Page 1

INDUSTRIAL

SEWING

F

INEST

STYLES

357

357

00AR

00CR

®

QUALITY

C 0 L U M B I A®

MACHINES

(

/)

CATALOG

No.

T95AR

CLASS

HIGH

FEED-OFF-

THE-ARM

SMALL

35700

SPEED

WITH

CYLINDER

UNION SPECIAL

CHICAGO

Price

$1.00

MACHINE

CORPORATION

Page 2

Catalog

No.

T95

AR

(Supplement

ADJUSTING

35700

to

Catalog

INSTRUCTIONS

FOR

LIST

CLASS

AR

AND

OF

Styles

OPERATING

PARTS

35700

35700

No.

CR

95

W)

First

Copyright

Union

Rights

Special

Reserved

UNION SPECIAL

INDUSTRIAL

SEWING

CHICAGO

Edition

1972

by

Corporation

in

All

Countries

CORPORATION

MACHINES

Printed

in

2

U.S.

A.

August,1977

Page 3

IDENTIFICATION

OF

MACHINES

Each

into

the

name

special.

tain

letter

suffixed

which

35700".

junction

Styles

the

page

numbers,

are

illustration.

the

part

herein.

Class

given

of

handwheel

Standard

the

letter

"Z".

to

Styles

differs

This

therewith.

35700

opposite

reference

number

This

It

35700.

from

UNIONSPECIALmachine

plate

"Z".

When

the

Standard

of

machines

from

catalog

AM

description

numbers

Reference

catalog

can

also

Reference

the

operator's

is

counterclockwise.

on

the

machine.

Style

only

the

is a supplement

or

the

listed

applies

be

numbers

Example:

minor

Style

similar

style

APPLICATION

Only

those

CM

are

illustration

and

number

only

numbers

in

the

specifically

applied

to

position

number,

illustrated

second

directions,

"Style

changes

number.

and

with

is

identified

have

35700

in

construction

in

to

Catalog

parts

will

should

used

be

of

pieces

merely

column.

to

discretion

while

by a Style

Style

one

Example:

numbers

or

more

AR".

are

made

"Style

are

that

it

contains

OF

CATALOG

No.

on

Styles

and

listed

found a listing

required.

indicate

never

such

the

Standard

seated

be

to

as

used

some

right,

at

number

are

classified

letters

Special

in a standard

95 W

the

the

Style

35700

grouped

no

and

35700

at

the

of

the

Numbers

position

in

ordering

Styles

Special

left,

machine.

letters.

back

which

as

suffixed,

numbers

ARZ".

under a class

should

AR

parts,

of

Styles

front,

but

machine, a "Z"

Example:

be

and

CR,

of

this

with

in

the

of

that

parts.

machines

of

back,

Operating

is

stamped

standard

never

contain

number

"Class

used

in

but

not

catalog.

their

first

column

part

Always

as

machines

etc.,

direction

and

con-

the

is

con-

on

On

part

in

the

use

listed

in

are

Feed-Off-The-Arm

in

Front,

Periphery

Single

and

Filter

35700

shorts,

Table

401-LSc-2.

35700

Each

type

details.

of

the

eye.

which

Selection

used.

stitch

Light

of

Cylinder

Disc

AR

CR

number

blade,

Collectively,

is

Thread

formation.

Take-up

Type

Machine

pajamas

mounted.

Same

UNION

The

size

measured

given

denotes

on

of

should

High

Weight

Oil

Maximum

as

SPECIAL

number,

the

the

at

for

Return

is

equipped

and

Standard

35700

the

type

label

proper

pass

Presser

the

in

STYLES

Speed,

Bar

Needle

Looper

for

AR,

stamped

thousandths

freely

Bar 6 3/8

Threads,

Pump,

with

similar

gauge

recommended

except

needle

kind

number

of

of

all

needles

needle

through

OF

Low

Throw

Mechanism,

Visual

tractor

operations

Nos.

prepared

NEEDLES

has

shank,

on

the

of

and

size

MACHINES

Machines,

Inches.

Automatic

Sight

speed

both a type

needle

an

size

packaged

should

the

type

8,

point,

inch,

number

be

needle

Oil

foot

on

10,

6000

for

shank,

Two

Adjustable

Space

light

midway

and

determined

in

Enclosed

Action

for

felling

to

12

and

R.

P.M.

Pedestal

number

length,

denotes

represent

sold

eye

in

Needles,

Looper

Front

and

medium

groove,

between

of

Type

Supply

sport

16.

Seam

Installation.

and a size

the

the

by

Union

by

order

Left

Needle

Avoid

Needles 8 Inches,

Oiling

Gauges.

shirts,

weight

Specification

number.

finish

largest

the

shank

complete

Special.

the

size

to

produce a good

Motion,

System

blouses,

material.

The

and

other

diameter

and

symbol

of

thread

the

3

Page 4

For

these

is

machines.

backed

quarters

best

results,

They

by a reputation

of a century.

use

are

for

NEEDLES

only

genuine

packaged

producing

(Continued)

UNION

under

highest

our

SPECIAL

brand

quality

name,

needles

needles

~

for

in

the

more

operation

®

,

which

than

three-

of

Standard

has a round

eye,

spotted,

090/036,

To

sample

on

label. A complete

Prices

ments

unless

The

must

bolt

viscosity

Oil

100/040,

have

needle,

are

are

forwarded

otherwise

oil

be

filled

is

filled

THREADING

"D".

the

of

main

the

One

is

frame

gauges.

recommended

shank,

round

chromiumplated

110/044,

needle

or

orders

the

type

order

strictly

net

f.

directed.

has

been

before

of

90

at

drained

beginning

to

125

the

caps

DIAGRAM".

located

under

at

the

the

needle

point,

would

cash

o.

b.

A

seconds

The

front

foot

for

extra

and

is

125/049.

promptly

and

size

read:

and

shipping

charge

OILING

from

to

operate.

at

"A"

and

oil

level

of

the

lifter

Styles

short,

available

and

number

''1

000

TERMS

are

subject

point.

is

made

AND

the

100°

THREADING

machine

Fahrenheit.

"B"

is

cylinder

lever.

35700

AR

double

in

sizes

accurately

should

be

Needles,

to

change

Parcel

to

cover

before

Use a straight

as

illustrated

checked

Maintain

and

at

the

oil

and

CR

is

Type

groove,

struck

070/027, 075/029,

filled,

forwarded.

Type

Post

the

shipping

the

other

level

an

empty

Use

108 GHS,

without

notice.

shipments

postage

and

and

mineral

in

Fig. 1 "OILING

two

sight

is

on

oil

gauges

the

between

108 GHS.

groove,

080/032,

package,

description

Size

090 I 03 6".

All

are

insured

insurance.

the

reservoir

with a Say-

"C"

right

the

side

red

It

ball

a

ship-

AND

and

of

lines

The

machine

action

and

when

of

the

back

beginning

necessary

To

do

holes

screws.

and

If

inoperative.

Oil

maybe

is

located

below

the

Keep

ion

discs

A

convenient

ers

are

at

of

position,

position.

oil

top

covers.

to

prime

this,

operate

oil

in

the

handw

the

threads

"M"

and

the

left

leaving

is

can

to

operate

remove

machine

does

drained

bottom

heel.

"N".

means

end

equipped

be

observed

When

the

pump.

the

not

bubble

from

of

in

the

Avoid

for

of

their

them

easily

with a continuous

through

starting

a

machine

two

until

when

the

the

cylinder

slots

crossing

threading

travel,

a

that

plug

screws

bubbling

machine

machine

"K"

in

the

press

new

threads

accessible.

the

lucite

machine

has

"G".

can

at

two

and

the

the

tension

loopers

After

4

running

been

be

is

places,

other

as

have

the

knob

rotary

windows

after

idle

Apply

oil

observed

running,

"H"

at

the

posts

much

as

been

"P"

threading,

driven

"E"

filling

for

some

from

at

the

the

circulating

and

back

"L"

and

possible.

provided.

and

loopers

push

and

"F"

the

reservoirs

time,

an

oil

windows.

"J".

One

of

the

between

When

loopers

oil

can

main

will

pump.

in

the

it

to

Replace

pump

plug

the

the

back

back

The

front

may

these

screw

frame

tens-

loop-

into

or

be

is

out

Page 5

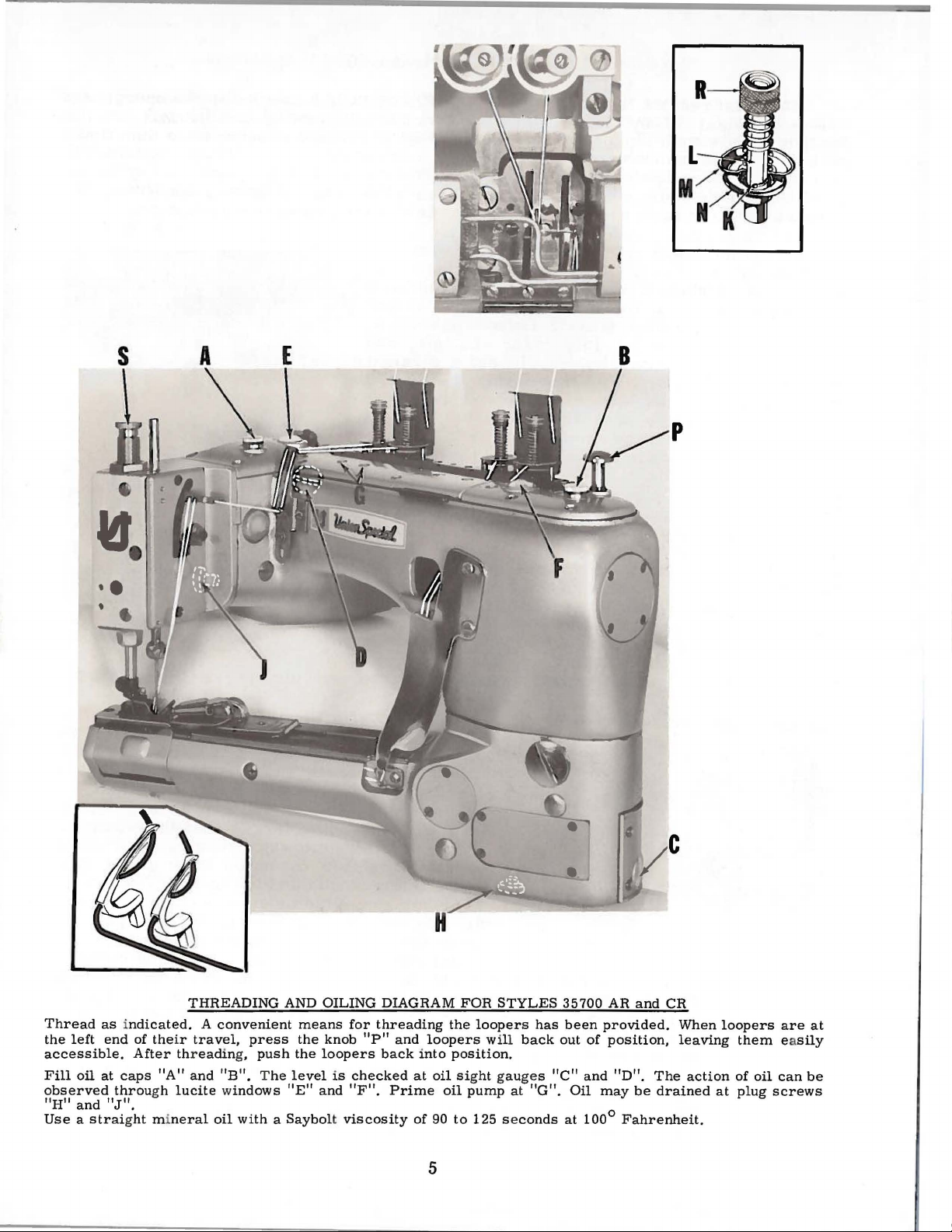

THREADING

Thread

the

accessible.

Fill

observed

"H"

Use a straight mineral

as indicated. A convenient

left

end

of

the

ir

travel,

"A"

and "B". T

gh

lucite windows

oil

and

at

throu

"J".

After thr

caps

eadin

oil

g,

AND

OILING

push

he

means

the

the

level

"E"

knob

loopers

and

press

with a Saybolt

for

"P"

is

checked

"F".

viscosity

DIAGRAM

threading

and

loopers

back into

at

oil sig

Prime

of

90

FOR

the

loopers has

position

ht gauges

oil

pump

to

125 s e

STYLES

will

back

.

at

conds

35700

out

"C"

"G".

5

been

and

Oil

at

100°

AR

provided.

of

position,

"D".

may

and

CR

When

leaving

The

be

drained

Fahrenheit

action

at

.

loopers

them easily

of

oil

can

plug

screws

are

at

be

Page 6

SYNCHRONIZING

NEEDLE

AND

LOOPER

MOTIONS

Needle

before

leaving

become

or

looper

be

required

of

an

adjustable

crankshaft

To

needles,

Rotate

the

just

Fig.

needle

steel

inches

screw

looper

cal

the

needle

begins

2)

from

rod

long)

(A).

holder

position

Continue

extreme

handwheel

bar

until

plate.

gauge

flush

(E).

until

At

(C)

against

Rotate

the

upstroke

edge

ance

of

the

between

and

looper

the

necessary

drive

to

facilitate

to

the

synchronize

presser

handw

bar

is

its

upward

and

remove

the

(B)

(5/32

into

It

may

so

when

to

turn

left,

replace

in

operating

rod

(B)

this

No.

point,

21225 H around

the

handwheel

gauge

of

contacts

the

needle

throat

gauge

mechanisms

factory,

to

disassemble

mechanisms,

proper

split

main

coupling

shaft,

the

foot,

heel

at

throat

in

the

operating

bottom

travel.

the

looper

looper

or

the

be

that

at

the

holder.

11/64

looper

necessary

the

rod

its

farthest

handwheel

the

direction,

contacts

clamp

underside

in

the

bar

plate.

Maximum

and

are

to

insure

the

main

re-synchronization

sewing

located

which

in

machine,

plate

and

direction

of

its

Loosen

for

Insert

inch

diameter

holder

(B)

and

to

re-position

will

be

travel

until

throat

plate.

raising

the

edge

Union

of

the

the

machine

or

the

Special

the

needle

machine

opposite

casting

rod

allowable

machine

casting

carefully

the

best

shaft

adjustments.

beneath

turn

drives

remove

feed

stroke

screw

the

left

a

straight

by 2 1/2

retighten

in a verti-

to

the

right.

the

rod

Turn

the

needle

of

the

throat

timing

bar

casting

direction

on

contacts

clear-

or

synchronized

possible

or

repla~e

of

needle

This

the

rear

the

looper

the

dog.

until

and

(A,

hand

the

is

at

the

(D)

the

the

rod

and

sewing

components

and

is

accomplished

top

throat

with

precision

conditions.

looper

cover,

connecting

mechanism.

Fig.

plate

is . 005

Should

of

the

motions

by

2

gauges

it

needle

will

means

the

inch.

(A,

Fig.

and

the

before

screw

wrench

of

operating

gauge

throat

is

turned

3)

gauge

the

which

in

to

insure

plate

in

Fig.

in

position.

(C,

rod

(B)

was

the

set

direction,

no

in

both,

reverse

3

Fig.

contacts

barely

screw

more

operating

of

If

the

2)

on

the

tightened,

(C,

Fig.

snug-up

than . 005

operating

are

spot

end

(B)

the

several

of

rotation

chronize

three

with

to

zontal

handwheel

the

needle

edge

of

while

3).

Rotate

the

uppermost

inch

and

reverse

direction

Both

secured

screws

of

thread

main

the

the

the

is

bar

the

throat

holding

exists

directions

and

ends

to

and

the

coupling

through

shaft

thousandths

screws,

in

either

the

needle

horizontal

rod

(B,

left,

clamp

turned

(D)

barely

screw

in

contacts

plate,

the

the

handwheel

horizontal

between

the

rod

of

the

the

crankshaft

set

screws.

the

end

of

allowing

direction

and

clamp

Fig.

tighten

enough

reverse

loosen

coupling

clamp

gauge

of

handwheel.

contacts

adjustable

(A,

Fig.

coupling.

the

coupling

larger

several

the

looper.

screws

2)

at

its

the

to

of

operating

the

machine

the

in

place

SLIGHTLY

screw

and

the

split

and

main

On

the

3)

three

The

than

the

to

properly

(B,

farthest

uppermost

hold

horizontal

with

and

casting

If

the

edge

of

coupling

shaft

main

shaft

screws

holes

are

drilled

diameter

degrees

syn-

Loosen

Fig.

3)

position

hori-

the

coupling

direction

casting

clamp

an

Allen

in

reverse

use a shim

or

rod

handwheel

the

throat

by

in

of

the

and

(E)

and

6

Page 7

SYNCHRONIZING

NEEDLE

AND

LOOPER

MOTIONS

(Continued)

plate

turn

end

has

before

the

of

been

curely,

slippage

3

32

inch

looper

versely,

the

3/32

the

handw

the

heel

coupling

accomplished,

recheck

occurred

Fig.

4

gauge

always

inch

looper

clamp

SLIGHTLY

with

both

while

setting

check

the

gauge.

gauge

the

contacts

Allen

tighten

clearance

tightening

fied.

needle,

the

(A)

tion

used

ment

holder,

the

screw

ion

the

and

looper.

(B,

holder,

tating

movement,

after

setting

the

in

the

operating

wrench

the

three

points

the

with

screws.

Insert a new

Always

first.

center

is

3/32

to

the

of

inch,

left.

advantageously

is

required,

allowing

3/32

to

needle

the

inch

(A,

Fig.

assure

and

descending

This

Fig.

5)

yet

rigid

machine

retighten

setting

of

the

the

looper

machine

direction

in

the

horizontal

a .

SETTING

set

adjust

Set

the

the

needle

when

Looper

in

loosen

movement

dimension

5).

Rotate

that

the

as

close

needle

adjustment

slightly,

enough

through

looper

to

casting,

set

005

of

needles,

the

looper

the

making

looper

so

screw

to

the

while

screw.

clamp

inch

THE

shim

LOOPER

looper

so

(B)

to

looperis

gauge

this

screw

in

either

as

shown

handwheel

point

as

possible

barely

can

be

the

looper

to

retain

its

cycle

(B).

the

back

back

of

adjust

holding

After

screws

gauge

type

(A,

Fig.

that

the

point

at

No.

adjustment.

(A,

in

in

passes

brushes

made

by

can

its

to

obtain

Always

of

the

the

needle

as

before,

the

main

this

adjustment

(B,

Fig.

to

assure

and

size

4)

for

the

distance

of

the

its

farthest

21225-3/32

Fig.

5)

direction

Fig.

4,

operating

to

the

without

the

back

contacting

loosening

be

moved

position

the

check

needle

after

except

shaft

3)

se-

as

speci-

the

left

from

looper

posi-

can

If

adjust-

in

looper

to

obtain

retighten

directrear

of

screw

in

while

ro-

required

the

3/32

and

con-

setting

no

be

of

the

the

If

more

a

void

remove

cover,

front

er

Fig.

joint

slot

of

moving

motion

located

left

avoid

8).

downward

increases

looper

it

the

side,

link

r e v e r s e .

joint

securely.

SETTINGS

Set

the

This

is

the

height

set

teeth

of

screw

extend

the

elongated

purpose.

(G)

flush

After

against

or

is

cylinder

at

loosen

ball

Moving

in

avoid

upwards

Retighten

RE-CHECK

AS

feed

neutral

feed

(D).

The

the

slot

in

less

looper

required,

the

lower

joint

the

the

the

amount

motion,

acts

BEFORE.

bar

eccentric

position

bar,

height

depth

the

feed

the

proper

the

bottom

side

loop-

(A,

ball

lever

the

ball

SETTING

of

if

required.

of

of a tooth

dog

height

of

pin

(C,

eccentricity

The

the

feed

above

for

its

attaching

has

feed

dog

THE

Fig.

feed

dog

the

been

(E)

FEED

5)

with

but

can

bar

(E)

is

throat

screw

obtained,

and

tighten

Fig

DOG

the

slot

be

turned

eccentric

set

correctly

plate,

(F)

position

support

. 5

in a horizontal

to

raise

pin

is

held

when

at

high

point

has

been

the

screw

or

in

position

the

of

travel.

provided

feed

dog

(H) s

position.

lower

tips

of

for

support

ecurely.

the

by

its

The

this

7

Page 8

The

plate.

link

(B),

(A).

Whenever

recheck

feed

dog

Adjustment

rotate

the

rear

should

can

feed

the

needle

SETTING

have

be

made

bar

eccentric

position

guard

equal

by

of

feed

setting.

THE

FEED

clearance

loosening

driving

bar

DOG

at

set

screw

stud

(C)

eccentric

(Continued)

both

ends

(A,

as

required,

driving stud

of

Fig.

its

travel

6)

in

retighten

has

feed

been

in

the

bar

set

throat

driving

screw

changed,

ALIGNING

Align

No.

21227

machine,

Fig.

The

height

the

needle's

points

tighten

even

screw

AND

the

AK-

using

7

of

the

eyes

with

(D).

SETTING

needle

of

the

test

needle

are

the

bar

(A,

gauge

pins

(C)

(D)

permitting

pins

the

the

shoulders

seated

needle

set

tighten

are

set

specified,

Fig.

needle

oblique

correspond

faces

bar

1/64

right

HEIGHT

Fig.

number

No.

699 D.

in

needle

into

needle

bottom

on

the

bar

at

its

screw

If

test

not

available,

of

needles,

7)

slightly,

bar

position

of

the

is

correct

inch

side

below

of

OF

NEEDLE BAR

7)

with

applicable

bar

alignment

the

test

bar

connection

of

its

of

the

test

is

now

proper

(D).

plate

type

loosen

lower

as

required

of

with

rear

when

the

the

needles.

test

plate

to

Loosen

connection

plate.

travel

test

plate

aligned

height.

and

insert

and

the

the

needle

underside

of

and

pins

(B),

test

size

screw

and

until

needles

vertical

guard.

the

screw

(E)

a

top

While

(B)

the

(E)

test

With

at

the

(C)

the

and

Re-

pins

new

as

(D,

turn

the

of

of

the

loopers,

maintaining

Fig.

with

both

6

the

looper

positions,

Set

the

ly

contacts

tion.

have

the

with

the

cylinder

frame.

Moving

moving

It

sb:>uld

its

guarding

points

the

right

When a change

large

just

Loosen

the

it

SETTING

rear

the

of

plug

feed.rocker

downward

needle

needles

be

the

loopers,

side

CHANGING

screw

below

feed

REAR

when

set

vertically

surface

of

the

in

stitch

located

the

rocker

acts

guard

at

in

contact

moving

needles.

STITCH

joining

driving

driving

the

reverse.

NEEDLE

horizontally

its

extreme

as

low

with

to

the

LENGTH

length

in

the

line

link

is

left

of

link

upward

GUARD

so

that

forward

as

possible,

the

needles

right,

required,

forward

cylinder

screw

Retighten

(B,

in

8

it

bare-

posi-

are

remove

side

and

Fig.

the

lever

link

main

yet

until

even

of

8).

screw

slot

lengthens

securely.

Fig.

8

the

stitch,

Page 9

The

tension

sistent

threads

amount

nuts

with

should

(R,

their

be

THREAD

of tension

Fig.

1).

strength

barely

to

inch

presser

is

Facing

the

counterclockwise

lease

on

needle

Set

the

and

avoid

sufficient

The

thread

function

above

foot

necessary,

the

machine,

action,

TENS

and

tension

puckering

to ste

tension

as

the

the

throat

has

loosen

tension

insert

as

ION

AND

looper

on

the

ady

presser

plate

reached

release

screwdriver

to

advance

required.

RELEASE

threads

needle

the

fabric.

them

release

foot

and

its

screw

Retighten

in

passing

is

is

highest

(A,

shaft

or

is

regulated

threads

The

set

correctly

is

raised

entirely

position.

Fig.

into

(C)

9)

from

slot

clockwise

screw

by

four

as

tight

tension

through

on the

the

when

approximately

released

If

in

lifter

the

pulley

in

shaft

to

retard

(A).

knurl

as

is

con

looper

machin

it

begins

1/8

when

the

adjustment

lever

(B).

end

and

rotate

the re-

ed

-

e .

of

Fig.

Set

the

let

(A,

Fig.

the

frame

liminary

between

centerline

Start

eyelet

mately

from

and

sewing

(A)

75

thread

20

to

downstroke

take-up

in

the

needle

the

needle

(C)

needle

bar

needle

thread

Regulate

enough

is

pressure

placed

9

adjustable

10)

in

needle

thread

setting,

centerline

of

mounting

on a piece

up

or

down

to

80

percent

cone

25

percent

of

needle

so

that

lever

at

the

thread

loop,

the

on

on

the

fabric.

frame

the

lower

eyelet

approximately

of

thread

screw

of

as

required

of

on

tl1e

upstroke

of

thread

bar.

it

barely

Set

thread

bottom

take-up

presser

the

if

desired

presser

of

(C)

spring

SETTING

needle

mounting

(B)

and

openings

(See

material

until

the

thread

of

is

drawn

the

needle

contacts

eyelet

its

stroke.

will

produce

to

suit

PRESSER

regulating

foot

thread

as a pre-

23/32

Fig.

and

approxiis

needle

the

(D)

with

sewing

FOOT

to

feed

NEEDLE

AND

eye-

hole

inch

and

10).

adjust

drawn

bar

on

the

thread

thread

the

Raising

more

screw

the

THREAD

FRAME

of

conditions.

PRESSURE

(S,

work

uniformly

EYELET

Fig.

1)

TAKE-UP

Fig.

so

that

10

it

exerts

when a slight

only

tension

9

Page 10

--......Q;,J..-22

~rl~

r~-_

10

16

21

23

Page 11

The

ively

Styles

described

represent

35700

Use

parts

AM

Catalog

in

this

illustrated

the

parts

and

CM

No.

95 W

catalog.

on

pages

that

respectively.

(Styles

10

are

and

used

35700

12,

on

AM

described

Styles

and

35700

CM)

below

AR

for

all

and

and

parts

on

CR,

page

but

not

illustrated

13

not

respect-

used

on

or

Reference

indented

Ref.

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

numbers

descriptions,

Part

No.

51292

35897

22571 B

35772

35772

22653

35876

36297

35883

35883

35856

36297

36284

36249

22560

36297

36286

36286

22766

22539

35787

36238

36237

22798

36284

35850

35883

22791 E

36256

36283

35883

22585 c

35883

35883

22564

F-8

660-207

CB

s

28

T

E-20

u

E

T

s

AA

G

531

c

A

A

660-202

H

A

s

531

87 A

H

E

F

E

531

D

89

R

B

c

u

N

p

J

that

are

inside a bracket

indicate

Needle

Oil

Oil

Cast-off

Screw

Cast-off

Screw

Washer--------------------------------------------

Oil

Cylinder

Cylinder

Looper

Oil

Screw

Cylinder

Looper

Screw

Oil

Oil

Gasket---------------------------------------------

Cylinder

Screw---------------------------------------------

Plug

Screw

Screw

Cylinder

Cylinder

Bushing,

Screw

Upper

Screw

Looper

Screw

Cylinder

Screw

Cylinder

Cylinder

Cylinder

Screw

Folder

Folder

Screw

they

are

component

Thread

Seal

Ring---------------------------------------

Pump

Plug

Intake

Filter

Seal

Drainage

Housing

Screw-------------------------------------

Plate

--------------------------------------------Plate

---------------------------------------------

Cover------------------------------------Cover

Thread

---------------------------------------------

Cover

Shaft

---------------------------------------------

Ring---------------------------------------

Side

Screw-----------------------------------------

---------------------------------------------

---------------------------------------------

Side

Side

for

--------------------------------------------Lint

--------------------------------------------Shaft

---------------------------------------------

Hinged

Pin

Looper

Hinged

Cover

---------------------------------------------

Gib,

Gib,

---------------------------------------------

Tension

Cover,

Eyelet,

Eyelet,

Filter

Assembly

Shield-----------------------------------

-----------------------------------------

Screen

Gasket

Shield

and

Bushing,

Screw

Cover

Cover--------------------------------Cover

feed

bar

Bushing,

Cover

Thread

Cover

Spring

left

------------------------------------

right-----------------------------------

or

box

on

parts

Description

Spring------------------------

rear-------------------------front--------------------------

-----------------------------

------------------------------

-------------------------------

--------------------------------

Oil

Gauge,

front

---------------------------------

--------------------------------

Gasket--------------------------

eccentric

rear--------------------------

-----------------------------Guide

Spring Support Stud

------------------------------

of a complete

front

front------------------

-------------------------

Wire

the

picture

----------------------

stud------------------

------------------

plates

part

------------

and

or

assembly.

hav

Amt.

Req.

2

1

1

1

1

2

1

3

3

1

1

1

1

1

1

1

1

1

1

1

1

1

4

1

2

3

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

8

e

11

Page 12

~10

4

11

12

"--

23

17

12

Page 13

FEED

LIFT,

FEED

DRIVE

AND

LOOPER A

VOID

MECHANISM

Ref.

No. No.

1

2 35834 X

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17 29478

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34 35766 B

35

36

37 35851 K

38 56341 F

39

40

41

42

43

44

45

46

47

48

49

50 35836 c

51

52

53

54 77

55

56

57

58

59

60

61

62

63

64

65

66

67

Part

22528

33174 B

29478

29103 s

22587 E

PI-18

22894

22894

269

36244

18

36244 A

97

41255 B

22747

29103 G

22587 E

PI-18

88

22764

269

43246

18

35846

22729 c

35846 B

35866

36236 B

660-207

22711

35842 J

36278

29478

35851 M

22560 A

36249 B

22729 D

652 C- 9

36236 A

258

6042 A

36236 H

36236

62238 A

35849 c

36236 A

35736 c

35735 D

35834 AB

22587 H

36234 G

22894

36234 D

35734 B

36234 c

22593

35834 z

35884 K

p

230

660-202

DX

AA

w

A

DW

c

DM

c

Description

Screw,

Feed

Screw

Feed

Ball

Screw-----------------------------------------------------------Feed

Ball

Nut

Bushing,

Oil

Screw-----------------------------------------------------------Feed

Nut,

Stud,

Looper

Screw-----------------------------------------------------------Looper

Feed

Nut

Was

Bushing,

Feed

Link

Feed

Looper

Feed

Feed

Screw-----------------------------------------------------------Feed

Feed

Screw-----------------------------------------------------------Feed

Feed

Feed

Screw

Screw------------------------------------------------------------

Feed

Lower

Oil

for

feed

Bar

Eccentric

-----------------------------------------------------------

Lift

Eccentric

Feed

Lift

Screw---------------------------------------------------Pin------------------------------------------------------

Spot Screw

Set Screw

left

Nut,

Connecting Rod

right

Nut,

Ball

Joint,

Screw----------------------------------------------------

Fork

Drive

Feed

Drive

Screw---------------------------------------------------Pin-----------------------------------------------------Set

Spot

Nut,

left

Connecting Rod

right

Nut,

Ball Joint,

Screw----------------------------------------------------

Stud

Washer----------------------------------------------

-------------------------------------------------------------for

Seal

Ring

Rocker,

for

looper

for

looper

Avoid Link

Screw----------------------------------------------------Ferrule

Connecting Rod------------------------------------------------

Shaft

Screw-------------------------------------------------------Washer

Drive

-------------------------------------------------------------her

---------------------------------------------------------for

Rocker

Pin

---------------------------------------------------------

Rocker

Rocker

Rocker

Rocker------------------------------------------------------

Bar

Drive

Bar--------------------------------------------------------Screw-------------------------------------------------------Feed

Bar

Bar

Eccentric

Bar

Spacer

Bar

Slide Block

------------------------------------------------------------

Dog

Support-------------------------------------------

Lint

Seal

Ring

dog------------------------------------------------

Driving

Assembly--------------------------------------

Eccentric

-----------------------------------------------

------------------------------------------------

thread-----------------------------------------------

-----------------------------------------------

thread----------------------------------------------

complete-------------------------------------------

-------------------------------------------------------Eccentric

Screw-------------------------------------------------

Screw------------------------------------------

thread-----------------------------------------------

thread----------------------------------------------

complete---------------------------------------

feed

-------------------------------------------------Looper

avoid

------------------------------------------------------

Sleeve

------------------------------------------------------

Shaft

feed

Drive

Driving

Shaft-----------------------------------------------

Shaft-------------------------------------------------

Link-----------------------------------------------

Plate------------------------------------------------

Shield

-----------------------------------------------------

Assembly

Eccentric

-----------------------------------------------

drive

Lever

link

shaft

sleeve

Assembly---------------------------------------

-----------------------------------------------

--------------------------------------------------

rocker

Link

Link

Stud

--------------------------------------------------

----------------------------------------------

-------------------------------------------------

Stud------------------------------------

Assembly

Assembly

shaft---------------------------------------

and

assembly---------------------------------

driving

------------------------------------------Screw------------------------------------

------------------

Ball

Joint-------------------------

-----------------------------------Ball

Joint-----------------------

Drive

---------------------------------------

link

Lever

-------------------------------

------------------------

-

------------------------

-- -

-

------

Am

Req.

---

-

---

----1

---4

2

1

1

1

1

---2

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

2

1

1

1

1

1

2

1

1

1

1

t.

1

1

1

1

1

2

1

1

1

1

1

1

1

2

1

1

1

1

2

1

1

1

1

1

1

1

2

1

2

13

Page 14

Union Special

reduce your sewing machine maintenance costs: a record keeping

system to help spot machines requiring

and a parts inventory system to speed routine repairs.

Machine Maintenance Records

Repair-prone machines

up your maintenance

Union Special suggests two variations

record keeping system using cards provided by Union

The first system utilizes a

(Fo

rm

237)

required, the card is

and their cost are entered in the spaces provided and the card is refiled .

is

offering two practical systems to help pinpoint and

abnormally high maintenance,

or

inexperienced competent operators can eat

dollars in short order.

..

for each sewing machine in a plant. When a repair is

pulled

.....

"

........

D4

fl

SYMKIL.fi4Mueflll

Machine Maintenance Record

from

the file and the repair date, parts used,

MACHINE

MAINTaHANCa

.....

~·

I I I I

-

To

help spot these problems,

of

a simple maintenance

lt&CORD

..._.

....

........

•""-.

.,

""'"

.

u•••

Special.

Dot.'h:;PU!Iat

..

-

card

.

and the completion time. This data is then transferred to the permanent

..

Machine Repair Record

Whichever system is used, management now has

to reduce needless maintenance costs.

Repair

Part

While

abnormally high maintenance,

caused by routine repairs.

recommends that manufacturers establish a formal parts inventory

system for each type

Excessive machine downtime and wasted hours

be eliminated with an orderly in-plant inventory

needed parts. There

for

spare parts. Long waits for deliveries are avoided and machine

downtime is kept to a minimum. The cost of a parts inventory is

when the overall savings are considered .

Inventories

record keeping tells management which machines require

MACHINE

RKPAIR

..

kept in the office.

it

does little to help reduce the

To

alleviate this situation, Union Special

of

sewing machine they operate.

is

no longer a need to cannibalize other machines

RECORD

CARD

an

by

mechanics can

of

the most

invaluable tool

downtime

commonly

small

2~1-

fO\tfl\

1

to\llc:"

~e

·

~

~

The second system

on repair costs

Request Card

233). When a machine requires service, the forelady

out

the

top

fills in the time the repair work is started, the parts used and their cost,

Part

Number

35720 AK8

35720 AK10

35720 AK12

35720 AK16

91

35730

73A

35730 AE

73A

35705 AM-8

35705 AM-12

22528

of a ..

AN

is

normally used when more detailed information

is

desired. Two record cards are used: a

..

(Form

234), and a

Repair Request Card

Description

Presser Foot 8 Gauge

Presser Foot 1 0 Gauge

Presser Foot 12 Gauge

Presser Foot 16 Gauge

Clamp Screw For Presser Foot

Spring For Presser Foot

Screw For Attaching Spring

#35730 AN

Spring For Presser Foot

Screw For Attaching Spring

#35730 AE

Feed Dog For 8 Gauge

Feed Dog For

Screw For Feed Dog

10-12-16 Gauge

11

tell

~'c:e

1'\11\Cl

c:otd

-

-

..

Machine Repair Record

..

and gives

-

it

to a mechanic. He

Minimum

Per 5

...

..

·-

..

Repair

..

(Form

or

foreman fills

Quantity

Machines

1

1

1

1

4

2

2

2

2

1

1

1

PARTBU

HD

L-----~--~--~--~------~~

For

free sample copies

inventory lists for a variety

local Union Special Representative

Suggested

Part

Number

35724 AM-8

AM-10

35724

35724 AM-12

35724 AM-16

22524

108 GS

35708

AK

35709 AK

21210 B

22564

22562 A

98

21225-3/32

29484

of

the machine record cards and spare

of

the most popular machines, contact

Minimum

Description

Throat Plate For 8 Gauge

Throat Plate For 1

Throat Plate For 12 Gauge

Throat Plate For 16 Gauge

Throat Plate Screw

Needles (specify size)

Left

Looper

Right Looper

Looper

Collar

Looper Set Screw

Clamp Screw For Looper Holder

Set Screw

Needle

Looper Gauge

Screw Assortment

~

;:

or

write direct

Spare Parts

0 Gauge

~~··==~

to

-

"

";_=_=_=

=

part

Union Special.

List*

Minimum

Per 5

Quantity

Machines

1

1

1

1

6

300

.1

1

4

4

4

4

1

1

your

*The

parts

and

inventory

actual

usage.

of

spare

quantities

The

parts.

nature

listed

An

of

above

efficient

the

sewing

are intended

inventory

can

operation

to

only

assist

will

you

in

be

established

determine

setting

actual

up

the

initial

according

usage.

to

Page 15

Helpful,

cient

types

machine

Sales

Promotion

esting,

obligation

illustrated

authoritative

of

equipment

sewed article

are

the

Department.

bulletins

following:

information

for

is

available

Among

that

on

the

making

from

are available

virtually

Union

the

many

most

effi-

Special's

inter-

without

any

HERE

B

ULLETIN

ARE

HELPFUL

S a

nd CATALOGS

No.

240,

No.

249,

No.

250,

No.

251,

No.

252,

No.

253,

No.

254,

No.

256,

No.

259,

No.

260,

No.

262,

No.

263,

No.

264,

No.

265,

No.

266,

No.

267,

No.

268,

No.

269,

No.

271,

No.

273,

No.

610,

No.

710,

No.

730,

No.

740,

No.

750,

No.

1100,

No.

1105,

"Columbia

ing

Machines"

No.

1500,

"Men's,

"Rainwear"

"Men's

"Service

"Men's

"Overalls, Coveralls, and Dungarees"

"Men's

"Knit

"Men's

"Work

"Cotton,

Bags"

"Men's

"Men's

"Women's

"Women's

"Corsets, Girdles, Brassieres"

"Children's

"Mattresses, Slip Covers,

Upholstery"

"Awnings,

"Curtains & Drapes"

"Kiipp-it"

"MCS

"MCS

Hemmer"

"MCS

"Fusing

"Lewis

stitch,

"Button

"Alteration

Women's,

Dress

Shirts"

Shirts

Shorts and Pajamas"

Knit

Underwear"

Outerwear"

Sports

Gloves"

Burlap,

Clothing"

Women's, Children's

Wear"

Wear

Wear"

Canopies, Tents, Tarps "

ForMation Uni

Automatic

Automatic

Presses"

Blindstitch,

Machines"

Sewers-Ticket

Blindstitch,

Saddle

Department

Children's

and

Pants"

Shirts"

Jute,

And

Dual

Rib-Knit

Footwear"

and

Multiwall

Jackets"

High

Fashion"

Furniture

t"

Underfront

Cuff

Chainstitch,

Tackers"

Stitch,

and

Machines"

Machine"

Lock·

Tie

Paper

Shirt

Clos-

TO

S

HELP

EWING

YO

U

SO

LVE

PROBLEM

S

UNION SPECIAL

fiNEST

QUALITY

CORPORATION

Page 16

.,.o

...

...

'

Q

WORLD'S

,_,lf

FINEST

QUALITY

*

INDUSTRIAL

SEWING

MACHINES

UNION

facilities throughout the

aid

you

SPECIAL

maintains sales

and

world. These offices

in

the selection of the right sewing

equipment for your particular operation. Union

and

Special representatives

tory trained

promptly

tion, there

and

and

is

a Union Special Representative

serve you. Check with

ATLANTA,

BOSTON, MASS.

CHICAGO,

DALLAS,

LOS ANGELES, CAL.

NEW

PHILADELPHIA,

TEXAS

YORK,

GA.

ILL.

N.

Y.

PA.

are

efficiently. Whatever your loca-

service men

able

to serve your needs

him

today.

MONTREAL, CANADA

TORONTO, CANADA

BRUSSELS, BELGIUM

LEICESTER,

LONDON,

PARIS, FRANCE

STUnGART,

service

will

are

fac-

to

ENGLAND

ENGLAND

GERMANY

Representative•

Industrial

UNION SPECIAL

400

N.

FRANKLIN

and

cities

dlstrfbuton

throughout

ST.,

Jn

all

Important

the

world.

CORPORATION

CHICAGO,

ILL.

60610

Loading...

Loading...