Page 1

ILLUSTRATED PARTS LIST

Three Needle, Wide Gauge, Plain Feed

Machines with Top Cover Thread

MANUAL NO. PT9511

STYLES

FS113L100MBV096

FS113L112MBV096

Page 2

Manual No. PT9511 Illustrated Parts List for FS100 Series Machines

Third Edition Copyright 1997

By

Union Special Corporation Rights Reserved In All Countries

Printed in U.S.A. May 1997

PREFACE

This parts manual has been prepared to assist you in locating individual parts or assemblies on FS100 Series machines.

It can be used in conjunction with Union Special Adjusting Manual IN9302.

It is the desire of Union Special that each machine run at its optimum performance. Parts listed in this manual are designed

specifically for your machine and are manufactured with the utmost precision to assure long lasting service.

This manual has been comprised on the basis of available information. Changes in design and/or improvements may

incorporate a slight modification of configuration in illustrations or part numbers.

On the following pages are illustrations and terminology used in describing the parts used on FS100 Series machines.

2

Page 3

SAFETY RULES

The sewing machines described in this instruction manual are prohibited from being put into service until it has been

ascertained that the sewing units, in which these sewing machines will be built-in have conformed with the EC Council

Directives (89/392/EEC, Annex II B).

1 . Before putting the machines described in this manual into service, carefully read the instructions. The starting of each

machine is only permitted after taking notice of the instructions and by qualified operators.

IMPORTANT! Before putting the machine into service, also read the safety rules and instruction from the motor supplier.

2 . Observe the national safety rules valid for your country.

3 . Each machine is only allowed to be used as foreseen. The foreseen use of the particular machine is described in paragraph

“STYLES OF MACHINES” of this instruction manual. Another use, going beyond the description, is not as foreseen.

4 . All safety devices must be in position when the machine is ready for work or in operation. Operation of the machine without

the appertaining safety devices is prohibited.

5 . Wear safety glasses.

6 . In case of machine conversions and changes all valid safety rules must be considered. Conversions and changes are made

at your own risk.

7 . The warning hints in the instructions are marked with one of these two symbols:

8 . For the following the machine has to be disconnected from the power supply by turning off the main switch or by pulling

out the main plug:

8. 1 For threading needle(s), looper, spreader etc.

8. 2 For replacing sewing parts such as needle, presser foot, throat plate, looper, spreader, feed dog, needle guard,

folder, fabric guide etc.

8 .3 When leaving the workplace and when the workplace is unattended.

8 .4 For maintenance work.

8. 5 When using clutch motors without actuation lock, wait until the motor is stopped totally.

9 . Maintenance, repair and conversion work (see item 8) must be done only by trained technicians or special skilled personnel

under consideration of the instructions.

10 . Any work on the electrical equipment must be done by an electrician or under direction and supervision of special skilled

personnel.

11 . Work on parts and equipment under electrical tension is not permitted. Permissible exceptions are described in the

applicable sections of standard sheet DIN VDE 0105.

12 . Before doing maintenance and repair work on the pneumatic equipment, the machine has to be disconnected from the

compressed air supply. In case of existing residual air pressure after disconnecting from compressed air supply (e.g.

pneumatic equipment with air tank), the pressure has to be removed by bleeding.

* Exceptions are only allowed for adjusting work and function checks done by special skilled personnel.

3

Page 4

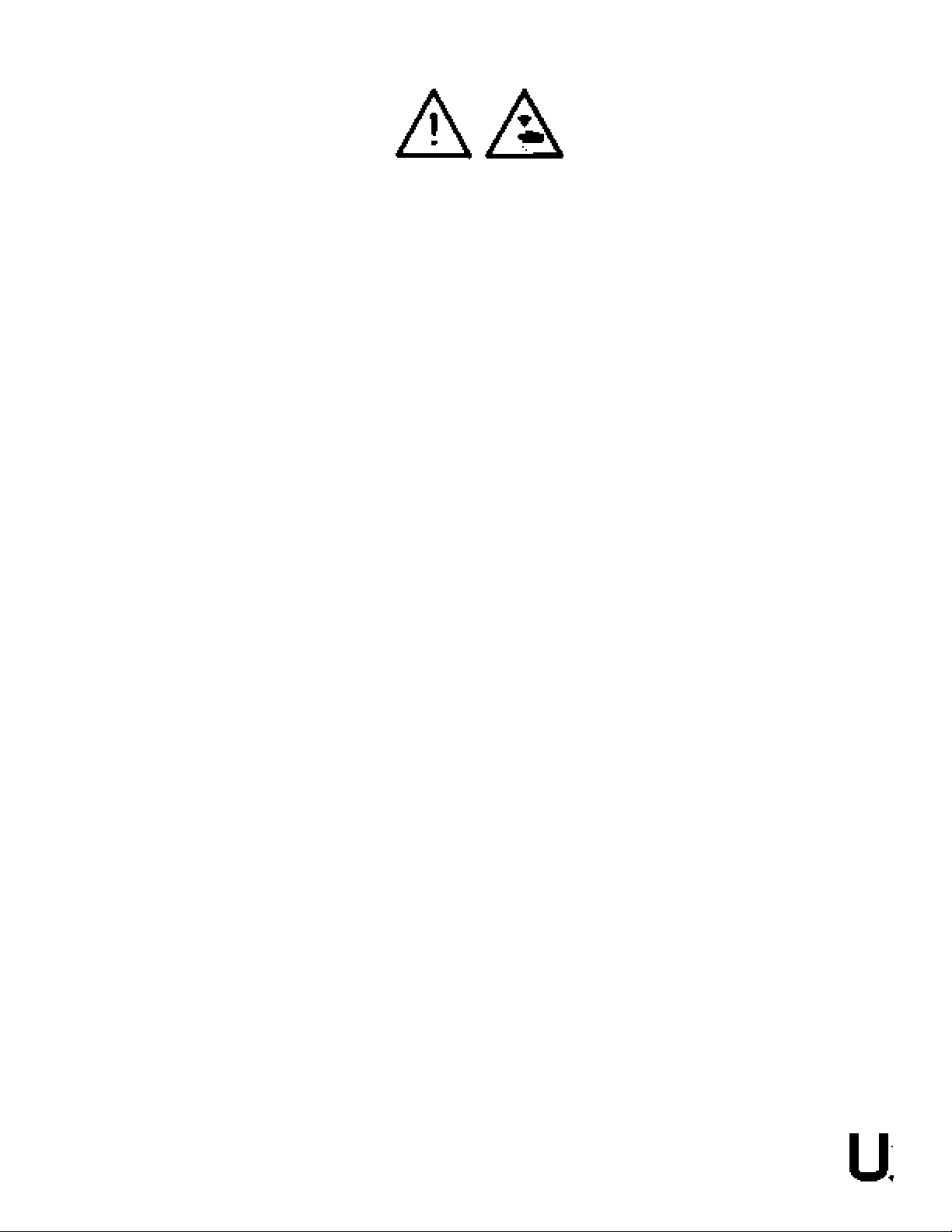

CAUTION

CAUTION AREAS

CAUTION

WEAR SAFETY

GLASSES, DO NOT

TAMPER WITH

SAFETY SHIELD.

USE WITHOUT

SHIELD MAY

CAUSE INJURY.

KEEP NEEDLE

BAR GUARD

IN PLACE

CAUTION

DO NOT OPERATE

MACHINE WITHOUT THIS

BELT GUARD IN PLACE

CAUTION

KEEP COVER

CLOSED DURING

OPERATION

4

CAUTION

KEEP

BELT GUARD

IN PLACE

Page 5

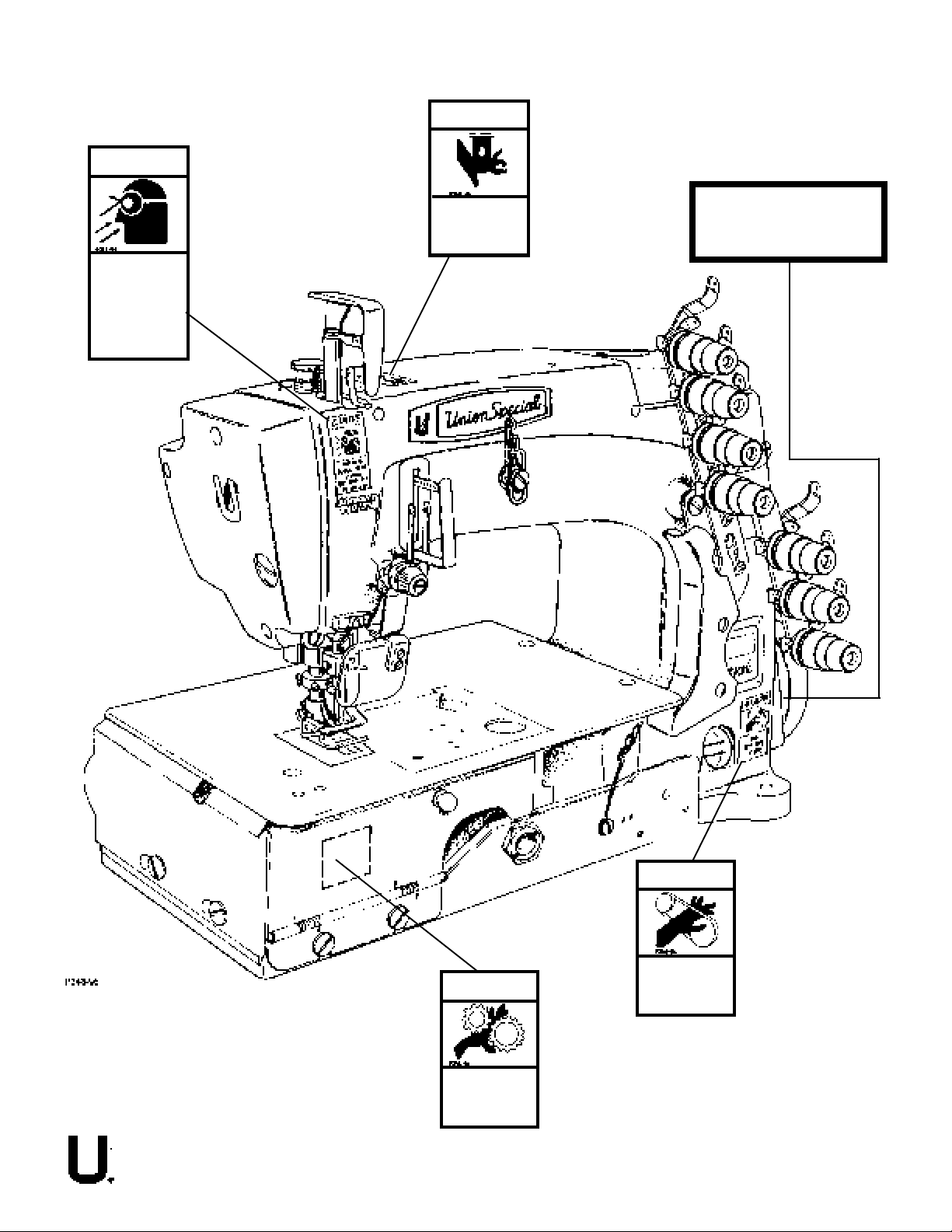

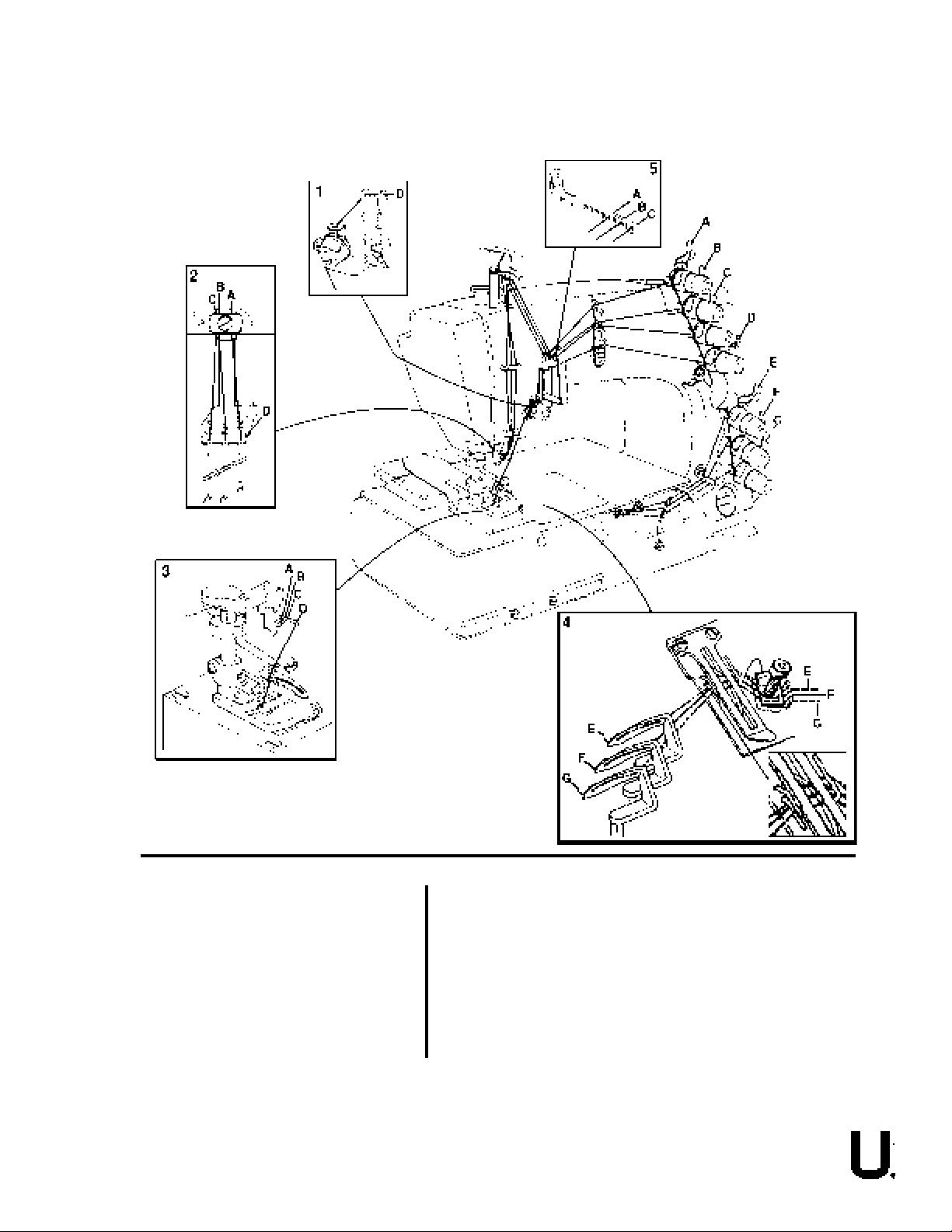

THREADING

A Right Needle Thread

B Middle Needle Thread

C Left Needle Thread

D Spreader Thread

E Rear/Right Looper Thread

F Middle Looper Thread

G Front/Left Looper Thread

1 Spreader Thread Take-Up & Nipper Area

2 Needle Head & Needle Thread Nipper Area

3 Sewing Area

4 Looper, Looper Thread Take-up & Nipper Area

5 Needle Lever Thread Eyelet Area

5

Page 6

CONTENTS

•PREFACE................................................................................................................................................................ 2

•SAFETY RULES....................................................................................................................................................... 3

•CAUTION AREAS ..................................................................................................................................................... 4

•THREADING ............................................................................................................................................................ 5

•IDENTIFICATION OF MACHINES .............................................................................................................................. 7

•MACHINE STYLES ................................................................................................................................................... 7

•NEEDLES ............................................................................................................................................................... 7

•TERMS ................................................................................................................................................................... 7

•ILLUSTRATIONS...................................................................................................................................................... 8

•IDENTIFYING PARTS ............................................................................................................................................... 8

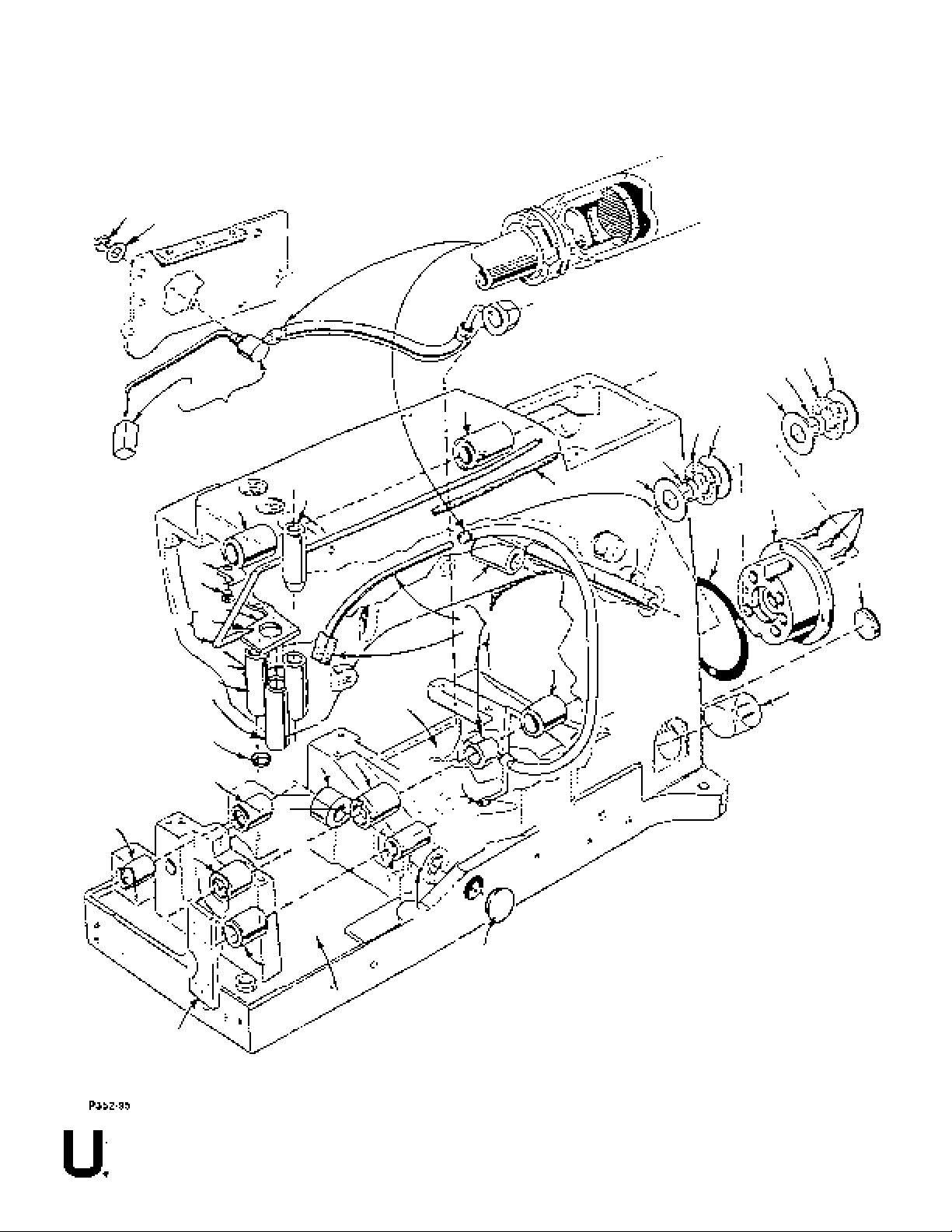

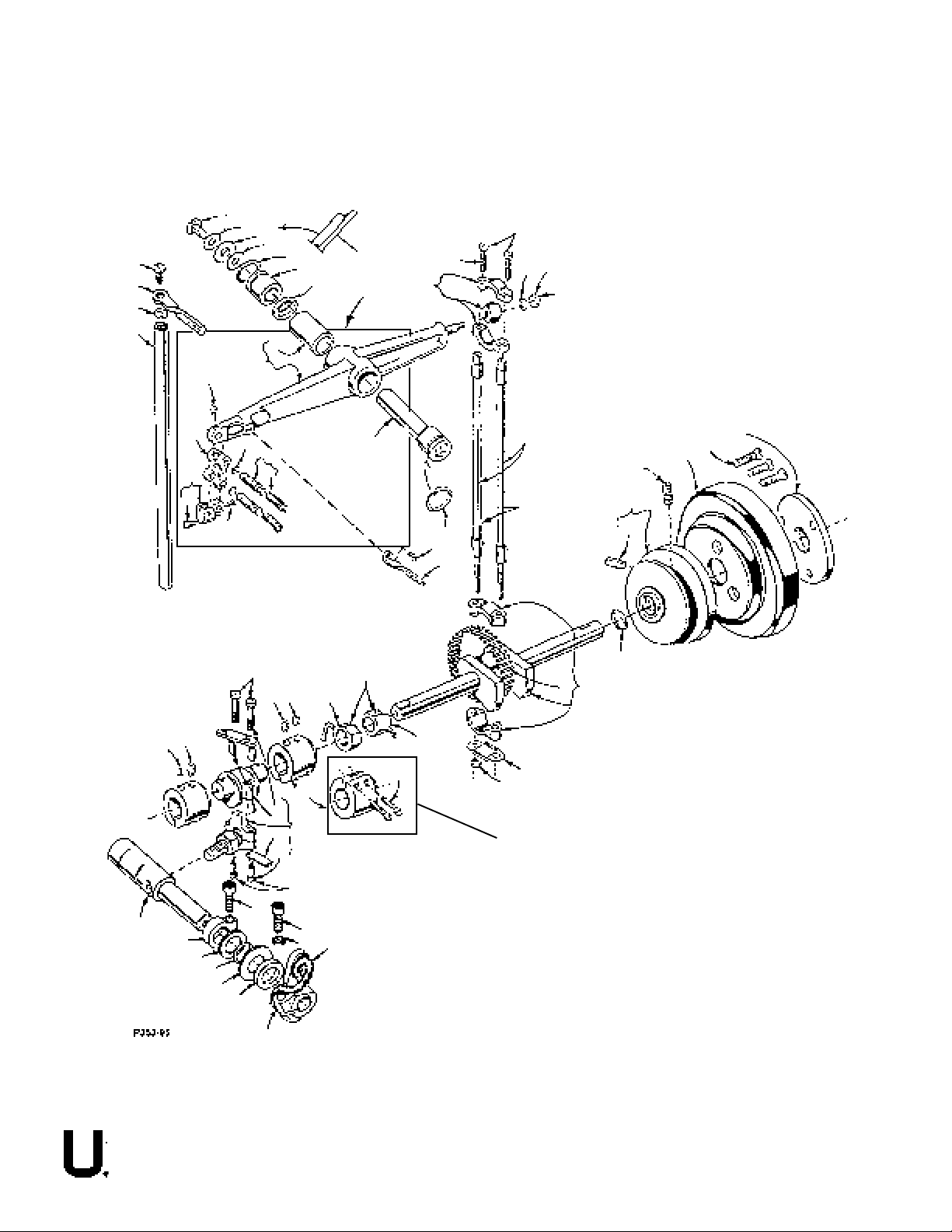

EXPLODED VIEWS

•MISCELLANEOUS COVERS, GUARDS, THREAD GUIDES & CAST-OFF PLATE......................................................... 11

•MISCELLANEOUS COVERS, GUARDS, THREAD GUIDES & CAST-OFF PLATE (CONT.) ........................................... 13

•LUBRICATION SYSTEM & BUSHINGS ..................................................................................................................... 15

•CRANKSHAFT, NEEDLE LEVER, NEEDLE BAR & LOOPER DRIVE MAECHANISM ................................................... 1 7

•CRANKSHAFT, NEEDLE LEVER, NEEDLE BAR & LOOPER DRIVE MECHANISM (CONT.) ........................................ 1 9

•SPREADER MECHANISM DRIVE ................................................................................................................... 21

•LOOPER ROCKER & CONNECTING ROD ............................................................................................................... 23

•FEED MECHANISM, MAIN SHAFT & TAKE-UP ........................................................................................................ 25

•FEED MECHANISM, MAIN SHAFT & TAKE-UP (CONT.) ........................................................................................... 27

•PRESSER FOOT LIFTER LEVER............................................................................................................................. 29

•THREAD TENSION ASSEMBLY .............................................................................................................................. 31

•COVERS & MISCELLANEOUS PARTS .................................................................................................................... 33

•PRESSER FOOT, THROAT PLATE & FEED DOG .................................................................................................... 35

•CHAIN CUTTER ASSEMBLY FOR STYLE:

FS113L112MBV096 ............................................................................................................................................. 37

•SHUTTLE VALVE ASSEMBLY FOR STYLE:

FS113L112MBV096 ............................................................................................................................................. 39

•MUFFLER/ CHAIN RECOVERY SYSTEM FOR STYLE:

FS113L112MBV096 ............................................................................................................................................. 41

•TREADLE OPERATED AIR VALVE ASSEMBLY FOR STYLE:

FS113L112MBV096 ............................................................................................................................................. 43

•FILTER, REGULATOR, LUBRICATOR, GAUGE ASSEMBLY FOR STYLE:

FS113L112MBV096 ............................................................................................................................................. 45

•AIR CIRCUIT DIAGRAM FOR STYLE:

FS113L112MBV096 ............................................................................................................................................. 46

•NOTES ................................................................................................................................................................. 47

•ACCESSORIES ...................................................................................................................................................... 49

•NUMERICAL INDEX OF PARTS .............................................................................................................................. 50

•NUMERICAL INDEX OF PARTS .............................................................................................................................. 51

•NOTES ................................................................................................................................................................. 52

•NOTES ................................................................................................................................................................. 53

6

Page 7

IDENTIFICATION OF MACHINES

Each Union Special machine carries a style number, which on this class machine is stamped in the style plate affixed

to the right front of the machine.

The serial number is stamped in the casting at the right rear base of machine.

MACHINE STYLES

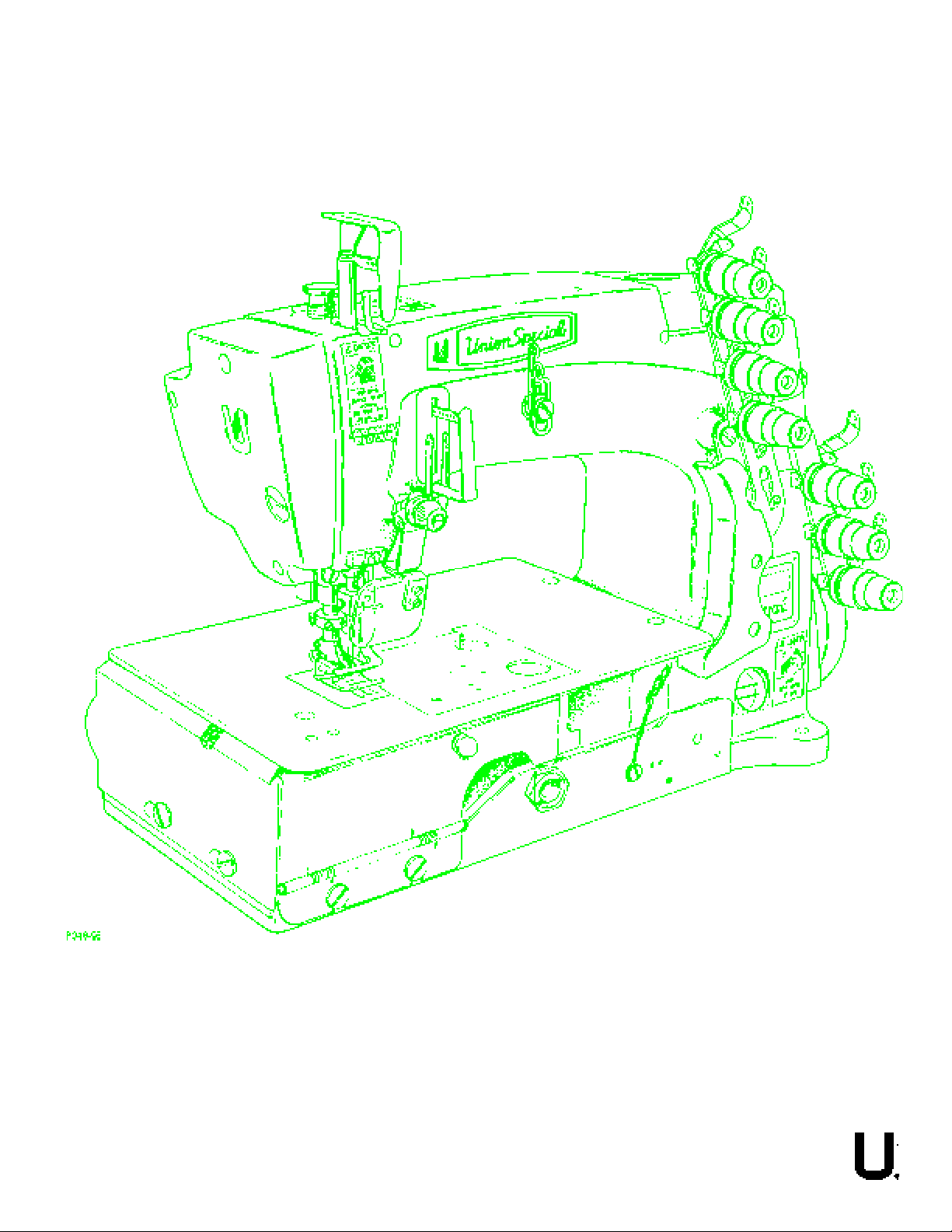

Advanced series, heavy duty flat bed machine. Three needles, three loopers, one spreader, one auxiliary spreader,

plain feed, enclosed automatic lubrication system. Maximum work space to right of needle bar 81/4" (210mm).

FS113L100MBV LAP-SEAMER: Three needle, top cover thread, plain feed machine - Typical application -

For pocket facing applications on medium to heavy weight denim. Seam specification

408LSbj-1 (Mod.). Standard Gauge Number 096 [3/8", 9.6 mm]. Maximum recommended

speed depending on application is 4500 R.P.M. Recommended needle 128 GS, size

125/049.

FS113L112MBV Same as style FS113L100MBV096 except fitted with a flat action (mounted on cloth plate),

compressed air operated chain cutter with venturi suction and chain disposal.

NEEDLES

Each needle has both a type and size number. The type number denotes the kind of shank, point, length, groove,

finish and other details. The size number, stamped on the needle shank, denotes the largest diameter of the blade

measured between the shank and the eye. Collectively, the type number and size number represent the complete

symbol which is given on the label of all needles packed and sold by Union Special.

TYPE DESCRIPTION

128 GS Short, double groove, struck groove, ball eye, spotted, undersize eye and grooves 27% of size of

needle, chromium plated - Sizes Available 090/036,100/040,110/044, 125/049, 140/054.

When changing the needle, make sure it is fully inserted in the needle head before the screw is tightened.

To have needles promptly and accurately filled, an empty package, a needle sample, or the type and size number

should be forwarded. Use the description on the label. A complete order should read as follows: "100 needles,

type 121 GBS, size 125/049".

TERMS

Prices are net cash and subject to change without notice. All shipments are forwarded F.O.B. shipping point. A

charge is made to cover postage and insurance.

7

Page 8

ILLUSTRATIONS

This manual has been arranged to simplify ordering repair parts. Exploded views of various sections of the

mechanism are shown so that the parts may be seen in their actual position in the machine. On the page opposite

the illustration will be found a listing of the parts with their part numbers, description and the number of pieces

required in the particular view being shown.

Numbers in the first column are reference numbers only, and merely indicate the position of the part in the

illustration. The reference number should never be used in ordering parts. Always use the part number listed in

the second column.

Component parts of sub-assemblies which can be furnished for repairs are indicated by indenting their descriptions

under the description of the main sub-assembly. As an example refer to the following text.

9. 29126EC Upper Looper Drive Shaft Assembly ........................................ 1

10. 22503F Screw ............................................................................. 1

11. 39543E Cam Follower Locking Clamp ............................................. 1

When a part is common to all machines covered in this manual, no specific usage will be mentioned in the description.

However, when the parts for the various machines are not the same, the specific usage will be mentioned in the

description and, if necessary, the difference will be shown in the illustration.

A numerical index of all the parts shown in this manual is located at the back. This will facilitate locating the

illustration and description when only a part number is known.

IDENTIFYING PARTS

Where the construction permits, each part is stamped with its part number. On some of the smaller parts and on

those where construction does not permit, an identification letter is stamped in, to distinguish the part from similar

ones.

PLEASE NOTE: Part numbers represent the same part, regardless of which manual they appear in. On all orders

please include part number, name and style of machine for which the part was ordered.

* For optimum performance, use only genuine Union Special replacement parts.

8

Page 9

EXPLODED

VIEWS ...

Page 10

8

10

9

11

12

70

71

7

6

5

4

3

80

79

50

52

44

42

43

51

41

40

62

63

64

68

70

69

2

76

73

75

74

71

55

56

57

58

1

72

77

78

53

54

59

60

61

13

17

48

49

48

47

46

45

39

38

14

15

16

17

18

19

22

20

21

20

21

23

24

81

87

83

84

82

85

88

86

89

90

65

66

24

37

67

29

28

27

30

32

31

35

36

33

34

25

26

10

Page 11

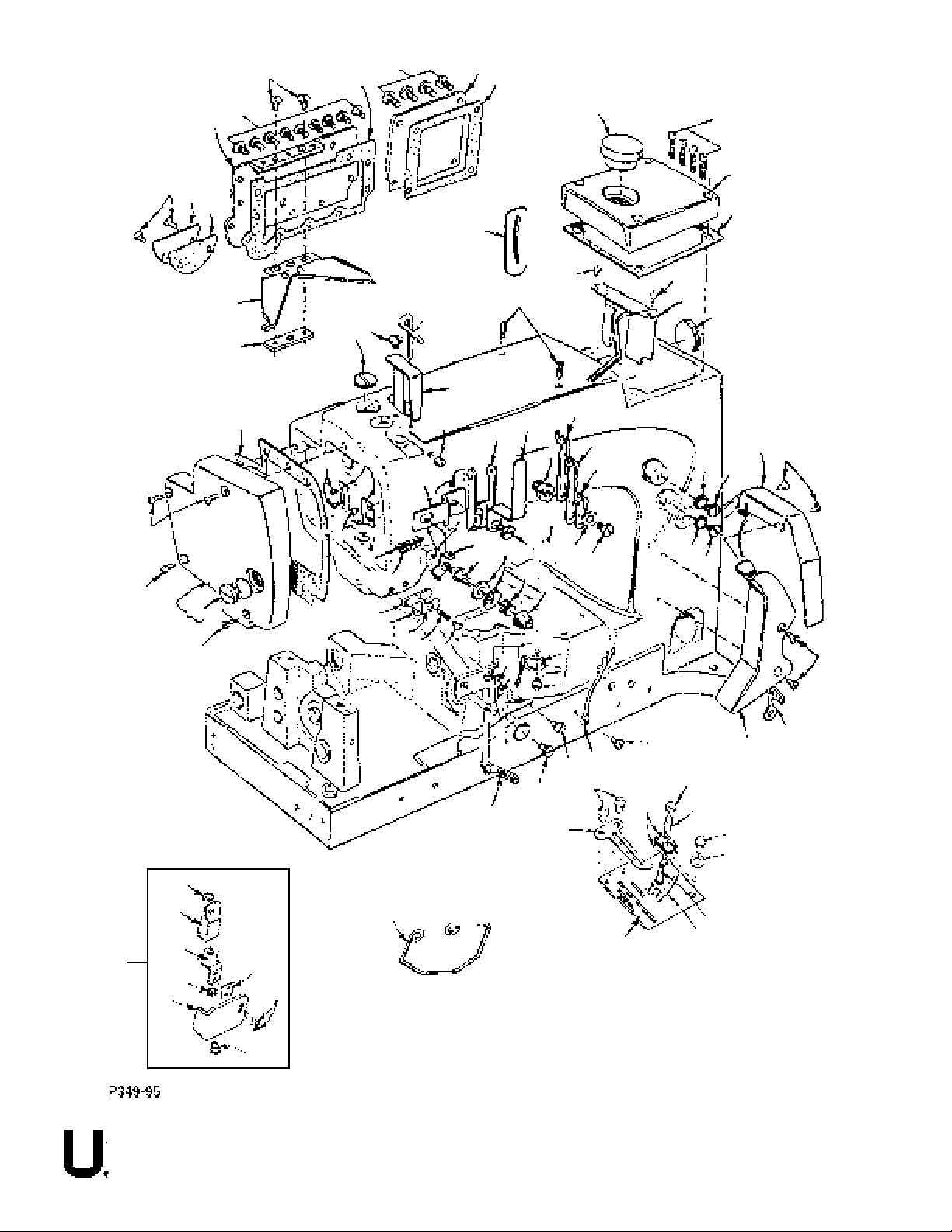

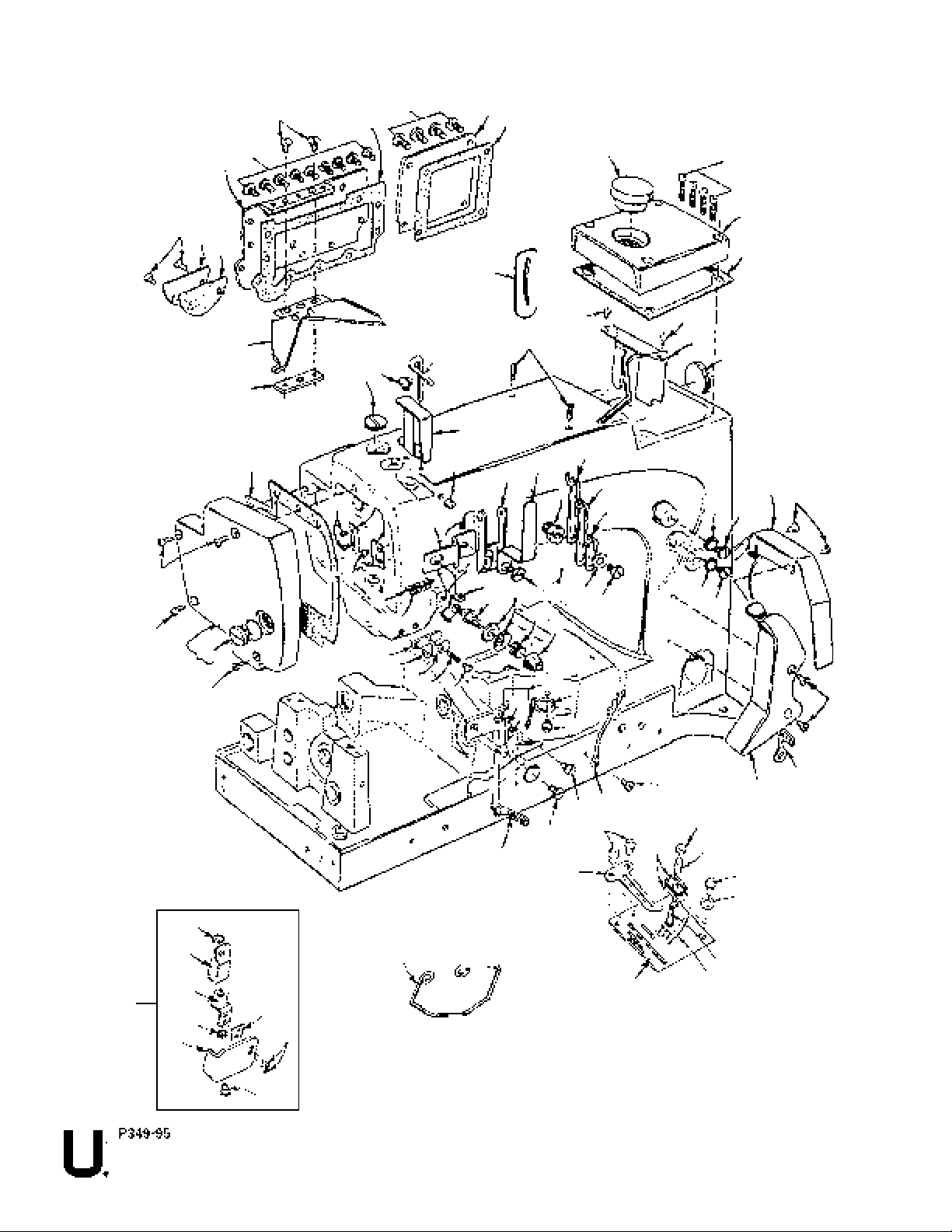

MISCELLANEOUS COVERS, GUARDS, THREAD GUIDES & CAST-OFF PLATE

Ref.

No.

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

16.

17.

18.

19.

20.

21.

22.

23.

24.

25.

26.

27.

28.

29.

30.

31.

32.

33.

34.

35.

36.

37.

38.

39.

40.

41.

42.

43.

44.

45.

46.

47.

48.

49.

50.

51.

Part No.

56382Y

56382AB

56382AV

56382J

22829

56382AA

22848

22524

56382AU

22548

56382D

56382AX

660-1002

22541C

57782M

56382AY

90

56382AC

22539S

80557

22839C

21375CE

22829

98A

158A

56391B

51457B

52804A

28

51959D

51959K

51959B

51492

51959J

22569C

69H

52958G

22585C

57858C

57892H

57892C5

80665F

57892J

57844

22848

20

51758

539

22889H

57882J

22585C

Description

Block, for oil drip plate ......................................................................

Oil Drip Plate ....................................................................................

Gasket, for looper drive shaft cover .....................................................

Cover, for looper drive shaft ................................................................

Screw, for looper drive shaft cover ........................................................

Oil Reservoir Cover, back .....................................................................

Screw, for oil reservoir cover, back .....................................................

Screw, for oil drip plate .....................................................................

Gasket, for oil reservoir cover, back ......................................................

Screw, for crank chamber cover, lower ..................................................

Crank Chamber Cover, lower ...............................................................

Gasket, for crank chamber cover, lower .................................................

Plug, for crank chamber cover, upper ....................................................

Screw, for crank chamber cover, upper ..................................................

Crank Chamber Cover, upper ...............................................................

Gasket, for crank chamber cover, upper ..................................................

Screw, for bearing oiler assembly ..........................................................

Bearing Oiler Assembly .......................................................................

Plug Screw, for bed ............................................................................

Washer, for tension assembly (see page 31) ............................................

Screw, for tension assembly (see page 31) .............................................

Belt Guard .......................................................................................

Screw, for belt guard ..........................................................................

Screw, for looper guard thread eyelet ....................................................

Looper Thread Eyelet ..........................................................................

Looper Thread Guard ..........................................................................................

Cast-Off Plate .....................................................................................................

Hold Down Plate, for looper thread ......................................................................

Screw, for hold down plate ..................................................................................

Tension Nut ......................................................................................................

Tension Spring ................................................................................

Tension Disc ..................................................................................

Tension Post ..................................................................................

Looper Thread Guide .........................................................................

Screw, for support plate ...................................................................

Washer, for support plate screw .........................................................

Eyelet, for looper thread ...................................................................

Screw, for eyelet ............................................................................

Eyelet, looper thread ......................................................................

Nut, for spreader thread post ..............................................................

Spreader Tension Spring ...................................................................

Disc, for tension post .........................................................................

Spreader Tension Post .....................................................................

Spreader Thread Guide .....................................................................

Screw, for thread eyelets ................................................................

Washer, for thread eyelets ................................................................

Eyelet, spreader thread ...................................................................

Eyelet, needle thread ....................................................................

Adapter Screw .................................................................................

Guard, for needle lever eyelet .............................................................

Screw, for needle lever eyelet ............................................................

Amt.

Req.

1

1

1

1

2

1

9

2

1

4

1

1

1

4

1

1

2

1

1

2

2

1

2

3

1

1

1

1

2

1

1

2

1

1

2

2

1

1

1

1

1

2

1

1

1

1

1

2

1

1

1

52. thru 88. See following page.

11

Page 12

8

10

9

11

12

70

71

7

6

5

4

3

80

79

50

52

44

42

43

51

41

40

62

63

64

68

70

69

2

76

73

75

74

71

55

56

57

58

1

72

77

78

53

54

59

60

61

13

17

48

49

48

47

46

45

39

38

14

15

16

17

18

19

22

20

21

20

21

23

24

81

87

83

84

82

85

88

86

89

90

12

65

66

24

37

67

29

28

27

30

32

31

35

36

33

34

25

26

Page 13

MISCELLANEUOS COVERS, GUARDS, THREAD GUIDES & CAST-OFF PLATE (CONT.)

Ref.

No.

Part No.

1. thru 51. See preceding page.

57858B

52.

95

53.

57844C

54.

34758

55.

57858A

56.

43296A

57.

22797

58.

57WB

59.

15438C

60.

57WD

61.

34844D

62.

28

63.

77

64.

57845E

65.

22585A

66.

22513B

67.

57882K

68.

22539AB

69.

22541C

70.

22851D

71.

57882P

72.

22564B

73.

34831C

74.

22539AA

75.

22585A

76.

56470

77.

33795

78.

22894E

79.

660-617

80.

81.

99682XF

82.

14077

83.

99683CN

84.

99682XC2

85.

95978

86.

56525F

87.

99696A

88.

22758E

89.

22766

90.

56525E

Description

Eyelet, spreader thread ...............................................................................

Set Screw .......................................................................................

Eyelet Mounting Plate .........................................................................

Needle Thread Guide ..........................................................................

Thread Guide Spring ..........................................................................

Base Nipper Spring ...........................................................................

Screw ...........................................................................................

Nipper Tension Plate ..........................................................................

Nipper Spring ..................................................................................

Screw, for nipper spring ....................................................................

Spreader Thread Guide Mounting Plate ...................................................

Screw ...................................................................................

Screw ...................................................................................

Spreader Thread Guide ...................................................................

Screw, for spreader thread mounting plate ..........................................

Screw , for spreader thread mounting plate ...........................................

Head Cover .....................................................................................

Plug Screw, for head cover .....................................................................

Screw, for head cover ...................................................................

Screw, for head cover .......................................................................

Gasket, for head cover ......................................................................

Screw, for guide plate ......................................................................

Guide Plate .................................................................................

Plug Screw, for bed ..........................................................................

Screw, for eyelet guard .................................................................

Needle Thread Take-Up ..................................................................

Guard, for needle thread eyelet ..........................................................

Screw, for needle lever stud ...........................................................

Gasket, for needle lever eyelet ........................................................

Needle Break Guard Assembly ..........................................................

Nut ......................................................................................

Mounting Plate .......................................................................

Bracket ................................................................................

Spring Washer ........................................................................

Spacer .................................................................................

Shield ....................................................................................

Shoulder Screw ........................................................................

Screw .....................................................................................

Sewing Guard ..................................................................................

Amt.

Req.

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

2

2

1

4

2

1

1

1

1

2

1

1

1

1

1

1

1

1

1

2

1

13

Page 14

3

2

7

9

8

4

1

41

5

5

9

8

6

7

7

7

13

12

23

36

40

39

22

37

34

32

23

38

35

33

19

24

25

19

27

18

26

10

30

31

17

29

28

11

14

15

16

21

20

14

Page 15

LUBRICATION SYSTEM & BUSHINGS

Ref.

No.

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

16.

17.

18.

19.

20.

21.

22.

23.

24.

25.

26.

27.

28.

29.

30.

31.

32.

33.

34.

35.

36.

37.

38.

39.

40.

41.

Part No.

59493A

660-230

258A

666-214

57849

CL21

56390H

56390J

660-665

52883R

21657X

22569B

57890B

56390E

22539R

51-902BLK

999-216K

52942AB

50-895BLK

56393P

666-259

56390

57836B

57842B

56190

35897BV

56393Q

56390G

57893

57893A

666-214

660-739

51257AA

57847B

57854

57893C

6-67-125

56393W

22585A

660-406

51154E

Description

Base Oil Pump Assembly ......................................................................

Gasket .......................................................................................

Nut ...........................................................................................

Felt Intake ..................................................................................

Bushing, for spreader rocker shaft .........................................................

Oil Wick ...........................................................................................

Thrust Washer ..................................................................................

Pilot Ring .........................................................................................

Needle Thrust Bearing ........................................................................

Bushing, for presser foot lifter ..............................................................

Release Bushing ................................................................................

Screw, for crankshaft bushing housing ...................................................

Crankshaft Bushing Housing .............................................................

Gasket, housing ................................................................................

Oil Drain Plug ...............................................................................

Oil Sight Gauge ...............................................................................

Plug, for bed ..................................................................................

Bushing, for looper drive lever shaft, front .............................................

Bushing, for looper rocker shaft ............................................................

Felt, base, front ................................................................................

Felt ...............................................................................................

Main Shaft Bushing, left ....................................................................

Bushing, for feed rocker shaft ..............................................................

Bushing, for looper drive shaft, rear ......................................................

Main Shaft Bushing, middle ..................................................................

Filter, for main shaft bushing ...............................................................

Felt, base, rear ................................................................................

Main Shaft Bushing, right ....................................................................

Oil Pump Assembly, head ...................................................................

Oil Tube ....................................................................................

Felt Intake .................................................................................

Oil Seal ..........................................................................................

Presser Bar Bushing ...........................................................................

Spreader Bushing .............................................................................

Needle Bar Bushing, lower ..................................................................

Oil Tube .........................................................................................

Felt ..........................................................................................

Felt, Oil Attraction ............................................................................

Screw, for clamp ...............................................................................

Clamp, for oil tube .............................................................................

Needle Bar Bushing, upper ..................................................................

Amt.

Req.

1

1

1

1

2

1

4

2

2

1

1

3

1

1

1

1

1

2

2

1

1

1

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

15

Page 16

61

62

60

63

TORQUE:

24

22

19-21 in. lbs.

2.1-2.3 Nm

25

TORQUE:

38 in. lbs.

(4.3 Nm)

27

26

TORQUE:

24-26 in. lbs.

(2.7-2.9 Nm)

28

29

32

31

32

30

1

2

3

4

5

6

7

10

11

12

13

14

9

16

17

18

15

No. 3

As viewed

from the side

8

19

23

20

21

TORQUE:

19-21 in. lbs.

2.1-2.3 Nm

42

43

43

42

40

45

46

44

47

48

TORQUE:

26-28 in. lbs.

2.9-3.2 Nm

49

50

52

53

51

57

58

54

55

56

NOTE:

Cut-out in Ref. No.

38 & 39 to be up

when assembling

39

59

33

34

35

38

41

See "Aligning main shaft to

crankshaft" in adjusting

manual for torque sequence

36

37

TORQUE:

Ref. No. 41, 42, 43

19-21 in. lbs.

2.1-2.3 Nm

NOTE:

16

Page 17

CRANKSHAFT, NEEDLE LEVER, NEEDLE BAR & LOOPER DRIVE MECHANISM

Ref.

No.

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

16.

17.

18.

19.

20.

21.

22.

23.

24.

25.

26.

27.

28.

29.

30.

Part No.

22586R

51250V

51250D

56382AK

660-625

56350J

56350K

29348AF

56315A

56350G

77

56354D

51254K

22562A

22564

660-215

52336A

WO3

56350D

660-625

22768

54458-9

29105BC

22559G

51216N

51216P

56316

61321L

22574

57821A

Description

Screw, for needle lever assembly ...........................................................

Washer ...........................................................................................

Washer ...........................................................................................

Gasket, for thrust collar ......................................................................

"O" Ring ...........................................................................................

Collar .............................................................................................

Torlon Washer ..................................................................................

Needle Lever Assembly .......................................................................

Needle Lever ...............................................................................

Bushing ................................................................................

Screw ........................................................................................

Link, for needle bar .......................................................................

Needle Bar Connection ..................................................................

Screw .................................................................................

Screw ........................................................................................

Retaining Ring .............................................................................

Link Pin ......................................................................................

Oil Wick ................................................................................

Needle Lever Stud ......................................................................

"O" Ring ........................................................................................

Screw, for needle lever eyelet ................................................................

Needle Lever Thread Eyelet ...............................................................

Ball Joint, for needle lever ...................................................................

Screw, for ball joint ............................................................................

Washer, for ball joint ..........................................................................

Nut, for ball joint ................................................................................

Needle Lever Connecting Rod ..............................................................

Retaining Plate ..................................................................................

Screw, for handwheel ..........................................................................

Handwheel .......................................................................................

Amt.

Req.

1

1

1

1

1

1

2

1

1

1

1

1

1

1

1

4

2

2

1

1

1

1

1

2

1

1

2

1

3

1

31. thru 61. See following page.

17

Page 18

62

61

63

60

TORQUE:

24

22

19-21 in. lbs.

2.1-2.3 Nm

25

TORQUE:

38 in. lbs.

(4.3 Nm)

27

26

TORQUE:

24-26 in. lbs.

(2.7-2.9 Nm)

28

29

32

31

32

30

1

2

3

4

5

6

7

10

11

12

13

14

9

16

17

18

15

No. 3

As viewed

from the

side

8

19

23

20

21

TORQUE:

19-21 in. lbs.

2.1-2.3 Nm

42

43

43

42

40

45

46

44

47

48

TORQUE:

26-28 in. lbs.

2.9-3.2 Nm

49

50

52

53

51

57

58

54

55

56

NOTE:

Cut-out in Ref. No.

38 & 39 to be up

when assembling

39

59

33

34

35

38

41

See "Aligning main shaft to

crankshaft" in adjusting

manual for torque sequence

36

37

TORQUE:

Ref. No. 41, 42, 43

19-21 in. lbs.

2.1-2.3 Nm

NOTE:

18

Page 19

CRANKSHAFT, NEEDLE LEVER, NEEDLE BAR & LOOPER DRIVE MECHANISM (CONT.)

Ref.

No.

Part No.

1. thru 30. See preceding page.

31.

56321R

32.

22894AB

33.

660-202

34.

29476PC

35.

51216M

36.

56316C

37.

12934A

38.

57893

39.

59493A

40.

56343F

41.

22653L8

42.

22894C

43.

22894D

44.

29105AK

45.

22587K

46.

56343C

47.

56343E

48.

22559A

49.

52942AF

50.

34342J

51.

22652A12

52.

57849C

53.

660-202

54.

56390H

55.

52951C

56.

56342K

57.

22882C

58.

51242M

59.

CL21

60.

31117A

61.

27-435BLK

62.

56958A

63.

22768

Description

Pulley .........................................................................................

Screw .......................................................................................

"O" Ring ...........................................................................................

Crankshaft Assembly .......................................................................

Needle Bearing ..........................................................................

Connecting Rod Guide ........................................................................

Nut, for connecting rod guide ................................................................

Oil Pump Assembly, head (see page 15, ref. no. 29) ......................................

Oil Pump Assembly, base (see page 15, ref. no. 1) .......................................

Coupling, for looper drive lever .............................................................

Screw, for looper drive lever coupling ..............................................

Set Screw, for looper drive lever coupling ...............................................

Spot Screw, for looper drive lever coupling ..............................................

Looper Lever Crank Assembly ...............................................................

Screw ......................................................................................

Ball Joint Guide ............................................................................

Oil Splasher ................................................................................

Screw .......................................................................................

Looper Drive Lever Rocker Shaft ............................................................

Binder Clamp ...................................................................................

Screw .....................................................................................

Thrust Washer ..................................................................................

"O" Ring ...........................................................................................

Washer ...........................................................................................

Thrust Washer ..................................................................................

Looper Drive Lever ......................................................................................

Screw ..........................................................................................................

Washer .........................................................................................................

Oil Wick .......................................................................................................

Needle Bar .......................................................................................................

Washer, for needle bar thread eyelet .............................................................

Needle Bar Thread Eyelet ...........................................................................

Screw, for needle bar thread eyelet ..............................................................

Amt.

Req.

1

2

1

1

28

1

1

1

1

2

2

2

2

1

2

1

1

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

19

Page 20

27

28

30

26

22

29

26

25

24

23

22

31

21

18

17

19

20

13

15

16

14

9

11

12

11

10

TORQUE:

24-26 in. lbs.

(2.7-2.9 Nm)

34

33

36

35

39

38

37

TORQUE:

19-21 in. lbs.

2.1-2.3 Nm

32

8

TORQUE:

19-21 in. lbs.

2.1-2.3 Nm

40

7

6

5

4

6

45

44

41

1

2

43

3

42

46

47

20

Page 21

SPREADER MECHANISM DRIVE

Ref.

No.

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

16.

17.

18.

19.

20.

21.

22.

23.

24.

25.

26.

27.

28.

29.

30.

31.

32.

33.

34.

35.

36.

37.

38.

39.

40.

41.

42.

43.

44.

45.

46.

47.

Part No.

57845D

22738B

57845F

57845G

77

94

41332J

34847A

WO3

57848E

22729

15430L

-

WI30

93

57835M

20

18

57849A

55235D

6042A

55235E

CL35

999-232

52849

57847

95

57849C

57849D

55235E

6042A

55235D

22559G

29105BD

52952C

55235D

6042A

55235E

18

HA20A

57852B

52916

29126CR

22597A

52951B

660-246

52951C

52947A

22587H

Description

Spreader ......................................................................................

Screw ......................................................................................

Auxiliary Spreader ..............................................................................

Spreader Holder ................................................................................

Screw ......................................................................................

Screw .......................................................................................

Thrust Washer ...................................................................................

Spreader Holder Drive Shaft ................................................................

Oil Wick .....................................................................................

Carrier Connecting Rod Assembly ..........................................................

Screw .......................................................................................

Oil Pad .................................................................................

Oil Wick ..................................................................................

Screw ......................................................................................

Washer, ball .....................................................................................

Washer, for carrier connecting rod assembly .......................................

Nut, for carrier connecting rod assembly ..............................................

Spreader Rocker Shaft Arm .................................................................

Locking Stud .............................................................................

Washer .....................................................................................

Nut ............................................................................................................

Wick, for spreader rocker shaft collar ...........................................................

"O" Ring, for spreader rocker shaft ........................................................

Spreader Rocker Shaft ........................................................................

Crankshaft Thrust Collar .....................................................................

Screw ........................................................................................

Washer ...........................................................................................

Spreader Rocker Shaft Collar, inner ........................................................

Nut ...........................................................................................

Washer ......................................................................................

Locking Stud ..............................................................................

Screw, for spreader connecting rod ball joint, upper ...................................

Spreader Connecting Rod Ball Joint, upper ...............................................

Segment Lever ..................................................................................

Locking Stud ..............................................................................

Washer .....................................................................................

Nut ..........................................................................................

Nut, for spreader connecting rod ball joint ................................................

Washer ...........................................................................................

Spacer ............................................................................................

Connecting Rod .................................................................................

Spreader Drive Eccentric Assembly ......................................................

Screw ........................................................................................

Retaining Washer ........................................................................

Retaining Ring .............................................................................

Spacer Washer .................................................................................

Counterweight ..................................................................................

Screw, for counterweight ....................................................................

Amt.

Req.

1

2

1

1

2

2

2

1

1

1

4

1

1

1

1

1

1

1

1

1

1

1

2

1

2

2

2

1

1

1

1

2

1

1

1

1

1

1

1

1

2

1

2

1

1

1

1

2

21

Page 22

10

17

18

19

11

12

13

14

15

1

16

45

46

22

20

21

26

35

34

38

37

36

33

3

4

5

9

8

2

1

23

47

42

44

40

41

42

39

43

44

48

49

TORQUE:

55 in. lbs.

(6.2 Nm)

32

6

7

25

27

29

TORQUE:

19-21 in. lbs.

2.1-2.3 Nm

28

24

29

30

31

22

Page 23

LOOPER ROCKER & CONNECTING ROD

Ref.

No.

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

16.

17.

18.

19.

20.

21.

22.

23.

24.

25.

26.

27.

28.

29.

30.

31.

32.

33.

34.

35.

36.

37.

38.

39.

40.

41.

42.

43.

44.

45.

46.

47.

48.

49.

Part No.

51244L

51246

56344C

98

719

96

22874

51236J

56344B

CO67E

WO3

56344

55244G

51244N

51216N

18

56342K

22882C

20

51908C24

51909E24

51909F24

18

29192AH

51745

56913B

22565

15465F

88

258

22829

56393J

87U

57841

22729C

269

51240D

18

56341N

56341V

56341T

660-210

56341W

660-310

56341P

56341S

56341R

20

627

Description

Thrust Washer ..................................................................................

Nut, for looper rocker assembly ............................................................

Looper Rocker Frame ..........................................................................

Set Screw ...................................................................................

Stop Screw .................................................................................

Spot Screw, for looper rocker frame ......................................................

Lock Screw, for looper rocker frame ....................................................

Connecting Pin ..................................................................................

Looper Rocker Arm ............................................................................

Cork Plug, for looper rocker shaft .........................................................

Wool Yarn, for looper rocker shaft ......................................................

Looper Rocker Shaft ...........................................................................

Stud, for looper rocker shaft collar ........................................................

Looper Rocker Shaft Collar ...................................................................

Washer, for shaft stud .......................................................................

Nut, for shaft stud ..............................................................................

Looper Drive Lever ............................................................................

Screw .......................................................................................

Washer ......................................................................................

Front Looper ...................................................................................

Middle Looper ..................................................................................

Rear Looper ....................................................................................

Nut ...............................................................................................

Looper Rocker Assembly ....................................................................

Stud Looper Rocker Cone ................................................................

Looper Rocker .............................................................................

Set Screw ...........................................................................

Cone .........................................................................................

Set Screw ............................................................................

Nut ........................................................................................

Screw .....................................................................................

Ball Joint Oiler ..................................................................................

Screw , for ball joint oiler ..................................................................

Looper Connecting Rod Ball Joint .........................................................

Screw .......................................................................................

Nut, left hand thread ...........................................................................

Looper Connecting Rod .......................................................................

Nut, right hand thread .........................................................................

Looper Connecting Rod Assembly, right .............................................

Spring ...................................................................................

Pin .......................................................................................

Retaining Ring .............................................................................

Pin ...........................................................................................

Retaining Ring .........................................................................

Looper Connecting Rod .............................................................

Lever .....................................................................................

Housing ....................................................................................

Washer ...........................................................................................

Screw ...........................................................................................

Amt.

Req.

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

3

1

2

1

1

1

1

1

2

1

1

1

1

1

1

2

1

2

1

1

1

1

1

23

Page 24

2

5

1

3

7

4

8

6

4

2

1

8

18

12

13

14

11

10

9

18

19

20

25

24

23

15

16

17

22

21

30

26

27

28

29

34

33

32

TORQUE:

19-21in. lbs.

(2.1-2.3Nm)

31

36

49

52

51

50

56

57

48

TORQUE:

55 in. lbs.

(6.2 Nm)

47

53

46

55

54

45

46

44

43

24

42

41

40

TORQUE:

19-21in. lbs.

(2.1-2.3Nm)

38

36

35

39

37

Page 25

FEED MECHANISM, MAIN SHAFT & TAKE-UP

Ref.

No.

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

16.

17.

18.

19.

20.

21.

22.

23.

24.

25.

26.

27.

28.

29.

30.

Part No.

660-1009

56384

56335B

22651CD4

56334B

56335L

56335D

98

41391

660-438

56334N

22651CB4

22637P24

258A

6042A

22863C

56334L

61341J

22834A

- - - - - 51236J

WO3

22528

56525D

22801

22875H

61434G

56122A

56322B

22891B

Description

Needle Bearing ...............................................................................

Seal ...............................................................................................

Feed Rocker .....................................................................................

Screw .......................................................................................

Feed Bar Shaft ..................................................................................

Feed Rocker Shaft ..............................................................................

Feed Rocker Shaft Collar .....................................................................

Screw ........................................................................................

Feed Rocker Shaft Thrust Washer ...........................................................

Retaining Ring ...................................................................................

Feed Bar Assembly .............................................................................

Screw ........................................................................................

Feed Dog Height Adjusting Screw ......................................................

Nut ...........................................................................................

Washer, for feed dog holder ..........................................................

Feed Dog Holder Adjusting Screw .....................................................

Feed Dog Holder ..........................................................................

Feed Bar Washer ................................................................................

Needle Guard Adjusting Screw .............................................................

Feed Dog (See Page 35) ........................................................................

Link Pin ...........................................................................................

Oil Wick ............................................................................

Screw, for feed dog ............................................................................

Needle Guard ...................................................................................

Screw .....................................................................................

Screw, for needle guard ......................................................................

Washer ..........................................................................................

Main Shaft ......................................................................................

Gasket .....................................................................................

Oil Flow Regulating Screw ...........................................................

Amt.

Req.

2

2

1

2

1

1

1

2

1

1

1

1

1

1

1

1

1

2

2

1

1

1

1

1

1

1

1

1

1

1

31. thru 57. See following page.

25

Page 26

2

5

1

3

7

4

8

6

4

2

1

8

18

12

13

14

11

10

9

18

19

20

25

24

23

15

16

17

22

21

30

26

27

28

29

34

33

32

TORQUE:

19-21in. lbs.

(2.1-2.3Nm)

31

36

49

51

52

56

50

57

48

TORQUE:

55 in. lbs.

(6.2 Nm)

47

53

46

55

54

45

46

44

43

26

42

41

40

TORQUE:

19-21in. lbs.

(2.1-2.3Nm)

38

36

35

39

37

Page 27

FEED MECHANISM, MAIN SHAFT & TAKE-UP (CONT.)

Ref.

No.

Part No.

1. thru 30. See preceding page.

31.

29476NM080

32.

22894AA

33.

77

34.

39543N

35.

56323B

36.

22580D

37.

29476NM062

38.

22894AA

39.

77

40.

56336D

41.

660-269B

42.

22543A

43.

56336

44.

22798C

45.

56322C

46.

22525A

47.

21657E

48.

269

49.

56335S

50.

55235D

51.

6042A

52.

55235E

53.

77

54.

56336K

55.

56336C

56.

51236J

57.

WO3

Description

Feed Lift Eccentric Assembly, .080", (2.03 mm) throw ..............................

Set Screw ...................................................................................

Screw .......................................................................................

Thrust Washer, for feed bar ................................................................

Looper Thread Take-Up .......................................................................

Set Screw ...............................................................................

Looper Avoid Eccentric Assembly, .062", (1.58 mm) throw ..........................

Set Screw ..................................................................................

Screw ........................................................................................

Feed Crank Stud Insert .......................................................................

Quad Ring ........................................................................................

Stitch Regulating Screw ......................................................................

Feed Crank Stud, marked "A" ................................................................

Screw .............................................................................................

Main Shaft Head Plate ........................................................................

Screw .............................................................................................

Washer ...........................................................................................

Nut, left thread ..................................................................................

Feed Rocker Arm ...........................................................................

Locking Stud .............................................................................

Washer ....................................................................................

Nut ...........................................................................................

Screw, for link pin .............................................................................

Feed Crank Link Pin ..........................................................................

Feed Crank Link Ferrule .............................................................

Feed Crank Link ................................................................................

Oil Wick .....................................................................................

Amt.

Req.

1

1

1

2

1

2

1

1

1

1

1

1

1

1

1

4

1

1

1

1

1

1

1

1

1

1

1

27

Page 28

23

22

24

14

15

7

19

11

8

18

10

17

21

20

16

13

12

9

6

5

4

25

26

3

2

1

28

Page 29

PRESSER FOOT LIFTER MECHANISM

Ref.

No.

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

16.

17.

18.

19.

20.

21.

22.

23.

24.

25.

26.

Part No.

50356B

22564D

51257K

51257M

22596F

22892E

34883

99392A

57883

22557G

56383D

34383BA

57893B

51256C

56356

56383AB

39552C

660-207

51283H

53783N

22537

21657Y

402

22596

21657W

660-283A

Description

Collar, for presser bar stop ..................................................................

Screw, for collar ..........................................................................

Presser Bar .....................................................................................

Presser Bar Guide ............................................................................

Screw .............................................................................................

Screw, for presser bar guide .................................................................

Lifter Lever Link ................................................................................

Screw, for lifter lever link ....................................................................

Spacer Bushing ...............................................................................

Screw ............................................................................................

Spring, for lifter lever .....................................................................

Lifter Lever ......................................................................................

Head Oil Tube Clamp ...........................................................................

Presser Bar Spring ............................................................................

Regulator, for presser spring ............................................................

Lifter Rod .....................................................................................

Washer, for lifter lever ........................................................................

"O" Ring, for lifter lever .......................................................................

Lifter Lever ......................................................................................

Lifter Lever, internal ........................................................................

Screw .......................................................................................

Lifter Lever Connection, tension release ..................................................

Screw .....................................................................................

Screw .......................................................................................

Lifter Lever Shaft ..............................................................................

Retainer Washer ................................................................................

Amt.

Req.

1

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

29

Page 30

INTERLEAF

30

Page 31

THREAD TENSION ASSEMBLY

Ref.

No.

Part No.

1.

29477NK

2.

NS6110420SP

3.

57865

4.

57892M

5.

57892K

6.

21657AP

7.

56392G

8.

B3120704000

9.

B3126012000

10.

B3120352000

11.

56392H

12.

51292F8

13.

B3101804000

-

B3103804000

14.

B3112704000

15.

56392R

-

56392L

-

56392M

Description

Thread Tension Assembly ...................................................................

Nut ...........................................................................................

Lead-In Thread Guide ....................................................................

Tension Post Support ...................................................................

Tension Thread Eyelet ..................................................................

Tension Disc Separator ................................................................

Tension Post ..............................................................................

Tension Disc Felt .........................................................................

Tension Disc ..............................................................................

Tension Disc Felt .........................................................................

Spring Shield ..............................................................................

Spring, needle thread tension (neutral) ...........................................

Spring, spreader thread tension (red) ..............................................

Spring, looper thread tension (blue) .................................................

Ferrule, tension spring ...................................................................

Knob, needle thread tension (neutral) ................................................

Knob, spreader thread tension (red) ................................................

Knob, looper thread tension (blue) ..................................................

Amt.

Req.

1

7

7

1

7

1

7

7

14

7

7

3

1

3

7

3

1

3

31

Page 32

2

3

1

4

5

3

4

3

4

25

8

7

6

9

13

16

12

10

11

14

24

13

17

15

19

13

15

18

20

26

22

12

21

23

32

Page 33

COVERS & MISCELLANEOUS PARTS

Ref.

No.

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

16.

17.

18.

19.

20.

21.

22.

23.

24.

25.

26.

Part No.

56381-212

51281AC

35772H

22760A

22845B

G51381BD

G51382BA

22848

99295

G51381BA

56380

51280J

660-313

22524

18-1424

22839

22585A

22524

56382G

56382AW

51282AJ

52978Z

25S

22526C

56301F

22839C

Description

Cloth Plate Cover ..............................................................................

Cloth Plate Cover Spring ................................................................

Spring Washer .............................................................................

Screw, for spring washer ...............................................................

Screw .......................................................................................

Oil Shield, rear ..................................................................................

Bracket, for oil shield .........................................................................