查询UCC1570供应商

Low Power Pulse Width Modulator

UCC1570

UCC2570

UCC3570

FEATURES

• Low Power BiCMOS Process

• 85µA Start-up Current

• 1mA Run Current

• 1A Peak Gate Drive Output

• Voltage Feed Forward

• Programmable Duty Cycle Clamp

• Optocoupler Interface

• 500kHz Operation

• Soft Start

• Fault Counting Shutdown

• Fault Latch Off or Automatic Restart

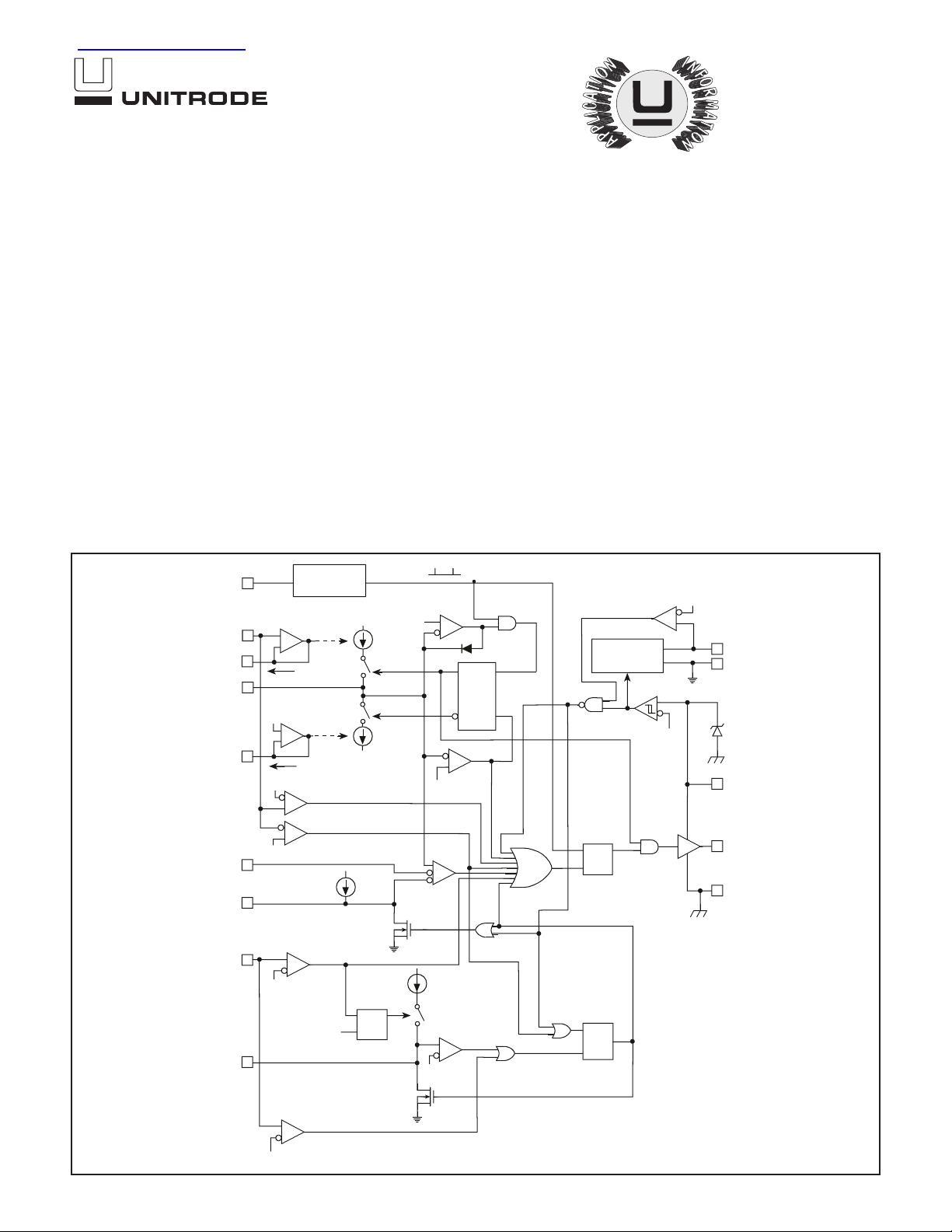

BLOCK DIAGRAM

1V

4V

1V

CLOCK

GENERATOR

I3

I4

HIGH

LINE

LOW

LINE

FREQ

VFWD

SLOPE

RAMP

ISET

FEEDBK

SOFTST

11

6

7

10

9

8

14

DESCRIPTION

The UCC1570 family of pulse width modulators is intended for application

in isolated switching supplies using primary side control and a voltage

mode feedback loop.Made with a BiCMOS process, these devices feature

low startup current for efficient off-line starting with a bootstrapped low voltage supply. Operating current is also very low; yet these devices maintain

the ability to drive a power MOSFET gate at frequencies above 500kHz.

Voltage feedforward provides fast and accurate response to wide line voltage variation without the noise sensitivity of current mode control. Fast current limiting is included with the ability to latch off after a programmable

number of repetitive faults has occurred. This allows the power supply to

ride through a temporary overload, while still shutting down in the event of

a permanent fault. Additional versatility is provided with a maximum duty

cycle clamp programmable within a 20% to 80% range and line voltage

sensing with a programmable window of allowable operation.

CLK

13/9V

4.5V

VREF

12

GND

13

15V

3

VCC

OUT

4

5

PGND

RAMP

VALLEY

1V

10 I3

S

RAMP

LATCH

R

10 I4

RAMP

PEAK

4V

I4

PWM

5V

GENERATOR

S

D

R

PWM

LATCH

04/99

CURLIM

COUNT

CURRENT

0.2V

LIMIT

CLK

SHUTDOWN

I4

SD

R

4V

R

D

S

SHUTDOWN

LATCH

2

1

0.6V

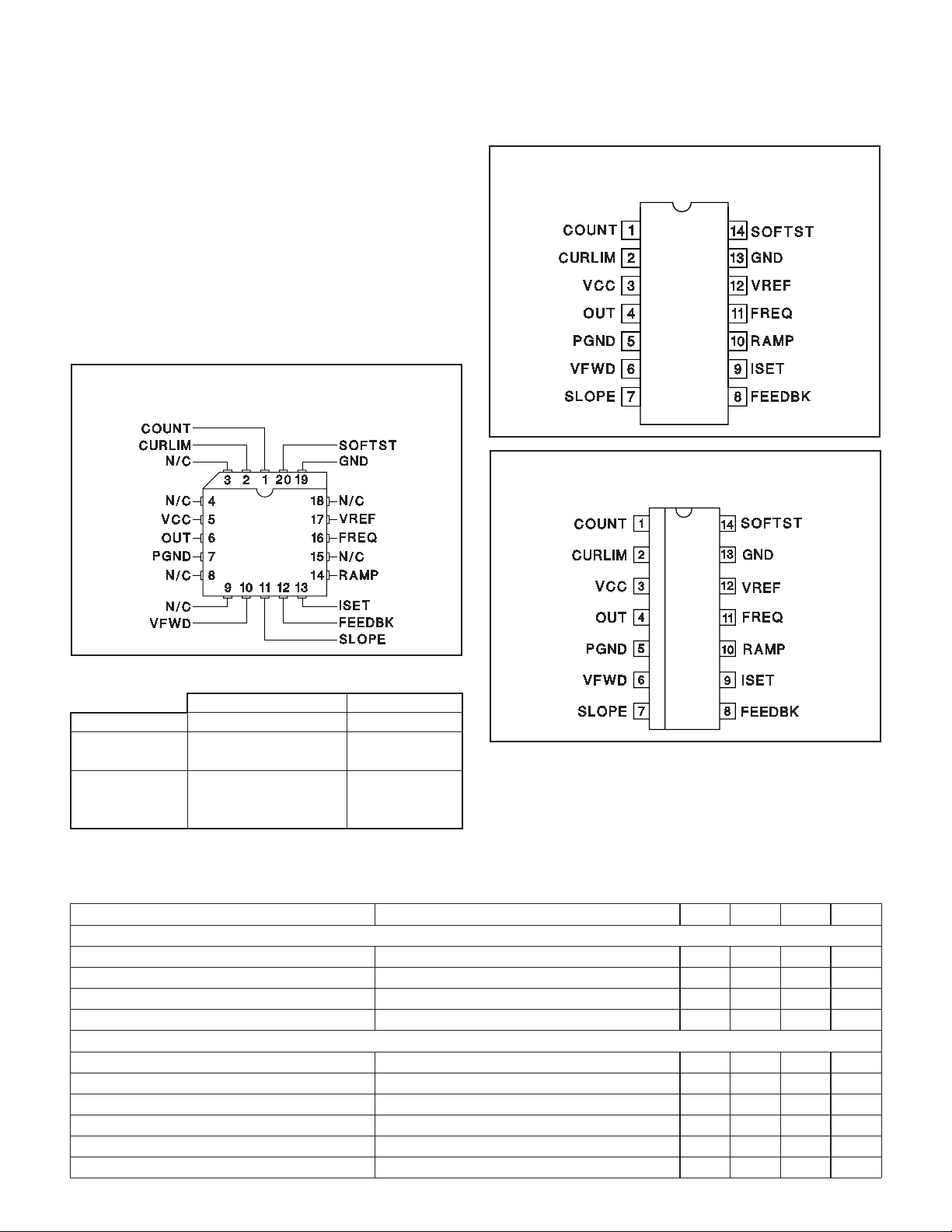

ABSOLUTE MAXIMUM RATINGS CONNECTION DIAGRAMS

Supply Voltage

(Limit Supply Current to 20mA) . . . . . . . Self Limiting at 15V

Supply Current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . +20mA

Analog Inputs (CURLIM, VFWD, FEEBK) . . . . . . . . . . . . . . 6V

Programming Current I

Output Current I

OUT

SLOPE,IISET

. . . . . . . . . . . . . . . . . –1mA

DC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ±180mA

Pulse (0.5ms) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ±1.2A

Note: All voltages are with respect to GND. Currents are positive into the specified terminal. Consult Packaging Section of

Databook for thermal limitations and considerations of package.

PLCC-20 (TOP VIEW)

Q Package

DIL-14 (TOP VIEW)

N or J Package

SOIC-14 (TOP VIEW)

D Package

UCC1570

UCC2570

UCC3570

ORDERING INFORMATION

Temperature Range Package

UCC1570J –55°C to +125°C Ceramic Dip

UCC2570D –40°C to +85°C SOIC

UCC2750N Plastic Dip

UCC3570D 0°C to +70°C SOIC

UCC3570N Plastic Dip

UCC3570Q PLCC

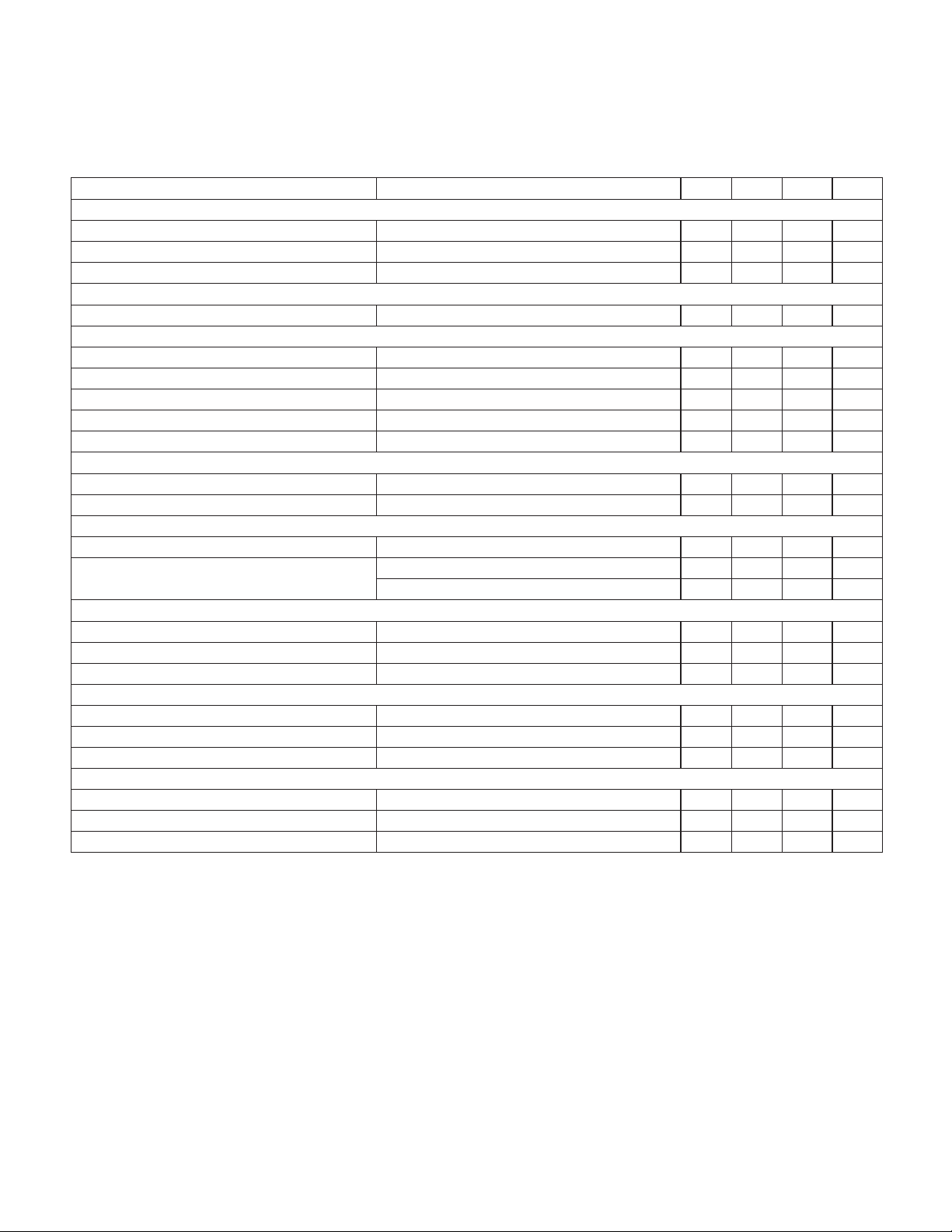

ELECTRICAL CHARACTERISTICS: Unless otherwise stated, these specifications apply for T

UCC3570, TA= –40 to 85°C for the UCC2570, TA=–55 to 125°C for the UCC1570, R

C

=150pF, VCC=11V and TA=TJ.

RAMP

PARAMETER TEST CONDITIONS Min Typ Max Units

Reference

VREF VCC =10 to 13V, I

= 0 to 2mA 4.9 5 5.1 V

VREF

Line Regulation VCC = 10 to 13V 2 10 mV

Load Regulation I

= 0 to 2mA 2 10 mV

VREF

Short Circuit Current VREF = 0 10 50 mA

VCC

Vth (On) 12 13 V

Vth (Off) 8 9 10 V

Hysteresis 345V

VCC I

Start VCC = 11V, VCC Comparator Off 85 150 µA

I

VCC

I

VCC Run

= 10mA 13.5 15 16 V

VCC

VCC Comparator On 1 1.5 mA

ISET

=100k, R

= 0 to 70°C for the

A

=121k, C

SLOPE

FREQ

=180pF,

2

UCC1570

UCC2570

UCC3570

ELECTRICAL CHARACTERISTICS:

UCC3570, TA= –40 to 85°C for the UCC2570, TA=–55 to 125°C for the UCC1570, R

C

=150pF, VCC=11V and TA=TJ.

RAMP

PARAMETER TEST CONDITIONS Min Typ Max Units

Line Sense

Vth High Line Comparator 3.9 4 4.1 V

Vth Low Line Comparator 0.96 1 1.04 V

lib (VFWD) 0 ±100 nA

Oscillator

Frequency 90 100 110 kHz

Ramp Generator

I

RAMP/ISLOPE

–I

RAMP/IISET

Peak Ramp Voltage 3.8 4 4.2 V

Valley Ramp Voltage 0.95 1 1.05 V

ISET Voltage Level 0.95 1 1.05 V

Soft Start

Saturation VCC = 11V, VCC Comparator Off 25 100 mV

I

SOFTST/IISET

Pulse Width Modulator

lib(FEEDBK) 0 ±100 n A

FEEDBK Zero Duty Cycle 0.9 1 1.1 V

Current Limit

lib(CURLIM) 0 ±100 nA

Vth Current Limit 180 200 220 mV

Vth Shutdown 500 600 700 mV

Fault Counter

Vth 3.8 4 4.2 V

Vsat 0 100 mV

I

COUNT/IISET

Output Driver

Vsat High I

Vsat Low I

Rise/Fall Time C

Unless otherwise stated, these specifications apply for TA= 0 to 70°C for the

=100k, R

ISET

Maximum Duty Cycle, (Note 1) 3.8 4 4.2 V

= –100mA 0.4 1 V

OUT

= 100mA 0.4 1 V

OUT

= 1nF, (Note 1) 20 100 ns

OUT

=121k, C

SLOPE

9 10 11 A/A

9 10 11 A/A

0.8 1 1.2 A/A

0.8 1 1.2 A/A

FREQ

=180pF,

Note 1: This parameter guaranteed by design but not 100% tested in production.

PIN DESCRIPTIONS

VCC: Chip supply voltage pin. Bypass to PGND with a

low ESL/ESR 0.1µF capacitor plus a capacitor for gate

charge storage.Lead lengths must be minimum.

PGND: Ground pin for the output driver. Keep connections less than 2cm. Carefully maintain low impedance

path for high current return.

OUT: Gate drive output pin. Connect to the gate of a

power MOSFET with a resistor greater than 2Ω. Keep

connection lengths under 2cm.

VFWD: Voltage Feed Forward and Line Sense pin. Connect to input DC line using a resistive divider.

SLOPE: Program the charging current for RAMP with a

resistor from this pin to GND. This pin will follow VFWD.

FEEDBK: Input to the pulse width modulator comparator.

Drive this pin with an optocoupler to GND and a resistor

to VREF. Modulation input range is from 1V to 4V.

ISET: A resistor from this pin to GND programs RAMP

discharge current, FREQ current, SOFTST current, and

COUNT current.

3

PIN DESCRIPTIONS (cont.)

RAMP: Ramp Pin. Connect a capacitor to GND. Rising

slope is programmed by current in SLOPE. This slope is

compared to FEEDBK for pulse width modulation. The

falling slope is programmed by the current in ISET and

used to limit maximum duty cycle.

FREQ: Oscillator pin. Program the frequency with a capacitor to GND.

VREF: Precision 5V reference, and bypass point for internal circuitry. Bypass this pin with a 1µF minimum capacitor to GND.

APPLICATION INFORMATION

(Note: Refer to Typical Application for external component names.) All the equations given below should be

considered as first order approximations with final values

determined empirically for a specific application.

Power Sequencing

VCC normally connects through a high impedance (R5)

to the rectified line, with an additional path(R6) to a low

voltage, bootstrap on the winding power transformer.

VFWD normally connects to a divider (R1 and R2) from

the rectified line. For circuit activation, all of the following

considerations are required:

1. VFWD between 1V and 4V

2. VCC has been under 9V (to reset the shutdown

latch)

3. VCC over 13V

At this time, the circuit will activate. I

from its start up value of 85µA to its run value of 1mA.

The capacitor on SOFTST is charged with a current determined by:

V

1

–

I

SOFTST

.

=

R

4

When SOFTST rises above 1V, output pulses will begin

and I

charge requirements asI

will further rise to a level dictated by gate

VCC

≈ 1mA + QTfs. With output

VCC

pulses, the low voltage bootstrap winding should now

power the controller. If VCC falls below 9V, the controller

will turn off and the start sequence will reset and retry.

VCC Clamp

An internal shunt regulator clamps VCC so that it will not

exceed 15V.

will increase

VCC

UCC1570

UCC2570

UCC3570

GND: Analog ground. Connect to a low impedance

ground plane containing all analog low current returns.

SOFTST: Soft start pin. Program with a capacitor to

GND.

COUNT: Program the time that fault events will be toler-

ated before shutdown occurs with a capacitor and resistor to GND.

CURLIM: Current Limit Sense pin. Terminates OUT gate

drive pulse for inputs over 0.2V. Enables fault counting

function (COUNT). For inputs over 0.6V, the shutdown

latch is activated.

Output Inhibit

During normal operation, OUT is driven high at the start

of a clock period and back low when RAMP either

crosses FEEDBK or equals 4V. If, however, any of the following occur, OUT is immediately driven low for the remainder of the clock period:

1. VFWD is outside the range of 1V to 4V

2. CURLIM is greater than 0.2V

3. FEEDBK or SOFTST is less than 1V

Normal output pulses will not resume until the beginning

of the next clock period in which none of the above conditions exist.

Current Limiting

CURLIM is monitored by two internal comparators. The

current limit comparator threshold is 0.2V. If the current

limit comparator is triggered, OUT is immediately driven

low and held low for the remainder of the clock cycle,

providing pulse-by-pulse overcurrent control for excessive loads. This comparator also causes C

charged for the remainder of the clock cycle. The charging current is

V

1

–

I

COUNT

.

=

R

4

If repetitive cycles are terminated by the current limit

comparator causing COUNT to rise above 4V, the shutdown latch is set. The COUNT integration delay feature

will be bypassed by the shutdown comparator which has

a 0.6V threshold. The shutdown comparator immediately

sets the shutdown latch. R

in parallel with CFresets the

F

COUNT integrator following transient faults. R

44

•

R

greater than

()

1

−

D

()

.

MAX

F to be

must be

F

4

APPLICATION INFORMATION (cont.)

Latched Shutdown

If CURLIM rises above 0.6V, or COUNT rises to 4V, the

shutdown latch will be set. This will force OUT low, discharge SOFTST and COUNT, and reduce I

proximately 1mA. When, and if, VCC falls below 9V, the

shutdown latch will reset and I

will fall to 85µA, allow-

VCC

ing the circuit to restart. If VCC remains above 9V, an alternate restart will occur if VFWD is momentarily reduced

below 1V. External shutdown commands from any source

may be added into either the COUNT or CURLIM pins.

Deadtime Control

The voltage waveform on RAMP has independently controlled rising and falling edges. At the start of the clock

period, RAMP is at 1V and rises to 4V. It then discharges

back to 1V and awaits the next clock period. OUT can

only be high during the rising part of the waveform, while

it is positively blanked off during the falling portion. Setting the –dV/dt slope by R4 from ISET to GND establishes a minimum deadtime as:

td R C

=••03 4.

R

VCC

to ap-

UCC1570

UCC2570

UCC3570

Choose R4 between 20k and 200k and C

50pF. In order to have a pulse at OUT in the next clock

period, RAMP must fall to 1V prior to the end of the current period. If it does not, OUT will remain low for the entire next clock period.

Voltage Feedforward

The +dV/dt on RAMP is made proportional to line voltage.The slope is:

dV

dt

=•

VFWD

10

RC

•

3

()

R

where VFWD is line voltage scaled by R1 and R2. Therefore, a changing line voltage will accomplish an immediate proportionate pulse width change without any action

from the feedback amplifier. This will result in constant

volt-second drive to the power transformer providing both

international voltage operation, and excellent dynamic

line regulation. VFWD is intended to operate over a 4:1

range (1V to 4V) with undervoltage and overvoltage sensors designed to drive OUT low if this range is exceeded.

Choose R3 between 20k and 200k.

R greater than

Figure 1. UCC1570 typical application.

5

APPLICATION INFORMATION (cont.)

Frequency Set

A capacitor from FREQ to GND will determine a constant

clock frequency. Frequency is:

F

If required, frequency can be trimmed down from the

above equation by the addition of R

The reduction in frequency is a function of the ratio of

R4. RTshould be greater than 2.4 • R4 for reliable op-

R

T/

eration.

External synchronization can be accomplished by cou-

pling a narrow pulse to a resistor inserted in series with

the ground side of C

R4/200 and the synchronizing pulse width should be less

than 5% of the oscillator period.

External synchronization can also be accomplished by

driving FREQ with an CMOS inverter. The inverter must

184.

=

RC

•

()

T

from FREQ to GND.

T

The value should be less than

T.

UCC1570

UCC2570

UCC3570

be able to sink (4 • I4) with at a voltage less than the

3.5V upper threshold of the oscillator. It must also be

able to source 36 • I4 at a voltage greater than the 1.5V

lower threshold of the oscillator. As long as FREQ is held

high, the output is guaranteed to be low.

Gate Drive Output

The UCC1570 is capable of 1A peak output current. Bypass VCC with at least 0.1µF directly to PGND. Use a

capacitor with low equivalent series resistance and inductance. The connection from OUT to the MOSFET

gate should have a 2Ω or greater damping resistor and

the length should be minimized. A low impedance connection must be established between the MOSFET

source (or the ground side of the current sense resistor),

the VCC bypass capacitor and PGND. PGND should

then be connected by a single path (shown as RGND in

the application) to GND.

CLOCK

FEEDBK

RAMP

OUT

HIGH V

IN

Figure 2. Ramp and PWM waveforms.

LOW V

IN

FAULT V

IN

6

APPLICATION INFORMATION (cont.)

Figure 3. Clock generator.

UCC1570

UCC2570

UCC3570

Figure 4. External clock synchronization.

Figure 5. Frequency dependence on RT/ R4 ratio.

7

APPLICATION INFORMATION (cont.)

UCC1570

UCC2570

UCC3570

UNITRODE CORPORATION

7 CONTINENTAL BLVD. • MERRIMACK, NH 03054

TEL. (603) 424-2410 FAX (603) 424-3460

8

IMPORTANT NOTICE

T exas Instruments and its subsidiaries (TI) reserve the right to make changes to their products or to discontinue

any product or service without notice, and advise customers to obtain the latest version of relevant information

to verify, before placing orders, that information being relied on is current and complete. All products are sold

subject to the terms and conditions of sale supplied at the time of order acknowledgement, including those

pertaining to warranty, patent infringement, and limitation of liability.

TI warrants performance of its semiconductor products to the specifications applicable at the time of sale in

accordance with TI’s standard warranty. Testing and other quality control techniques are utilized to the extent

TI deems necessary to support this warranty . Specific testing of all parameters of each device is not necessarily

performed, except those mandated by government requirements.

CERTAIN APPLICATIONS USING SEMICONDUCTOR PRODUCTS MAY INVOLVE POTENTIAL RISKS OF

DEATH, PERSONAL INJURY, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE (“CRITICAL

APPLICATIONS”). TI SEMICONDUCTOR PRODUCTS ARE NOT DESIGNED, AUTHORIZED, OR

WARRANTED TO BE SUITABLE FOR USE IN LIFE-SUPPORT DEVICES OR SYSTEMS OR OTHER

CRITICAL APPLICA TIONS. INCLUSION OF TI PRODUCTS IN SUCH APPLICATIONS IS UNDERST OOD TO

BE FULLY AT THE CUSTOMER’S RISK.

In order to minimize risks associated with the customer’s applications, adequate design and operating

safeguards must be provided by the customer to minimize inherent or procedural hazards.

TI assumes no liability for applications assistance or customer product design. TI does not warrant or represent

that any license, either express or implied, is granted under any patent right, copyright, mask work right, or other

intellectual property right of TI covering or relating to any combination, machine, or process in which such

semiconductor products or services might be or are used. TI’s publication of information regarding any third

party’s products or services does not constitute TI’s approval, warranty or endorsement thereof.

Copyright 1999, Texas Instruments Incorporated

Loading...

Loading...