Page 1

INDUSTRIAL

SEWING

FINES

T

STYLES

80800E

80800f

80800H

C 0 L U M B I A®

MACHINES

CLASS

HIGH

80800

SPEED

CATALOG

No.

137M

Second

Edition

FILLED

BAG

CLOSING

UNION SPECIAL

CHICAGO

MACHINES

CORPORATION

Page 2

Union Special is offering

ce

your

redu

system to he

and a parts inventory system to speed routine repairs .

Machine

Repairup your

Unio n Special suggests two variations

rec

ord

The first system utilizes a

orm

(F

requ ired,

and

th

sewing machine maintenance costs : a record keeping

lp

spot machines requiring abnormally high maintenance,

Maintenance

pron

e machines or inexperienced competent operators

maint

enance dollars in s

keeping system using cards provided by

237)

for each sewing machine in a plant. When a repair is

th

e card is pulled fr

eir cost are entered in the spaces provided and the card is refiled.

..

......

tt.U4

04fl

••

-.

two

practi

cal

systems

Records

hort

order.

To

help spot these problems,

of

a simple maintenance

"Ma

chin e Maintenance Record" card

om

the file and the repair date, parts used,

MA

CHIN& MAINTIINAHC.C ft£

........

-...-..

I I I I

..

,..r""

~

-

fO\tt'\

. e

f'\11\1\

f'\llch'~clltd

~ecot

~~

2'31-

tel\111\ce

CORD

---

•n•-.

to

help pinpoint and

Union

OA

,.•.,.

•~a

-

-

--

The second system is

on

repair costs is desired. Two record cards are used: a "Repair

Request

233)

out

fill s in the time the repair

Card"

. When a machine requires service, the forelady

the

top

of

a "Repair Request Card" and gives

(Form

normally

234)

used when more detailed information

, and a "Machine Repair Record"

work

is started, the parts used and their cost,

or

it

to

a mechanic. He

can

Special.

TaPu

K N

-·

....

(Fo

rm

foreman fills

and the

completion

"Machi

ne

Repair Record"

Whichever system is used, management now has an invaluable

to

reduce needless maintenance costs.

Repair

eat

Part

While record keeping tells management which machines require

abnormally high maintenance, it does little to help reduce the

caused by routine repairs.

recommends that manufacturers establish a formal parts

system

for

ve

Excessi

be eliminated with an orderly in-plant inventory

needed parts. There is

for

spare parts.

downtime

when the overall savings are considered.

is

MACHINE.

IIIA

III

••

~n

- fOttt'\

r--

-

c:...

time. This data is then transferred to the

kept

in the office.

Inventories

To

alleviate this situation,

each type

mach i

kept

Nlollll

of

sewing machine they operate.

ne

downtime

no

Long

RIIPAift

"'olll'

longer a need to cannibalize

waits

to

a minimum . The cost

ftECOftD

CARO

'1!111

"

WI'

and wasted hours by mechanics can

for

deliveries are avoided and

=

~

I

~·

--·

I

--·

-.-

OO...

•

mt

ll!W'

-

. e

~eva•t

f'\ach•~'

~'3~;td

catd_

-~-

- fOttt'\ 1

:~ra•

T

.. lff

n••

M&c:H

of

a parts

-.

REPAIR ftllQU

.....

...

••·-

~

AJtTBu

-·

.

~e~ue

l

AitTI.

c.ow

~

....

ICI

..,

__

of

-----

For free sample copi

inventory lists

local Union Special Representative or write direct

for

a variety

es

of

the machine record cards and spare part

of

the most popular machines, contact

Union

the most

other

inventory

UT

CARD

sm

-·

2'34-

catd

s

J=

MM

--

--

to

Union

permanent

downtime

Special

inventory

commonly

machines

machine

is small

1

;-

I~

1-

I=

1-

I=

-::

I=

I=

I=

I=

your

Special.

tool

Part

Number

80627

C41

88

22570

22707

80605

93

80624

80

HA56

•The

setti

can

the sewi

parts

ng

only

E

E

E

and

qua

up

the tniti

be

established accordi

ng

operati

on

Description

Presser

Feed

Throat plate

Needle clamp

foot

Hinge

screw

for

Clamp

screw

screw

Screw

to

foot

bottom

dog

Screw

for

Screw

for

ntttle s hsted above

al

inventory of spare parts. An effictent inventory

will determi

#80627

adj. presser

feed

dog

throat

plate

nut

are

ng

to actual usage. The nature of

ne

actual usage.

Minimum

Per 5 Machines

E

intended to

1

2

1

1 Clamp

1

1

1

1

3

2

ass

ist you in

Quantity

Part

Number

1975

80675

88

D

80677

92127

AS26

73

80604

AS22

80623

21225

29484

Style

S

uggested Minim

Description

G

XA

D

5 /

Needles

Lower

Screw

Upper

Screw

Looper

Looper

Thread hook

Screw

Looper thread take

16

Looper gauge

Screw assortment

80800

um

Spare Parts Li

(speci

fy

size)

knife

for

lower

knife

for

set

for

knife

upper kni

screw

thread hook

fe

up

E

st

•

Minimum

Per 5 Machines

Quantity

200

1

1

1

1

1

2

1

2

1

Page 3

Catalog

No.

INSTRUCTIONS

FOR

137

M

ADJUSTING

80800

E

LIST

CLASS

Second

AND

OF

Styles

80800

OPERATING

PARTS

80800

F

Edition

80800

H

May~

1979

Copyright®

1973

By

Union

Rights

Special

Reserved

Corporation

in

All

Countries

UNION SPECIAL CORPORATION

INDUSTRIAl

Printed

SEWING

CHICAGO

in

U.S.A.

3

MACHINES

Page 4

IDENTIFICATION

OF

MACHINES

Each

ed

in

the

special.

tain

the

letter

suffixed

which

80800

herein.

this

described

table.

direction

"Z".

Styles

differs

".

This

Class.

with

UNION

name

Standard

letter

When

to

the

of

from

catalog

It

can

References

as

viewing

the

of

handwheel

SPECIAL

plate

"Z".

Standard

machines

also

pulley

on

Style

Example:

only

the

applies

be

the

numbers

minor

Style

similar

Style

specifically

applied

to

the

machine

to

the

is

away

machine

machine.

''Style

changes

number.

number.

APPLICATION

with

direction.

right

from

STYLES

is

identified

Style

have

in

one

80800

are

Example:

construction

in

to

discretion

such

as

it

sits

and

the

the

OF

numbers

or

more

E".

made

that

it

contains

OF

CATALOG

the

Standard

to

as

in

front

needle

operator.

MACHINES

by a Style

are

classified

letters

Special

in a standard

"Style

are

some

right.

bar

Style

80800

grouped

no

Styles

Special

left,

of

the

in

vertical

letters.

mechanic

number

suffixed.

numbers

machine.

EZ".

under

of

machines

Styles

front.

position.

which

as

a

Example:

back.

on

standard

but

never

contain

Class

of

machines

an

is

etc

Operating

stamp-

and

con-

the

a

"Z"

is

number

"Class

as

listed

in

.•

are

adjusting

Enclosed

Lubrication.

Eccentrics

Left

Edge

80 800 E

burlap,

foot.

Type

80800

burlap,

foot.

NOTE:

by

80 800 H

ply

Filter

Seam

speed

F

Type

Styles

removing

Sewing

or

Sewing

Sewing

Type

and

of

Equipped

1975 G needle.

Equipped

1975 G needle.

multi

cord

specification

2500

Flat

Lateral

Coil

Throat

head.

jute

head,

jute

80800 E and F machines

head,

wall

guided

R.

and

and

the

P.M.

Bed

Looper

Type

Plate

single

with

for

single

with

filter

for

paper

Bag

Closing

Travel.

Presser

7/8

Inch.

for

closing

or

mechanical

Maximum

closing

or

mechanical

Maximum

cord.

tape

bound

bags.

under

401-BSa-1.

presser

with

Springs.

filled

multiwall

chain

recommended

filled

multiwall

chain

recommended

closures

using

Union

Type

Machine.

Improved

Distance

medium

paper.

cutter.

medium

paper.

cutter.

can

foot.

1975 G needle.

One

and

Filter

and

Filter

also

on

filled

Special

Equipped

From

heaVY

Seam

speed

heaVY

Seam

speed

be

used

tape

Needle.

Bearings.

Center

weight

cord

cord

medium

with

guided

specification

2500

weight

guided

specification

2500

for

bound

automatic

Maximum

High

Smaller

Line

bags

R.

P.M.

bags

R.

P.M.

seaming

and

large

closing

Throw.

under

under

tape

recommended

Manual

Diameter

of

Needle

made

401-SSa-1.

made

101-SSa-1.

fabric

size

attachment.

from

presser

from

presser

bags

sfngle

cutter.

to

NOTE:

On

bly

are

21884

designed

Cis

Style

not

to

80800

included

available

use a strip

H.

the

with

as

ranging

tape

an

the

extra

reel,

machine.

folder.

send

from 2 1/8

4

Tape

and

filter

folder

charge

to 2 1/2

cord

item.

inches.

stand

and

and

adaptor

The

included

adaptor

assembly

assem-

folder

No.

is

Page 5

NEEDLES

Each

denotes

number,

in

thousandths

the

size

needles

Needle

by

this

Type

1975

To

sample

on

label. A complete

Selection

should

Success

use

of

a

reputation

more

UNION

the

stamped

number

packaged

catalog.

No.

G

have

needle,

pass

needles

than

kind

Type

Round

chromium

400/156,

freely

three-quarters

SPECIAL

of

on

of

an

represent

and

1975

The

needle

or

of

proper

in

the

packaged

for

producing

shank,

the

needle

inch,

sold

G,

description

shank,

plated-

480/188.

orders

the

type

order

needle

through

operation

under

needle

point,

midway

the

by

Size

square

promptly

and

would

needle

highest

of a century.

has

length,

shank,

between

complete

Union

100

is

and

point,

sizes

size

read:

size

eye

of

UNION

our

brand

quality

both a type

groove,

denotes

shank

symbol,

Special.

recommended

sizes

200/080,

and

number

is

available

Description

long

230/090, 250/100,

accurately

should

''100

needles,

determined

in

order

SPECIAL

name,

needles

and

size

number.

finish

largest

and

which

Antaeus,

by

to

produce a good

machines

~

in

and

diameter

eye.

Collectively,

is

for

the

are

listed

and

Sizes

double

filled,

be

forwarded.

Type

size

materials

other

of

given

machine

below:

300/120,

an

empty

1975

of

thread

can

be

•

which

and

The

type

details.

blade,

on

the

Styles

groove,

Use

G,

Size

used.

stitch

secured

workmanship

The

measured

the

label

350/140.

package,

description

250/100".

formation

is

backed

number

size

type

and

of

all

covered

spotted,

Thread

only

by

by

for

a

•

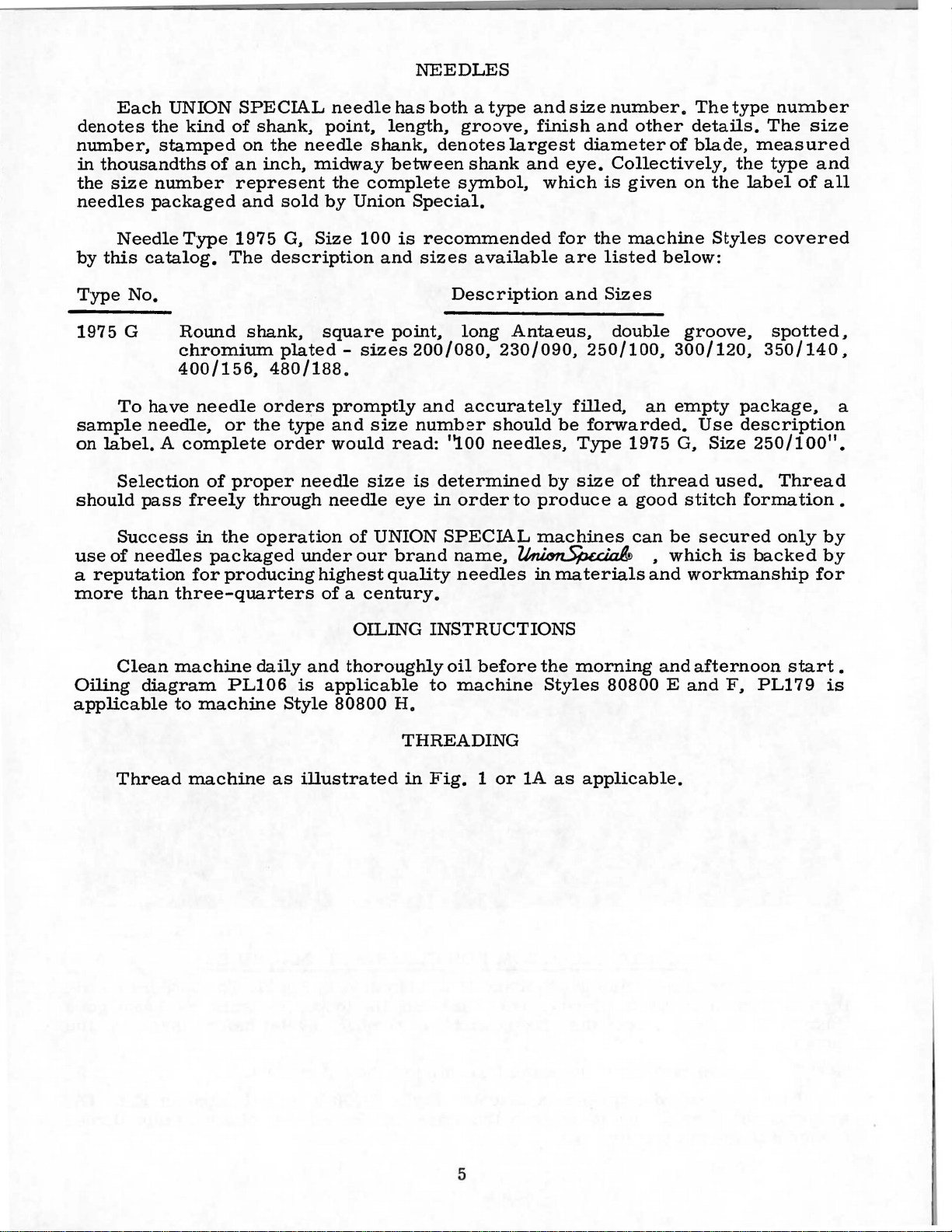

Clean

Oiling

applicable

diagram

Thread

machine

PL106

to

machine

machine

daily

Style

as

OILING

and

thoroughly

is

applicable

80800

illustrated

INSTRUCTIONS

oil

before

to

machine

H.

THREADING

in

Fig. 1 or

the

Styles

lA

morning

80800 E and

as

applicable.

and

afternoon

F,

start

PL179

•

is

5

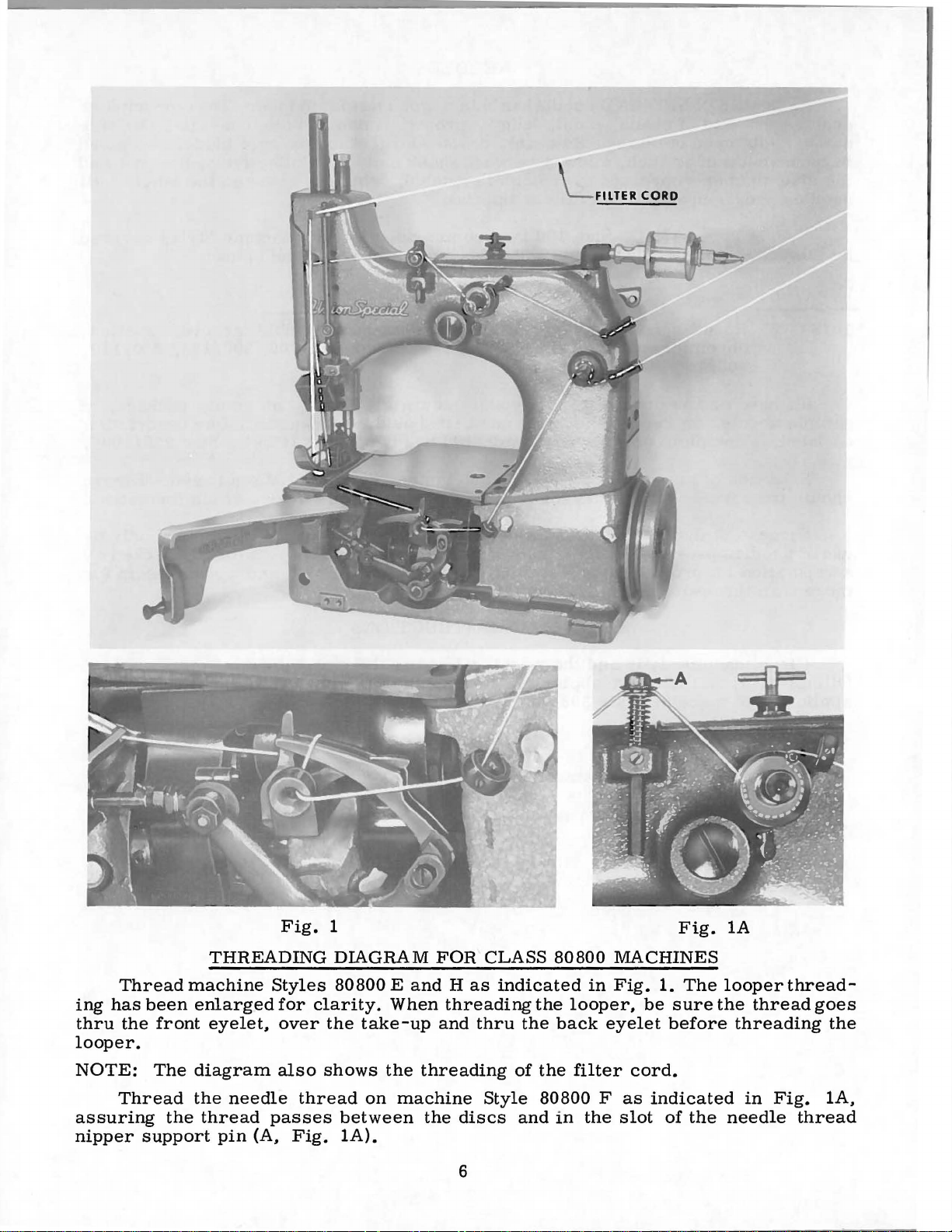

Page 6

FILTER CORD

ing

thru

Thread

has

been

the

machine

front

Fig.

THREADING

Styles

enlarged

eyelet,

for

over

1

DIAGRAM

80800 E and

clarity.

the

When

take-up

FOR

Has

CLASS

indicated

threading

and

thru

the

the

80800

back

looper.

NOTE:

assuring

nipper

The

Thread

the

support

diagram

the

needle

thread

pin

(A,

also

thread

passes

Fig.

shows

on

between

lA).

the

threading

machine

the

Style

discs

6

of

the

80800 F as

and

in

MACHINES

in

Fig.

looper,

eyelet

filter

the

slot

Fig.

1.

be

sure

before

cord.

indicated

of

The

the

lA

looper

the

thread

threading

in

needle

thread-

Fig.

thread

goes

the

lA,

Page 7

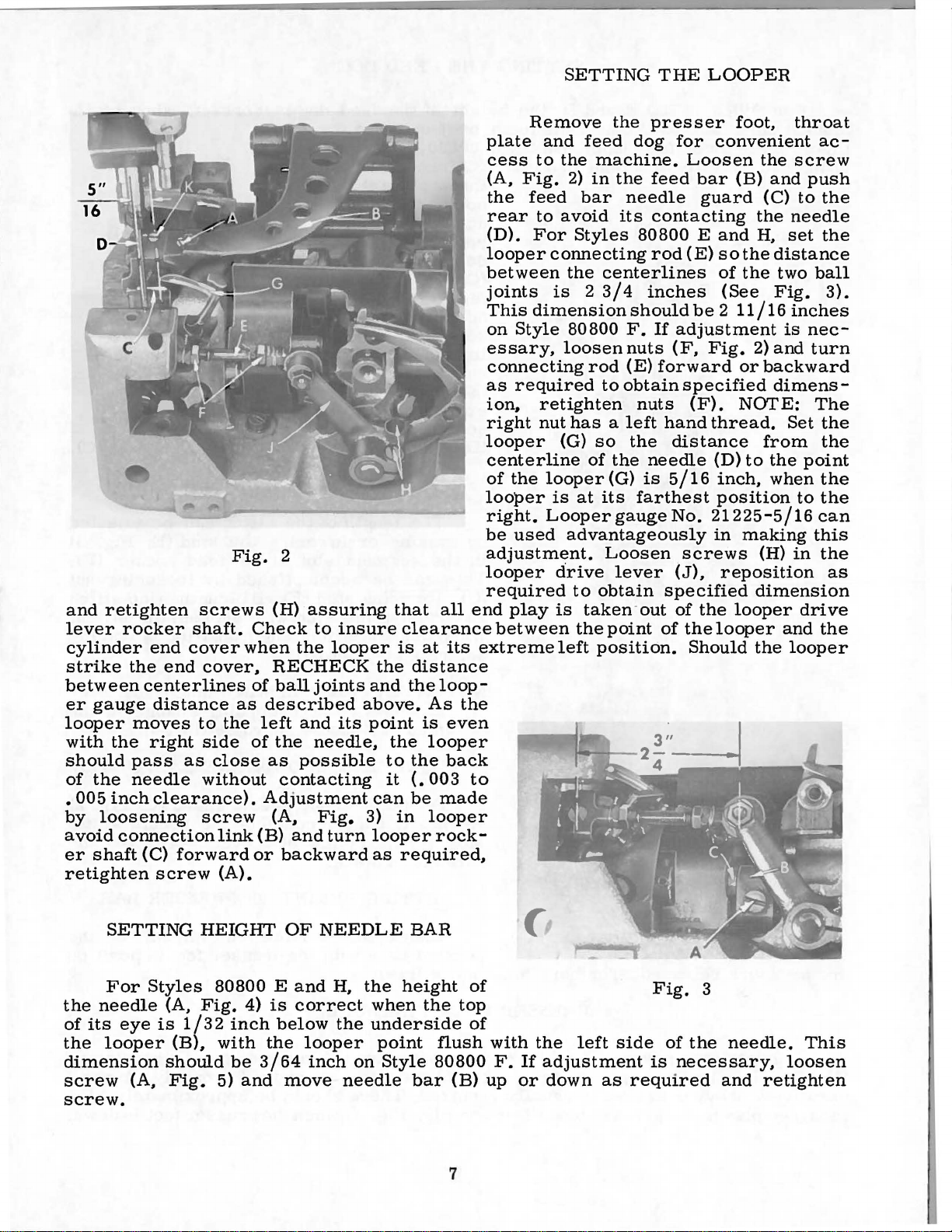

SETTING

THE

LOOPER

and

retighten

lever

rocker

cylinder

strike

the

between

er

gauge

looper

with

the

should

of

the

•

005

inch

by

loosening

avoid

er

connection

shaft

retighten

end

cover

end

center

distance

moves

right

pass

as

needle

clearance).

(C)

forward

screw

Fig.

screws

shaft.

cover,

lines

as

to

the

side

close

without

screw

link

(A).

2

(H)

assuring

Check

when

the

RECHECK

of

ball

described

left

and

of

the

as

possible

contacting

Adjustment

(A,

(B)

and

or

backward

to

insure

looper

joints

above.

its

needle,

Fig.

turn

that

clearance

is

the

and

point

the

to

it

can

3)

in

looper

as

required,

all

at

its

distance

the

loop-

As

the

is

even

looper

the

back

(.

003

be

made

looper

rock-

Remove

plate

cess

(A,

the

rear

(D).

and

to

Fig.

feed

to

For

looper

between

joints

This

dimension

on

Style

essary,

connecting

as

required

ion..

right

retighten

nut

looper

centerline

of

the

looper

right.

be

used

adjustment.

looper

required

end

play

between

extreme

to

the

feed

the

2)

bar

avoid

Styles

dog

machine.

in

the

needle

its

80800 E and

connecting

the

centerlines

is 2 3/4

should

80800

loosen

rod

to

F.

nuts

(E)

obtain

nuts

has a left

(G)

so

the

of

the

looper

is

Looper

at

(G)

its

gauge

farthest

advantageously

Loosen

cirive

is

left

lever

to

obtain

taken·out

the

point

position.

presser

for

Loosen

feed

bar

guard

contacting

rod

(E)

inches

be 2 11/16

If

adjustment

(F,

Fig.

forward

specified

(F).

hand

thread.

distance

needle

is

5/16

No.

21225-5/16

screws

(J),

specified

of

the

of

the

Should

foot,

throat

convenient

the

screw

(B)

and

(C)

the

needle

H,

set

so

the

distance

of

the

two

(See

Fig.

inches

is

2)

and

or

backward

dimens-

NOI'E:

Set

from

(D)

to

the

inch,

when

position

in

making

(H)

in

reposition

dimension

looper

looper

the

and

looper

ac-

push

to

the

the

ball

3).

nec-

turn

The

the

the

point

the

to

the

can

this

the

as

drive

the

SETTING

For

the

needle

of

its

eye

the

looper

dimension

screw

(A,

Styles

(A,

is

1/32

(B),

should

Fig.

HEIGHT

80800 E and

Fig.

4)

is

inch

below

with

5)

be

and

the

3/64

move

OF

NEEDLE

correct

looper

inch

H,

the

the

on

needle

BAR

height

when

the

underside

point

Style

flush

80800

bar

of

top

of

(B)

with

F.

up

the

If

adjustment

or

down

screw.

7

left

side

as

required

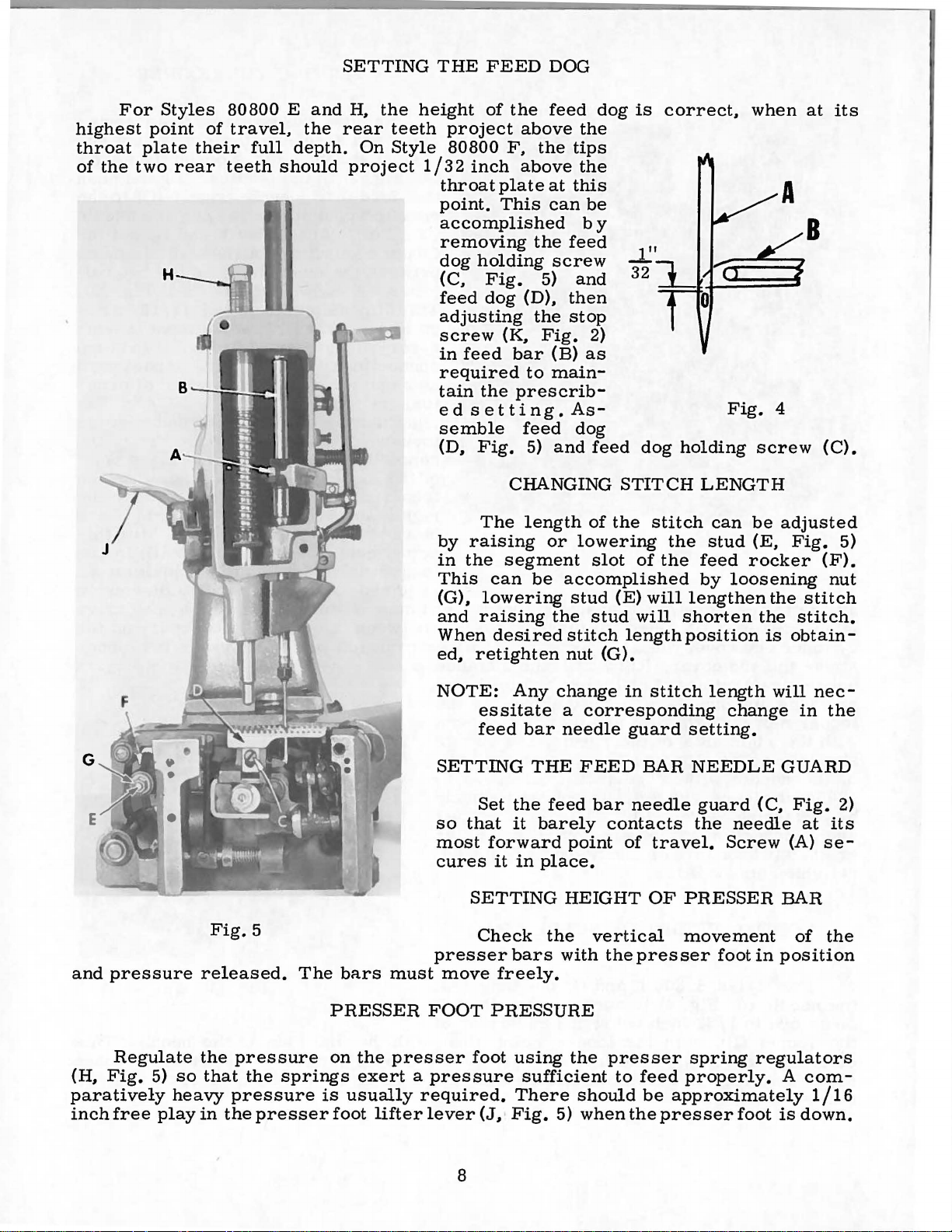

Fig.

is

3

of

the

necessary,

needle.

and

retighten

This

loosen

Page 8

For

highest

throat

of

the

Styles

point

plate

two

H

their

rear

80800 E and

of

travel,

full

teeth

should

the

depth.

SETTING

H,

the

rear

teeth

On

Style

project

THE

height

1/32

throat

point.

accomplished

removing

dog

(C,

feed

adjusting

screw

in

required

tain

ed

semble

(D,

FEED

of

project

80800

inch

plate

This

holding

Fig.

dog

(K,

feed

the

setting.

Fig.

DOG

the

feed

above

F,

the

above

at

can

the

screw

5)

(D),

the

Fig.

bar

(B)

to

main-

prescrib-

feed

5)

and

the

tips

the

this

be

by

feed

and

then

stop

2)

as

As-

dog

feed

dog

is

dog

correct,

holding

when

Fig.

4

screw

at

B

its

(C).

G

and

pressure

Fig.

5

released.

The

bars

must

The

by

raising

in

the

segment

This

(G),

and

When

ed,

NOTE:

SETTING

so

most

cures

presser

move

can

lowering

raising

desired

retighten

essitate

feed

Set

that

forward

it

SETTING

Check

freely.

CHANGING

length

be

Any

bar

THE

the

it

barely

in

place.

bars

of

or

lowering

slot

accomplished

stud

the

stud

stitch

nut

(G).

change

a

corresponding

needle

FEED

feed

bar

point

HEIGHT

the

vertical

with

STITCH

the

stitch

of

the

(E)

will

will

length

in

stitch

guard

BAR

needle

contacts

of

travel.

OF

the

presser

LENGTH

can

the

stud

feed

by

loosening

lengthen

shorten

position

length

change

setting.

NEEDLE

guard

the

Screw

PRESSER

movement

foot

be

(E,

rocker

the

the

is

will

(C,

needle

in

adjusted

Fig.

obtain-

GUARD

Fig.

(A)

BAR

position

(F).

nut

stitch

stitch.

nec-

in

the

at

its

se-

of

the

5)

2)

Regulate

(H,

Fig.

paratively

inch

free

5)

heavy

play

so

the

that

in

the

pressure

the

springs

pressure

presser

PRESSER

on

the

exert a pressure

is

usually

foot

lifter

FOOT

presser

required.

lever

PRESSURE

foot

using

There

(J,

·

Fig.

8

sufficient

5)

the

presser

should

when

to

spring

feed

properly.

be

approximately

the

presser

regulators

A

foot

is

com-

1/16

down.

Page 9

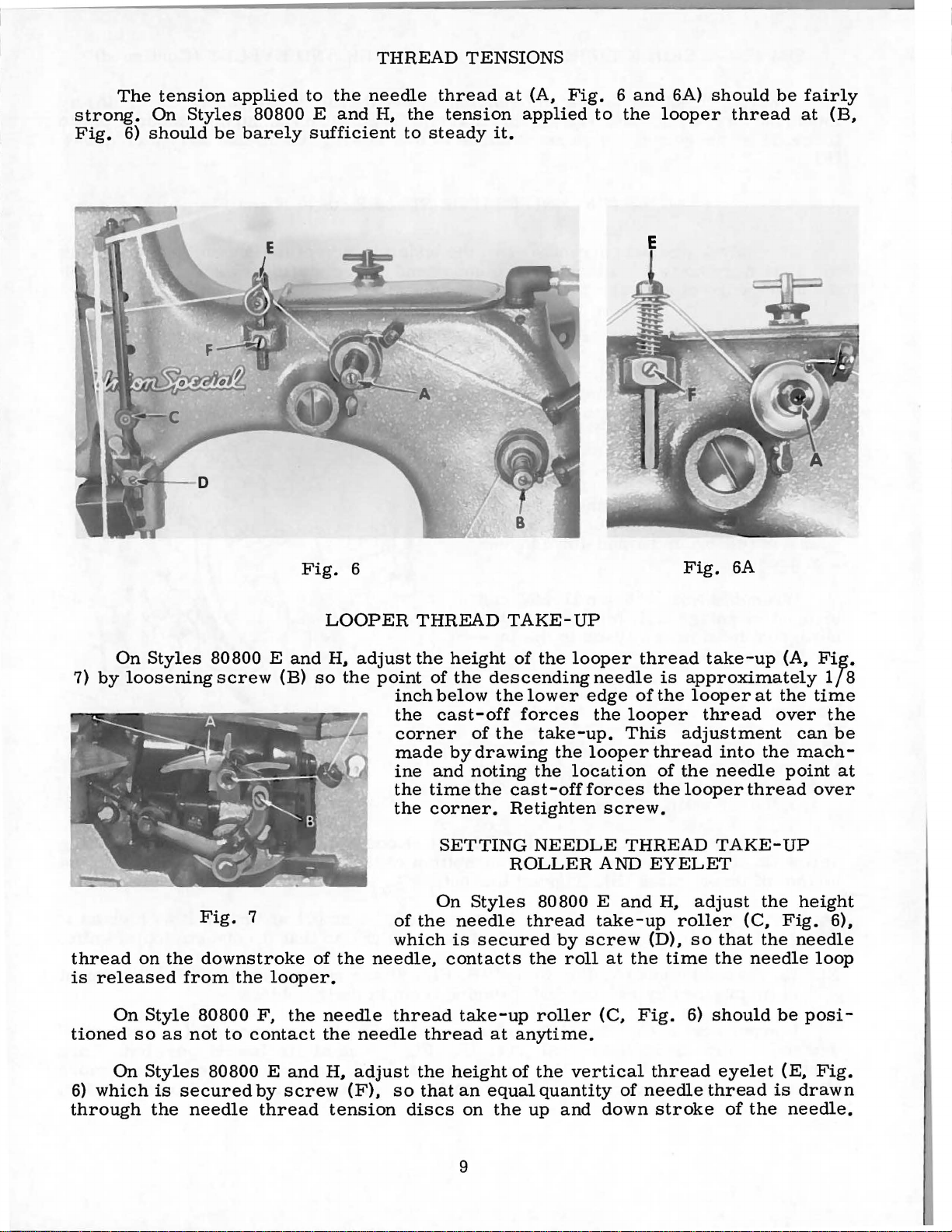

The

strong.

Fig.

6)

tension

On

Styles

should

applied

80800 E and

be

barely

to

the

needle

sufficient

THREAD

thread

H,

the

tension

to

steady

TENSIONS

at

(A,

applied

it.

Fig. 6 and

to

the

6A)

looper

should

thread

be

fairly

at

(B,

7)

by

thread

is

released

On

tioned

On

Styles

loosening

on

the

Style

so

as

80800 E

screw

Fig.

7

downstroke

from

the

80800

not

to

contact

and

(B)

looper.

F,

the

Fig.

LOOPER

H,

so

the

of

the

needle

the

6

adjust

point

of

which

needle,

thread

needle

THREAD

the

of

inch

below

the

cast-off

corner

made

ine

and

the

time

the

corner.

SETTING

On

the

thread

height

the

descending

the

of

the

by

drawing

noting

the

Styles

needle

is

secured

contacts

take-up

at

TAKE-UP

of

the

looper

lower

forces

take-up.

the

the

location

cast

-off

Retighten

NEEDLE

ROLLER

80800 E

thread

by

screw

the

roll

roller

anytime.

needle

edge

the

looper

This

looper

forces

screw.

THREAD

AND

and

take-up

at

the

(C.

Fig.

thread

is

approximately

of

the

adjustment

thread

of

the

the

looper

EYELET

H,

roller

(D),

time

Fig.

6)

6A

take-up

looper

thread

into

needle

TAKE-UP

adjust

(C,

so

that

the

should

(A,

at

the

over

the

point

thread

the

Fig.

the

needle

be

Fi~.

lf

time

the

can

be

mach-

at

over

height

6),

needle

loop

posi-

8

On

6)

which

through

Styles

is

the

80800 E

secured

needle

and

by

screw

thread

H,

adjust

(F),

tension

so

discs

the

that

height

an

equal

on

the

9

of

the

quantity

up

and

vertical

of

down

thread

needle

stroke

eyelet

thread

of

the

(E,

is

drawn

needle.

Fig.

Page 10

SETTING

On

loosening

increase

(F).

Style

screw

or

NEEDLE

80800

(F)

decrease

THREAD

F,

adjust

and

tension

the

raising

as

TAKE-UP

tension

or

lowering

required

ROLLER

on

needle

to

suit

needle

sewing

AND

thread

thread

conditions.

EYELET

nipper

nipper

(Continued)

(E,

Fig.

support

Retighten

6A)

by

pin

screw

to

The

the

stationary

the

upper

To

turn

until

the

the

the

cloth

operating

tape

cutter

housing

the

upper

foot,

guard

ient

throat

in

access.

Wrenches

be

used

hexagonal

cutting

mechanism.

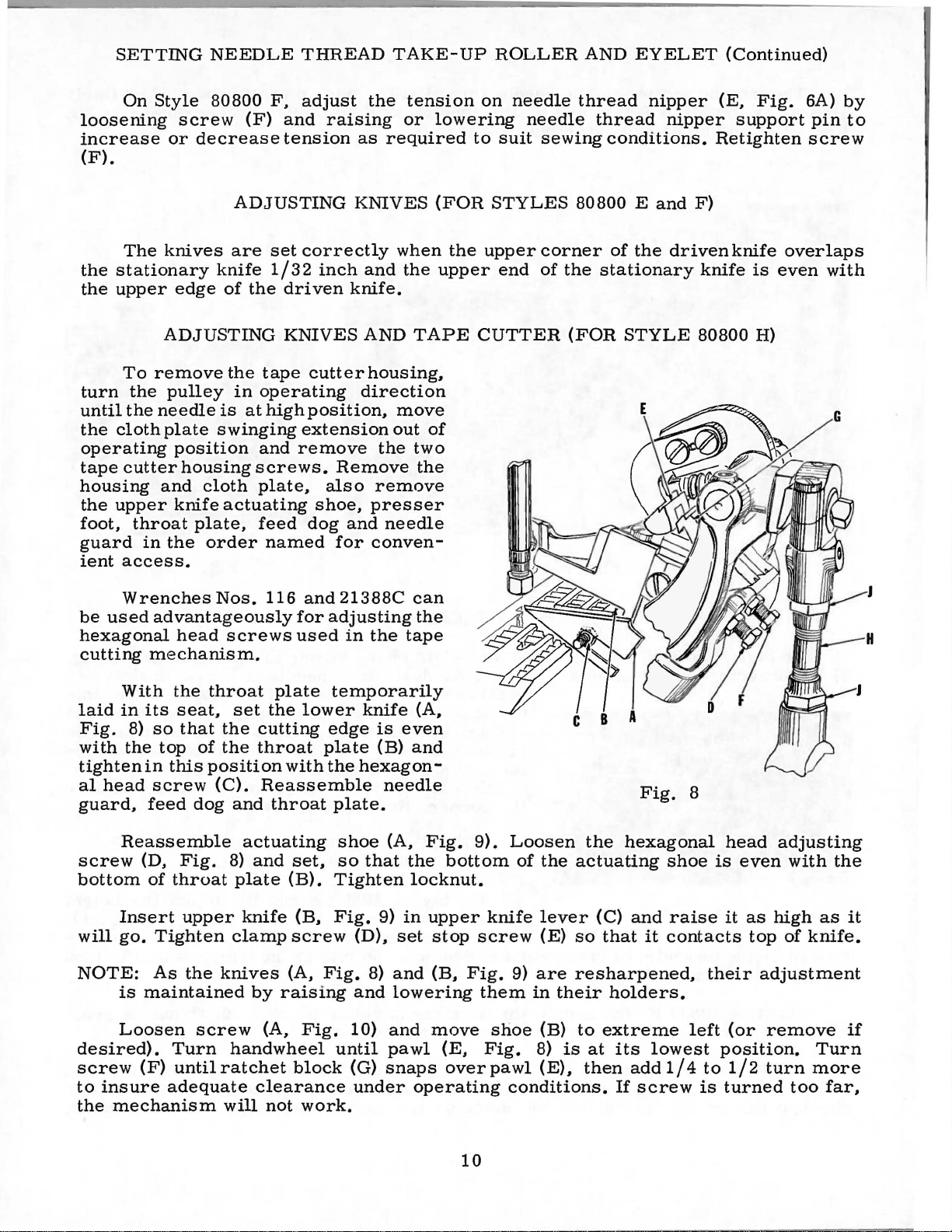

ADJUSTING

knives

are

knife

edge

of

the

ADJUSTING

remove

pulley

needle

plate

position

and

knife

the

the

in

is

swinging

housing

cloth

actuating

plate,

order

Nos.

tape

operating

at

high

and

screws.

plate,

feed

named

116

advantageously

head

screws

set

correctly

1/32

inch

driven

KNIVES

cutter

position,

extension

remove

shoe,

dog

and

for

used

KNIVES

and

knife.

AND

housing.

direction

the

Remove

also

remove

presser

and

needle

for

conven-

21388C

adjusting

in

the

when

the

TAPE

move

out

two

the

can

the

tape

(FOR

the

upper

of

STYLES

upper

end

corner

of

CUTTER

80800 E and

of

the

the

stationary

(FOR

STYLE

F)

driven

knife

80800

knife

is

H)

overlaps

even

with

With

laid

in

Fig.

with

8)

the

tighten

al

head

guard,

Reassemble

screw

bottom

Insert

will

go.

NOTE:

is

Loosen

desired).

screw

to

insure

the

mechanism

the

throat

its

seat,

so

that

top

of

in

this

position

screw

feed

(D,

of

(C).

dog

Fig.

throat

upper

Tighten

As

the

maintained

screw

Turn

(F)

until

adequate

plate

set

the

the

cutting

the

throat

with

Reassemble

and

throat

actuating

8)

and

plate

knife

clamp

knives

by

(A.

raising

(A,

handwheel

ratchet

clearance

will

not

temporarily

lower

edge

plate

the

set.

(B).

(B.

screw

Fig.

Fig.

block

work.

knife

is

(B)

hexagon-

needle

plate.

shoe

so

(A,

that

Tighten

Fig.

9)

(D).

8)

and

10)

until

(G)

snaps

under

(A.

even

and

Fig.

the

bottom

locknut.

in

upper

set

stop

and

(B.

lowering

and

move

pawl

(E.

over

operating

9).

knife

screw

Fig.

them

shoe

Fig.

pawl

Loosen

of

the

the

actuating

lever

(E)

so

9)

are

resharpened.

in

their

(B)

to

8)

is

at

(E).

then

conditions.

Fig.

hexagonal

(C)

and

that

holders.

extreme

its

add

If

screw

shoe

raise

it

contacts

lowest

1/4

8

is

their

left

position.

to

is

head

even

it

as

top

adjustment

(or

remove

1/2

turn

turned

adjusting

with

the

high

as

of

knife.

Turn

more

too

far.

it

if

10

Page 11

ADJUSTING

If

ratchet

ing

rod

distance

require

facture.

(H,

Fig.

of

the

slightly

KNIVES

block

and

8)

connecting

different

by

AND

pawl

means

rod

settings

TAPE

will

of

should

CUTTER

not

engage,

the

due

to

(FOR

it

locknuts

be 4 1/16

slight

STYLE

may

(J).

inch.

be

necessary

The

Individual

accumulation

80800

correct

of

H)

(Continued)

to

adjust

center

tape

clippers

tolerances

connect-

to

center

may

in

manu-

The

length

at

the

Fig.

finish

9

is

not

adjustable.

Move

(or

reassemble

that

pawl

extreme

have

of

side

polished

pawl

to

may

operation

When

is

raised

10)

should

shoe

tape

(B,

within 1 1/2

handwheel.

engage

there

the

9).

for

should

pilot

The

uating

length

shoe

of

material

shoe

(C)

right

end

overlap

insure

of

machine.

actuating

slightly,

allow

Fig.

Make

their

be

end

of

position

(A,

tape

at

the

(B,

if

it

will

rest

end

of

to

trigger

pawl

10)

and

turns

sure

full

len&th.

about

the

knives

of

the

Fig.

extending

start

Fig.

was

on

shoe.

the

right

slightly

action

shoe

trip

(C)

knife

or

that

3116"

tape

9)

of

10)

to

removed)

top

Shoe

and

over

(A.

Fig.

dog

(D,

to

slide

should

less

the

When

opening

(See

Figure

cutter

controls

beyond

the

closure.

right

so

of

the

should

point

out-

during

9)

Fig.

off

clip

of

the

knives

open

at

act-

the

the

The

Fig.

to

start

(F

toward

chine

the

10)

vary

of

and

G)

the

to

opposite

distance.

spring

weights

(H)

of

Attach

housing.

The

cord

ate

stand

unit

installation

wood

paper

ling

core

the

tape

tape.

trip

dog

can

be

retarded

the

length

the

closure.

and

turn

handwheel

shorten

the

direction

The

actuating

is

adjustable

material.

cloth

folder,

are

under

is

plate

tape

furnished

No.

is

shown

provided

and a tension

operating

or

of

the

Loosen

the

operating

end

distance

to

lengthen

shoe

for

and

reel

as a separ-

21884

on

for

for

cam

advanced

tape

screws

of

the

and

tension

various

tape

cutter

a:nd

C.

Their

PL162.

the

roll

control-

(E,

at

the

cam

ma-

the

filter

in

A

of

11

Fig.

10

Page 12

ADJUSTING

A

width

It

is

adjusted

have

accomplished

folder

to

and

The

(a)

(b)

(c)

(d)

(e)

be

folder

The

of

The

yet

There

livery

delivery

plate.

The

The

KNIVES

of

tape

to

suit

readjusted,

by

loosening

moving

is

upper

the

conveyor

front

the

tape

is

end

end

line

of

tape

AND

ranging

the

if

the

folder

set

correctly

surface

and

rear

passes

approximately

of

folder

and

stitches

guide

TAPE

from

widest

the

the

sections

of

belt.

sections

freely

the

is

collars

CUTTER

2 1 I 8

width

tape

two

when

the

1164

and a space

presser

approximately

are

when

used

hexagonal

and

the

middle

are

and

the

inch

foot

set

(FOR

to

2 1 I 2

it

leaves

is

less

head

resetting

following

section

set

so

two

edges

space

of

approximately

when

5116

to

lead

STYLE

inches

the

than 2 112

bolts

the

tape

conditions

is

level

that

they

are

between

the

latter

inch

the

tape

80800

can

be

factory,

inches

nearest

guide

prevail:

and

parallel

guide

even.

the

1132

is

bearing

from

the

centrally

H)

(Continued)

used

the

throat

in

consequently

wide.

the

left

collars.

with

tape

plate

inch

on

edge

into

the

folder.

This

end

of

the

side

accurately,

and

between

the

throat

of

the

tape.

the

folder.

will

is

the

de-

the

12

Page 13

ILLUSTRATIONS

This

catalog

of

various

actual

listing

required

sections

position

of

the

in

the

parts

has

been

of

the

in

the

machine.

with

particular

ORDERING

arranged

mechanism

On

their

view

part

being

REPAIR

to

simplify

are

the

page

number,

shown.

shown

opposite

PARTS

ordering

so

that

the

the

description,

repair

parts

illustration

and

parts.

may

the

Exploded

be

seen

will

number

be

of

views

in

the

ir

found a

pieces

Numbers

position

ordering

dicated

Example:

23

24

of

parts.

Component

by

29442 p

80636 c

25

26

27

28

29

30

31

32

33

replacement

should

this

part

80649

80642

22894 L

22894 c

80645

80636 A

22515 A

It

will

be

At

the

book.

number

in

that

indenting

88 F

A

660-90

be

noted

of

this

ordered.

back

This

will

is

known.

the

first

part

in

Always

parts

their

Looper

in

the

part

of

the

facilitate

column

the

illustration.

use

the

of

sub-assemblies

descriptions

Drive

Looper

Screw,

Oil

Felt

Felt

Oil

Looper

Spot

Set

Looper

Ball

Fork,

Screw,

above

example

individually

book

will

locating

are

reference

Reference

part

number

which

under

Eccentric

Lever

Holder,

Wick

Drive

Screw

Drive

for

be

IDENTIFYING

Connection

for

looper

for

---------------------------------------Eccentric-------------------------------

Screw

found a numerical

--------------------------------------

---------------------------------------

Ball

for

looper

ball

fork----------------------------------

that

is

not

recommended,

the

illustration

numbers

listed

the

Assembly

Stud

the

in

can

description

lever

looper

-------------------------------

drive

bearing

PARTS

only,

numbers

the

second

be

furnished

of

-------------------------

----------------------------connection-----------------

lever

connection-------------

ball

stud

is

not

so

index

and

description

and

merely

should

the

-------------------

listed.

complele

of

column.

for

main

all

the

never

repairs

sub-assembly.

The

parts

indicate

be

used

are

in-

reason

sub-assembly

when

is

shown

only

that

the

in

1

1

4

1

1

1

1

1

1

1

1

in

the

Where

some

identification

appear.

OF

SPECIAL

subsidiaries

proved

and

parts

Emblem.

workmanship.

forwarded

directed.

of

the

Part

numbers

IMPORTANT!

MACHINE

Success

Needles

scientific

durability

Genuine

are

stamped

Each

Prices

A

the

smaller

letter

in

and

are

needles

are

f.

o.

charge

FOR

the

net

b.

construction

parts,

is

represent

ON

WHICH

USE

operation

and

authorized

principles,

assured.

are

with a reproduction

trademark

cash

shipping

is

made

permits,

and

stamped

ALL

ORDERS,

PART

GENUINE

of

Repair

distributors.

and

packaged

is

and

are

point.

to

on

in

the

these

Parts

are

your

subject

cover

same

IS

each

those

to

distinguish

part,

PLEASE

ORDERED.

NEEDLES

machines

as

furnished

They

made

with

labels

of

guarantee

TERMS

to

Parcel

Post

postage

part

where

regardless

AND

with

the

change

and

is

stamped

the

construction

the

part

INCLUDE

REPAIR

can

be

secured

by

the

are

designed

utmost

marked

familiar

of

the

highest

without

shipments

insurance.

with its

from

similar

of

the

PART

PARTS

only

Union

precision.

~

Union

Special

according to

Special

quality

notice.

are

insured

part

does not

ones.

catalo

g in

NAME

with genuine

Corporation,

Maximum

•

Genuine

trademark,

in

All

shipments

unless

numbe

permit,

which

AND

the

rna

terials

r . On

an

they

STYLE

UNION

its

most

ap-

efficiency

repair

U S

and

are

otherwise

13

Page 14

A B C

'

..

~YJ~

A 1

~

13

12

14

Page 15

MAIN

FRAME,

BUSHINGS,

OILING

PARTS

AND

BASE

PLATE

Ref.

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

':'14

':'15

,;'16

':'17

':'18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

Part

No.

80673

80689

80689

80690

41046

80644

88

80898

666-79

22

894

99256

664

HA81

HA95

11667

652-24

22639

11667

22638

21388

80640

80639

80639

80692

22539

80698

79048

69

50-430

80694

80692

22539

22814

22894

89

80646

80647

80662

80673

660-457

E

A

A

A

G

J

F-16

v

B

K

B

AH

E

F

E

D

A

H

D

E

B

J

B

D

Blk.

Description

Needle

Oil

Oi.l

Oil

Spring

Plug

Set

Oiler,

Sight

Set

Screw,

Taper

Spot

Set

Adapter

Washer,

Screw,

Adapter

Screw,

Wrench,

Bar

Cup,

Cup,

Cup,

Bushing,

small,

small,

large-------------------

Valve

Oiler------------------------------

for

for

upper-------

Styles

Style

80800 E and F ---------

80800 H only------------

Screw-------------------------------------

Screw,

Feed

Screw,

Screw,

Screw,

for

needle

Oiler

for

Dowel

Base,

for

for

Plate,

for

1/4

for

plug

for

needle

arm

------------------

Pin

for

crankshaft

for

crankshaft

for

Styles

adapter

for

adapter

inch

screw

lever

Assembly

-----------------------

connection

--------------------

lever

oiler----------------

------------------------------bearing

bearing

Styles

80800 E and F ----------80800 E and

base,

Styles

plate,

open

for

Styles

80800 E and F ----------

for

Styles

end,

for

and F ----------------------------------------

Transverse

Looper

Looper

Knife

Plug

Shaft

Screw------------------------------------Thread

Screw,

and F ---------------------

Washer,

Dowel

Main

Feed

Plug

Pin.

Shaft

Rocker

Screw-------------------------------------

Screw,

Set

Screw.

Spot

Screw,

Needle

Needle

Presser

Needle

Dust

Cover

Shaft

Shaft

Shaft

Bushing,

Lubricator,

for

thread

for

Styles

for

Bushing.

for

arm---------------------------------

for

for

Lever

Lever

Bar

Bar

Bushing,

(not

Bushing-----------------------Bushing,

Bushing,

right---------

left-----------------------

for

Styles

for

Styles

lubricator,

80800 E and F ----------------

Style

Shaft

Shaft

Shaft

Bushing,

80800 H only

left

Bushing

needle

needle

Bushing,

Bushing,

lower

shown

and

----------------------

lever

lever

lower---------------------

----------------------

on

picture

80800 E and F ------

for

-

middle---------------

oiler---------------shaft

front----------------

rear

-

--------------

-

--------------

bearing

-

-------------

--------

housing--------

housing---------

F

----------------

80800 E and

80800 E and

Styles

80800

-

------------

E

80800 E and F -----

Styles

80800

E

------------------

----------------

bushings--------

----------------

plate)

-----------

1

9

6

2

2

2

2

1

- - 1

1

1

2

1

1

1

3

F - 3

1

F - 4

1

2

1

1

2

1

1

2

2

2

2

2

1

2

1

2

1

1

2

1

1

'

~

Available

as

an

extra

send

and

charge

item.

15

Page 16

2

16

16

Page 17

MAIN

FRAME.

CLOTH

PLATES,

HOUSINGS

AND

MISCELLANEOUS

COVERS

Ref.

No.

1

2

3

4

5

6

7

8

9

10

lOA

11

12

13

13A

14

15

16

17

18

19

20

21

22

22A

Part

No.

80887

376

64

y

35733

80888

99256

22814 B

80897

29479

29479 X

22574

80284

80684

80438

80440

81239

8564

92121

12957

80683 H

80683

93 A

664

94

89

B

y

F-16

H

E

Description

Face

Screw,

Screw,

Lock

Top

Screw,

Screw.

Tape

Screw.

Cloth

Cloth

Screw.

Taper

Looper

Looper

Screw.

Spring,

Cloth

Cloth

Screw.

Hinge

Screw.

Spring

End

End

Plate-----------------------------------------

for

face

plate

for

top

cover--------------------------------

Nut,

Cover-----------------------------------------

Cutter

orily----------------------------------------------

Cover,

Cover,

for

for

for

for

Plate

Plate

for

Dowel

Thread

Thread

for

for

Plate

Plate

for

Pin.

for

for

Washer,

screw

arm------------------------------------arm-------------------------------------

Housing.

tape

cloth

looper

hinge

end

cutter

Assembly,

Assembly,

plate

Pin------------------------------------

Guard,

Guard.

cloth

Bolt

Extension

for

for

plate

Knob

pin

swing-out

cover

for

Style

Styles

-------------------------------

No.

64

Y------------------------

for

Style

housing.

for

for

assembly----------------------

for

for

thread

end

guard

extension

------------------------------Bolt---------------------------

-------------------------------cover-----------------------

------------------------------cover------------------------

80800

80800 E and F -----------------

80800

Style

Styles

Style

Styles

H orily

for

80800 H only----------

80800 E and

80800

80800 E and

---------------------bolt------------------

--------------------

H

---------------

Style

H orily

80800 H

F--------

----------

F--------

Amt.

Req.

1

2

1

1

1

1

2

1

2

1

1

3

2

1

1

2

1

1

1

2

1

1

1

1

1

17

Page 18

18

Page 19

ROLLING

THREAD

GUIDES,

THREAD

EYELETS

AND

THREAD

TENSION

PARTS

Ref.

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

*13A

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

Part

No.

88

80665

80665

80665

88

80668

HS53 B

12964

81086

HA1286

22560

22894

G-111

80250

80250

80250

22743

88

80668

HS52 B

81086

12964

HA1286

22560

22894

AS137

28

HA103

AS137

22560

80665

51292

80665

81256

81256

AS137

28

22560

108

107

110-4

110-3

110-2

HA1349

80676

HA1348

80667

HS106

22894

AS137

HA103

28

AS137

c

A

B

c

G

B

AD

B

A

c

c

B

AD

A

c

B

B

'E

F-4

F

A

c

B

A

AD

A

B

c

Description

Screw,

Filter

Rolling

Screw,

Thread

Rolling

and

Screw,

Thread

Screw,

Needle

only---------------------------------------------------Needle

Needle

only

Thread

Screw,

Tension

Tension

Tension

F

Tension

Tension

and F --------------------------------------------------

Tension

Tension

Tension

Tension

Tension

Screw,

Thread

for

filter

Cord

Thread

Thread

Screw,

Thread

Needle

H

Rolling

Rolling

Screw,

Screw,

Thread

Needle

Screw,

Thread

Thread

Thread

Thread

Screw------------------------------------------------

and

Thread

Screw,

Thread

Thread

Spring

Rolling

Spring

Screw,

for

rolling

Guide,

Thread

--------------------------------------------------

Thread

Rolling

Spring

Spring

Screw

for

rolling

Eyelet

for

thread

Thread

Thread

Thread

--------------------------------------------------Eyelet

for

thread

Regulating

Spring

Spring,

H

-----------------------------------------------

Spring,

Spring,

Post

Disc

Post

Disc

Post---------------------------------------------

for

thread

Eyelet

Eyelet

for

Eyelet

cord

guide--------------------------------

Guide-----------------------------------------

Guide

Roller

for

thread

Guide

Ball

-------------------------------------------

for

Guide

Thread

Thread

for

rolling

for

thread

Guide

Ball---------------------------------------

-------------------------------------------

-------------------------------------------

and

for

thread

Eyelet

Eyelet

Nipper

Tension

Nipper

Assembly

Sleeve

Eyelet

Ferrule------------------------------------

Ferrule

--------------------------------------------Ferrule

Stop

and

thread

Assembly

Support

guide

Roller

Rolling

Thread

for

spring

thread

Styles

Guide

Guide

Roller

Rolling

Thread

thread

Support

---------------------------------------Support---------------------------------

eyelet

---------------------------------------Support---------------------------------

eyelet

Nut

for

needle

for

looper

for

looper

Pin

eyelet

Support

---------------------------------------

Support

---------------------------------Thread

-------------------------------------Guide

guide

80800 E and

Assembly,

Wire

Holder

thread

guide

---------------------------------Thread

Guide

guide

Assembly------------------------

eyelet

and

Support

Spring,

Support

---------------------------------

assembly----------------------:_

-----------------------------------thread

thread

thread

-------------------------------------

-------------------------------------

------------------------------------and

Assembly

eyelet

--------------------------------

---------------------------

-------------------------------

roller

--------------------------------

guide

roller

------------------------------

support

support

------------------------------

-------------------------

Guide

Axle

Axle

Pin,

Disc,

------------------------

assembly

H

for

Styles

----------------------------

-------------------------wire

-------------------------

Guide

-------------------------

assembly--------------------

assembly---------------

for

Style

for

Style

for

on

Styles

on

Style

on

Styles

assembly

-----------------------

Axle

Axle

80800 F only

Style

---------------

-------------------

-------------------80800 E and

--------------------

---------------

80800

80800

80800 H -----------

80800

F

80800

F

E,

E

--------------

--------

Amt.

Req.

'1

1

1

1

___ 2

2

2

1

1

1

2

4

2

2

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

2

2

Replaced

*

by

Ref.

No

13

on

late

model

machines.

19

Page 20

4

~

29

20

Page 21

NEEDLE,

NEEDLE

AND

BAR,

NEEDLE

LOOPER

LEVER,

THREAD

LOOPER,

CAST-OFF

LOOPER

PARTS

DRIVE

Ref.

No.

Page

80673 c

80617

HA

1975

806

BP108

51134 v

HA54A

80615

80643

22811

29066

29793 A

22738 B

80649 c

22768 B

80642 c

22894 c

22894 L

51236 A

W0-2

80642 B

22811 B

W0-3

AS26 XA

80608 A

15465 F

12987 A

15745 B

80657 A

22729 c

6040 A

HA61 D

41331 G

80641 B

HS-36

35841 c

22729 c

80623

80637

22517

12538

80653 A

80653 I

80604

HA102 A

80653

80653 H

23

1

2

3

4

5

6

7 22564 D

8

9

10

11

12

13 22565 c

14

15 22894 K

16 22894

17

18

*19

20

21

22

23

24

25

26 80842

27

28

29

30

31

32

33

34

35 22894 c

36 1280

37 80639

38

39

39A

40

40A 29479

41 80613 A

42

43

44

45

46

47

48

49

50

51 269

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

66A

67

63 AS22

69

70

70A

71 22743

~'

See

Part

No.

56

G

334

59 A

91

666-260

AD

u

666-149

482

c

18

73

88

237 A

666-149

18

666-149

K

36 E

J79

J

D

for

component

Description

Needle

Needle

Needle

Needle

Needle

Needle

Screw,

Needle

Needle

Screw,

Needle

Spot

Set

Needle

Screw,

Needle

Looper

Link

Looper

Wool

Collar,

Nut,

Looper

Nut,

Looper,

Looper,

Screw,

Looper

Looper

Oil

Nut,

Screw,

Connecting

Nut,

Oil

Looper

Looper

Screw,

Looper

Nut,

Looper

Looper

parts.

Bar

Guard-------------------------------------------------------------

Bar

-------------------------------------------------------------------

Clamp

Nut-------------------------------------------------------------

----------------------------------------------------------------------Thread

Bar

Screw,

Screw,

for

Lever

Felt

Bar

for

Lever

Screw,

Screw

L~ver

for

Lever

Avoid

Oil

Screw,

Oil

Screw,

Strap,

Looper

Pin,

Wool

Avoid

Screw--------------------------------------------------------------------

Yarn--------------------------------------------------------------------

for

Screw,

for

Rocker

for

for

Rocker

Looper

Differential

Check

Looper

Rocker

Screw,

Shell---------------------------------------------------------------------

Ball

Wick,

for

for

for

Wick,

Rocker

Steel

BallStud-----------------------------------------------------------------

Shell--------------------------------------------------------------------Screw,

Thread

for

Drive

Screw,

for

Thread

Thread

ThreadHook--------------------------------------------------------------

Screw,

ThreadEyelet-------------------------------------------------------------

Holder,

Holder,

Screw,

Eyelet----------------------------------------------------------

Connection---------------------------------------------------------

for

needle

for

link

Link

Oil

Wick

Link---------------------------------------------------------------

link

-----------------------------------------------------------------

for

for

needle

Shaft

needle

Connecting

Eccentric

Wick------------------------------------------------------------------

for

Wick

looper

oil

Holder-----------------------------------------------------------

for

link

for

looper

Avoid

SetScrew-------------~-----------------------------------------------

Spot

Screw------------------------------------------------------------

for

looper

Yarn, 2 strands------------------------------------------------------

Connecting

looper

for

collar----------------------------------------------------------

looper

rocker

Shaft-----------------------------------------------------------

looper

rocker

for

Styles

for

Style

looper

Assembly-------------------------------------------------------

Rocker------------------------------------------------------------

Screw----------------------------------------------------------------

NUt----------------------------------------------------------------

Rocker

Ball

for

shell-----------------------------------------------------------

Stud

-----------------------------------------------------------------

for

No.

connecting

looper

Rod----------------------------------------------------------------

connecting

for

No. 80641

Ball

Washer,

for

shell-----------------------------------------------------------

Take-up--------------------------------------------------------

looper

Lever-----------------------------------------------------------

for

looper

rocker

Cast-off

Cast-off

for

thread

for

for

for

thread

thread

needle

bar

pin

------------------------------------------------------------

Pin---------------------------------------------------------

-------------------------------------------------------------

pin

------------------------------------------------------------

needle

lever-----------------------------------------------------

------------------------------------------------------------

lever

wick

pin

avoid

Eccentric----------------------------------------------------

avoid

rocker

assembly------------------------------------------------

80800 E and

80800 F only,

-------------------------------------------------------------

Rocker

Cone

Joint

80657

rod,

thread

rod,

Joint

for

ball

thread

drive

ball

hook-----------------------------------------------------

No.

80653 A -----------

No.

80653 I ---------------------------------------------------

eyelet

eyelet---------------------------------------------

connection--------------------------------------------

lever----------------------------------------------------

connecting

Rod

Assembly

holder--------------------------------------------------

-------------------------------------------------------eccentric--------------------------------------------

eccentric

Link--------------------------------------------------

shaft

ball

joint

Cone---------------------------------------------------

Stud,

Assembly,

A------------------------------------------------------

right

cast-off

left

B------------------------------------------------------

Assembly,

stud-------------------------------------------------

take-up------------------------------------------------

lever-----------------------------------------------

joint

Assembly,

Assembly,

rod

Bearing

-------------------------------------------------

H, 401

marked'~"---------------------------------------

hand

hand

assembly

---------------------------------------------------

bearing-----------------------------------

Assembly----------------------------------

----------------------------------------------

assembly------------------------------------

assembly

101

assembly

thread

for

for

---------------------------------------

stitch-------------------------------------

stitch

--------------------------------------

left

----------------------------------------

thread

---------------------------------------

--------------------------------------

----------------------------------------

right

---------------------------------------

---------------------------------------

Styles

80800 E

Style

80800 H only

-

---------------------------------------

and F -----------------------

-------------------------

Amt.

~

1

1

1

1

1

1

1

1

1

1

1

1

1

1

2

1

1

1

1

1

2

1

1

1

2

1

1

1

2

1

1

1

1

1

1

1

1

1

1

1

1

2

1

1

1

2

1

1

1

1

2

2

1

1

2

1

1

1

1

1

1

1

1

1

2

1

1

1

1

1

1

1

1

1

1

21

Page 22

22

Page 23

TAPE

CUTTER

DRIVE,

LOOPER

AND

PULLEY

DRIVE,

RIM

CRANKSHAFT

ASSEMBLY

Ref.

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

39A

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

55A

56

57

Part

No.

29139 E

G21710

22586 A

1230 B

1230 D

80630

22587

15430 c

80230

15430

15430

29132

80630

22587

21703 L

22894

22894 L

80638

136

96

80691

80640

29442 p

80636 c

88 F

80649 A

660-90

80642

22894

22894

80645

80636

22515 A

29781 A

29781 B

29066 u

80650 B

22587

80656 A

80630 c

W0-3

80630

80630

80636 B

80652

22587

80622 B

80622 A

HA66 K

80681

22891

22539

80685 E

HA95

HA81

80621 A

80821 H

80821 B

80

80674

E

L

D

AG

F

c

A

L

c

A

D

A

Description

Tape

Cutter

Ball

Screw,

Spring,

Spring

Tape

Nut,

left

only

Connecting

Felt,

Nut,

Tape

Looper

Nut,

Looper

Looper

Crankshaft

Crankshaft

Woodruff

Crankshaft

Plug

Crankshaft

Set

Spot

PulleyHub

Pulley

Pulley

Screw,

Lock

--------------------------------------------------------

for

right

only

--------------------------------------------------------

Cutter

Tape

Tape

Clamp

Spot

for

Looper

Oil

Felt

Looper

Looper

Ball

Screw,

Needle

Nut,

Wool

Felt

Needle

Nut,

tube

Guide

Crankshaft

Crankshaft,

Crankshaft,

Set

Screw,

Screw,

Screw,

and

F-------------------------------------------------------

Washer,

Bearing

Stud

-------------------------------------------------

for

for

Pin------------------------------------------------

Cutter

Screw,

hand

thread,

Rod

connecting

hand

Driving

Cutter

Screw,

Cutter

Set

Screw

Spot

Screw--------------------------------------------

Drive

Drive

Drive

Screw

Rim, 6 inch

Rim, 4 1/4

for

Lever

Screw

Screw------------------------------------------------

looper

Lever

Eccentric

Lever

Screw,

Felt

Holder,

Oil

Wick

Drive

Spot

Screw

Set

Screw

Drive

Fork,

for

Eccentric

Eccentric

Lever

Needle

Screw,

Needle

left

hand

Yarn------------------------------------------------

Oil

Wick,

Lever

right

hand

---------------------------------------------------Fork,