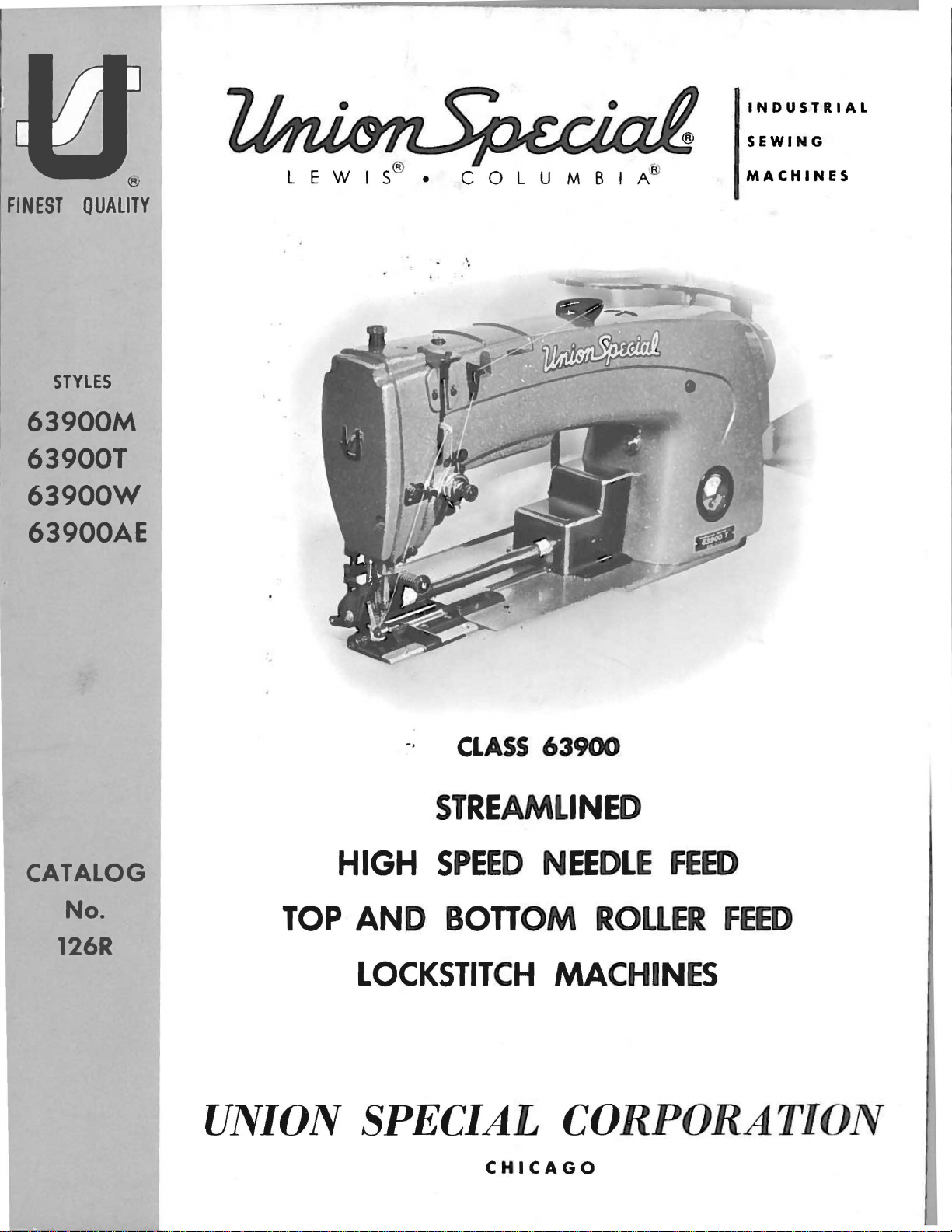

Page 1

INDUSTRIAL

SEWING

FINEST

QUAliTY

STYLES

63900M

639001

63900W

63900AE

C 0 L U M B I A®

'·

MACHINES

CATALOG

No.

126R

··

CLASS

STREAMLINED

HIGH

TOP

AND

SPEED

BOTTOM

LOCKSTITCH

UNION SPECIAL

CHICAGO

63900

NEEDLE

ROLLER

FEED

FEED

MACHINES

CORPORATION

Page 2

Catalog

INSTRUCTIONS

No.

FOR

126

R

ADJUSTING

LIST

Needle

Top

and

63900

63900

CLASS

Feed

Bottom

Styles

M

w

First

AND

OF

Edition

OPERATING

PARTS

63900

Lockstitch

R.oller

63900

63900

Feed

T

AE

Rights

Union

Reserved

Copyright

By

Special

1966

Corporation

in

All

Countries

UNION SPECIAL CORPORATION

INDUSTRIAl

Printed

SEWING

CHICAGO

in

2

MACHINES

U.S.A.

Reprinted in 4/92

Page 3

The

predom-inant

machines

machines

gauges

1.

2.

insu:r;-ing

A

few

QUICK

The

average

box

to

STREAMLINED

idea

behind~®

in

the

world.

are a decidedachievement

complete

of

the

outstanding

INSTALLATION

installation

production

The

interchangeability.

sewing,

DESIGN

new

features

time

if

FOREWORD

high

installation

spe.ed,

along

are:

required

is

to

streamlined

these

lines.

will

be

instructions

build

Parts

about

the

Class

10

are

best

industrial

63900

are

made

minutes

followed.

lockstitch

to

precision

from

sewing

packing

Pleasing

gedness

is

more·

3.

SIMPLIFIED

Lubrication

for

trouble

system

reservoir,

ance.

4.

RAPID

Precision

oiling

higher

5.

FEED

Machines

the

stitch

It

is

which

SPECIALmachines.The

enables

in

appearance,

and

freedom

restful

OILING

of

these

free

provides

sealed

ACCELERATION

methods

system,

productive

REGULATING

are

fitted

length,

the

constant

customers

this

from

to

the

operator's

machines

operation.

long

hook

against

in

the

makes

plus a readily

aim

possible

rates

and

GEARS

with

feed

of

Union

to

procure

following

functional

difficult-to-clean

eye.

is

automatic.

A

completely

life.

lint

manufacture

lower

A

and

dust,

top

costs.

regulating

accessible

Special

all

pages

discuss

design

single,

reduces

of

operating

gears

to

furnish

possible

provides

recesses.

Oil

is

adjustable,

large

to a minimum

all

parts,

speed

for

means

advantages

valuable

for

concisely

greater

New

supplied

double

capacity,

coupled

almost

quick

Adjusting

and

adjusting

from

stability,

neutral

to

all

filtered

accurately

oiling

with

instantaneous

easy

prepared

the

the

and

Operating

adjustment

taupe

moving

hook

gauged

mainten-

an

advanced

needle

information

use

of

UNION

rug-

finish

parts

oiling

for

of

feed.

data.

Adjusting

call

attention

Illustrations

Exploded

name»

are

requirements.

follow

Union

anxious

Instructions

to

are

views,

the

Special

to

cooperate

for

many

used

Instructions.

representatives,

parts

to

pinpoint

together

in

Mechanics,

which

areas

with

to

planning

covering

must

explanations

be

under

and

meet

found

making

discussion.

in

Styles

exacting

as

to

all

leading

estimates

UNION SPECIAL CORPORATION

3

63900

conditional

quantity,

manufacturing

tailored

M,

T, W and

adjustments.

part

number

to

centers»

meet

AE»

and

your

Page 4

IDENTIFICATION OF

MACHINES

Each

stamped

standard

fixed,

Style

standard

"Style

Styies

number

Example: "63900".

This

listed

of

machines

back,

chine.

High

Light,

Horizontal

Adjusting

Automatic

Needle

Timing

Speed

UNION

into

and

but

never

numbers

machine,

63900

which

catalog

herein.

etc.,

Operating

Streamlined

Medium

Hook

Needle

Lubricating

Bearings

on

Upper

the

special.

contain

MZ".

of

differs

in

are

and

SPECIAL

name

contain

a

"Z"

machines

applies

It

can

this

given

direction

Heavy

Shaft,

Feed,

for

Shaft,

Class.

Take-up

machine

plate

Standard

the

from

also

from

Long

Gears

1

System,

Maximum Work

on

the

letter

letter

is

suffixed

similar

the

style

APPLICATION OF

specifically

be

Reference

the

of

STYLES

Arm

Duty,

1/4

Continuous

for

Inch

Head

Lever

is

identified

the

machine.

Style

"Z".

"Z".

to

in

construction

number,

applied

operator's

handwheel

OF

Needle

Changing

Needle

Oil

and

Space

Style

numbers

Example:

When

the

to

with

to

MACHINES

Feed

Siphon,

Needle

only

Standard

in

CATALOG

the

discretion

direction,

position

is

toward

Lockstitch

Running

Stitch

Bar

Travel,

Bar

to

Right

by a Style

numbers

have

Standard

one

"Style

minor

Style

are

grouped

that

Adjustable

it

such

while

the

Roller

Length,

One

Driving

of

Needle

number

are

or

more

63900

changes

number.

under

contains

Styles

to

some

as

right,

seated

operator.

Machines.

Feed,

Slotted

Reservoir

Hook

Link,

Bar 8 Inches.

which

classified

letters

M".

are

made

Example:

a

class

no

letter.

of

machines

Special

left,

at

the

One

Rotary

Segment

Enclosed

Oil

Control,

Needle

is

as

suf-

Special

in

Styles

front,

ma-

Needle,

Hook,

for

Feed

a

as

63900 M For

alls

of

hem . Maximum

63900 T For

men's

reaches

mum

recommended

63900 W For

to

sew

cation

63900

the

number,

measured

size

needles

recommended

are

AE

foot

Each

kind

number

Needle

listed

Same

of

stamped

in

packaged

making

and

dungarees.

making a 1/2

dress

over

301-SSa-1.

in

needle

below

pants,

machine

topstitching

belt

as

line

shank,

on

thousandths

represent

Type

for

Styles

3/8

recommended

inside

speed

loops.

Style

with

has

both

point,

the

and

sold

180

GVS

and

on

to

1/2

Seam

to 2 1/2

semi-dress

out.

5200

waistbands

Maximum

63900

centerline

a

type

length,

needle

of

an

the

complete

by

is

recommended

63900

the

next

inch

Specification

Fitted

W,

shank,

inch

UNION

T, W and

turned

speed

inch

pants

Seam

R.P.M.

on

with

recommended

except

of

needle

NEEDLES

and

groove,

across

symbol,

SPECIAL.

page.

down

301-EFb-1

5200

hem

Specification

twill

fitted

size

denotes

AE.

and

cloth

number.

finish

the

which

for

The

R.P.M.

turned

work

speed

hole.

Style

hem

by

pants.

and

woolen

plate

5200

with

The

and

the

largest

eye.

is

63900

descriptions

on

legs

inverted.

hand

301-EFb-1

extension.

spring

other

Collectively,

given

on

Sewn

pants.

R.P.M.

guide

type

diameter

on

M

and

of

overalls,

children's

when

or

number

details.

the

Type

and

Specify

garment

EFa-1.

Machine

Seam

keel

sizes

denotes

of

the

label

180

on

The

the

cover-

size

wear,

Maxi-

equipped

Specifi-

presser

size

blade,

type

available

of

GWS

and

all

is

Type

180

No.

GVS

Round

1/16

struck

125/049, 140/054,

shank,

inch

groove,

round

longer

than

deep

point,

standard,

spot,

150/060.

Description

lockstitch,

oversized

chromium

short

plated-

4

ball

length,

eye,

sizes

long

single

100/040,

blade,

groove,

110/044,

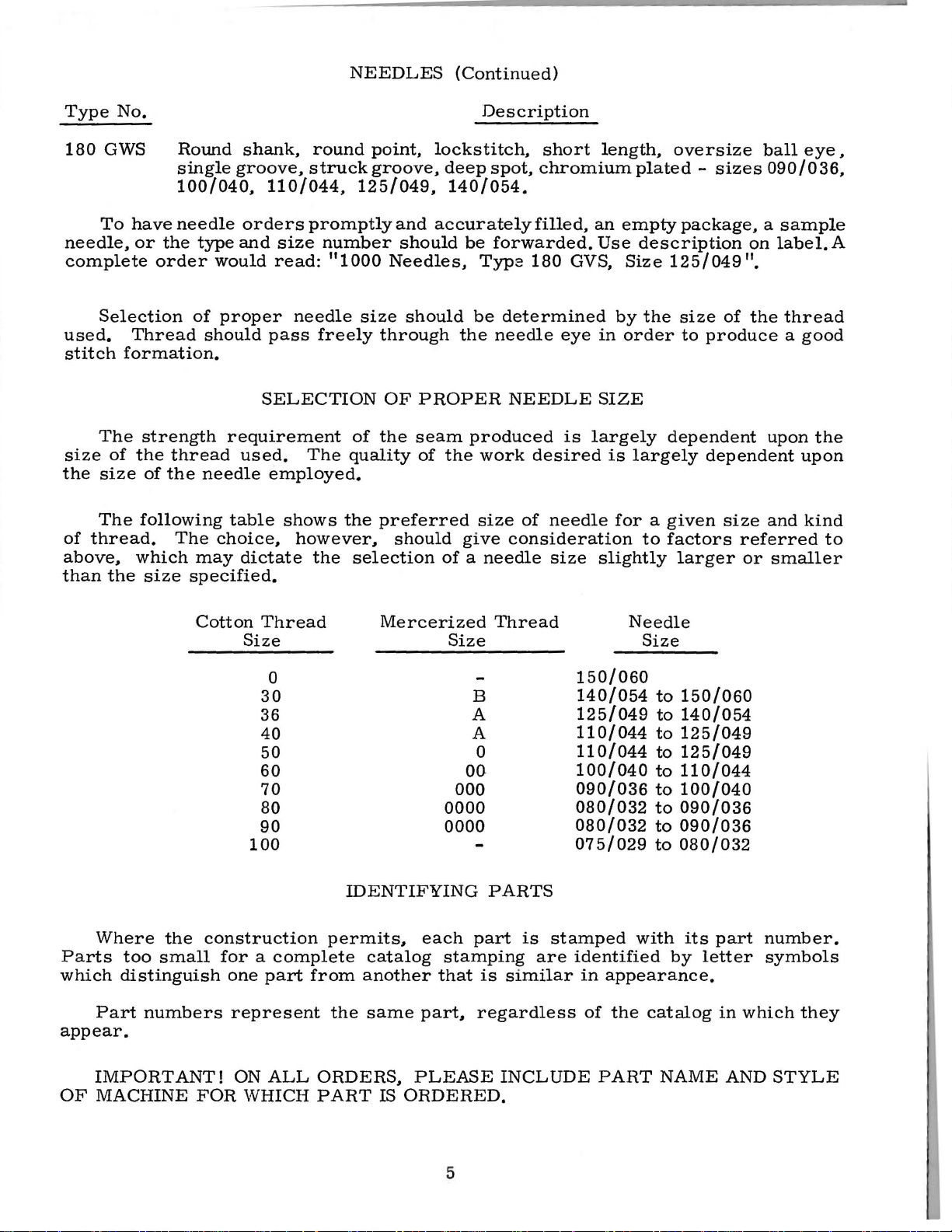

Page 5

NEEDLES

(Continued)

Type

180

No.

GWS

To

needle.

complete

Selection

used.

stitch

formation.

The

size

of

the

size

The

of

thread.

above.

than

the

Round

single

100/040.

have

needle

or

the

order

of

Thread

strength

the

thread

of

the

following

The

which

size

specified.

shank,

groove,

orders

type

and

would

proper

should

requirement

used.

needle

table

choice,

may

dictate

round

struck

110/044,

125/049.

promptly

size

number

read: 111000

needle

pass

size

freely

SELECTION

of

The

quality

employed.

shows

the

however.

the

selection

point,

groove.

and

should

Needles,

should

through

OF

PROPER

the

seam

of

preferred

should

Description

lockstitch,

deep

spot,

140/054.

accurately

be

forwarded.

Typz

be

determined

the

needle

NEEDLE

produced

the

work

size

give

consideration

of a needle

short

chromium

filled,

180

GVS.

eye

is

desired

of

needle

size

length,

plated-

an

empty

Use

description

Size

by

the

in

order

SIZE

largely

is

largely

for a given

to

slightly

oversize

sizes

ball

090/036,

package, a sample

on

label.

125/049

size

to

dependent

11

•

of

the

thread

produce a good

upon

dependent

size

and

factors

larger

referred

or

smaller

eye,

A

the

upon

kind

to

Where

Parts

which

Part

appear.

Cotton

the

too

small

distinguish

numbers

Thread

Size

0

30

36

40

50

60

70

80

90

100

construction

for a complete

one

part

represent

Mercerized

IDENTIFYING

permits,

catalog

from

the

another

same

Size

00-

000

0000

0000

each

stamping

that

part,

Thread

B

A

A

0

PARTS

part

is

are

is

similar

regardless

150/060

140/054

125/049

110/044

110/044

100/040

090/036

080/032

080/032

075/029

stamped

identified

in

appearance.

of

Needle

Size

with

the

to

150/060

to

140/054

to

125/049

~

125/049

to

110/044

to

100/040

to

090/036

to

090/036

to

080/032

its

by

catalog

part

letter

in

number.

symbols

which

they

IMPORT

OF

MACHINE

ANT!

FOR

ON

ALL

WHICH

ORDERS,

PART

IS

PLEASE

ORDERED.

INCLUDE

5

PART

NAME

AND

STYLE

Page 6

ILLUSTRATIONS

The

arrangement

ordering

of

Class

of

63900

ORDERING

this

catalog

replacement

OF

REPAIR

is

to

parts.

PARTS

facilitate

easy

and

accurate

Eight

catalog.

ed

as

in

ened

area

machine.

of

the

pieces

exploded

Each

their

exactly

On

parts

required

Numbers

indicate

should

ed

in

number

never

the

for

the

second

each

Sub-assemblies,

a

bracket

or

sub-assemblies,

denting

bly.

18

19

ed

by

tion.

the

sary,

their

Example:

29126

22894

In

those

this

However,

specific

the

EL

J

catalog,

difference

view

plate

assembled

where

the

page

with

in

in

the

their

the

first

position

be

used

column.

part

a

solid

which

descriptions

Needle

Rod

Set

cases

where

no

when

u~age

will

plates

presents

position.

the

opposite

part

particular

column

of

the

in

ordering

Each

for

sale.

which

line

can

box

be

Feed

are

under

cover

a

sector

parts

the

numbers,

are

part

parts.

exploded

sold

on

the

furnished

the

Driving

the

of

Small

being

discussed

illustration

descriptions

view

being

reference

in

the

view

complete

picture

for

description

Eccentric

Standard

the

machine,

keyline

will

shown.

numbers

illustration.

Always

use

plate

or

by

plate.

repairs,

of

and

Styles

views

fit

in

be

and

the

carries

separate

Component

are

the

Connecting

Assembly----------------------------------------

Screw-----------------------------------------

a

specific

the

be

will

part

parts

mentioned

be

is

usage

for

shown

common

will

the

various

in

in

the

to

all

be

mentioned

the

description,

illustration.

of

the

machines

listed

parts

show

being

by a black-

the

assembled

found

the

number

only,

and

Reference

part

number

a

reference

part,

indicated

main

sub-assem-

machines

in

the

are

not

and,

in

a

listing

of

merely

numbers

are

parts

by

cover-

descrip-

the

if

neces-

this

align-

list-

in

of

in-

1

2

same,

At

the

parts

and

shown

description

Success

genuine

UNION

Corporation,

signed

with

according

utmost

Prices

All

shipments

are

insured

postage

and

back

in

of

this

when

in

the

SPECIAL

its

subsidiaries

to

precision.

are

strictly

are

forwarded

unless

otherwise

insurance.

the

book

book.

only

the

USE

operation

repair

the

most

Maximum

net

will

This

will

part

GENUINE

of

these

parts

and

approved

efficiency

TERMS

cash

f.o.b.

directed.

be

found

facilitate

number

REPAIR

machines

as

furnished

authorized

scientific

and

subject

shipping

A

6

a

numerical

is

known.

PARTS

distributors.

and

durability

to

point.

charge

locating

can

be

by

the

principles,

change

Parcel

is

made

index

the

secured

Union

They

are

without

Post

to

cover

of

all

the

illustration

only

with

Special

are

and

are

made

assured.

notice.

shipments

the

de-

Page 7

UNPACKING

CAUTION!

Using

packed.

steps

STANDARD

eyelet,

base

(1)

extension

pivot

for

both

Before

After

should

Included

(1)

plate,

can

of

Included

Included

Included

brackets,

pivot

oil

and

pin

When

unpacking,

hands

screw

(1)

on

bed

leaving

be

ACCESSORIES

with

and

also

also

also

and

the

machine

followed:

each

for

knee

(1)

with

with

(3)

screws

with

(1)

(1)

the

upper

press

extra

Style

folder

rock

casting,

factory,

and

machine

frame

rod,

bobbin.

Style

Styles

for

actuator

shaft

DO

lift

each

accessories

is a box

eyelet,

(1)

bobbin

63900 T is

63900 W and

cloth

plate

63900 M is

finger,

connecting

NOT

gently.

Union

(1)

winder

(1)

extension.

(1)

(1)

of

front

arm.

INSTALLING

lift

m?.chine

Special

have

standard

base

bell

63

900

pivot

machine

been

plate,

assembly,

crank

AE

is

pivot

bracket,

pin

out

of

box

removed

accessories

(1)

hook

(2)

actuator

(1)

bell

for

folder

is

sewed

from

screws

rod.

crank

(1)

actuator

by

oil

rear

placing

off,

the

packing

--

containing

return

for

actuator

pivot

finger,

one

hand

inspected

channel,

bobbin

rod,

bracket,

box,

(1)

winder

(2)

retaining

on

handwheel.

and

the

upper

(3)

screws

asserpbly,

(1)

cloth

(2)

screws

carefully

following

frame

for

plate

for

rings

650

21661

==:~

These

AC

and

-36

~:

p..:.._

are

(4

*

___

parts

not

Fig.

'

are

components

furnished

1

with

of

1400 D pedestal

the

machine.

660-168

Cushion

69

FD

664

Screw*

J

7

Page 8

PREPARATION

Before

machine.

Style

and

21662

the

bottom.

pin

(21664

base

plate

hook

oil

to

hold

Styles

{21680

(63996)

used

to

NOTE:

the

machine

machine

The

63900 M {Fig.

AE)

Now

J).

now

return

the

base

63900

AX)

to

is

mounted

hold

the

Cloth

is

PREPARATION

The

pedestal

the

hemmer,

be

accomplished

The

pedestal

knee

final

press

adjustment

assembly

al.

the

ment

the

for

Place

pedestal

On

"S"

lifting

of

the

the

Style

hook

the

so

knee

to

OF

machine

on

top

assemble

Snap

can

channel

plate

T,

the

bottom

base

plate

set

OF

for

in

the

after

for

of

four

the

press

63900

the

presser

MACHINE

can

be

also

1)

of

the

retaining

be

assembled

{63996)

to

the

63900

of

under

the

plate.

extension

on

the

pedestal,

PEDESTAL

Style

left

hole

the

machine

Styles

for

lifting

the

knee

isolators

four

holes

assemblies

M, a

treadle

chain

hook

foot

INSTALLING

FOR

INSTALLATION

placed

has

is

folder

to

prepared

base

rings

is

onto

be

prepared,

plate

actuator

{660-254

to

the

under

machine.

Wand

63900

machine,

base

Attach

using

plate

upper

{63982

using

FOR

INSTALLATION

63900 M {Fig.

of

the

pedestal.

has

63900

press

the

assembly

{51295

in

base

T,

63900

presser

B)

can

and

chain

on

the

underside

can

also

be

the

pedestal,

by

mounting

(21680

AX),

finger

D)

machine~

the

base

AE

{Fig.

three

and

is

held

frame

E)

three

1)

can

screws

is

prepared

eyelet

Final

been

placed

Wand

foot,

will

be

in

the

recesses

plate

align

now

be

made.

is

required

used

for

Styles

(Continued)

the

prior

to

the

using

{21665 H)

onto

using

plate

2)

are

screws

in

be

mounted

adjustment

on

the

63900

in

the

after

with

the

of

bed

63900

pedestal

being

front

two

between

the

pivot

three

and

is

prepared

(22652

position

(A,

Fig.

{22517

by

mounting

pedestal.

AE

left

hole

the

machine

of

the

pins

to

lift

plate

T,

has

to

placed

and

rear

screws

the

pin

and

screws

attached,

by

merely

D-8).

by

the

3)

using

on Sty

le

B).

the

of

the

{Fig.

of

2)

the

has

pedestal.

in

the

the

presser

at

the

back.

63900 W and

be

prepared

on

the

pedestal.

pivot

{22517

two

brackets

B)

brackets,

locate

(22652

using

D-8),

the

mounting

The

hook

left

hand

screw

screw

(22570

63900 W and

knee

press

knee

press

is

prepared

pedestal.

been

placed

Now

place

isolators.

foot

and

The

treadle

63900

coming

in

being

left

oil

return

63900

assembly

by

Once

on

the

The

roller.

AE,

to

receive

(21662

up

using

grooves.

sure

screw

the

base

marked

A).

AE

for

collapsing

mounting

again,

the

machine

final

mechanism

if

desired.

the

AF

from

pivot

The

the

used

plate

channel

"X"

after

will

the

the

pedest-

on

adjust-

Attach

~'

These

parts

and are

8

not

are

components

furnished

with

of

1400 D pedestal

the

machine.

Fig.

2

Page 9

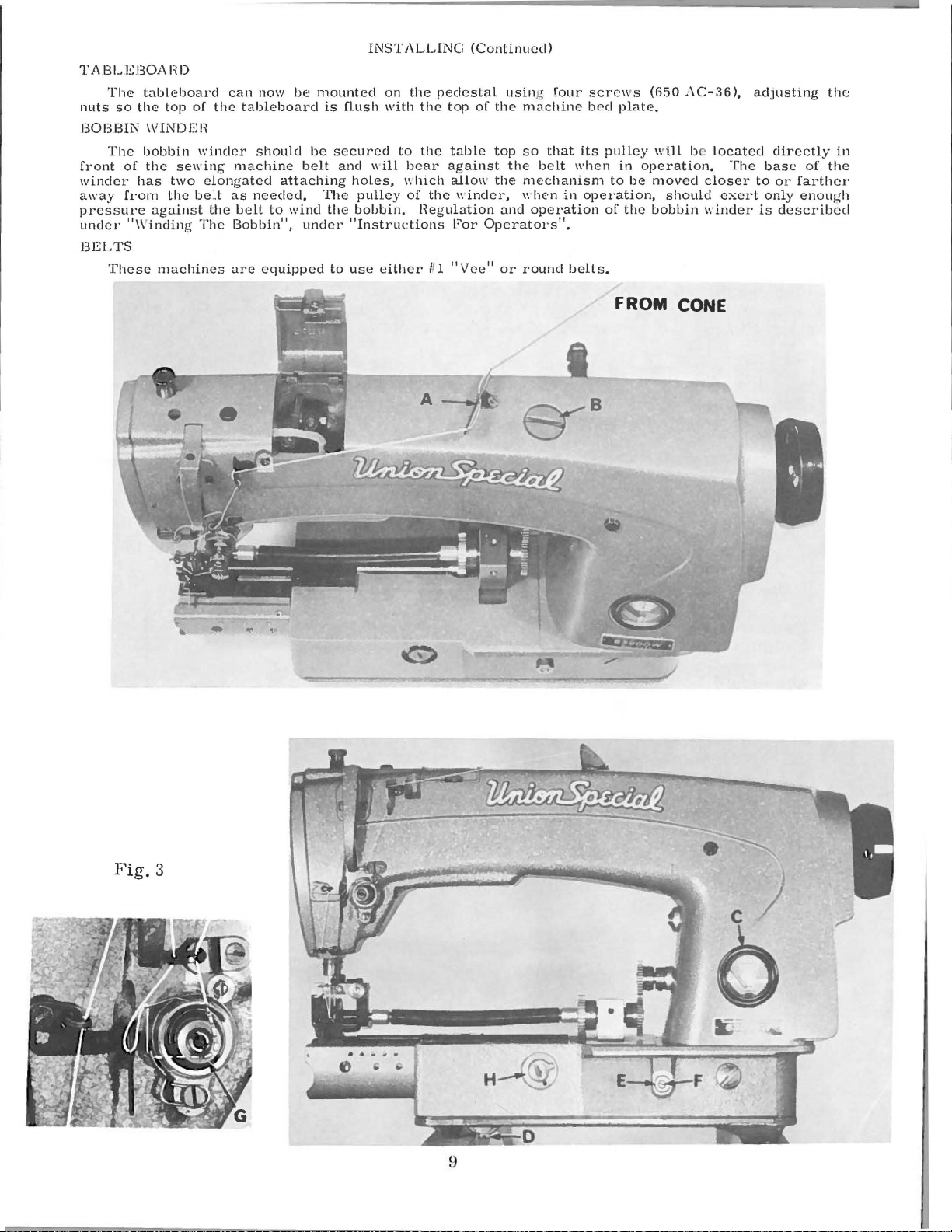

TABU::BOAI~D

The

so

the

The

of

has

from

"Winding

These

tableboard

top

of

\\'INDEH

bobbin

the

sewint;

two

the

belt

against

machines

nuts

BOBBIN

front

winder

away

pressure

under

BELTS

can

the

tableboard

winder

machine

elongated

as

the

beLt

The

Bobbin",

are

now

be

should

attaching

needed,

to

wind

equipped

mounted

is

be

belt

The

the

under

to

INSTALLING

on

flush

with

secured

and

\\ill

holes,

pulley

bobbin.

"Instructions

use

either

the

pedestal

the

to

the

bear

\\

hich

of

the

Hegulation

Il l

(Continued)

top

of

table

against

allo\\'

\\'indcr,

For

Operators".

"Vee"

using l'our

the

machine

top

so

that

the

belt

the

mechanism

\\he-n

and

operation

or

round

screws

b0d

its

when

in

operation,

belts.

(650

plate.

pulley

in

to

be

of

the

AC-36),

will b Located

operation.

moved

should

bobbin

FROM CONE

The

closer

exert

winder

adJusting

directly

base

to

or

farther

only

enough

is

described

of

the

in

the

Fig.

3

9

Page 10

LUBRICATION

CAUTION!

the

reservoir

Lubricate

and

speed

run

slowly

operation

must

machine

RECOMMENDED

Use a stainless

125

seconds

Special

check

marked

_

It

an

extended

oil

the

Replace

Oil

OIL

GAUGE

The

Should

oil

is

an

at

specification

level

"FULL".

recommended

period,

bearings

end

cover,

may

oil

be

gauge

adjustment

Oil

has

be

for

several

can

then

OIL

water-white

100°

at

gauge

Oil

of

the

as

drained

is

set

been

filled

before

thoroughly,

minutes

be

expected

Fahrenheit

No.

175.

(C):

should

be

that a new

be

lubricated

needle

no

further

from

at

the

become

drained

straight

in

the

Fill

oil

is

at

added

machine,

as

bar

hand

main

factory

necessary,

from

starting

in

accordance

to

distribute

without

mineral

main

main

reservoir

maximum

when

follows:

link,

the

oiling

reservoir

to

show

the

main

to

operate.

the

damage.

oil

reservoir.

level

needle

or

one

Remove

take-up

will

be

by

removing

the

the

following

reservoir

with

instructions

oil

to

of a Saybolt

This

at

plug

when

is

in

yellow

that

has

the

and

required.

proper

oil

steps

the

is

screw

needle

band

been

head

its

lever

plug

level

before

which

various

viscosity

equivalent

(B,

is

in

marked

out

of

cover

and

screw

in

the

should

shipment

follow,

parts.

of

to

Fig.

3)

yellow

"LOW".

service

and

directly

needle

(D,

Fig.

reservoir.

be

followed:

and

Full

90

to

Union

and

band

for

bar.

3 ).

1.

2.

3.

4.

5.

Place

Remove

bottom

Oil

should

below

Loosen

right

so

Tighten

the

the

of

the

lock

the

lock

machine

reservoir

the

machine).

be

added

bottom

nut

(E,

gauge

nut

upright

edge

needle

and

plug

or

removed

of

the

Fig.

3)

replace

on a level

screw

hole.

on

the

rests

on

plug

table

(located

so

that

calibrating

the

yellow

screw.

the

or

below

oil

band

bench.

level

screw

marked

the

handwheel

is

approximately

(F),

and

"FULL".

turn

and

screw

on

gauge

near

1/8

left

the

inch

or

(C).

10

Page 11

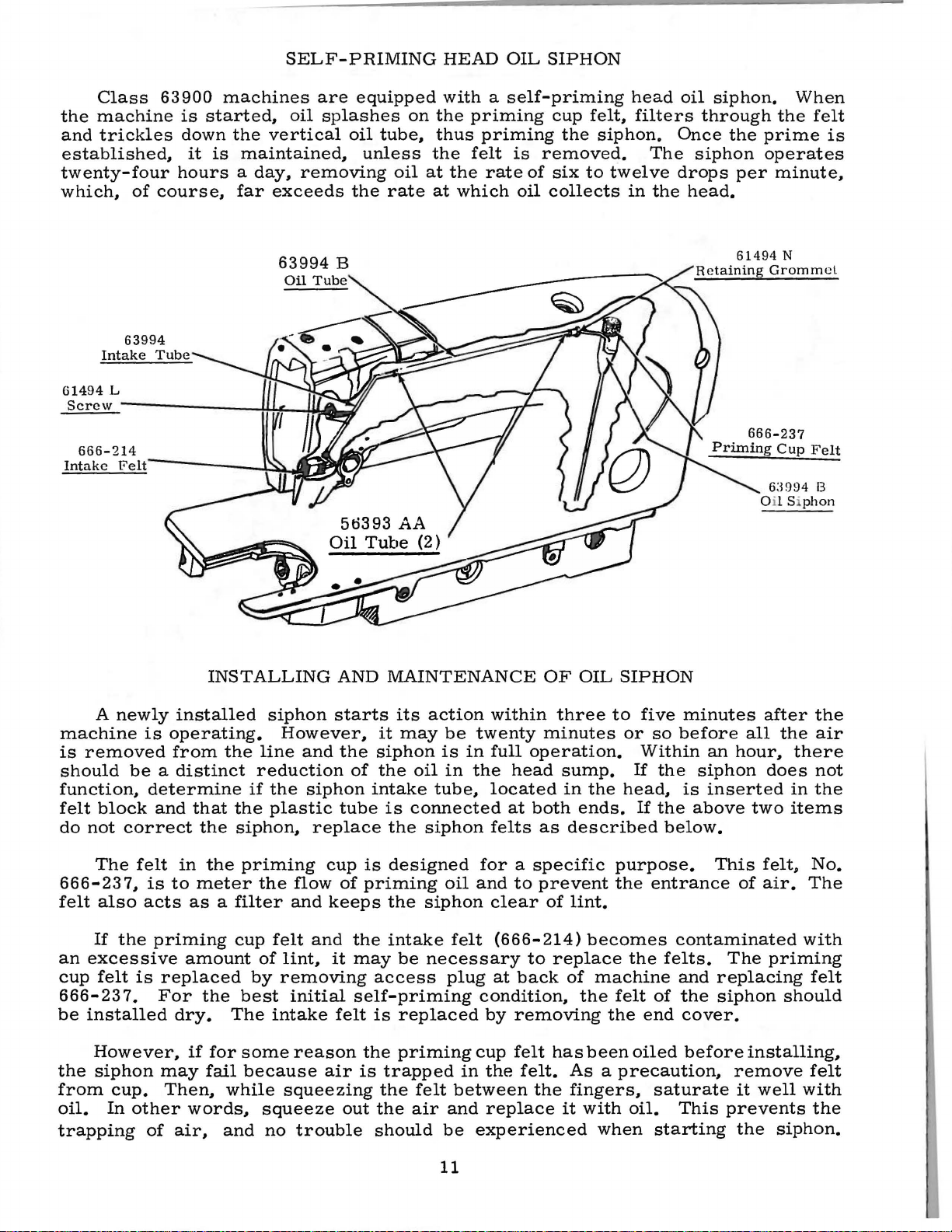

SELF-PRIMING

HEAD

OIL

SIPHON

Class

the

machine

and

trickles

established,

twenty-four

which,

61494

Screw

of

L

--------------~~~~~

63900

is

started,

down

it

is

machines

the

maintained,

hours a day,

course,

far

are

oil

splashes

vertical

removing

exceeds

equipped

on

oil

tube,

unless

oil

the

rate

with a self-priming

the

thus

the

at

at

priming

priming

felt

the

which

rate

cup

is

removed.

of

six

oil

collects

the

felt,

siphon.

to

twelve

head

filters

The

in

the

oil

siphon.

through

Once

siphon

drops

head.

the

per

61494

When

the

felt

prime

operates

minute,

N

6:l994

OilS

phon

is

8

A

newly

machine

is

removed

should

function,

felt

block

do

not

The

666-237,

felt

also

If

the

an

excessive

cup

felt

666-23

be

installed

However,

the

siphon

from

oil.

cup.

In

trapping

INSTALLING

installed

is

operating.

from

be a distinct

determine

and

that

correct

felt

is

acts

the

in

the

to

meter

as a filter

priming

amount

is

replaced

7.

For

the

dry.

if

for

may

fail

Then,

other

of

words,

air,

the

line

reduction

if

the

siphon,

priming

the

cup

of

by

best

The

some

because

while

squeeze

and

siphon

However,

and

the

siphon

plastic

replace

flow

and

felt

and

lint,

removing

initial

intake

reason

squeezing

no

trouble

AND

MAINTENANCE

starts

it

the

siphon

of

the

intake

tube

is

the

cup

is

of

priming

keeps

it

the

may

the

intake

access

self-priming

felt

is

the

air

is

trapped

the

out

the

should

its

action

may

be

is

oil

in

tube,

connected

siphon

designed

oil

siphon

felt

be

necessary

plug

replaced

priming

felt

between

air

and

be

OF

within

twenty

in

full

the

minutes

operation.

head

located

at

both

felts

as

for a specific

and

to

prevent

clear

of

(666-214)

to

at

back

condition,

by

removing

cup

felt

in

the

felt.

the

replace

experienced

OIL

SIPHON

three

to

or

five

so

Within

sump.

in

ends.

described

the

If

the

head,

If

the

below.

purpose.

the

entrance

lint.

becomes

replace

of

the

has

the

machine

felt

the

been

oiled

felts.

of

end

As a precaution,

fingers,

it

with

when

saturate

oil.

starting

minutes

before

an

siphon

is

inserted

above

This

after

all

hour,

does

two

felt»

of

air.

contaminated

The

priming

and

replacing

the

siphon

cover.

before

installing,

remove

it

well

This

prevents

the

siphon.

the

the

air

there

not

in

the

items

No.

The

with

felt

should

felt

with

the

11

Page 12

THREAD

INSTRUCTIONS

FOR

OPERATORS

While

of

the

the

direction

of

each

WINDING

Thread

from

down

post.

(B).

bobbin a few

downwardly

into

position.

will

automatic

pulley.

be

between

up

contact

be

varied

hook

hand.

Fig.

the

Press

to

rotated

The

the

THE

supply

the

When

throw-out

by

direction

rotation

of

twist.

Turn

5

BOBBIN

the

bobbin

down

the

tension

an

empty

stop.

turns

on

with

extent

regulating

in a clockwise

hand

machine

the

and

of

the

favors

grasp a short

the

thread

unwind.

REMOVING

direction

the

machine.

the

the

be

winder

through

discs.

bobbin

wind

lever

machine

filled

member.

to

the

belt,

until

which

the

twist

the

use

away

To

remove

left

hand,

bobbin

Opening

latch

removed.

by

the

and

on

end

direction

(D)

until

and

is

operated.

the

which

the

bobbin

screw

in

the

of a left

length

from

it

is a left

THE

until

open

case

the

is

closed.

leading

eyelet

under

the

of

thread

pulley

is

locked

thread

disengages

(C).

bobbin

twist

of

you

BOBBIN

the

bobbin

needle

reach

the

bobbin

out

latch

the

(A,

the

winder

and

is

the

engages

is

filled

thread

thread

thread

with

twist.

case.

reaches

in

under

of

the

retains

the

bobbin

thread

Fig. 6 ).

tension

shaft

around

press

moved

in

that

bobbin

the

the

can

is

in

between

your

if

not.

CASE

turn

its

the

case

sewing

the

is

immaterial.

the

needle.

thumb

right

latch

hand.

it

handwheel

highest

throat

(A.

hook.

bobbin

released

is a right

plate

and

If

position.

Fig.

in

the

and

the

direction

To

determine

forefinger

the

in

operating

at

left

5).

case.

can

strands

twist.

Using

end

and

pull

When

readily

of

The

base.

ing

wind

all

and

machine

and

screw

unevenly

The

times.

begin

tension

can

purpose

is

be

(E)

so

may

When

to

wind

sewing.

Fig.

post

shifted

that

of

the

7

bracket

be

readily

the

bobbin

the

from

any

tendancy

bobbin

empty

is

mounted

left

to

right

of

corrected.

winder

in

the

machine

one

immediately.

THREADING

The

the

thumb,

hand.

The

thumb

coming

on

the

by

the

is

to

bobbin

forefinger

bobbin

and

forefinger

off

the

12

winder

loosen-

bobbin

assure

is

used

THE

case

(B)

bottom

to

up.

Bobbins

BOBBIN

(A.

itself

an

replace

Fig.

and

of

of

the

operator

can

be

CASE

7)

should

second

should

the

right

bobbin.

Fig.

of a full

it

with

rewound

be

finger

be

held

hand

6

bobbin

the

full

while

held

between

of

the

between

with

at

one.

the

LEFT

the

thread

Page 13

INSTRUCTIONS

FOR

OPERATORS

(Continued)

THREADING

Place

finger

Fig.

8)

direction

at

the

the

of

right

under

of

bobbin

Fig.

the

handwheel.

The

cross

(A,

Fig.

as

far

mulated

as

lint

9 )1 is

it

THE

bobbin

hand~

the

the

case

8

hole

will

from

BOBBIN

in

draw

tension

rotation

from

REPLACING

and

latch

the

be

be

INSERTING

with

Tighten

in

to

show

go

and

1

needle

CASE

bobbin

the

spring

of

the

the

Have

one

should

throat

placed

released

Insert

the

set

the

needle

the

to

(Continued)

case.

bobbin

bobbin

back.

the

half

plate

part

the

spot

screw

In

one

thread

(B)

and

as

The

bobbin

THE

BOBBIN

needle

inches

be

opened

and

way

and

bobbin

THE

NEEDLE

needle

(sometimes

securely.

into

the

bar

through

into

bar1 about

operator

when

provide a means

hole

so

the

needle

continuous

through

self

threading

end

of

should

CASE

at

its

of

thread

with

the

the

sewing

case

into

the

called

1/4

needle

for

will

motion1 with

diagonal

the

thread

rotate

highest

to

hang

left

hand1 and

the

bed

hook.

snapped

needle

scarf)

inch

from

has

been

cleaning

seat

thumb

slot

in

bobbin

slot

(C)

on

is

pulled

when

counterclockwise.

position1 allow

free.

plate

into

bar

toward

the

The

position.

The

by

reaching

extension~

latch

as

far

the

right1 facing

end

inserted

the

accu-

properly.

and

case.

about

bobbin

it

should

as

it

A

fore-

case

Note

looking

two

case

under

should

then

will

(A

go

1

1

THREADING

Threading

thread

the

passes.

needle

eye

PREPARATION

With

the

handwheel

highest

it,

through

your

position.

the

foot.

--.: •

..,,~

Fig.

tension

bobbin

this

adjustment

1 0

on

the

suspended

THE

NEEDLE

diagram

Please

from

left

FOR

left

hand1 hold

in

operating

Pull

needle

TENSIONS

B A

.,.

thread

sewn.

on

BOBBIN

screw

spring

by

check.

(Fig.

note

to

right.

SEWING

direction

up

the

hole

in

perfect

are

A

both

threads.

THREAD

The

tension

(A,

is

correct

the

bobbin

3)

that

the

needle

the

locked

stitch

Fig.

when

shows

the

end

of

until

thread

throat

stitch

of

this

TENSION

on

10)

it

thread.

the

places

needle

the

needle

the

and

plate.

is

one

together

kind

the

bobbin

which

is

just

The

where

thread

passes

thread1 leaving

needle

Draw

in

in

is

the

bobbin

both

which

the

secured

moves

center

case

regulates

sufficient

thread

should

the

threads

the

is

applied

the

to

needle

through

down

thread

needle

of

by

regulating

tension

hold

not

it

slack1 and

and

will

under

thread

the

material

by

spring

the

bobbin

be

in

Fig.

up

again

come

the

and

the

means

the

eyelet

9

turn

to

up

with

presser

bobbin

being

tensions

of a set

(B).

The

case

its

and

for

13

Page 14

INSTRUCTIONS

FOR

OPERATORS

(Continued)

BOBBIN

THREAD

Remove

turn

set

to

apply

release

When

rarely

as

varying

screw

more

tension.

the

becomes

attain a good

NEEDLE

The

the

tension

the

nut

tension,

This

in

its

the

machine

THREAD

needle

in a clockwise

while

should

raised

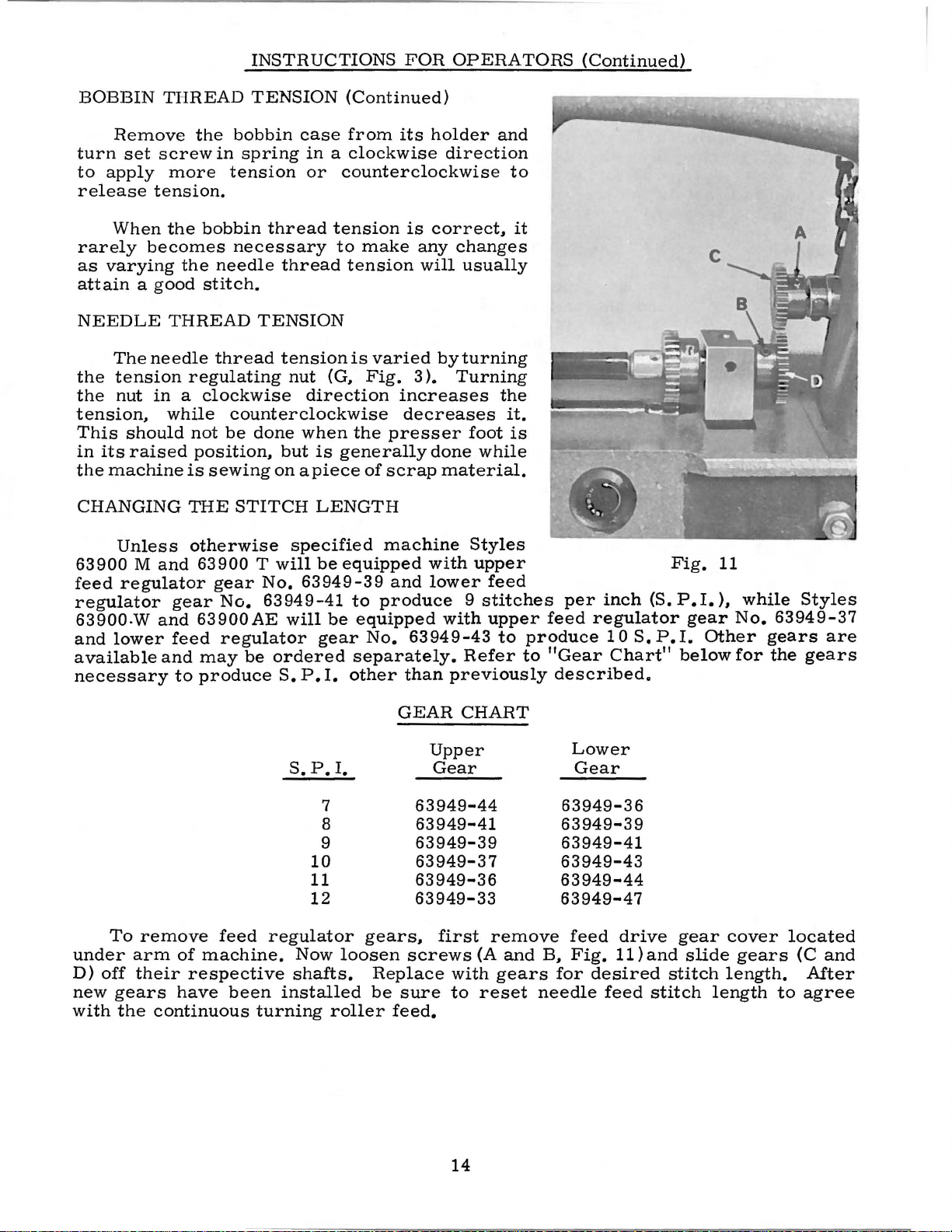

CHANGING

Unless

63900 M and

feed

regulator

regulator

63900.W

and

lower

available

necessary

gear

and

feed

and

to

the

bobbin

in

spring

tension

bobbin

necessary

the

needle

stitch.

thread

regulating

counterclockwise

not

be

position,

is

sewing

THE

STITCH

otherwise

63900

gear

No.

63900AE

regulator

may

be

produce

TENSION

case

in a clockwise

or

thread

thread

TENSION

tensionis

nut

(G,

direction

done

but

on

when

is

apiece

LENGTH

specified

Twill

No.

be

63949-39

63949-41

will

be

gear

ordered

S.

P.

I.

(Continued)

from

its

holder

direction

counterclockwise

tension

to

tension

make

varied

Fig.

is

correct,

any

will

byturning

3 ).

changes

Turning

increases

decreases

the

presser

generally

of

scrap

done

material.

machine

equipped

to

produce 9 stitches

equipped

No.

with

and

lower

63949-43

with

separately.

other

than

previously

and

to

usually

the

it.

foot

is

while

Styles

upper

feed

upper

to

Refer

it

feed

produce

to

"Gear

described.

per

regulator

inch

10

S.

Chart"

(S.

P.

. • •

..

" . \

~-"· . ~

~

.:

Fig.

P.I.

gear

I.

Other

below

11

),

'1,

......

...

---c

while

No.

for

A

:.

•. -·:

~ .·~

,, ,.

.

p

""'~.~

..

~

~a..t

~

..

_1\

.,_,

Styles

63949-37

gears

the

are

gears

•

under

D)

off

new

with

To

remove

arm

their

gears

the

feed

of

machine.

respective

have

been

continuous

S.

P.

10

11

12

regulator

Now

shafts.

installed

turning

I.

7

8

9

loosen

roller

GEAR

63949-44

gears,

screws

Replace

be

sure

feed.

CHART

Upper

Gear

Lower

Gear

63949-36

63949-41

63949-39

63949-39

63949-41

63949-37 63949-43

63949-36

63949-33

first

(A

with

to

reset

remove

and

gears

63949-44

63949-47

feed

B,

Fig.

for

needle

drive

11)and

desired

feed

gear

slide

stitch

stitch

cover

gears

length.

length

located

(C

After

to

agree

and

14

Page 15

INSTRUCTIONS

FOR

MECHANICS

TIMING

Fig.

THE

NEEDLE

12

FEED

and

WITH

loosen

connection

per

inch

arm

entric

the

bottom

the

timing

hub

coincide.

Rotate

its

stroke.

not,

forward

making

needle

To

drive

designated

Vary

of

needle

thickest

Open

top

of

at

letter

Loosen

(D).

loosen

or

sure

bar

set

segment

the

needle

deflection

section

THE

CONTINUOUS

cover

needle

stud

needle

two

(C)

11811

frame

•

set

Rotate

of

its

stroke.

line

(E)

Tighten

handwheel

The

needle

clamp

backward

all

side

frame

needle

and

feed

locking

letter

travel

to

(A,

to

point

feed.

screws

the

handwheel

on

the

all

until

screw

until

play

the

with

nut.

on

segment

when

be

sewn.

Fig.

drive

of

This

on

12)

segment

maximum

would

the

Rotate

connecting

screws.

the

bar

should

(F)

and

bar

is

removed

segment.

roller

Set

so

as

to

the

needle

TURNING

in

the

head

locking

locate

needle

until

the

the

eccentric

arm

needle

bar

be

move

is

vertical.

feed

loosen

connection

for

approximate

obtain

enters

ROLLER

of

number

the

frame

needle

and

the

is

vertical.

needle

Tighten

from

between

needle

toward

the

least

or

FEED

the

machine

nut

(B).Set

of

stitches

connecting

drive

bar

only,

eccentric

at

bottom

If

bar

frame

screw,

frame

higher

setting.

amount

leaves

eccis

at

until

of

it

is

the

the

PRESSURE

The

only

enough

work

the

Fig.

gulator

feed

presser

17)

in a clockwise

counterclockwise

SETTING

The

lower

to

which

at

the

frame

is

2 1 I 4

used

fer

red

length

Styles

factory.

(A,

inches.

The

in

setting

to

The

two

needle

63900

the

four

ON

MATERIAL

presser

pressure

uniformly.

foot,

THE

NEEDLE

end

needle

The

Fig.

13)

lines

needle

as

TIMING

lower

Type

M,

spring

on

To

turn

of

the

bar

distance

to

the

engraved

LINES.

lines

180,

63900

(A,_

the

feed

increase

presser

direction.

decreases

BAR

needle

is

timed,

bottom

bar

are

which

T,

63900 W and

Fig.

spring

TO

from

on

to

height,

used

is

17)

should

rollers

the

to

pressure

regulator

Turning

the

pressure.

HEIGHT

bar

frame,

is

faced

the

bottom

of

the

throat

the

needle

and

with

the

recommended

63900

exert

make

the

the

to

height

of

bar

are

short

the

on

(

B,

re-

one

the

plate

are

re-

for

AE.

the

with

When

upper

the

the

timing

lower

needle

line

edge

of

bar

(B,

the

is

Fig.

lower

at

its

13)

needle

lowest

should

bar

position,

be

EVEN

frame

(A).

15

Fig.

13

Page 16

INSTHUCTIONS

FOR

MECHANICS

(Continued)

SETTING

To

change

handwhcel

Then,

bar

bar

securely.

setting

TIMING

screws

bobbin

interference

operating

lowest

the

lower

loosen

to

the

line

at

The

illustration

of

THE

Remove

(A)

case

position,

lower

edge

THE

proper

direction

NEEDLE

the

until

the

its

lowest

the

needle

HOOK

throat

in

the

holder

with

timing

of

the

the

and

BAR

position

bar

clamp

timing

(Fig.

plate.

hook,

in

such a position

the

until

continue

mark

needle

of

is

screw

line.

position,

bar.

and

needle.

the

(Fig.

bar

is

tighten

Then,

hook

be

TO

the

at

its

(C)

Keeping

tighten

13)

shows

Loosen

hold

Turn

needle

to

turn

13)

frame

Turn

even

needle

•

003

to

hook

recheck

is

timing

about

HEIGHT

needle

lowest

and

the

the

the

hook

as

handwheel

bar

the

used

(A).

the

with

as

possible

•

005

sat

the

set

tighten

the

1/64

(Continued)

bar,

turn

position.

move

the

needle

the

screw

proper

three

and

to

prevent

is

at

handwheel

in

setting

hook

the

center

inch

is

factory.

screw

the

timing

position

inch

the

set

the

in

its

the

on

the

of

without

between

opposite

two

remaining

of

the

the

top

below

until

needle

shaft

the

the

With

hook

of

the

the

needle

bar

until

needle

deflecting

needle

the

hook

the

hook

screws

with

the

eye

bottom

Fig.

the

and

and

the

of

is

is

point

it.

the

of

in

the

14

ascending

even

of

as

close

A

spacing

the

point

this

point

securely,

needle.

needle

hook

and

with

the

position,

securely.

the

hook

to

the

of

the

and

At

the

should

point.

of

----------between

Fig.

NEEDLE

In

the

is

found a needle

The

purpose

to

prevent

contact

should

point.

needle

vertical

(At

no

ciallywith

removal

be

with

the

The

slightly

travel

loop-taking

deflection

For

additional

of

necessary.

15

GUARD

hook,

needle

use

the

needle

needle

of

of

some

at

guarding

hook

when

if

time

needle

size.

of

INSTRUCTIONS

the

of

this

point

(D)

be

deflected

guard

needle

the

hook

there

needle

needle

right

048

side

surface

guarding

(C)

at

loop-taking

will

is

is

properly

should

by

the

clearance,

and

guarding

Replace

bobbin

FOR

of

(A,

surface

from

toward

deflect

at

bottom

be

needle

larger

surface

throat

the

outside

case

No.

the

needle

Fig.

coming

time,

the

hook

of

timed.

little

guard.

espe-

needles,

may

recess.

29474

15).

is

in

the

its

or

)

16

plate,

edge

hole

of

S

in

bobbin

allowing

projection

case

Fig.

1/32

and

holder

16

inch

the

clearance

inside

(B,

Fig.

edge

15)

Page 17

INSTRUCTIONS

FOR

MECHANICS

(Continued)

NEEDLE

GUARD

INSTRUCTIONS

all

1.

2.

3.

4.

FOR

Before

related

See

that

Check

Rotate

Check

is

cited

If

needle

and

(b)

(a)

Remove

(b)

Remove

surface.

strip

secured

surface

removed.

needle

should

proper

No.

metal

settings

the

for

proper

the

handwheel

for

excessive

on

preceding

deflection

below.

of

guarding

be

needle

29474 S (Continued)

removal

should

needle

bobbin

excess

This

fine

emery

to

the

back

When

reinserted

hook

case

may

and

guarding

from

be

bar

timing.

in

operating

needle

page

is

excessive.

holder

metal

be

bench.

forth

metal

surface.

checked

is

deflection

as a desirable

from

done

cloth

and

until

is

frequently

is

the

guarding

as

set

to

direction

from

the

by

(#320).

rubbing

sufficient

being

the

bobbin

obtained.

follows:

correct

beyond

follow

hook.

needle

using

with

the

removed

case

and

tested

surface

height.

by

hand.

what

condition.

steps

guarding

a

1/8

inch

one

end

guarding

metal

from

holder

until

(a)

is

The

bobbin

hook

REMOVED

and

slightly.

HOOK

bobbin

a

under

After

definite

observed.

base.

When

The

pulling

LUBRICATION

CAUTION!

case

With

full

minute.

the

about

and

Fig.

altering

or

bobbin

on

in

the

bobbin

hook

five

distinct

17

case

disturbed

bobbin

the

Place a piece

holder

needle

case

Do

not

hook

case

and

continue

seconds.

from

holder

case

run

as

in

pattern

CAUTION!

too

much

surface.

should

guarding

its

only

stem

the

machine

hook

damage

hook.

of

white

running

remove

of

oil

be

thoroughly

surface.

timed

may

as

the

run

paper

the

the

spots

metal

position.

be

removed

handwheel

without

may

machine

directly

machine.

paper

should

Damage

is

removed

cleaned

it

is

the

result.

for

and

a

be

to

the

from

before

suggested

by

removing

is

rocked

hook

the

reassembly

that

gib

backward

Fig.

point

needle

the

may

hook

screws

and

E

18

result

guarding

into

the

NOT

forward

and

BE

gib

if

Should

located

of

the

run

about

more

on

the

change

one

or

less

front

required.

minute

oil

be

of

the

machine

After a change

before

checking

required.

just

for

turn

below

in

the

the

oil

control

the

hook

desired

cloth

oil

oil

17

adjusting

plate

flow.

flow.

surface.

the

machine

shaft

(H.

in

direction

should

Fig.

3 ).

be

Page 18

INSTRUCTIONS

FOR

MECHANICS

(Continued)

PRESSER

When

presser

plate.

between

top

of

setting,

and

loosen

insure

to

the

turning

slot

top

4

5/8

and

feed

Set

inches

BAR

GUIDE

locating

foot

Proper

underside

throat

remove

set

it

is

5

3/64

it

so

retighten

roller

needle

must

setting

plate

pressure

screw

down

inch

needle

by

thread

above

presser

rest

of

against

directly

of

presser

(Fig.

(D).

dimension,

enters

screw

turning

pull-up

throat

PRESSER

be

Fig.

er

machine,

tion.

bar

guide

17).

from

Tap

throat

(D).

regulator

plate

set

(C).

lever

right

guide

against

is

5

bar

guide

To

obtain

presser

on

presser

plate.

center

the

middle

Apply

bracket

(Fig.

BAR

Presser

about

Accomplish

16),

and

bell

under

or

left,

Tighten

(C,

Fig.

throat

3/64

pressure

CONNECTION

inches

and

this

spring

foot

Set

foot

(E)

bar

1/16

by

of

its

clockwise.

(F)

17).

connection

inch

this

relocating

crank

bed

properly

lock

the

guide

to

so

by

(C),

plate.

nut

17)

(A)

to

that

below

loosening

sets

(A)

underside

(G,

presser

stop

located

Turning

presser

to

Fig.

Fig.

screw

at

lock

lock

(B)

the

stop

stop

19

of

17)

bar

bar

wire

should

guide

nut

on

back

screw

connec-

screw.

is

(A,

lift-

of

to

Fig.

Test

sion

released.

under

bly.

(C).

away

in

ceed

correctly

not

by

turning

thread

place

foot

TENSION RELEASE

not

when

tension

and

required

to

assure

arm

Partially

Turn

from

a

clockwise

further

forcefully.

inserting

in

Replace

take-up

tension

is

resting

Tension

to

release

presser

release

out

position

check

Should

and

tension

upper

set

required

for

20

in

a

tension

post

release

foot

proper

spring

a

good

it

require

to

the

loosen

post

stop

direction

same

tension

Further

screwdriver

direction.

bracket

assembly

on

throat

when

is

cam

of

sewing

(H,

tension

operation

TENSION

tension

returning

right

tension

(D)

(E)

and

until

direction

post

adjustment

assembly

(A,

plate.

should

raised.

Fig.

ASSEMBLY

(A,

Fig.

snap

adjusting,

of

tension

post

counterclockwise

has

spring

until

set

screw

into

Fig.

over

slotted

with

19).

while

be

set

seams

Adjustment

17)

assembly

.

set

no

tension

of

check

presser

so

and

when

assembly

again

desired

(B)

check

Re-

as

or

in

are

ADJUSTMENT

18).

loosen

screw

end

of

There

the

until

on

touches

tension

should

spring

of

spring

spring

set

(B)

should

screw

and

remove

in

check

it.

Turn

be

drawn

tension

tension

about

is

depressed

in

tension

spring

tension

upper

is

obtained.

post

3/8

Fig.

be

head

tension

post

stop

up

snugly,

can

(D)

inch

21

enough

located

socket

moves

post

(E).

be

and

above

ten-

and

assem-

(D)

Pro-

When

yet

made

18

Page 19

INSTRUCTIONS

FOR

MECHANICS

(Continued)

TENSION

The

in

are

in

line

so

that

when

maintained.

The

tension

screw

average

throat

(

J)

release

plate.

THREAD

Check

There

Fig.

should

20)

is

about 1 to

Fig.

stop.

20).

The

tightened

post

tension

(D,

Fig.

discs,

RELEASE

and

out

position

with

the

the

flange

Tighten

release

and

then

point

Tighten

CONTROL

the

adjustment

be

enough

depressed

11/4

This

ounces

is

tension

(B,

Fig.

18).

should

(Continued)

check

spring

of

the

tension

cam

raising

is

between

tension

of

tension

and

when

measured

post

18).

The

be

set

The

check

set

of

the

the

tension

( H,

or

lowering

release

tension

released.

measured

when

screw

tension

spring

for

tension

eyelet

(B,

as$embly

assembly

Fig.

17)

cam

114

and

cam

assembly

to

insure

The

the

check

should

release

eyelet

correct

assembly

Fig.

is

19 ).

rests

set

screw.

should

5116

set

(H)

now

to

inch

screw

(A,

a

good

check

spring

with a postal

spring

be

drawn

pin

should

(B,

Fig.

height

as

follows:

correct

Set

the

against

be

positioned

suit

the

of

presser

securely.

Fig.

20).

returning

scale,

is

1132

up

move

19),

when

stop

sewing

Check

snap

tension

to

snugly

freely

located

the

screw

it,

this

by

conditions.

foot

spring

when

is

adjusted

No.

21227 CW,

1/16

but

inch

not

in

just

tension

(C,

Fig.

position

loosening

lift

above

tension.

spring

from

forcefully

the

tension

below

discs

19)

is

set

The

the

{B,

from

(C,

the

the

With a thread

Fig.

below

so

this

The

when

tension

19)

the

that

setting,

Sew

thread

the

in a straight

thread

the

check

line

proceed

slowly

on a piece

from

the

take-up

may

be

necessary

maintain a uniform

ounces

(A,

will

required

BOTTOM

is

accessible

some

cover

pry

needle

Fig.

feel

21

heavy

setting

Before

convenient

screws.

the

cover

thread

).

Depress

to

COVER

removing

from

Cover

loose

for

running

line,

{Fig.

spring

to

will

thread

check

is

at

the