UNI-T UT58A, UT58C, UT58B Operating Manual

(See Figure 5)

Transistor Test

for

Overview

Warning

To avoid electric shock or personal injury, read the

“Safety Information”,

carefully before using the Meter.

Digital Multimeters Model UT58A, UT58B and UT58C

are 2000-count hand-held instruments with remarkable

features: ex-large LCD, steady operations, overload

protection for all ranges and unique structure. The

Meter can measure AC/DC voltage, AC/DC current,

resistance, capacitance, temperature, frequency,

transistor, diode and continuity, and is equipped with

data hold, full icon display and sleep mode functions.

Unpacking Inspection

In the event you find any missing or damaged part,

please contact your dealer immediately.

1 English Operating Manual

2 Test Lead

3 Multi-Purpose Socket

4 Point Contact Temperature Probe

(UT58B/UT58C only)

5 9V Battery (NEDA 1604, 6F22 or 009P)

Item

Description

Qty

1 pc

1 pair

1 pc

1 pc

1 pc

Safety Information

This Meter complies with the standards IEC61010:

Pollution Degree2, Overvoltage Category (CAT. II 1000V,

CAT. III 600V) and Double Insulation.

CAT. II: Local level, appliance, PORTABLE EQUIPMENT

etc., with smaller transient voltage overvoltages than

CAT. III

CAT. III: Distribution level, fixed installation, with smaller

transient overvoltages than CAT. IV

Use the Meter only as specified in this operating manual,

otherwise the protection provided by the Meter may be

impaired.

In this manual, a Warning identifies conditions and

actions that pose hazards to the user, or may damage

the Meter or the equipment under test.

A Note identifies the information that user should pay

Warning

To avoid possible electric shock or personal injury,

and to avoid possible damage to the Meter or to the

equipment under test, adhere to the following rules:

z Before using the Meter inspect the case. Do not

use the Meter if it is damaged or the case (or part

of the case) is removed. Look for cracks or missing

plastic. Pay attention to the insulation around the

connectors.

z Inspect the test leads for damaged insulation or

exposed metal. Check the test leads for continuity.

Replace damaged test leads with identical model

number or electrical specifications before using

the Meter.

z Do not apply more than the rated voltage, as

marked on the Meter, between the terminals or

between any terminal and grounding.

z The rotary switch should be placed in the right

position and no any changeover of range shall

be made during measurement to prevent damage

of the Meter.

z When the Meter working at an effective voltage

over 60V in DC or 30V rms in AC, special care

should be taken for there is danger of electric

shock.

z Use the proper terminals, function, and range

for your measurements.

z If the value to be measured is unknown, use the

maximum measurement position and reduce the

range step by step until a satisfactory reading is

obtained.

do not alter the internal circuit of the Meter randomly.

z Soft cloth and mild detergent should be used to

clean the surface of the Meter when servicing.

No abrasive and solvent should be used to prevent

the surface of the Meter from corrosion, damage

and accident.

z The Meter is suitable for indoor use.

z Turn the Meter power off when it is not in use

and take out the battery when not using for a long

time.

z Constantly check the battery as it may leak when

it has been using for some time, replace the battery

as soon as leaking appears. A leaking battery will

damage the Meter.

z Do not use or store the Meter in an environment

of high temperature,humidity,explosive,inflammable

and strong magnetic field. The performance of

the Meter may deteriorate after dampened.

z When using the test leads, keep your fingers

behind the finger guards.

z Disconnect circuit power and discharge all high

-voltage capacitors before testing resistance,

continuity, diodes, capacitance or current.

z Before measuring current, check the Meter’s

fuses and turn off power to the circuit before

connecting the Meter to the circuit.

z Rep

lace the battery as soon as the battery indicator

appears. With a low battery, the Meter might

produce false readings that can lead to electric

shock and personal injury.

z Remove test leads, test clips and temperature

probe from the Meter and turn the Meter power

off before opening the Meter case.

z When servicing the Meter, use the replacement

parts with the same model or identical electrical

specifications.

z To avoid any damage to the meter or any accident,

International Electrical Symbols

AC (Alternating Current).

DC (Direct Current).

Grounding.

Double Insulated.

Low Battery Indication.

Warning. Refer to the Operating Manual.

Conforms to Standards of European Union.

(Figure 1)

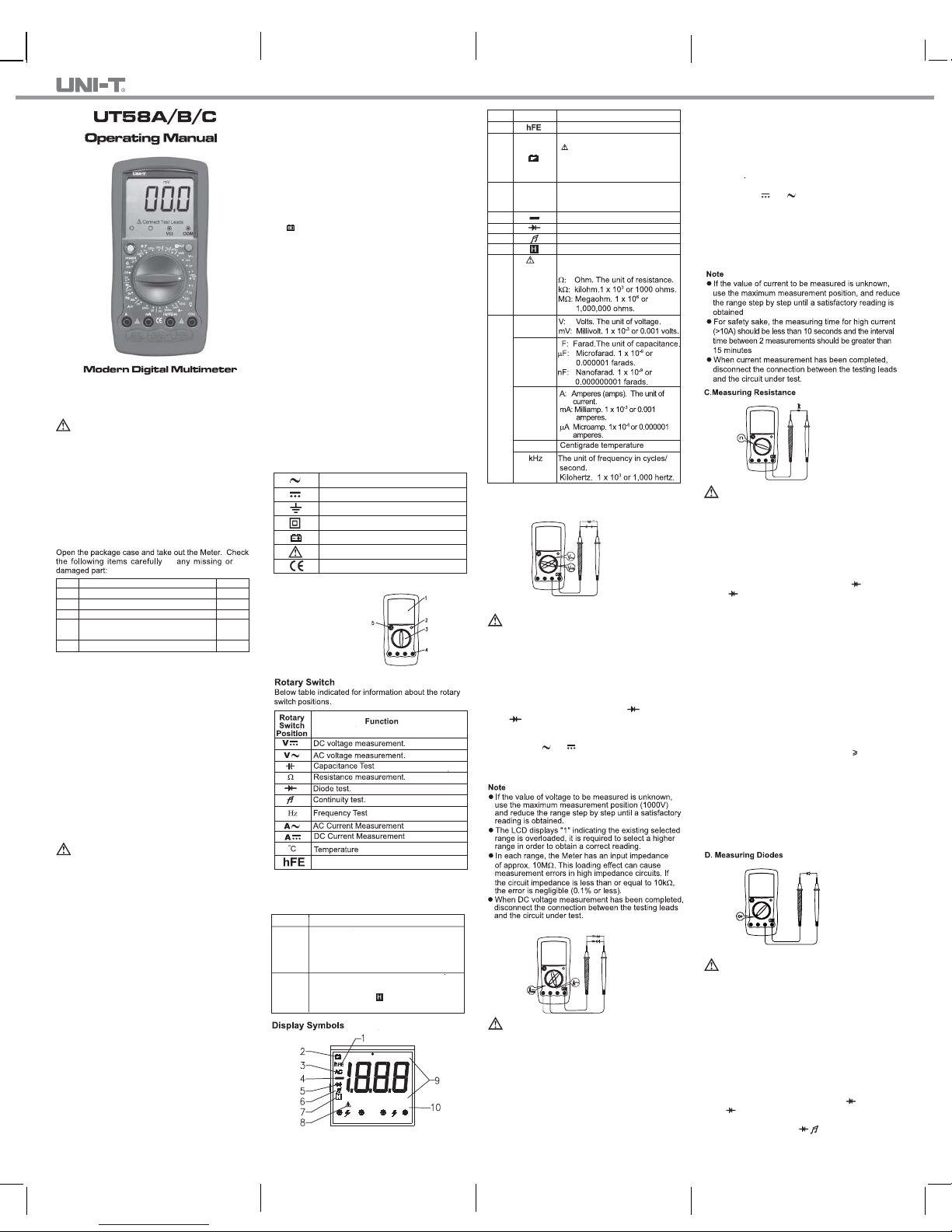

The Meter Structure (See Figure 1)

1. LCD Display.

2. HOLD Button.

3. Rotary Switch.

4. Input Terminals.

5. POWER

Functional Buttons

Below table indicated for information about the functional

button operations.

POWER

(Yellow

Button)

Turn the Meter on and off.

z Press down the POWER to turn on

the Meter.

z Press up the POWER to turn off the

Meter.

HOLD

(Blue

Button)

z Press HOLD once to enter hold mode.

z Press HOLD again to exit hold mode.

z In Hold mode, is displayed and the

present value is shown.

Button Description

No. Symbol Description

The battery is low.

Warning: To avoid false

readings, replace the battery as

soon as the battery indicator

appears.

4

Indicates negative reading.

5

Test of diode.

6

The continuity buzzer is on.

7

Date hold is active.

8

Indicator for AC voltage or current.

The displayed value is the mean

value.

3

AC

Connect

Terminal

Indicator of connecting test leads

into different input terminals.

(Figure 2)

(See Figure 2)

2

1

Connect Test Leads

COM

ΩΩ Ω

μ

nF FkHz AmAA

μ

A

Ω

V

μ

AmA

CmVV k M

μA, mA, A

9

Ω,kΩ,MΩ

mV, V

μF nF

o

C

(Figure 3)

black red

Warning

To avoid harms to you or damages to the Meter from

electric shock, please do not attempt to measure

voltages higher than 1000V although readings may

be obtained.

The DC Voltage ranges are: 200mV, 2V, 20V, 200V and

1000V.

The AC Voltage ranges are: 2V, 20V, 200V and 750V

Measurement Operation

A. Measuring DC and AC Voltage

B. Measuring DC and AC Current (See Figure 4)

(See Figure 3)

To measure DC orAC Voltage, connect the Meter as follows:

1. Insert the red test lead into the HzVΩ (UT58C) or

VΩ (UT58A/UT58B) terminal and the black test

lead into the COM input terminal.

2. Set the rotary switch to an appropriate measurement

position in V or V range.

3. Connect the test leads across with the object to be

measured.

The measured value shows on the display.

black red

(figure 4)

Warning

Never attempt an in-circuit current measurement

where the open circuit voltage between terminals

and ground is greater than 250V .

If the fuse burns out during measurement, the Meter

may be damaged or the operator himself may be hurt.

Warning

To avoid damages to the Meter or to the devices

under test, disconnect circuit power and discharge

all the high-voltage capacitors before measuring

resistance.

(Figure 5)

black red

The resistance ranges are:

Model UT 58A/UT58B:200Ω,2kΩ ,20kΩ,2M Ω,20MΩ and

200MΩ.

Model UT 58C:200Ω, 2kΩ, 20kΩ, 2MΩ and 20MΩ.

1. Insert the red test lead into the Hz VΩ (UT58C) or

VΩ (UT58A/UT58B) terminal and the black test

lead into the COM terminal.

2. Set the rotary switch to an appropriate measurement

position in Ω range.

3. Connect the test leads across with the object being

measured.

The measured value shows on the display.

Use proper terminals, function, and range for the

measurement. When the testing leads are connected

to the current terminals, do not parallel them across

any circuit.

The DC Current ranges are:

Model UT58A/ UT58B: 20μ

A,2mA,20mA,200mA and 20A.

Model UT58C: 2mA, 200mA, 20A

The AC Current ranges are: 2mA, 200mA and 20A

To measure current, do the following:

1.Turn off power to the circuit. Discharge all high voltage capacitors.

2. Insert the red test lead into the A or μAmA (UT58A)

or mA (UT58B/UT58C) terminal and the black test

lead into the COM terminal.

3.Set the rotary switch to an appropriate measurement

position in A or A range.

4. Break the current path to be tested. Connect the red

test lead to the more positive side of the break and

the black test lead to the more negative side of the

break.

5. Turn on power to the circuit.

The measured value shows on the display.

black red

(Figure 6)

Note

z The test leads can add 0.1to 0.2Ω of error to the slow-

resistance measurement. To obtain accurate readings

in low-resistance, short-circuit the input terminals

beforehand and record the reading obtained (called

this reading as X). (X) is the additional resistance from

the test lead. Then use the equation:

measured resistance value (Y) – (X)=accurate readings

of resistance.

z If the input terminal short-circuit reading 0.5,check

the test leads for any looseness or other cause.

z For high resistance (>1MΩ), it is normal taking several

seconds to obtain a stable reading; select short test

leads for stable and precise readings.

z When the resistance is higher than the maximum range

or in open circuit condition, the Meter displays “1”.

z When resistance measurement has been completed,

disconnect the connection between the testing leads

and the circuit under test.

Warning

To avoid damage to the Meter or to the equipment

under test, disconnect circuit power and discharge

all high-voltage capacitors before measuring diodes.

To avoid harms to you, please do not attempt to input

voltages higher than 60V DC or 30V rms AC.

Use the diode test to check diodes, transistors, and other

semiconductor devices. The diode test sends a current

through the semiconductor junction, and then measures

the voltage drop across the junction. A good silicon junction

drops between 0.5V and 0.8V

To test out a diode out of a circuit, connect the Meter as

follows:

1. Insert the red test lead into the Hz VΩ (UT58C) or

VΩ (UT58A/UT58B) terminal and the black test

lead into the COM terminal

2. Set the rotary switch to .

3. For forward voltage drop readings on any semiconductor

component, place the red test lead on the component’s

attention to.

The unit of transistor test

(See Figure 6)

(See Figure 8)

(See Figure 7)

3. Remove the 3 screws from the case bottom, and

Fused Protection for

uA mA Input Terminals:

G. Measuring Temperature

capacitance

F. Measuring Capacitance (See Figure 8)

I. Measuring Frequency (UT58C Only)

(See Figure 9)

P/N:110401104226

anode and place the black test lead on the component’s

cathode.

The measured value shows on the display.

z The open-circuit voltage is around 3V.

z When diode testing has been completed, disconnect

the connection between the testing leads and the

circuit under test.

(Figure 7)

black red

Warning

To avoid harms to you, please do not attempt to input

voltages higher than 60V DC or 30V rms AC.

To avoid damages to the Meter or to the devices under

test, disconnect circuit power and discharge all the

high-voltage capacitors before testing for continuity.

To test for continuity, connect the Meter as below:

1. Insert the red test lead into Hz VΩ (UT58C) or

VΩ (UT58A/UT58B) terminal and the black test

lead into the COM terminal.

2. Set the rotary switch to

.

3. Connect the test leads across with the object being

measured.

4. The buzzer does not sound if the resistance of a

circuit under test is >70

Ω

The buzzer sounds continuously if the circuit is in

good condition with resistance value 10Ω.

The measured value shows on the display and the

unit is Ω.

for

(Figure 9)

POWER

General Specifications

Maximum Voltage or Current between input Terminals

and Grounding: According to different functional input

protection value.

z

CE Version: 0.5A, 250V fast

type, 5x20mm.

z Maximum Display : 1999,updates 2~3 times/

second.

z Range : Manual ranging.

z Polarity display : Automatically

z Overloading : Display “1”.

z Low Battery Indication : Display “ ”.

z Temperature: Operating: 0

o

C~40oC (32oF~104oF);

Storage : -10

o

C~50oC(14oF~122oF)

z Electromagnetic

Compatibility : In a radio field of 1 V/m,

Overall Accuracy = Specified

Accuracy + 5% of Range;

in a radio field of more than

1 V/m, no assigned accuracy

is specified.

z Battery Type : One piece of9V (NEDA1604

or 6F22 or 006P).

z Dimensions : 179x88x39mm.

z Weight : Approx.380g (including

holster and battery)

z Safety/Compliances : IEC61010 CAT II 1000V,

CATIII 600V overvoltage

and double insulation standard.

z Certificate:

z Relative Humidity : 75%@00C~300C;

50%@300C~400C

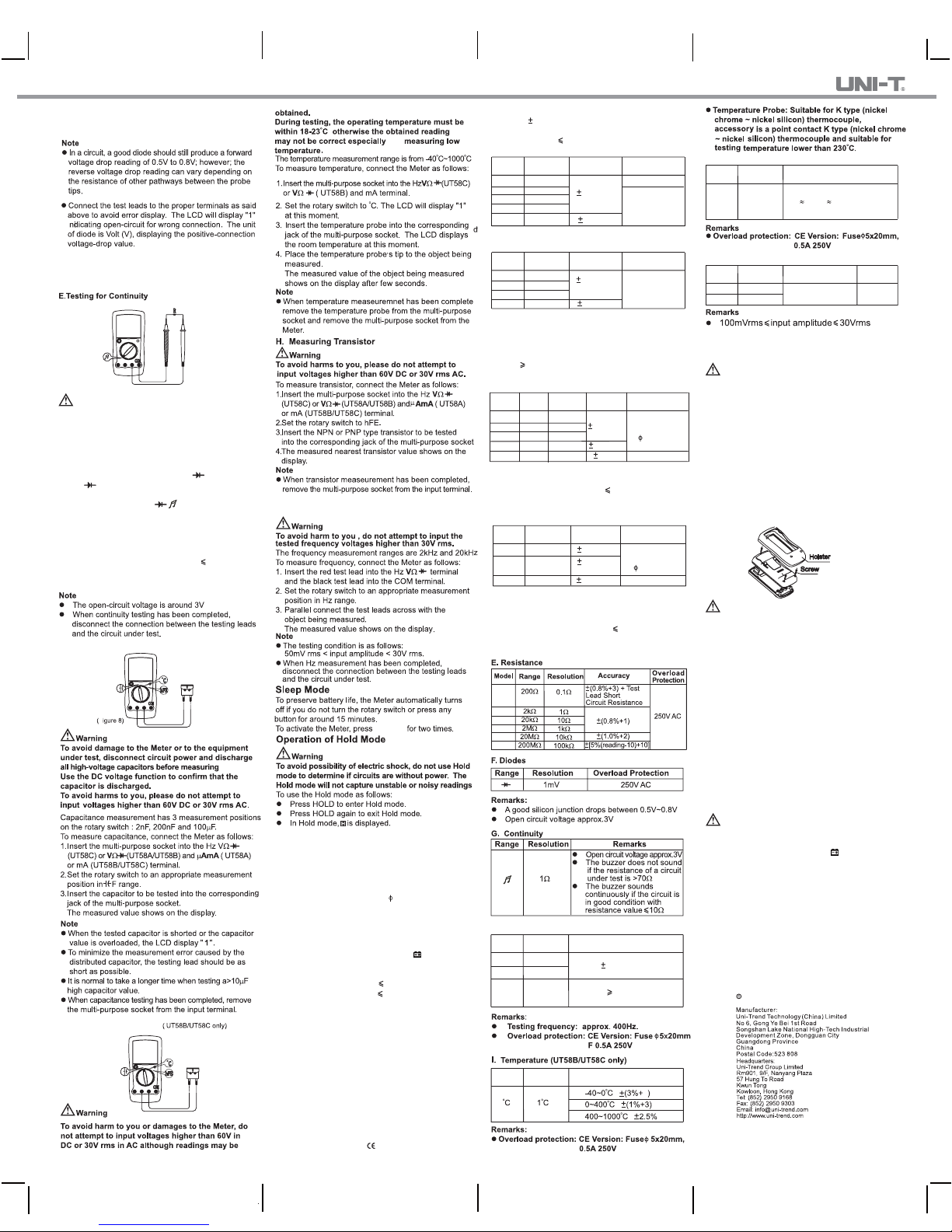

A. DC Voltage

200mV

2V

20V

200V

1000V

0.1mV

1mV

10mV

100mV

1V

Range Resolution

(0.5%+1)

Overload

Protection

Accuracy

250VAC

(0.8%+2)

1000V AC

Remarks:Input Impedance: approx.10MΩ.

B. AC Voltage

2V

20V

200V

750V

1mV

10mV

100mV

1V

Range Resolution

(0.8%+3)

Overload

Protection

Accuracy

(1.2%+3)

1000V AC

Remarks:

z Input Impedance: approx.10MΩ.

z Frequency response:

40Hz~1kHz< 500V;

40Hz~400Hz > 500V

The

500Hz reading is for reference

z Display sinewave RMS value(AVG response)

Accuracy Specifications

Accuracy: (a% reading + b digits),guarantee for 1 year.

Operating temperature:18oC~28oC.

Relative humidity: 75%RH.

C. DC Current

Remarks:

z At 20A Range:

For continuous measurement 10 seconds and

interval time between 2 measurement greater than

15 minutes.

D. AC Current

Remarks:

z Frequency reaponse: 40Hz~400Hz

z At 20A Range:

For continuous measurement 10 seconds and

interval time between 2 measurement greater than

15 minutes

20μA

2mA

20mA

200mA

20A

0.01μA

1μA

10μA

0.1mA

10mA

Range

Resolution

(0.8%+1)

Overload

Protection

Accuracy

(2%+5)

(1.5%+1)

Un-Fused

2mA

200mA

20A

1μA

0.1mA

10mA

Range

Resolution

(1.0%+3)

Overload

Protection

Accuracy

Un-Fused

(1.8%+3)

(3.0%+5)

Fuse 0.5A, 250V,

fast type,

5x20mm

Fuse 0.5A, 250V,

fast type,

5x20mm

Model

UT58A

UT58ABC

UT58AB

UT58ABC

UT58ABC

UT58ABC

UT58ABC

UT58ABC

UT58ABC

UT58ABC

UT58AB

H. Capacitance

±(5.0%+4)

When it is 40μF: the obtained

reading is only for reference

2nF 1pF

200nF 0.1nF

100μF 0.1μF

Range Resolution

Accuracy

(4.0%+3)

Range Resolution

Accuracy

7

the

J. Transistor

Range Resolution

Accuracy±(a% reading + b digits)

hFE 1β Vce 3V Ibo 10μA 1000βMAX

K. Frequency ( UT58C only)

Range Resolution

Overload

Protection

Accuracy

2kHz 1Hz

20kHz 10Hz

±(1.5%+5) 250V AC

Maintenance

This section provides basic maintenance information

including battery and fuse replacement instruction.

Warning

Do not attempt to repair or service your Meter unless

you are qualified to do so and have the relevant

calibration, performance test, and service information.

To avoid electrical shock or damage to the Meter, do

not get water inside the case.

A. General Service

z Periodically wipe the case with damp cloth and mild

detergent. Do not use chemical solvent.

z To clean the terminals with cotton bar with detergent,

as dirt or moisture in the terminals can affect readings.

z Turn the Meter off when it is not in use and take out

the battery when not using for a long time.

z Do not store the Meter in place of humidity, high

temperature, explosive, inflammable and strong

magnetic field

B. Replacing the Fuse (See Figure 10)

Warning

To avoid electrical shock or arc blast, or personal

injury or damage to the Meter, use specified fuses

ONLY in accordance with the following procedure.

( Figure 10)

To replace the Meter’s fuse:

1. Turn the Meter off and remove all connections from

the terminals.

2. Remove the holster from the Meter.

3. Remove the 3 screws from the case bottom, and

separate the case top from the case bottom.

4. Remove the fuse by gently prying one end loose,

then take out the fuse from its bracket.

5. Install ONLY replacement fuses with the identical type

and specification and make sure the fuse is fixed

firmly in the bracket.

Fuse: 0.5A, 250V, fast type,φ5x20mm

6. Rejoin the case bottom and case top, and reinstall

the 3 screws and holster.

Replacement of the fuses is seldom required. Burning

of a fuse always results from improper operation.

C.Replacing the Battery

(See Figure 10)

To replace the Meter’s battery:

1. Turn the Meter power off and remove all connections

from the terminals.

2. Remove the holster from the Meter.

separate the case top from the case bottom.

4. Remove the battery from the battery connector.

5. Replace with a new 9V battery (NEDA1604, 6F22

or 006P).

6. Rejoin the case bottom and case top, and reinstall

the 3 screws and the holster.

Warning

To avoid false readings, which could lead to possible

electric shock or personal injury, replace the battery

as soon as the battery indicator “ ” a ppear s.

** END **

This operating manual is subject to change without notice.

Copyright 2001 Uni-Trend Group Limited.

All rights reserved.

F

(See Figure 9)

Loading...

Loading...