Page 1

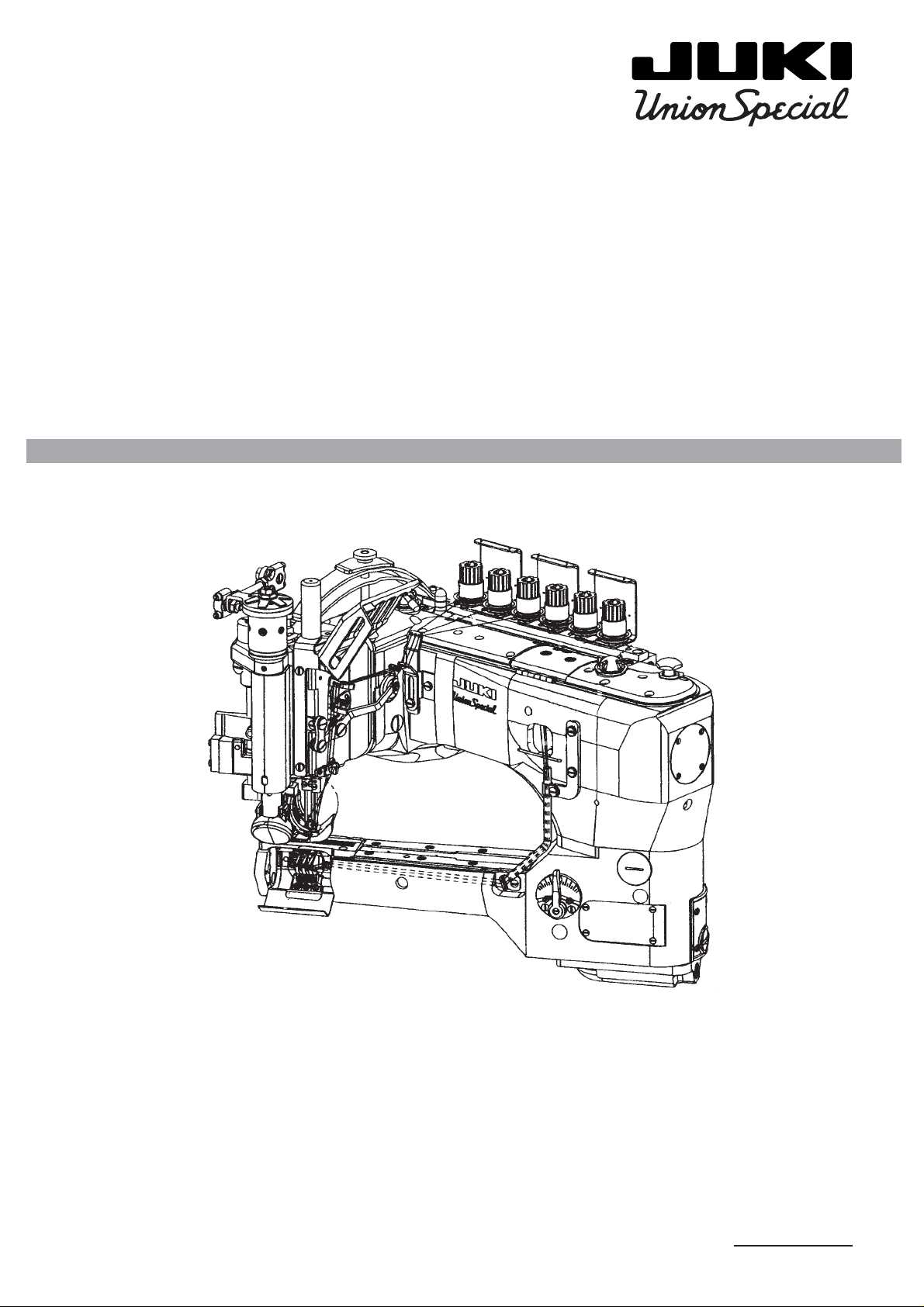

Feed-off-the arm, 3-Needle, Double Chainstitch Machine

35800 Series

ENGINEER’S MANUAL

®

40052737

No.E376-00

Page 2

Introduction

This Engineer’s Manual is written for the technical personnel who are responsible for the service and maintenance of the machine.

The maintenance services to be done on this sewing machine should be based on this manual.

This manual gives the "Standard Adjustment" on the former section under which the most basic adjustment

value is described and on the latter section the "Results of Improper Adjustment" under which stitching errors

and troubles arising from mechanical failures and "How To Adjust" are described.

Page 3

CONTENTS

1. Specifications ........................................................................................................ 1

(1) Roller mechanism/clutch type............................................................................................... 1

(2) Roller mechanism/belt type ...................................................................................................2

2. Model list ................................................................................................................ 3

(1) Model list using the roller mechanism of the clutch type................................................... 3

(2) Model list using the roller mechanism of the belt type....................................................... 3

3. Description of US model code.................................................................... 5

4. Description of model code .......................................................................... 6

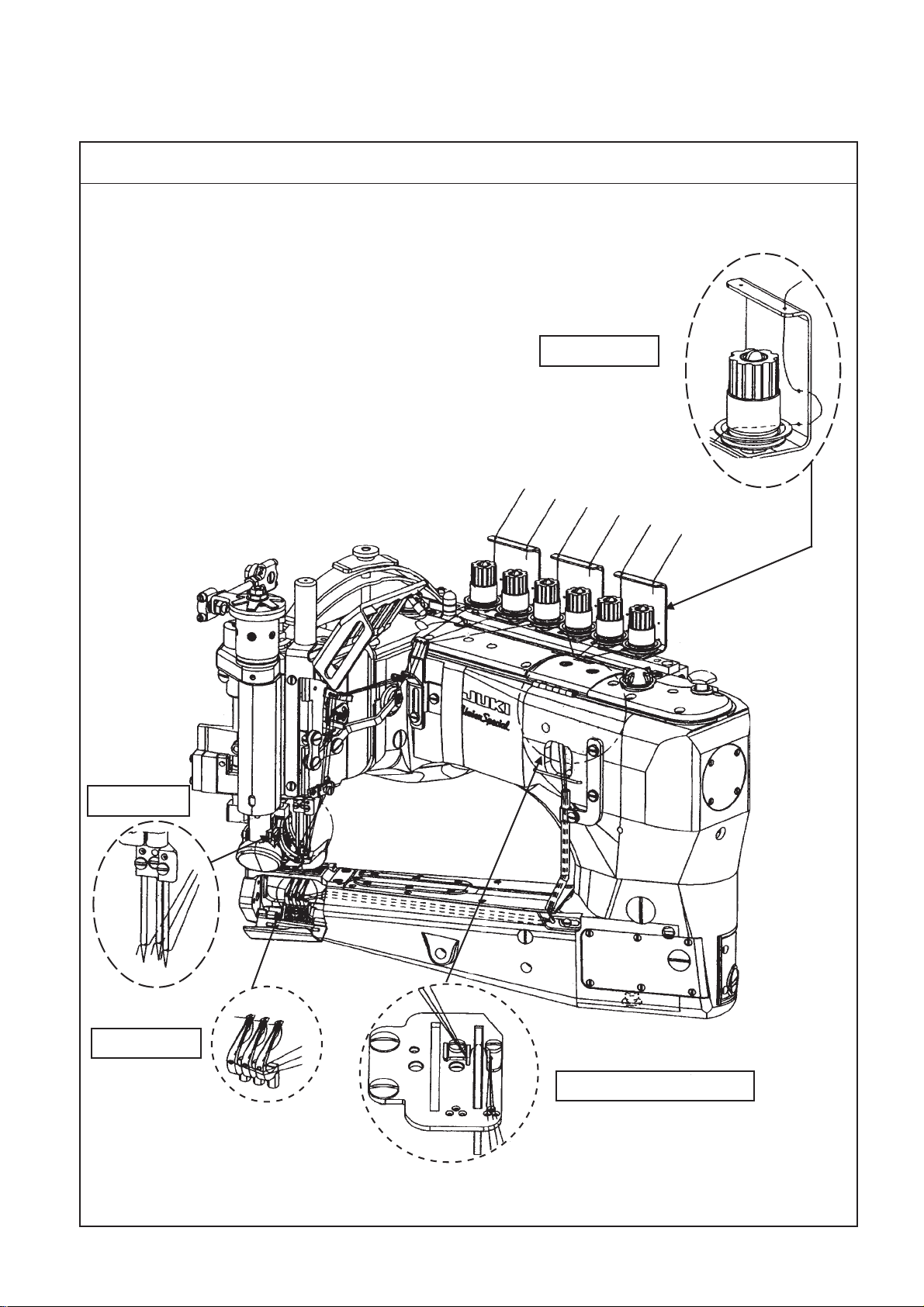

5. Names of machine head .............................................................................. 7

6. How to pass the threads.............................................................................. 8

(1) Differential feed....................................................................................................................... 8

(2) 1 piece feed ............................................................................................................................. 9

7. Standard adjustment ............................................................................................10

(1) How to remove the gauge components and upper feed roller......................................... 10

(differential feed mechanism and 1 piece feed mechanism)

(2) Timing between the looper and needle bar........................................................................ 12

(3) Adjustment of the needle entry positions in the right-left and front-rear directions ..... 14

(4) Looper adjustment ............................................................................................................... 16

1) Looper return .....................................................................................................................................16

2) Adjustment of the clearance between the looper and needle ............................................................16

(5) Adjustment of the needle bar height .................................................................................. 18

(6) Adjustment of the looper motion paths.............................................................................. 20

(7) Adjustment of rear needle guide......................................................................................... 22

1) Longitudinal adjustment of the rear needle guide ..............................................................................22

2) Height adjustment of rear needle guide .............................................................................................22

(8) Adjustment of feed dog height and longitudinal movement

(differential feed dog mechanism) ...................................................................................... 24

1) Height of main feed dog.....................................................................................................................24

2) Height of differential feed dog ............................................................................................................24

3) Adjustment of longitudinal movement of main feed dog ....................................................................24

4) Adjsutment of vertical height of main feed dog and differential feed dog ..........................................24

5) Gradient of main feed dog and differential feed dog......................................................................... 24

(9) Adjustment of feed dog height and longitudinal movement

(1 piece feed dog mechanism) ............................................................................................ 26

1) Height of main feed dog.....................................................................................................................26

2) Adjustment of longitudinal movement of main feed dog ....................................................................26

(10)Adjustment of feed mechanisms ........................................................................................ 28

1) Adjustment of stitch length.................................................................................................................28

2) Adjustment of differential feed amount ..............................................................................................28

(11)Presser adjustment .............................................................................................................. 30

1) Adjustment of amount of rise of presser ............................................................................................30

2) Adjustment of presser bar pressure...................................................................................................30

(12)Adjustment of upper feed roller .......................................................................................... 32

(13)Replacement of upper feed roller........................................................................................ 34

(14)Adjustment of drawing amount of upper feed roller ......................................................... 36

Page 4

(15)Adjustment of needle thread path....................................................................................... 38

1) Height of needle thread adjusting path ..............................................................................................38

2) Height of rocking take-up path ...........................................................................................................38

3) Height of needle thread guide adjuster ..............................................................................................38

(16) Adjustment of bobbin thread cam...................................................................................... 40

(17) Adjustment of tension disk rise.......................................................................................... 42

(18) Adjustment of air nozzle (air blow)..................................................................................... 44

(19) Adjustment of folder ............................................................................................................ 46

8. Lubrication ........................................................................................................... 48

9. Folder types .........................................................................................................

49

10. Maintenance ........................................................................................................ 50

(1) Spare parts ............................................................................................................................. 50

11. Part numbers and names of the modification parts for the

35800 Class – B8/B9 soft chain stitches (balloon stitches)............................ 52

Troubles and corrective measures........................................................... 53

12.

Page 5

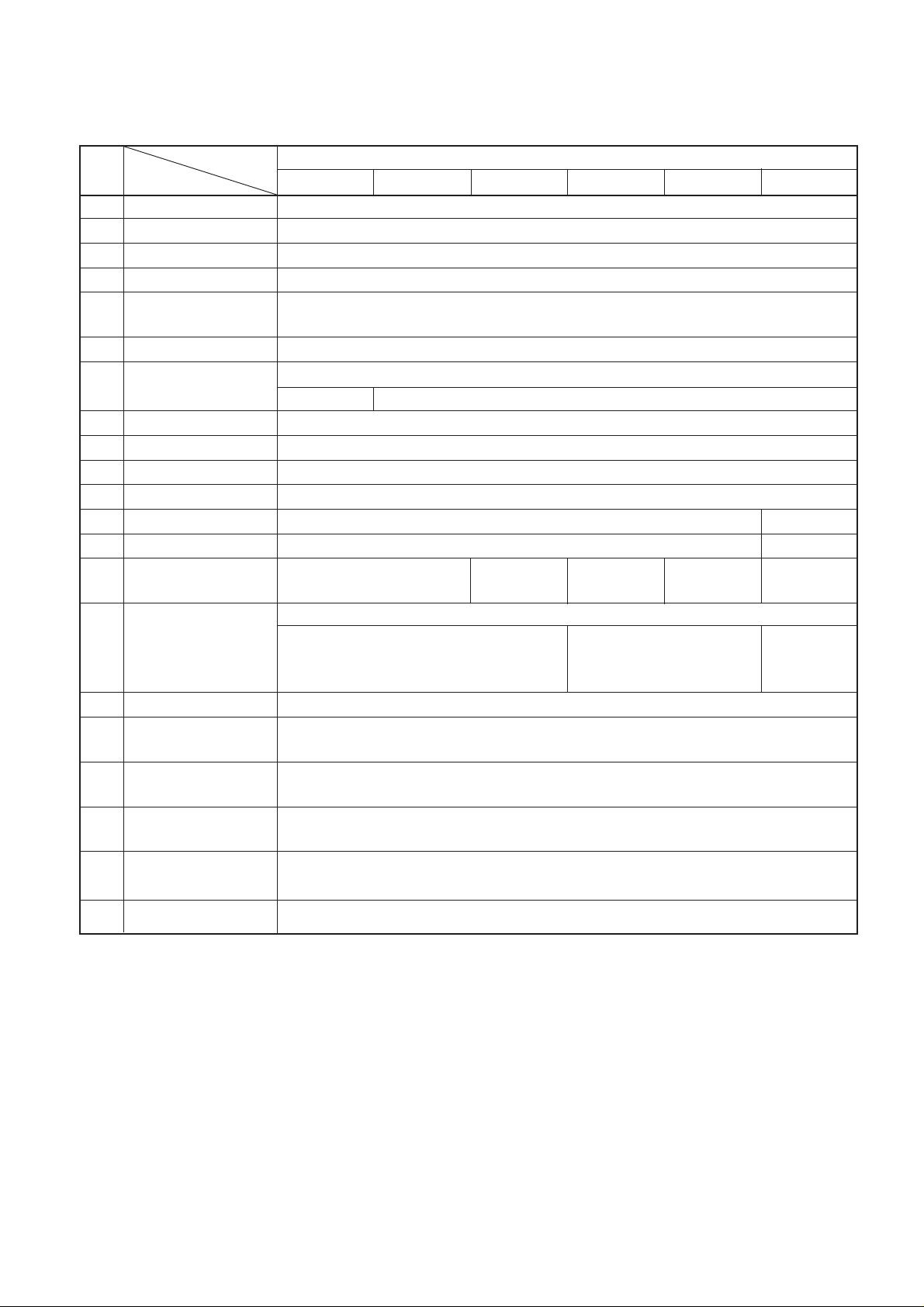

1. Specifications

(1) Roller mechanism/clutch type

No. Specifications

Item

1 Stitch type 3-needle, 6-thread, double chainstitch machine (401 LSc-3)

2 Application Denim, working clothes, felt, etc.

3 Max. sewing speed 4500 rpm

4 Sewing speed 3500 rpm

5 Needle gauge

6 Stitch length 2.1 to 3.6 mm (standard: 3.2 mm) at 1-inch intervals

7 Needle (standard size)

8 Needle bar stroke 33mm

9 Number of threads 6 pcs.

10 External dimensions H : 420 x W : 285 x D : 345 mm

11 Machine head weight 23.5 kg

12 Lifting amount of presser 9mm 10mm

13 Feed roller width 11.9mm 14.9mm

14 Feed roller shape

15 Feed adjustment

16 Lubrication Automatic rotary pump lubrication system

17 Lubricating oil

18 Oil tank capacity

19 Installation

Working temperature/

20 Temperature: 5 - 35°C, humidity: 35 - 85% (No dew condensation permissible)

humidity ranges

Model

35800DLU9 35800DNU8/9 35800DZ32/36 35800DRU8/9 35800PZ32/36 35800DWW8/9

8 gauge: 3.2 mm, total width: 6.4 mm

9 gauge: 3.6 mm, total width: 7.2 mm

UY130GS (standard) (Caution 1)

125 (#21) 140 (#24)

Standard Inverted Standard Inverted Standard

(narrow type) (narrow type) (narrow type) (narrow type) (wide type)

Main feed: Slide type stitch pitch adjusting system

Differential feed Differential feed

lever adjusting system 1 piece feed lever adjusting

system

Union Special Spec 175 (ISO grade 22) or

JUKI OIL SUP2000-1L

Front tank capacity: 70 to 80 ml

Rear tank capacity: 60 to 70 ml

Pedestal type

Table and auxiliary drive type

Supply voltage/frequency

21

Rated voltage ±10%, 50/60Hz

(Caution 1) Please be aware that many customers use the needle of UY128GLS with the needle size of 125

(No. 21) in Japan and check the needle number at shipment.

– 1 –

Page 6

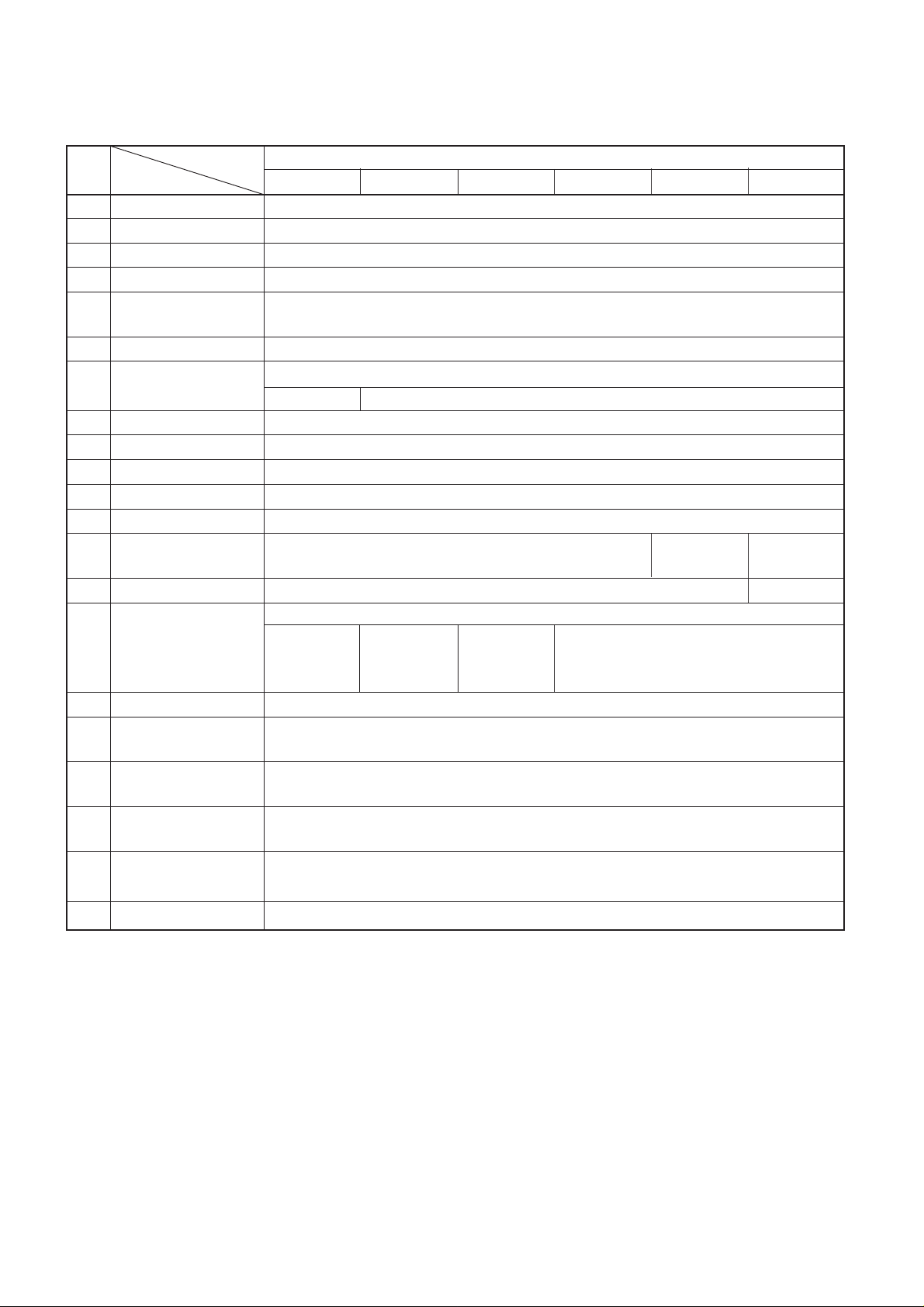

(2) Roller mechanism/belt type

No. Specifications

Item

1 Stitch type 3-needle, 6-thread, double chainstitch machine (401 LSc-3)

2 Application Denim, working clothes, felt, etc.

3 Max. sewing speed 4500rpm

4 Sewing speed 3500rpm

5 Needle gauge

6 Stitch length 2.1 to 3.6 mm (standard: 3.2 mm) at 1-inch intervals

7 Needle (standard size)

8 Needle bar stroke 33mm

9 Number of threads 6 pcs.

10 External dimensions H : 420 x W : 285 x D : 345 mm

11 Machine head weight 23.5kg

12 Feed roller width 14.9mm

13 Feed roller shape

14 Lifting amount of presser 9mm 10mm

15 Feed adjustment

16 Lubrication Automatic rotary pump lubrication system

17 Lubricating oil

18 Oil tank capacity

19 Installation

Working temperature/

20 Temperature: 5 - 35°C, humidity: 35 - 85% (No dew condensation permissible)

humidity ranges

Model

35800BLW9 35800BQW8/9 35800BWDN8/935800BWDR8/9 35800BRWH9 35800BWW8/9

8 gauge: 3.2 mm, total width: 6.4 mm

9 gauge: 3.6 mm, total width: 7.2 mm

UY130GS (standard) (Caution 1)

125 (#21) 140 (#24)

Standard Rubber Standard

(wide type) (wide type) (wide type)

Main feed: Slide type stitch pitch adjusting system

Differential feed Differential feed

lever adjusting 1 piece feed lever adjusting 1 piece feed

system system

Union Special Spec 175 (ISO grade 22) or

JUKI OIL SUP2000-1L

Front tank capacity: 70 to 80 ml

Rear tank capacity: 60 to 70 ml

Pedestal type

Table and auxiliary drive type

Supply voltage/frequency

21

Rated voltage ±10%, 50/60Hz

(Caution 1) Please be aware that many customers use the needle of UY128GLS with the needle size of 125

(No. 21) in Japan and check the needle number at shipment.

– 2 –

Page 7

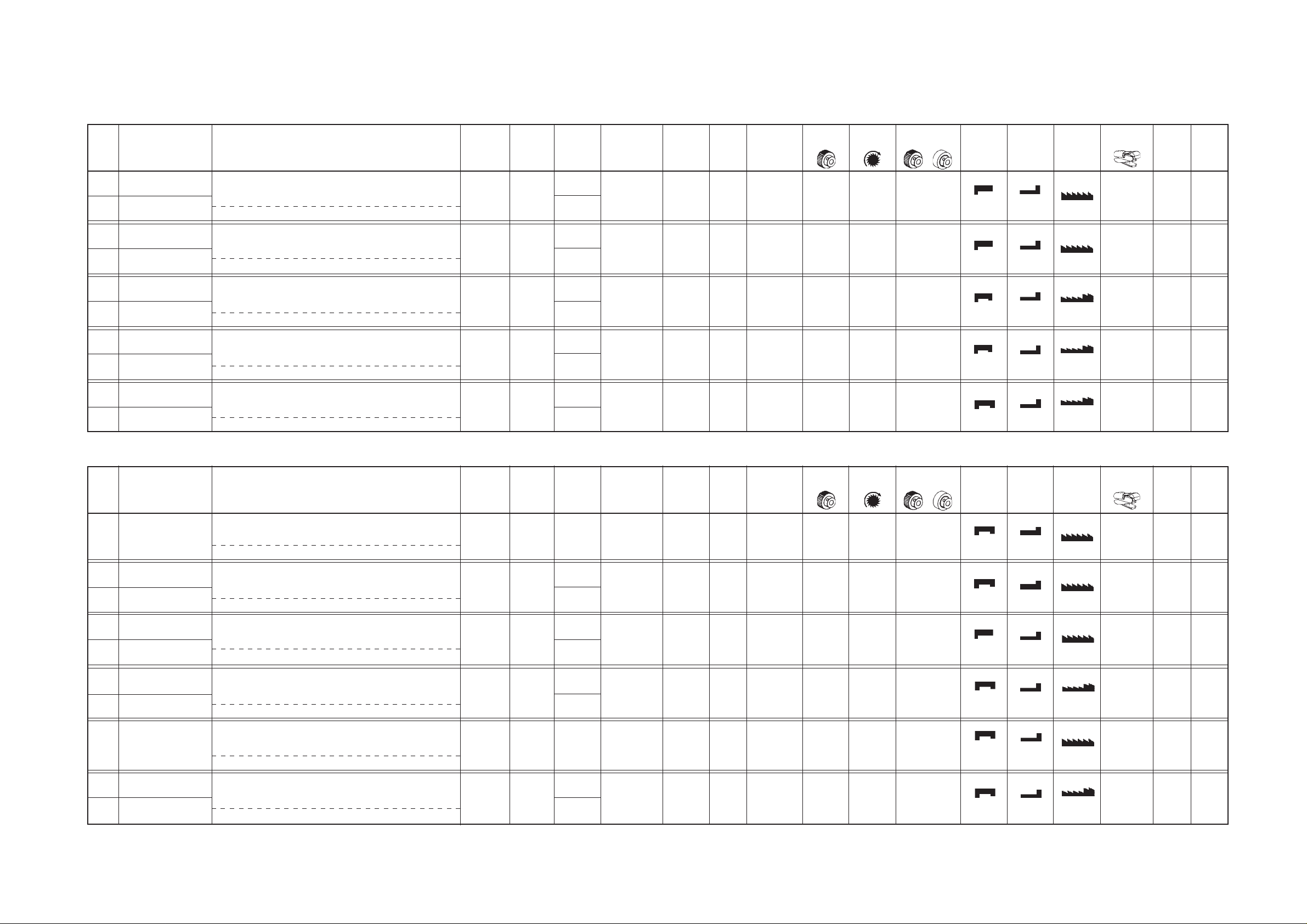

2. Model list

The standard model is the feed-off-the-arm 3-needle, double chainstitch machine for double lap seam

(1) Model list using the roller mechanism of the clutch type

No. Model Application

1 35800DNU8

Double lap seam, hip overlapped seam

(Denim fabric of 10 to 14 oz.)

2 35800DNU9

3 35800DZ32

For medium-weight to heavy-weight materials

Double lap seam, hip overlapped seam

(Denim fabric of 10 to 14 oz.)

4 35800DZ36

5 35800DRU8

For medium-weight to heavy-weight materials

Double lap seam

Denim (denim fabric of 10 to 14 oz.)

6 35800DRU9

7 35800PZ32

For medium-weight to heavy-weight materials

Double lap seam

Denim (denim fabric of 10 to 14 oz.)

8 35800PZ36

9 35800DWW8

For medium-weight to heavy-weight materials

Double lap seam/high throw feed eccentric mechanism

Denim (denim fabric of 15 to 14 oz.), felt, etc.

10 35800DWW9

For heavy-weight to extra-heavy-weight materials

Needle

Number of needles

3 pieces as

standard

Number of

threads

6 pieces as

standard

130GS

(140)

2-3

130GS

(140)

2-3

130GS

(140)

2-3

130GS

(140)

2-3

130GS

(140)

2-3

4-6

4-6

4-6

4-6

4-6

Needle gauge

8ga-3.2mm

9ga-3.6mm

3.2+3.2

6.4mm

3.6+3.6

7.2mm

3.2+3.2

6.4mm

3.6+3.6

7.2mm

3.2+3.2

6.4mm

3.6+3.6

7.2mm

3.2+3.2

6.4mm

3.6+3.6

7.2mm

3.2+3.2

6.4mm

3.6+3.6

7.2mm

Number of

stitches (mm)

8 stitches as

standard

2.1 to 3.6mm

(at 1-inch intervals)

7 to 12 stitches

2.1 to 3.6mm

(at 1-inch intervals)

7 to 12 stitches

2.1 to 3.6mm

(at 1-inch intervals)

7 to 12 stitches

2.1 to 3.6mm

(at 1-inch intervals)

7 to 12 stitches

2.1 to 3.6mm

(at 1-inch intervals)

7 to 12 stitches

Differential

motion

Yes

Yes

No

No

Yes

Lifting

amount

of

presser

9mm

9mm

9mm

9mm

10mm

Upper puller

drive

Clutch type

Clutch type

Clutch type

Clutch type

Clutch type

Roller width

11.9mm

11.9mm

11.9mm

11.9mm

14.9mm

Roller

shape

Standard

type narrow

roller

(35875AV)

Inverted

type narrow

roller

(35875AW)

Standard

type narrow

roller

(35875AV)

Inverted

type narrow

roller

(35875AW)

Standard

type wide

roller

(35826X)

Optional roller

Inverted type

narrow roller

(35875AW)

Rubber type narrow

roller (35826EF)

Standard type

narrow roller

(35875AV)

Rubber type narrow

roller (35826EF)

Inverted type

narrow roller

(35875AW)

Rubber type narrow

roller (35826EF)

Standard type

narrow roller

(35875AV)

Rubber type narrow

roller (35826EF)

Inverted type wide

roller (35826CB)

Rubber type wide

roller (35826DZ)

Presser

width

(front view)

Narrow

Narrow

Narrow

Narrow

Wide

Unevenness

of throat

plate

2.4mm

2.4mm

2.4mm

2.4mm

2.4mm

Feed shape

(side view)

0.8 mm of

unevenness

0.8 mm of

unevenness

0.8 mm of

unevenness

Standard

type folder

23420

AY18-1/8

23420

AY18-1/8

23420

AY18-1/8

23420

AY18-1/8

23420

AY18-1/8

Sewing

speed

(rpm)

3500

3500

3500

3500

3500

Max.

sewing

speed

(rpm)

4500

4500

4500

4500

4500

(2) Model list using the roller mechanism of the belt type

No. Model Application

Double lap seam, denim (denim fabric of 6 to 9 oz.),

1 35800BLW9

2 35800BQW8

3 35800BQW9

4 35800BWDN8

5 35800BWDN9

6 35800BWDR8

7 35800BWDR9

8 35800BRWH9

9 35800BWW8

10 35800BWW9

denim (denim fabric of 6 to 9 oz.), jacket, working clothes, etc.

Double lap seam/high throw feed eccentric mechanism

working clothes, working pants, etc

For light-weight to medium-weight materials

Double lap seam,

For light-weight to medium-weight materials

Double lap seam,

denim (denim fabric of 10 to 14 oz.)

For medium-weight to heavy-weight materials

Double lap seam,

denim (denim fabric of 10 to 14 oz.)

For medium-weight to heavy-weight materials

Double lap seam,

(denim fabric of 10 to 14 oz.)

For medium-weight to heavy-weight materials

Denim (denim fabric of 15 to 14 oz.), felt, etc.

For heavy-weight to extra-heavy-weight materials

Needle

Number of needles

3 pieces as

standard

Number of

threads

6 pieces as

standard

130GS

(125)

2-3

130GS

(125)

2-3

130GS

(140)

2-3

130GS

(140)

2-3

130GS

(140)

2-3

130GS

(140)

2-3

4-6

4-6

4-6

4-6

4-6

4-6

Needle gauge

8ga-3.2mm

9ga-3.6mm

3.6+3.6

7.2mm

3.2+3.2

6.4mm

3.6+3.6

7.2mm

3.2+3.2

6.4mm

3.6+3.6

7.2mm

3.2+3.2

6.4mm

3.6+3.6

7.2mm

3.6+3.6

7.2mm

3.2+3.2

6.4mm

3.6+3.6

7.2mm

Number of

stitches (mm)

8 stitches as

standard

2.1 to 3.6mm

(at 1-inch intervals)

7 to 12 stitches

2.1 to 3.6mm

(at 1-inch intervals)

7 to 12 stitches

2.1 to 3.6mm

(at 1-inch intervals)

7 to 12 stitches

2.1 to 3.6mm

(at 1-inch intervals)

7 to 12 stitches

2.1 to 3.6mm

(at 1-inch intervals)

7 to 12 stitches

2.1 to 3.6mm

(at 1-inch intervals)

7 to 12 stitches

Differential

motion

Yes

No

Yes

No

No

No

Lifting

amount

of

presser

9mm

9mm

9mm

9mm

9mm

10mm

Upper puller

drive

Belt type

Belt type

Belt type

Belth type

Belt type

Belt type

Roller width

14.9mm

14.9mm

14.9mm

14.9mm

14.9mm

14.9mm

Roller

shape

Standard

type narrow

roller

(35826X)

Standard

type narrow

roller

(35826X)

Standard

type narrow

roller

(35826X)

Inverted

type narrow

roller

(35875AW)

Standard

type wide

roller

(35826X)

Standard

type narrow

roller

(35826X)

Optional roller

Inverted type wide

roller (35826CB)

Rubber type wide

roller (35826DZ)

Inverted type wide

roller (35826CB)

Rubber type wide

roller (35826DZ)

Inverted type wide

roller (35826CB)

Rubber type wide

roller (35826DZ)

Inverted type wide

roller (35826CB)

Rubber type wide

roller (35826DZ)

Standard type

wide roller

(35826X)

Rubber type wide

roller (35826CB)

Inverted type wide

roller (35826CB)

Rubber type wide

roller (35826DZ)

Presser

width

(front view)

Wide

Wide

Wide

Wide

Wide

Wide

Unevenness

of throat

plate

1.0mm

1.0mm

2.4mm

2.4mm

2.4mm

2.4mm

Feed shape

(side view)

0.8 mm of

unevenness

0.8 mm of

unevenness

Standard

type folder

23420

AY18-1/8

23420

AY18-1/8

23420

AY18-1/8

23420

AY18-1/8

23420

AY18-1/8

234-20

AY18-1/8

Sewing

speed

(rpm)

3500

3500

3500

3500

3500

3500

Max.

sewing

speed

(rpm)

4500

4500

4500

4500

4500

4500

* In regard to the JUKI part numbers, refer to [10. Maintenance-(1) Spare parts.]

– 3 –

Page 8

MEMO

– 4 –

Page 9

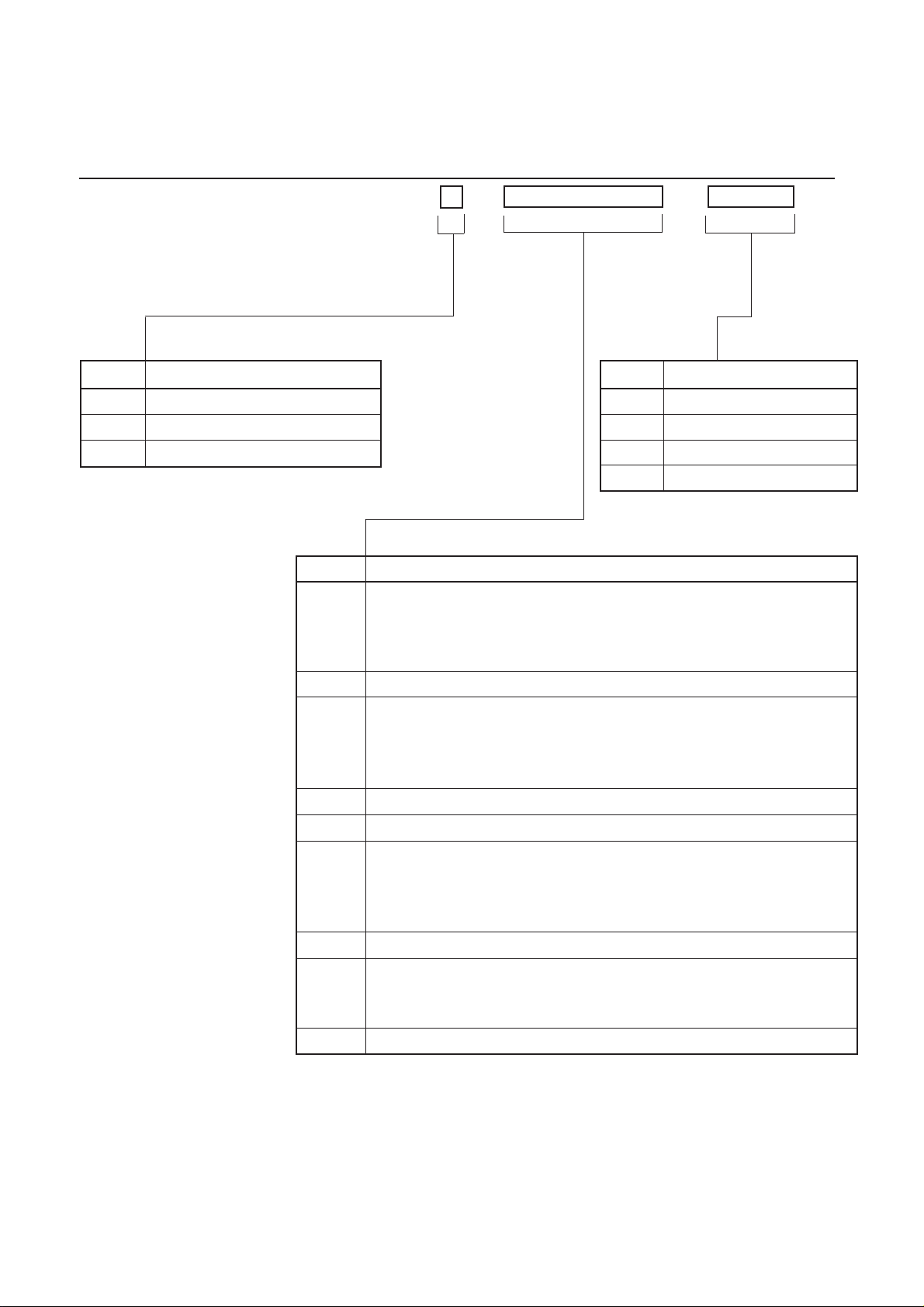

3. Description of US model code

Model name: Feed-off-the-arm, 3-Needle, Double Chainstitch Machine

123 4567891011

358 00

Code Puller drive

B Belt type

D Clutch type (mechanical type)

P Same as "D", only for PZ

Code Application and outline

LW

QW Same as above, but 1 piece feed mechanism

WDN

WDR Same as above, but 1 piece feed mechanism

RWH Same as WDN, but rubber type wide roller equipped

NU

RU Same as above, but 1 piece feed mechanism

WW

Code

32 3.2mm

36 3.6mm

Differential feed mechanism/Double lap seam/For light- and mediumweight materials (denim fabric of 6 to 9 oz.)/1 mm of throat plate unevenness/Standard type wide roller equipped/Denim, jacket, working

clothes, etc.

Differential feed mechanism/Double lap seam/For medium- and heavyweight materials (denim fabric of 10 – 14 oz.)/2.4 mm of throat plate

unevenness/Standard type wide roller equipped/Denim, jacket, working clothes, etc.

Differential feed mechanism/Double lap seam/For medium- and heavyweight materials (denim fabric of 10 – 14 oz.)/2.4 mm of throat plate

unevenness/Standard type narrow roller equipped/Denim, jacket, working clothes, etc.

Differential feed mechanism/Double lap seam/For heavy-weight materials (denim fabric of 15 – 16 oz.)/2.4 mm of throat plate unevenness/Standard type wide roller equipped/Denim, felt, etc.

Z Same as DNU and DRU, but inverted type narrow roller equipped

Classification of needle gauge

8 3.2mm

9 3.6mm

– 5 –

Page 10

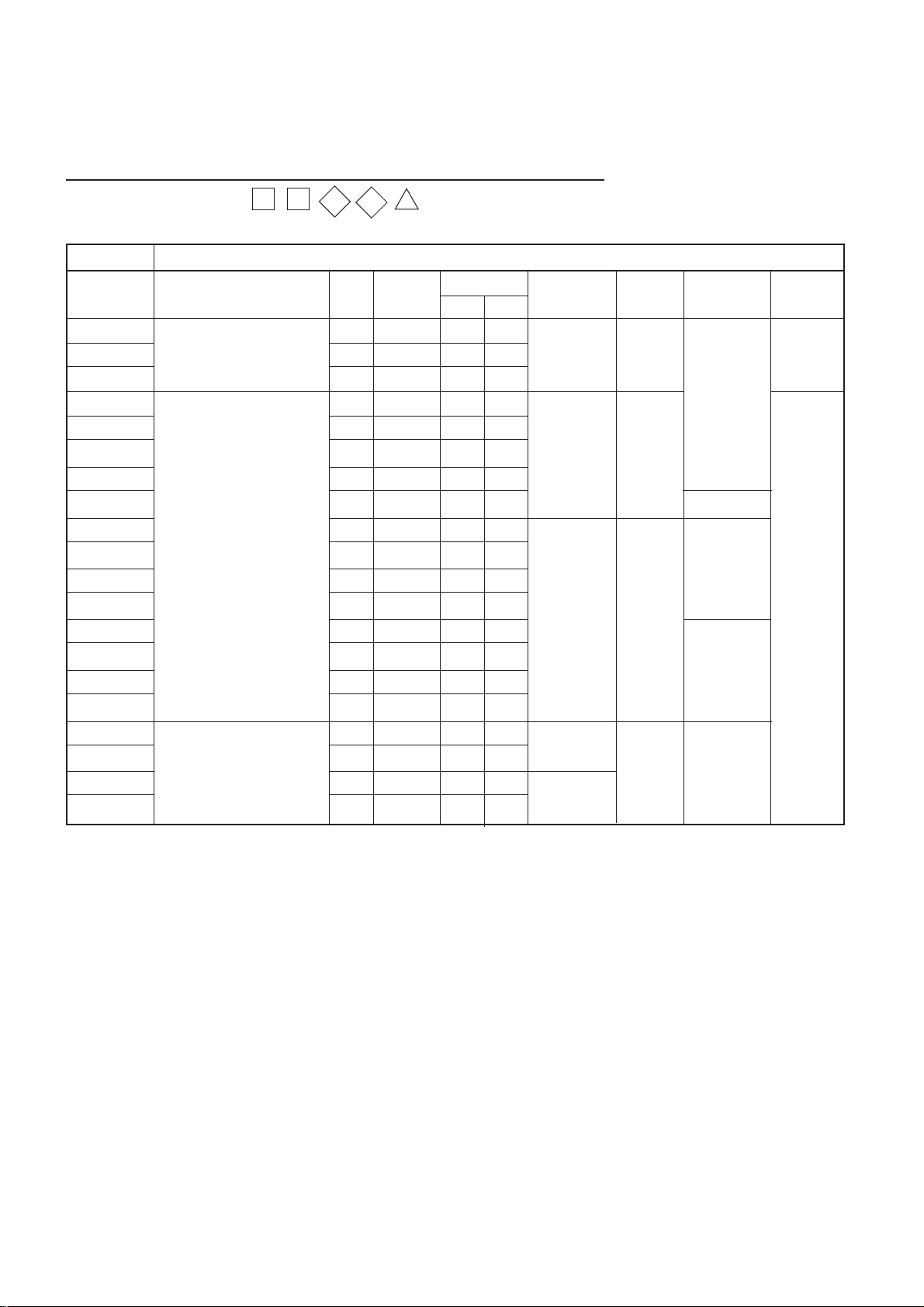

4. Description of model code

Machine name: Feed-off-the-arm, 3-needle, double chainstitch machine

123456789101112131415

35800 –AA

6 to 10 Name

Sewing material Puller drive Roller width Roller shape

BLW 9 3 3.6mm ●

BQW 8 3 3.2mm ● Belt type 14.9mm 1.0mm

BQW 9 3 3.6mm ●

BWDN 8 3 3.2mm ● Steel gear

BWDN 9 3 3.6mm ●

BWDR 8 3 3.2mm ● Belt type 14.9mm

BWDR 9 3 3.6mm ●

BRWH 9 3 3.6mm ● Rubber roller

DNU 8 3 3.2mm ●

DNU 9 3 3.6mm ●

DRU 8 3 3.2mm ●

DRU 9 3 3.6mm ●

DZ 32 3 3.2mm ●

DZ 36 3 3.6mm ●

PZ 32 3 3.2mm ●

PZ 36 3 3.6mm ●

BWW 8 3 3.2mm ●

BWW 9 3 3.6mm ●

DWW 8 3 3.2mm ●

DWW 9 3 3.6mm ●

For light- and medium-

weight materials (6 to 9 oz.),

denim, working clothes,

pants, etc.

For medium- and heavy-

weight materials (10 to 14

oz.), denim, etc.

For extra-heavy-weight

(15 to 16 oz.), denim, felt,

etc.

Stitch

count

Needle

gauge

Differential motion

Yes No

Clutch type

Belt type

Clutch type

11.9mm

14.9mm

Unevenness

of throat plate

Steel gear

2.4mm

Steel gear

(inverted)

Steel gear

– 6 –

Page 11

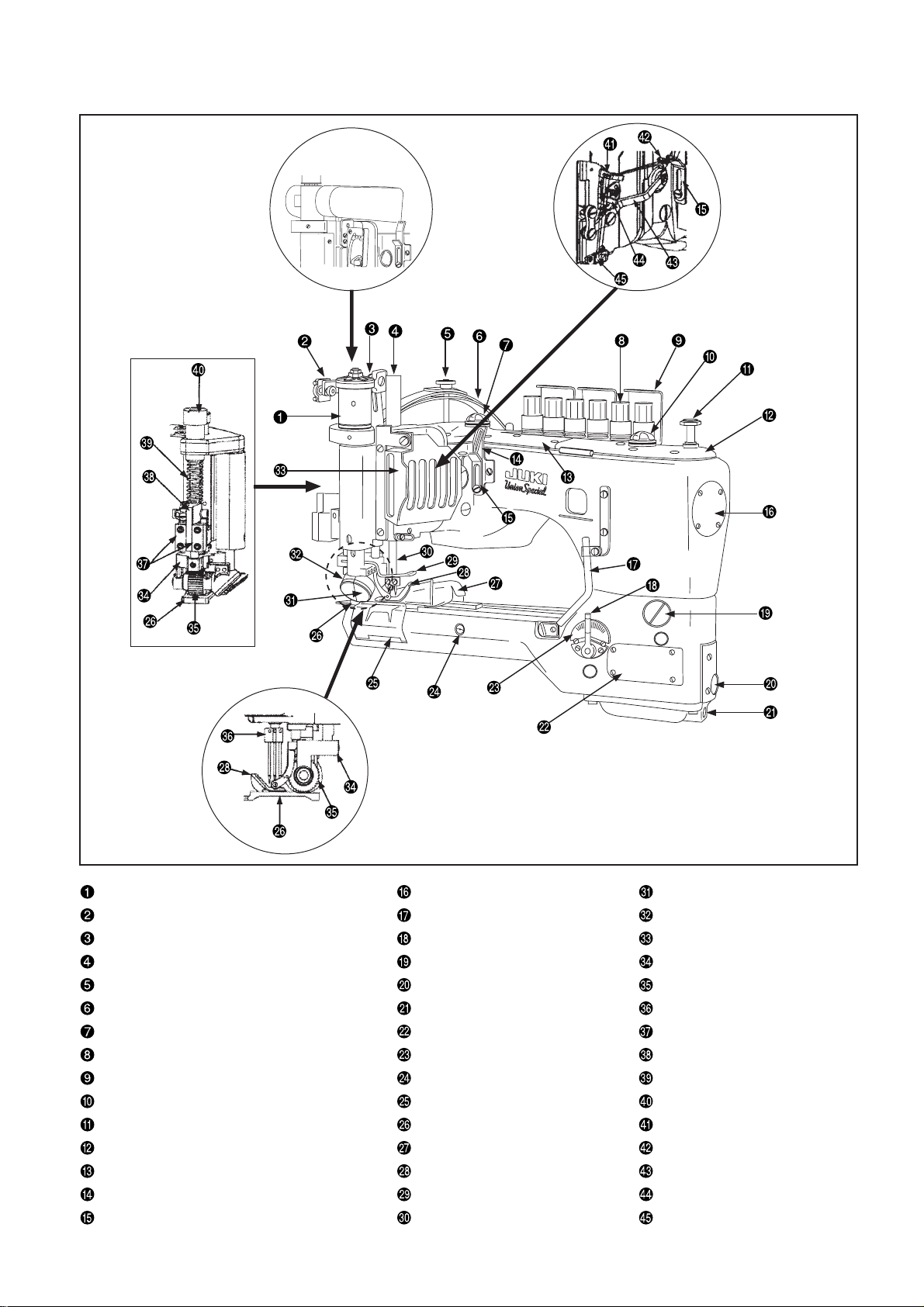

5. Names of machine head

Belt drive upper

feed roller

Clutch drive upper feed roller End cover Gear cover (front)

Clutch rod Bobbin thread guide pipe Gear cover (rear)

Clutch lever Differential regulation lever Swing guard

Cover for needle bar and roller

Pressure regulating nut Oil gauge (front) Upper feed roller

Pressure regulating plate spring assembly Oil discharge screw (front) Needle clamp

Oil circulation inspection window (rear) Cylinder side cover Right and left guide plates

Thread tension knob Gauge plate Guide finger

Thread guide Feed rocking lever eccentric pin

Oil circulation inspection window (front) Looper cover

Looper push button Throat plate

Front top cover Three folding device Rocking balance thread guide

Rear top cover Presser Needle thread rocking balance

Needle thread guide path

Needle thread adjusting path Needle bar Needle thread small tensioner

Window screw for stitch length adjustment

Needle guard & needle cooling pipe

Upper feed roller assembly

Roller pressure regulating spring

Roller pressure regulating screw

Needle thread lever-thread guide

Needle thread support adjuster

– 7 –

Page 12

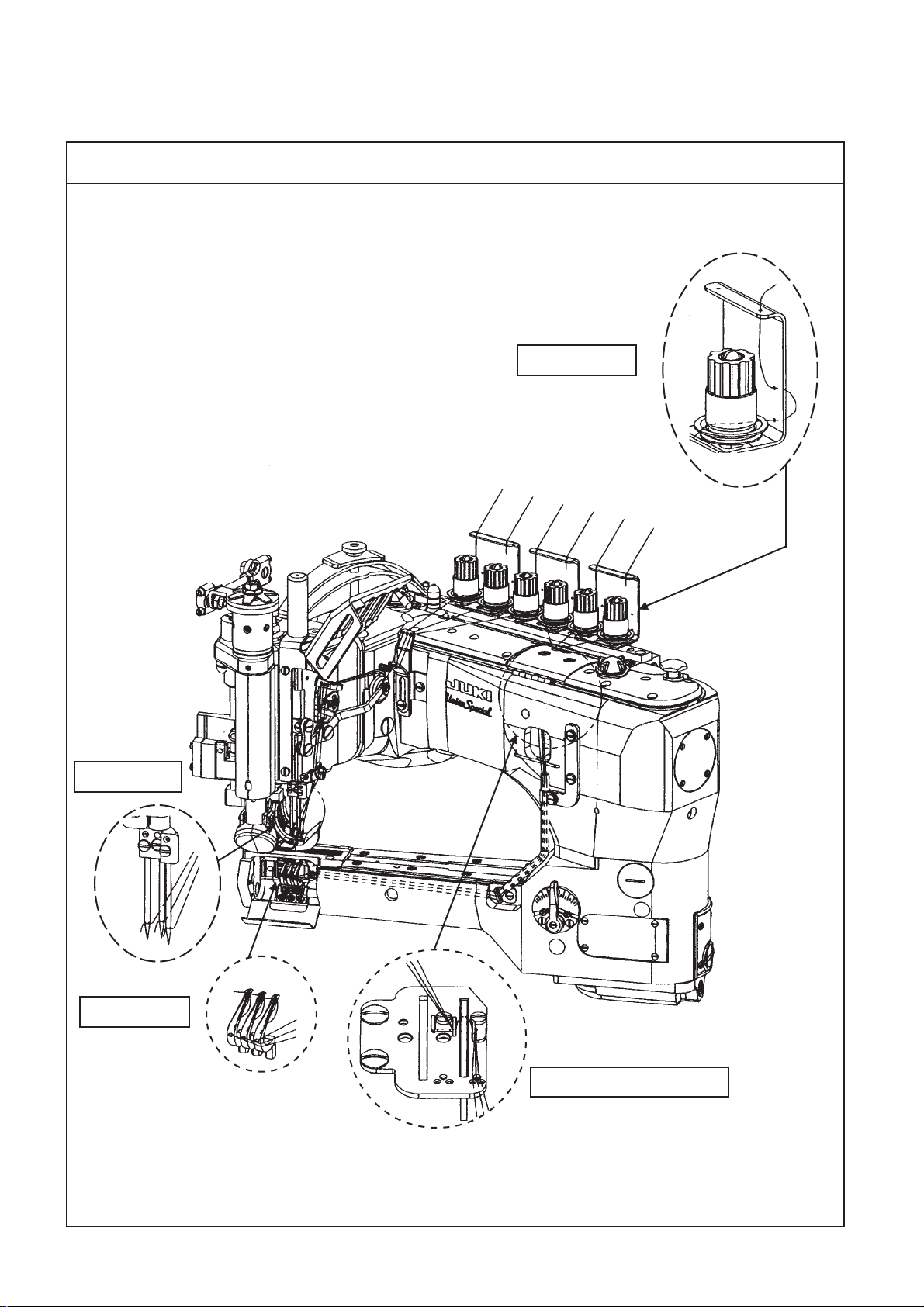

6. How to pass the threads

(1) Differential feed

How to pass the needle threads and looper threads

1. Drawing of differential feed threading (sample model: 35800DNU & BWDN)

Needle thread: 1 for left needle thread, 2 for middle needle thread, 3 for right needle thread

Looper: 4 for front looper, 5 for middle looper, 6 for rear looper

Follow the drawing below to pass the threads.

Tension section

[Model: 35800DNU]

Needle section

1

2

3

4

5

6

3

2

1

Looper section

5

4

6

Looper thread cam section

– 8 –

Page 13

(2) 1 piece feed

How to pass the needle threads and looper threads

1. Drawing of 1 piece feed threading (sample model: 35800DRU & BWDR)

Needle thread: 1 for left needle thread, 2 for middle needle thread, 3 for right needle

thread

Looper: 4 for front looper, 5 for middle looper, 6 for rear looper

Follow the drawing below to pass the threads.

Tension section

[Model: 35800DRU]

Needle section

1

2

3

4

5

6

3

2

1

Looper section

5

4

6

Looper thread cam section

– 9 –

Page 14

7. Standard adjustment

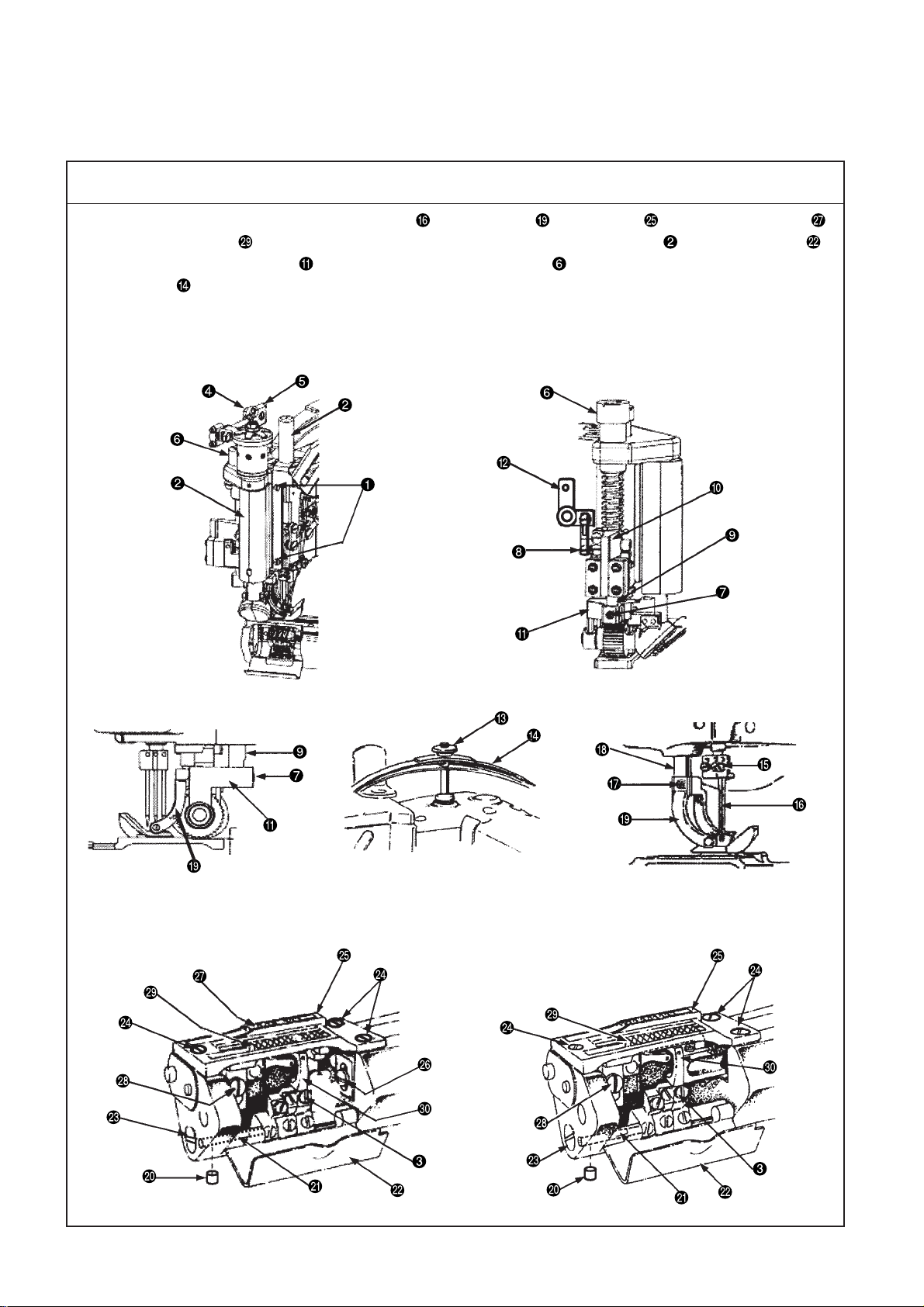

(1) How to remove the gauge components and upper feed roller (differential feed

mechanism and 1 piece feed mechanism)

Disassembly procedure

1. Remove the gauge, its related parts (needle , presser yoke , throat plate , differential feed dog ,

and main feed dog ), the cover, its related parts (cover for needle bar and roller and looper cover ),

upper feed roller assembly , roller pressure regulating screw , and pressure regulating plate spring

assembly before adjustment.

(Caution) The directions of front, rear, right, and left during standard adjustment are based on the operator

working position. Therefore, the forward rotation of the pulley is counterclockwise.

Left side of the machine head

Right side of the machine head

Rear side of the machine head

Pressure regulating plate spring

and its related parts

Left side of the machine head

Gauge and its related parts

(Differential feed mechanism)

Gauge and its related parts

(1 piece feed mechanism)

– 10 –

Page 15

Disassembly procedure

Removal procedure of the gauge and upper feed roller

1. Loosen the setscrew and remove the needle bar and the roller cover together with the face cover and

the packing, which are attached to the rear side.

2. Loosen the nut with a 3/8” spanner and remove the washer and clutch rod .

3. Remove the roller pressure regulating screw .

4. Loosen the setscrew securing the upper feed roller shaft with a 3/32" key wrench, remove the setscrew

securing the link, lift the upper feed roller shaft and the guide finger , and remove the upper feed

roller assembly .

(Caution) When the upper feed roller shaft is lifted, the guide finger interferes with the lift lever

crank . Therefore, remove the upper feed roller assembly after lifting the lift lever crank

slightly.

5. Loosen the pressure regulating nut and remove the pressure regulating plate spring assembly .

6. Loosen each setscrew that securing corresponding needles and remove three of each needle .

7. Loosen the setscrew securing the presser yoke with a 5/64" or 2mm key wrench and remove the

presser yoke after lifting the presser shaft .

8. Loosen the setscrew with a 3/32" key wrench and remove the setscrew securing the cover.

Removal of the setscrew allows you to remove the looper cover and spring stud .

9. Loosen three setscrews securing the throat plate and remove the throat plate .

10. Loosen the setscrew and remove the differential feed dog .

11. Loosen the setscrew and remove the main feed dog .

12. Loosen the setscrews securing the loopers and remove the loopers .

(Caution) The disassembly procedure mentioned above mainly describes about the differential feed

mechanism.

As to the 1 piece feed mechanism, the differential feed dog and setscrew are not

provided.

– 11 –

Page 16

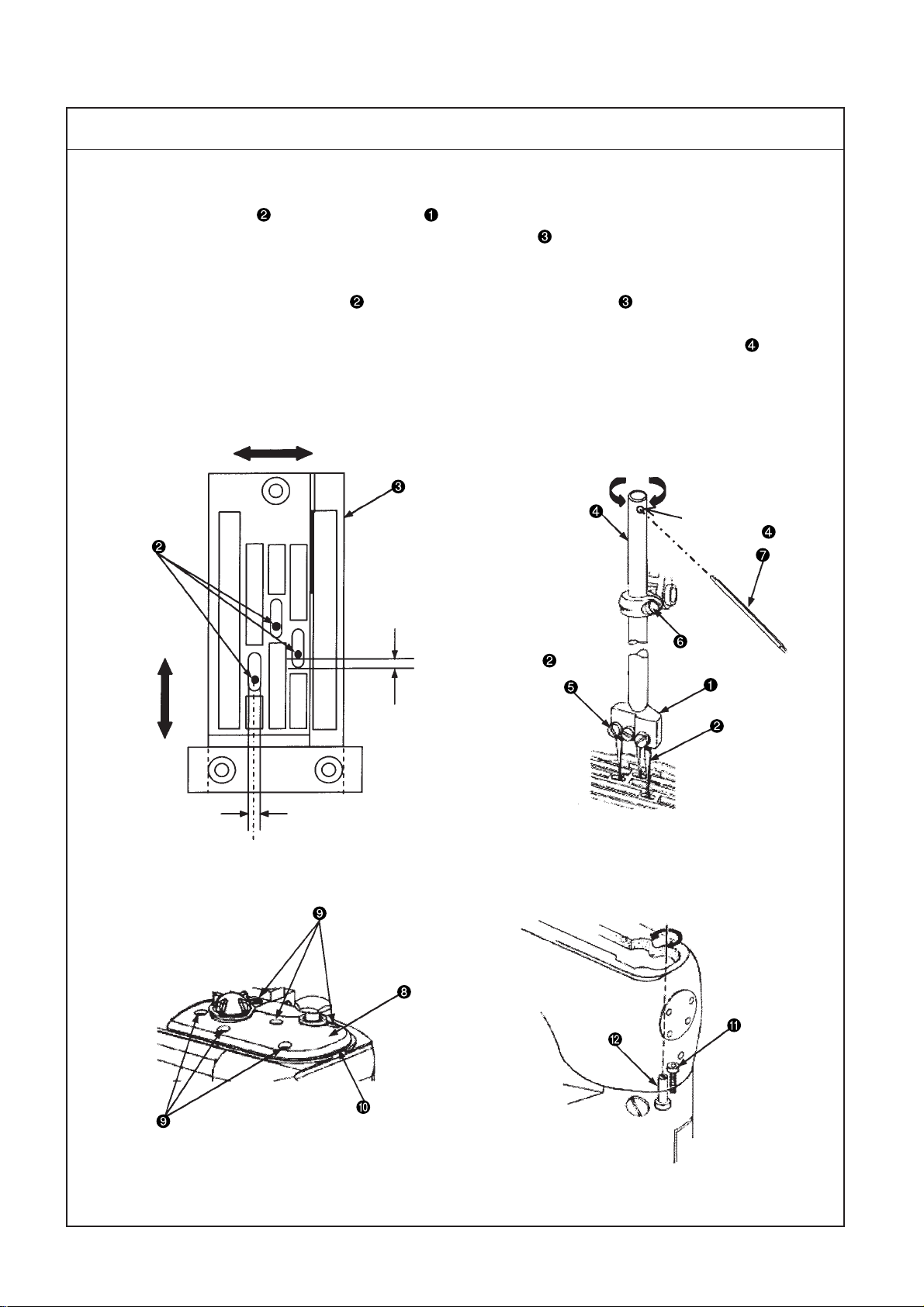

(2) Timing between the looper and needle bar

Standard Adjustment

1. Timing between the looper and needle bar (synchronization)

Gauging equipment is mounted to perform synchronization adjustment.

The reference state is that there is no clearance between the bottom surface of the lower needle bar bushing

and the top surface of the timing gauge when the steel rod touches the throat plate by rotating

the pulley in the forward and backward directions. (Be sure to rotate the pulley in both directions to check the

clearance.) The allowable clearance range is from 0 to 0.1 mm.

(Caution) The allowable clearance between the steel rod and the throat plate ranges from 0 to 0.1

mm when the bottom surface of the lower needle bar bushing touches the top surface of

the timing gauge ahead of the other touch by rotating the pulley in both directions.

Right-left direction

Clearance at rotation in both

directions: 0 to 0.1 mm

19mm

Touch between the steel rod

and throad plate

Match mark

Clockwise-counterclockwise

direction

– 12 –

Page 17

Adjustment Procedures Results of Improper Adjustment

1. How to install and use the synchronization adjustment gauge

(1) Put the steel rod in the front looper base and tighten the

setscrew .

(Caution) Use a key wrench (3 mm) instead of the steel rod if

necessary.

(2) Loosen the setscrew slightly and move the front looper base

with the steel rod integrated to the most left position.

(3) Install the throat plate and tighten the setscrew .

(4) Rotate the pulley to move the steel rod to the most left position,

set the clearance between the right surface of the steel rod and the

left surface of the throat plate to 19 mm, and tighten the setscrew

securing the front looper base .

(5) Rotate the pulley counterclockwise and stop it when the steel rod

touches the left surface of the throat plate .

(6) Mount the timing gauge to the needle bar . Be sure to mount

the timing gauge so that the top surface of the timing gauge

touches the bottom surface of the lower needle bar bushing .

(Caution) Use a clip instead of the timing gauge if necessary.

(7) When the pulley is rotated clockwise, the steel rod moves from

side to side.

Touch the steel rod with the left surface of the throat plate again.At

this moment, make sure that the clearance between the bottom

surface of the lower needle bar bushing and the top surface of

the timing gauge is within the allowable range.

(Caution) The bottom surface of the lower needle bar bushing

may touch the top surface of the timing gauge ahead

of the other touch. In such a case, make sure that the

clearance between the steel rod and the throat plate

is within the allowable range.

(8) If the timing between the looper (steel rod ) and the needle bar

is inappropriate, follow the procedure below.

oImproper synchronization position

adjustment may cause stitch

skipping or thread breakage.

2. Corrective points and corrective measures

(1) For adjusting the timing between the looper (steel rod ) and the

needle bar , loosen 9 setscrews securing the rear top cover

and remove the rear top cover and the packing.

(2) Loosen 3 fixing nuts securing the front and rear main shaft

couplings ( and ) and engage a key wrench (3/32") with the

setscrew to move the front main shaft coupling in the clockwise-

counterclockwise direction for adjustment while keeping the rear

main shaft coupling unmoved. (For the fixing nut , use a 1/4"

spanner.)

(Caution) 1. Align the match marks.

2. For moving the front main shaft coupling ,

temporarily tighten one of the fixing nuts , which

is close to the match mark, and make an adjustment.

oTo increase the clearance between the steel rod and throat plate

, rotate the front main shaft coupling clockwise.

oTo decrease the clearance between the steel rod and throat plate

, rotate the front main shaft coupling counterclockwise.

(3) After adjustment, put the rear top cover and packing back on

and tighten the setscrew .

– 13 –

Page 18

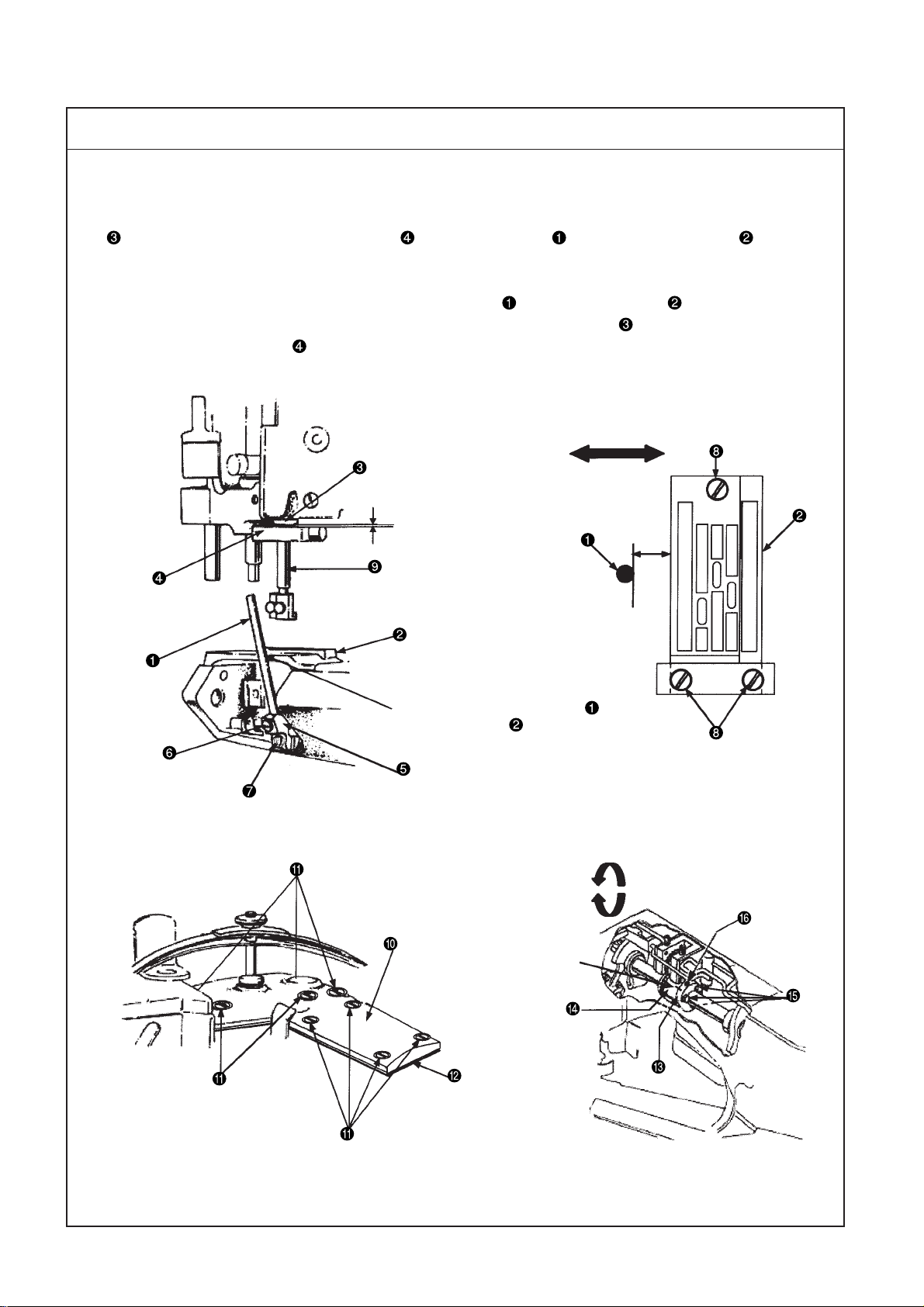

(3) Adjustment of the needle entry positions in the right-left and front-rear directions

Standard Adjustment

1. Needle entry

1) Needle entry position in the right-left direction

Mount 3 needles to the needle clamp . The standard needle entry position "A" in the right-left

direction is the center of the needle hole of the throat plate .

2) Needle entry position in the front-rear direction

The standard needle entry position in the front-rear direction is decided under the condition that the

clearance between the needle and needle hole of the throat plate , "B", is the same for all of 3

positions.

(Caution) Adjust the needle entry position in accordance with the temporary needle bar height of

12.5 mm.

Refer to "(5) Adjustment of the needle bar height".

Right-left direction

Clockwise-counterclockwise direction

Hole at the top of the

needle bar

Front-rear

direction

B

Same in 3 needles

A

Center

Clockwise-counterclockwise direction

– 14 –

Page 19

Adjustment Procedures Results of Improper Adjustment

1. Checking procedure of needle entry

(1) Mount 3 needles to the needle clamp and tighten the setscrew

.

(2) Loosen the needle bar holding screw , set the temporary needle

bar height (12.5 mm), and tighten the needle bar holding screw

{6} temporarily (approximately 4 turns of the needle bar ).

(3) Insert the torque rod into the hole at the top of the needle bar

and rotate the needle bar in the right-left direction to adjust the

needle entry position in the front-rear and right-left directions.

(Caution) 1. When the needle position is not in the center of

the needle hole of the throat plate in the right-left

direction, follow the procedure below.

2. For needle entry adjustment, mount the rear needle

guides temporarily and make sure that 3 needles

touch evenly.

2. Needle entry adjustment

(1) For adjusting the needle entry position in the right-left direction,

remove 6 setscrews securing the front top cover to remove

the front top cover and packing .

(2) Loosen the hexagon head bolt , engage a driver with the eccentric

pin , and rotate the driver in the right-left direction. Then, the

sylinder arm moves in the right-left direction.

(3) Adjust the needle entry position in the right-left direction.

o Rotation of the eccentric pin clockwise moves the cylinder arm

leftward.

o Rotation of the eccentric pin counterclockwise moves the cylinder

arm rightward.

(4) After adjustments, tighten the hexagon head bolt .

(5) After adjusting the needle entry position, put the front top cover

and packing back on and tighten the setscrew .

o Improper needle entry position

adjustment may cause stitch

skipping, needle breakage, or

thread breakage.

– 15 –

Page 20

(4) Looper adjustment

Standard Adjustment

1) Looper return

When each looper ( , , and ) is at the most left position, the standard distance from the tip of each

looper ( , , and ) to the center of each needle ( , , and ) is 3.6 mm (9/64").

1. Standardization of the front looper

When the front looper is at the most left position, measure the distance from the tip of the front looper

to the center of the left needle with the gauge and a scale and adjust the distance to the

standard value, i.e. 3.6 mm (9/64").

2. Standardization of middle and rear loopers

When the tips of the middle and rear loopers ( and ) are simultaneously aligned with each left

surface of the middle and right needles as well as the tip of the front looper with the left surface of the

left needle , the middle and rear loopers are in the standard positions.

(Caution) For the front looper , the looper return is adjusted with the gauge and a scale, and for

the middle and rear loopers ( and ), the looper return is adjusted by aligning the tips

of the middle and rear loopers ( and ) with the left surfaces of the needles ( and ),

respectively.

Alignment

Alignment

Front-rear direction

Right-left direction

3.6mm

9/64

2) Adjustment of the clearance between the looper and needle

When the tips of each looper ( , , and ) are at the center of each needle ( , , and ), the standard

clearance is 0.0mm (slight touch).

After adjusting the rear needle guide , make sure again that the clearance between the loopers ( , ,

and ) and the needles ( , , and ) is 0.0 mm respectively, and perform final adjustment of the clearance

after threading.

(Caution) If clearance adjustment is performed without the rear needle guide , a little strongly touch

the tips of the loopers ( , , and ) with the needles ( , , and ), respectively.

Center of needle

• •

• •

Front-rear direction

Clearance of

0.0 mm

(slight touch)

Looper tip

Clearance of 0.0 mm (slight touch)

– 16 –

Page 21

Adjustment Procedures Results of Improper Adjustment

1) Looper return

(1) Front looper

1. Loosen the setscrews to remove the throat plate .

2. Mount the front looper on the front looper base and tighten

the setscrew .

3. Rotate the pulley counterclockwise, move the front looper to

the most left position, and measure the clearance from the tip of

the front looper to the left needle with the looper gauge

or a scale.

4. For adjusting the clearance to the standard distance, loosen the

setscrew securing the front looper base to adjust the position

of the front looper base in the right-left direction.

5. After adjustment, tighten the setscrew to secure the front looper

base setscrew .

(2) Middle looper

1. Rotate the pulley counterclockwise and align the tip of the front

looper with the left surface of the left needle .

2. Mount the middle looper on the middle looper base and

tighten the setscrew .

3. Loosen the setscrew securing the middle looper base and

move the middle looper base in the right-left direction to align

the tip of the middle looper with the left surface of the right

needle .

4. After adjustment, tighten the setscrew to secure the middle

looper base.

(3) Rear looper

1. Rotate the pulley counterclockwise and align the tip of the front

looper with the left surface of the left needle .

2. Mount the rear looper on the rear looper base and tighten

the setscrew .

3. Loosen the setscrew securing the rear looper base and move

the rear looper base in the right-left direction to align the tip of

the rear looper with the left surface of the middle needle .

4. After adjustment, tighten the setscrew to secure the rear looper

base.

(Caution) When the positions of each looper base ( , , and )

are adjusted in the right-left direction, adjust the

clearances from the tips of the loopers ( , , and )

to the needles ( , , and ) as well.

o Insufficient or excessive looper

return may cause stitch skipping,

needle breakage, or thread

breakage.

2) Adjustment of the clearance between the looper and needle

1. Loosen the setscrews ( , , and ) securing the looper bases

to adjust the positions of the looper bases ( , , and ) in the

front-rear direction.

2. After adjustments, tighten the setscrews ( , , and ) to secure

the looper bases.

(Caution) When the clearances are adjusted, check the looper

return positions for each looper ( , , and ) in the

right-left direction because the looper bases ( , , and

) may move in the right-left direction.

– 17 –

o When each looper base ( , ,

and ) is moved leftward, each

tip of loopers ( , , and ) is

detached from each needle ( ,

, and ).

o When each looper base ( , ,

and ) is moved rightward, each

tip of loopers ( , , and )

touches each needle ( , , and

).

Page 22

(5) Adjusting the height of the needle bar

Standard Adjustment

1. Height of the needle bar

(1) Alignment between the bottom surface of the front looper and the top hole end of the left needle

When the pulley is rotated counterclockwise and the bottom surface of the front looper is aligned with

the top hole end of the left needle

distance from the tip of the front looper

(2) Alignment between the tip of the front looper and the left surface of the left needle

When the pulley is rotated counterclockwise and the tip of the front looper is aligned with the left

surface of the left needle , the standard needle bar height is achieved by adjusting the distance from

the bottom surface of the front looper to the top hole end of the left needle to 1.6 mm.

(Caution) For adjusting the needle bar height, select an easier-to-adjust one from either (1) or (2)

mentioned above.

(3) Checking of the middle and rear looper heights shall be also checking of each looper return.

(Caution) 1. Needle entry adjustment is performed in accordance with the temporary needle bar

height.

When the needle bar is at the upper dead point, the temporary clearance between the

top surface of the throat plate and the tips of the needles is 12.5 mm.

2. The needle bar height is temporarily adjusted for needle enty adjustment. If there is no

problem with the needle bar height, readjustment of the needle bar height is not required.

Advance to the next step.

, the standard needle bar height is achieved by adjusting the

to the right surface of the left needle to 0.8 mm.

Alignment between the bottom surface of the

looper and the top hole end of the needle

Right surface of

the left needle

Temporary needle bar height

Alignment

0.8 mm

Alignment between the tip of the looper and the

right surface of the needle

Right surface of

the left needle

Alignment

1.6 mm

12.5mm

Top surface of the throat plate

– 18 –

Page 23

Adjustment Procedures Results of Improper Adjustment

1. Adjustment of the needle bar height

(1) Remove the needle bar, roller cover, surface cover, and packing.

(2) Loosen the setscrew and adjust the needle bar position

vertically.

(3) After adjustment, tighten the setscrew .

(Caution) Use cau tio n not to ro tate the needle bar at adjustment

of needle bar height.

Failure to observe this changes needle entry positions.

o Remarkably improper needle bar

height adjustment may cause

stitch skipping, needle breakage,

or thread breakage.

– 19 –

Page 24

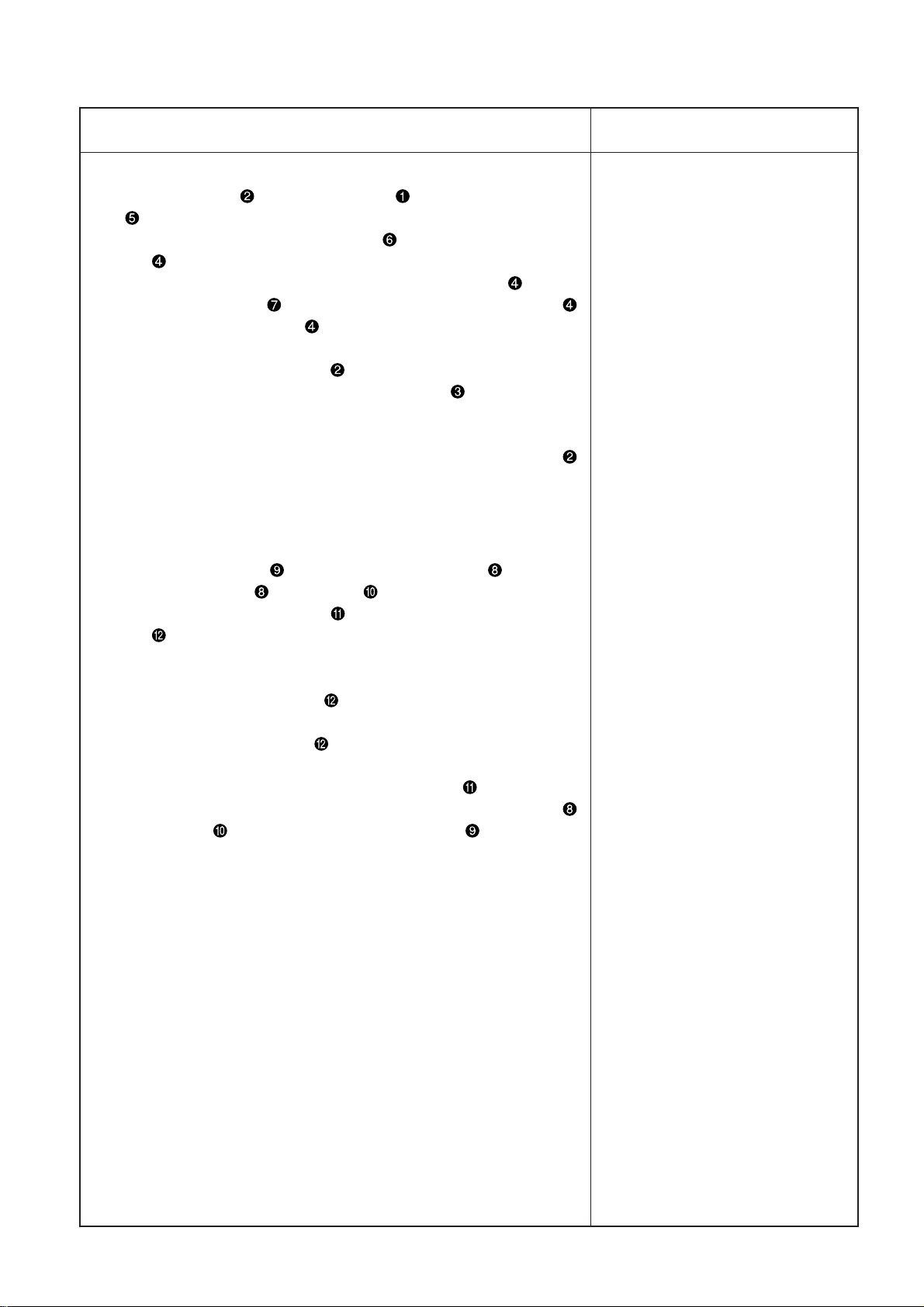

(6) Adjustment of the looper motion paths

Standard Adjustment

1. Looper momentum in the front-rear direction

(1) The standard position of the front looper is decided under the condition that the tip of the needle

touches the rear of the front looper at 1/4" from the bottom surface when the pulley is rotated

counterclockwise and the front looper is moved from right to left after mounting the front looper in a

standard manner.

(2) For the middle and rear loopers ( and ), the standard position for each is decided under the same

condition as the front looper, i.e. the tips of the needles ( and ) touch the rear of the loopers at 1/4" from

the bottom surfaces, respectively.

(Caution) If the material has a thick unevenness during sewing, contact areas between the needle tips

and the rear surfaces of the loopers ( and ) may become smaller. (to prevent needle tip

breakage)

• •

Right-left direction

• •

1/4" from the

bottom surface

Differential feed model

Model: 35800DNU

Up-down direction

1 piece feed model

Model: 35800DRU

Up-down direction

– 20 –

Page 25

Adjustment Procedures Results of Improper Adjustment

1. Adjustment of longitudinal movement of differential feed looper

(1) Loosen the setscrews (4 pcs.) and remove the cylinder side cover

.

(2) Loosen the setscrew of the ball joint with a spanner wrench

(TT85), and adjust the the forward/reverse movement by moving

the setscrew forward or backward.

(3) After adjustments, mount the cylinder side cover , and tighten the

setscrews .

2. Adjustment of longitudinal movement of 1 piece feed looper

(1) Loosen the setscrews (4 pcs.) and remove the cylinder side cover

.

(2) Loosen the setscrew of the ball joint with a screwdriver, and

adjust the the forward/reverse movement by moving the setscrew

forward or backward.

(3) After adjustments, mount the cylinder side cover , and tighten the

setscrews .

o When reducing the front and rear momentum amount of the looper,

move the ball joints and upwards.

o When increasing the front and rear momentum amount of the looper ,

move the ball joints and downwards.

(Caution) 1. When the front and rear momentum amount of the

looper has been adjusted, move the respective looper

bases , , and and readjust the front/rear

positions of the needles ( , , and ) and the

loopers ( , , and ).

2. When the above-mentioned adjustments are carried

out, the throat plate should be removed.

o When the front and rear momentum

amount of the looper is small:

The amount of contact becomes

large between tips of the needles

( , , and ) and rear parts of

the loopers ( , , and ) and

this can be a cause of needle tip

being blunt.

o When the front and rear momentum

amount of the looper is large:

The clearance becomes large

between tips of the needles ( ,

, and ) and rear parts of the

loopers ( , , and ) and this

can be a cause of stitch skipping.

– 21 –

Page 26

(7) Adjustment of rear needle guide

Standard Adjustment

1) Longitudinal adjustment of the rear needle guide

1. When the pulley is turned counterclockwise and the rear needle holder advances to the most front

position, it lightly touches the left needle and then tip of the front looper passes.

When tip of the front looper reaches the position 1.5mm apart from the left side of the left needle

while this front looper moves in right direction, the standard position is that the needle tip comes in

contact with the rear needle holder .

2. The relationship between the middle needle and the rear looper and between the right needle and

the middle looper is also required to assume the same conditions as 1. above in standard positioning.

(Caution) 1. The rear needle holder somewhat changes its contact position with the respective

needles ( , , and ) according to the needle entry position.

Recheck the needle entry condition for adjustments if the contact positions of the right

and left needles ( and ) seem to be different.

2. To change the stitch length, readjustment of the front and rear positions is also needed

for the rear needle holder .

2) Height adjustment of rear needle guide

1. When tip of the front looper coincides with the right side of the left needle , the standard dimension is

2.0mm between the lower position "A" of the needle hole and Point B of the rear looper .

2. The relationship between the middle needle and the rear looper and between the right needle and

the middle looper is also required to assume the same conditions as 1. above in standard positioning.

Longitudinal directions of rear needle guide

1.5mm

Longitudinal directions

• •

• •

Vertical direction of rear needle guide

Right and left directions

A

B

2.0mm

The clearance between tip of looper

and needle is 0.0 mm.

(Light contact)

– 22 –

Page 27

Adjustment Procedures Results of Improper Adjustment

1) Longitudinal adjustment of the rear needle guide

1. Loosen the setscrew and move the rear needle guide forward

or backward to adjust the height.

2. After adjustments, tighten the setscrew .

(Caution) When the rear needle holder is adjusted, recheck the

presence of a clearance between the respective needles

( , , and ) and the respective loopers ( , , and

). If any clearance is perceived, readjust the related

conditions.

2) Height adjustment of rear needle guide

1. Loosen the setscrew and move the rear needle guide base

vertically to adjust the height.

2. After adjustments, tighten the setscrew .

o If a clearance is actually

developed between the needles

, , and the rear needle

holder , this can be a cause of

needle breakage or stitch

skipping.

o When the rear needle holder

presses the respective needles

( , , and ) too much, this can

be a cause of needle tip being

blunt.

– 23 –

Page 28

(8) Adjustment of feed dog height and longitudinal movement (differential feed dog mechanism)

Standard Adjustment

1) Height of main feed dog

The standard height is defined when the main feed dog attains the highest level and the root section of

the main feed dog coincides with the upper face of the main feed dog throat plate .

2) Height of differential feed dog

The standard height of the differential feed dog is defined when the main feed dog attains the highest

level and a clearance of 0.05 to 0.1mm is secured between the upper face "A" of the main feed dog and

the bottom face "B" of the differential feed dog .

3) Adjustment of longitudinal movement of main feed dog

The maximum amount of feed of the main feed dog is 3.6 mm. (Standard: 3.2 mm)

When the main feed dog attains its maximum feeding amount, the standard positioning is secured when

Clearance "C" and Clearance "D" are equalized. Clearance "C" is defined as the distance from the feed

groove front section of the throat plate to the front section of the main feed dog in position where the

main feed dog stays in the most advanced position. Clearance "D" is defined as the distance from the

feed groove rear section of the throat plate to the rear section of the main feed dog {1} in position where

the main feed dog has attained the most retreated position.

4) Adjsutment of vertical height of main feed dog and differential feed dog

For the feed rocking lever eccentric pin of the feed dog, the standard positioning of the driver groove is

horizontal.

The vertical height of the main and differential feed dogs ( and ) can be simultaneously adjusted by

turning the feed rocking lever eccentric pin . Basically, however, this function should be used in standard

position.

5) Gradient of main feed dog and differential feed dog

Front lowering condition is standard.

Height of main feed dog

Top surface

0.05 to 0.1mm

Height of differential feed dog

B

A

Coincidence

Clearance of the main feed dog

in the most advanced position

C

Clearance of the main feed dog in

the most retreated position

Longitudinal

directions

D

Driver groove

– 24 –

Page 29

Adjustment Procedures Results of Improper Adjustment

Adjustment of main feed dog and differential feed dog

1. For the feed rocking lever eccentric pin of the feed dog, the

standard positioning of the driver groove is horizontal.

If the driver groove seems to be inclined deviating from the standard

positioning, loosen the setscrew and adjust the feed rocking lever

eccentric pin of the feed dog until it assumes its horizontal posture.

Since then, tighten the setscrew .

2. Mount the main feed dog , differential feed dog and throat

plate , and fix the throat plate .

3. In the first place, adjust the height of the main feed dog to the

standard position. Then fix it by tightening the setscrew .

4. Apply the feed dog support to the bottom of the front section of

the main feed dog and tighten the setscrew .

5. Then, adjust the height of the differential feed dog to the standard

position. After that, fix it by tightening the setscrew .

6. According to "(10) Feed adjustments, 1) Adjustment of stitch length",

adjust the maximum feed amount of the main feed dog to 3.6mm.

(Apply a ruler to the side of the main feed dog and confirm the

result by turning the pulley counterclockwise.)

7. Turn the pulley counterclockwise and confirm that there is no contact

between the main feed dog and the feed groove front/rear section

of the throat plate .

If there is any contact, loosen the setscrew of the main feed

rocking lever link and turn the main feed rocking eccentric drive

stud to adjust the throat plate not to contact the feed groove

front/rear section. After adjustments, tighten the setscrew .

8. After the front and rear momentum amount has been adjusted for

the main feed dog , adjust the sewing length to the standard value

of 3.2mm.

(Caution) 1. In t he cas e of fr ont and re ar a dju stments of the

differential feed dog mechanism, specific attention

should be paid to the fine feed dog section of the

main feed dog .

2. To make front and rear adjustments of the main feed

dog , loosen eight setscrews of the cylinder

cover and remove the cylinder cover set .

After adjustments, mount the cylinder cover set ,

and tighten the setscrews .

3. For the main feed dog and the differential feed

dog , the longitudinal gradients and the

horizontality are kept constant and cannot be

adjusted.

When the height of feed dogs ,

is insufficient

o The amount of feed is decreased

and uneven feeding can occur.

oWhen the height of the rear

needle guide is lowered, this will

cause breakage of a needle or

stitch skipping.

When the height of feed dogs ,

is excessive

o This can be a cause of the

materials pushed back to the front

side, or of giving rise to feed flaws.

oWhen the height of the rear

needle holder is raised and the

margin of the needle contact

position is increased, this will

cause failure in producing loops

and stitch skipping.

– 25 –

Page 30

(9) Adjustment of feed dog height and longitudinal movement (1 piece feed dog mechanism)

Standard Adjustment

1) Height of main feed dog

The standard height is defined when the main feed dog

of the main feed dog

coincides with the upper face of the throat plate of the main feed dog .

2) Adjustment of longitudinal movement of main feed dog

The maximum amount of feed of the main feed dog is 3.6 mm. (Standard: 3.2 mm)

When the main feed dog attains its maximum feeding amount, the standard positioning is secured when

Clearance "A" and Clearance "B" are equalized. Clearance "A" is defined as the distance from the feed

groove front section of the throat plate to the front section of the main feed dog iin position where the

main feed dog stays in the most advanced position. Clearance "B" is defined as the distance from the

feed groove rear section of the throat plate to the rear section of the main feed dog in position where

the main feed dog has attained the most retreated position. (A = B)

Height of main feed dog

attains the highest level and the rear root section

Clearance of the main feed dog

in the most advanced position

Coincidence

A

B

Clearance of the main feed dog

in the most retreated position

– 26 –

Page 31

Adjustment Procedures Results of Improper Adjustment

1) Height of main feed dog

1. Apply the rear support screw to the bottom right of the main feed

dog , tighten the setscrew , and mount the throat plate .

2. Check the standard height of the main feed dog.

o If the main feed dog is low, raise the rear support screw .

o If the main feed dog is high, raise the rear support screw .

3. Remove the throat plate , loosen the setscrew to remove the

main feed dog , and adjust height of the front support screw .

4. After adjustments, mount the main feed dog , tighten the setscrew

, mount the throat plate , and tighten the setscrew .

2) Adjustment of longitudinal movement of main feed dog

1. Loosen the setscrews ( and ) and remove the plug female screw

.

2. Using a screwdriver, turn the eccentric pin clockwise and

counterclockwise until the front and rear positions of the main feed

dog are properly adjusted.

When the height of main feed dog

is insufficient

o The amount of feed is decreased

and uneven feeding can occur.

oWhen the height of the rear

needle guide is lowered, this will

cause breakage of a needle or

stitch skipping.

When the height of main feed dog

is excessive

o This can be a cause of the

materials pushed back to the front

side, or of giving rise to feed flaws.

oWhen the height of the rear

needle holder is raised and the

margin of the needle contact

position is increased, this will

cause failure in producing loops

and stitch skipping.

– 27 –

Page 32

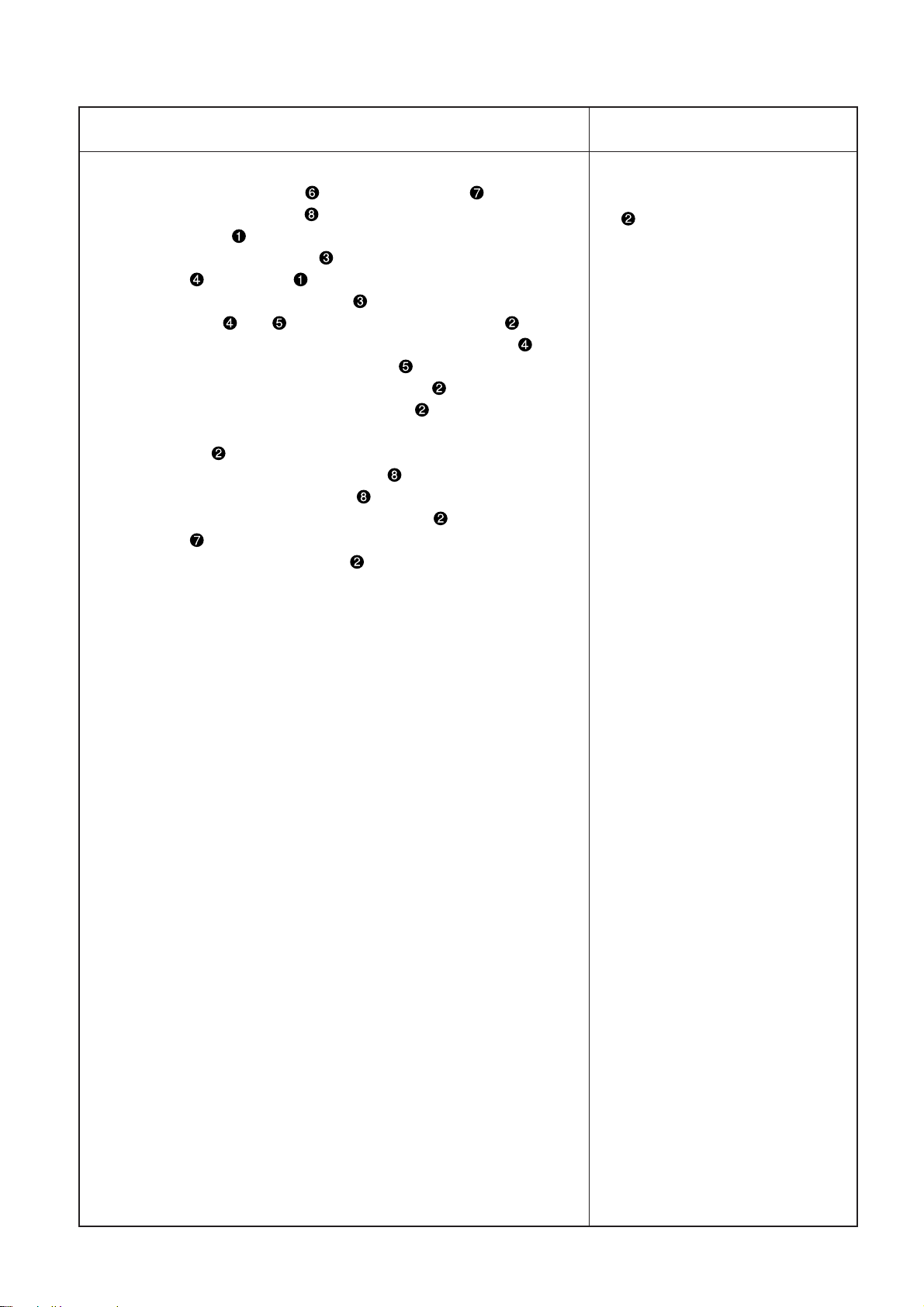

(10) Adjustment of feed mechanisms

Standard Adjustment

1) Adjustment of stitch length (standard: 8 stitches/inch interval)

The stitch length can be adjusted within the range of 2.1 mm to 3.6 mm. Standard adjustment is 3.2 mm.

For the adjustment of the stitch length, loosen the lever setscrew and move the lever upwards or

downwards until the required length is secured.

(Caution) If the stitch length has been changed, check "(7) Adjustment of rear needle guide" and

make a proper readjustment.

Vertical direction

2) Adjustment of differential feed amount

The amount of differential feed can be adjusted by moving the differential adjusting lever forward or

backward.

The graduation plate is provided with the engraved numbers of 1 to 9. Numbers 1 to 4 denote differential

motion, Number 5 denotes no differential motion, and 6 to 9 denote forward differential.

(Caution) No differential function is provided to the single feed mechanism.

Longitudinal directions

1

9

– 28 –

Page 33

Adjustment Procedures Results of Improper Adjustment

1) Stitch length adjustment

1. When the stitch length adjusting window screw is removed, the

lever setscrew can be seen.

o Loosen the lever setscrew to move the lever upwards and fasten

the lever setscrew there. This action increases the stitch length.

o Loosen the lever setscrew to move the lever downwards and

fasten the lever setscrew there. This action decreases the stitch

length.

(Caution) No graduation is available for the adjustment of the

stitch length.

2) Adjustment of differential feed amount

o When the differential adjusting lever is advanced in the reverse

differential direction (1 to 4), the differential ratio is decreased and

the sewed materials are extended.

o When the differential adjusting lever is retreated in the forward

differential direction (6 to 9), the differential ratio is increased and

the sewed materials are shrunk.

* When fixing the differential adjusting lever , pinch it with two

setscrews and .

When the stitch length is changed

o If the forward or backward

movement of the main feed dog

is changed, the contact amount is

also changed between each

needle and the rear needle holder.

Since this can be a cause of stitch

skipping, the rear needle holder

should be readjusted.

– 29 –

Page 34

(11) Presser adjustment

Standard Adjustment

1) Adjustment of amount of rise of presser

The standard amount of rise is 6.5mm for the standard class of the presser

9 mm)

In standard positioning, the presser

begins to rise faster by 3.2mm above the upper face of the throat

plate before the upper feed roller begins to rise.

(Caution) 35800BWW-DWW: The maximum amount of rise is 10mm for extra-heavy materials.

2) Adjustment of presser bar pressure

Proper pressure of the presser shall be applied to the material while it is sewn.

Turn the pressure adjusting nut clockwise and counterclockwise to adjust pressure.

. (Maximum amount of rise:

6.5mm

6.5mm

C

D

0.8mm

A

B

1.6mm

– 30 –

Right direction

Page 35

Adjustment Procedures Results of Improper Adjustment

1. Installation and pressure adjustment of presser and presser yoke

(1) Raise the presser shaft , mount the presser yoke on the presser

shaft , and tighten the setscrew .

(2) Confirm whether the presser shaft smoothly moves up and down,

being free from rattling on the right and left.

If there is rattling on the right and left, loosen four setscrews to

set up the presser shaft guide to eliminate right and left rattling

by means of the right/left holding guide plate . Make adjustments

to permit the presser shaft to perform light movement up and down.

Since then, tighten the setscrew .

(3) Install the pressure adjusting leaf spring set and turn the pressure

adjusting nut until pressure of the presser is duly adjusted.

oTurning the pressure adjusting nut clockwise causes the pressure

to increase.

0Turning the pressure adjusting nut counterclockwise causes the

pressure to decrease.

(4) In order to make the presser rise by 3.2mm faster than the upper

feed roller, loosen the setscrew of the presser shaft guide

and move the presser shaft guide up and down until a clearance

of 0.8mm is secured between the lower hole face of the lever link

and the bottom face of the lever link hanger setscrew . (Lower

dead point of the needle bar)

(Caution) When the above-mentioned adjustments are made, the

connecting positions shall be secured for the lifter lever

with slide hole and the lifter lever by moving the

lifter lever with slide hole in the right direction. When

proper positioning has been secured, tighten the

setscrew .

(5) To secure the standard amount of rise of 6.5mm for the presser ,

loosen the setscrew and move the stop collar up and down

until a clearance of 6.5mm is secured between the lower face "C" of

the mounting position of the presser shaft guide bush and the

upper face "D" of the stop collar . Since then, tighten the setscrew

.

(Caution) At the same time, check the mounting position of the

needle thread rocking thread take-up bar connecting

base .

At the lower dead point of the needle bar, a clearance of

1.6mm shall be secured between the bottom face A of

the needle thread rocking thread take-up bar connecting

base and the upper face B of the cut section of the

front cover .

o If the amount of presser rise is too

excessive than required, the

presser will touch the needle

clamp, thus causing needle

breakage or stitch skipping.

o If pressure of the presser is too

insufficient or excessive than

required, the material cloth will

advance awkwardly.

2. Removal and installation of presser only

(1) To replace presser only, loosen the right and left setscrews

and change the presser .

Then, tighten the right and left setscrews .

– 31 –

Page 36

(12) Adjustment of upper feed roller

Standard Adjustment

1. Adjustment of upper feed roller

(1) The standard clearance is 0.08mm minimum to 0.13mm maximum between the lower position of the

upper feed roller

(2) The standard front/rear and right/left clearances shall be uniform between the upper feed roller

the feed dog .

(3) The standard positioning of the upper feed roller shall be free from right and left rattling, permitting

smooth movement up and down.

and the upper face of the throat plate .

Unified right and left

clearances

0.08mm to 0.13mm

and

Standard clearance

toward the throat plate

Vertical direction

Frame shaft hole of the

upper feed roller

Right and left directions

– 32 –

Page 37

Adjustment Procedures Results of Improper Adjustment

1. Installation of upper feed roller

(1) Raise the upper feed roller pressing shaft and insert the upper

feed roller pressing shaft in the frame shaft hole of the upper

feed roller frame set . Then, tighten the setscrew .

Simultaneously at that time, insert the lever connecting section

in between the roller connecting section to join it.

(2) Install the roller pressure adjusting screw .

(3) Confirm that a standard clearance (Clearance gauge: 0.08mm to

0.13mm) is secured between the upper feed roller and the upper

face of the throat plate .

(4) Confirm that there is proper pressure at the upper feed roller ,

enough to feed the material cloth.

c Pressure adjustment

oTurning the roller pressure adjusting screw clockwise causes the

pressure to increase.

oTurning the roller pressure adjusting screw counterclockwise

causes the pressure to decrease.

(Caution) Confirm that the upper feed roller pressing shaft can

be raised by both hands when installing the roller

pressure adjusting screw .

2. Clearance adjustment between upper feed roller and throat plate

(1) If the standard clearance adjustment seems to be improper, loosen

two setscrews and raise the upper feed roller pressing shaft .

Insert the clearance gauge in between the upper face of the throat

plate and the lower position of the upper feed roller . Then,

lower the upper feed roller pressing shaft .

(2) Tighten two setscrews under the condition that the bottom face

of the guide finger is put on to keep contact with the upper face of

the guide support block .

(3) In the state as seen from behind, confirm that the vertical clearance

of the upper feed roller is maintained at the standard level in

conjunction with the throat plate

(4) In the state as seen from behind, confirm that the front and rear

right/left clearances on the right side of the upper feed roller are

uniformly maintained in conjunction with the feed dog .

(Caution) The right/left clearance between the upper feed roller

and the feed dog shall be confirmed while the

feed dog is positioned at the highest level.

3. Adjustment of parallelism between upper feed roller and feed dog

(1) Loosen the setscrew and turn the upper feed roller pressing shaft

to the right and left to confirm that uniform clearances are retained

in front / rear and right / left positions between the upper feed roller

and the feed dog . Since then, tighten the setscrew .

4. Adjustment to eliminate right and left rattling in the upper feed roller

(1) If there is right and left rattling in the upper feed roller , loosen the

setscrew and hold the guide finger to eliminate right and left

rattling, using the right/left guide plate . Since then, tighten the

setscrew .

o If the upper feed roller touches

the throat plate and there is too

much pressure, this will be a

cause of cutting off the .

o If the clearance is too much

between the upper feed roller

and the throat plate , this will

be a cause of failure in supplying

the

o If pressure of the upper feed roller

is too weak for the material

cloth, uneven feeding may arise.

– 33 –

Page 38

(13) Replacement and adjustent of upper feed roller

Standard Adjustment

1. Replacement of upper feed roller

Each version is provided with the standard upper feed roller

The replacing parts for the upper feed roller

come in six types. According to the sewing materials, use

these parts replacing the upper feed roller .

(Caution) In the case of replacement of the roller from narrow width to wide width, and vice versa, both

the throat plate and the feed dog should also be replaced.

Upper feed roller name and US part No., JUKI part No.

No. Name US Part No. JUKI Part No.

1 Standard type narrow roller 35875AV 30539100

2 Inverted type narrow roller 35875AW 30555106

3 Narrow rubber roller 35826EF 30327100

4 Standard type wide roller 35826X 30515704

5 Inverted type wide roller 35826CB 30553804

6Wide rubber roller 35826DZ 40059568

.

Key groove

Screw contact face

(Left direction)

(Right direction)

Feed roller support arm (left)

Feed roller support arm (right)

Screw contact face

(Rear direction)

(Front direction)

– 34 –

Page 39

Adjustment Procedures Results of Improper Adjustment

1. Replacement of upper feed roller

(1) Loosen the setscrews and remove the front gear cover .

(2) Loosen the setscrews and remove the rear gear cover .

(3) Loosen two setscrews ( and ) and pull out the roller shaft

from the upper feed roller frame in the left direction. Then, the

upper feed roller can be dislodged.

(Caution) Pull it out with the key groove of the roller shaft

positioned just above.

When the key groove is positioned just under, the

key falls down.

(4) Insert the replacing upper feed roller in between the right and left

feed roller support arms of the upper feed roller frame . Then,

insert the roller shaft in the right direction from the left direction of

the feed roller support arm (left).

(Caution) Adjust the key position, attached with the roller shaft

, to the key groove hole of the horizontal drive gear

, and insert it.

(5) Apply the right side of the horizontal drive gear to the left side of

the feed roller support arm (left). Then, apply the left side of the

upper feed roller to the right side of the feed roller support arm

(left). Tighten the setscrew after confirming that there is no rattling

on the right and left and light revolution seems to be secured. Tighten

the remaining setscrew .

(Caution) The upper feed roller screws ( and ) are positioned

on the right as seen from the front. In regard to the screw

contact face of the roller shaft , the screw keeps a

rear contact in conjunction with the revolving direction.

(6) Mount the rear gear cover , and tighten the setscrews .

(7) Mount the front gear cover , and tighten the setscrews .

o The upper feed roller should

be selected according to the type

of material cloth. Otherwise, the

material cloth may get roller-borne

flaws.

2. Installation of vertical drive gear

(1) Insert the vertical drive gear in the mounting hole of the upper

feed roller frame . Then, install the collar and tighten the

setscrew so that the vertical drive gear is free from vertical

rattling.

(2) Mount the roller connector on the shaft section of the vertical

drive gear and adjust it to the contact face of the shaft section.

Tighten the setscrew and also the remaining setscrew .

(Caution) When replacing the vertical drive gear , remove the

horizontal drive gear in the first place.

– 35 –

Page 40

(14) Adjustment of drawing amount of upper feed roller

Standard Adjustment

1. Drawing amount of upper feed roller

The standard amount of draw for the upper feed roller

sewing length (8 stitches/inch) of the feed dog.

The clutch connecting lever

cloth can be changed by moving the clutch connecting rod vertically.

and the clutch set are connected. The amount of draw for the material

is defined to cause a slight pulling force for the

Vertical direction

– 36 –

Page 41

Adjustment Procedures Results of Improper Adjustment

1. Adjustment of drawing amount of upper feed roller

(1) Loosen the nut (spanner: 3/8), tighten the nut after adjusting

the clutch connecting rod vertically.

oWhen the clutch connecting rod is raised, the amount of draw for

the material cloth is increased.

o When the clutch connecting rod is lowered, the amount of draw

for the material cloth is decreased.

o If the amount of draw for the upper

feed roller is too much in

conjunction with the sewing feed

amount, the number of stitches is

increased.

o If the amount of draw for the upper

feed roller is too less, sewing

problem occurs and this is a

cause of feed error. In particular,

this problem occurs around the

hinged section.

– 37 –

Page 42

(15) Adjustment of needle thread path

Standard Adjustment

Adjustment of needle thread path

The needle thread adjusting thread path is installed just under the needle thread guide so that there

is no sag of the needle thread that passes through the lever thread path from the needle thread adjusting

thread path when the needle bar is positioned at the upper dead point.

1) Height of needle thread adjusting path

The standard dimension is 27mm from the hole bottom "A" of the needle thread guide to the hole

bottom "B" of the needle thread adjusting thread path .

When tightening the needle thread in particular, the dimension shall be 36mm from the hole bottom "C"

of the needle thread guide to the hole bottom "D" of the needle thread adjusting thread path .

2) Height of rocking take-up path

The standard dimension is 15mm from the hole bottom "E" of the rocking thread take-up lever thread

path to the center "F" of the setscrew .

3) Height of needle thread guide adjuster

When the needle bar stays at the lower dead point, the standard dimension is 1.6mm from the upper

end "G" of the lever thread path to the upper end "H" of the needle thread holding adjuster .

Standard dimension

E

F

Needle bar at the

upper dead point

15mm

Standard dimension

A

B

27mm

Standard dimension for tightening

the needle thread

C

36mm

D

Rocking thread take-up lever

– 38 –

Needle bar at the lower dead point

H

1.6mm1.6mm

1.6mm

1.6mm1.6mm

G

Page 43

Adjustment Procedures Results of Improper Adjustment

1. Mounting position of needle thread adjusting path

(1) Mount the needle thread path guide , and tighten the setscrew

.

(2) Mount the needle thread adjusting path in the needle thread path

guide .

Measure the standard dimension (27mm) and tighten the setscrew

.

o Raising the needle thread adjusting path causes the needle thread

to be loosened.

o Lowering the needle thread adjusting path causes the needle

thread to be tightened.

2. Mounting position for the rocking thread take-up lever thread path

(1) When the needle bar is positioned at the upper dead point, vertically

hold the rocking thread take-up lever thread path and measure

the standard dimension (15mm). Tighten the setscrew .

3. Mounting position of needle thread guide adjuster

(1) Let the lever thread path stay at the lower dead point.