Page 1

INSTRUCTIONS / ILLUSTRATED PARTS LIST

SPECIAL SOFT STITCH FORMATION PARTS

CATALOG NO.

PT0601

FIRST EDITION

SUPPLEMENT TO

PT9804

35800 LAPSEAMER WITH

MECHANICAL DRIVE PULLER AND

STYLES

35800DNUB8 35800DNUB9

35800DNWB8 35800DNWB9

35800DRUB8 35800DRUB9

35800DRWB9 35800PZB32

35800PZB36

04/16/06

Page 2

Manual No. PT0601 Adjusting Instructions & Illustrated Parts List for

35800 Series Balloon Stitch Machines

First Edition Copyright 2006

By

Union Special Corporation Rights Reserved In All Countries

Printed in U.S.A. May 2006

2

Page 3

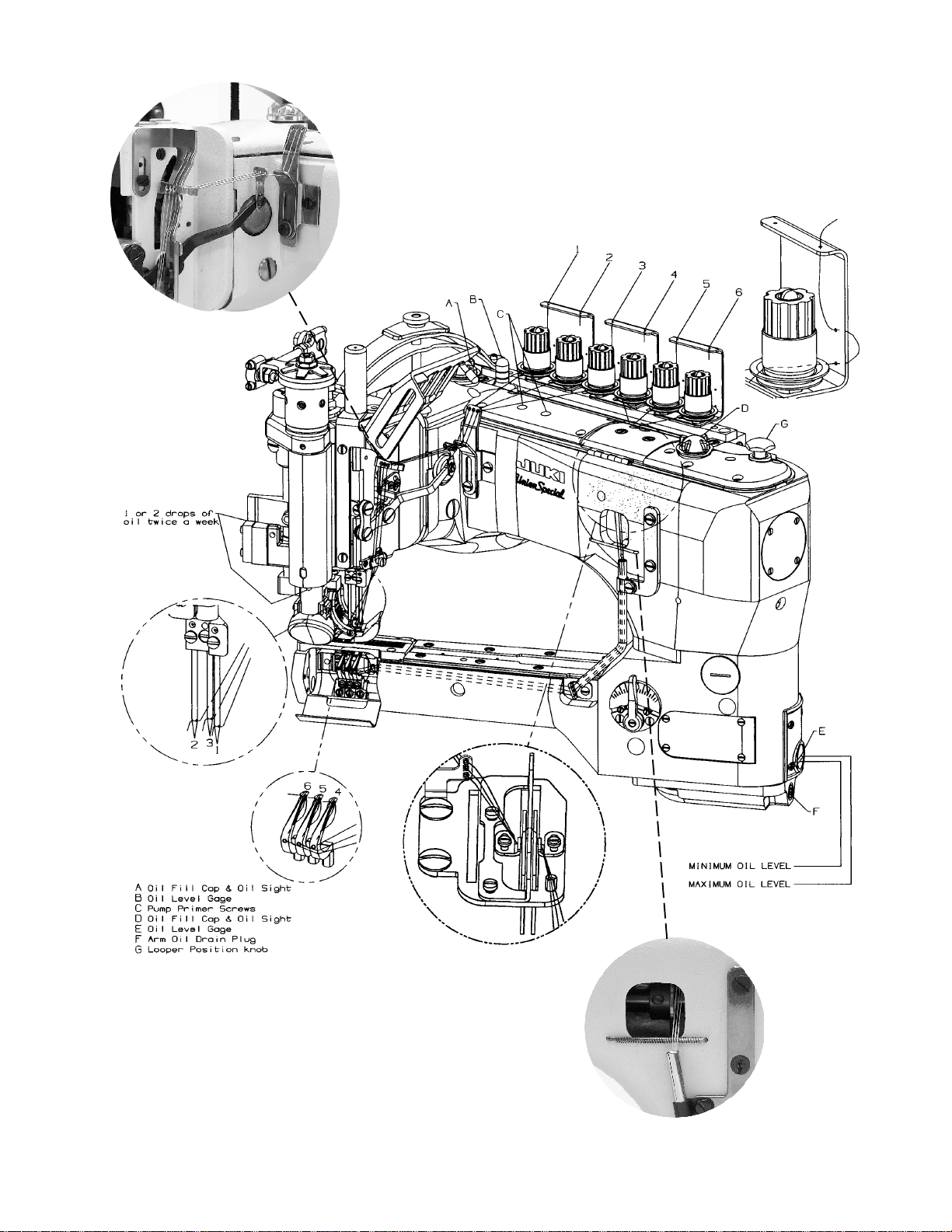

IDENTIFICATION OF MACHINES

Each UNION SPECIAL machine is identified by a style number, which is stamped into the style plate affixed to the middle of the

machine under the tension assembly.

The serial number is stamped in the casting at the right rear base of the machine.

CLASS DESCRIPTION

High Speed, Feed-Off-The-Arm High Throw Machines, Two and Three Needle, Left Needle In Front. Light Weight Presser Bar

Mechanism, Adjustable Looper Avoid, Space in Front of Needles 8" (203.2 mm), Double Disc Looper Thread Take-Up, Automatic

Enclosed Type Oiling System and Filter Type Oil Pump, Visual Sight Oil Action and Supply Gauges. Special soft stitch formation parts.

STYLE OF MACHINES

35800DNUB DOUBLE LAP SEAM. Three needle, high capacity, differential feed with upper driven roller feed. -Typical

Application- For in and out seaming on heavy weight denim garments. Seam Specification 401 LSc-

3. Standard gauge Numbers 8 [1/8", 3.2mm] and 9 [9/64", 3.6mm]. Recommended needle 130GS,

size 140/054. Maximum recommended speed 4500 R.P.M.. .094 step sewing parts. .468 (15/32,

11.9mm) narrow roller.

35800DNWB DOUBLE LAP SEAM. Three needle, high capacity, differential feed with upper driven roller feed. -Typical

Application- For in and out seaming on heavy weight denim garments. Seam Specification 401 LSc-

3. Standard gauge Numbers 8 [1/8", 3.2mm] and 9 [9/64", 3.6mm]. Recommended needle 130GS,

size 140/054. Maximum recommended speed 4500 R.P.M.. .094 step sewing parts. .588 (19/32,

15.0mm) wide roller.

35800DRUB DOUBLE LAP SEAM. Three needle, high capacity, plain feed, upper driven, roller feed. Feed Dogs have

higher teeth on front. - Typical Application- For seat seaming, in and out seams on medium to heavy

weight denim garments. Seam Specifications 401LSc-3. Standard gauge Numbers 8 [1/8", 3.2mm]

and 9 [9/64", 3.6mm]. Recommended needle 130GS, size 140/054. Maximum recommended speed

4500 R.P.M.. .094 step sewing parts. .468 (15/32", 11.9mm) narrow roller.

35800PZB Same as 35800DRUB except with reverse teeth roller.

35800DRWB DOUBLE LAP SEAM. Three needle, high capacity, plain feed, upper driven, roller feed (wide roller).

Feeds have higher teeth on front of feeds. - Typical Application- For seat seaming, in and out seams

on medium to heavy weight denim garments. Seam Specifications 401LSc-3. Standard gauge 9 [9/

64", 3.6mm]. Recommended needle 130GS, size 140/054. Maximum recommended speed 4500

R.P.M.. .094 step sewing parts. .588" (19/32", 15mm) wide roller.

selytSllA

SG031

3

6

mm2.7ro,mm6.3

devomereldeenretnechtiw

6.3~1.2

)dradnats2.3(

mm0.9

MPR0054

mumixam

3

Page 4

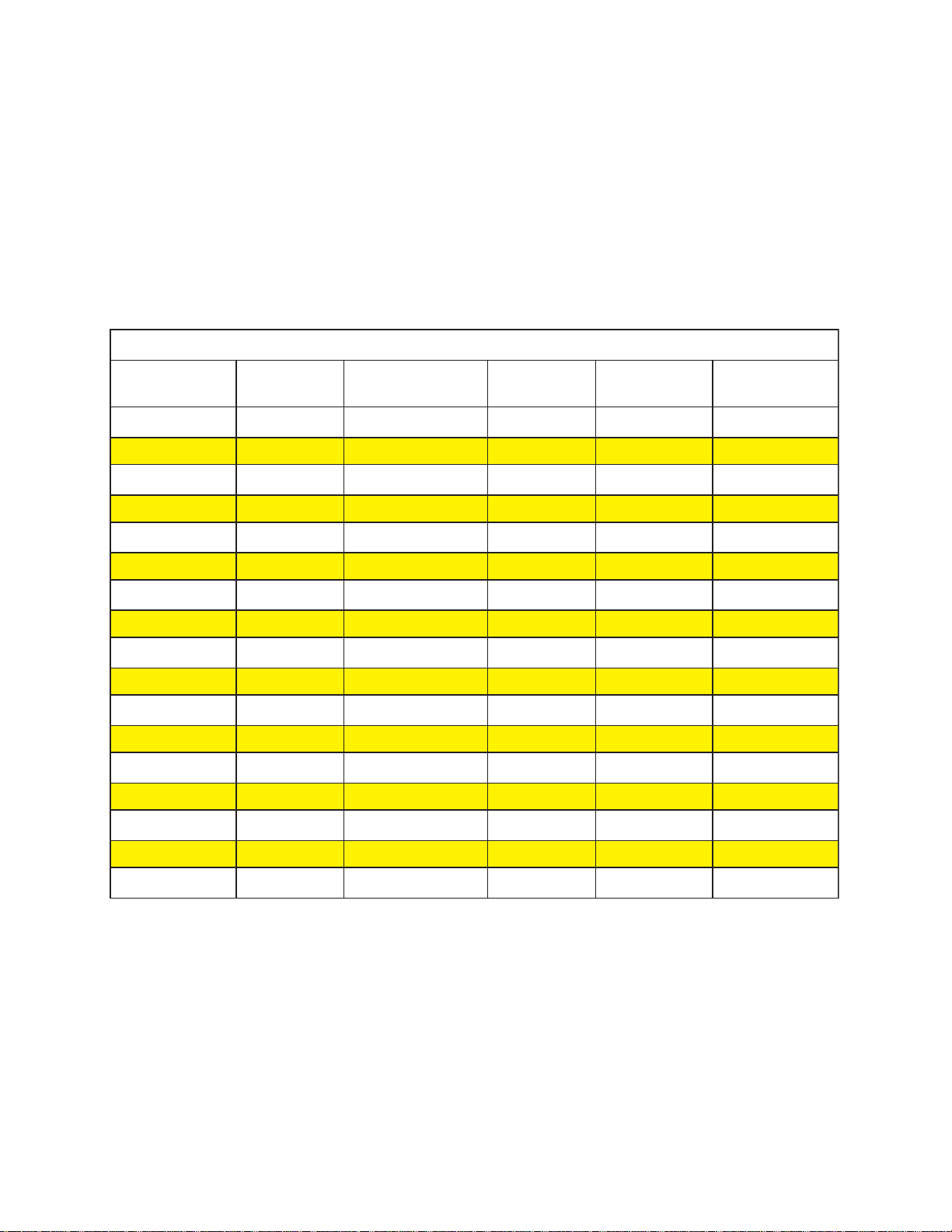

00853HCTITSNOOLLAB

DRADNATS

ETALPTAORHT

8ND428538UND008538BUND00853BEB084928DE428538DE

9ND428539UND008539BUND00853YDB084929CE428539CE

8XD428538BWND00853AEB084928ZD428538ZD

9XD428539BWND00853ZDB084929ZD428539ZD

8QD428538URD008538BURD00853CEB084928FE428538FE

9QD428539URD008539BURD00853DEB084929DE428539DE

8QD4285323ZP0085323BZP00853CEB084928FE428538FE

9QD4285363ZP0085363BZP00853DEB084929DE428539DE

DRADNATS

ELYTS

HCTITSNOOLLAB

ELYTSENIHCAM

TIFORTER

TIK

TAORHTWEN

ETALP

ET

ALPTAORHT

KRAM.D.I

9WQD428539WRD008539BWRD00853HEB084929FE428539FE

4

Page 5

5

Page 6

6

Page 7

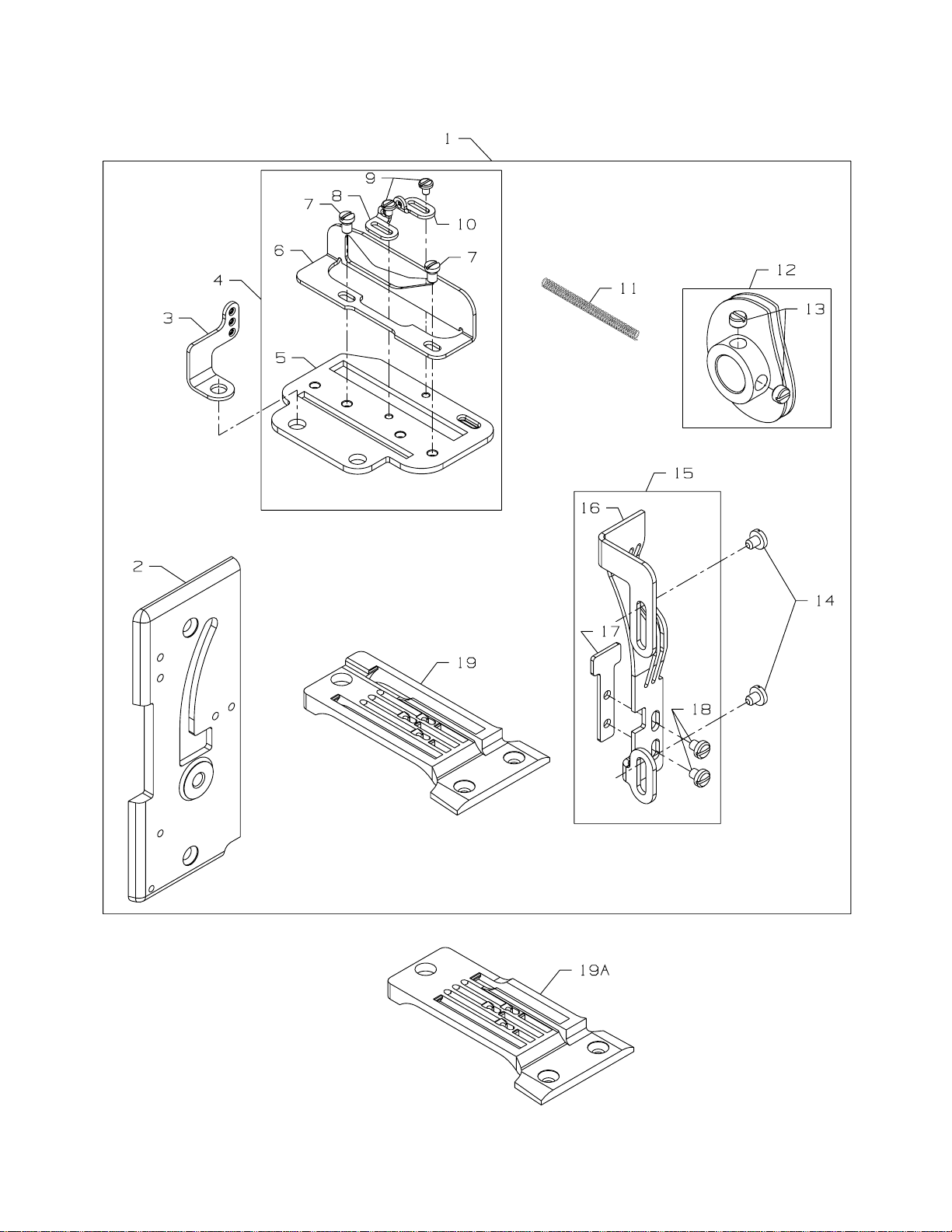

BALLOON STITCH PARTS

Ref.

No.

10.

11.

12.

13.

14.

15.

16.

17.

18.

19.

19A.

.

Part No.

1.

29480BEB

-

29480BDY

-

29480BEA

-

29480BDZ

-

29480BEC

-

29480BED

-

29480BEH

2.

35882K

3.

50658A

4.

29476CA

5.

35804B

6.

36204A

7.

22KH

8.

52958C

9.

73A

52958F

35853AN

35823D

22580

22704

29476CB

35804C

35804B

25B

35824DN8

-

35824DN9

-

35824DQ8

-

35824DQ9

35824DX8

-

35824DX9

-

35824DQW9

Description

Kit of Parts, for 35800DNUB8 .........................................................................

Kit of Parts, for 35800DNUB9 .........................................................................

Kit of Parts, for 35800DNWB8 ........................................................................

Kit of Parts, for 35800DNWB9 ........................................................................

Kit of Parts, for 35800DRUB8, 35800PZB32 .....................................................

Kit of Parts, for 35800DRUB9, 35800PZB36 .....................................................

Kit of Parts, for 35800DRWB9 ........................................................................

Front Cover ...........................................................................................

Looper Thread Eyelet ............................................................................

Cast-Off Plate Assembly .......................................................................

Cast-Off Plate .................................................................................

Cast-Off .........................................................................................

Screw .............................................................................................

Eyelet .............................................................................................

Screw .............................................................................................

Eyelet .............................................................................................

Looper Thread Spring ............................................................................

Double Disc Take-up Cam ....................................................................

Screw .............................................................................................

Screw ....................................................................................................

Needle Thread Take-up Assembly ........................................................

Needle Thread Take-up ..................................................................

Needle Thread Strike-off ................................................................

Screw .............................................................................................

Throat Plate, I. D. marked "ED8", for 29480BEB kit of parts ......................

Throat Plate, I. D. marked "EC9", for 29480BDY kit of parts .....................

Throat Plate, I. D. marked "EF8", for 29480BEC kit of parts .......................

Throat Plate, I. D. marked "ED9", for 29480BED kit of parts ......................

Throat Plate, I. D. marked "DZ8", for 29480BEA kit of parts ......................

Throat Plate, I. D. marked "DZ9", for 29480BDZ kit of parts ......................

Throat Plate, I. D. marked "EF9", for 29480BEH kit of parts .......................

Amt.

Req.

1

1

1

1

1

1

1

1

1

1

1

1

2

1

2

1

1

1

2

2

1

1

1

2

1

1

1

1

1

1

1

7

Page 8

Appearance of Standard vs. Soft

Double-locked Stitch

Standard Double-locked Stitch Soft Double-locked Stitch

NOTE:

THIS MANUAL IS USED FOR CHANGING THE

STANDARD PARTS TO SOFT DOUBLE-LOCKED

STITCH PARTS ON BOTH THE DIFFERENTIAL AND

PLAIN FEED 35800 MACHINES. THE STEPS ARE THE

SAME FOR BOTH MACHINE TYPES EXCEPT WHERE

NOTED.

8

Page 9

PROCEDURE FOR REMOVAL OF STANDARD STITCH PARTS

Step 1A. Remove screw for control lever

connecting link. Remove 2 screws

for front head cover, then remove

cover. Remove control lever

assembly and nipper plate

assembly.

Attach control lever assembly

and nipper plate assembly to

new cover supplied with kit.

Step 1A

Step 1B. Remove pressure regulating screw,

spring plate and upper and lower

leaf springs. Remove 9 screws for

chamber cover, then remove cover

and gasket. Remove 6 screws for

front top cover, then remove cover

and gasket. Remove 4 screws for

main frame end cover, then

remove cover and gasket.

Step 1B

9

Page 10

REMOVAL PROCEDURE, continued

Step 1C. Remove screw for plastic oil

reservoir, then remove reservoir.

Step 1C

Step 2

Step 3. Remove screw for stop shaft

washer, then remove washer.

Carefully slide looper drive

connection from end of

mainshaft.

Step 2. Remove 2 screws from cast off

plate, then remove plate. Loosen

but do not remove 2 screws for

take up cam.

10

Step 3

Page 11

NOTE: For differential feed machines, follow Steps 4A and 4B.

For plain feed machines, go to Step 5.

Step 4A. Loosen 2 cap screws for feed lift

eccentric assembly, and remove

top half of eccentric strap.

Note strap position when

removing—strap must be

reinstalled later in same

position to avoid binding.

Step 4A

Step 4B

Step 5. Loosen 2 screws in the double

feed eccentric assembly just

enough so eccentric will move

freely.

Step 4B. Loosen 2 screws in feed lift

eccentric and 2 screws in feed

drive eccentric just enough so that

eccentrics will turn freely on shaft.

11

Step 5

Page 12

REMOVAL PROCEDURE, continued

Step 6. Loosen 3 screws in mainshaft and

crankshaft coupling just enough

so that mainshaft will turn freely

inside of coupling.

Step 6

Step 7

Step 8. Lift presser foot and roller assembly ,

and remove standard throat plate.

Step 7. Pull mainshaft out from front of

machine only far enough so that

take up cam can be removed.

Remove take up cam.

12

Step 8

Page 13

PROCEDURE FOR INSTALLATION OF SOFT STITCH PARTS

Locate and identify new parts from kit.

Step 9. Install new throat plate and release

presser foot and roller assembly.

Step 9

Step 10

Step 11. Push mainshaft towards pulley

end of machine until timing spot

in the mainshaft aligns with spot

screw in coupling. T ighten spot

screw into spot of mainshaft and

then tighten remaining 2 screws.

Step 10. Locate new double disc take up

cam, and slide cam onto end of

mainshaft with collar side toward

the pulley end of the machine.

13

Step 11

Page 14

INSTALLATION PROCEDURE, continued

Note: For differential feed machines follow Steps 12A, 12B and 12C.

For plain feed machines follow Step 13.

Step 12A. Align spot screw in feed lift

eccentric with spot in mainshaft

and tighten spot screw, then

tighten remaining screw.

Step 12A

Step 12B

Step 12C. Locate top half of eccentric strap

which was removed previously.

Reassemble strap in same

position as it was prior to

removal, and tighten screws.

After assembly turn machine over

for several revolutions to make

certain machine does not bind. If

machine binds, check strap

position and repeat step 15.

Step 12B. Align spot screw in feed drive

eccentric with spot in mainshaft

and tighten spot screw, then tighten

remaining screw.

Step 12C

14

Page 15

Step 13. Align spot screw in double feed

eccentric assembly with spot in

mainshaft and tighten spot screw,

then tighten the remaining screw.

Step 13

Step 14

Step 15. A) Assemble new cast off plate

and eyelet from kit and tighten

with 2 screws.

B) Center double disc take up so

that cast-off plate is centered

between the take up discs.

Step 14. Reassemble looper drive to end of

mainshaft, replace washer and

tighten in place with screw.

15

Step 15

Page 16

INSTALLATION PROCEDURE, continued

Step 16. A.) Assemble new front head

cover and gasket to machine with

its 2 screws.

B) Attach connecting link to lever

with its screw.

Step 16

Step 17A. With needle bar at top of stroke,

position new needle thread take-up

so that notch in take-up fits over

needle thread eyelet.

Step 17A

16

Page 17

Step 17B. Rotate take-up clockwise, lower

it into position over control lever,

and attach to cover with its two

screws.

Step 17B

Step 18. Position new needle thread take-up

vertically so bottom of take-up

surface is even with top of cover

screw.

Thread machine so that one needle

thread passes through each hole

in needle lever thread eyelet.*

Needle thread strike-off

is set so it just touches needle

threads at bottom of needle stroke.

Step 18

*Same as standard threading.

17

Page 18

INSTALLATION PROCEDURE, continued

Step 19A. Reassemble plastic oil reservoir

with its screw.

Step 19A

Step 19B

Step 19C. Remove Looper thread guide

wire and slide spring from kit

over the wire and then replace

guide wire on machine.

Step 19B. Reassemble chamber cover, top

cover, main frame end cover and

presser foot tension springs.

18

Step 19C

Page 19

Step 20

Step 20 Set both looper thread pull-off

eyelets maximum to the right.

Set double disc take-up cam so that

looper thread casts off from high

point of cam when tips of

the needles on down stroke are

between bottom of throat plate

and top of loopers.

Thread one looper thread through

each hole in new eyelet from kit.

Step 21 Set needle thread tensions to

high, so that needle threads are

pulled up very tight against

material. Set looper thread

tensions to low, so that maximum

amount of looper thread is in the

material.

Step 21

19

Page 20

Loading...

Loading...