Union Special 35700, 35800 User Manual

INDUSTRIAL

SEWING

FINE

ST

CL

35700

35800

QUALITY

ASS

ES

®

C O L U M B I A® .

MACHINES

C

CATALOG

No.

95W

HIGH

FEED-OFF-THE-ARM

SPEED

MACHINES

UNION SPECIAL

CHICAGO

CORPORATION

Catalog

No.

95

W

35700

35700

35700

35700

35700

35700

35700

35700

35700

35700

LIST

CLASSES

AK

AL

AM

AN

BS

CK

CL

CM

CN

DS

OF

35700,

Styles

35800

35800

35800

35800

35800

35800

35800

35800

35800

35800

PARTS

AC

AD

AV

AX

AY

BQ

BR

BV

BX

BY

35800

35800

35800

35800

35800

35800

35800

35800

35800

35800

35800

cc

CD

CV

ex

CY

DQ

DR

DV

DX

DY

Rights

Copyright

Union

First

Special

Reserved

Edition

1959,

By

Corporation

in

All

1964

Countries

UNION SPECIAL CORPORATION

INDUSTRIAL

Printed

SEWING

CHICAGO

in

U.S.

MACHINES

A.

2

July,

198(

FOREWORD

These

machines

garments

play

suits,

and

similar

A new

and

smoother

required

Increased

running

oil

enable

SPECIAL

to

It

rotary

the

is

our

latest

offer

such

to

two

our

machines.

as

men's

garments.

light

operating,

lift

speed

driven

main

constant

customers

improved

many

men's

shorts

weight

the

foot.

has

oil

reservoirs

aim

to

The

UNION

advantages

dress,

and

pajamas,

presser

practically

been

secure

made

pump

to

following

which

where

furnish

all

SPECIAL

on

felling

sport,

bar

mechanism

eliminates

possilile

assures

it

carefully

possilile

pages

high

work

overalls,

by

is

automatically

advantages

illustrate

speed

operations

and

makes

marking,

design

an

prepared

Class

on

uniform

jackets,

them

and

changes

adequate

information

from

and

35700and

various

shirts,

trousers,

lighter

reduces

and a continuous

supply

fed

to

the

use

describe

types

children's

pressure

of

all

bearings.

which

of

the

35800

of

coats,

running

filtered

will

UNION

parts

for

Styles

UNION

ready

in

SPECIAL

to

cooperate

Classes

35700

representatives

with

you

and

to

UNION SPECIAL

35800.

plan

will

and

be

found

estimate

in

all

manufacturing

requirements.

CORPORATION

centers,

3

Each

the

name

Standard

"Z".

only

Style

Example:

minor

number. Example:

UNION

plate

Style

changes

SPECIAL

on

the

numbers

"Style

are

machine

machine.

have

one

35700 AK".

made

in a standard

"Style

35700

IDENTIFICATION

is

identified

Style

or

numbers

more

Special

AKZ".

letters

Style

machine,

OF

MACHINE

by a Style

are

classified

suffixed,

numbers

a "Z"

number

as

but

contain

is

suffixed

which

standard

never

the

is

stamped

and

contain

letter

to

the

special.

the

letter

"Z".

standard

into

When

Styles

differs

This

herein.

Classes

Reference

ator's

terclo~kwise.

Feed-Off-The-Arm

Needle

Periphery

Single

tem and

*35700

*35700

AK

similar

12

AL

children's

rial,

of

from

catalog

It

can

35700 and 35800.

to

direction,

position

in

Front,

of

Cylinder

Disc

Take-ups

Filter

Low

operations

and

16.

High

standard

machines

the

Style

applies

also

while

High

Light

Type

throw,

Seam

throw,

play

similar

number,

be

applied

such

seated

Speed,

Weight

at

Needle

for

Oil

Return

two

needle

on .

Spec.

two

suits

gauges

in

in

specifically

with

Parts

Looper

needle

used

as

right,

at

the

STYLES

Low

Presser

Bar 6 1/2

and

Pump,

machine

light

401-LSc-2.

and

for similar

Nos.

12

construction

that

it

contains

APPLICATION

to

the

discretion

on

the

left,

machine.

OF

MACHINES

and

High Throw

Bar

Mechanism,

Inches,

Needle

Visual

to

medium

machine

and

Threads,

for

weight

for

operations

16.

are

OF

CATALOG

Standard

to

pedestals

front,

Operating

IN

CLASS

Machines,

Space

Sight

felling

Seam

Oil

material,

felling

Spec,

grouped

no

letters.

Styles

some

Special

are

back,

direction

35700

Adjustable

in

Automatic

Action

house

sport

on medium

401-LSc-2.

under a Class

Example:

of

machines

Styles

listed

etc.,

Two

Front

dresses,

shirts,

in

are

of

and

Three

Looper

of

Enclosed

and

Supply

standard

to

dress

uniform

heavy

number

"35700".

as

of

machines

Catalog

given

Needles 8 Inches,

from

handwheel

Needles,

Avoid

Type

Gauges.

shirts

gauges

shirts,

weight

listed

No.

95

the

is

Motion,

Oiling

and

Nos.

mate-

which

in

R.

oper-

coun-

Left

Sys-

8,

for

10,

*35700

*35700

*35700

35700

*35700

*35700

*35700

*35700

*DISCONTINUED -In

AM

Low

for

similar

gauges

AN

Low

rial

standard

BS

High

for

similar

Nos. 7

Same

CK

CL

Same

Same

CM

CN

Same

DS

Same

throw,

Nos.

throw,

throw,

and

as

as

as

as

as

two

operations

8,

10,

two

gauges

three

operations

8.

Seam

35700

35700

35700

35700

35700

most

needle

on

12

and

needle

Nos.

needle

on medium

Spec.

except

AK,

except

AL,

except

AM,

except

AN,

except

BS,

instances,

machine

light

16.

12

401-LSc-3.

to

Seam

m~chine

and

16.

machine

heavy

prepared

prepared

prepared

prepared

prepared

component

for

felling

medium

Spec.

for

felling

Seam

for

to

for

for

for

for

for

parts

4

sport

weight

401-LSc-2.

Spec.

felling

heavy

Pedestal

Pedestal

Pedestal

Pedestal

Pedestal

material,

light

401-LSc-2.

weight

can

be

work

shirts,

tractor

weight

Installation.

Installation.

Installation.

Installation.

Installation.

ordered

wash

shirts,

material,

for

shorts,

and

uniform

standard

customer

pajamas

feed,

wear

shirts

and

standard

mate-

and

gauges

repair.

STYLES

OF

MACHINES

IN

CLASS

35800

Feed-Off-The-Arm

Light

at

Thread

Pump,

*35800

*35800

*35800

*35800

Weight

Needle

Bar 6 1/2

Take-up,

Visual

AC

Two

trousers,

ilar

operations

ard

gauges

AD

Two

seams

non-sanforized

and 16. Seam

trousers,

operations

non-sanforized

trousers,

operations

6

Nos.

AV

AX

1/2

of

Two

Two

oz.)

16

Presser

Sight

and

High Throw

Bar Mechanism,

Inches,

Automatic

Oil

needle

side

needle

trousers

needle

side

needle

side

machine

and

on medium

Nos. 16 and 18. Seam

machine

material,

Spec.

machine

and

on medium

material,

machine

and

on

med-ium

non-sanforized

18.

Seam

Machines,

Space

Enclosed

Action

for

sleeve

for

and

for

401-LSc-2.

for

sleeve

heavy

for

sleeve

heavy

Spec.

and

seams

heavy

similar

.025

seams

standard

seams

material,

Tw~

Adjustable

in

Front

Type

Supply

felling

of

and heavy

Spec.

felling

operations

inch

felling

of

to

heavy

gauges

felling

of

to

heavy

401-LSc-2.

and·Three

of

Needles 8 Inches,

Oiling

Gauges.

the

"in

coats

step

shop

shop

and

401-LSc-2.

seersucker

on

"in

and

coats,

weight

Nos.

"in

and

coats,

weight

.070

inch

Needles,

Looper

System and

weight

right

2.00

2.00

Avoid,

and

out"

jackets,

non-sanforized

and

on medium

side,

out"

seams

denim

to

16

and

out"

seams

denim

to

step

Filter

seams

for

jackets

4.00

18.

jackets

2.40

on

right

Left

Needle

Periphery

Single

Type

of

laundry

use

on

to

medium heavy

standard

of

overalls

and

yard

of

yard

(8

Seam

overalls

and

(8

side,

of

Disc

Oil

overalls

bags

and

material,

"in

and

gauges

and

for

oz.

Spec.

and

for

oz.

standard

in

Front,

Cylinder

Looper

Return

and

for

sim-

stand-

out"

weight

Nos. 12

similar

to 4 oz.)

401-LSc-2.

similar

to

gauges

*35800

*35800

*35800

*35800

*35800

AY

Two

trousers,

operations

sanforized

gauges

BQ

overalls,

seams

heavy

Spec.

BR

heavy

coats,

operations

standard

BV

trousers,

jackets,

heavy

gauges

BX

trousers,

medium

forized

Seam

Nos. 16 and

Three

of

weight

401-LSc-3.

Three

weight.denim

"in

Three

to

Nos. 8 and

Three

heavy

Spec.

needle

side

and

on

medium

and

non-sanforized

needle

lined

shop

coats,

non-sanforized

needle

and

out"

on

heavy

gauges

needle

side

and

mackinaws,

heavy

material,

weight

needle

side

and

to

401-LSc-3.

machine

upper

or

upper

Nos. 8 and

machine

9.

machine

heavy

.070

for

sleeve

heavy

18.

Seam

roller

unlined

denim

roller

jackets,

seams

to

extra

sleeve

melton

2.00

Seam

sleeve

weight

inch

felling

seams

of

for

seams

cloth

to

Spec.

for

seams

of

to

heavy

material,

Spec.

feed

dungarees,

jackets

material,

feed

blanket

heavy

heavy

9.

Seam

felling

of

coats

4.00

401-LSc-3.

felling

of

2.00

step

on

"in

and

shop

coats,

weight

.094

401-LSc-2.

machine

mackinaws and

and

for

standard

machine

lined

weight

sanforized

Spec.

shop

yard

coats,

to

right

"in

coats,

and

(8

"in

2.40

jackets,

overalls,

401-LSc-3.

and

and

jackets

yard

side,

out"

denim

1.55

inch

for

similar

gauges

for

and

out"

denim

for

similar

oz.

to 4 oz.)

out"

(8

seams

to

felling

felling

oz.

standard

of

jackets

2.20

yard

step

on

"in

trousers,

operations

Nos. 8 and

sides

mackinaws,

dungarees

non-sanforized

seams

seams

and

of

jackets,

operations

material,

of

for

to 6 1/2 oz. )

gauges

overalls

and

(11

right

and

side

on medium

and

melton

and

overalls

blanket

overalls

similar

and

for

similar

oz.

to 7 oz.)

side,

out"

material,

Nos. 8 and

standard

seams

and

sleeve

to

9.

Seam

sleeves

cloth

similar

and

lined

on

m.edium

standard

and

operations

non-san-

of

of

on

9.

*DISCONTINUED -In

most

instances,

component

parts

5

can

be

ordered

for

customer

repair.

STYLES

OF

MACHINES

IN

CLASS

35800

(Continued)

35800

*35800

*35800

*35800

*35800

*35800

35800

35800

*35800

35800

35800

BY

Three

side

and

medium heavy

sanforized

Seam

Spec.

cc

Same

CD

Same

CV

Same

ex

Same

CY

Same

DQ

Same

DR

Same

DV

Same

DX

Same

DY

Same

needle

sleeve

material,

as

as

as

as

as

as

as

as

as

as

machine

seams

to

heavy

401-LSc-3.

35800

35800

35800

35800

35800

35800

35800

35800

35800

35800

AC,

AD,

AV,

AX,

AY,

BQ,

BR,

BV,

BX,

BY,

of

shop

weight

.094

except

except

except

except

except

except

except

except

except

except

for

inch

felling

coats,

1.55

to

step

prepared

prepared

prepared

prepared

prepared

prepared

prepared

prepared

prepared

prepared

"in

and

denim

2.20

yard

on

right

for

for

for

for

for

for

for

for

for

for

NEEDLES

out"

jackets

(11

side,

Pedestal

Pedestal

Pedestal

Pedestal

Pedestal

Pedestal

Pedestal

Pedestal

Pedestal

Pedestal

seams

and

oz.

standard

of

for

similar

to 7 oz.)

Ins

tal

la

Installation.

Installation.

Installation.

Installation.

Installation.

Installation.

Installation.

Installation.

Ins

tall a tion.

overalls

sanforized

gauges

tion.

and

trousers,

operations

Nos.

8 and

and

on

non-

9.

Each

UNION

denotes

number, stamped on

in

number and

Thread

mation.

round

ball

100/040, 110/044,

It

one

undersize -one

in

of

the

thousandths

Selection

should

Standard

shank,

point,

Standard

is a round

step

increase,

sizes

needles

090/036,

The machine

SPECIAL

kind

of

the

size

of

pass

needle

round

chromium

needle

shank,

step

as

shown

MACHINE

of

shank,

the

an

inch,

number

proper

freely

for

point,

plated

125/049.

for

round

short

reduction,

100/040,

styles

in

STYLE

needle

point,

needle

listed

the

shank,

midway

is

the

needle

through

Styles

extra

and

Styles

point,

blade -1/8

110/044,

in

following

has

both a type

length,

between

complete

size

the

35700

short,

is

available

35700

short,

spotted,

125/049.

this

groove,

denotes

the

should

needle

AK,

AM,

double

AL,

BS,

double

inch

less

ball

catalog

chart:

number

the

shank

symbol.

be

determined

eye

AN,

groove,

in

sizes

CL,

groove,

than

point,

are

NEEDLE

finish

largest

and

in

order

CK,

DS

and

standard,

chromium

equipped

TYPE

and a size

and

other

diameter

the

eye.

by

the

to

produce

CM,

CN

is

struck

070/027,

all

struck

with

groove,

Class

width

plated

number. The

details.

of

the

Collectively,

size

of

a good

Type 108

ball

075/029, 080/032, 090/036,

35800

groove,

the

of

and

types

oversize

eye

The

blade

thread

stitch

GHS.

eye,

is

Type 128

and

is

available

and

NEEDLE

SIZE

type

number

size

measured

the

type

used.

for-

It

is

spotted,

ball

grooves

sizes

a

GLS.

eye,

35700

35700

35700

35800

*DISCONTINUED -In

AK,

AM,

AL,

(All

CK

AN,

BS,

Styles)

most

CM,

CN

CL,

DS

instances,

component

parts

6

108

108

128

128

can

GHS

GHS

GLS

GLS

be

ordered

for

080/032

090/036

100/040

110/044

customer

repair.

To

have

sample

on

label. A complete

needle,

needle

orders

or

the

type

orderwouldread:

NEEDLES

promptly

and

size

(Continued)

and

number

11

1000

accurately

should

Needles,

filled,

be

forwarded.

Type

108

an

GHS,

empty

Use

Size

package,

description

080/032

a

11

•

ILLUSTRATIONS

The

arrangement

Class

presents

Small

fit

listing

required

the

in

exploded

35700

Exploded

keyline

in

the

of

Numbers

position

ordering

view

and

view

a

sector

views

assembled

the

parts

in

the

particular

in

of

the

parts.

plate·

Sub-assemblies,

or a solid

which

under

23

24

25

26

line

can

be

the

description

29101

22587

22764

box

furnished

G

E

88

35800

plates

of

show

with

the

first

part

Always

carries

on

ORDERING

of

this

replacement

cover

the

machine,

by a blackened

machine.

their

view

column

in

the

use

which

the

are

exploded

for

of

the

Feed

Eccentric

CL,

Screw-----------------------------------------

Screw-----------------------------------------

Screw-----------------------------------------

catalog

parts.

the

Standard

parts

On

the

part

numbers,

being

are

illustration.

the

part

a

reference

sold

complete,

view

repairs,

main

sub-assembly.

Lift,

Feed

Assembly,

BS,

DS

OF

REPAIR

is

to

facilitate

being

area

page

shown.

reference

Reference

number

number

plate.

are

indicated

Rocker

and

all

PARTS

Styles

listed

aligned

exactly

where

opposite

descriptions

numbers

listed

for

or

by

Component

by

Example:

and

Looper

for

Styles

Class

35800

easy

as

in

and

in

their

this

the

the

illustration

and

only,

numbers

in

the

second

each

separate

part

part,

parts

indenting

Avoid

35700

--------------------

accurate

catalog.

assembled

parts

being

will

the

number

and

merely

should

never

column.

for

sale.

are

of

sub-assemblies,

their

AL,

ordering

Each

plate

position.

discussed

be

found

of

pieces

indicate

be

used

Each

in a bracket

descriptions

of

a

1

4

1

1

It

will

be

The

reason

the

complete

In

those

catalog,

parts

in

the

At

this

part

no

for

the

description

the

back

book.

number

Where

some

of

the

identification

Part

numbers

IMPORTANT!

OF

MAClilNE

noted

is

in

that

replacement

sub-assembly

cases

specific

various

where a part_ is

usage

machines

and,

of

the

This

is

known.

will

faciliate

construction

smaller

letter

is

represent

ON

FOR

WHICH

the

above

will

if

necessary,

book

permits,

parts,

stamped

ALL

example

of

these

should

be

common

be

mentioned

are

not

will

be

found a numerical

locating

IDENTIFYING

each

and

on

those

in

to

the

same

ORDERS,

PART

IS

ORDERED.

that

the

parts

ordered.

to

in

the

same,

the

difference

the

illustration

part

is

where

distinguish

part,

regardless

PLEASE

7

eccentric

individually

all

of

the

the

description.

the

specific

will

index

and

PARTS

stamped

construction

the

part

of

INCLUDE

and

bearing

is

not

machines

usage

be

shown

of

all

description

with

its

from

similar

catalog

PART

are

recommended,

covered

However,

will

be

in

the

illustration.

the

parts

when

part

does

number.

not

ones.

in

which

NAME

they

AND

not

listed.

by

this

when

mentioned

shown

only

permit,

appear.

STYLE

so

the

in

the

On

an

USE

GENUINE

NEEDLES

AND

REPAIR

PARTS

Success

UNION

subsidiaries

approved

efficiency

ments

unless

must

viscosity

pages

is

located

under

SPECIAL

scientific

Prices

are

otherwise

The

oil

be

filled

Oil

is

9, 10

the

in

the

and

and

durability

are

strictly

forwarded

has

before

of

90

to

filled

and

at

the

foot

lifter

operation

Repair

authorized

principles,

f.

directed.

been

at

11.

front

drained

beginning

125

seconds

the

The

of

lever.

caps

the

of

Parts

distributors.

are

assured.

net

cash

o.

b.

shipping

A

charge

OILING

from

"G"

level

is

cylinder

Maintain

these

as

and

and

to

operate.

at

100°

and

checked

machines

furnished

are

made

TERMS

are

subject

point.

is

made

AND

the

"H"

and

the

THREADING

machine

Fahrenheit.

in

at

the

oil

can

be

by

the

Union

They

Use a straight

the

level

are

with

the

to

change

Parcel

to

cover

before

accompanying

the

two

other

on

between

designed

utmost

Post

sight

the

secured

Special

according

precision.

without

shipments

the

postage

shipping,

mineral

threadi~

gauges

right

the

side

red

only

and

"J"

of

lines

with

Corporation,

notice.

are

and

the

oil

with a Saybolt

dia~rams

and

the

main

of

genuine

to

the

most

Maximum

All

ship-

insured

insurance.

reservoir

K".

One

frame

the

gauges.

its

on

The

machine

action

and

when

necessary

holes

screws.

inoperative.

screw

frame

35700

35700

same

threading

tension

are

position,

position.

of

the

back

A

at

top

beginning

To

do

and

If

Oil

may

is

located

below

The

accompanying

and

and

manner.

Keep

discs

convenient

the

leaving

is

equipped

oil

can

be

covers.

to

to

prime

this,

operate

machines

two

of a particular

the

left

oil

be

the

threads

"D"

does

needle

Refer

end

remove

handwheel.

When

operate a machine

the

machine

not

drained

in

the

in

and

means

of

their

them

observed

starting

pump.

the

two

until

bubble

from

bottom

drawings

Class

machines

to

the

machine

in

the

"E".

Avoid

for

travel,

easily

threading

with a continuous

through

plug

bubbling

when

the

machine

of

the

also

35800

in

threading

style.

slots

crossing

press

accessible.

the

a

new

that

screws

machine

cylinder

show

are

threaded.

Class

"F"

in

the

lucite

machine

has

"N".

can

at

the

35800

diagrams

the

threads

looper

the

knob 11S"

After

running

windows

been

Apply

be

observed

is

running,

two

and

the

manner

Three

are

tension

has

threading,

rotary

after

idle

oil

places,

other

in

threaded

on

pages

posts

as

much

been

and

driven

"L"

filling

for

some

from

at

the

the

"P"

at

which

needle

9,

"C"

as

provided.

loopers

push

oil

and

"M"

the

reservoirs,

time,

an

oil

can

windows.

circulating

and

"R".

the

back

machines

machines

in

substantially

10

and

and

between

possible.

When

will

loopers

pump.

in

the

it

may

to

Replace

pump

One

of

the

in

in

11

loopers

back

back

front

these

main

Class

Class

for

out

The

or

be

is

plug

the

the

the

of

into

8

a

3

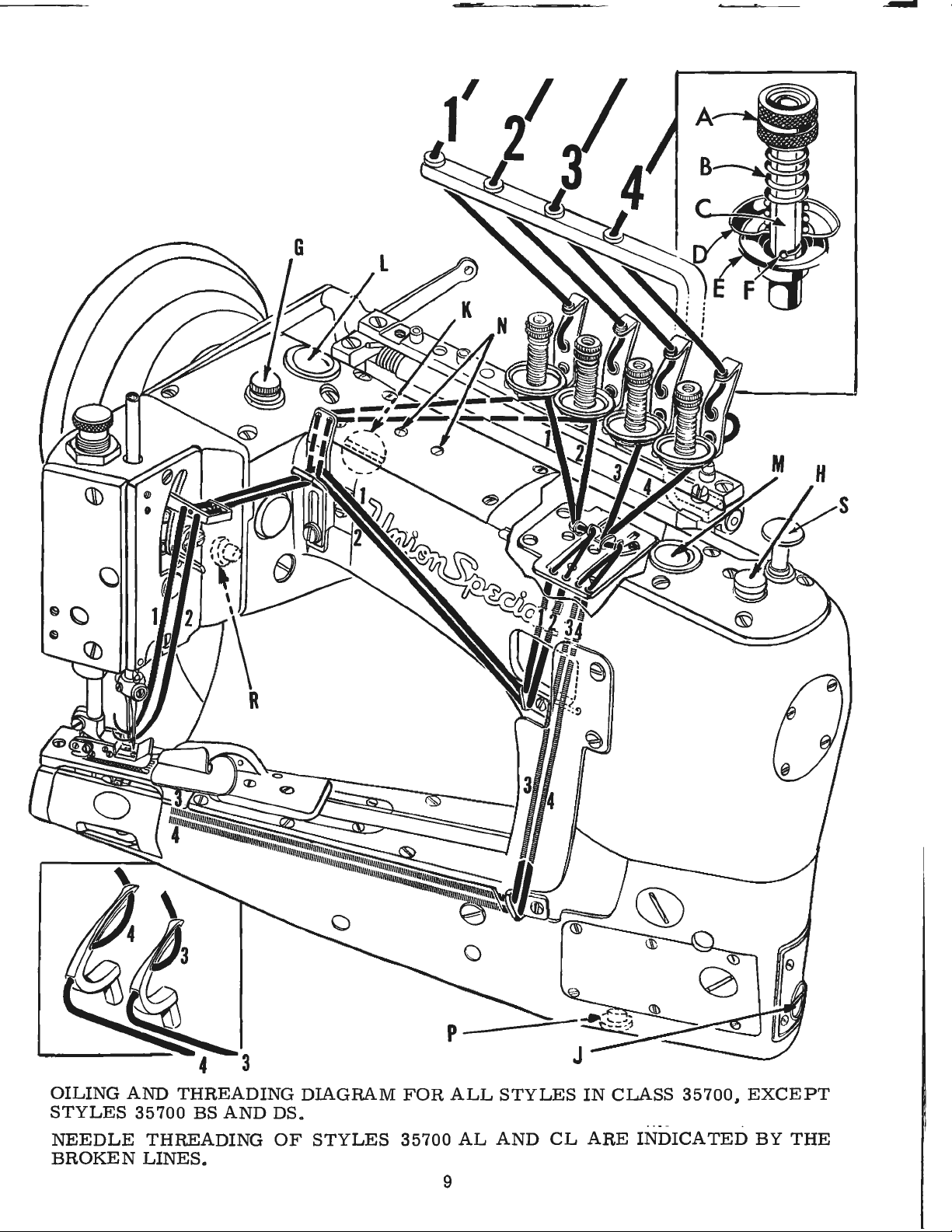

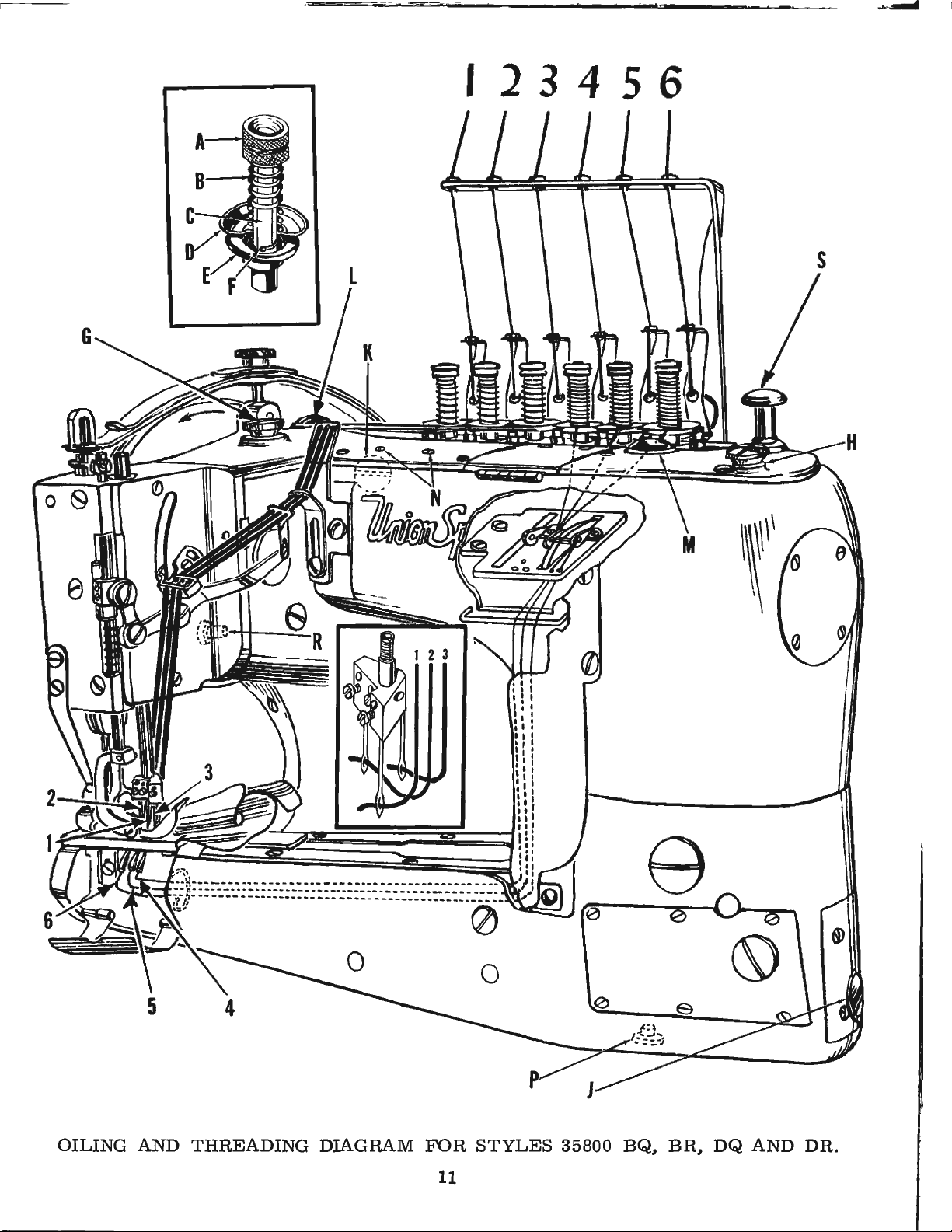

OILING

STYLES

NEEDLE

BROKEN

AND

THREADING

35700

THREADING

LINES.

BS

AND

DIAGRAM

DS.

OF

STYLES

FOR

35700

9

ALL

AL

STYLES

AND

CL

IN

CLASS

ARE

35700,

INDICATED

EXCEPT

BY

THE

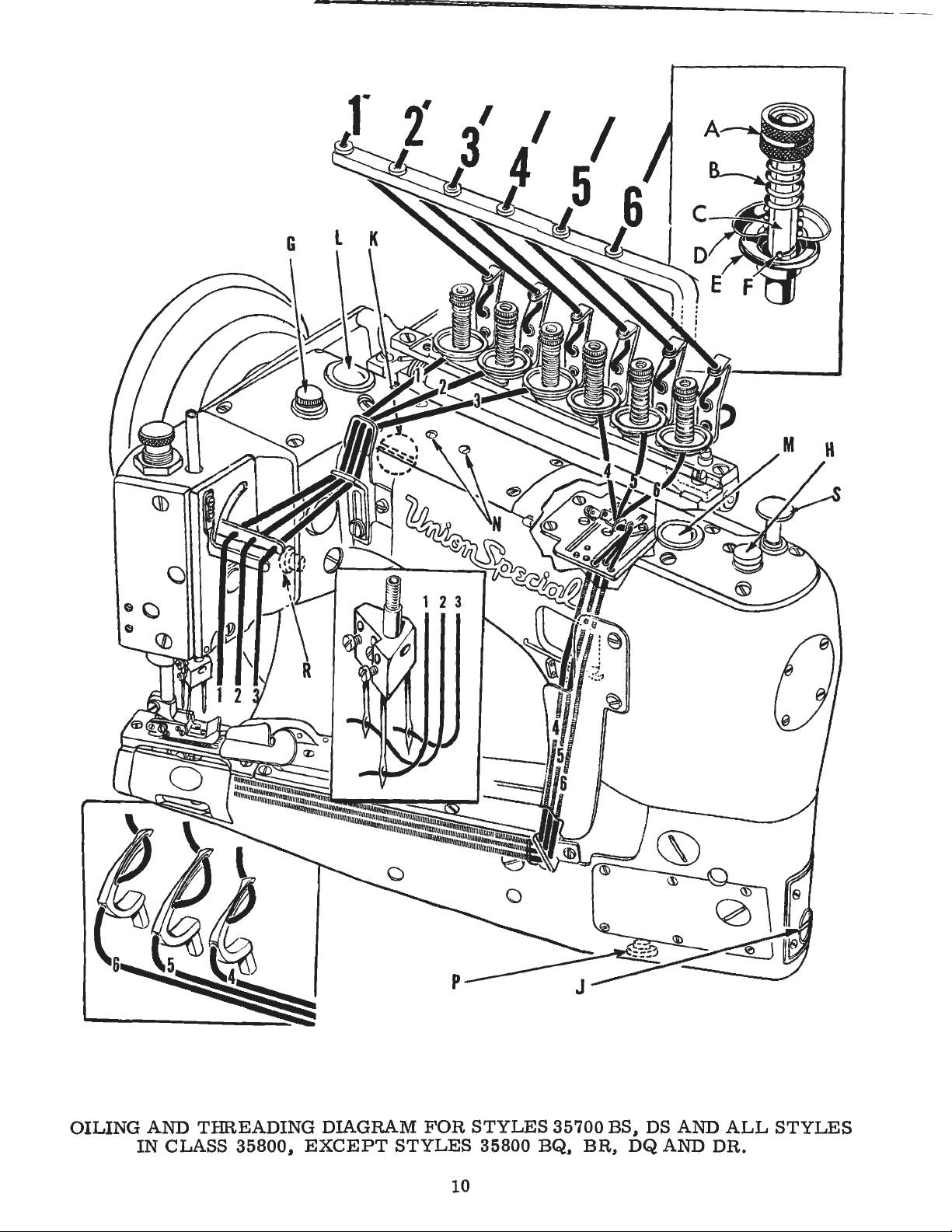

OILING

AND

IN

THREADING

CLASS

35800,

DIAGRAM

EXCEPT

FOR

STYLES

STYLES

35800

35700

BQ.

10

BS,

BR,

DS AND

DQ

AND

ALL

DR.

STYLES

.

123456

0

0

0

M

e

e

e

0

OILING

AND

THREADING

DIAGRAM

FOR

11

STYLES

35800

BQ,

BR,

DQ

AND

DR.

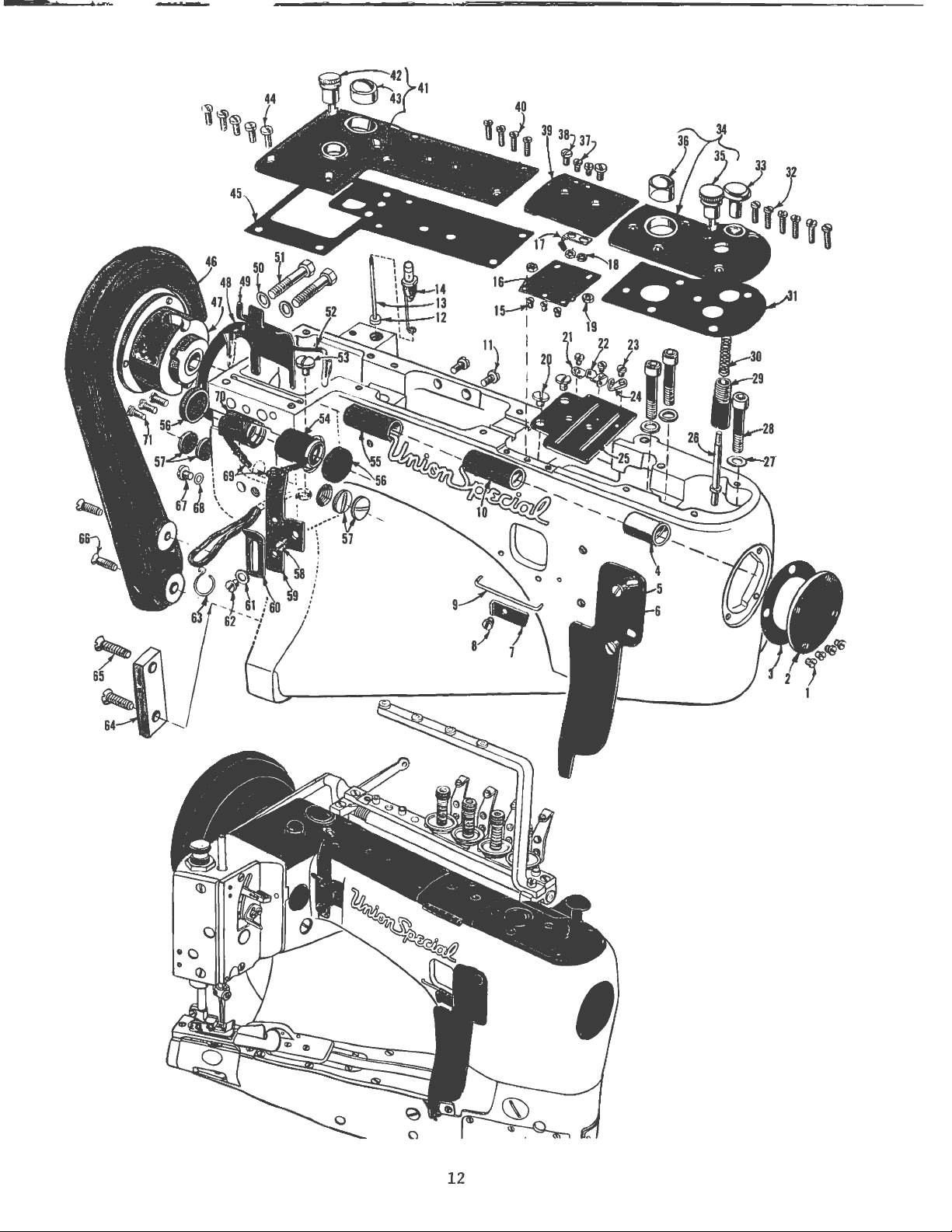

12

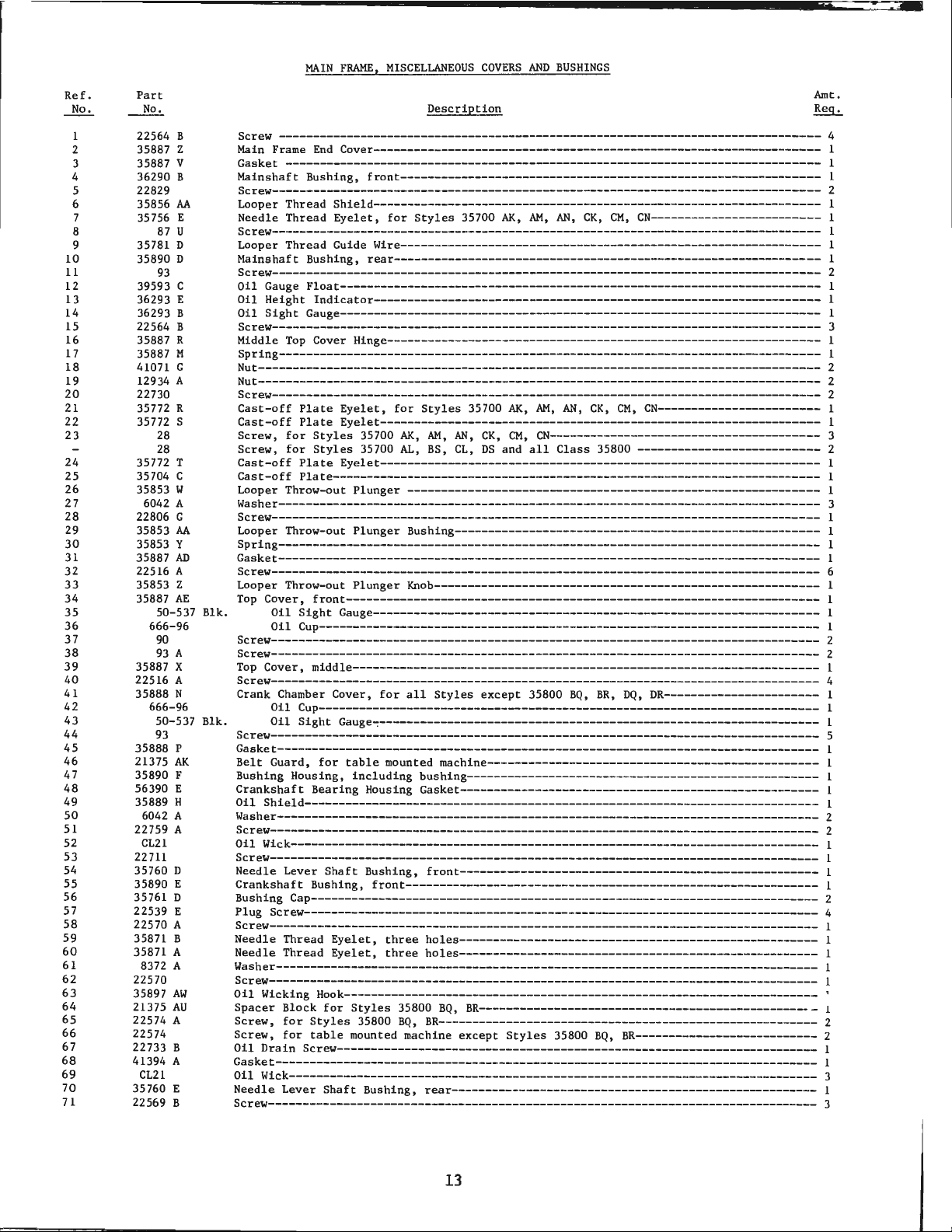

MAIN

FRAME,

MISCELLANEOUS

COVERS

AND

BUSHINGS

Ref.

No.

1 22564 B

2 35887 Z

3 35887 V

4 36290 B

5

6

7

8

9

10

11

12 39593 C

13

14

15 22564 B

16 35887 R

17 35887 M

18

19

20

21

22

23

24

25 35704 C

26

27

28

29

30

31 35887

32 22516 A

33 35853 Z

34 35887

35

36

37

38

39

40

41

42

43

44

45

46

47 35890 F

48 56390 E

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

Part

No.

22829

35856

35756 E

87

35781 D

35890

93

36293 E

36293 B

41071

12934 A

22730

35772 R

35772 S

28

28

35772 T

35853 W

6042

22806 G

35853

35853 Y

50-537

666-96

90

93

35887 X

22516 A

35888 N

666-96

50-537

93

35888 P

21375

35889 H

6042

22759 A

CL21

22711

35760 D

35890 E

35761 D

22539 E

22570 A

35871 B

35871 A

8372 A

22570

35897

21375

22574 A

22574

22733

41394

CL21

35760 E

22569

AA

U

D

G

A

AA

AD

AE

A

AK

A

AW

AU

B

A

B

Description

Screw----

Main Frame

Gasket------------------------------------------------------------------------------Mainshaft

Screw--------------------------------------------------------------------------

Looper Thread

Needle Thread

Screw--------------------------------------------------------------------------------Looper Thread Guide

Mainshaft

Screw--------------------------------------------------------------------Oil

Gauge

Oil

Height

Oil

Sight

Screw--------------------------------------------------------------------------Middle

Spring-------------------------------------------------------------------------------Nut-----------------------------------------------------------------------------Nut-----------------------------------------------------------------------Screw-----------------------------------------------------------·-------------

Cast-off

Cast-off

Screw,

Screw,

Cast-off

Cast-off

Looper Throw-out

Washer-------------------------------------------------------------------------------Screw--------------------------------------------------------------------------------Looper Throw-out

Spring--------------------------------------------------------------------Gasket-------------------------------------------------------------------------------Screw--------------------------------------------------------------------------------Looper Throw-out

Top

Blk.

Blk.

Cover,

Screw-----·----------------------------------------------------------------------Screw-----------·----------------------------------------------------------------Top

Cover,

Screw-------------·--------------------------------------------------------Crank Chamber Cover,

Screw-----·-----------------------------------------------·-----------------

Gasket------·----·-------------------------------------------------------------

Belt

Bushing Housing,

Crankshaft

Oil

Shield-----------------------------------------------------------------Washer------------------------------------------Screw--------------------------------------------------------------------------Oil

Wick--------------------------------------------------------------------Screw------------------------------------------------------------------------Needle Lever

Crankshaft

Bushing

Plug

Screw----------------------------------------------------------------------------Needle Thread

Needle Thread

Washer----------------------------------------------------------------------

Screw----------------------------------------------------------------------------

Oil

Wicking

Spacer

Screw,

Screw,

Oil

Drain

Gasket-------------------------------------------------------------------------------Oil

Wick----------------------------------------------------------------------Needle Lever

Screw----------------------------------------------------------------------------

End

Bushing,

Bushing,

Float--------------------------------------------------------------Gauge------------------------------------------------------------

Top

Cover

Plate

Plate

for

Styles

for

Styles

Plate

Plate------------------------------------------------------------------

front------------·-------------------------------------------------

Oil

Sight

Oil

Cup-------·-------------------------------------------------------------

middle--------------------------------------------·------

Oil

Cup-------------------------------------------------------------------

Oil

Sight

Guard,

Bearing

Bushing,

Cap---------------------------------------------------------------------------

Screw----------------------------------------------------------------------------

Block

for

Styles

for

table

Screw-------------------------------------------------------------------

-----·-----------

Cover------------------------------------------------------

front-----------------------------------------------

Shield-------------------------------------------------------------Eyelet,

Indicator------------------------------------------------------------------

Eyelet,

Eyelet-----------------------------------------------------

Eyelet-----------------------------------------------·--------------

Gauge------------------------------------------------------------------

Gauge~------·------------------------------------------------------

for

Shaft

Eyelet,

Eyelet,

Hook---------------------------------------------------------

for

Shaft

for

Styles

Wire--------------------------------------------------------

rear---------------------------------------------------

Hinge----------------------------------------------------------

for

35700

AK,

35700

AL,

Plunger------------------------------------------------------------

Plunger

Plunger

table

including

Styles

35800

mounted machine

Bushing---------------------------------------------

Knob---------------------------------------------------------

for

all

mounted

Housing

Bushing,

front-----------------------------------------------

three

three

35800

BQ,

Bushing,

35700

Styles

bushing---------------------------------------------------Gasket-----------------------------------------------------

35700

AM,

AN,

BS,

Styles

front-----------------------------------------------------

holes----------------------holes----------------------------------------

BR----------------------

rear-----------------------------------------------------

CK,

CL,

DS

except

machine-------------------------------------------------

BQ,

BR--------------------

except

-

--------------------------------------

AK,

AM,

AN,

CK,

AK,

AM,

AN,

CK,

CM,

CN----------------------------

and

all

Class

35800

35800

BQ,

BR,

Styles

35800

BQ,

CM,

CN-----------------

CM,

CN,-----

-------------------

DQ,

DR---------------

---------------------

---------------

----·----

BR---------------------------

----

------

Amt.

Req.

4

l

1

1

2

1

1

1

1

l

2

1

l

1

3

l

1

2

2

2

l

1

3

2

1

1

1

3

1

1

1

1

6

1

l

1

1

2

2

1

4

1

1

1

5

l

1

l

I

l

2

2

l

l

l

l

2

4

l

1

1

1

l

l

2

2

l

1

3

l

3

13

1

1~

13

14

·

LO

LL

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

28A

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

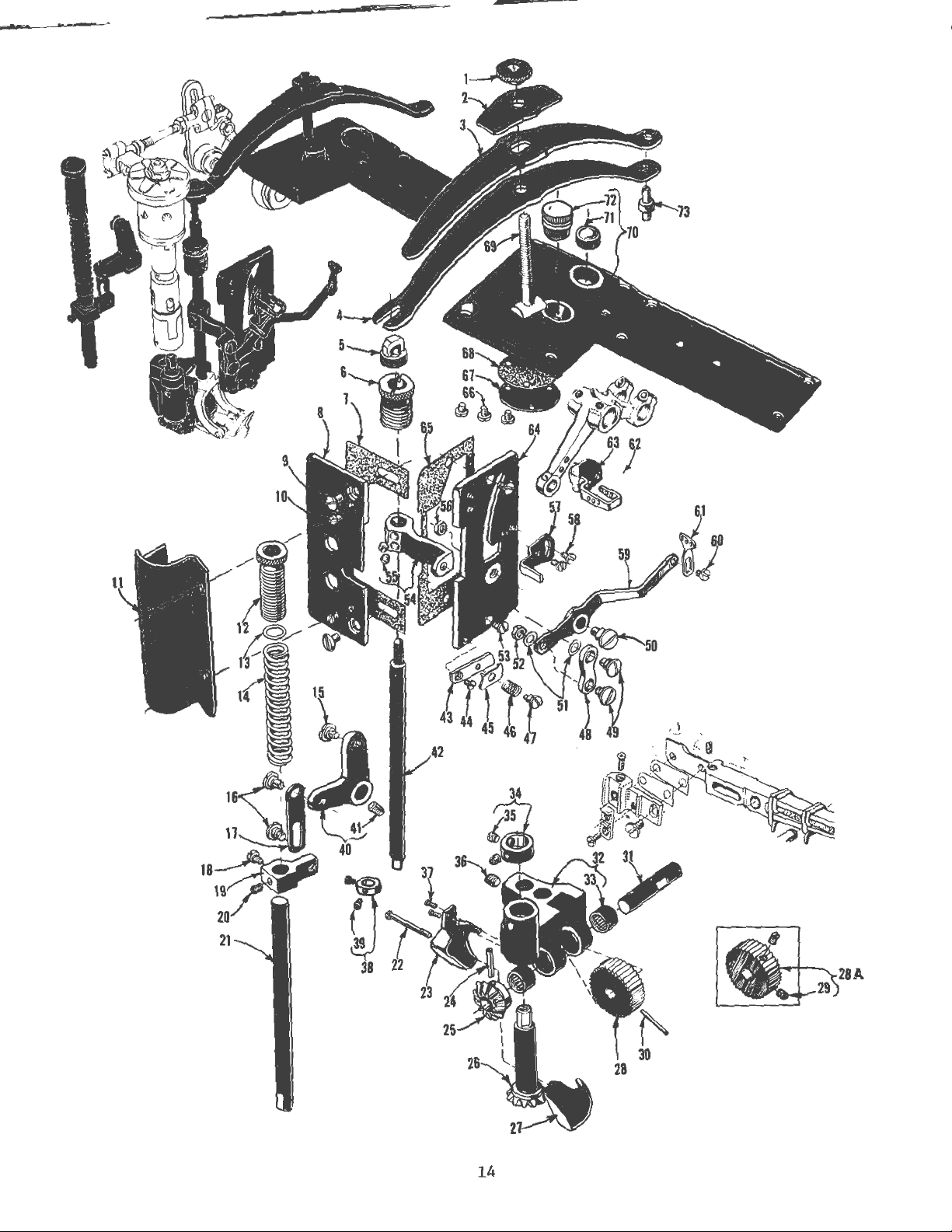

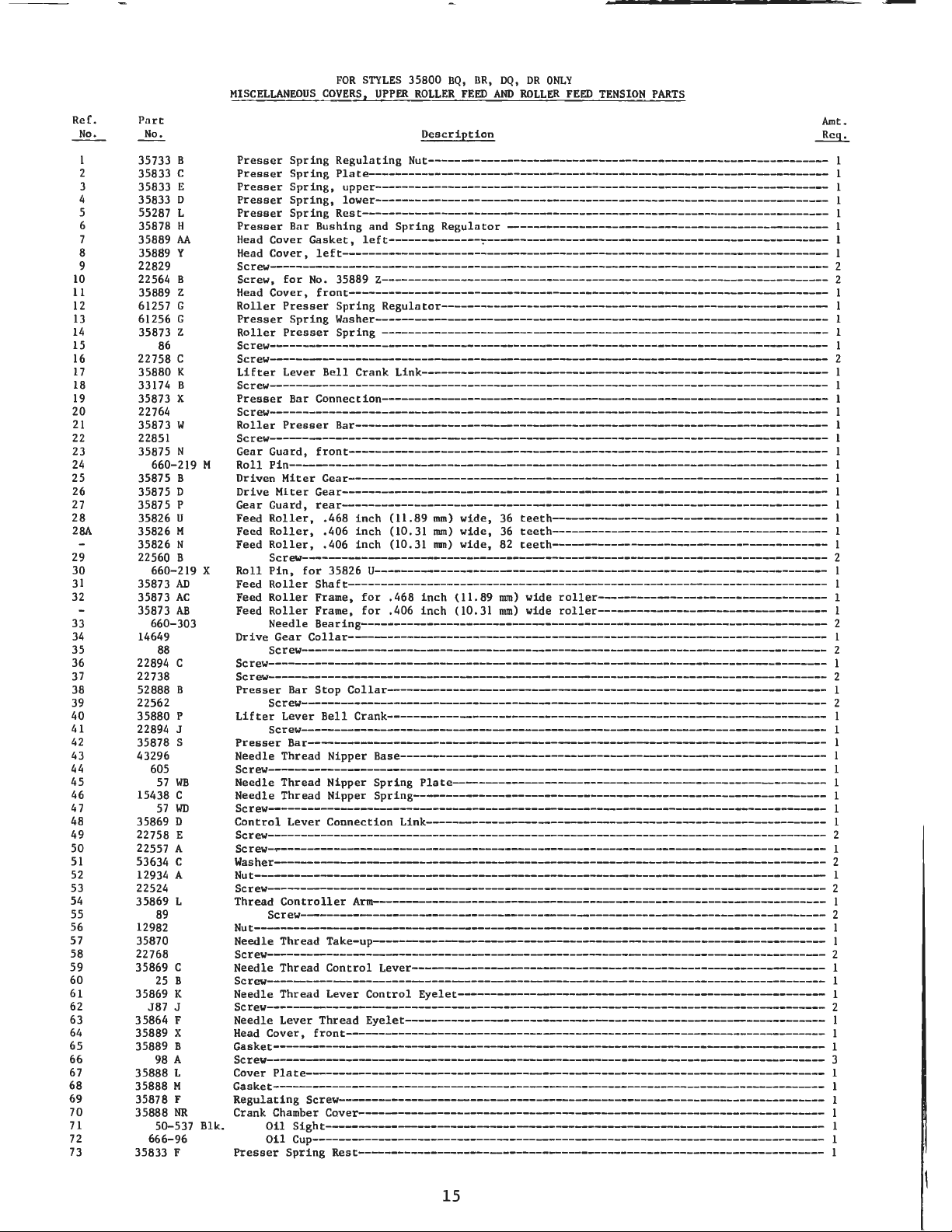

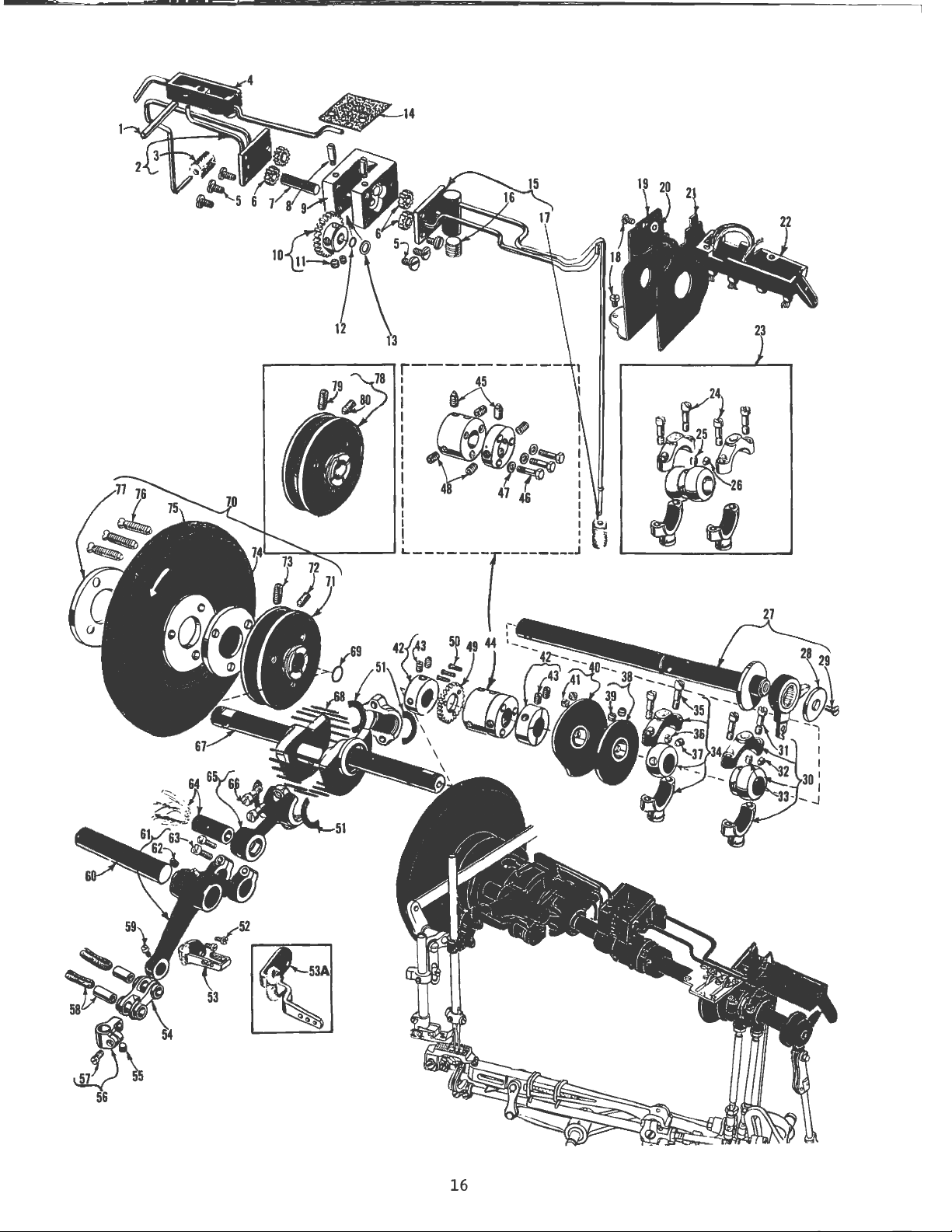

FOR

STYLES

35800

BQ,

BR,

DQ,

DR

MISCELLANEOUS

COVERS,

UPPER

ROLLER

FEED

AND

Part

No.

l

2

3

4

5

6

7

8

9

35733

35833 C

35833 E

35833 D

55287 L

35878 H

35889

35889 Y

22829

22564

35889 Z

61257

61256 G

35873 Z

86

22758

35880 K

33174 B

35873 X

22764

35873

22851

35875

660-219

35875 B

35875 D

35875 P

35826 U

35826 M

35826 N

22560 B

660-219

35873

35873

35873

660-303

14649

88

22894 C

22738

52888

22562

35880

22894 J

35878 S

43296

605

57

15438 C

57

35869 D

22758

22557 A

53634 C

12934 A

22524

35869

89

12982

35870

22768

35869 C

25 B

35869 K

J87

35864 F

35889

35889 B

98 A

35888 L

35888 M

35878 F

35888

50-537

666-96

35833 F

B

AA

B

G

C

W

N

AD

AC

AB

B

P

WB

WD

E

L

J

X

NR

Presser

Presser

Presser

Presser

Presser

Presser

Head

Head

Spring

Spring

Spring,

Spring,

Spring

Bar

Cover

Cover,

Regulating

Plate--------------------------------------------------------------

upper----------------------------------------------------------------

lower-----------------------------------------------------------------

Rest-------------------------

Bushing

Gasket,

and

left-----------------------------------------------

left-----------------------------------------------------------

Screw---------------------·---------------------------------------Screw,

Head

Roller

Presser

Roller

Screw----------------------------------------------------------

for

No. 35889 z--------------------------------------------------- 2

Cover,

front------------------------------------------

Presser

Spring

Presser

Spring

Washer-----------------------Spring--------------------------

Screw-----------------------------------------------------Lifter

Lever

Bell

Crank

Screw----------------------------------------------------Presser

Bar

Connection------------------------------------------------Screw---------------Roller

Presser

Screw-------------------------------------------------------------------Gear

Guard,

Roll

Driven

Pin--

Miter

M

Drive Miter

Gear

Guard,

Feed

Roller,

Roller,

Feed

Roller,

Feed

Bar----------------------------------------

front------------

Gear-----------------------------------------

Gear-------

rear------------------------------------------------------------

.468

inch

.406

inch

.406

inch

Screw------------------------------------

X

Roll

Pin,

for

35826

Feed

Feed

Feed

Drive

Roller

Shaft---------------------------

Roller

Frame,

Roller

Frame,

Needle

Bearing--------

Gear

Collar---------------------------------

U--------------------------

for

for

Screw------------Screw-----------------Screw------------------------

Presser

Lifter

Bar

Stop

Scre,w-------

Lever

Bell

Collar---------·-------------

Crank----------------------------------

Screw-----------------------------------------------Presser

Needle

Bar------------------------------

Thread

Nipper

Base--------------·--------Screw-----------------------------Needle

Thread

Nipper

Needle

Thread

Spring

Nipper

Spring---------------------------------------Screw--------------------------·-------Control

Lever

Connection

Screw 2

Screw---------Washer 2

Nut------Screw---

Thread

Controller

Screw------------------------

Nut----

- l

Needle

Thread Take-u

Screw-

- -

Needle

Thread

Ar l

---------------Control

Screw-----

Needle

Head

Screw---Needle

Cover,

Thread

Lever

Control

Lever

Thread

Eyelet----------------------------

front---------------------------

Gasket-------

Screw--------------------------

Cov

er Plat

Gasket----------------------------------------------------------------Regulating

Crank Chamber

Blk.

Presser

Screw------------

Co.ver----------

Oil

Sight--------------------------------------

Oil

Cup---------------

Spring

Rest---

Description

Nut--------------------------------------------

Spring

Regulator----------------------------------------------

Regulator-----------------

Link------------

(11.89

mm)

wide,

(10.31

(10.31

.468

.406

mm)

RID)

inch

inch

wide,

wide,

(ll.89

(10.31

36

36

82

mm)

mm)

----------------------------

Plate---------------------------------

Link----------

----------

-

Lever------------

Eyelet---------------------------------

---

----------------------------

ONLY

ROLLER

FEED

TENSION

--------------

PARTS

--------------

----------------------------

--------------------------

-------------------------

teeth---teeth

-------------

teeth-----------

wide

roller-------------

wide

roller-------

--

----------------------------

-----------------------

---------

--

------------------------

-----------------------------

-------------

-

-------

--------------------------------------

----------------------------------

--

-----------------

---------

-

--------------

- 2

·-

------

----·-------

--------

------

Amt.

~

- l

l

l

l

l

l

l

2

l

l

l

l

2

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

2

l

2

l

2

l

2

l

l

l

l

l

l

l

l

l

1

1

2

2

l

2

l

1

1

2

l

l

l

3

1

l

l

l

l

l

l

15

16

Loading...

Loading...