Page 1

INDUSTRIAL

SEWING

FINEST

STYLES

20030

200

QUALITY

35

LEWIS

•

COLUMBI

a

MACHINES

(sc

‘

Ci)O)

I

,.

U

a

CATALOG

No.

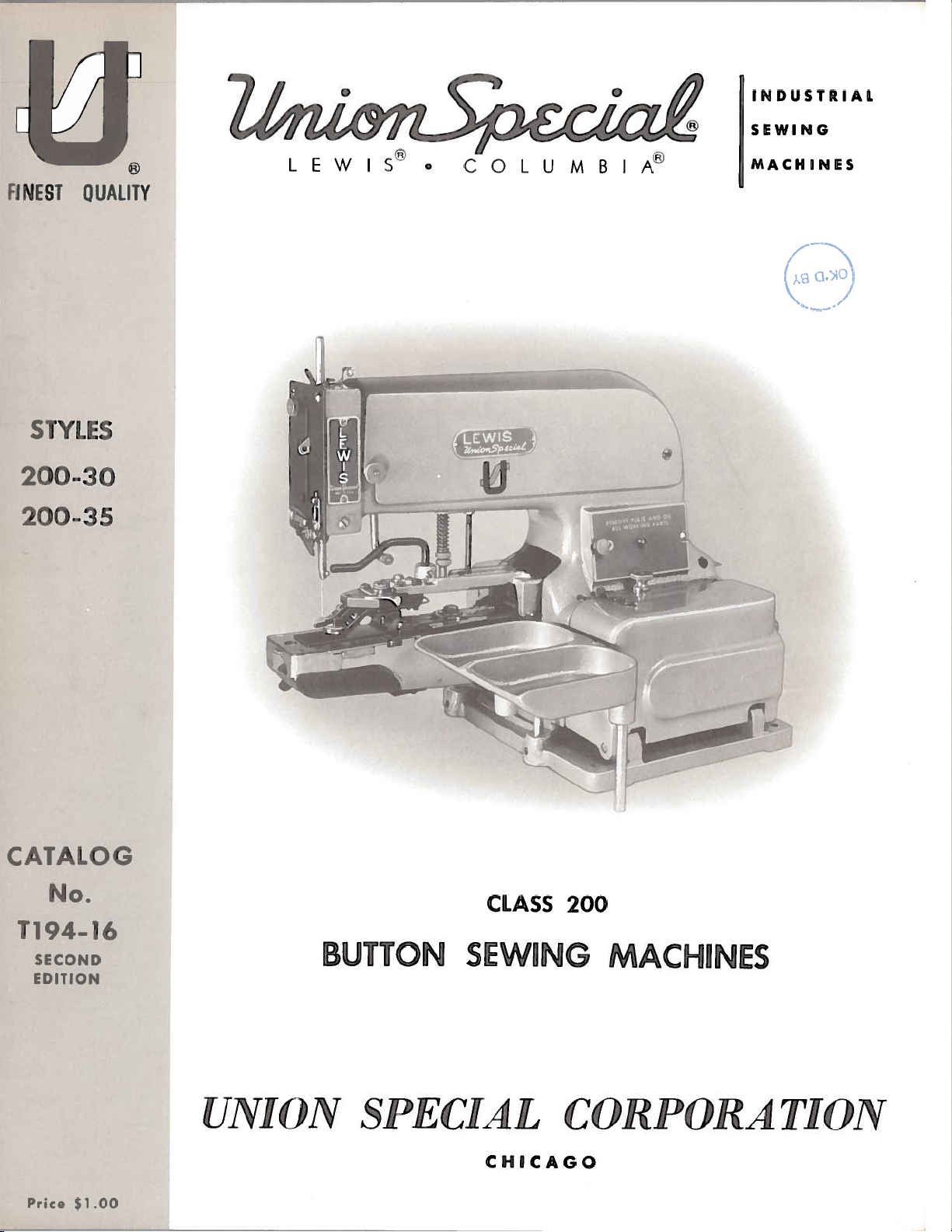

CLASS

T194-16

SECOND

EDITION

UNION

Price

$1

.00

BUTTON

SPECIAL

SEWING

CHICAGO

200

MACHINES

CORPORATION

Page 2

Catalog

No.

1194—16

(Supplernoni

AILJ

200-30

INST

TSTINC

LIST

lv

Styles

Catalog

IUCT

1

0

ANI)

OF

IONS

R

OPERATING

PA

RTS

No.

194-4)

200-35

Union

Rights

UNION

INDUSTRIAL

Second

Copyright

Special

Reserved

SPECIAL

Edition

1967

by

in

SEWING

CHICAGO

&

1969

Corporation

All

Countries

CORPORATION

MACHINES

S.

Printed

in

U.

2

A.

July,

1976

Page 3

ClasS

toward

1ach

01

The

UNION

machines,

sei’iu

hack.

the

I.

SPECIAL

i

in

lI)lNI’[l’[C’

1

’I’[0N

LEWIS

stnuped

is

iii

mr

of

in

(‘ad)

the

macli

machine

style

inc

is

01’

carries

plate

stamped

.Vl.P(ll[NlS

a

on

the

in

the

style

left

side

right

number,

of

side

the

of

which

arm.

he

in

cylinder

this

rlhiS

:iunction

lot’

all

in

this

number,

This

Reference

from

pulley

high

t;ypes

and

Aul;omatic

200-

production,

eyes,

30

stitches

Equipped

the

stitches

high

200-35

stitches

Equipped

cycle

Primarily

with

certain

Can

be

button

parts

catalog.

t;he

is

of

used

during

catah’g

herewith.

t

used

name

catalog

to

operator’s

away

flat.

two

and

stitching

Right

stitch

of

quality

Right

in

and

types

with

on

At

and

applies

direction

from

single

hole

for

in

two

with

cycle

two

garments

two

with

automatic

used

or

the

raising

is

a

Consu

styles

the

amount,

position

the

and

shank

cycle,

to

Left

hole

improved

(between

hole

Left

to

hole

improved

with

of

automatic

without

APPLICATION

supplement;

Ii.

catalog

200-

hack

of

required.

specilically

such

as

while

operator.

DESCRIPTION

thread,

four

hole

buttons.

cam

Stitching

a

or

trimming

the

buttons,

such

Stitching

buttons

trimming

button

heavy

the

of

the

:o

the

right,

button

Lever

drive

total

two

also

as

men’s

or

clamp

thread

button

automatic

clamp.

to

No.

and

book

to

seated

buttons.

with

Flat

of

of

rows

if

of

Flat

atotal

OV

catalog

tJl—

1

200-35

the

parts

the

Standard

left,

front,

at;

OF

sewing

Attachments

adjusted

stop

Buttons

parallel

16

mechanism

of

desired

sack

Buttons

of

16

mechanism

opener.

where

feeders

button

CA’I’A.[

No.

104—4

machine

4,

respectively

are

Style

back,

the

machine.

MACHINES

machines.

stitch

motion

With

stitches

for

parallel

at

the

coats,

suit

With

parallel

for

thread

and

for

clamp

OG

illustrated

range

clutch.

No

cutting

stitches)

end

coats,

a

cutting

cutter

use

and

styles

not

of

machine

or

up

Operating

Sews

available

Cross-

in

of

cycle.

Cross-

stitches

thread

is

with

opener,

should

illustrated

down,

all

to

sew

Single

four

thread

or

ladies

over

infour

needed.

necking

be

used

200—

10

or

and

listed

as

listed

etc.,

direction

popular

to

sew

snaps,

8

or

treadle

over

hole

at

in

the

Stitch.

buttons

the

end

Recommended

suits

Stitch.

holebuttons.

at

the

Recommended

attachment.

which

releases

and

described

are

sizes

16

stitches.

operation.

middle

and

end

in

200—

by

herein.

of

hooks

Sews

of

coats

Sews

of

stitch

con

15

part

given

the

and

8

only.

of

cycle

for

16

the

under

29

S-100/040

long,

Needle

diameter

29

29

29

29

The

recommended

Use

only

our

Needle

short

type

SHORT

S—090/036

S-100/040

S-110/044

S-125/049

brand

type

shank,

29

blade.

genuine

name

29

recommended

is

S-100/040

Other

speed

UNION

ZlnL,nE’pccaze

LSS-110!044

sharp

point

is

diameter

BLADE

INCHES

.036

.040

.044

.049

of

SPECIAL

for

needle

short,

a

these

is

recommended

Style

needles

DIA

MM.

.90

1.00

1.10

1.25

SPEED

machines

NEEDLES

LEWIS

200-35.

with

an

sharp

point

are

LONG

SHORT

29

29

29

29

29

3

1500

is

needles.

for

Needle

.044

inch

needlewith

available

with

SHANK

LSS—090/036

LSS-100/040

LSS-110/044

LSS—125/049

LSS-140/054

Style

as

P.

R.

The

type

(1.10

follows:

M.

needles

200-30

mm)

an

.040

BLADE

INCHES

and

29

LSS-110/044

diameter

inch

.036

.040

.044

.049

.054

are

packaged

needle

(1.00

DIA.

MM.

.90

1.00

1.10

1.25

1.40

type

is

blade.

mm)

a

Page 4

Selection

material

and

of

type

proper

of

button

needle

used.

NEEDLES

size

is

(Continued)

determined

by

size

of

thread,

weight

of

sample

read:

far

and

has

Page

on

starts.

seconds

fact

beneficial.

be

To

have

needle,

“100

When

as

it

will

that

set

A

cross

been

inserted

Immediately

To

thread

5.

These

Use

at

Most

they

of

are

needle

Needles,

changing

go,

screw

hole

machine,

machines

a

good

1000

the oiling

painted

orders

or

the

Type

the

with the

is

tightened

drilled

as

far

discard

should

grade

Fahrenheit.

places

red.

type

needle,

long

in

as

put

of

promptly

number

29

LSS-llO/044”

CHANGING

groove

securely.

the needle

it

will

any

needle

ThREADING

in

stop

oiled

be

straight

on

However,

make

the

and

should

to

bar

go.

which

position,

twice

mineral

machines

reference

sure

the

accurately

be

forwarded.

NEEDLES

that

front

can

also

may

AND

and

daily,

oil

are

to

filled,

it

is

inserted

and

the

be

used

have

a

OILING

thread

before

ofaSaybolt

readily

the

oiling

an

A

complete

spot

to

determine

hooked

in

accordance

the morning

viscosity

identifiable

diagram

empty

in

or

or

the

scarf

blunt

container,

order

needle

to the

point.

with

and

of

because

on

Page

if

the

afternoon

90

would

bar

rear,

needle

diagram

to

of

5,

will

a

as

125

the

Please

open

to

places.

Also

of

grease

pulley

The

shown

should

greasing

are

Tubes

Where

some

of

identification

Part

appear.

Important!

Which

Part

the

note

the

numbers

note

hinged

furnished

is

place

oiled.

of

grease

the

smaller

letter

is

that

base

that

there

removed,

be

construction

represent

All

On

Ordered.

it

is

may

parts,

is

stamped

will

covers

a

is

with

indicated

be

Orders,

be

necessary

and

tilt

label

the

machine,

the

grease

by

ordered

IDENTIFYING

permits,

and

on

in

to

the

same

Please

to

machine

on

the

pulleywhich

and

level

the

letter

under

each

part

those where

distinguish

part

Include

TERMS

remove

on

periodically,

checked

“A”

part

No.

PARTS

is

construction

the

regardless

Part

arm

its

side

in

the

28604

stamped

part

Name

reads

and

of

cover

to

reach

“Grease

the

replenished

diagram.

P.

with

from

the

and

and

plug

its

does

similar

catalog

Style

side

some

All

part

not

of

cover,

of

Here”.

screw

if

other

number.

permit,

ones.

in

which

Machine

the oiling

A

tube

in

required.

places

they

For

and

the

On

an

Prices

warded

directed.

F.

0.

A

B.

charge

cash

shipping

and

subject

point.

to

is

made

cover postage

Parcel

to

change

Post

without

shipments

and

insurance.

are

net

4

notice.

are

All

insured

shipments

unless

are

for

otherwise

Page 5

X

-l

--rn

111

Q;o

r

C)

z

rD

1

0

)

(1)

ro

o

C

z

C)

Page 6

IViost

200-15

additional

of

are

instructions

the

adjusting

applicable

SETTING

ASSE

MB

LING

instructions

for

Styles

required

THREAD

AND

200-30

for

ADJUSTING

in

Styles

PULL

Catalog

and

200-30

OFF

INSTRUCTIONS

No.

200-35

and

LEVER

194—4

respectively.

200-

35

(Style

for

arc

200

Styles

The

listed

30)

200—

new

as

10

and/or

follows:

and

Refer

ent;ered

tever

way

than

Cat.

to be

should

to

the

when

No.

repeated.

The

front

edge

The

the

in

operation.

screws

by

The

eighth

the

soon

so

accomplished

is

and

ing

visible

screws,

advance

Adjusting

increase

feed

the

194-4)

knives

knives

the

knives

as

the

the

the

to

plate

then

left,

of

the

cutter

stitch,

to

moving

time

cutting

machine

in

machine

is

should

slot

should

should

for

catch

adjusting

by

whenthe

of

pawl

Style

times

7

start

middle

the

is

changed,

have

in

SETTING

overlap

lever

be

cutting

the

machine

the

cut,

to

protrude

stroke

200—

and

to

move.

in

the

enough

casting

the

link

TIMING

set

loop

as

the

operating

moving

or

TIMING

10

has

of

the

stop

setting

SIDE

THE

just

adjust

THE

to

cut

the

cross

it

operating

is

the

a

cross

THE

except

risen

When

cycle,

position

of

PLAY

clearance

allow

to

OVERLAP

enough

knives

the

KNIVES

the

back

pulled

is

in

stop

pawl

pawl

greater

over

KNIVES

to

the

cam

IN

to

over

pawl,

position.

the

in

in

of

continue

top

the

Ibread

it

should

or

end

(B,

Fig.

KNIVES

between

free

movement.

OF

the

cut

for

the

(Style

thread

stitch.

to the

bottom

located

direction

opposite

the

distance

the

knives.

(Style 200-3

turning

of

pull

be

of

the

15,

THE

back

proper

200-30)

of

the

The

on

Loosen

from

pulley

travel,

its

off

lever

1/8

inch

cycle.

Cal

the

yoke

No.

slides

KNIVES

thread

cut,

triangle

knives

the

of

left

the

operating

the

of

rotation

direction acts

the

edge

Retighten

5)

the

has

further

If

link

of

the

which

after

should

button.

side

screws.

until

thread

moved

194-4)

insert

triangle.

is

of

of

of

needle

to

Fig.

(B,

will

determined

the

setting

not

move

This

left cam

the

pawl

the

cam

the

reverse.

the

cam

puii

all

the

have

and

can

attach

has

off

the

left

16,

the

The

of

too

be

will

will

The

of

the

This

(A,

nut

ward

adjusting

drive

which

(C)

ward

arm

have

nut

and

NOTE:

care

cutting

strike

(C),

ing

or

sewing

from

of

the

knives

stitch

last

can

be

Fig.

downward

or

stud

lever

(B,

will

repositioning

(D).

been

(A)

When

obtained,

securely.

While

must

be

knife

shoulder

the

either

at

closing

cycle,

needle

the

diagonal

should

before

accomplished

which

18)

repositioning

(A,

Fig.

Fig.

18)

permit

of

satisfactory

tighten

making

the

(E)

(B,

of

the

of

upper

as

to

its

knives.

in

taken

lever

end

of

the

slots

be

“Stop

will

or

forward

the

this

assure

Fig.

mounting

slots

knife

is

the

set

by

in

19)

loosen

knife

adjustment,

19)

possible

drive

to

cut

Position”.

loosening

permit

the

screws

or

drive

conditions

screws

that

does

screws

while

During

should

(D)

lever

the

up

of

the

knife

rear

link

(C)

the

not

open-

the

without

back

be

(B).

retracted

the

6

thread

knife

of

to

drive

the

Fig.

provide

pins

triangle

(F)

after

18

maximum

striking

setting

the

clearance

the

ends

Page 7

guide

When

(H)

the

should

culling

be

set

knife

to

TI1VIING

(A,

enter

L{ig

the

TilE

IKNIVES

20)

thread

begins

(All

it

t:riangle

Styles)

cutting

formed

stroke,

by

the

threads

wider

point:.

made

(C),

guide

tighten

as

portion

Adjustment

by

reposition thread

as

screws.

the

thread

spreading

they

of

loosening

required

slide

the

finger

of

up

looper

can

screws

finger

and

the

the

be

re

the

ing

front

the

The

clamping

If

adjustment

the

ing

move

drive

sooner

jaws

condition

place

(D).

block

knife

tripping

lever

wider

screw

acts

button

position

or

is

(B)

move

and

to

the

rearwill

the

reverse.

clamp

after

is necessary,

drive

link

block

to

actuate

tripping

for

alonger

obtained,

(H)

that

arm.

(K)

retighten

holds

Fig.

19

advance

Tighten

jaws

should

clearing

remove screw

Loosen

downwardly

trip

off

block

duration.

the

knife

screws

return

the

and

closing

upwardly

screw

drive

the

sewn

screw

in

When

(J)

time

(H)

the

to open

desired

and

link

of

(F).

to

button.

secur

(J)

knife

of

jaws

arm

jaw

the

and

re

BUTTON CLAMP

The

should

ing

Fig.

the

be

button

13)

begins

can

be

screws

front

opening

tripping

and

--

(St:yle

button

set

200-35)

clamp

to

clamp jaws

before

just

to

lift. Adjustment

made

(F)

by

and

block

moving

--

the

OPENER

opener

start open

the

clamp

loosening

moving

Mov

(G).

block

(E,

the

to

NOTE:

reposition

do

not

In

1/32

inch

Thread

bushing

last

tying

6

in

Catalog

Turn

face

the

glazed

or

of

the

ance

between

passage

paragraph

To

come

using

or

of

knives.

of

disengage

tripping

in

contact.

various

to

1/64

take-up

slot

stitch

No.

the

nipper

the

nipper.

thread

For

the

the

thread

for

thet1THREAD

blocks

inch

in

face

out of

194-4.

and

cutting

nipper

button

threads

with

should

plate,

the

block

This

helps

during the

clamp

(Gand

K,

ADJUSTING

it

may

reference

ADJUSTING

be

set

as

to

assist

way

of

the

THREAD

that

so

provides

draw

most

and

threads

the

up

nipper

sewing

NIPPERH

opener,

Fig.

become

high

cutting

one

a

more

the

18)

STOP

Fig.

to

THREAD

as

possible

in

drawing

NIPPER

of

its

positive

last

tying

it

is

block

cycle.

on

page

7

merely

so

they

MOTION

necessary

2

in

TAKE-UP

knife

two

stitch

necessary

to

Refer

15,

Catalog

without

up

and

micro-

nipping

1/64

both

the

its

to

to

to

finger

serrated

loop

inch

in

change

No.

striking

cast

action

before

change

or

Fig.

Catalog

Fig.

the

194-4.

off

guide.

the

just

12

20

dimension

upper needle

thread

Refer

faces

when

the

will

using

cutting

3/64

enough

on

page

No.

194-4.

loop

inch

13

to

contact

smooth

action

clear

for

and

from

of

Fig.

free

bar

the

the

Page 8

4

a

if/

‘7-’

1

8

Page 9

pa

‘the

used

are

200—15

illust

it

s

hot

on

respectively.

rat

h

id

Styles

on

200—30

pages

tt

and

and

200—35

10,

aix!

(unless

(IC

seethed

otherwise

on

this

specified),

page

and

page

hut

not

11

repre

used

on

sent

Styles

lie

200—10

part

I

tat

s

antI

Catalog

Use

this

in

Reference

indicate

NO’lIi:

Ref.

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

*

*

*

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

*

*

*

catalog.

numbers

they

‘I’lte

Part

No,

430—63—7

99-353

80265

21-440

115-169

22894

71-119

40-3ht

22542

1731

166-14

99—316

1189

22-205

21-337

45-347

45-346

21-336

45-332

158-11

157-10

18-945

18-931

21-315

18-272

18-873

1005

71—112

18-929

18-930

20-123

17-178

CS337

45-481

40

22596

45-477-1

122-29

45-482

51170

815

115-168

94

18-1089

4119-84

4119-86

75-253

22564

22542

46-204

CS337

46-203

14-365

71-122

20-45

No.

are

part

W

L

L

L

C-615

D

L

F

194—4

(Styles

that

component

descriptions

A

are

Rutton

Knife

Screw,

Knife

Washer,

Screw,

Button

Looper

Knife

Nut,

Washer,

Knife

Screw,

Screw,

Knife,

Knife,

Screw,

Knife

Screw,

Knife

Stop

Button

Nut,

200—10

inside

part.s

below

l3utton

Thrust

Spring,

Push

Push

Washer,

Screw,

Screw,

Button

J:lolder

Screw,

Pin,

Left

Left

Right

Right

Adjusting

Slide

Spacer,

Adjusting

Screw,

Spring,

Screw,

Screw,

Screw,

Lifting

Screw,

Guide

Lock

Drive

Driving

Activating

for

Clamp

Finger

Screw

Driving

Driving

Motion

for

bracket

a

a

of

are

Clamp

Clamp

Washer,

Rod

Screw

Rod

for

for

Clamp

for

for

Spring,

Lever

Lever

Spring,

in

for

for

for

for

Rod

for

Screw,

Nut,

Lever

No,

for

for

No.

for

Clamp

Positioning

No.

for

for

No.

No,

for

upper,

lower,

Guide

No,

for

No,

for

Clamp

button

and

complete

for

Assembly

No,

for

Tripping

for

No,

No,

Nos,

Nos.

Lever

Holder

for

Screw

No,

No,

for

No,

No,

No,

Nos,

for

46-203

Lever

No.

45-481

Lifting

17-178

No,

Tripping

115-168

45-482

complete

complete,

46-204

Link

46-203

Link

frip

Lifting

clamp

200—15

or

Style

Holder

for

71-119

No,

166-14

45-332

Pawl

21-336,

for

for

No,

99-316

158-11

99-316

99-316

71-112

for

No,

Adjusting

22596

Finger,

Lever,

knife

17-178

Arm

Lever

respectively)

box

part

200-35

No.

Bloel

18-873

21-336,

45-347

No,

No,

18-945

45-346,

Nos,

158-il

knife

screw

knife

Lever

for

knife

Block

knife

knife

with

for

knife

knife

Shaft

Rod

lifting

the

on

or

71-119

push

serex

button

adjusting

21-337

45-346

adjusting

holder

slide

holde

holde

lifting

45-346,

Stud

drivinglink

driving

for

Styles

drive

activating

pin,

Styles

driving

driving

rod

picture

assembly.

only,

Description

rod

clamp

21-337

right

left

right

in

rod

45-347

slide

Styles

200-30,

lever

drive

clamp

for

200-30,

for

unless

push

lever

right

lever

lever

screw

holder

right

45-347

holder

in

lever

200-30,

adjusting

lever

tripping

lever

Styles

link

link

all

plates

rod

pawl

and

and

and

arm

200-35

adjusting

arm

parts

and

otherwise

left

left

left

right

200-35

block

200-30,

200-35

spring

and

stud

not

have

spring

lever

left

stud

200-35

illustrated

indented

specified,

lever

described

or

descriptions

Arnt

Req

1

1

1

1

1

2

1

2

1

1

1

1

2

2

1

I

1

1

1

1

1

1

1

1

1

2

1

1

2

2

1

1

1

1

4

2

1

1

1

1

I

1

1

2

1

1

1

2

1

1

2

1

1

1

2

*

shown

Not

on

picture

plate.

9

Page 10

N

a

0t

Page 11

No.

I

(lot

ar

No.

l)ot

It

Styles

200—

JVliS(

30

and

IIA

200-35,

N

IX)

IS

I

I

tin

I)escript

A

ess

tTS

otherwise

ion

specified.)

Req

10

11

12

13

14

No.

166—13

30

onty

Operating

set

large,

22538

1

Screw,

fot

166—13

31--

93

Thread

Cain,

two

4

5

122—29

110-213

A

I

ooper

A

Spacer

for

Style

(titter

for

No.

Positioning

Plate,

200

vibrating

13-984

plate

6

7

3

45-482

1039

13—

21-163

Knife

Screw,

Spring,

Activating

for

No.

for

Lever

45-482

thread

only

9

46—205

Thread

Cutting

Knife

only

No.

22542

4119-84

4119-86

22564

F

75-253

Screw,

for

Knife,

Knife,

for

Style

200-30

upper,

lower, complete

Screw

Finger

46-205

only

complete

Guide

button

screws

Finger

to

cutting

Lever

thread

Pawl,

plate

raise

knife

thread

with

activating

lever

Link,

pin

cutter

for

lengthwise,

No.

110-302

link,

for

cutting

operating

Style

for

Style

knife

200—30

lever

Style

includes

needle

200—30

lever

pawl,

only————

200-30

link,

4

2

1

1

1

1

2

1

1

1

1

1

2

1

ii

Page 12

btE

Se

WORLD’S

ATLANTA,

BOSTON,

CHICAGO,

DALLAS,

LOS

FINEST

‘NCE

UNION

facilities

aid

equipment

Special

tory

promptly

tion,

serve

ANGELES,

QUALITY

*

SPECIAL

throughout

in

you

the

for

representatives

trained and

and

there

isaUnion

you.

Check

GA.

MASS.

ILL.

TEXAS

CAL.

INDUSTRIAL

maintains

the

world.

selection

your

particular operation.

are

efficiently.

and

able

of

service

to

Whatever

Special

with

him

today.

MONTREAL,

TORONTO,

LEICESTER,

LONDON,

SEWING

soles

and

These

offices

the

right

men

serve

your

your

Representative

BRUSSELS,

MACHINES

service

will

sewing

Union

are

fac

needs

loca

to

CANADA

CANADA

BELGIUM

ENGLAND

ENGLAND

NEW

YORK,

PHILADELPHIA,

UNION

400

N.

N.

PA.

Representatives

industrial

SPECIAL

FRANKLIN

Y.

cities

and

distributors

throughout

ST.,

PARIS,

STUTTGART,

in

the

all

world.

FRANCE

GERMANY

important

CORPORATION

CHICAGO,

ILL.

60610

Loading...

Loading...