have any reducing coupling installed in the

discharge line.

• Shall not be capped, blocked, plugged or contain

any valve between the relief valve and the end of the

discharge line.

• Shall terminate a maximum of six inches above a floor

drain or external to the building. In cold climates, it is

recommended that the discharge pipe be terminated at

an adequate drain inside the building.

• Shall be of material listed for hot water distribution.

• Shall be installed to allow complete drainage of both

the valve and discharge line.

Temperature/Pressure Relief Valve and

Pipe Insulation

Locate the temperature and pressure relief valve on the 1.

water heater (also known as a T&P relief valve). See

Figure 5.

Locate the slit running the length of the T&P relief valve 2.

insulation.

Spread the slit open and fi t the insulation over the T&P 3.

relief valve. See Figure 6. Apply gentle pressure to the

insulation to ensure that it is fully seated on the T&P Relief Valve. Once seated, secure the insulation with duct

tape, electrical tape, or equivalent.

IMPORTANT: The insulation and tape must not block

the discharge opening or hinder access to the manual

relief lever (Figure 6). Ensure a discharge pipe is installed into the T&P valve discharge opening per the

instructions in this manual.

7

Page 8

Figure 6

T&P Relief Valve Insulation

T&P Relief Valve Insulation

Manual Relief Lever

T&P Relief Valve

T&P Relief Valve

Drain Line

Locate the hot water (outlet) & cold water (inlet) pipes 4.

to the water heater.

Locate the slit running the length of a section of pipe 5.

insulation.

Spread the slit open and slip the insulation over the 6.

cold water (inlet) pipe. Apply gentle pressure along the

length of the insulation to ensure that it is fully seated

around the pipe. Also, ensure that the base of the

insulation is fl ush with the water heater. Once seated,

secure the insulation with duct tape, electrical tape, or

equivalent.

Repeat steps 5 and 6 for the hot water (outlet) pipe.7.

Add additional sections of pipe insulation as needed.8.

Electrical Requirements

If you lack the necessary skills required to properly install the

electrical wiring to this water heater, do not proceed but have a

qualifi ed electrician perform the installation.

When making the electrical connections, always make sure:

The electrical service provides 240 VAC to the water heater •

for proper operation. DO NOT use 208 VAC.

Wire sizes and connections comply with all applicable •

codes or in the absence of local or state codes follow

NFPA-70, the National Electrical Code-current edition.

Wiring enclosed in approved conduit (if required by local •

codes).

The water heater and electrical supply are properly •

grounded.

The electrical supply has the proper overload fuse or •

breaker protection.

Figures 8A & 9 are provided as reference drawings. Always

reference the wiring diagram located on the water heater for the

correct electrical connections and connect the electrical supply

to the water heater in accordance with local utility requirements

and codes.

When installing the electrical wiring to the water heater:

Although this water heater is equipped with “Dry Fire” 1.

protection circuitry, be sure tank is completely filled with

water, and all air is purged from the tank before making

any electrical connections. See “Draining and Flushing

Section”.

Turn off power to the electrical wiring for the water heater at 2.

the circuit breaker/fuse box.

Remove the left louvered access panel (when facing the 3.

water heater) by loosening the screws securing it to the

water heater.

Loosen the screws securing the electrical junction box 4.

Figure 7

Louvered Panel

WARNING

Electric Shock Hazard

Disconnect power before

servicing.

Replace all parts and panels

before operating.

Failure to do so can result in

death or electrical shock.

WARNING

Fire Hazard

Use 10 gauge solid copper

wire.

Use a UL listed or

CSA approved strain relief.

Connect ground wire to green

ground wire.

Failure to do so can result in

death, fire, or electrical shock.

8

cover to the water heater and set aside.

Connect the electrical supply to the water heater. 5.

A standard 1/2 inch opening has been made in the junction

box for conduit connections.

Connect ground wire to green ground wire in the electrical 6.

junction box of the water heater.

Reinstall the junction box cover.7.

Reattach the left louvered access panel to the water heater 8.

and secure it using the screws loosened earlier.

Turn on electrical power to the water heater.9.

Press the power button to turn the water heater on, then 10.

press the Efficiency button to set the operating mode.

NOTE: The water heater will conduct a system diagnostic

(approximately 8 minutes) prior to returning to operation.

Once the diagnostic sequence has finished, the fan should 11.

turn on.

NOTE: The heat pump’s fan will not turn on if the incoming

water temperature is less than 59 °F and/or the ambient

air temperature is above 109 °F or below 45 °F. Should the

internal diagnostics detect a problem with the heat pump,

an error message will be displayed.

Set the operational mode. For standard installation, the 12.

Hybrid Mode offers the best combination of efficiency

and hot water delivery. For detailed descriptions of all

operational modes see “Adjusting the User Interface

Module/Operational Modes” section.

Page 9

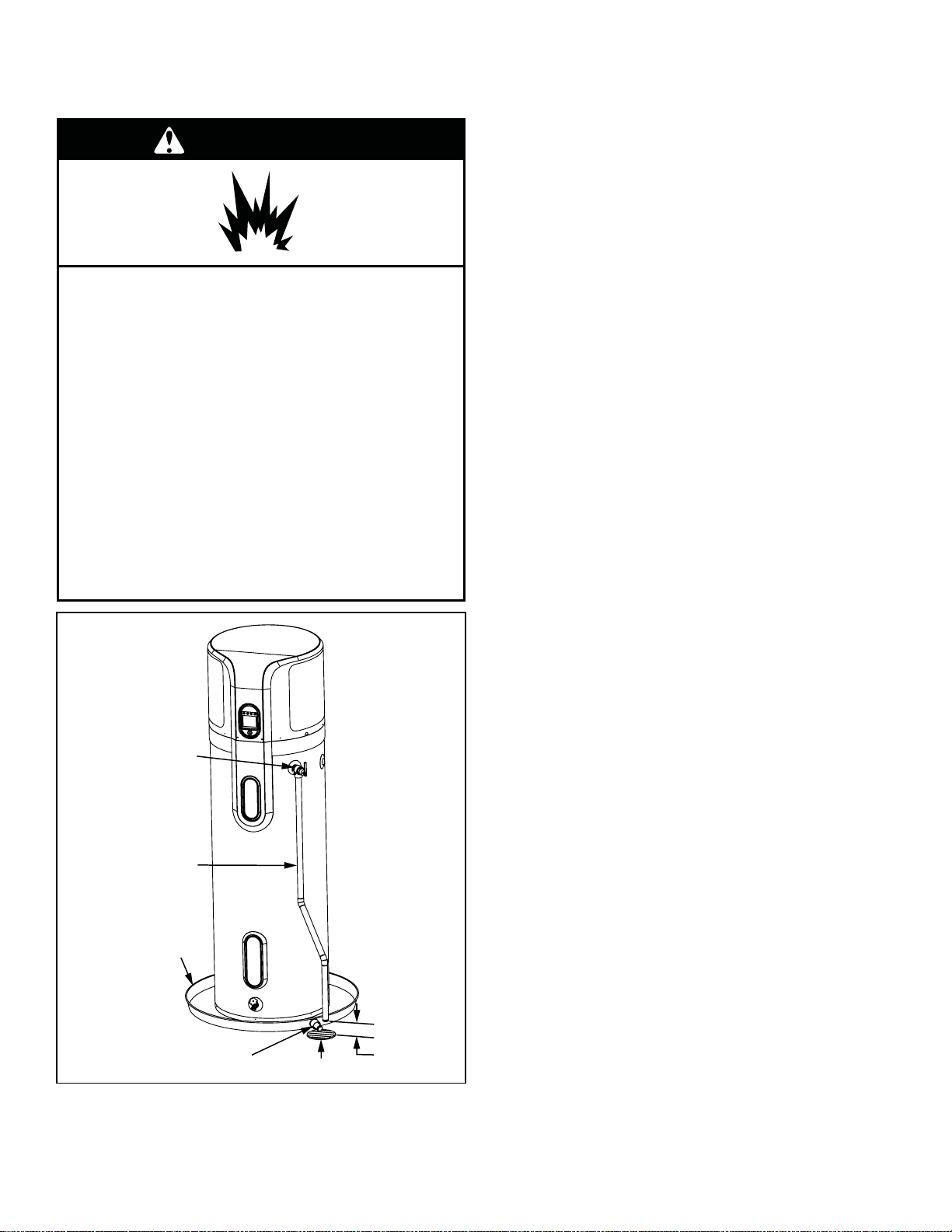

Figure 8A

Junction Box

Black Wire

Red Wire

Figure 8B

Condensate Pump Wiring

Condensate Pump Wiring Loop

18 AWG - White

(Loop Located Behind Junction Box)

Green

Ground

Wire

Ground

Wire

Conduit

(Field Connection)

Connect these two wires to the two wires on the water 5.

heater using wire nuts or other connectors.

Connect the free ends of the two wires to the shut off 6.

switch on the condensate pump in accordance with the

manufacturers recommendations.

Turn on electrical power to the water heater.7.

Press the power button to turn the water heater on 8. and

select the desired operational mode. After about 8

minutes, the heat pump will turn on.

Test the operation of the shut off switch by unplugging 9.

the condensate pump and filling the condensate

reservoir with water until the float switch opens the

circuit.

The heat pump should turn off and the error code 10.

“CONDENSATE DRAIN ALARM “will appear on the

user interface screen.

Plug the condensate pump in and verify that the pump 11.

operates and pumps the water out of the condensate

reservoir.

The error on the user interface should clear and the 12.

heat pump should operate after 8 minutes.

White Wires

From Water Heater

Figure 9

Wiring Diagram

Overload

Protection

Approved Connectors

Red

Black

Green

Ground

Wire

Electrical

Service ground

Wires to Condensate

Pump Overflow

Shut Off Switch

(18 AWG or Larger)

Circuit

Breaker

L1

L2

To 240v

1 Phase

Power supply

Connecting the Condensate Pump

Overfl ow Shut Off Switch

Turn off power to the electrical wiring for the water 1.

heater at the circuit breaker/fuse box.

Locate the white 18 AWG wire loop behind the field 2.

wiring junction box. See Figure 8B.

Cut the loop and strip insulation off of the two ends.3.

Measure the distance from the field wiring junction box 4.

to the condensate pump, and cut two 18 AWG or larger

wires to correct length and strip the insulation at both

ends of each wire. See Figure 8B.

Insulation Blankets

The use of an insulation blanket on this water heater is not

needed or recommended. The purpose of an insulation

blanket is to reduce the standby heat loss encountered with

storage tank heaters. Your water heater meets or exceeds

the National Appliance Energy Conservation Act standards

with respect to insulation and standby loss requirements,

making an insulation blanket unnecessary.

9

Page 10

INSTALLATION CHECKLIST

Water Heater Location

Centrally located with the water piping system. □

The fl ooring beneath the water heater must be able to □

support the weight of the water heater when fi lled with

water (967 lbs. full).

Located indoors (such as a basement or garage) □

and in a vertical position. Sheltered from freezing

temperatures.

Provisions made to shelter the area from water □

damage. Metal drain pan installed and piped to an

adequate drain.

Sufficient room to service the water heater. □

Sufficient air for the heat pump to function. □

heater must be located in a space 750 cubic feet or

larger, and must have unrestricted airfl ow. As an

example, a room that has an 8 foot tall ceiling and is

10 feet long by 9-1/2 feet wide would contain 760 cubic

feet.

NOTE: For optimal effi ciency and serviceability, the

following clearances should be maintained: 3 feet on

the air inlet side, 5 feet on the air outlet side, 6 inches in

the back, and 2 feet in the front.

The unit cannot be placed into any type of closet or □

small enclosure.

The site location must be free from any corrosive □

elements in the atmosphere such as sulfur, fl uorine,

and chlorine. These elements are found in aerosol

sprays, detergents, bleaches, cleaning solvents, air

fresheners, paint, and varnish removers, refrigerants,

and many other commercial and household products.

In addition excessive dust and lint may affect the

operation of the unit and require more frequent

cleaning (See “Cleaning the Heat Pump” section).

Ambient air temperature must be above 45°F and □

below 109°F. If the ambient air temperature falls

outside these upper and lower limits the electrical

elements will activate to meet the hot water demand.

The water

Water System Piping

Temperature and pressure relief valve properly □

installed with a discharge pipe run to an adequate drain

and sheltered from freezing (See Figure 5).

All piping properly installed and free of leaks. □

Heater completely filled with water (See “Water Piping □

System” section).

Closed system pressure buildup precautions installed □

(See “Closed System/Thermal Expansion” section).

Mixing valve (when applicable) installed per □

manufacturer’s instructions (See “Water Temperature

Regulation” section).

Condensate Drain Line Installation

Must be located with access to an adequate drain or □

condensate pump.

Condensate drain lines installed and piped to an □

adequate drain or condensate pump (See Figure 4).

Electrical Connections

The water heater requires 240 VAC for proper □

operation.

Wiring size and connections comply with all applicable □

codes or in the absence of local or state codes follow

NFPA-70, the National Electrical Code-current edition.

Water heater and electrical supply are properly □

grounded.

Wiring enclosed in approved conduit (if required by □

local codes).

Proper overload fuse or circuit breaker protection □

installed.

Post Installation Review

Understand how to use the User Interface Module to □

set the various modes and functions (See “Adjusting

the User Interface Module/Operating Modes” section).

Hybrid Mode is the recommended Operating Mode. □

Understand the various Operating Modes and which

mode may be best based on season, ambient

temperature, and usage (See “Operating Mode

Description” section).

NOTE: It may be necessary to temporarily change

modes if for example filling a spa or hot tub.

Understand the importance of routine inspection/ □

maintenance of the condensate drain pan and lines

(See “

Inspection/Cleaning of the Condensate Drain

Pan & Condensate Drain Lines” section). This is to

help prevent any possible drain line blockage resulting

in the condensate drain pan overflowing.

IMPORTANT: Water coming from the plastic shroud is

an indicator that both condensation drain lines may be

blocked. Immediate action is required.

To maintain optimal operation check, remove and clean □

the air filter (See “Air Filter Cleaning/Replacement”

section).

The Installation Instructions and Use & Care Guide □

should be kept with the water heater for reference.

10

Page 11

OPERATING YOUR WATER HEATER

Before Using

Make sure the water heater has been properly 1.

installed. See “Installing Your Water Heater” section.

Make sure the air filter is correctly seated, as it may 2.

shift during shipping or installation. See “Repair Parts

Illustration” section.

Completely fill the tank with water (See “Water Piping” 3.

section).

After the water heater tank is completely filled with water, 4.

connect electrical power to the water heater.

Read the “Water Temperature Regulation” section of this 5.

manual.

contact a qualifi ed person.

Press the power button (See Figure 10) to turn the water 6.

heater on and allow it to run a system diagnostic. This

typically takes eight minutes. Once complete, proceed to

the next step.

NOTE: If the system diagnostic yields any codes,

reference the Diagnostic Code section in this manual.

Adjust the thermostat to the desired temperature7.

setting as described under “Adjusting the User Interface

Module/Operational Modes” section.

IMPORTANT:

if the unit has been submerged, subjected to fl ooding, or

surrounding insulation has been exposed to water in any

way.

Do not attempt to repair a unit subjected to fl ood conditions.

Water heaters subjected to fl ood conditions or any time the

unit has been submerged in water require replacement of

the entire water heater.

Safety Shut-off (ECO)

This water heater is designed to automatically shut-off in the

event that the water temperature exceeds 190°F or 87.8°C.

A temperature limit switch or ECO (Energy Cut Off) is used

to shut off the power to the system if the water temperature

exceeds 190°F or 87.8°C (See “Water Temperature

Regulation” section). To reset the ECO disconnect power at

the circuit breaker/fuse box then remove the upper access

panel. Reset the ECO by fi rmly pushing in the red reset

button located on the ECO block. If the ECO continues

to shut-off the water heater contact a qualifi ed person for

service.

If you do not fully understand these instruction,

Do not attempt to operate this water heater

Water Temperature Regulation

WARNING

Water temperature over 125°F can cause

severe burns instantly or death from scalds.

Children, disabled and elderly are at highest

risk of being scalded.

Feel water before bathing or showering.

Temperature limiting valves are available.

The water heater is adjusted to a temperature setting of

no higher than 120°F when it is shipped from the factory.

Water temperature can be regulated by adjusting the User

Interface Module to the preferred setting as shown in

“Adjusting the User Interface Module/Operational Mode”

The preferred starting point is 120°F. There is a hot water

scald potential if the temperature set point is set too high.

IMPORTANT: Adjusting the set point above 120°F on the

User Interface Module will increase the risk of scald injury in

the times shown below.

Table 1

Water

Temperature °F

110

116

116

122

131

140

149

154

(U.S. Government Memorandum, C.P.S.C., Peter L. Armstrong, Sept. 15,1978)

Time for 1st

Degree Burn

(Less Severe Burns)

(normal shower temp.)

(pain threshold)

35 minutes

1 minute

5 seconds

2 seconds

1 second

instantaneous

Time for

Permanent Burns

2nd & 3rd Degree

(Most Severe Burns)

45 minutes

5 minutes

25 seconds

5 seconds

2 seconds

1 seconds

NOTE: During low demand periods when hot water is not

being used, a lower temperature set point will reduce energy

losses and may satisfy your normal hot water needs. If hot

water use is expected to be more than normal, a higher

temperature set point may be required to meet the increased

demand.

When leaving your home for extended periods (vacations,

etc.) set the water heater to Vacation Mode. See “Adjusting the

User Interface Module/Operational Modes” section. This will

maintain the water at low temperatures with minimum energy

losses and prevent the tank from freezing during cold weather.

NOTE: When returning from an extended stay remember to

set the water heater back to the desired Operational Mode.

11

Page 12

Adjusting the User Interface Module/Operational Modes

Water Temperature Adjustment

The water temperature can be adjusted from 95°F to 150°F.

Use the Up and Down Buttons

on the front

panel to set the desired temperature.

IMPORTANT: Before attempting to adjust the thermostat,

read the “Water Temperature Regulation” section. If the

instructions are not clear, contact a qualifi ed person.

IMPORTANT: Filling a spa or hot tub from this water heater

may result in extended recovery/re-heat time. Switching

(temporarily) to Hybrid Mode or Electric Mode will decrease

the recovery/re-heat time. Be sure to switch back to the

desired operational mode when fi nished.

Operating Mode Descriptions

The operating modes can be changed by touching the

desired mode icon on the User Interface Module (see

Figure 10.)

NOTE: All buttons on the User Interface are touch sensitive

and require only a light touch to actuate.

Effi ciency Mode - Is the most energy effi cient

EFFICIENCY

HYBRID

ELECTRIC

mode. This mode uses the heat pump to heat water

in the tank. The elements are not used unless the

ambient operating temperature is below 45°F or

above 109°F. If hot water demands are not met in

Effi ciency Mode it may be necessary to switch to

Hybrid Mode.

Hybrid Mode (recommended setting) - Combines

high energy effi ciency with reduced recovery time.

This mode uses the heat pump as the primary

heating source. The heating element will heat

water if demand exceeds a predetermined level so

that the set point temperature can be recovered

more quickly.

Electric Mode - The water heater functions as a

conventional electric unit, relying totally on the

elements to heat the water in the tank. This mode

may be useful in winter to eliminate the output of

cold air from the unit.

Other Controls

Lock - Holding this button for more than 3

seconds switches the lock mode on or off. When

the User Interface Module is locked a symbol

and “Lock” text will be visible on the display (see

Figure 10).

°F/°C

°F/°C - The button switches the display to show

the set temperature in Fahrenheit or Celsius.

Figure 10 User Interface Module

Operational Mode Buttons

EFFICIENCY

Element

Functioning

Icon

Heat Pump

Functioning

Icon

Temperature

Up (Increase)

Button

Fahrenheit/Celsius

Temperature Display

Button

HEAT PUMP

Power Button: On - Green

Standby - Red

HYBRID

ELEMENT

°F/°C

LOCK

ELECTRIC

VACATION

F

EFFICIENCY

LCD Display Panel

Lock Button

Water

Temperature

Set Point

Water Heater

Mode/Status

Indicator

Water Heater

Efficiency Status

Icon

LCD Control

Panel Lock Icon

Temperature

Down (Decrease)

Button

Vacation Mode - The controller adjusts the water

VACATION

temperature to approximately 60°F. This mode is

recommended when the water heater is not in use

for a long period of time. This mode minimizes

energy consumption and prevents the water heater

from freezing during cold weather.

12

Page 13

Operational Conditions

Powered Anode Operation

To shelter the glass-lined water tank from corrosion

through electrolysis, this water heater is equipped with a

non-sacrificial powered anode which should not need to be

replaced under normal operating conditions.

If the powered anode malfunctions it should be replaced by

a qualified technician.

IMPORTANT: If a faulty powered anode is not repaired or

has been removed permanently, then all warranties are

void.

Water Heater Sounds

During the normal operation of the water heater, sounds or

noises may be heard. These noises are common and may

result from the following:

Normal expansion and contraction of metal parts 1.

during periods of heat-up and cool-down.

Sediment buildup on or around the elements could 2.

create varying amounts of noise and may cause

premature tank failure. Drain and flush the tank as

directed under the “Draining and Flushing” section.

The heat pump compressor or fan running.3.

Stacking

Stacking occurs when a series of short draws of hot water

(3 gallons or less) are taken from the water heater tank.

This causes increased cycling of the heat pump and/

or heater elements and can result in increased water

temperatures at the hot water outlet. An anti-scald device

is recommended in the hot water supply line to reduce the

risk of scald injury.

13

Page 14

MAINTENANCE OF YOUR WATER HEATER

Temperature and Pressure

Relief Valve

WARNING

Explosion Hazard

If the temperature and pressure relief valve

is dripping or leaking, have a qualified

person replace it.

Examples of a qualified person include:

licensed plumbers, authorized electric

company personnel, and authorized service

personnel.

Place the water heater in Standby Mode by pressing 1.

the power button on the user interface module.

Turn off the power to the water heater at the circuit 2.

breaker/fuse box.

Open a nearby hot water faucet until the water is no 3.

longer hot.

Close the cold water inlet valve.4.

Connect a hose to the drain valve and terminate it to an 5.

adequate drain or external to the building.

Open the water heater drain valve and allow all of the 6.

water to drain from the tank. Flush the tank with water

as needed to remove sediment.

Close the drain valve, refi ll the tank (open the cold 7.

water inlet valve), and restart the heater as directed in

this manual.

IMPORTANT: Do not turn on power to the water heater

unless it is completely fi lled with water. To ensure that

the tank is full, open a hot water faucet and allow the

water to run until the air is purged and the water fl ows

uninterrupted from the faucet.

Press the power button to turn the water heater on. 8.

NOTE: The water heater will conduct a system

diagnostic prior to operation.

If the water heater is going to be shut down for an extended

period, the drain valve should be left open.

Do not plug valve.

Do not remove valve.

Failure to follow these instructions can

result in death or explosion.

Manually operate the temperature and pressure relief valve

at least once a year to make sure it is working properly.

To prevent water

damage, the valve

must be properly

connected to a

discharge line which

terminates at an

adequate drain.

Standing clear of the

outlet (discharged

water may be

hot), slowly lift and

release the lever

handle on the

temperature and

pressure relief valve to allow the valve to operate freely and

return to its closed position. If the valve fails to completely

reset and continues to release water, immediately

disconnect the electrical power, close the cold water inlet

valve and call a qualifi ed person.

Figure 11

T emperature and Pressure

Relief V alve

Manual Relief

Va lv e

Discharge line to drain

Draining and Flushing

It is recommended that the tank be drained and fl ushed

every 6 months to remove sediment which may build up

during operation. The water heater should be drained if

being shut down during freezing temperatures. To drain the

tank, perform the following steps:

14

Heating Element Replacement

WARNING

Electric Shock Hazard

Disconnect power before

servicing.

Replace all parts and panels

before operating.

Failure to do so can result in

death or electrical shock.

Replacement heating elements must be of the same style

and voltage/wattage rating as the ones originally in the water

heater. This information can be found on the fl ange or terminal

block of the element or on the water heater data plate.

IMPORTANT: Before replacing any element confi rm that

you have the correct replacement element (wattage). This

water heater has a 4500 watt upper element and a 2000

watt lower element. DO NOT replace the element(s) with a

wattage different than the ones specifi ed for the upper and/

or lower element.

IMPORTANT: Using an element greater than 2000 watts

in place of the lower element will damage the water heater

and void the warranty.

Press the power button on the user interface module to 1.

place the water heater in Standby Mode.

Turn off the power to the water heater.2.

Drain the water heater as directed in the “Draining 3.

and Flushing” section.

Page 15

Figure 12:

Wires

Element

Screws

Remove the access cover(s), then remove the foam 4.

insulation block.

Remove the protective plastic cover(s) over the 5.

elements from their attachment point.

Disconnect the electrical wires from the heating 6.

element(s) by loosening the screws (Figure 12).

Remove the screw-in element(s) by turning the

element(s) counterclockwise with a 1-1/2 inch socket

wrench. Remove the existing gasket(s).

Clean the area where the gasket(s) fits to the tank 7.

and internal threads. If you are replacing the bottom

element, remove any accumulated sediment on the

bottom of the tank.

Make sure the replacement element(s) has the correct 8.

voltage and wattage rating by matching it to the rating

plate on the water heater. Position the new gasket(s)

on the element and insert it into the water heater tank

(Figure 13).

NOTE: Apply a light coat of hand dishwashing soap

and water to the gasket. Tighten the element by turning

it clockwise until secure.

Close the drain valve and open the nearest hot water 9.

faucet.

allow the tank to fill completely with water. To purge

the lines of any excess air and sediment, keep the hot

water faucet open for 3 minutes after a constant flow of

water is obtained.

Figure 13:

Then open the cold water shut off valve and

Screw-in

Element

Spud

Routine Preventive Maintenance

At least monthly, a visual inspection should be made of the

following:

Air Filter (Remove and inspect, clean if needed, and •

reinstall).

Condensate drain pan and condensate lines.•

The lower metal drain pan for standing water which may •

indicate a clogged condensate drain pan, condensate

lines, or plumbing leak.

Leaking or damaged water piping.•

Presence of corrosive materials in the installation area.•

Presence of combustible materials near the water heater.•

After servicing this water heater, check to make sure it •

is working properly. (See “Operating Your Water Heater”

section of this manual.)

IMPORTANT: If you lack the necessary skills required to

properly perform this visual inspection, you should not

proceed, but get help from a qualified person.

Cleaning the Heat Pump

Air Filter Cleaning/Replacement

IMPORTANT: Before attempting to clean or replace the air

fi lter press the power button to place the water heater in

Standby Mode and turn-off power to the water heater at the

circuit breaker/fuse box.

Locate the screw securing the filter panel to the heat 1.

pump shroud and loosening it.

Remove (slide) the filter from the unit.2.

If you are replacing the filter skip to step 4. To clean the 3.

filter use a vacuum with a hose attachment to remove

any dust or debris.

Place the new or cleaned filter into the water heater 4.

and secure the filter to the shroud with the screw

loosened earlier.

NOTE: The guides/slots when inserting the filter into

the water heater.

Restore power to the water heater and press the 5.

power button to turn the water heater on. NOTE: the

water heater will conduct a system diagnostic prior to

operation.

Gasket

Check for leaks around the element(s).10.

Reconnect the electrical wires to the element and 11.

securely tighten the screws (See Figure 12).

Replace the 12.

Make sure the cover(s) are securely engaged on the

attachment point(s).

Replace the foam block(s) and access cover(s).13.

Although this water heater is equipped with “Dry Fire” 14.

protection circuitry, be sure tank is completely filled with

water before applying electrical power to the water heater.

Reconnect electrical power to the water heater at the 15.

circuit breaker/fuse box.

Press the power button to turn the water heater on. Set 16.

the desired water temperature and operating mode.

NOTE: The water heater will conduct a system

diagnostic (approximately 8 minutes) prior to operation.

protective plastic cover(s) removed earlier.

Inspection/Cleaning of the Condensate

Drain Pan & Condensate Drain Lines

IMPORTANT: Before attempting to clean or replace the

condensate drain pan or lines press the power button to

place the water heater in Standby Mode and shut-off power

to the water heater at the circuit breaker/fuse box.

Remove the access panel (fan side) by loosening the 1.

screws securing it to the unit.

Check the condensate drain pan and drain lines for any 2.

dirt or debris that might interfere with proper drainage.

Wipe out any dirt or debris with a damp cloth.

Once the condensate drain pan and lines have been 3.

inspected/cleaned, secure the access panel to the water

heater.

Restore power to the water heater and press the power 4.

button to turn the water heater on.

NOTE: The water heater will conduct a system diagnostic

prior to operation.

15

Page 16

DIAGNOSTIC CODES

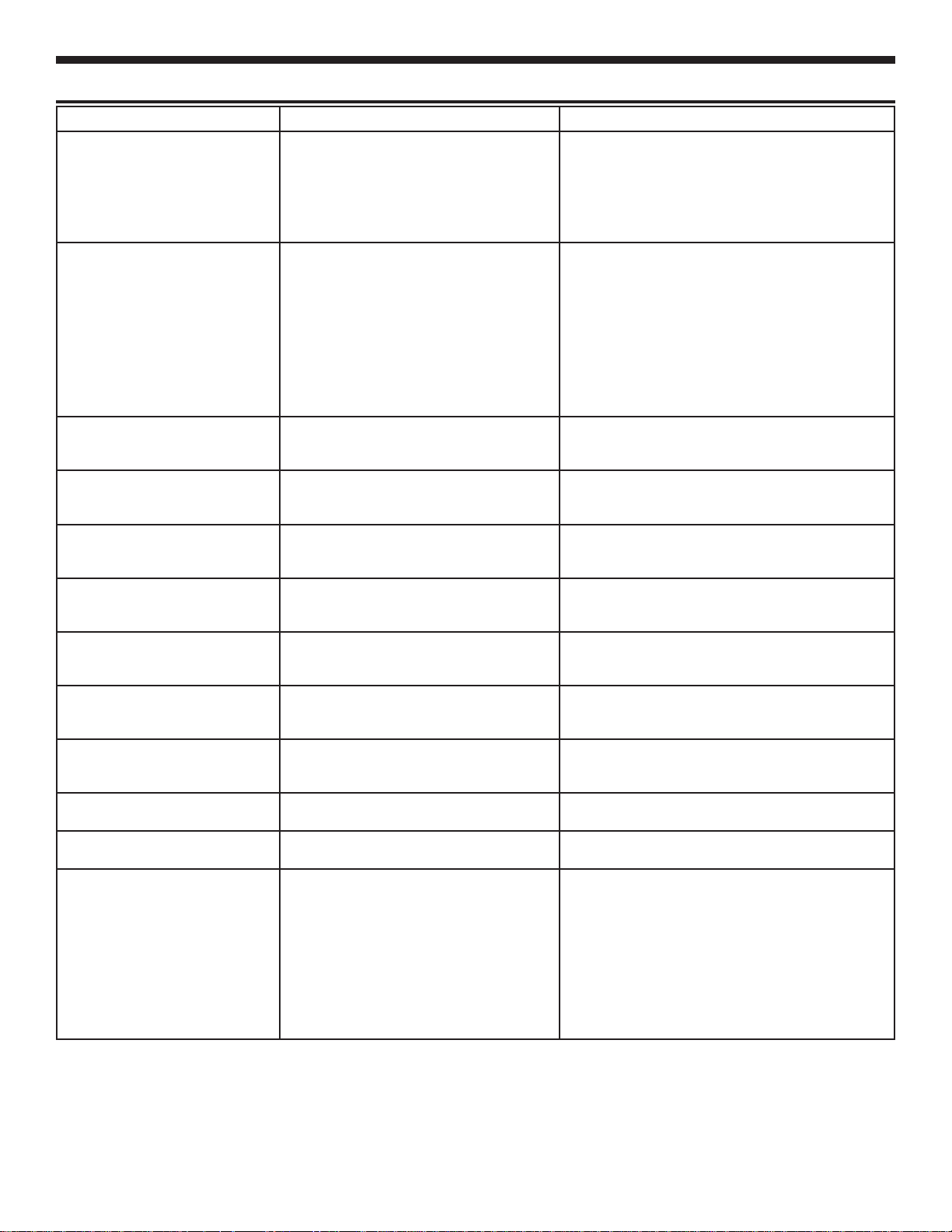

DISPLAY SHOWS INDICATES CORRECTIVE ACTION

UPPER ELEMENT

CONNECT

FAULT

LOWER ELEMENT

CONNECT

FAULT

HEAT PUMP

CONNECT

FAULT

FAN

CONNECT

FAULT

AMBIENT TEMP

SENSOR SHORT OR OPEN

OR AD ERROR

UPPER TEMP

SENSOR SHORT OR OPEN

OR AD ERROR

LOWER TEMP

SENSOR SHORT OR OPEN

OR AD ERROR

DISCHARGE TEMP

SENSOR SHORT OR OPEN

OR AD ERROR

COIL TEMP

SENSOR FAULT

OR AD ERROR

MAIN CIRCUIT BOARD

FAULT

HIGH TEMP

LOCKOUT

CONDENSATE

DRAIN

ALARM

(If Accessory Condensate

Pump is Installed)

1. Upper element is not functioning Turn off power at the circuit breaker/fuse 1.

1. Lower element is not functioning Turn off power at the circuit breaker/fuse 1.

1. Heat Pump compressor is not

functioning.

1. Heat Pump fan is not functioning. Contact a qualified person to service the unit. 1.

1. Ambient Temperature Sensor is not

functioning.

1. Upper Temperature Sensor is not

functioning.

1. Lower Temperature Sensor is not

functioning.

1. Discharge Temperature Sensor is not

functioning.

1. Coil Temperature Sensor is not

functioning.

1. Main Circuit Board is not functioning. Contact a qualified person to service the unit.1.

1. Water temperature in unit has

exceeded 190° F.

1. Condensate pump failure. Check to see if accessory condensate pump is 1.

1. Contact a qualified person to service the heat

1. See “Safety Shut-off” section.

box and check for a loose connection at the

element. For access directions see “Heating

Element Replacement” section. If error persists

proceed to the next step.

Replace non-functioning element. See “Heating 2.

Element Replacement” section.

box and check for a loose connection at the

element. For access directions see “Heating

Element Replacement” section. If error persists

proceed to the next step.

Replace 2.

Element Replacement” section.

non-functioning element. See “Heating

IMPORTANT: Using an element greater

than 2000 watts in place of the lower element

will damage the water heater and void the

warranty.

pump.

Contact a qualified person to service the unit.1.

Contact a qualified person to service the unit.1.

Contact a qualified person to service the unit.1.

Contact a qualified person to service the unit.1.

Contact a qualified person to service the unit.1.

plugged in and has power. Also check circuit

breaker/fuse box and GFCI (if used). if error

persists proceed to the next step.

Check condensate pump outlet tube for 2.

blockage. if error persists proceed to the next

step.

Check control wire connections to condensate 3.

pump. If error persists proceed to the next step.

Replace accessory condensate pump. If error 4.

persists contact a Qualified Person.

NOTE: The diagnostic codes listed above are the most common. If a diagnostic code not listed above is displayed,

contact Residential Technical Assistance referencing the number on the front of this manual.

16

Page 17

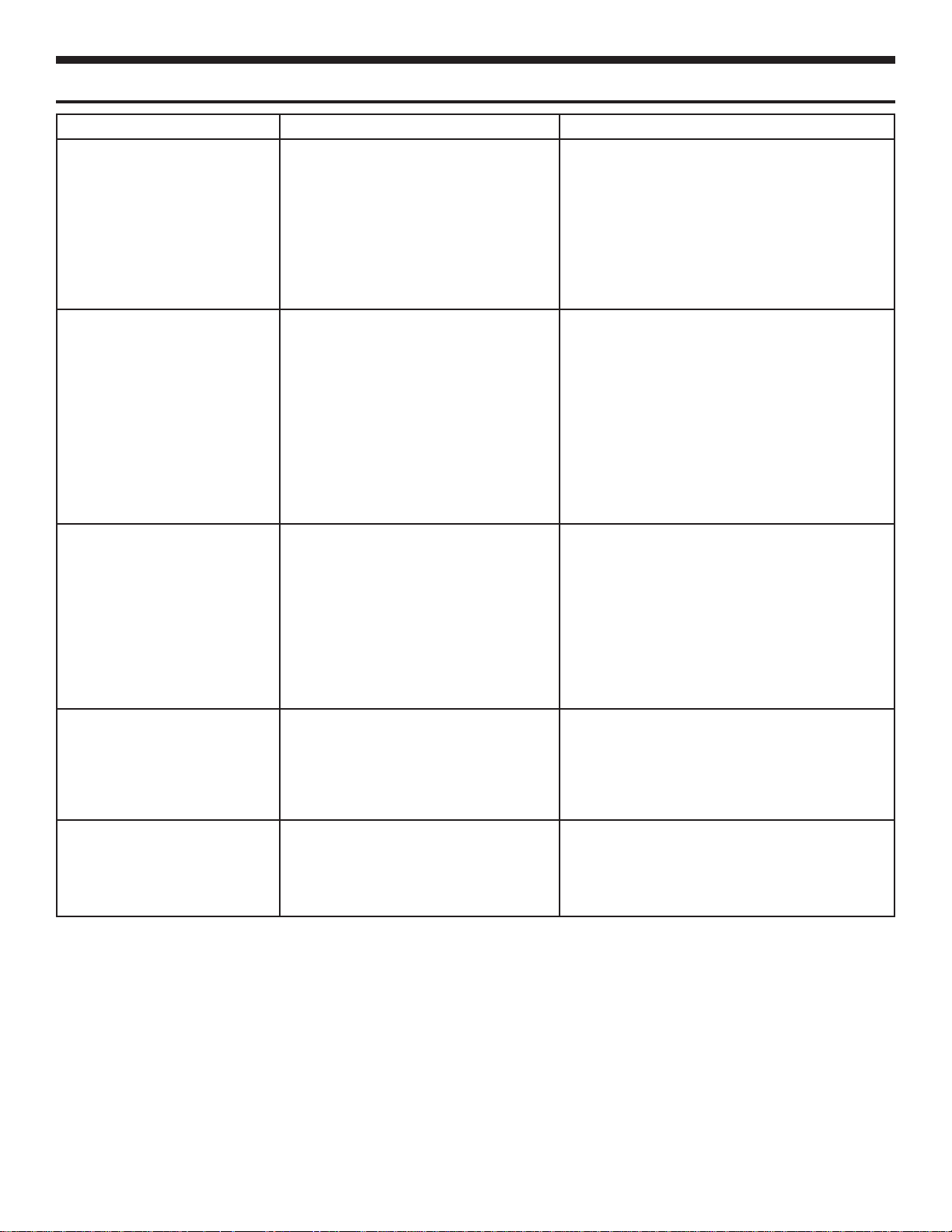

TROUBLESHOOTING CHART

PROBLEM POSSIBLE CAUSE(S) CORRECTIVE ACTION

NO HOT WATER Hot water usage pattern exceeds the 1.

INSUFFICIENT HOT WATER/

SLOW HOT WATER

RECOVERY

HIGH OPERATION COSTS

DRIP FROM TEMPERATURE &

PRESSURE RELIEF VALVE

(Warning: Do not plug or cap

T&P discharge pipe.)

OTHER The water heater does not 1.

capability of the water heater in

current mode

No power to the water heater2.

Unit in standby3.

Unit in Vacation mode4.

High temperature limit switch open5.

Non-functioning upper temperature 6.

sensor

Temperature set-point too low1.

Air filter dirty2.

Hot water usage pattern exceeds the 3.

capability of the water heater in

current mode

Water connections to unit reversed4.

Heat lost through long run of exposed 5.

pipe

Hot water leak at faucet or piping6.

Non-functioning heating element7.

Sediment or scale build up in tank8.

Temperature set-point too high1.

Air filter dirty2.

Electric mode selected3.

Water connections to unit reversed4.

Heat lost thru long run of exposed 5.

pipe

Hot water leak at faucet or piping6.

Sediment or scale build up in tank7.

1. Excessive water pressure

2. Add or service a thermal expansion

tank.

3. Non-functioning Temperature &

Pressure Relief Valve

immediately start

The heat pump does not run in 2.

Efficiency mode.

The heat pump runs when set to 3.

Electric mode.

Change to different mode or modify usage 1.

patterns

Check for blown fuse or tripped breaker. 2.

Restore power to unit then press power button.

Press the power button to turn the unit on3.

Select mode other than Vacation4.

Reset the high temperature limit switch; see 5.

“Safety shut-off” section for more information

Contact a qualified person for service6.

Increase set point temperature; see “Adjusting 1.

the User Interface Module” section

Clean air filter2.

Change to different mode or modify usage 3.

patterns (For example if in Efficiency Mode

switch to Hybrid Mode)

Ensure the cold connection is at the bottom 4.

and that the hot connection is at the top

Insulate exposed piping5.

Repair hot water leaks6.

Call qualified person for service7.

Drain and flush tank. Water conditioning may 8.

be necessary to minimize build up

Decrease set point temperature; see “Adjusting 1.

the User Interface Module”

Clean air filter2.

Change to Efficiency or Hybrid mode for re-3.

duced energy costs

Ensure the cold connection is at the bottom 4.

and that the hot connection is at the top

Insulate exposed piping5.

Repair hot water leaks6.

Drain and flush tank. Water conditioning may 7.

be required to minimze build up

1. Check water supply inlet pressure. If higher

than 80 PSIG, install a pressure reducing

valve

2. See “Closed System/Thermal Expansion” section

3. Replace the Temperature & PressureRelief

Valve

When first started the water heater takes about 8 1.

minutes to complete a diagnostic routine

Contact a qualified person for service2.

Contact a qualified person for service3.

17

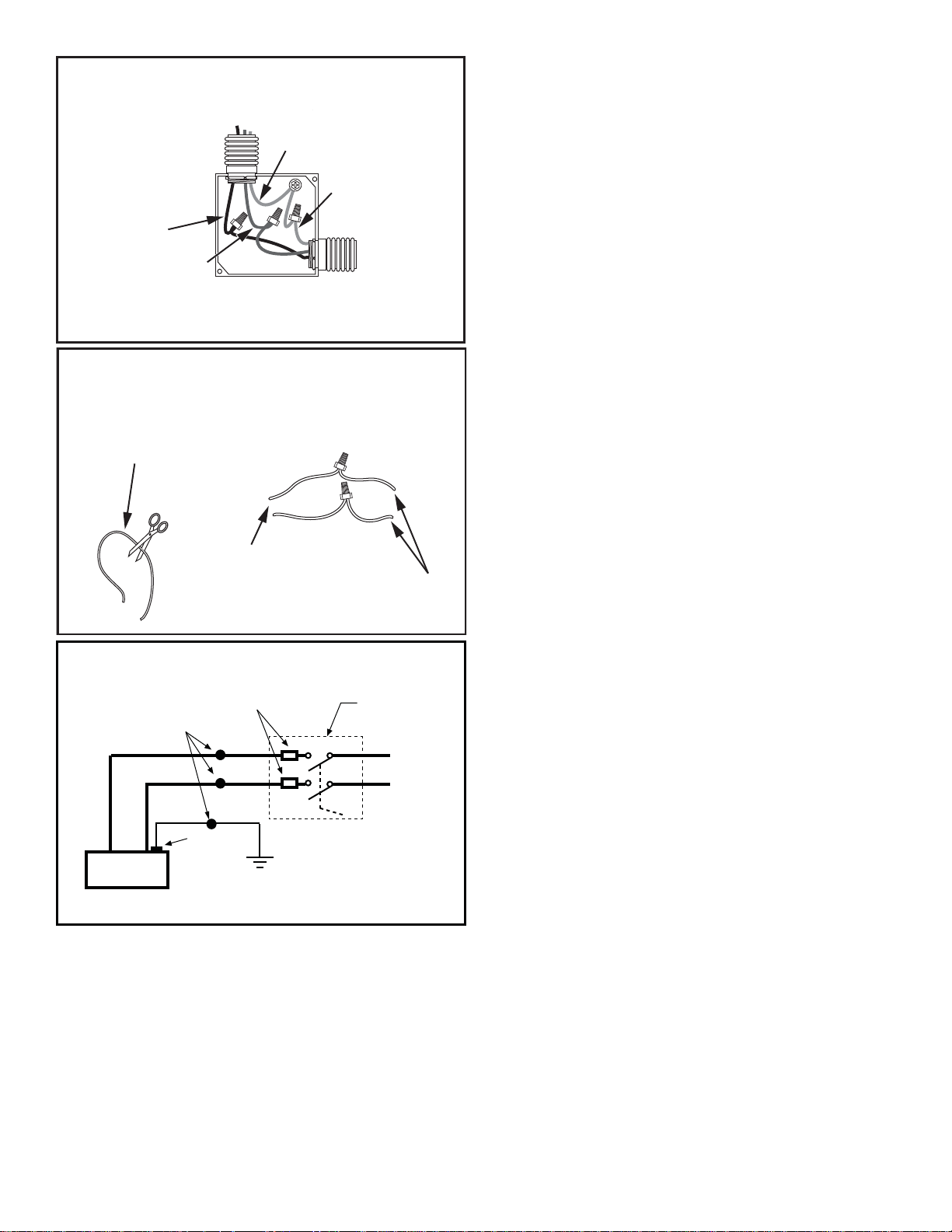

Page 18

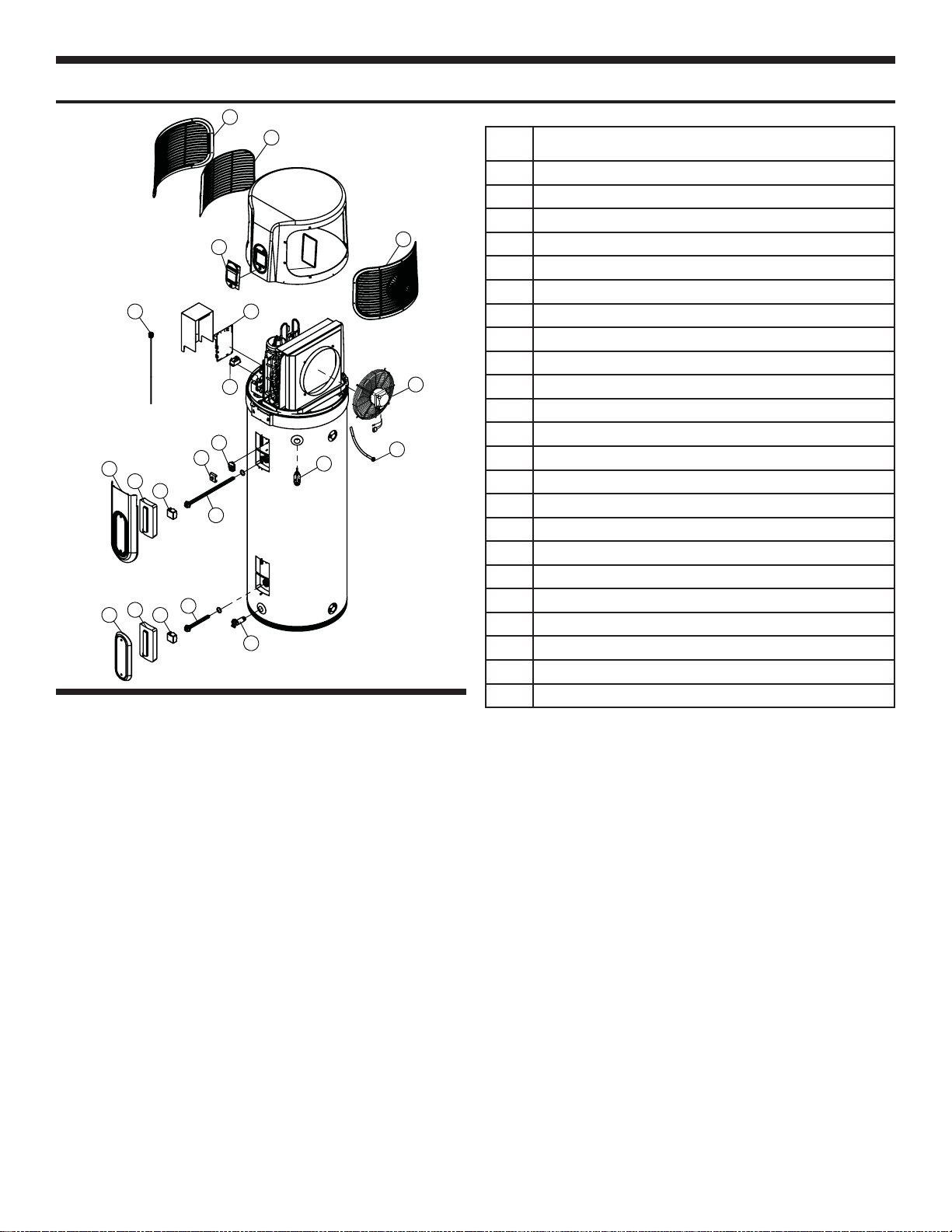

REPAIR PART ILLUSTRATION

11

10

9

8

1

19

19

2

16

15

4

15

17

18

5

6

3

14

12

13

7

REPAIR PARTS

Repair parts may be ordered through your plumber, local

distributor, home improvement center, or by calling

1-800-365-0024. When ordering repair parts always give

the following information:

1. Model, serial and product number

2. Item number

3. Parts description

REPAIR PARTS LIST

ITEM

NO.

1

Upper Access Cover

2

Lower Access Cover

3

Upper Element (4500 Watts)

4

Lower Element (2000 Watts)

5

Energy Cut-Off (ECO) Switch

6

Temperature & Pressure Relief Valve (T&P)

7

Dip Tube (at hot water outlet)

8

Powered Anode Rod

9

User Interface Module

10

11

12

13

14

15

16

17

18

19

20*

21*

22*

23*

* NOT SHOWN

Air Filter

Air Inlet Side Panel

Air Outlet Side Panel

Fan Assembly

Drain Valve

Protective Plastic Cover

ECO Cover

Control Board

Relay

EPS Cover

Ambient / Coil / Discharge Temperature Sensor

Upper / Lower Tank Temperature Sensor

Run Capacitor

Control Board Module Fuses

PARTS DESCRIPTION

18

Page 19

NOTES

19

Page 20

20

Copyright © 2010 State Industries, Inc. All rights reserved.

Loading...

Loading...