Page 1

Page 2

Introductio

n

Dear users

:

Thank you for purchasing UNI-T product. To operate the instrument correctly, please

read this Operating Manual carefully and especially its “Safety Notice” before use

.

Afer reading it, you are suggested to keep the manual properly. Please keep it with the

instrument together or place it in an accessible location for future use

.

Page 3

General Safety Overview

The instrument is designed and manufactured strictl

y

according to “Safety Requirements of Electronic

Measuring Instruments” (GB4793) and IEC61010-1

Safety Standard . It conforms to “Insulation Overvoltage

Standard” (CAT 600V) and Safety Standard wit

h

Pollution Level You are expected to know the followin

g

safety precaution measures to avoid personal injury or

product damage or any other product connected to it

.

Please use the product according to the regulations so

as to avoid the possible damage

.

Only personnel with professional training can execute

maintenance procedure to avoid fire or personal

injury. Appropriate power wires should be used and

special power wires must be approved by the state

.

Reliable grounding of products: The product is

grounded by ground conductor of power supply

.

Ground conductor must be connected to earth to

avoid electric shock. Please guarantee correct

grounding before connecting input/output terminal of

the product

.

Correct connection of oscillograph probe: Earth wire

of probe is the same to earth potential. Ple ase do not

connect earth wire to high volt age

.

Review of rated values of all terminals: Please refer to

all rated values and marks on the product surface to

avoid fire or excessive current shock. Please refer to

product manual before connecting products so as to

know details of rated value s.D o not open cover plate

of machine box: It is not allowed to start or operate the

product when opening external cover or panel

.

Ċ

Ċ

Correct plug-in/out: Please do not plug in/out whe

n

connecting probe or testing conduits to voltage

source

.

Operating Manual for UTD2000/3000

Page 4

Operating Manual for UTD2000/3000

Usage of appropriate fuse: It is only allowed to use

fuse type and rated indicator designated by the

product

.

To avoid exposed circuits: It is not allowed to touc

h

exposed connector or element after power supply

.

Operation is not allowed if there is any doubt for

product trouble: Please consult qualified maintenance

personnel to inspect the product if there is any trouble

doubt

.

It has to maintain appropriate ventilation. It is not

allowed to operate in wet locations. It is not allowed

to operate in combustible and explosive

environment. It has to keep product surface clea

n

and dry

.

Page 5

Terms in the manual: The following terms may be

seen in the manual

:

Terms for products: The following terms may be

Danger: It refers to direct injury near the mark

.

Warning: It refers to potential injury near the mark

.

Note: It refers to potential danger for the product

and other properties

.

Warning: Warning s tatement means the

conditions and behaviors that may endanger lives.

Note: Notice statement means the conditions

and behaviors that may cause other property

damage

Protective

ground terminal

Ground terminal

for chassis

Ground terminal

for testin

g

Caution

!

Refer to manual

High voltage

Safety Ter ms and Symbols

Product symbol: Following symbols may be show

n

on the product surface

.

Operating Manual for UTD2000/3000

Page 6

Operating Manual for UTD2000/3000

The manual is about operation information of OPERATING MANUAL FOR UTD2000/3000 digital storage

oscillograph. The manual includes the following chapters

Chapter 1: User Guideline: It is to introduce functions of digital storage oscillograph easily and provide

installation guidelines

.

Chapter 2: Instrument Setup:Operation methods of OPERATING MANUAL FOR UTD2000/3000 digital

storage oscillograph

.

Chapter 3: Application example: Examples to solve various measurement problems

Chapter 4: System Prompt and Troubleshootin

g

Chapter 5: Appendix: Technical Indicators

A

ppendix B: Fittings of OPERATING MANUAL FOR UTD2000/3000 series digital storage oscillograph

A

ppendix C: Maintenance and Cleaning Maintenance

Preface

Page 7

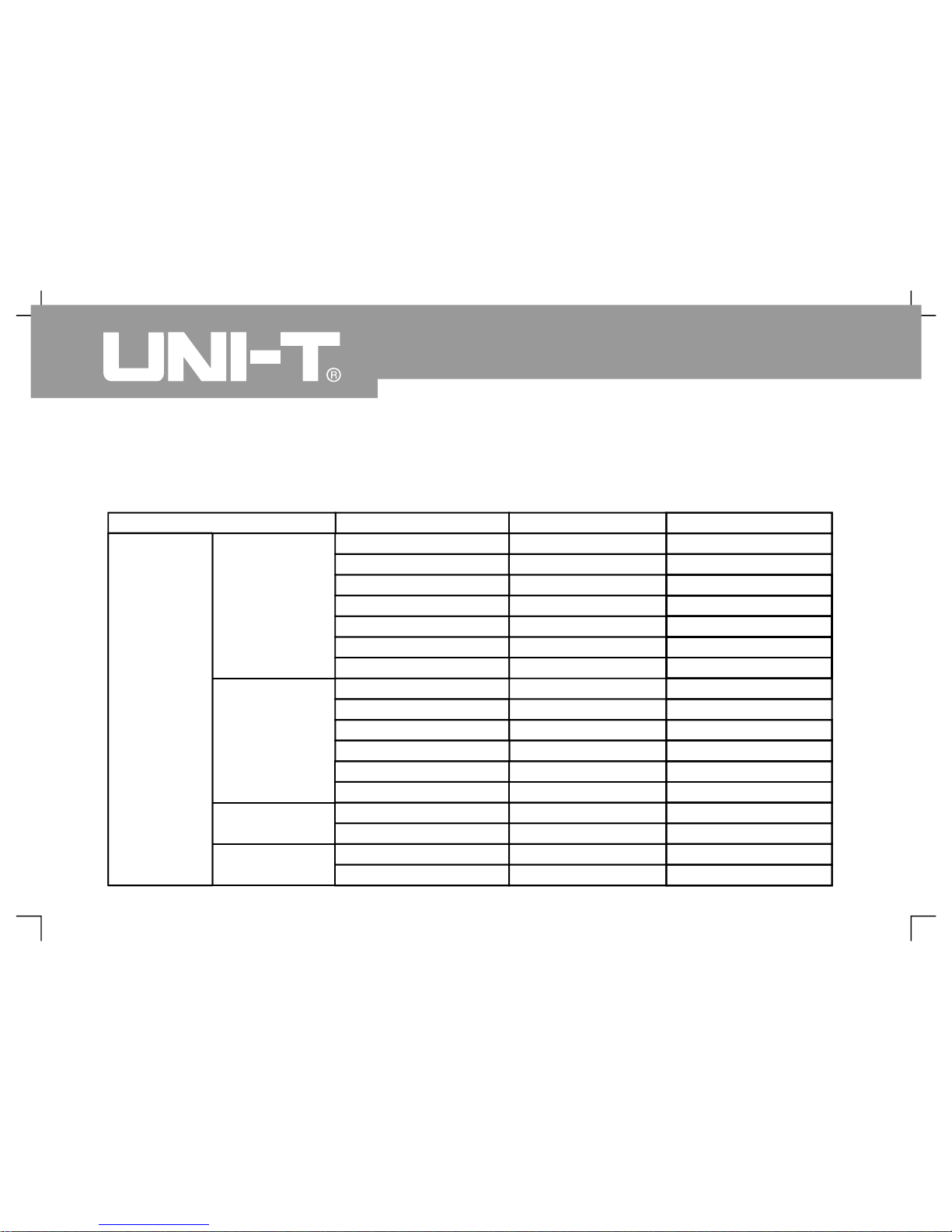

The manual includes 3 series of digital storage oscillograph as follows. Detailed models are shown in the

following form

:

Operating Manual for UTD2000/3000

UTD2 C/UTD3025

C

02

5

UTD2 C/UTD3042

C

04

2

UTD2 C/UTD3062

C

06

2

UTD2 C/UTD3082

C

08

2

UTD2 C/UTD3102

C

10

2

UTD2 C/UTD3152

C

15

2

UTD2 C/UTD3202

C

20

2

UTD2 CE/UTD3042CE04

2

UTD2 CE/UTD3062CE06

2

UTD2 CE/UTD3082CE08

2

UTD2 CE/UTD3102CE10

2

UTD2 CE/UTD3152CE15

2

UTD2202CE/UTD3202CE

UTD2025C

L

UTD2052C

L

UTD2052CE

X

UTD2102CE

X

25MH

z

40MH

z

60MH

z

80MH

z

100MH

z

150MH

z

200MH

z

40MH

z

60MH

z

80MH

z

100MH

z

150MH

z

200MH

z

25MH

z

50MH

z

50MH

z

100MH

z

250MS/s

500MS/s

500MS/s

500MS/s

500MS/s

500MS/s

500MS/s

1GS/s

1GS/s

1GS/s

1GS/s

1GS/s

1GS/s

1GS/s

1GS/s

250MS/s

500MS/s

UTD2000C/3000

C

UTD2000E/3000E

UTD2000

L

UTD2000E

X

UTD2000/300

0

Series Model

Band width

Real-time

Page 8

Operatin g Manual for UTD2000/3000

UTD2000/3000 series digital storage oscillograp

h

provides simple front panel with clear functions to

users for all basic operations. Scale and position of

various channels can provide intuitional operatio

n

to meet usage habits of traditional instruments

.

Users can use it skillfully without learning and

being familiar with operation for a long time. Users

can also press AUTO key directly to accelerate

adjustment and facilitate measurement

.

A

ppropriate waveform and gear setup can be

shown on the instrument panel

.

UTD2000/3000 series digital storage oscillograp

h

also has high-performance indicators and powerful

functions to fulfill measurement tasks quickl

y

besides easy usage. Quicker signals can be

observed by UTD2000/3000 series digital storage

oscillograph by real-time sampling of 500MS/s (or

1GS/s) and equivalent sampling of 25GS/s (or

50GS/s). It can capture and analyze waveform

easily by powerful trigger and analysis capacity

.

Users can also observe and analyze signal

problems quickly and clearly by clear LCD displa

y

and mathematical calculation function. We can see

that such series of digital storage oscillograph ca

n

meet your measurement requirements by following

performance characteristics

:

Double analog channels

High-resolution colorful LCD display system wit

h

resolution of 320 240 or 800 480

To support plug and play USB storage instrument

to communicate with computer

A

utomatic waveform and status setup

Waveform, setup, bitmap storage, waveform and

setup reoccurrence

Ɣ

Ɣ

Ɣ

Ɣ

Ɣ

h h

Page 9

Ɣ

Ɣ

Ɣ

Ɣ

Ɣ

Ɣ

Ɣ

Ɣ

Ɣ

Ɣ

Ɣ

Ɣ

hr

Āā

Āā

Elaborate view window extension function for

delicate analysis of w aveform details and profile

A

utomatic measurement of 28 kinds of

waveform parameters

A

utomatic cursor tracing and measurement

functio

n

Unique waveform recording and playback

functions

Embedded FFT

Multiple mathematical calculation functions

(including +, -, for waveform

Edge, video, pulse width and ALT TRIG

functions

Multi-language menu displa

y

Fittings of UTD2000/3000 series digital storage

oscillograp

h

2 probes of 1.2m 1:1/10:1 please refer to

manual of probe Fittings of probe details so as

to meet EN61010-031:2008 standar

d

1 power wire to meet national standards

1 Operating Manual

1 Product Warrant

y

USB connecting wire: UT-D06 or UT-D0

5

Communication control software for

UTD2000/3000 series oscillograp

h

㧦

Operating Manual for UTD2000/3000

Page 10

Item

Elementary understanding of Trigger System..........................................

.

Page

..........................................................................................

.

.........................................................................................

.

......................................................................................

.

............................................................

.

Elementary understanding of Vertical System...............................................

.

Elementary understanding of Horizontal System..........................................

.

General Safet y Overvi ew

Preface

Setup of Vertical System........................................................................

.

Setup of Horizontal System.....................................................................

.

Setup of Trigger System..........................................................................

.

General Inspectio

n

Function Inspectio

n

Probe Compensatio

n

A

utomaticSetup of Waveform Displa

y

Chapter 1: User Guideline ..................................................................................

.

5

5

8

9

9

11

1

4151627

31

Operatin g Manual for UTD2000/3000

Content

s

Chapter 2: Instr ument Setup.......................................................................

1

Page 11

Page

...................................................................................

.

..........................................................................................

.

Setup of Auxiliary Functions .............................................................................

.

A

utomatic Measurement...................................................................................

.

Cursor Measurement ........................................................................................

.

....................................................................................................

....................................................

.

.............

.

..................................................................

.

Setup of Display System

Storage and Callout

Operation Ke

y

Chapter 3: Application Examples

Example 1: Measurement of Simple Signals

Example 2: Delay Obser vati on of Sin e Sig na l s by Circ ui t.. ... .... ... ... ... ... .... ... .

.

Example 3: Capture of Sing le S igna l .... ... ... ... .... ... ... ... .... ... ... ... ... .... ... ... ... .... .

.

Example 4: Reduction of Ran do m Noi se for S igna ls. ... ....................... ... ... ....

.

Example 5: A p plic a tion Cu r sor Me asu r em en t.. ... .... ... ... ... .... ... ... ... .... ... ... ... ...

.

Example 6: Application of X-Y Functio

n

Example 7: Trigger of Video Signals

................. ... .... ... ... ... .... ... ... ....... ... ...

.

.................. ... .... ... ... ... ... .... ... ...

.

4

8505560687072727375767879

81

4

4

Operating Manual for UTD2000/3000

Item

Setup of Sampling System................................................................

.

Page 12

Item Page

.......................................................

.

............................................................................

.

....................

.

.....................................................

.

...............................................................................................

.

.........................................

Examp

Examp : Usage of Upgrading Procedure of U disk

System Prompt Informatio

n

Troubleshootin

g

A

ppendix A: Technical Indicators......................................................

.

A

ppendix B: Fittings of UTD2000/3000 Series Digital Storage Oscillograph..

.

A

ppendix C: Maintenan ce and Clea ning Mai nte nan ce... ..... .... .... .... ..... .. ....

.

Example 10: Usage of Storage Functio

n

Chapter 4: S ystem Prompt and Troubleshooting

Chapter 5: Technical Indicators............................................................

Example 8: Pass/Fail Detectio

n

Example

9

8

889

91

91

10

4

10

583848588

Operating Manual for UTD2000/3000

Page 13

Operating Manual for UTD2000/3000

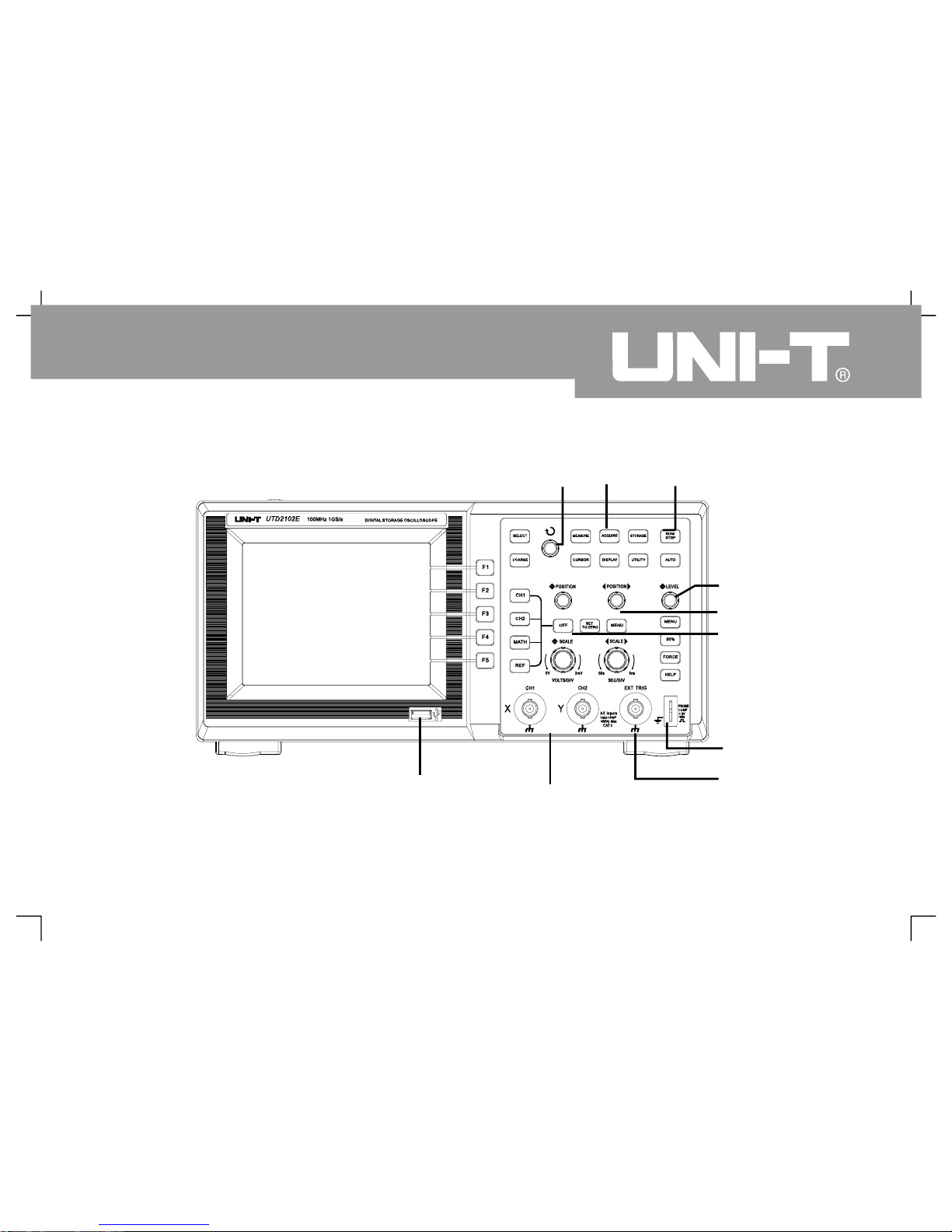

Chapter 1: User Guideline

Ƹ

Ƹ

Ƹ

Function inspectio

n

Elementary understanding of vertical system

Elementary understanding of horizontal system

UTD2000/3000 series digital storage oscillograph is

a small and handy desktop product. Basic test can be

done by providing convenient front panel to facilitate

operation for users

.

UTD2000/3000 series are to provide simple front

panel with clear functions to users for basic

operation. Panel also includes knob and function key

.

Knob functions are similar to those of other digital

storage oscillograph

.

The chapter is to show execution of following steps

General inspectio

n

5 keys in a row in the right side of display panel are

menu operation keys. (They are defined as F1 to F

5

keys from top to bottom.) You can also set different

options for current menu by them. Other keys are

function keys. You can enter into different functio

n

menus or gain specific function application directly

by them

.

㧦

Elementary understanding of trigger system

Please know front operation panel firstly after

getting UTD2000/3000 series digital storage

oscillograph. The chapter is to introduce operation

and functions of front panel for

UTD2000/3000products so as to be familiar wit

h

usage within the shortest period

.

General inspectio

n

Ƹ

Ƹ

Ƹ

A

utomatic setup of waveform displa

y

Probe compensatio

n

Ƹ

1

Page 14

Operating Manual for UTD2000/3000

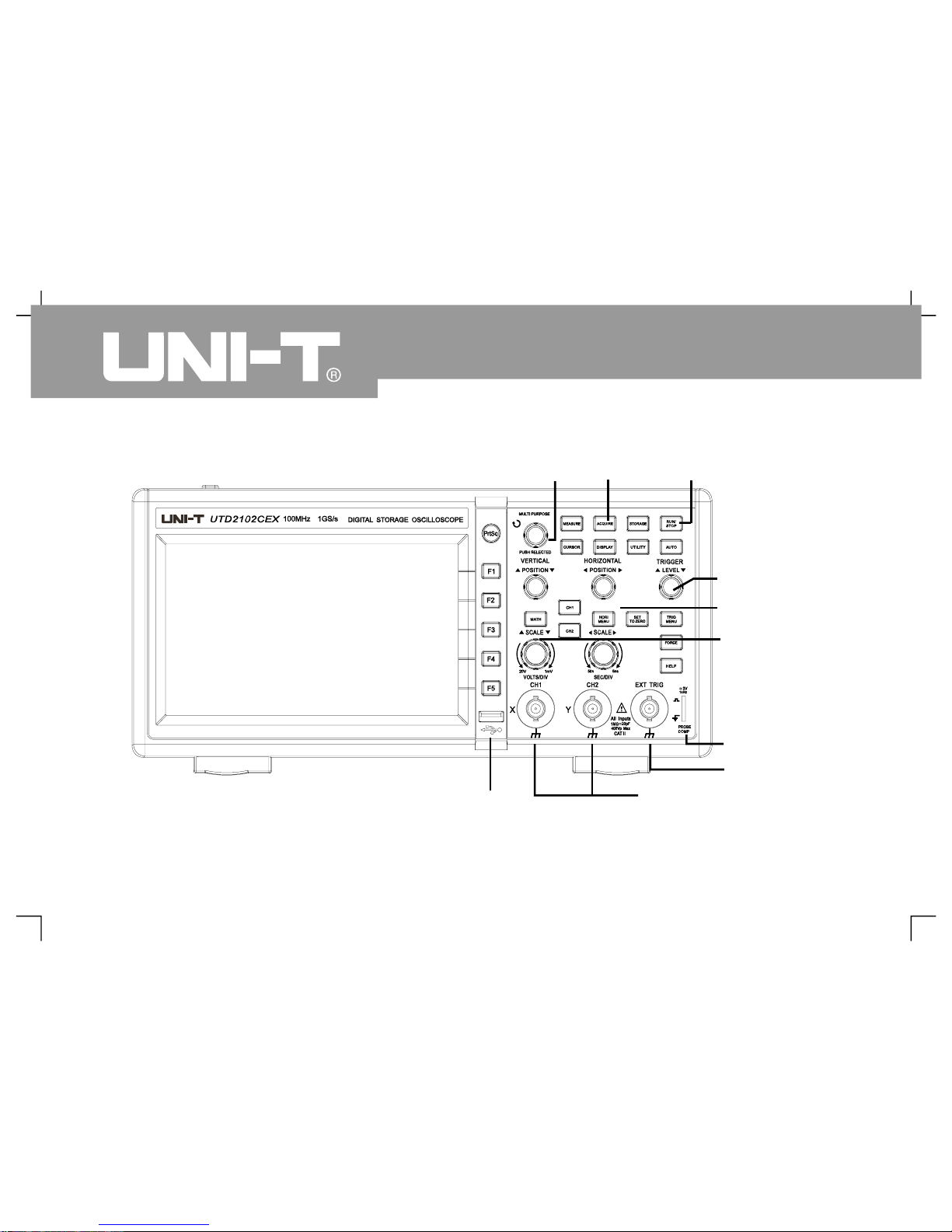

2

5.7 inch front panel of UNI-T

probe compensatio

n

signal output

vertical control

horizontal control

Operatio

n

controls

multi-purpose

knob controller

commo

n

men

u

trigger control

EXT TRIG INPUT

analog signal input

interface

Page 15

Operating Man ual for UT D2000/30 00

3

probe compensatio

n

signal output

vertical control

horizontal control

Operatio

n

controls

multi-purpose

knob controller

commo

n

men

u

trigger control

EXT TRIG INPUT

analog signal input

interface

7 inch front panel of UNI-T

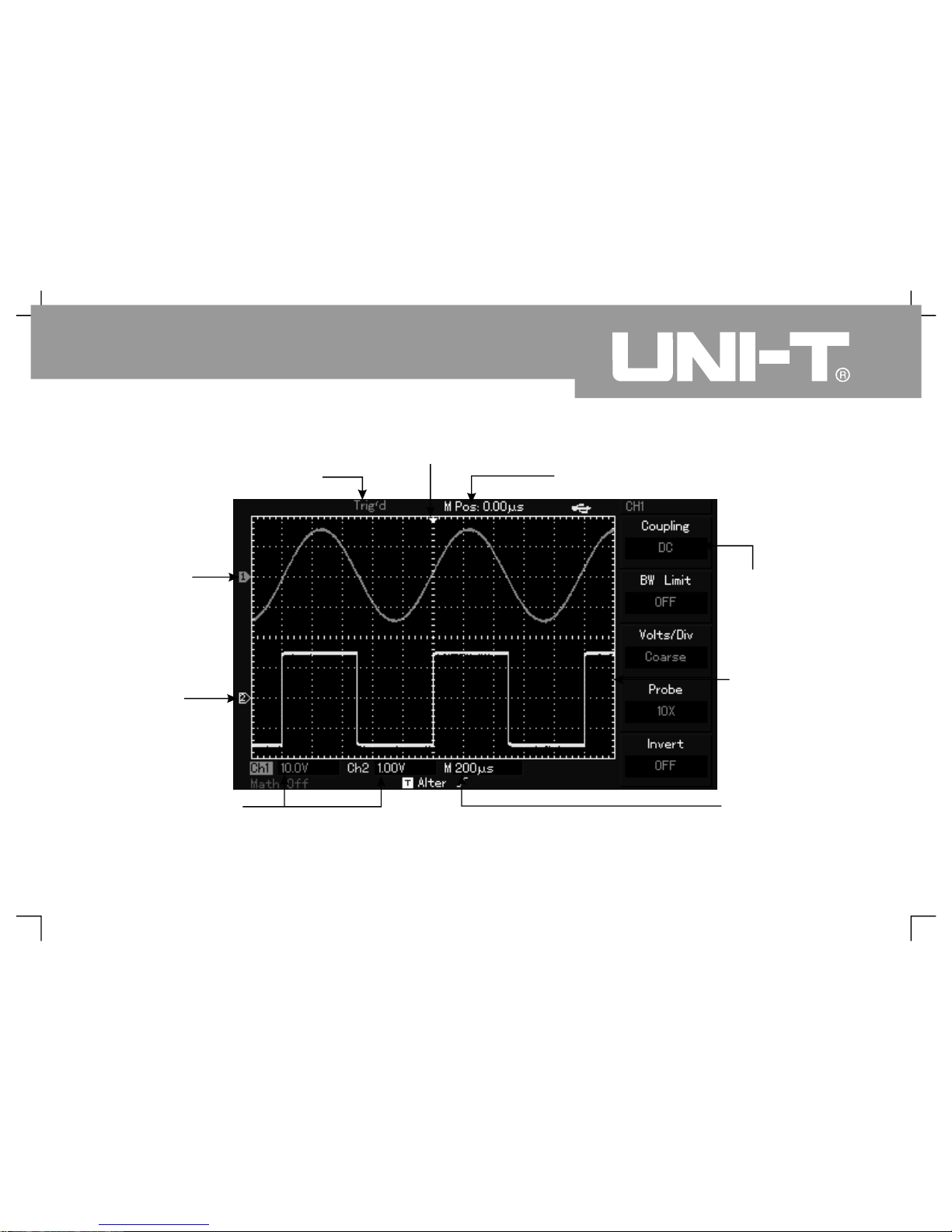

Page 16

Operatin g Manual for UTD2000/3000

4

display of horizontal trigger positio

n

time display of central scale line

vertical scale

coefficient of

display channel

display setup of

main time base

waveform

display window

Menu varies wit

h

different functio

n

keys

.

mark of

channel

2

display of trigger status

mark of

channel 1

Interface display diagram of digital storage oscillograph (i.e. UTD2000L series

)

Page 17

Operating Manual for UTD2000/3000

5

General inspectio

n

Function inspectio

n

It is suggested to inspect the instrument b

y

following steps when getting a new UTD2000/3000

series digital storage oscillograph

.

1. To check if there is damage due to transportatio

n

or not

.

Please replace carton or foaming plastic protectio

n

cushion with severe damage instantly

.

2. Please inspect fitting details and shown it i

n

“Fittings of UTD2000/3000 series digital Storage

Oscillograph” shown in the manual. You can check

if there are deficient fittings or not by referring to it

.

Please contact UNI-T distributor or local agent if

there are deficient or damaged fittings

.

3. Please inspect the entire machine and contact UNI-T

distributor or local agent for damaged appearance

,

abnormal operation or failing to pass performance test

.

Please pay attention to packages and report to

transportation department and UNI-T distributor if

machine damage is caused by transportation

.

1. Connect the power suppl

y

You can supply power to the machine and voltage is A

C

100V to AC 240V. Frequency is 45Hz to 440Hz. It has

to press [UTILITY] menu and [F1] for self-correctio

n

after power supply 30 minutes after operation of hot

machine so that digital storage oscillograph operates

under the

best status. As shown in Figure 1 4, please

enter into next page and press [F1] to call out ex-factor

y

setup

.

㧙

UNI-T will arrange maintenance or replacement

.

Please carry out once fast function inspection to

check if the machine operates normally or not

.

Please operate according to following steps

:

Page 18

Warning: Please confirm safety grounding of digital

storage oscillograph to avoid dangers

.

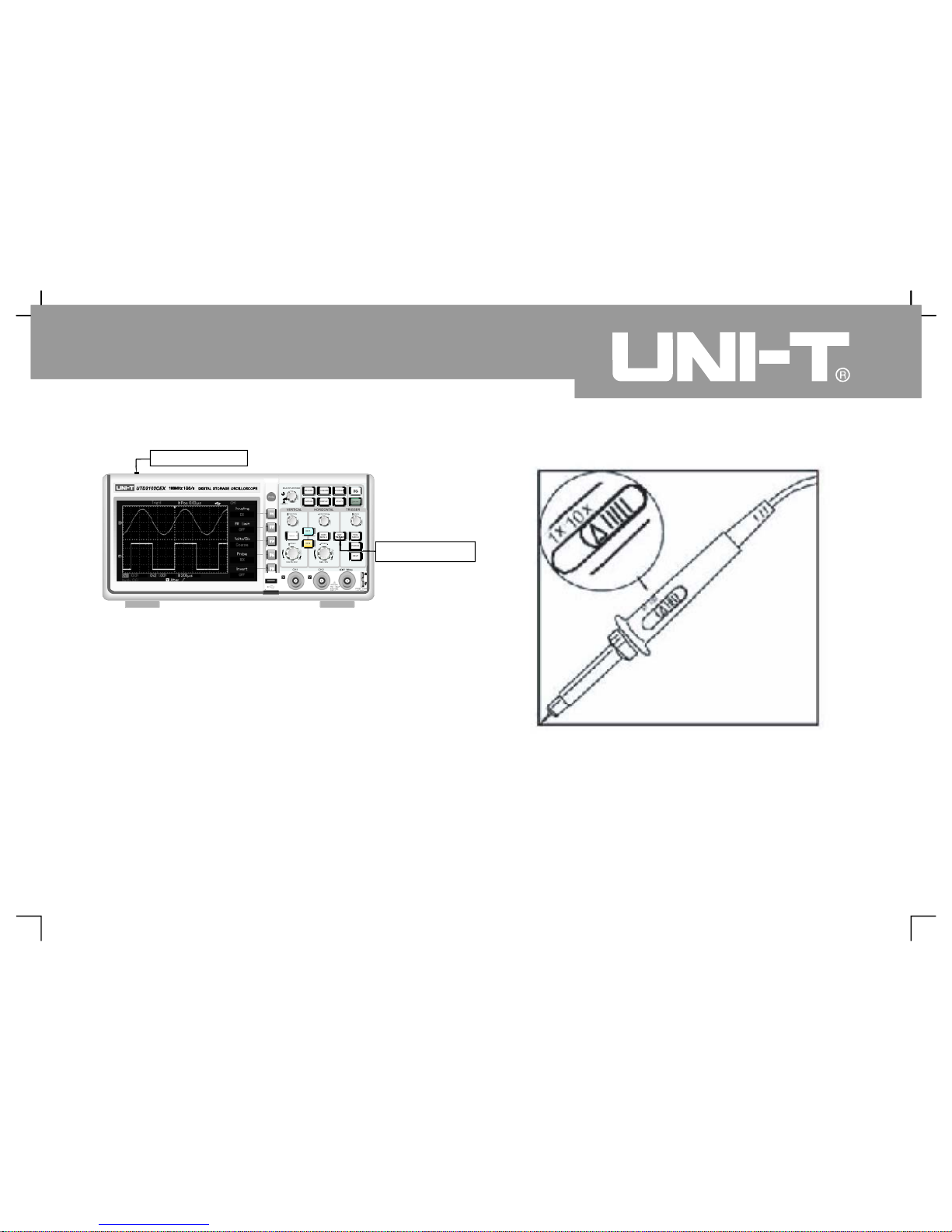

2. Signal access of digital storage oscillograph is

double-channel input for UTD2000/3000 series

digital storage oscillograph. There is also 1 EXT

TRIG INPUT channel. Please connect signals

according to following steps

:

(As shown in Figure 1-5), connect probe of

digital storage oscillograph to CH1 input terminal

and set attenuation ratio switch on probe to 10×

Á

Figure 1 5 Setup of attenuation ratio switch o

n

probe

㧙

ķ

ˊ

Operating Manual for UTD2000/3000

6

Figure 1-

4

power switc

h

function butto

n

F

1

MEASURE

CURSO

R

DISPLAY

A

CQUIRE STORAGE

UTILITY

MULTIPURPOSE

SELECT

AUTO

CH

1CH2

F

2F3

F

4

F

5

POSITION

SCALE SCALE

VOLTS DIV

VVm

POSITION

SECD IV

SS

LEVEL

MATH

FORCE

HELP

MENU

TRI

G

MENU

HORI

VERTICA

L

CH

1

TRIGGE

R

HORIZONTA

L

CH2

SET

Operating Man ual for UT D2000/30 00

Page 19

Operating Man ual for UT D2000/30 00

7

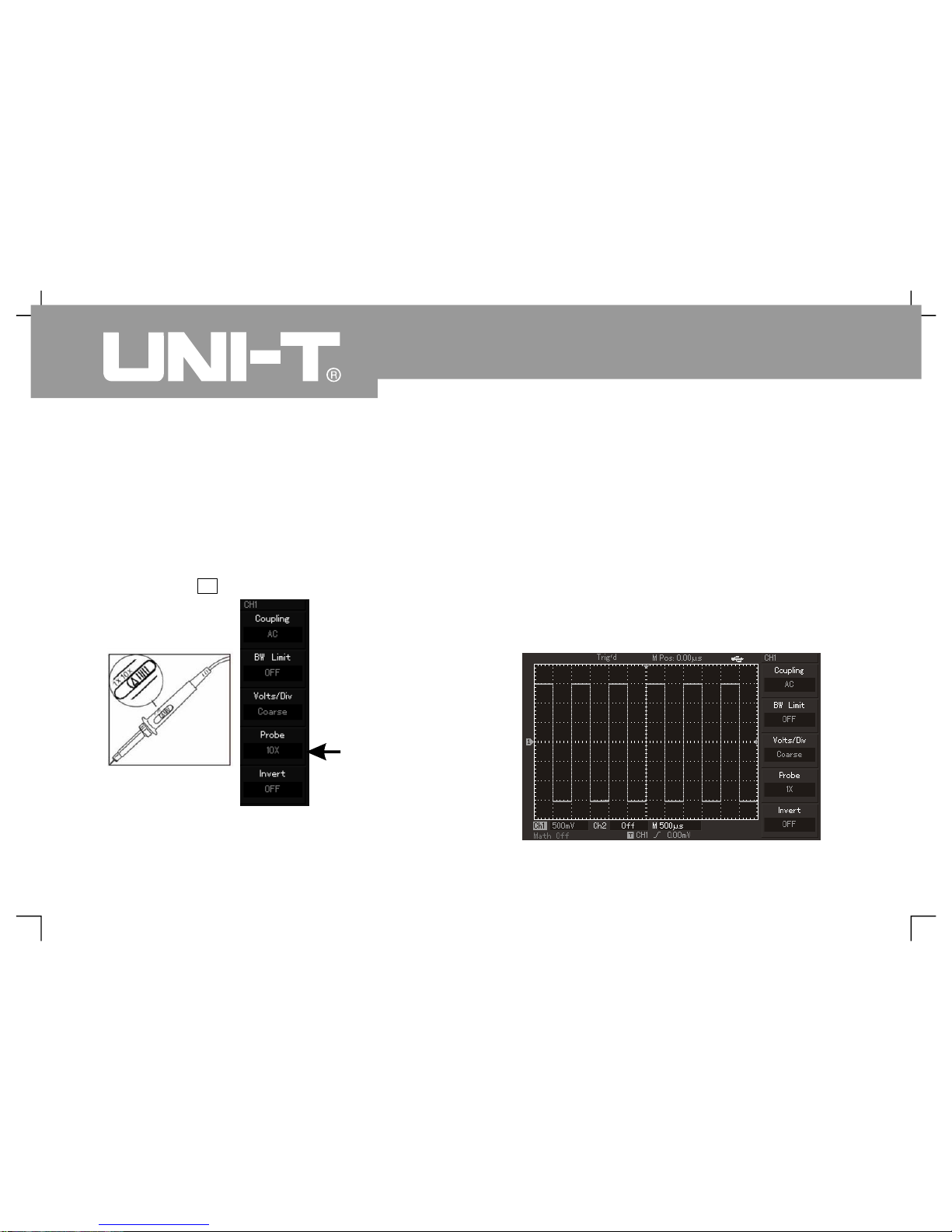

ĸIn digital storage oscilloscope to set the probe

attenuation factor. The attenuation coefficient of

vertical gear ratio change instruments, whic

h

makes measurement resultsSetup method of

attenuation coefficient of pr obe is as follows to

show amplitude of measured s ignals correctly

.

Please press

Figure 1-6 Setup of deflection coefficient of probe

on digital storage oscillograp

h

F4 key for menu display of 10

×

Connect probe and grounding clip to

corresponding connection ends then press [AUTO]

button. As shown in Figure 1-7, square wave (1kHz

,

about 3V and peak value) can be displayed withi

n

several seconds. It has to inspect CH2 by the same

method then press [OFF] function button so as to

power off CH1. It has to press [CH2] function butto

n

to power on CH2 and repeat the second and third

steps.

Ĺ

Proberatio

n

Figure 17㧙

Page 20

Operating Manual for UTD2000/3000

Probe compensatio

n

It needs to adjust it when connecting probe to an

y

input channel for the first time so that probe can be

appropriate to input channel. Probe without

compensation correction can also bring i

n

measurement tolerance or error. Please operate

according to following steps for adjustment of

probe compensation

:

1. To set probe menu attenuation coefficient to

10× and place probe switch to 10× then connect

digital storage oscillograph probe to CH1. Please

guarantee reliable contact to probe. It has to

connect probe end to signal output connector2of

probe compensator then connect grounding clip to

earth wire connector of probe compensator. It also

has to power on CH1 and press [AUTO]

.

3. Adjust variable capacitance on the probe b

y

screwdriver of non-metallic handle for waveform

display of “insufficient compensation” or

“excessive compensation” shown in above figure

until “correct compensation” for waveform displa

y

on the screen as above

.

Warning: Please guarantee perfect insulatio

n

conduits of probe and do not contact metallic part

of probe when connecting to HV source to avoid

electric shock of probe during HV measurement

.

Observation of displayed waveform

8

Exceedin

g

compensatio

n

Correct

compensation

Insufficient

compensation Figure 1

8

㧙

Compensation correction of probe

Page 21

Operatin g Manual for UTD2000/3000

9

Automatic setup of waveform displa

y

UTD2000/3000 series digital storage oscillograp

h

has automatic setup functions. It can adjust vertical

deflection coefficient, scanning time base and

trigger mode automatically according to input

signal for the most appropriate waveform display

.

Frequency of measured signals shall be more tha

n

or equal to 50Hz and duty cycle shall exceed 1%

according to automatic setup requirements

.

1. Connect measured signals to signal input

channel

.

2. Press [AUTO] button so that digital storage

oscillograph can set ver tical deflection coefficient

,

scanning time base and trigger mode

automatically. They can be adjusted again after

careful observation and automatic setup so that

waveform display can realize the best effect

.

A

s shown in the following figure, there are a series

of keys and knobs in vertical control a rea. Please

introduce usage of vertical setup gradually as

follows

.

Automatic setup

Elementary understanding of vertical system

㧦

5.7-inch vertical

control panel of scree

n

7-inch vertical control

panel of scree

n

Figure 1 9 Vertical control area on the panel㧙

Page 22

Operating Manual for UTD2000/3000

10

1. Use vertical position knob so that middle displa

y

of waveform signal in the window. Vertical displa

y

position of signal can be controlled by vertical

position knob

.

Ground mark moves vertically with waveform whe

n

rotating vertical position knob

.

Measurement knack

You can observe difference between waveform

and signal ground to measure DC component

of signal quickly if adopting DC channel

coupling mode. DC components in the signal

will be filtered if adopting AC coupling mode

. You can also display AC component of signal

by higher sensitivity conveniently

.

Vertical position of double analog channels shall be

restored to short-cut key of zero pointnamely

,

SET TO ZERO

.

The key is to return vertical displacement/horizontal

displacement/hold off position to zero point

(or middle point)

.

Of w hich: UTD2000L /2000EX se ries will trigger

electric level Return to 50% of position

.

2 Alter vertical setup and observe alternation of

status information. You can determine variation of an

y

vertical gear by s tatus bar below waveform window

.

Vertical gear of “volt/grid” can be altered by rotatin

g

vertical scale knob to show corresponding variation for

channel gear display which corresponds to status bar

.

User can press [CH1], [CH2] , [MATH] and [REF] to

display operation menu, mark, and waveform and

gear status information of corresponding channels

.

Page 23

Operating Manual for UTD2000/3000

1

1

Users can also press [OFF] key to c lose currentl

y

selected channels for UTD2000C/3000C and

UTD2000E/3000E oscillograph. They can also

click on CH1, CH2 and MATH keys twice to close

corresponding channels for UTD2000L/2000EX

oscillograph

.

A

s shown in following figure, there is 1 key and

2

knobs in horizontal control area. Please be familiar

with setup of horizontal time base gradually as

follows

:

Elementary understanding of horizontal system

Horizontal cont rol

panel of 5.7-inc

h

Horizontal cont rol

panel of 7-inc

h

Figure 1 10 Horizontal control area on the panel㧙

Page 24

Operating Manual for UTD2000/3000

1. Use horizontal SCALE knob to alter horizontal

time base gear then observe alternation of status

information. To rotate horizontal SCALE knob to

alter “s/div” time base gear so as to show

corresponding variation of time base gear displa

y

for corresponding channels of status bar

.

Horizontal scanning speed steps from 2ns/di

v

s/div by way of 1 mode

.

Note: Horizontal scanning time base gear varies

for UTD2000/3000 series digital storage

oscillograph due to different models

.

γ

㨪

㧙㧙50 2

5

2. Use horizontal POSITION knob to adjust

horizontal position of signals in waveform window

.

To use horizontal POSITION knob to control trigger

displacement of signals. Horizontal movement of

waveform with knob can be observed when rotatin

g

horizontal POSITION knob for application for

trigger displacement

.

3. Please press [MENU] button for 5.7-inc

h

oscillograph (and press [HORI MENU] button for 7inch oscillograph) to display Zoom menu. Please

press [F3] to open view window extension under

this menu then press [F1] to close view window

extension and return to main time base. Hold off

time can be set under this menu

.

1

2

Page 25

Operating Manual for UTD2000/3000

1

3

Trigger point can be r estored to vertical m iddle

point quickly by short-cut key of [SET TO ZERO] so

as to restoring displacement of trigger point to

horizontal zero point short-cut key. Users can also

adjust horizontal position of signal in waveform

window by rotating horizontal knob

.

Term explanatio

n

Trigger point: It refers to posi tion of actual trigger

point by comparing with middle point of storage

instrument. Users can move trigger horizontally b

y

rotating horizontal POSITION knob

.

Hold off: It refers to interval to start up trigger

circuit a gain

.

Hold off time can be set by rotatingmulti-purpose

knob controller

.

A

s shown in Figure 1 there is 1 knob and

3

(or 2) keys in control area of trigger menu. Pleas e

be familiar with setup of trigger system gradually as

follows

:

POSITIO

N

Elementary understanding of trigger system

㧙11

5.7-inch screen 7-inch scree

n

Figure 1-1

2

Trigger men

u

Figure 1 Trigger menu on the panel㧙11

Page 26

1. To user trigger level knob to alter trigger level

and instruct trigger level line by seeing trigger mark

on the screen so that it moves vertical ly with knob

rotation. Variation of tr igger level in lower part of

screen can be observed when moving trigger level

at the same time

.

2. (As shown in Figure 1-12,) TRIGGER MENU ca

n

be used to alter trigger setup

.

User can press [F1] key to select “edge” trigger

.

n trigger signal amplitude

.

i

4.To press FORCE button: To produce 1 trigger

signal forcefully for mainly application for normal

and single trigger mode

.

Operating Manual for UTD2000/3000

14

They can press [F2]key to select “trigger source

”

to CH1

.

They can press [F3] key to set “gradient” of edge

type to ascending

.

They can press [F4 ]key to set “trigger mode” to

automatic. They can also press F5 key to set

“trigger coupling” to AC

.

They can press [50%] button for 5.7-inch oscillograp

h

and press [SET TO ZERO] key for 7-inch oscill ograph

.

It also has to set vertical middle point of trigger level

2

.

Page 27

Operating Manual for UTD2000/3000

1

5

Chapter 2: Instrument Setup

By now, you have been familiar with operation of

vertical control area, horizontal control area and

trigger system menu for UTD2000/3000 series digital

storage oscillograph preliminarily. You should be

familiar with setup of digital storage oscillograph b

y

menu operation by introduction shown in previous

chapter. It is suggested to read Chapter 1 if you have

not been familiar with above operation and methods

.

The chapter is mainly to introduce following themes

Set trigger systems of [TRIGGER LEVEL]

,

[MENU], ]50%] and] FORCE]

;

Set sampling mode of [ACQUIRE]

;

It is suggested to read the chapter carefully to know

many measurement functions for UTD2000/3000

and system operation method

.

㧦

Ƶ

Ƶ

Ƶ

Ƶ

Ƶ

Ƶ

Ƶ

Ƶ

Ƶ

Ƶ Set vertical systems of [CH1], ]CH2],] MATH]

,

]REF] , ]OFF] ]VERTICAL POSITION] and

]VERTICAL SCALE]

;

Set horizontal systems of ]MENU] or ]HO

R

MENU], ]HORIZONTAL POSITION] or

[HORIZONTAL SCALE]

;

Set display mode of [DISPLAY]

;

Store and call-out for [STORAGE]

;

Set auxiliary system of [UTILITY]

;

A

utomatic measurement of [MEASURE]

;

Cursor measurement of [CURSOR]

;

Use execution buttons of [AUTO] and

[RUN/STOP]

;

Page 28

Operating Manual for UTD2000/3000

Setup of vertical system

CH1 and CH2 channels and setup

Every channel has its own vertical menu. Ever

y

item can be set individually acc ording to different

channels. As shown in Form 2-1, the system ca

n

display operation menu of CH1 or CH2 channel b

y

pressing CH1 or CH2 function key

.

1

6

1

1

0100

100

0

h

h

h

h

Setup

Descriptio

n

Function menu

Couplin

g

ACDC

To obstruct DC component

of input signal

.

To cut off input signals by A

C

and DC components of input

signals

.

Groundin

g

Bandwidt

h

limit

O

N

OFF

To limit band width to 20MH

z

so as to reduce display noise.

Full band widt

h

Volt /g ri

d

Coarse

tunin

g

To set vertical deflectio

n

coefficient for coarse tunin

g

by 1-2-5 system. To refine

within setup scope of coarse

tuningforfinetuningsoasto

improve vertical resolution

.

Fine

tunin

g

Probe

To select one value according

to probe attenuatio

n

coefficient to keep correct

vertical deflection coefficient

.

There are totally 4 kinds

,

namely,1 ,10 ,10

0

and 1000

.

hh h

h

Reverse phase

O

N

OFF

To realize reverse directio

n

function for waveform

;

To display waveform normally.

Form 2-1

Page 29

1

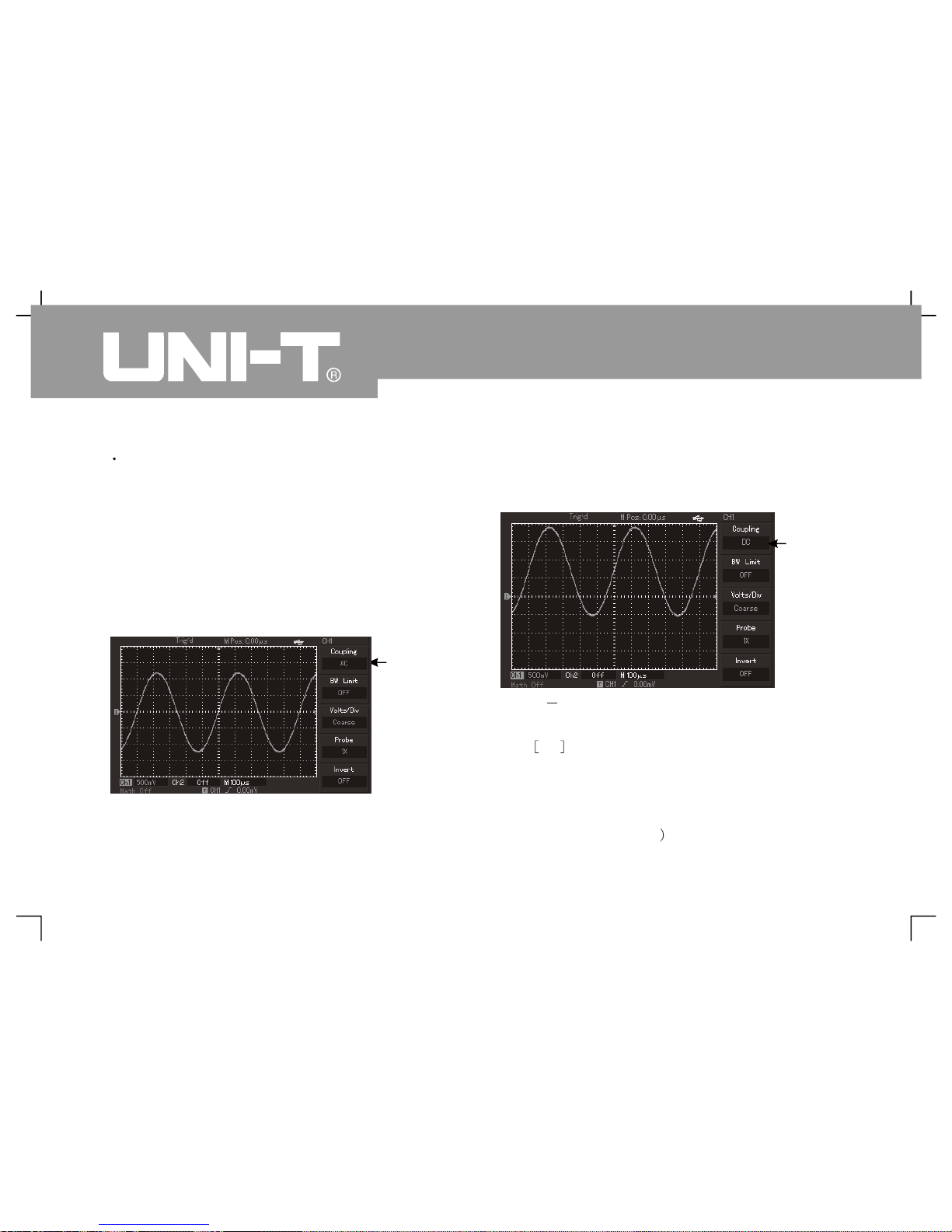

Measured signal is a sine signal with DC component

by taking exerting signal to CH1 channel as a

n

example

.

To press F1 to select AC and AC coupling mode. D

C

component contained by measured signal will be

obstructed. Waveform display is shown in followin

g

figure

.

Press F1 to DC to pass through DC and A

C

components of measured signals of CH1 channel

.

Waveform display is also shown in following figure

:

Figure 2 2 S ynchronous dis play o f DC and A

C

components of signal

Press F1 to select grounding and set channels to

grounding mode. DC and AC components

contained by measured signals will be obstructed.

Waveform display is shown in following figure

:

displayed on the scr een

.

Setup of channel coupling㧦

1

7

Operatin g Manual for UTD2000/3000

Figure 2 Jammed DC component of signal㧙1

Setup of

A

C couplin

g

DC couplin

g

setup

Page 30

Operating Manual for UTD2000/3000

(Note: Input signal still shall be connected to

channel circuit under such mode althoug

h

waveform is not

Figure 2 3 Synchronous obstruction of DC and

A

C components of signal

㧙

18

Ground couplin

g

setup

2.

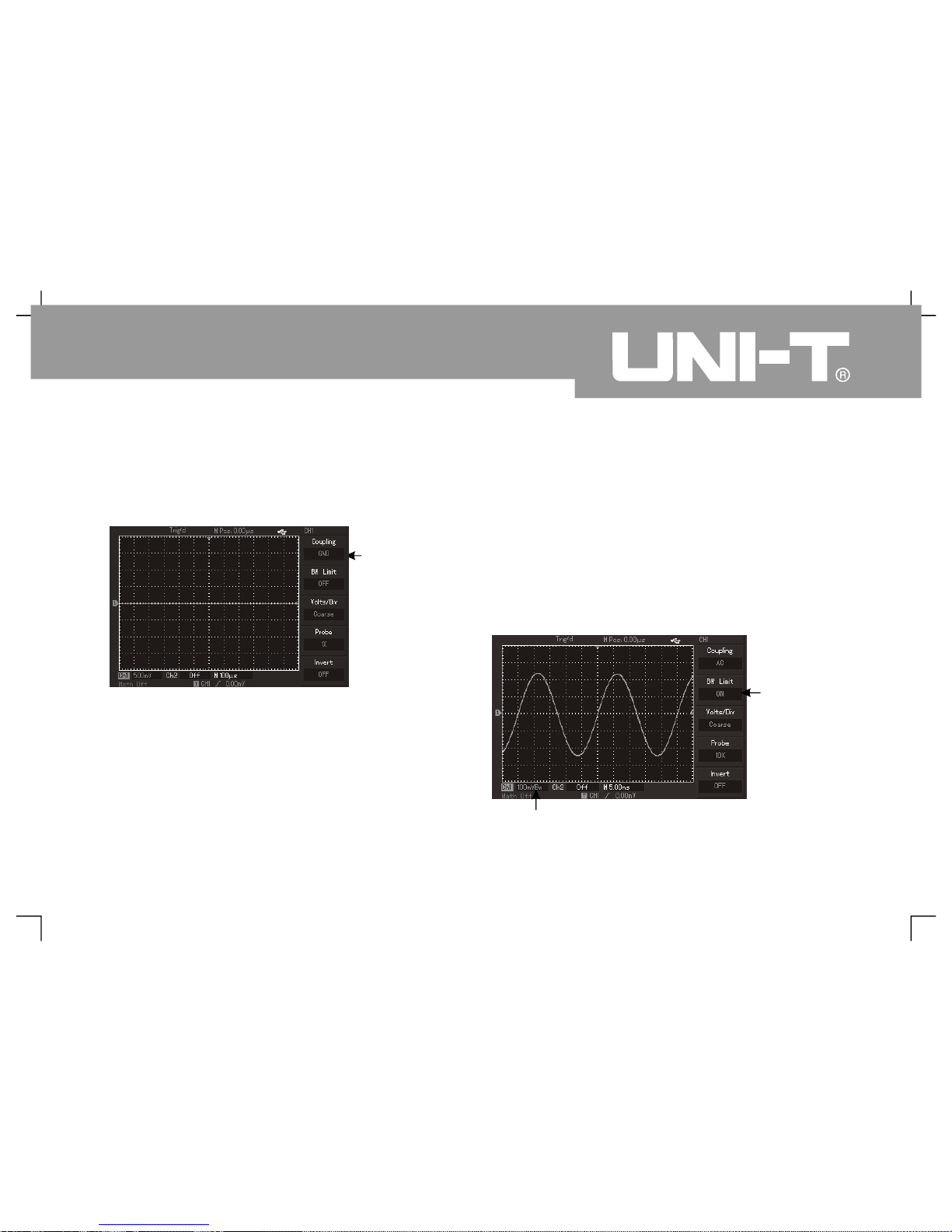

Setup of cha nnel bandwidth limit㧦

Input one sine signal of about 40MHz for CH1 as an

example. It has to press [CH1] to open CH1 channel

then press [F2] to set bandwidth limit to OFF

.

Channel band width is full band width to pass

through high-frequency components contained by

measured signal. Waveform display is also shown

in following figure

.

Figure 2 Waveform display when closin

g

bandwidth limit

㧙4

Bandwidt

h

suppressio

n

20MH

z

Bandwidth suppression icon

Page 31

Operating Man ual for UT D2000/30 00

1

9

Please press [F2] to set band width limitation to ON

for great attenuation of high-frequency component

and noise of more than 20MHz contained b

y

measured signals. Waveform display is also show

n

in following figure

.

Figure 2 5Waveform display when openin

g

bandwidth limit

It has to set probe attenuation coefficient i

n

operation menu of channel to coordinate wit

h

attenuation coefficient setup of probe. Probe

coefficient in channel menu shall be set to 10× if

probe attenuation coefficient is 10:1. It has to

analogize to guarantee correct voltage

.

Volt/grid gears of vertical deflection coefficient can

be divided into coarse tuning and fine tuning

.

Please refer to following figure for setup and

vertical gear when using 10:1 probe

.

㧙

㧦3. Setup of multiplying factor for probe

Close

bandwidt

h

limit

Probe

attenuatio

n

coefficient

Figure 2 Probe attenuation coefficient shown

in channel men

u

㧙6

Page 32

Operating Manual for UTD2000/3000

4.

2

025

Regulation setup of vertical volt/grid Setup of reverse phase of waveform

Reverse phase of waveform:

㧦

㨪

㨪

㧙㧙

Volt/grid scope is 2mV/di

v

V/div (or 10V/div), or 1mV/div V/div with step

by way of 1 Deflection coefficient shall be

altered within current vertical gear scope by less

step during fine tuning so as to realize

uninterrupted and continuous adjustment of vertical

deflection coefficient within all vertical gears

.

5

20

Setup of

fine tunin

g

Figure 2 Coarse tuning and fine tuning of

vertical deflection coefficient

㧙7

It is to show overturning degree of phase location of

displayed signals. Please refer to Figure 2 for

waveform without reverse phase. Please refer to

Figure 2 for waveform with reverse phase

.

㧙㧙8

9

Without

reverse phase

Figure 2 Setup of reverse phase of vertical

channel (or without reverse phase

)

㧙8

Page 33

Operating Manual for UTD2000/3000

2

1

Figure 2 9 Setup of reverse phase of vertical

channel

㧙

I. Realization of mathematical calculation

functio

n

Mathematical calculation functions are to show +, -

,

, / as well as FFT calculation results for CH1 and

CH2 channel waveform. Menu is shown as follows:

h

Reverse phase

of waveform

Mathematical calculation

Figure 2 Mathematical calculatio

n

㧙1

0

Page 34

Operatin g Manual for UTD2000/3000

Analysis of FFT frequency spectrum

Time domain signal can be converted to frequency

domain signal when using mathematical calculatio

n

of fast Fourier transtable (FFT). Following types of

signals can be observed conveniently by usin

g

FFT

Measure harmonic content and distortion withi

n

measurement system

;

㧦

Ɣ

ƔƔShow noise characteristics in DC power

;

A

nalyze vibration

;

2

2

Function Menu

Setup Descriptio

n

Type

Mat

h

,.---hr

Informatio

n

source

CH1

CH

2

To set information source 1

as Ch1 channel waveform

.

To set information source 1

as Ch2 channel waveform

.

,

.

Information source 1

Information source

2

Information source 1

Information source

2

Information source 1

Information source

2

Information source 1

Information source

2

,

.

Ø

r

Operator

Informatio

n

source

2

CH1

CH

2

To set information source

2

as CH1 channel waveform

.

To set information source

2

as CH2 channel waveform

.

Form 2-2: Introduction to mathematical calculatio

n

Ø

r

Page 35

Form 2-3: FFT menu Descriptio

n

FFT operation knack:

Signals with DC component or deviation will brin

g

in error or deviation of FFT waveform component

.

A

C coupling mode can be selected to reduce D

C

component.

A

verage obtainment mode of digital storage

oscillograph can be set to reduce random noise

and aliasing frequency component of repeated or

single pulse event

.

Operating Manual for UTD2000/3000

2

3

Functio

n

Setup

Descriptio

n

Typ

e

FFT

FFT mathematical

calculation

Informatio

n

source

CH1

CH

2

To set CH1 and CH2 as

calculation waveform

.

Window

Hammin

g

Blackma

n

Rectangle

Set Hanning window

functio

n

Set Hamming window

functio

n

Set Blackman window

functio

n

Set Rectangle window

functio

n

Hannin

g

Vertical unit

Vrm s

dBVrm

To set vertical unit to

Vrms or dBVrms

.

Page 36

Operating Manual for UTD2000/3000

Selection of FFT window

Mathematical storage oscillograph will carry out FFT conversion for time record with limited length when

assuming continuous repetition of YT waveform. YT waveform will have the same amplitude in beginning

and ending locations for no interrupation. However, high-frequency transient interruption will be caused in

connector due to different waveform amplitudes for non-integral cycle of YT waveform. Such effect shall be

called as leakage in frequency domain. Therefore, value in forced beginning and ending locations is 0 b

y

multiplying original waveform by a window function to avoid leakage. Please refer to following form for

application of window function

.

Form 2-

4

24

FFT window

Characteristic

s

The most appropriate measurement content

Rectangle

The best frequency and the poorest

amplitude resolution to be basicall

y

similar to circumstances without window

;

Transient or short impulse with basically equivalent

signal level; Sine with equivalent amplitude wit

h

similar frequency; Wide band random noise of wave

spectrum with slow variation

;

Hannin

g

With excellent frequency resolution and

poor amplitude resolution by comparin

g

with rectangular window

;

Sine, cycle and narrow band random noise

Hammin

g

Frequency resolution of Hamming window

is better than that of Hanning window slightly

.

Transient or s hort impulse with large difference

for signal level

;

Blackma

n

The best amplitude resolution and the

poorest frequency resolutio

n

Mainly used for single-frequency signal to search

for higher order of harmonic wave

.

Page 37

Operating Manual for UTD2000/3000

2

5

Term expl an atio n:

FFT resolution:

Nyquist frequency:

Reference waveform

It is defined as factor of samplin

g

and calculation point. FFT resolution increases

when sampling rate decreases for fixed calculatio

n

point quantity

.

Original waveform can not be

reset until using sampling rate of at least 2f for

waveform with the maximum frequency of “f”. It is

also called as Nyquist guideline. “f” refers to Nyquist

frequency and “2f” refers to Nyquist sampling rate

.

Please refer to waveform stored in nonvolatile

memory (NVM) of digital storage oscillograph or

peripheral U disk with name of RefA and RefB as

follows. Please operate acc ording to followin

g

steps to call out or close reference waveform

.

5. Please press REF menu key on the front panel

for 5.7-screen oscillograp

h

Please press [STORAGE]key and enter into the

second page to select call-out for 7-inc

h

oscillograph (namely, UTD2000L/2000EX series).

2. Please press [RefA] (RefA reference option) and

select information source then select its position b

y

rotating multi-purpose knob in upper part of front

panel. 1 10 (or 1 20) can be selected for the

position. Press “call-out” to call out waveform

which is stored inthe position originally after

selecting a certain position such as “1”. Pleas e

plug in U disk if waveform is stored in the U d isk

.

There are 2 options for magnetic disk as follows

:

DSO/USB; Please press [F2] key and select USB

.

(The menu can not be activated until plugging in U

disk.) Called out waveform is displayed on the

screen for waveform called out and stored from U

disk. Please press cancel key (F5) Return to

previous menu after waveform call-out

.

3. To press [RefB] (RefB reference option) and

select

㧧

Page 38

information source 2 which participates i

n

calculation and method is the same to the

secondstep. Please measure and observe related

waveform by UTD2000/3000 series digital storage

oscillograph during actual application. Please

compare current waveform with reference

waveform for analysis. Please press REF key to

display reference waveform menu. Setup is also

shown in following form

.

Form 2-5 Selection of storage positio

n

It is allowed to select from 1 to 20 for internal

storage position. Please plug in U disk and press

F2 to select USB magnetic disk for external storage

instrument. Please refer to STORAGE menu for

waveform storage

.

Operating Manual for UTD2000/3000

2

6

Function menu

Setup

Descriptio

n

Storage positio

n

120a

12

0

a refer to positions of

20 groups of waveform

respectively

;

There are 200 groups of

waveform positions for

storage to USB

;

(Storage position and quantity

vary withmachine model.

)

Magnetic disk

DSO

USB

To select internal storage position;

To select external storagepositio

n

(until plugging inU disk)

;

Close

To close called out waveform

;

Callout

To call out selected wavefo rm;

Cancel

Return to previous menu;

Page 39

Operating Man ual for UT D2000/30 00

2

7

Setup of horizontal system

Horizontal control knob

Control knob on horizontal surface can be used to

alter horizontal scale (or time base) to trigger

horizontal position (or trigger position) shown i

n

RAM. Vertical middle point toward horizontal

direction on the screen is time reference point for

waveform. Horizontal scale can be altered for

waveform extension or shrinkage by comparin

g

with screen center. Horizontal position can also

alter by comparing with position of waveform

trigger point

.

Horizontal position: To adjust horizontal position of

channel waveform (including mathematical

calculation). Resolution of such control key varies

according to time base

.

Horizontal scale: To adjust main time base, namely

,

s/div. Window width can vary with delay scannin

g

time base by rotating horizontal scale knob whe

n

opening extension time base. Please refer to

introduction to extension time base for details. (As

shown in the following form), horizontal menu ca

n

be displayed for horizontal control key menu

.

Form 2 -

6

Function menu

Setup

Descriptio

n

Main time base

1

.2.

To open main time base

;

To close view window

extensionaccordingtomai

n

time base after opening

;

View window

extensio

n

To open extension time base

;

Hold off

To regulate inhibition period

;

üü

üü

üü

üü

üü

Page 40

Mark Description:

Trigger horizontal distance of position b

y

comparing with middle point of view window

.

ķ

ˊĸˊĹˊ

Ļ

ˊ

Mark represents position of current waveform

view window in RAM

Mark position of trigger point in RAM

.

Mark position of trigger point in current

waveform view window

.

Display horizontal time base (or main time

base), namely, s/div

.

ĺ

ˊ

Term explanation:

Y

-T mode:

X-Y mode:

Y axle refers to voltage and X axle

refers to time quantum under this mode

.

X axle refers to CH1 voltage and Y axle

refers to CH2 voltage under this mode

.

Slow scanning mode: Instrument will enter into

slow scanning sampling mode when settin

g

horizontal time base control to 100ms/div or less. It

is suggested to set channel coupling to DC whe

n

observing low-frequency signal by applying for

slow scanning mode

.

s-div: Time base control can expand or compress

waveform for horizontal scale (or time base) unit if

stopping waveform sampling (by using RUN/STOP

key).

Operatin g Manual for UTD2000/3000

2

8

Figure 2-11 Interface of horizontal system

Page 41

Operating Manual for UTD2000/3000

2

9

View window extension

View window extension is to argument a section of

waveform to review image details conveniently

.

Setup of view window extension can not be slower

than that of main time base

.

A

s shown in above figure), it can be divided into

2

display areas under extension time base. Original

waveform is displaye d for upper part. Sel ected ar ea

can move horizontally by rotating horizontal

POSITION knob or increase or decrease by rotating

horizontal SCAL E knob

.

(

Waveform with horizontal extension in originall

y

selected waveform area is shown in lower part. (As

shown in above figure,) please pay attention that

resolution increases for extension time base b

y

comparing with main time base. Waveform displayed

by the entire lower party corresponds to area

selected for upper part so users can rotate horizontal

SCALE knob to reduce selected area and increase

extension time base, namely, horizontal extensio

n

multiple of waveform

.

ThemodemustbeusedforCH1andCH2atthe

same time

.

CH1 voltage will be displayed on X axle and CH

2

voltage

Extensio

n

time base

Horizontal extensio

n

of the waveform

Horizontally extended part of the waveform

Figure 2 1 Screen display under view window

extensio

n

㧙 2

Page 42

Operatin g Manual for UTD2000/3000

will be displayed on Y axle after selecting X-

Y

display mode

.

Note: Digital storage oscillograph can capture

waveform by any sampling speed under normal X-

Y

mode. Similarly, it is allowed to adjust samplin

g

rate, vertical gear of channels and time base gear

under X-Y mode. Default sampling rate is 100MS/s

under X-Y mode. In general, sampling rate ca

n

reduce to gain excellent Lissajou’s figure. Followin

g

functions do not effect during X-Y display

.

Automatic testing mode

Cursor measurement mode

Reference or mathematical calculation waveform

View window extension functio

n

Trigger cont

rol

Ƶ

Ƶ

Ƶ

Ƶ

Ƶ

30

Figure 2 Waveform display under X-Y mode㧙1

3

Page 43

Operatin g Manual for UTD2000/3000

3

1

Setup of trigger system

Trigger can determine data acquisition time and

waveform display for digital storage oscillograph. It

can convert instable display to meaningful

waveform once correct setup. Digital storage

oscillograph will collect sufficient data to map

waveform in the left side of trigger point firstly. It

will acquire data continuously and synchronousl

y

when waiting for trigger conditions. It also will

acquire sufficient data continuously to map

waveform in the right side of trigger point. Trigger

control area of operation panel of digital storage

oscillograph includes trigger level adjustment knob

and trigger menu key of [TRIG MENU]

;

5.7-inch oscillograph will set 50% of trigger level i

n

vertical middle point of signal (and realize

UTD2000L /2000EX by press [SET TO ZERO] key)

.

It has to press forced trigger key of [FORCE]

.

Trigger level: Trigger level will set signal voltage

which corresponds to trigger point

.

50%: To set trigger level to vertical point of trigger

signal amplitude

.

FORCE: To produc e 1 trigger signal forcefully for

mainly application for normal and single modes

shown in trigger modes

.

TRIG MENU: To trigger and set menu key

.

Page 44

Operating Manual for UTD2000/3000

3

2

Trigger control

Trigger mode: Edge, pulse width, video and ALT TRIG

;

Edge trigger: Trigger when edge of trigger signal reaches a certain given level

.

Pulse width trigger: Trigger when pulse width of trigger signal reaches certain set trigger conditions

Video trigger: Carry out field or line trigger for standard video signals. (UTD2025CL/UTD2000EXseriesis

no such function.

)

A

LT TRIG: It is appropriate to trigger signal without frequency relevance. Various kinds of trigger menus

are also shown as follows

:

Edge trigger

:

Edge trigger mode is to trigger threshold value of input signal edge. That is, to trigger in ascending

/

descending edge of input signal when selecting “edge trigger”

.

Form 2-

7

Page 45

Operating Manual for UTD2000/3000

3

3

Function menu

Setup

Descriptio

n

Type

Edge

Selection of

information source

CH1

CH

2

EXT

EXT/

5

Municipal power

A

lteratio

n

Set CH1 as trigger signal of info r ma ti on s ou rce

.

et CH2 as trigger signal of inf or m atio n sou r ce

.

Set EXT TRIG INPUT channel as trigge r sig na l of information sourc e

.

Divide outer trigge r so ur c e by 5 to ex pa nd outer trigger level sco pe

.

Set municipal powe r tri gg er

A

LT TR IG of CH1 an d CH2 si gn als ;

.

Gradient

A

scen

d

Descen

d

A

scend/descend

Set ascending edge trigger for signal

;

Set descending edge trigger for signal

;

Set ascending/descending edge trigger of signal

;

Trigger mode

A

utomatic

Normal

Single

Set waveform acquisition without detecting trigger conditions

;

Set waveform acquisition after meeting trigger conditions

;

Set sampling of a waveform and shutdown after detecting once

trigger

;

Trigger couplin

g

ACDC

High-frequenc

y

inhibitio

n

Low-frequenc

y

inhibitio

n

Obstruct DC component of input signal

;

Pass through AC & DC components of input signal

;

Inhibit high-frequency components of more than 80kHz for signal

;

Inhibit low-frequency components of less than 80kHz for signal

Page 46

Operating Manual for UTD2000/3000

Pulse width trigge

r

Trigger time s hall be determined for pulse width trigger according to pulse width. You can capture

abnormal pulse by setting pulse width conditions

.

Form 2-8 (the first page

)

34

Function menu

Setup

Descriptio

n

Type

Pulse widt

h

Selection of

informatio

n

source

CH1

CH

2

EXT

EXT/

5

Municipal power

A

lteratio

n

To set CH1 as trigger signal of information source

.

To set CH2 as trigger signal of information source

.

To set EXT TRIG INPUT channel as trigger signal of information source.

To divide outer trigger source by 5 to expand outer trigger level scope.

To set municipal power for tri gger

.

A

LT TRIG of CH1 and CH2 signals

Pulse widt

h

conditions

More tha

n

Less tha

n

Equal t

o

To trigger when pulse width exceeds set value

;

To trigger when pulse width is less than set value

;

To trigger when pulse width is equivale

Pulse widt

h

setup

To set pulse wi dth of 2 0ns to 1 0s then regulate by multi -purpose knob in

upper part of front panel

.

Next page

1/

2

Enter into next page

.

Page 47

Operating Manual for UTD2000/3000

3

5

Form 2-9 (the second page

)

Function menu

Setup

Descriptio

n

Type

Pulse widt

h

Trigger polarit

y

Positive pulse widt

h

Negative pulse widt

h

Trigger mode

To set positive pulse width as trigger signal

;

To set negative pulse width as trigger signal

;

A

utomatic

Normal

Single

The system will acquire waveform data automaticall

y

and display scanning base line on the screen without

trigger signal input. It will convert to trigger scannin

g

automatically when producing trigger signal

.

To produce trigger scanning if any trigger signal is produced

.

To produce once trigger then stop during trigger signal input

.

Trigger couplin

g

D

C

AC

High-frequenc

y

inhibitio

n

High-frequency inhibitionTo pass through AC & D

C

components of trigger signal

.

To obstruct DC components of trigger signal

.

To obstruct pass through of high-frequency c omponents of

signal and only low-frequency components can pass through

.

Previous page

2/

2

Return to previous page

.

Page 48

Operatin g Manual for UTD2000/3000

Video touc

h

To trigger in field or row with NTSC or PAL standard video signals after selecting video trigger for

UTD2025CL oscillograph shown in 5.7-inch or 7- inch screen. Trigger coupling is pre-set to DC. P lease

refer to following form for trigger menu

.

Form 2-10 Setup of video trigger

3

6

Function menu

Setup

Descriptio

n

Type

Selection of

Pulse widt

h

information source

CH1

CH

2

EXT

To set CH1 as trigger signal of information source

.

To set CH2 as trigger signal of information source

.

To set EXT TRIG INPUT channel as trigger signal of

information source

.

To set 5 times of attenuation for outer trigger signal as trigger

signal

.

A

LT TRI G of CH1 and CH2 signals

EXT/

5

A

lteratio

n

Standar

d

PA

L

NTS

C

Video signal to be appropriate to PAL system

;

Video signal to be appropriate to NTSC system

;

Synchronizatio

n

A

ll rows

Designated row

Odd f iel

d

Even fiel

d

To set synchronous trigger of video row

.

To set synchronous trigger of designated video row for

adjustment by multifunctional knob in upper part of front panel

.

To set synchronous trigger for video odd field

.

To set synchronous trigger for video even field

.

Page 49

Operating Man ual for UT D2000/30 00

3

7

Please refer to Figure 2-14 for screen display whe

n

selecting standard system of PA L and row

synchronization as synchronization mode. Please

refer to Figure 2-15 for field synchronization of

synchronization mode

.

Figure 2 14 Video trigger: Row synchronizatio

n

㧙

Figure 2 15 Video trigger: Field synchronizatio

n

㧙

A

LT TRIG mode

A

LT TRIGTrigger signal comes from 2 vertical

channels durin g ALT TRIG. Suc h trigge r mode can be

adopted for synchronous observation of 2 signals

without regard to signal frequency. Please refer to

following figure for trigger alternation waveform

display

.

Page 50

Setup of trigger coupling mode

Please enter into trigger setup menu for setup of

trigger coupling mode and gain the most sform

synchronization. Please refer to following form for

menu of trigger coupling mode

.

Operating Manual for UTD2000/3000

Form 2-11 Trigger alternation menu

Function menu

Setup Descriptio

n

Type

Edge

Set trigger mode to edge

Trigger source

A

lternatio

n

A

LT TRIG of CH1 and

CH

2

Gradient

A

scendin

g

Set trigger gradient to

ascending edge

.

Trigger mode

A

utomatic

Set trigger mode as

automatic one

Trigger couplin

g

AC

Set trigger couplin

g

modeto AC mode

Figure 2 Observation of 2 signals wit

h

different frequency by

.

㧙16

3

8

Page 51

Form 2-1

2

Operating Manual for UTD2000/3000

3

9

Function menu

Setup

Descriptio

n

Type

Trigger source

Gradient

Trigger mode

Coupling

ACDC

High-frequency inhibitio

n

Low-frequencyinhibitio

n

Set pass-throu gh obstr ucti on of DC compone nts

.

Set pass-through of all components

.

Obstruct pass-through of high-frequency part of signal. Only lowfrequency components can pass through

.

Obstruct pass-through of low-frequency part of signal. Only highfrequency components can pass through

.

üü

üü

üü

üü

Page 52

Adjustme nt of hold off time

A

djustment of hold off time can be used to observe complex waveform (such as pulse s tring series)

.

Inhibition time refers to waiting period of digital storage oscillograph to start up trigger circuit again

.

Digital storage oscillograph will not trigger until inhibition time ends during inhibition period. For instance

,

as shown in Figure 2-17, the first pulse among a group of pulse series shall be triggered to set inhibition

time to width of pulse string

.

Please refer to following form for hold off menu

.

Form 2-1

3

Operating Manual for UTD2000/3000

40

Function menu

Setup

Description

Main time base

1. To open main time base

;

2. To close view window extension according to main t ime base after openin

g

view window extension

.

View window extensio

n

To open extension time base

.

Hold off

To adjust inhibition time

.

üü

üü

üü

üü

Page 53

Operating Manual for UTD2000/3000

4

1

Figure 2—17 Hold off used for synchronization

of complex waveform

Operation Description

1. To select edge, trigger source and gradient show

n

in TRIG MENU according to synchronization mode of

normal signal then adjust trigger level for stable

waveform display as practicable as possible

.

2. To press HORI MENU key to display horizontal

menu

.

3. To adjust multi-purpose knob in upper part of

panel to alter inhibition time for stable waveform

display as practicable as possible

.

Term explanations

1. Trigger source: To gain trigger from many kinds of

information sources, namely, input channel (CH1

&

CH2), external trigger (EXT & EXT/5) and municipal

power

.

Input channel The most common trigger

information source is optional input channel

Selected one is used as channel of trigger

information source for normal operation regardless

of input displa

y

External trigger: Such trigger information source

can be used for trigger on the third informatio

n

channel during synchronous data acquisition o

n

channels For instance signals f rom external clock

or circuit t

o

meas

ure can be used as trigger information source

.

EXT and EXT/5 trigger sources shall use external

trigger signals

Ƶ

Ƶ

Trigger

Holdoff

Page 54

connected to EXT TRIG interface. Signal can be

used for EXT and EXT can be used within signal

trigger level scope of -3V to +3V

.

A

utomatic trigger: The system will acquire

waveform data automatically so as to displa

y

scanning base line on the screen without trigger

signal input. It will convert to trigger scannin

g

automatically for signal synchronization whe

n

producing trigger signal

.

It is allowed to select EXT/5 for oscillograph of 5.7inch screen. Outer tri gger shall be divided by 5 so

that trigger scope can expand to -15V to +15V for

trigger of digital storage oscillograph under large

signal

.

Municipal power: Such trigger mode can be used

to observe signal with regard to municipal power

.

For instance, it can provide relationship betwee

n

lighting equipment and power supply equipment so

as to gain stable synchronization

.

2 Trigger mode: It is to determine behavior mode

of digital storage oscillograph without trigger event

.

This digital storage oscillograph can also provide

3

triggers, namely, automatic, normal and single

trigger modes

.

Ƶ

Ƶ

Operating Manual for UTD2000/3000

4

2

Note: Without trigger signal is allowed under

“

automatic” mode when setting scanning waveform to

5-ms/div or less time base

.

Normal trigger: Digital storage oscillograph ca

n

not acquire waveform until meeting trigger conditions

under ordinary trigger mode. Trigger scanning can be

produced when producing trigger signal

.

Single trigger: User can press “operation” button

once under single trigger mode for entry and trigger

waiting for digital storage oscillograph. It will sample

and display all acquired waveform then stop after

digital storage oscillograph detects once trigger

.

Ƶ

Ƶ

Page 55

Operatin g Manual for UTD2000/3000

4

3

3

.

4. Pre-trigger/delay trigger: To trigger data acquired

in ahead/after event. Trigger position is often set i

n

the horizontal center on the screen. You ca

n

observe pre-trigger and delay information of 5di

v

(or 6div). You can also rotate horizontal position to

regulate horizontal displacement of waveform and

review more pre-trigger details. You can observe

waveform in ahead of trigger by observing pretrigger data. For instance, burring reason can be

shown by observation and analysis on pre-trigger

data after capturing burring during circuit startup

.

Trigger coupling: Trigger coupling can determ ine

category of signal component conveyed to trigger

circuit. Coupling types include DC, AC, lowfrequency inhibition and high-frequency inhibition

.

Pass through all components of signals under

DC mode

.

Ƶ

Ƶ

Ƶ

Ƶ

Obstruct DC components with signal attenuatio

n

to be less than 400Hz under AC mode

.

Obstruct DC components with attenuation of

low-frequency component of less than 80kHz under

“low-frequency inhibition” mode

.

A

ttenuate high-frequency components of more

than 80kHz under “high-frequency inhibition” mode

.

Page 56

Operating Manual for UTD2000/3000

Setup of sampling system

As shown in following figure, ACQ UIRE in

control area is function key of sampling

system

.

Figure 2 18 Function key of sampling system

User can use ACQUIRE key to pop out samplin

g

setup menu so as to adjust sampling mode b

y

control button shown in the menu

.

㧙

44

Page 57

Operating Manual for UTD2000/3000

4

5

Form 2-14 Sampling men

u

Function menu

Setup

Descriptio

n

Obtainment mode

Samplin

g

Peak-value detectio

n

A

verage

A

ctivate ordinary sampling mode

.

A

ctivate peak-value detection mode

.

Set average sampling mode and display average times

.

A

verage times

2~25

6

Set average times for step by multiples of 2, namely, 2, 4, 8, 16

,

32, 64, 128 and 256. As shown in Figure 2-18, average times ca

n

alter by pressing left multi-purpose knob

.

Sampling mode

Real-time

Equivalent

Set sampling mode to real-time sampling mode

.

Set sampling mode to equivalent sampling mode

.

Fast acquisitio

n

O

N

A

cquire by higher screen refreshing rate to reflect dynamic

effect of waveform excell ently

.

Close fast acquisition

.

Page 58

It has to observe waveform display variation b

y

altering obtainment mode. Please refer to Figure 219 and 2-20 for sampled waveform display if signal

contains large noise when adopting 32 times of

average mode or without adopting average mode

.

Operating Manual for UTD2000/3000

4

6

Figure 2-20 Waveform by adopting 32 times of average mode

Figure 2 Waveform without adoptin

g

㧙1

9

Note

Please select real-time sampling mode for observation

of single signal

.

2. Please select equivalent sampling mode for observatio

n

of high-frequency periodic signal

.

3. Please select peak-value detection mode to avoid mixed

signal envelope. Please select average sampling mode wit

h

step of multiples of 2 for average value to reduce random

noise of displayed signal. Average times can be selected

form 2 to 256.

㧦

1

Page 59

Term explanatio

n

Real-time sampling: It refers to data required for once acquisition

.

Equivalent sampling: It refers to repeated sampling mode. It can facilitate careful observation of repeated

periodic signals. It can be adopted to gain horizontal resolution which is higher than real-time sampling

resolution greatly

.

Sampling mode: It can be classified into equivalent and real-time modes

.

Peak-value detection mode

:

Digital storage oscillograph will find out the maximum and minimum input signals within ev ery sampling

interval for waveform display by using such values under such obtainment mode. It can also obtain and

display narrow impulse or they may be omitted for larger noise under such mode. Average mode is as

follows: Digital storage oscillograph may obtain several waveform and calculate average value then

display final waveform under this obtainment mode. Such mode can be adopted to reduce random noise

.

Operating Manual for UTD2000/3000

4

7

Page 60

Operating Manual for UTD2000/3000

Setup of display system

A

s shown in following figure, DISPLAY in control area is function k ey of display sy stem

Figure 2 Function key of sampl ing system

Please press DISPLAY button to pop out setup menu shown in following figure. Display mode can be

adjusted by pressing menu control button

.

㧙

4

8

Page 61

Operatin g Manual for UTD2000/3000

4

9

Key points

:

Display type: To fill in blank between adjacent sampling points during vector display. Only sampling points

will be displayed for point display

.

Function menu Setup

Description

s

Display type

Vector point

Only to display sampling points by wiring

.

Format

YT

X

Y

Operation mode of digital storage oscillograp

h

X-Y display mode; X input for CH1 and Y input for CH2

;

Continuous

Close

1s

2s

5s

Infinite

Real-time updating of screen waveform

;

To update after keeping waveform data shown in the screen for 1s

;

To update after keeping waveform data shown in the screen for 2s

;

To update after keeping waveform data shown in the screen for 5s

;

To always keep display of original waveform data shown in the screen

until this function is inactivated if new data is added into displa

y

continuously

;

Waveform brightness

1% - 100%

To set waveform brightness (without this function for

UTD2000C/3000C

)

Form 2-15 Display menu

Page 62

Storage and callout

A

s shown in following figure, STORAGE in MENU

control area is f unction k ey of storage system

.

Operation steps

Please press STORAGE Enter into type menus

.

There are 3 types, namely, waveform, setup and

bitmap

.

Please refer to Figure 2-16 for selection of type

waveform and entry into following waveform

storage menu. Please call out REF (reference

waveform shown in the second page) from Section

2 of the chapter after saving waveform

.

Form 2-16 Waveform storage menu (the first page)

㧦

2.

Operating Manual for UTD2000/3000

50

Figure 2 22 Function key (storage) for sampling system

STORAGE key can be used to display storage setup menu. You

can save oscillograph waveform or setup status to internal

storage area or U disk to call out saved waveform by Ref

A

(or RefB) or call out setup status by STORAGE key. Waveform

display area of oscillograph can be saved to DSO contents in U

disk in a form of bitmap. Saved bitmap can be read by PC computer

.

㧙

Page 63

Operatin g Manual for UTD2000/3000

5

1

Form 2-16

Function menu

Setup

Descriptio

n

Type

Wav e form

Select waveform storage and callout menu

Information source

CH1

CH

2

Select waveform from CH1 channel

.

Select waveform from CH2 channel

.

Storage positio

n

120a

12

0

a refer to positions to store 20 groups of waveform

.

There are 200 groups of waveform positions for storage to USB

.

(Storage position and quantity vary with machine model.

)

Save

Save wavef orm

Next page

1/

2

Enter into next page

.

Figure 2-23 Waveform storage

Figure 2-24 Waveform storage by U disk

üü

üü

Page 64

Operatin g Manual for UTD2000/3000

Form 2-17 Storage menu (the second page

)

5

2

Function menu

Setup

Descriptio

n

Magnetic disk

DSO

USB