Page 1

INDUSTRIAL

SEWING

S

20

TYLE

0-2

C 0 L U M B I A®

MACHINES

CLASS

REMOVABLE

CATALOG

"TACK"

FOR

No.

194-17

TICKETS

OR

UNION SPECIAL

CHICAGO

200

MACHINE

LABELS

CORPORATION

Page 2

Union Special is offering two practical systems to help pinpoint and

reduce

your

system to help spot machines requiring

and a parts inventory system to speed routine repairs.

Machine Maintenance Records

Repair-prone machines

up

your maintenance dollars in short order. To help spot the

Union Special suggests two variations

record keeping system using cards provided by Union

The first system utilizes a

(Form

required, the card is

and their cost are entered in the spaces provided and the card is refiled.

The second system is normally used when more detailed information

on repair costs is desired . Two record cards are used: a

Request Card

233). When a machine requires service, the fore lady

out the

fills in the time the repair work is started, the parts used and their cost,

sewing machine maintenance costs: a record keeping

or

inexperienced competent operators can eat

..

237)

I>Afl

for

each sewing machine in a plant. When a repair is

pulled

MA-~IISNUOI.

:

. , ..

-.~

Machine Maintenance Record

from

MAC:HINK MAINU .NA

.,.

....

I I I I

.... ,\1 ...

fO\tt'\

Recotd . -

~"""'\••

-

-

---

..

(Form

234), and a

top

of a ..

Repair Request Card

abnormally high maintenance,

of

a simple maintenance

the file and the repair date, parts used,

NCC RECORD

..,,.,..,o.,,

_,

-·

~::L

~3~

.

fl\11'~'

AlllloA~NG

•

... -.,. •

.,.

ul.a»

-

-

te~>a~'

c

e

~

lf

-

--

-

-

-

..

Machine

Repa

ir Record

..

and gives it to a mechanic. He

or

se

problems,

Special.

..

card

••n~oo

-·

~

1-

~

~$

..

Repair

..

(Form

foreman fills

and the completi

..

Machine Repair Record

Whichever system is used, management now has an invaluable tool

to reduce needless maintenance costs.

Part

Repair

While record keeping tells management which machines requ ire

abnormally high maintenance, it does little to help reduce the

caused by routine repairs. To alleviate this situation,

recommends that manufacturers establish a formal parts

system for each type

Excessi

be e

li

minated with an orderly in-plant inventory

needed parts. There is

for spare parts.

downtime is

when the overall savings are considered.

-

- ·

=

=-

-~

-1--

For free sample

inventory

local Union Speci

on

time. This data is then transferred to the per

..

kept in the office.

Inventories

of

ve

machine

Long

kept

MACHIN£

REPAIR

111••

11••

H"'"•

C

_

,.

..

~

-

fi>IICI;\\~

fO~

lists

for

sewing machine they operate.

downt

ime and wasted hours

no

longer a need to cannibalize

waits for deliveries are avoided and machine

to a minimum. The cost

RECORD

CARD

:

:.:

~

.

..::~

1-

{'1\

eRe

__

cop1es

a variety

al

Representative

m

~

...

WI"

·

-

'2.33-

9'11

catd "-

6

----

--

-

of

the machine record cards and spare part

of

the most popular machines, contact

u ...

I

.......

......

I

--

O" u '

1 .

,-:w

~·

=

-

. . \l.eques

- Ri

1!

1'UUCIOM"'UI.II

... c.t ....

or writ

Union

inventory

by

mechanics can

of

the most

other

of

a parts inventory is small

.....

.

RE

PAIR REQU

EST

-

PA

RH US&D

~···-·-

-

__ ...

CARD

-·

z3A-

t

catd

-~

-~-

__

Union

...

_.

....

.

,..

_

···

· ~

..

• NO

-_

fO\tt'\

'i>a't

Mir.

. l#IIIIC:O

c, ..,

- -···-·--·--

e direct to

man

downtime

Special

commonly

machines

-

:!.__

-

-

-

~

=

-

=

=

-

SpeciaL

nt

your

u

1

111111 ""'"

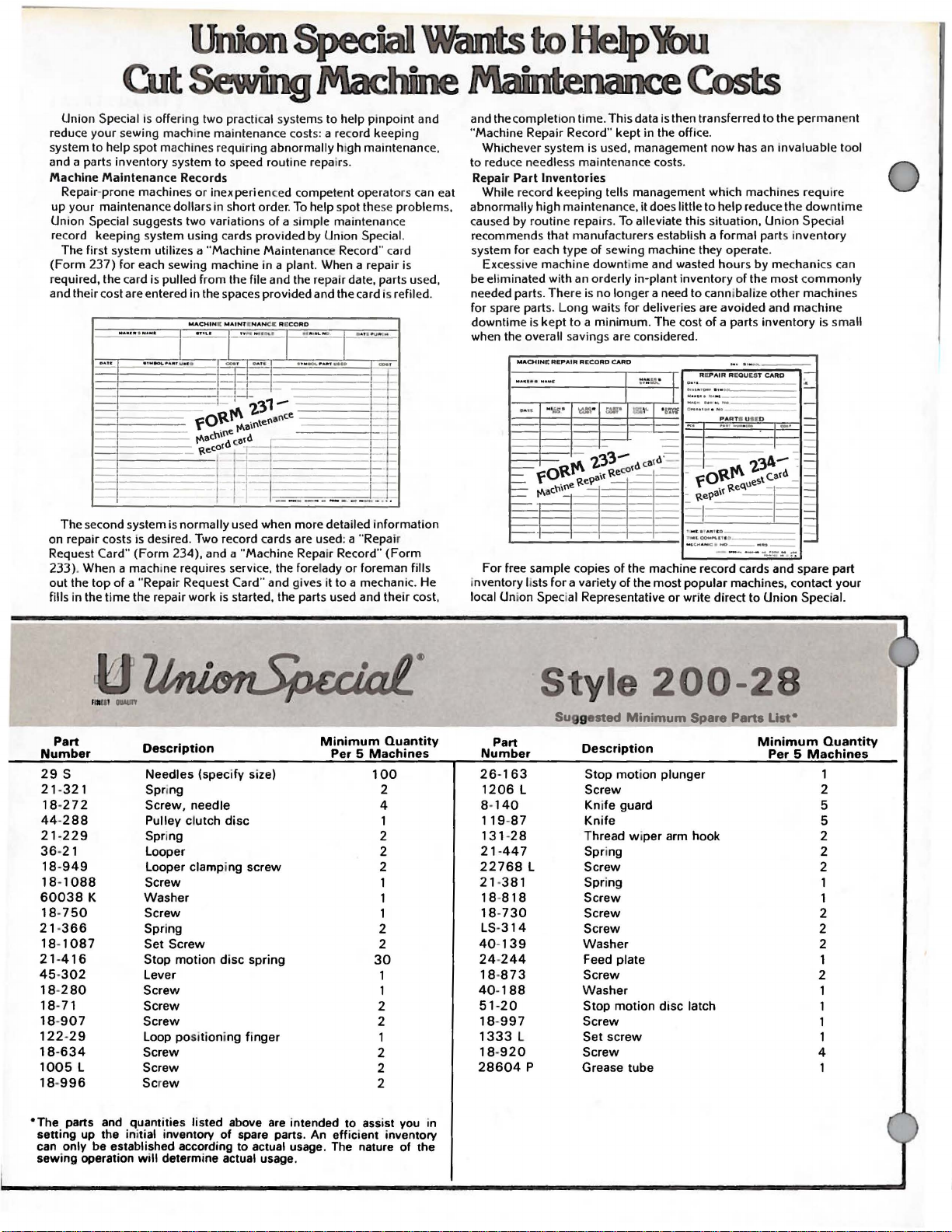

Part

Number

29

s

21-321

18

-2 7 2

44-288

21-229

36-21

18-949

18-1088

60038

18-750

21 18-1087

21-416

45·302

18-280

18

18-907

122-29

18-634

1005

18-996

*The

setting up the initial inventory

can

sewing operation

K

366

-71

L

parts and quan

only be established according to actual usage. The nature

Description

Needles

Spri

Screw,

Pulley clutch

Spring

Looper

Looper clamping

Screw

Washer

Screw

Spring

Set

Stop

Lever

Screw

Screw

Screw

Loop posi

Screw

Screw

Scr

will

(specify size)

ng

needle

disc

screw

Screw

motion

disc

spring

tion

ing

finger

ew

titie

s listed above are intended to assist you in

of

spare parts. An efficient inventory

determine actual usage.

Minimum

Per 5 Machines

Quantity

100

2

4

1

2

2

2

1

1

1

2

2

30

1

1

2

2

1

2

2

2

of

the

Part

Number

26-163

1206

8-

140

119-87

131-28

21 -

447

22768

21-381

18-818

18-730

LS

-3

14

40-139

24-244

18-873

40-188

20

51 -

18-997

1333

18-920

28604

tyle

Description

L

L

L

p

Stop

Screw

Kni

fe

Knife

Thread w i

Spr

ing

Screw

Spring

Screw

Screw

Screw

Washer

Feed

Screw

Washer

Stop

Screw

Set

Screw

Grease

200-28

Minimum

Per 5 Machines

mot

ion

plunger

guard 5

per

arm hook 2

plate

motion

disc

latch

screw

tube

Quantity

1

2

5

2

2

1

1

2

2

2

1

2

1

1

1

4

Page 3

(Supplement

Catalog

INSTRUCTIONS

to

No.

Catalog

FOR

194-17

No.

194-4)

ADJUSTING

Union

Rights

LIST

CLASS

Style

First

Copyright

Special

Reserved

AND

OF

200-28

Edition

by

in

OPERATING

PARTS

200

1972

Corporation

All

Countries

UNION SPECIAL CORPORATION

INDUSTRIAl

Printed

•

May,1976

SEWING

CHICAGO

in

U.S.

3

MACHINES

A.

Page 4

IDENTIFICATION

OF

MACHINES

Each

class

of

machines~

The

toward

the

This

junction

200-1

a

reference

therewith.

are

description

illustrated

a

bracket

description

number

when

in

ordering

The

It

can

also

References

operator's

is

away

from

UNION

serial

back.

catalog

illustrated

number

and

on

the

or

box.

under

the

second

repair

catalog

be

to

direction,

position

the

SPECIAL

is

stamped

number

of

each

is a supplement

Only

amount

picture

On

the

those

and

listed

and

this

required.

plate

the

copy

description

column~

parts.

applies

applied

specifically

with

such

while

seated

operator.

LEWIS

in

machine

the

style

machine

APPLICATION

to

Catalog

parts

reference

at

by

which

the

back

number

Any

having

part

page a component

of

the

assembly

never

discretion

as

use

to

the

to

right~

at

the

machine.

carries

plate

is

stamped

OF

CATALOG

No.

are

used

of

this

is

that

the

reference

the

reference

Standard

other

left~

front~

a

style

on

the

left

side

in

the

right

194-4

book.

then

on

used

and

Style

The

to

200-28,

is a component

number

part

or

is

base

indicated

part.

number

Style

Styles

back,

machine

of

machines

etc.,

Operating

number~

of

the

side

of

should

be

but

parts

obtain

are

the

of

another

or

numbers

by

Always

in

the

as

in

are

given

direction

which

arm.

the

cylind

used

not

in

on

identified

part

number,

indenting

use

the

first

listed

column

herein.

this

from

of

the

in

this

con-

Style

part

inside

part

class.

the

pulley

er

by

is

its

200-28

Removable

"Tack"

Equipped

tack~

Type

These

starts.

seconds

Most

fact

they

be

beneficial.

Please

to

open

oiling

Also

of

grease

should

ing

place

oiled.

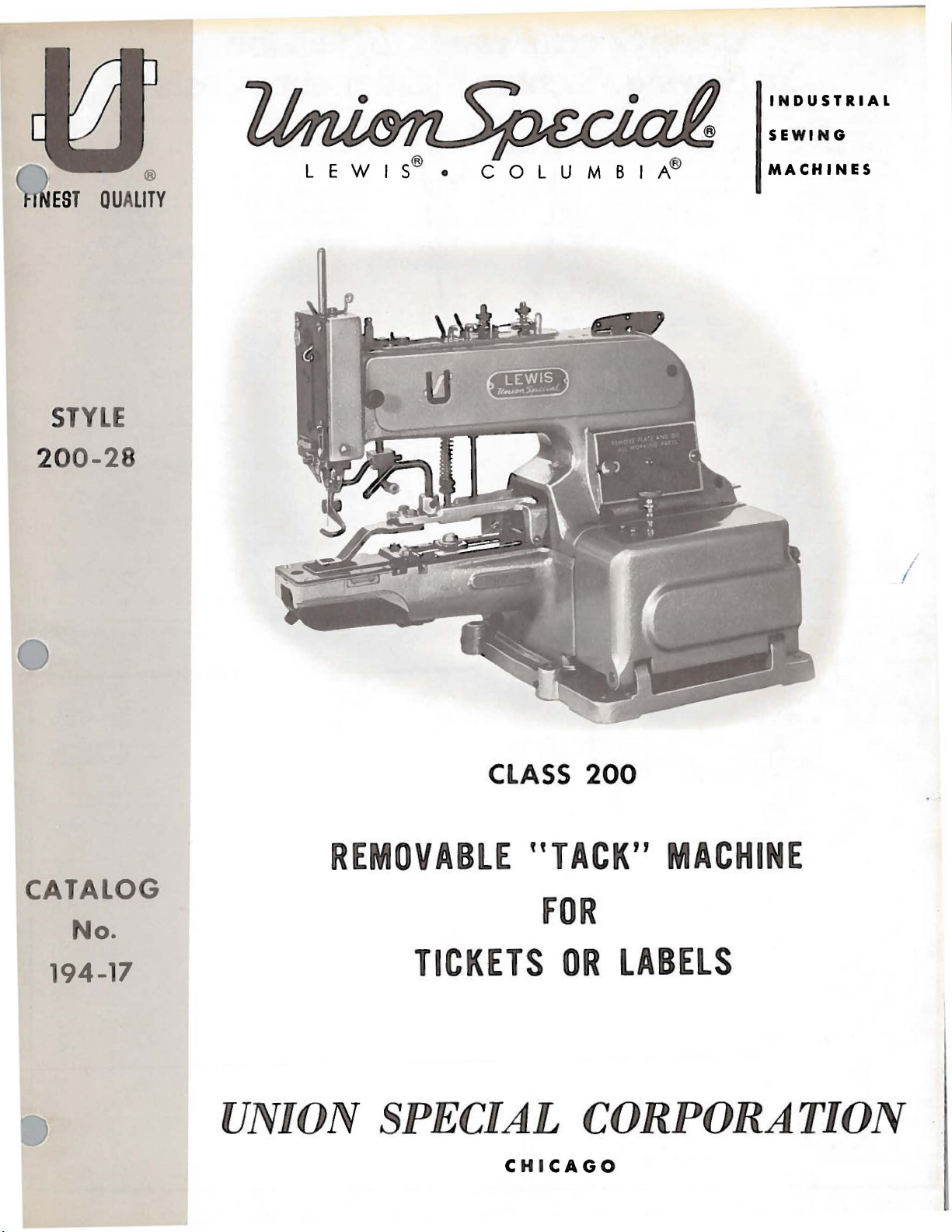

High

with

with

after

29S-100/040

machines

Use a good

at

1000

of

the

are

painted

note

the

hinged

places.

note

that

is

furnished

be

removed,

is

indicated

Production~

Tacks.

a

1/8

thread

the

sewing

Single

Sews

inch

protruding

wiperwhich

cycle.

needle.

should

grade

be

of

straight

Fahrenheit.

oiling

that

places

red.

it

base

there

with

the

by

on

However,

will

be

covers

is a label

the

grease

the

letter

STYLE

Needle,

eight

stitches

Equipped

Maximum

oiled

twice

mineral

the

machines

reference

necessary

and

tilt

on

machine

level

checked

"A"

OF

MACHINE

Single

tail

pulls

the

recommended

OILING

daily,

to

machine

the

pulley

and

periodically

and

in

the

right

permitting

severed

to

sew

before

oil

of a Saybolt

are

readily

to

the

remove

on

which

replenished

diagram.

Thread

to

left

thread

up

speed

oiling

arm

its

reads

the

All

Machine

for

stitching

easy

removal

tail

to

1/4

inch

1500

the

morning

viscosity

identifiable

diagram

cover

side

to

and

reach

"Grease

plug

screw

if

required.

other

for

free

wide

R.

P.M.

and

because

Fig.

side

Here".

places

Stitching

a

of

of

the

afternoon

of

90

cover

some

in

the

The

shown

two

hole

'Tack".

sewn

'Tack".

to

of

11,

will

of

A

tube

pulley

greas-

125

the

and

the

are

Tubes

of

grease

may

be

ordered

under

part

No.

4

28604

P.

Page 5

word

Use

only

"LEWIS

Renuine

on

the

UNION

shank.

NEEDLES

SPECIAL

LEWIS

needles.

They

are

stamped

with

the

Unless

sewed

off

and

with a sharp

Selection

weight

sample

read:

as

tighten

has

To

When

it

will

A

been

of

have

needle.

''1.00

go,

set

cross

inserted

material.

changing

Immediately

instructions

shipped

point

of

and

the

needle

or

Needles.

with

the

screw

hole

securely.

drilled

as

discard

with

has

proper

orders

the

type

Type

the

long

far

to

the

contrary

needle

a .

040

needle

promptly

number

29S-100/040".

CHANGING

needle.

make

groove

in

the

needle

as

it

will

any

needle

are

Type

inch

29S-100/040.

(1.

02

size

is

and

should

determined

accurately

be

NEEDLES

sure

to

the

bar

that

front

can

go.

which

may

THREADING

received.

This

mm)

diameter

forwarded.

it

is

inserted

and

the

also

be

used

have a hooked

machine

needle

blade.

by

the

filled,an

A

spot

or

to

Style

is a short

size

of

empty

complete

in

the

needle

scarf

determine

or

blunt

200-28

thread

container.

order

bar

to

the

if

the

point.

will

needle.

and

would

as

rear

needle

be

the

a

far

and

To

thread

diagram

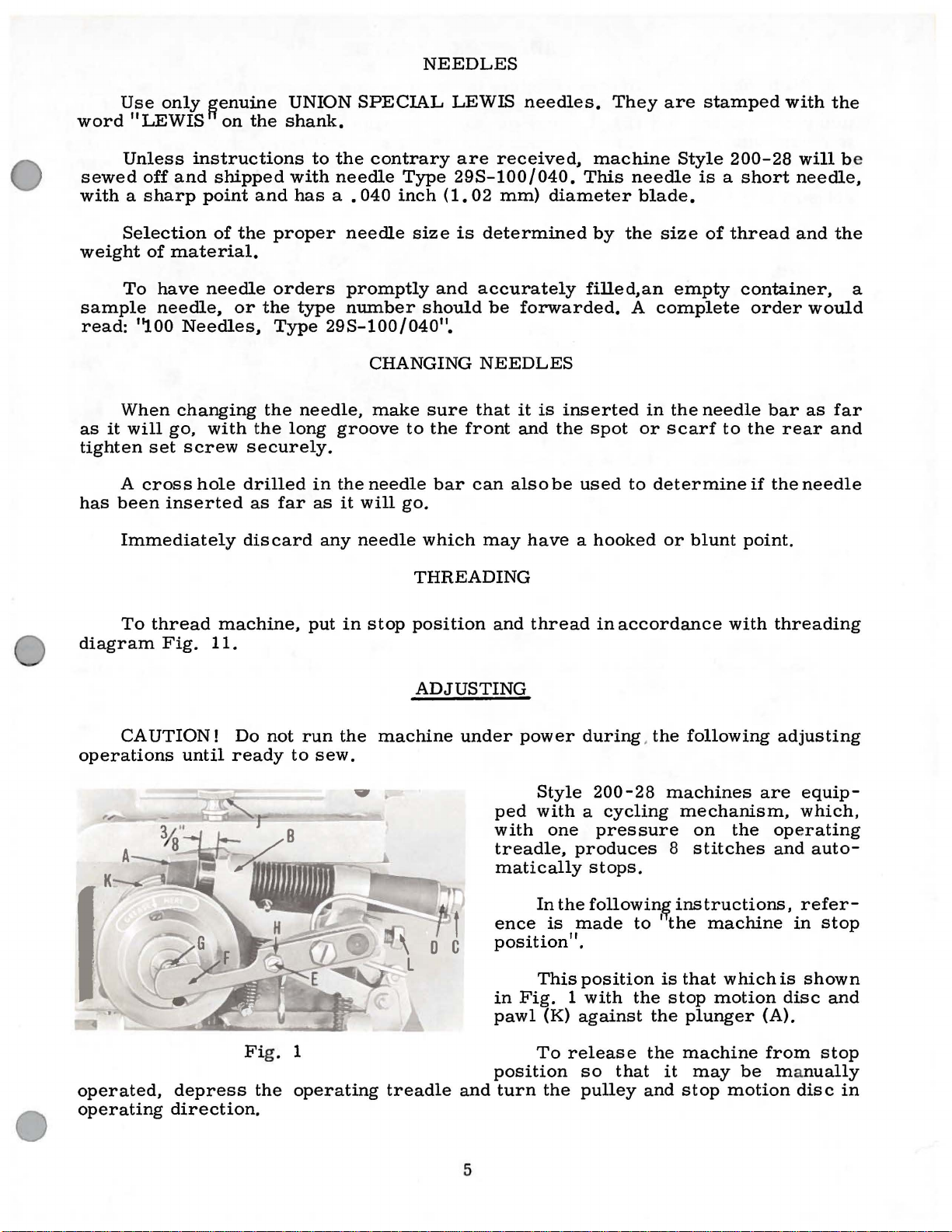

CAUTION!

operations

operated,

operating

machine,

Fig.

11.

until

depress

direction.

Do

not

ready

Fi

g.

the

put

in

run

the

to

sew.

1

operating

stop

position

ADJUSTING

machine

treadle

and

under

ped

with

treadle,

matically

ence

position".

in

pawl

position

and

thread

power

Style

with a cycling

one

produces

In

the

is

made

This

Fig. 1 with

(K)

against

To

release

turn

the

in

accordance

during. the

200-28

following

machines

mechanism,

pressure

8

stops.

followin~

instructions,

to ' the

position

so

pulley

the

that

is

the

the

it

and

that

stop

plunger

machine

stop

with

on

the

stitches

machine

which

motion

may

be

motion

threading

adjusting

are

equip-

which,

operating

and

auto-

refer-

in

is

shown

disc

(A).

from

ma

nually

disc

stop

and

stop

in

5

Page 6

ADJUSTING

CLUTCH

With

set

so

plunger

to

obtain

there

the

set

is

pulley

screw

ADJUSTING

With

loosen

(A,

Fig.

rotate

ance

in

cam

between

cam.

Depress

ine

out

of

two

complete

direction.

ure

distance

3)

and

highest

This

trip

lever

it

be

necessary

the

that

there

lever

this

1/32

is

pressed

(L)

the

the

two

2)

in

to

roller

stop

Release

adjustment

and

machine

is

brack

et

setting.

inch

is

securely

clearance

STOP

machine

socket

stop

motion

secure

(C)

the

treadle

position

revolutions

treadle

between

point

on

moving

to

move

in

3/8

inch

(B).

Lock

in

towards

MOTION

in

head

1/32

and

to

and

plunger

disc

is

made

lever

lever

stop

position,

clearance

Loos

the

between

tightened.

stop

position,

set

screws

cam

(B)

inch

front

take

rotate

in

operating

and

(A,

(B).

by

up

down,

en the

back

nut.

ball

machine.

and

clearof

slot

mach-

pulley

meas-

Fig.

The

distance

loosening

or

down

depress

the

stop

between

back

Adjust

(G)

Lock

clamp

to

secure

lock

and

should

the

motion

the

nut

(C)

screw

the

screw

screw

the

treadle

plunger

bottom

and

(E)

thin

with

be

3/32

(D,

3/32

while

(A,

of

the

adjust

in

cam

section

nut

(H).

Fig.

inch.

Fig.

inch

Fig.

plunger

the

lever

of

lever

Make

2

2)

in

clearance.

making

1)

should

and

front

(F)

so

(F)

nut

when

sure

stop

motion

Should

adjustment.

be

the

(D)

that

that

Loosen

lines

(C)

ly.

The

machine

link.

the

on

cams

tacking

in

stop

Fig.

two

screws

with

clamp

position,

3

(B)

and

timing

pins

ADJUSTING

lifting

the

link

lip

turn

cams

(D)

in

bed.

CLAMP

(E, Fig. 4)

on

the

fork

Depress

out

of

stop

two

complete

direction.

Fig.

until

1)

Turn

first

and

pulley

screws

coming into

loosen

turn

machine

screws

(A)

Retighten

LIFTING

is

lev

these

pulley

in

in

proper

er

(F)

is

(B)

either

all

LINK

is engag

TIMING

treadle

position

revolutions

Loosen

lay

machine

in

view

two

in

operating

again

are

in

direction

four

position,

CAMS

to

and

knurled

operating

in

cams

are

screws.

in

stop

view.

cam

screws

ed

in

take

machine

rotate

in

operating

screw

on

its

direction

(A,

accessible

Continue

direction

position

to

align

secure-

when,

the

with

slot

pulley

side.

Fig.

and

until

and

timing

the

of

the

(J,

4)

to

clamp

Forward

screw

and

(G)

backward

in

lever

adjustment

(H)

and

moving

of

lever

6

the

on

link

shaft.

is

accomplished

by

loosening

Page 7

ADJUSTING

CLAMP

LIFTING

LINK

(Continued)

Adjustment

moving

rest

against

fork

lever

the

of

the

on

Fig.

needle

fork

shaft.

4

bar

lever

clamp.

(F)

is

made

by

loosening

the

needle

middle

long

tion

volutions

position,

of

timing

ing

on

should

the

loosen

and

bar

screws.

screws

ADJUSTING

When

upper

needles,

Take

and

With

needle

To

take-up

to

pair

bar;

pair

machine

turn

in

the

the

lines

which

be

even

raise

needle

desired

The

using

for

of

operating

length

bar

clamp

short

of

timing

long

timing

use

pulley

needle

upper

(A,

with

bushing.

or

lower

bar

height

take-up

in

collars

NEEDLE

needles,

lines

needles,

lines;

the

lower

out

of

two

complete

direction.

bar

in

line

of

Fig.

of

the

clamp

screw

5),

needle

lower

needle

and

clamp

(J)

BAR

on

use

for

extra

pair.

stop

posi-

its

lowest

each

dependis

used,

edge

screw

(C),

move

retighten

must

and

use

the

the

re-

pair

of

bar,

(B)

The

needle

dle

set

screw

ing

freely.

The

position

gauge

the

(Fig.

that

its

moving

feed

done

to

at

the

machinedsurface

5).

Make

it

does

travel.

Adjustment

feed

NOTE:

plate

for

clarity

make

the

bar

is

(D)

enters

of

factory.

ALIGNING

sure

that

not

interfere

is

made

plate

TIMING

Fig. 7 shows

and

adjustments.

to

desired

NEEDLE

tacking

only.

correctly

the

the

needle

The

distance

of

the

FEED

the

feed

by

clamp

These

slot

cylinder

plate

with

the

loosening

position.

WITH

the

machine

removed.

parts

positioned

in

the

needle

bar

bushing

from

PLATE

needle

baseis

(A,

two

HOOK

need

its

Fig.

with

when

lower

3

6)

at

any

screws

needle

This

not

be

the

nee-

bar

bush-

is

set

to

edge

1/32inches

is

set

point

(B)

and

plate,

has

been

removed

to

so

of

a

Fig.

5

7

Page 8

TIMING

NEEDLE

WITH

HOOK

(Continued)

Take

operating

raise

pair

it

of

equipped

machine

direction.

until

the

timing

with

out

of

stop

Lower

lower

lines

on

edge

the

long needles,

position

the

needle

of

the

bar

use

needle

when

the

and

bar

Fig.

using

lower

rotate

until

6

bar

short

pair

pulley

it

reaches

bushing

needles.

of

timing

two

is

midway

lines).

complete

its

lowest

(When

revolutions

position,

between

the

then,

the

upper

machine

in

is

proper

the

screws

Rotate

bar

is

that

the

both

(G)

so

and

retighten

that

its

in

cam,

ting

direction

(B,

Fig.

inch

clearance

even

point

screws

that

there

timing

making

7)

between

in

the

the

pulley

with

of

(A)

hook cla

line

sure

until

in

the

it

and

Fig.

between

cam

the

lower

the

hook

in

the

is

the

coincides

the

direction

the

7

the

and

slide

in

operating

edge

is

sleeve.

smallest

mp

screw.

that

the

needle

needle.

loop

the

of

at

the

Loosen

amount

Loosen

with

cam

bar

of

the

Retighten

positioning

sleeve

direction

the

needle

center

hook

of

set

the

timing

is

against

is

at

its

needle

Loosen

Fig.

7)

ward.

loop

positioning

finger

slightest

finger

inch.

To

screws

sleeve

the

screws

sliding

loosen

in

the

finger

back

until

bar

of

the

collar

clearance

screw

line

the

lowest

until

clamp

needle

and

Insert

forward.

amount

and

needle,

make

(A,

Fig.

forward

enough

on

the

screws

direction

and

so

that

the

lower

bushing.

needle

clamp

between

(C)

on

the

sleeve.

position

there

is a clearance

screw

slide

a

screwdriver

finger

There

of

this

8)

slightly

shaft

(C)

in

necessary

the

it

contacts

timing

Rotate

on

the

screw

in

cam

sleeve

Turn

and

(A)

securely.

guard

clamp

needle

(C)

should

clearance

approximately

adjustment,

in

the

sleeve

and

to

prevent

during

adjustment.

cam

(D)

needle.

the

line

the

back

side

(E)

its

point

(D)

and

(F).

the

pulley

slide

the

screw

guard

behind

and

be

between

loosen

(B),

retighten

the

and

slide

to

secure

Tighten

cam.

on

the

sleeve

and

and

slide

and

the

rotate

Tighten

in

needle

of

about . 002

(B)

for-

pull

only

.

slide

one

sleeve

Now,

cam

one

needle

(B)

tighten

hook

needle

cam

screws

opera-

guard

(A,

the

the

the

the

002

set

of

the

of

so

so

8

Page 9

HEIGHT

OF

TACKING

CLAMP

With

tacking

adjustment,

stop

the

tween

Height

has

clamp

Return

pin

(F,

needle

the

of

been

the

machine

to

loosen

the

machine

Fig.

will

not

stop

pin

stop

pin

obtained,

the

Fig.

6).

strike

and

(F)

tighten

in

top

set

8

Its

stop

of

screw

to

stop

purpose

any

the

tacking

can

be

nut

position,

the

feed

(C)

position

is

part

adjusted

(G)

the

plate

and

raise

to

prevent

of

the

clamp

after

against

normal

should

or

lower

Take

turn

tacking

to

clearance

ing

lifting

loosening

This

clamp

previously

setting

lifting

and

tacking

holder

bed

pulley

the

rear.

rod

roller

will

of

rod

check

overthrow

will

loosening

arm

distance

be

1/2

rod

machine

clamp

between

(D,

Fig.

screw

affect

in

relation

described,

1/2

and

the

clamp.

cause

securely.

between

inch

(D).

out

in

operating

is

in

At

this

6)

(E).

Adjustment

(C)

the

inch,

position

nut

no

roller

of

the

Insufficient

the

(G).

the

(Fig.

the

and

and

to

6).

of

stop

its

furthest

point,

tacking

the

moving

height

the

but

interference

will

occur.

of

the

tacking

machine

When

bottom

To

make

position

direction

there

tacking

of

feed

for

tacking

clamp

clearance

correct

must

clamp

is

made

rod

the

plate

the

to

re-cycle.

of

the

this

and

until

position

be

lif

t-

clamp

by

(D)

up.

tacking

as

normal

between

clamp

so

that

be-

height

Accurately

indicator

ing

to

the

Take

tion,

that

clears

Equal

from

knife

of

tacking

to

screws

ment

necessary

turn

the

the

when

and

obtain

.....

The

the

distance

behind

(H,

Fig.

distance

the

machine

slowly

needle

cutting

needle

the

needle

the

clamp

(J,

graduations

may

this

Fig.

retighten

to

deviate

POSITIONING

measure

6)

between

by

enters

knife

should

holes

cutting

have

condition.

6)

to

screws.

the

and

spring

out

of

hand

make

and

the

of

be

to

enters

to

on

the

slightly

the

the

maintained

the

knife.

be

this

AND

distance

indicator

holes

stop

posi-

observe

tack

clamp.

cutting

in

front

The

shifted

Loosen

adjust-

indicator

from

THREAD

ADJUSTING

between

(A,

in

the

and

scales

them.

TENSION

the

Fig.

tack.

are

TACKING

holes

9)

only

of

to

the

approximate

CLAMP

the

tack

and

graduations

Fig

. 9

set

the

correspond-

and

it

pivot

may

be

The

tension

in

relation

ly,

only a light

regular

(B)

and

to

thread

controls

the

types

tension

tension

the

of

thread

is

required.

(A,

tightness

and

Fig.

10)

of

the

thickness

9

is

located

tack.

of

The

materials

behind

tension

and

the

automatic

required

label

used.

thread

will

vary

Normal-

Page 10

THREAD

TENSION

(Continued)

Take

direction

Check

ion

releasing

see

that

ble

to

contacting

made

moving

quired

AUTOMATIC

The

the

tightness

underside

With

12)

turned

turns,

ion

should

point

edge

ines

using

to

rise

dimension

machine

and

it

comes

the

tension

by

loosening

the

direction.

automatic

of

the

the

where

of

the

short

until

should

out

thread

the

position

lever

as

discs

them.

lever

THREAD

of

the

the

fabric.

tension

down

automatic

release

upper

about

the

lower

needle

needles.

dimension

be 2 1/8

of

stop

machine

of

the

(C,

Fig.

close

Adjustment

screw

(C)

tension

the

as

(D)

in

the

TENSION

controls

stitch

nut

(A,

four

thread

thread

edge

bar

When

"X"

without

(E)

+ 1/32.

position,

in

accordance

tens-

10)

to

possi-

rotate

A

is

and

re-

on

the

Fig.

or

five

tens-

when

of

its

bushing

is 1 15716 + 1/32

bevelled

using

inch.

the

as

long

needle

shown

-

pulley

with

top

needles,

threading

bar,

is 1 9/16

at

inch.

two

complete

8

Fig.

on

its

dimension

the

needle

For

diagram

10

upstroke,

~

1l32

'X"

bar

extra

turns

inch

(Fig.

must

long

in

(Fig.

has

above

12)

needles,

operating

11).

risen

the

on

mach-

be

allowed

to

top-

this

a

To

make

has

risen

(B,

Fig.

screwdriver

to

12)

this

the

in

needle

until

adjustment,

heights

lever

the

tension

..

X"

turn

described

hub

releases.

Fig.

pulley

above.

and

turn

10

12

in

operating

Loosen

needle

direction

the

lever

two

shaft

until

hexagonal

(F,

Fig.

the

head

needle

screws

10)

with

bar

a

Page 11

THREADING AND OILING

DIAGRAM

LEWIS CLASS

FOR

200

Fig.

11

11

Page 12

Hold

head

be

underside

tension

screws

rechecked.

If,

the

after

of

nut

needle

(B,

Fig.

rechecking,

the

fabric,

(A,

Fig.

AUTOMATIC

lever

12).

12).

shaft

This

it

the

is

situation

THREAD

in

this

is

an

found

TENSION

position

extremely

that

excessively

can

be

while

important

helped

(Continued)

retightening

adjustment

large

by

loops

applying

the

still

more

two

hexagonal

and

exist

tension

should

on

the

at

With

thread

thread

Fig.

the

pull-off

guides

13

machine

lever

(M).

out

(L)

of

and

holds

clamp

break

is

block

(J)

quired

the

tensions,

vide

following

stop

the

thread,

The

the

at

off

The

3/64

(H)

and

move

direction

The

amount

sufficient

position,

thread

thread

the

conclusion

the

thread.

thread

inch

when

clearance

when

THREAD

thread

of

at

the

cycle.

there

THREAD

nipper

so

nipper

the

nipper

the

nipper

to

make

PULL-OFF

pull-off

thread

end

thread

should

the

thread

NIPPER

(G,

Fig.

that

the

raising

of

the

should

between

is

open.

bar

block

the

adjustment.

lever

which

of a stitching

for

be

is

(L,

is

the

no

pulled

10)

sewing

be

set

it

and

LEVER

Fig.

pulled

first

contact

taut

pinches

of

the

cyc

so

that

the

Loosen

(K)

in

10)

through

cycle,

stitch

between

against

and

tacking

le

will

there

nipper

screw

the

re-

controls

the

to

pro-

of

the

the

the

(N)

ble

off

side

left.

13)

•

also

should

top

the

the

mately

the

This

and

If,

when

on

the

lever

If

too

of

The

should

against

With

be

of

the

arm

wiper

5/16

needle

adjustment

moving

right

to

much

the

ADJUSTING

thread

be

the

at

thread

casting

arm

(Fig.

block

sewing,

side

the

right

thread

tack,

wiper

up

tight

the

rear

machine

least

wiper

(Fig.

hook

inch

14).

to

is

too

as

move

of

in

1/8

(A,

the

The

made

(P)

forward

much

of

the

tack,

described

tail

is

the

pull-off

THREAD

mounting

against

the

needle

"STOP

inch

drive

13).

Fig.

right

wiper

clearance

lever

The

14)

by

loosening

or

thread

visible

WIPER

bracket

the

POSITION",

wiping

should

of

the

arm

tail

move

earlier.

lever

bed

bar

bushing

between

bracket

be

centerline

hook

casting

screw

backward.

is

visi-

the

pull-

on

the

left

to

the

(A,

Fig.

and

(B).

there

the

(C)

and

portion

approxi-

(A,

Fig.

of

of

Fig.

14

12

Page 13

14)

must

head

protrude

not

casting.

into

swing

through

the

path

freely

The

the

of,

ADJUSTING

towards

forward

cam

or

opening

strike

end

the

THREAD

the

left

of

the

of

needle

until

thread

the

WIPER

it

wiper

bar.

strikes

wiper

arm

(Continued)

the

under

drive

hook

lever

(E)

at

surface

(D,

Fig.

least

1/32

of

13)

inch,

the

should

arm

but

With

wiper

the

locking

inch

clearance

By

arm

hook

enough

tail

free

the

machine

hook

should

portion

from

co-ordinating

and

wiper

inertia

of

the

at

sewn

in

be

locked

of

the

the

adjustments

drive

stop

motion,

tack.

"SEWING

in

cam

bottom

lever

POSITION"

position

slot,

of

after

but

the

of

the

bracket,

the

by

slot.

the

the

lever

wiper

the

sewing

without

wiper

drive

wiper

cycle,

drive

should

lever

arm

material

lever

have a minimum

in

hook

to

pull

under

the

shall

the

being

cam

have

severed

clamp,

engaged

of

of

the

developed

thread

the

in

1/3

wiper

2

13

Page 14

>·

14

Page 15

parts

The

that

parts

are

illustrated

used

on

on

Style

the

preceding

200-28,

but

not

page

used

and

on

Style

described

200-1.

below

represent

the

Those

common

Use

in

this

catalog.

Reference

indented

assembly.

Ref.

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

Part

22704

HA18 A

22548

1776

22894

parts

to

Styles

Catalog

numbers

descriptions

No.

430-91

30-92

99-356

119-87

8-140

18-1087

99-270

40-38

18-873

71-112

131-28

L

18-330

50-298

45-484

50-299

p

18-730

434-42-1

34-100

18-984

shown

200-1

No.

in

phantom

and

194-4

that

indicate

Tacking

Nut,

Screw,

Thread

Screw,

Screw,

Thread

Thread

Thread

Set

Screw,

Cam

Cam,

Set

views

200-28.

(Style

are

Tacking

Set

Tacking

VVasher

Screw-----------------------------------------

Tacking

for

Set

and

left

200-1)

inside

they

Clamp

Screw,

Knife

Knife

Knife

Screw

---------------------------------------

thread

for

thread

VViper

for

thread

for

thread

VViper

VViper

VViper

Screw

for

Gear

side,

Screw

are

Clamp---------------------------------

Clamp

Clamp

Arm

Mounting

Drive

Drive

Assembly----------------------------

-------------------------------------

and

bearing

for

all

parts

a

bracket

component

Description

Assembly

for

knife

Holding

-------------------------------------

Guard

-------------------------------------

-------------------------------------

Holder--------------------------

Lifting

wiper

wiper

Hook---------------------------wiper

wiper

Lever-------------------------Lever

cam

and

for

vibrating

--------------------------holding

Clamp------------------------

-------------------------------

Rod----------------------

arm

hook----------------------

arm

arm

mounting

Bracket

Bracket

gear

no

reference

not

illustrated

on

the

picture

parts

hook

hook

assembly

tacking

of a

clamp

-------------------

-------------------

bracket

---------------------

------------------

plate

numbers

or

plate

complete

--------------

------------

--------------lengthwise--

are

described

and

have

part

or

Amt.

Req.

1

1

1

1

1

1

1

1

2

2

1

1

1

1

1

1

1

1

1

4

2

1

1

2

Page 16

.,.o

..

...

"

0

WORLD'S

-

....

l f

FINEST

QUALITY

*

INDUSTRIAL

SEWING

MACHINES

UNION

SPECIAL

maintains sales

and

facilities throughout the world. These offices

aid

you

in

the selection of

the

right sewing

equipment for your particular operation. Union

and

Special representatives

tory trained

promptly

tion, there

and

and

is

serve you. Check with

ATLANTA, GA.

BOSTON, MASS.

CHICAGO,

DALLAS,

LOS ANGELES,

NEW

PHILADELPHIA, PA.

ILL.

TEXAS

YORK, N.

CAL.

Y.

are

efficiently. Whatever your loca-

a Union Special Representative to

service men

able

to serve your needs

him

today.

MONTREAL,

TORONTO, CANADA

BRUSSELS,

LEICESTER,

LONDON, ENGLAND

PARIS,

STUnGART,

FRANCE

service

will

are

fac-

CANADA

BELGIUM

ENGLAND

GERMANY

Representatives

industrial

UNION SPECIAL

400

N.

FRANKLIN

and

cities

distributors

throughout

in

the

all

Important

world.

CORPORATION

ST.,

CHICAGO,

ILL.

60610

Loading...

Loading...