Page 1

l11iLG7t..3€CtQ®

W

L E

I

S

C

•

0

U

L

M

I

B

MACHINES

:,NEST

STYLES

200-1

200-2

200-6

200-7

200-8

200-9

200-10

200-15

200-16

200-17

QUALITY

F

0

\

200-21

200-22

200-23

200-24

200-25

200-26

200-27

CATALOG

No.

194-4

Third

Edition

BUTTON

CLASS

200

SEWING

MACHINES

UNION

SPECIAL

CHICAGO

CORPORATION

Page 2

Catalog

INSTRUCTIONS

FOR

No.

194-4

200-1

200—2

200—6

200—7

200-8

ADJUSTING

200—26

LIST

Third

AND

OF

Styles

200-9

200-tO

200-15

200—16

200-17

Edition

OPERATING

PARTS

200-21

200—22

200—23

200-24

200-25

200—27

Union

Rights

UNION

INDUSTRIAL

1962

©

Special

Reserved

SPECIAL

SEWING

CHICAGO

Printed

and

By

1977

Corporation

All

in

Countries

CORPORATION

MACHINES

in

U.S.A.

2

April,

1981

Page 3

ii)HN’i[I’[(’A’i’i()N

OP

M/\(

‘III

NIS

Each

ni;o’hi;ies,

‘[he

it

LI

tack.

rililis

All

from

the

Tile

I

[igh

production,

of

fiat

and

eyes,

stitches

drive

200—1

coats,

Sews

ligne.

NOTE:

UNION

seriaL

cataLog

references

operator’s

operating

two

on

with

Right

right

is

hole,

and

some

stop

to

shirts,

Can

1

Ligne

SPEC[AL

stamped

nuinher

applies

single

four

for

motion

Left

to

left,

be

in

of’

to

direction,

position

direction

hole,

tacking

styles,

clutch.

Stitching

pajamas,

equipped

equals

LEWIS

the

each

specifically

of

thread,

and

operations.

and

8,

16,

to

.

025

maclone

style

while

plate

machine

APPLICATION

to

such

as

seated

the

pulley

DESCRIPTION

button

shank

6,

buttons.

12,

Single

Flat

Buttons.

and

similar

32

or

sew

parallel

buttons

inch.

on

is

the

right

is

sewing

Lever

or

24

treadle

garments

40

earrwi;

the

stamped

OF

styles

anti

at

the

away

OF

machines.

Attachments

on

operation.

For

stitches.

30

to

Ligne

a

left

side

in

CATALOG

of

machines

left,

machine.

from

MAChINES

adjusted

others,

two

of

60

ligne

equals

style

of

the

forward

the

or

light,

Equipped

1

tinnihe

the

LLt’lll

right

operator.

Sews

available

stitch

Automatic

four

medium

when

inch.

r,

of

side

listed

as

and

all

popular

range

hole

to

specified.

which

the

herein,

jack,

to

sew

to

sew

stitching

buttons

and

heavy

sew

in

eyhiiidei’

ete,

sizes

snaps,

buttons

this

,

are

and

8,

16

cycle,

on

blouses,

materials.

14

class

towit’d

types

hooks

or

taken

cam

to

of’

32

45

200-2

200-6

diagonal

or

200-7

200-8

32

200—9

200-10

stitches

to

high

200-15

cycle.

with

200-16

Recommended

pockets

200-17

Same

Diagonal

back

Same

Back

parallel

Same

Right

cut

cross-over

quality

Same

certain

Tacking,

Same

as

stitches

to

front

as

Front

to

stitches

as

to

in

four

garments,

as

Primarily

on

trousers,

as

Style

200-1,

Stitching

in

four

with8or

Style

200-6,

Stitching

back

200-8,

except

Left Stitching

hole

buttons

stitch

Style

200-1,

used

types

of

Equipped

for

tacking

size

Style

200-16,

except

Flat

hole

16

except

Flat

to

sews

Flat

between

such

except

with

heavy

automatic

with

bows

tickets,

except

Buttons,

buttons,

stitches.

Buttons,

front

6,

Buttons

only.

men’s

as

tacking

on

sews

sews

in

two

12,

Equipped

the

two

equipped

thread

button

blouses,

and

sews

6,

12,

or

Similar

Two

hole

12,

6,

or

Same

or four

or

24

stitches,

With

No

with

rows

sack coats,

with

where

feeders

clamp.

dresses,

similar

12

6

or

24

stitches.

to

Style 200-1,

buttons

24

stitches.

as

Style

hole

Cross-over

special

of

parallel

suit

knife

for

thread

and

for

Sews

operations.

stitches.

200-1,

buttons,

coats,

cutting

cutter

use

8

or

etc.,

can

Stitch.

knife

stitches.

is

with

16

cuffs

except

be

stitched

except

and

ladies’

thread

needed,

stitches

sews

sews

Sews

nipper

Recommended

suits

at

Recommended

necking

back

on

trousers,

16

right

8,

16

parallel

mechanism

and

of

end

attachment,

to

or

to

16,

coats.

stitch

front.

side

32

left

or

/

for

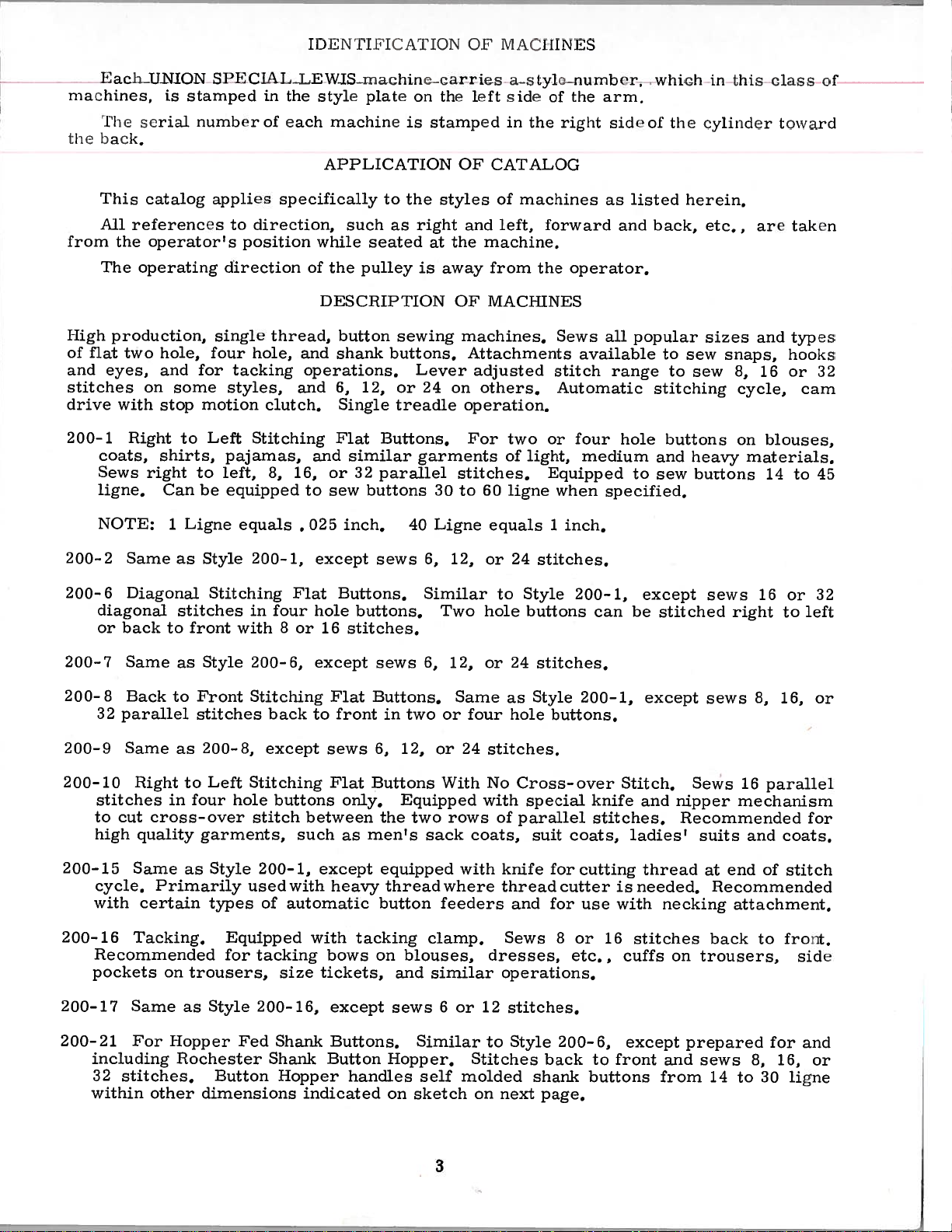

200-21

For

including

32

stitches.

within

Hopper

other

Rochester

Button

dimensions

Fed

Shank

Shank

Hopper

Buttons,

Button

indicated

handles

Similar

Hopper.

self

on

sketch

to

Stitches

molded

on

Style

next

200-6,

back

shank

page.

3

front

to

buttons

except

and

from

prepared

sews

14

for

and

8,

16,

or

to

30

higne

Page 4

DES

C

IUPTJON

OF

MACI

[INES

(continued)

200-22

200-23

left

Same

APP[LOX,

(SO

OVERLAPPING)

•I5O

(THIS

VERY

For

Rochester

garments

on

furnished.

available

as

AS

NOT

WIDTH

IMPORTANT)

Hopper

So-Thru

where

two

or

Sample

Rochester

Style

four

200-21,

.065

TO

GET

IS

Flat

Fed

Button

continued

hole

button

So-Thru

except

SHARP

Buttons.

Hopper.

use

buttons

must

Button

sews

±po4

CORNERS

Similar

of

similar

and

be

submitted

Hoppers.

225

For

sews

6,

12,

SIZES

to

use

size

8,

or

1

Style

on

buttons

16,

with

24

14-30

NO.

200-1,

shirts,

or

stitches.

45

is

32

order.

LIGNE

212

DRILL

except

pajamas,

required.

stitches.

•

See

INCLUSIVE

-

.082

prepared

blouses,

Stitches

No

button

Page

35

•05(

DIA.

to

right

for

receive

or

clamp

list

any

to

of

200-24

200-25

200-26

200-27

of

this

for

200-1

Same

Right

coats,

material.

stitches

diagonal

used

Same

Produces

produce

14

to

Right

coats,

material.

buttons

By

the

book,

which

Can

necking

shirts,

on

1/2

24

45

ligne.

shirts,

10

selection

they

be

operations.

Style

as

Left

to

Sews

four

and

there

cycle

as

Style

12

stitches

stitches

to

Left

Sews

to

40

many

are

used for

200-23,

Stitching

pajamas

right

hole

or8stitches.

pajamas

right

buttons

no

is

200-1,

on

on

Stitching

to

to

L[gnc.

of

the

proper

of

these

described.

shank

except

Flat

and

left,

tacking

two

four

Shank

and

left,

machine

A

buttons,

Buttons.

similar

16

and

stitch

Equipped

except

hole

hole

similar

8,

16,

OTHER

attachments,

Styles

list

of

sews

when

buttons

buttons

Buttons.

6,

garments

:J2

or

sews

these

snaps,

parallel

used

previous

to

right

in

in

garments

::2

or

APPLICATIONS

can

variations

12,

For

this

sew

the

the

For

parallel

listed

be

hooks

24

or

two

of

way,

to

buttons

to

half

full

shank

of

and

used

and

stitches.

hole

buttons

light,

stitches.

the

cross-over.

14

to

left,

light,

12

cycle.

cycle.

buttons

stitches.

illustrated

for operations

follows:

eyes,

medium

Can

cross-over

45

ligne.

or

It

Equipped

medium

Equipped

tacking,

on

24

also

on

in

dresses,

and

also

Machine

parallel

may

dresses,

and

the

other

heavy

be

used

stitch

cannot

be

to

sew

heavy

to

sew

Parts

than

shanking,

blouses,

weight

for

will

stitches.

used

buttons

blouses,

weight

shank

section

those

16

be

be

to

and

200-2

Same

variations

as

for

Style

200-1.

4

Page 5

200—6

(biii

and

be

ice

used

ipopo

k

for

oil!

shank

rat

CRACP

buttons,

ions

I

;inc]

niwd)

t

shank—

eyes,

drapery

rings,

laRki

ug,

(Con

()NS

[CA

I.

hooks

200—]

200—8

200—P

200—10

200—

and

200—16

rings.

200—17

starts.

seconds

tile

Page

Same

Can

Same

Can

IuCan

neck

(bun

Same

These

at

Most

fact

14,

ing

machines

Use

1000

of

they

will

var

used

he

var

used

be

used

be

opera

used

he

variations

a

good

tile

are

be

ions

Lt

Co

oils

i

i

at

for

for

1

t

for

should

grade

Fahrenheit.

oiling

painted

beneficial.

as

snaps

r

as

shanking

shank

Oils

two

as

places

for

for

for

be

of

red.

,

buttons,

ho

straight

Style

drapery

Style

operations

buttons,

e

1

Style

oiled

on

However,

OILING

the

200—6.

rings

200—8.

snaps

200—16.

twice

mineral

machines

,

,

sti

telied

daily,

reference

Lacking

hooks

before

oil

are

and

back

of

readily

to

,

a

the

and

eves

to

tile

Saybolt

sluanking

,

tacking,

front

morning

identifiable

oiling

only,

viscosity

diagram

ope

and

ions

rat

shanking

and

drapery

afternoon

of

because

Fig.

90

13,

,

and

125

to

of

on

open

places.

of

grease

pulley

greasing

are

short

should

of

the

a

stay

Please

the

Also

should

oiled.

Tubes

The

Needles

shank,

Generally

be

button,

button

note

hinged

note

is

base

that

furnished

be

place

is

grease

of

recommended

for

and

speaking,

used.

thickness

is

that

covers

there

removed,

indicated

may

speed

these

long

making

In

be

to

it

will

with

be

machines

with

the

of

used.

and

is

the

the

by

ordered

of

extra

the

material,

be

tilt

label

a

machine,

grease

the

these

are

shortest

selection,

necessary

machine

on

level

letter

under

SPEED

machines

NEEDLES

divided

short

the

and

shank.

needle

amount

to

remove

on

its

pulley

periodically,

checked

‘TAfl

part

is

into

in

the

No.

1500

three

required

consideration

of

shanking

arm

side

which

and

diagram.

28604

R.P.M.

cover

to reach

reads

replenished

P.

categories

to

perform

should

required,

the

and s-ide

some

HGrease

plug

screw

if

other

All

—

short,

a

given

be

given

and

cover,

of

the

Her&’.

in

recuuired.

places

long

operation

to

the

whether

oiling

the

and

tube

A

shown

with

height

or

to

Tile

not

5

Page 6

the

height

long

the

extra

be

set

catalog.

For

shank

Available

Blade

Dia.

•

036”

•

040”

•

044”

•

049”

•

057”

For

use

needle

For

use

long

In

changing

to

the

of

the

needles

29S—090/036

29S—100/040

29S—1l0/044

29S—125/049

with

with

with

needle

proper

buttons,

work

Short

large

extra

extra

from

support

for

short

with

short

timing

the

the

diameter

large

extra

to

lines

NEEDLES

diameter

block

Class

29LSS-090/036

29LSS-100/040

29LSS-ll0/044

29LSS—125/049

29LSS-140/054

shank

diameter

short

long

of

should

200

Long

With

Short

Shank

shank

recommended.

is

needles,

described

as

(Continued)

the

machines

buttons,

shank

shank

button,

considered.

be

29LES-J

29LES—110/044

29LES—125/049

buttons

is

recommended.

or

vice

in

are:

and

versa,

the

the

Long

With

Extra

Short

Shank

high

and

adjusting

thickness

00/040

work

high

the

needle

the

of

Extra

With

Short

29ELS-l10/044

29ELS—125/049

support

work

instructions

support

bar

shank,

Long

Extra

Shank

block,

height

block,

must

in

this

and

the

sewed

and

sample

read:

it

as

tighten

has

Unless

off

Machine

200—15

200—16

Selection

the

type

To

have

needle,

“100

When

wiligo,

set

A

cross

been

instructions

and

200—1

200—2

200—6

200—7

200—8

200—9

200—10

of

Needles,

changing

with

screw

hole

inserted

shipped

Style

proper

of

button

needle

or

used.

orders

the

Type

the

the

long

securely.

drilled

as

far

to

the

contrary

with

the

following

Needle

29S—

100

040

/

29S—100/040

29LSS-110/044

29LSS—110/044

29LSS—110/044

29LSS—100/040

29LSS—110/044

29S—100/040

29S—110/044

needle

type

needle,

in

as

size

promptly

number

29LSS-110/044”.

CHANGING

make

groove

the

needle

it

will

is

determined

and

should

sure

to

the

bar

go.

are

received,

needle

accurately

be

NEEDLES

that

front

can

specifications:

Machine

200—17

200—21

200-22

200—23

200-24

200—25

200—26

200—27

size

by

forwarded.

it

is

inserted

and

the

also

be

machines

Style

thread,

of

filled,

spot

used

an

A

in

or

scarf

to

determine

in

Class

Needle

29S—

29LSS—110/044

29LSS—110/044

29S—100/040

29S—100/040

29S—100/040

29S-100/040

29LES—110/044

weight

empty

complete

the

needle

to

200

110/044

of

container,

order

bar

the

rear,

if

the

will

material,

would

as

needle

be

a

far

and

Immediately

discard

any

needle

which

6

may

have

hooked

a

or

blunt

point.

Page 7

lip.

‘Jo

13,

Lb

iad

Page

iuaeli

Ui.

‘l’i

I

RIAI).[NC1

ii

IC,

)UI.

ill

S

IOJ)

position,

ADJUSTING

and

thread

ill

accordance

with

cliagrani.

opu

‘I

‘

b

I

operated,

operating

With

set

so

plunger

obtain

to

there

the

pulley

set

CAUTION

i’ations

ALb

depress

direction.

the

that

lever

this

is

1/32

is

screw

UntIl

—

machine

there

bracket

setting.

inch

pressed

(L)

Do

L’eady

ZB

A—

I

ig.

the

is

clearance

is

nut

run

to

H

1

operating

in

stop

3/8

(B).

Lock

intowards

securely

the

sew.

ADJUSTING

position,

inch

Loosenthe

the

between

tightened.

machine

-.P’

treadle,

clearance

back

machine.

nut.

ball

the

back

Lindel’

with

one

produce

and

ence

position’’

in

pawl

position

and

CLUTCH

stop

between

lock

Adjust

(G)

Lock

power

The

a

pressure

automatically

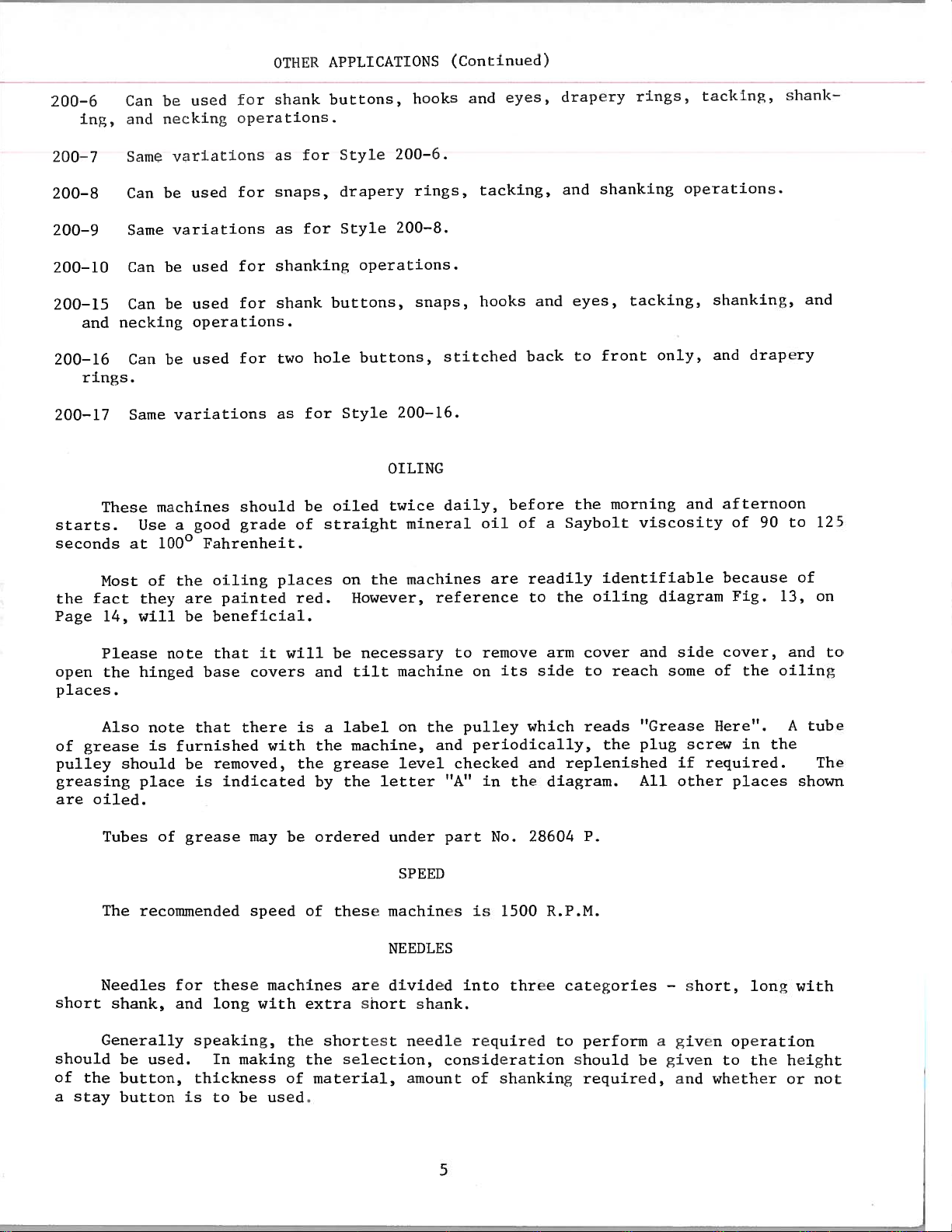

In

the

is

This

Fig.

(K)

To

turn

motion

nut

screw

and

screw

Class

cycling

6,

made

1

against

release

the

the

(C),

the

during

12,

followinç

position

with

so

pulley

plunger

bottom

and

(E)

thin

with

the

200

mechanism,

on

the

24,

to

‘

is

the

the

the

that

and

of

adjust

in

section

nut(H).

following

machines

operating

or

8,

stops.

instructions,

the

machine

that

stop

plunger

machine

it

may

stop

(A,

Fig.

the

cam

lever

of

16,

which

motion

motion

plunger

the

lever

Make

are

which,

(A).

be

1)

front

(F)

adjusting

equipped

treadle,

32

stitches

in

is

disc

from

manually

disc

should

and

nut

so

(F)

sure

with

refer

stop

shown

and

stop

in

be

the

(D)

that

when

that

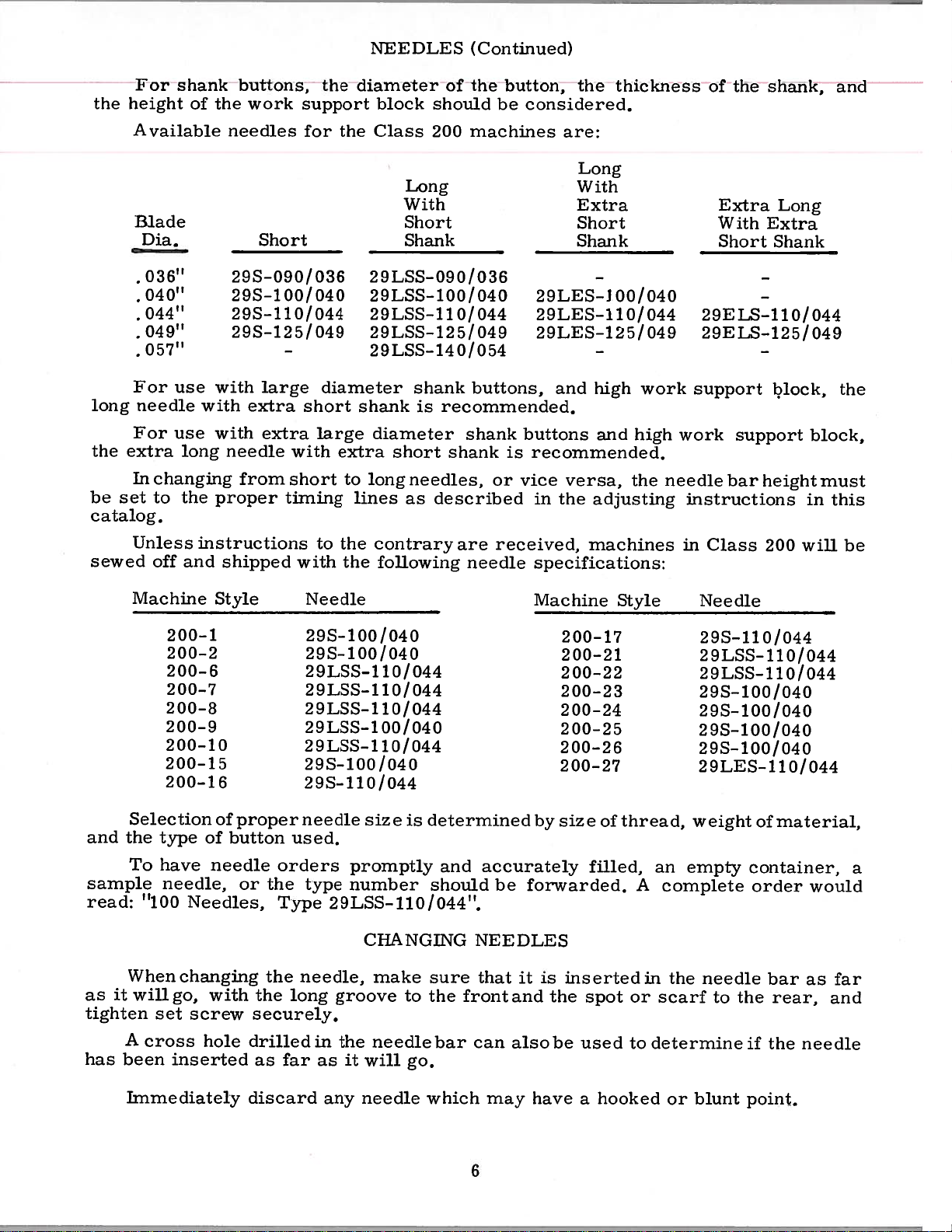

(PRIOR

With

loosen

(A,

rotate

between

cam.

Depress

out

of

complete

tion.

distance

highest

This

trip

lever

it

be

ADJUSTING

TOSER.

the

the

Fig.

2)

cam

roller

stop

revolutions

Release

between

point

adjustment

and

necessary

to

position,

two

in

secure

the

on

STOP

machine

socket

stop

(C)

treadle

treadle

plunger

disc

moving

to

NO.

motion

1

and

and

in

(B).

is

move

MOTION

in

head

32

/

front

to

rotate

operating

made

lever

lever

1368377)

stop

set

cam

inch

clearance

of

take

pulley

and

Fig.

(A,

The

by

up

position,

screws

(B)

slot

machine

direc

measure

3)

distance

loosening

or

down

down,

and

in

two

and

depress

should

to

secure

7

p

clamp

the

be

C

3/32

screw

the

treadle

inch.

3/32

Fig.

(D,

while

,(

Fig.

inch

—.

2

2)

clearance.

making

NI

in

stop

adjustment.

motion

Should

Page 8

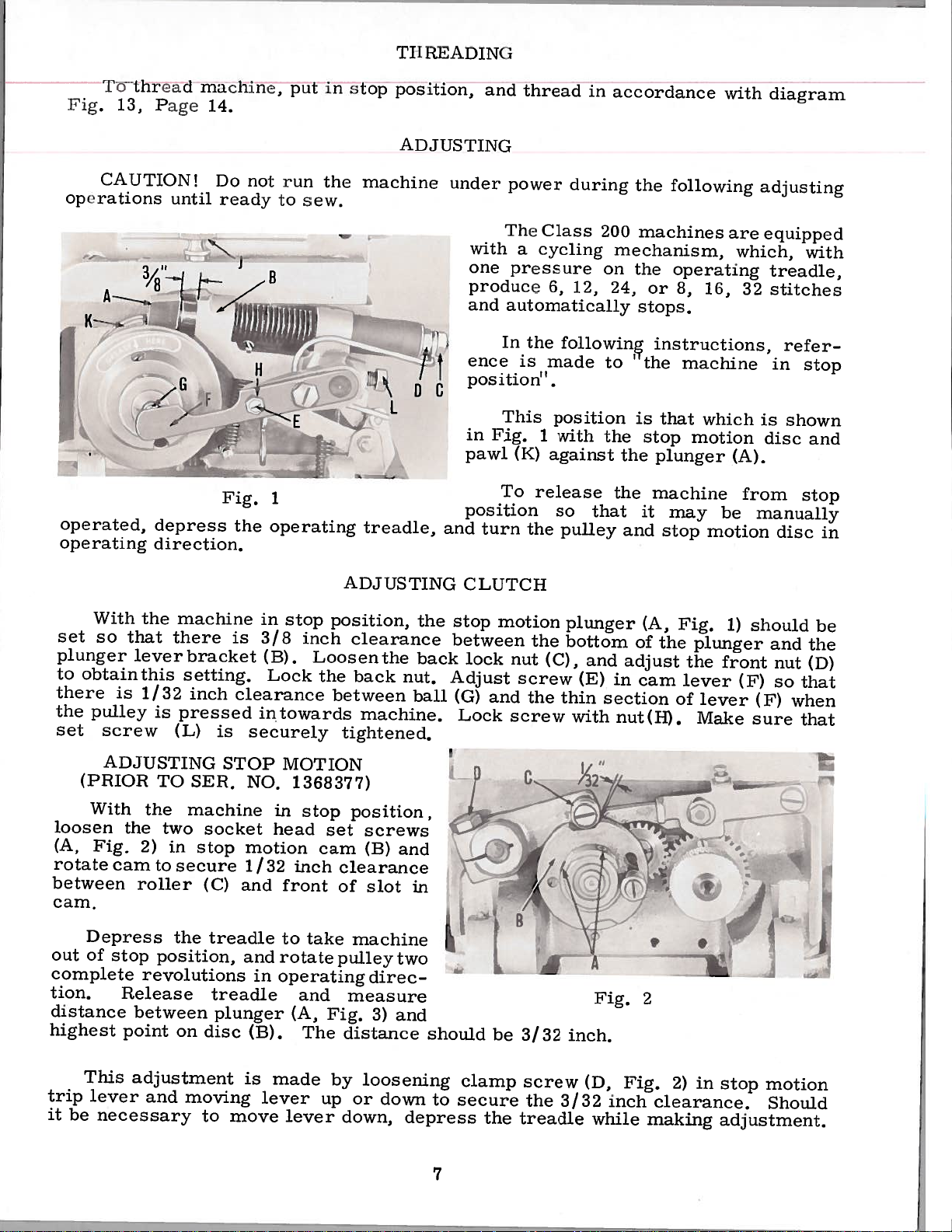

Iffective

Assembly

With

2A)

lig.

elongated

“right

front

the

NOTE:

Depress

complete

between

1/4

be

stop

Should

adiustment.

motion

the

and

cam”

of

1.

revolutions

plunger

inch.

become

it

with

has

machine

screw

slot

(I))

slot

This

associated

the

Adjustment

trip

Retighten

been

(as

as

in

dimension

treadle

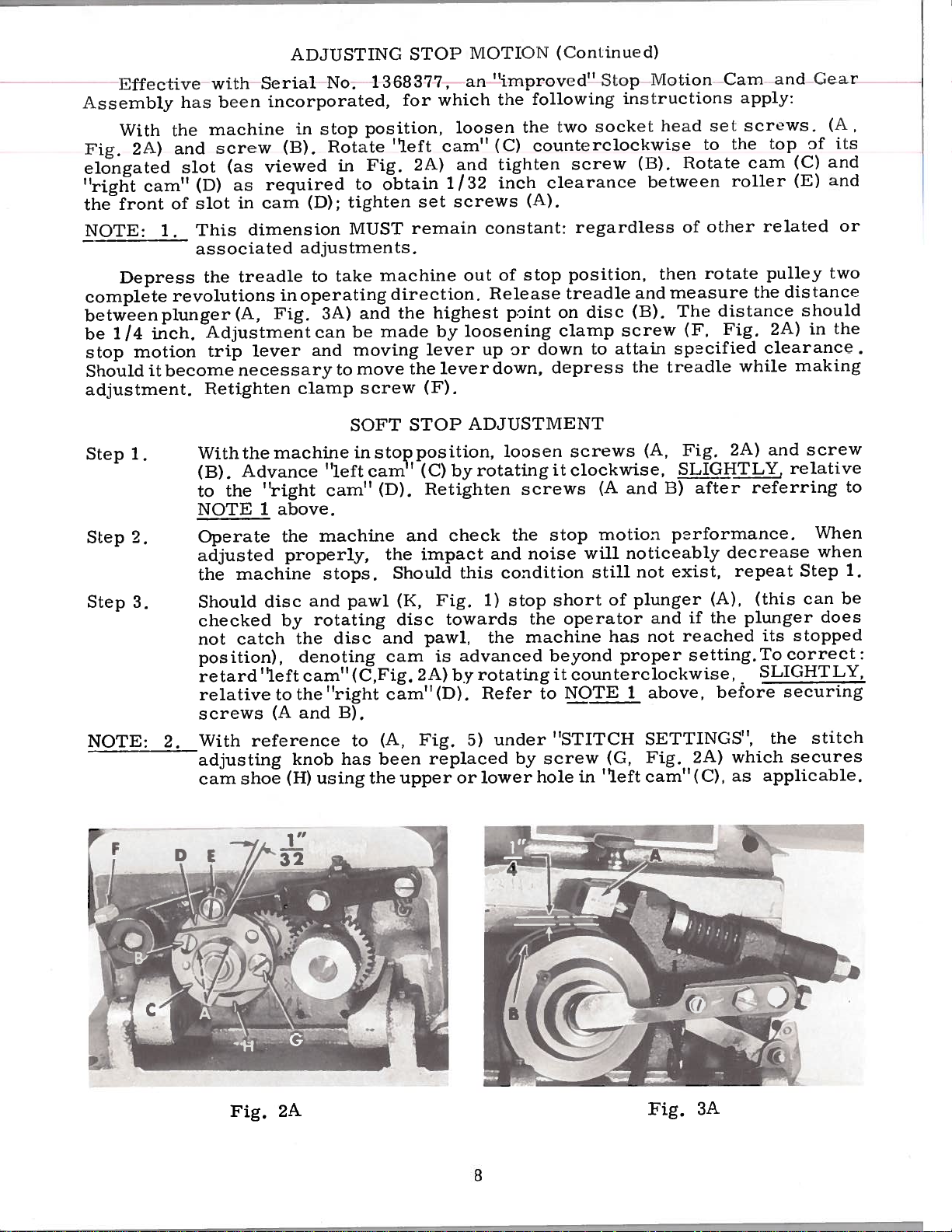

(A,

necessary

AI)J

Serial

incorporated,

in

(13).

viewed

required

cam

adjustments.

in

operating

Fig.

lever

clamp

No.

stop

(D);

to

3A)

can

and

USTIN(

position,

Rotate

Fig.

in

to

tighten

MUST

take

and

be

moving

move

to

screw

STOP

1368377,

for

“left

2A)

obtain

set

remain

machine

direction.

the

made

the

which

cam”

1/32

highest

by

lever

lever

(F).

I\IOTI(

an

loosen

and

screws

constant:

out

Release

loosening

up

)N

‘improved’’

following

the

the

counterclockwise

(C)

tighten

stop

point

or

clearance

(A).

down

depress

inch

of

down,

(Conlin

two

screw

regardless

position,

treadle

disc

on

clamp

to

ued)

Stop

instructions

socket

screw

attain

Motion

(B).

between

and

(13).

the

head

Rotate

of

then

measure

The

(F,

sp3cified

treadle

Cam

set

to

other

rotate

distance

Fig.

apply:

screws.

the

cam

roller

the

while

(e:

and

of

top

(C)

(1)

related

pulley

distance

should

2A)

in

clearance.

making

r

(A

its

and

and

or

two

the

Step

Step

Step

NOTE:

SOFT

1.

2.

3.

Withthemachineinsto?position,

Advance

(B).

“right

the

to

above.

1

machine

disc

catch

“left

to

(A

reference

shoe

the

properly,

and

rotating

by

the

denoting

cam”(C,Fig.

the”right

and

knob

using

(H)

I,

2.

NOTE

Operate

adjusted

the

Should

checked

not

position),

retard

relative

screws

With

adjusting

cam

“left

cam”

machine

stops.

pawl

disc

B).

to

has

STOP

carn’(C)

(D).

and

the

Should

(K,

disc

and pawl,

cam

cam”(D).

(A,

been

upper

the

impact

2A)

Fig.

ADJUSTMENT

by

Retighten

check

this

Fig.

towards

is

advanced

by

5)

replaced

or

loosen

rotating

the

and

condition

stop

1)

the

rotating

Refer

under

lower

screws

noise

the

machine

to

screw

by

hole

screws

it

clockwise,

(A

and

stop

beyond

motion

will

noticeably

still

short

it

“STITCH

of

operator

has

proper

counterclockwise,

NOTE

in

1

(G,

“eft

(A,

Fig.

SLIGHTLY,

after

13)

parformance.

exist,

not

plunger

if the

and

reached

not

setting.To

above,

SETTINGS”,

2A)

Fig.

cam”(C),

2A)

decrease

repeat

(A),

before

which

as

and

relative

referring

(this

plunger

its

stopped

correct:

SLIGHTLY,

securing

the

secures

applicable.

screw

When

when

Step

can

stitch

to

1.

be

does

cJ7jzñ

Fig.

2A

8

Fig.

3A

Page 9

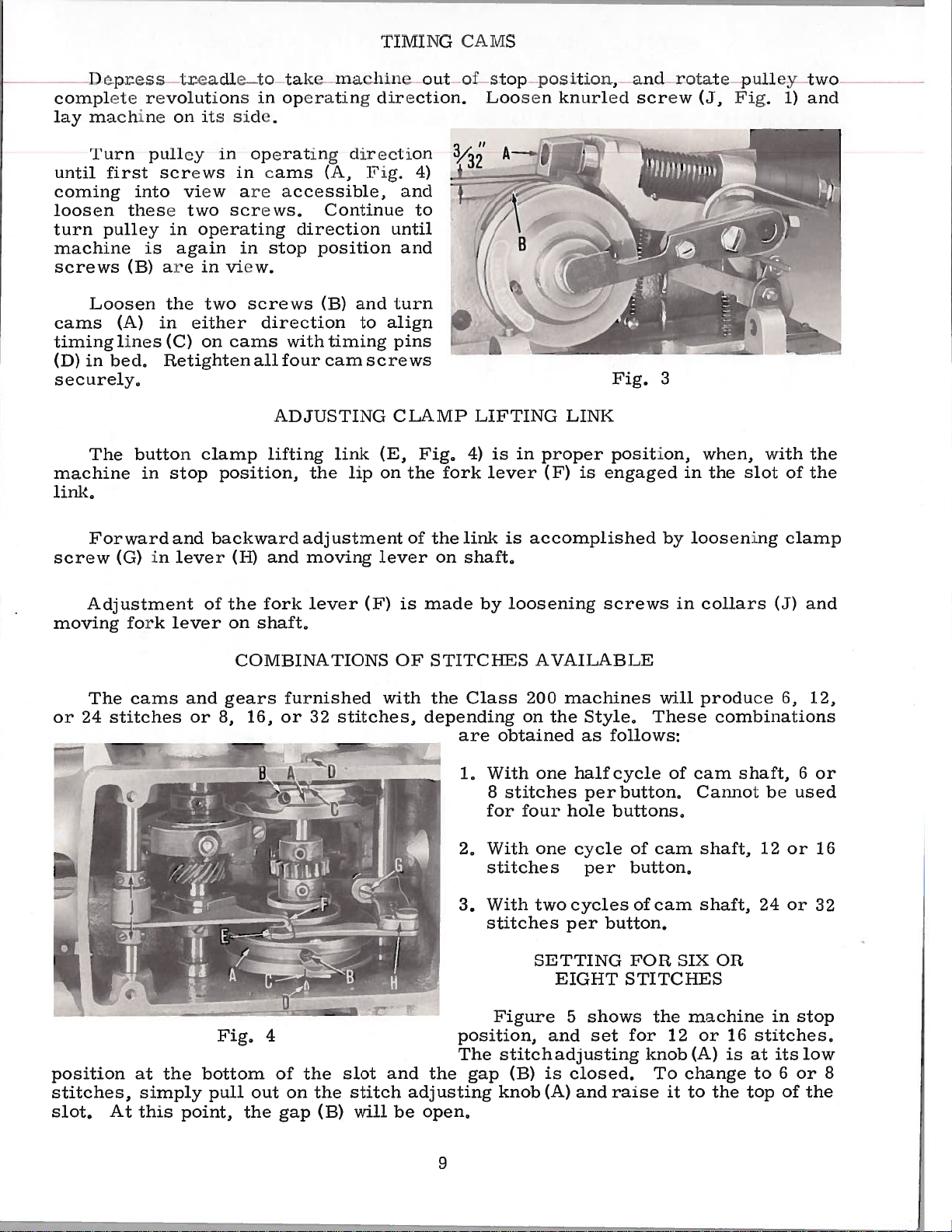

—

complete

n:i.eiunc

Liy

.[urti

unLL[

coming

loosen

turn

machine

screws

Loosen

cams

timing

iii

(D)

securely,

rfhe

machine

link,

p

iirst

these

pulley

(B)

(A)

lines

bed,

I.

revolutions

on

pulLey

screws

].nLO

View

in

again

is

arc

the

in

(C)

Itetighten

button

in

stop

it

two

ope

at

its

in

two

I.e

5

iii

in

arc

Sc

rati.i

view.

to

III

(ic

o)e1:aLiIig

LcceSSItilc,

ec

w5,

ig

in

stop

screws

Lake

01

in-

either direction

on

cams

all

whh

four

ADJUSTING

clamp

lilting

position,

)C

I

eec

position

the

(

i

iaeii

atLng

(lirertiodi

iig.

(A,

Conlinue

on

Li

and

U)

to

timing

cam

sc

link

lip

‘r[IVIiNG

on

inc

(I

LecuLon.

4)

and

1:0

until

and

turn

align

pins

CWS

CLAMP

iig.

(E,

on

the

L

fork

CAMS

ol

to1)

S

oosen

LIFTING

is

4)

lever

in

pos

knurled

proper

(F)

it

LINK

is

ii,

and

Screw

Fig.

position,

engaged

3

rotate

(J,

in

when,

the

pn

Fig.

slot

[Icy

with

1)

of

two

and

the

the

Forward

screw

Adjustment

moving

The

or

24

(G)

fork

cams

stitches

in

and

lever

lever

and

or

backward

(Ii)

and

the

on

fork

shaft,

of

COMBINATIONS

gears

8,

16,

furnished

or

w

H

ad,j

ustment

moving

lever

32

0

(F)

stitches,

of

lever

is

made

OF

STITCHES AVAILABLE

with the

depending

the

on

link

is

accomplished

shaft,

loosening

by

Class

are

1,

2,

obtained

With

8

stitches

for

With

200

on

four

stitches per

3.

With

stitches per

SETTING

screws

machines

Style,

the

as

follows:

one

half

cycle

per

button,

buttons,

hole

one

cycle

of

button,

two

cycles

of

button.

FOR

EIGHT STITCHES

by

in

will

loosening

collars

produce

clamp

(J)

6,

These combinations

cam

Cannot

shaft,

shaft,

OR

shaft,

12

24

be

or

or

of

cam

cam

SIX

and

12,

6

used

or

16

32

Figure

position

stitches,

slot,

At

at the

simply

this

bottom

point,

Fig,

pull

out

the

the

open,

position,

The

stitch

gap

knob

4

the

slot

stitch

will

arid

adjusting

be

of

gap

on

the

(B)

(B)

and

adjusting

is

(A)

9

shows

5

set

closed.

and

for

raise

the

knob

To

12

it

change

to

machine

or

16

(A)

is

the

in

stitches,

at

its

6

to

top

of

stop

low

or

the

8

Page 10

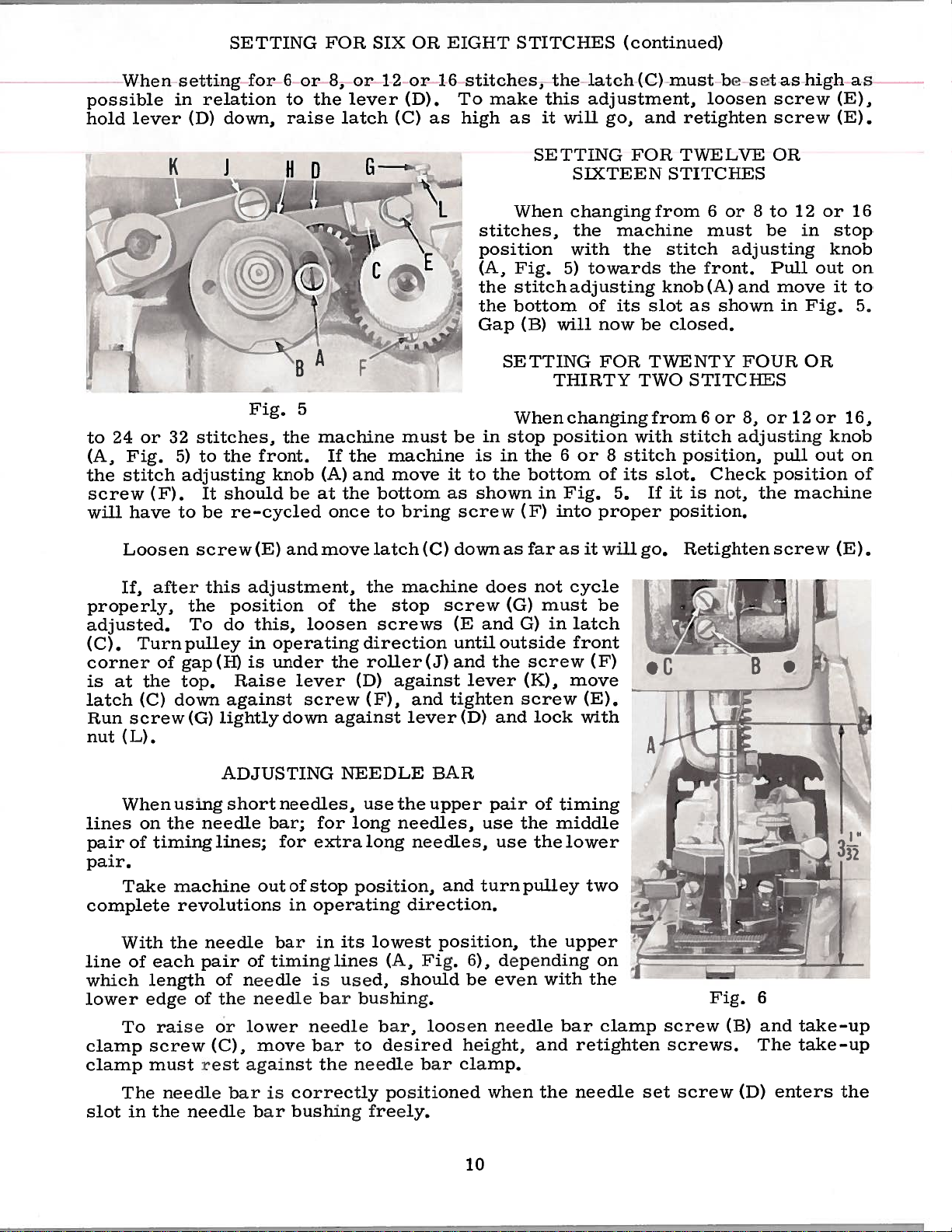

SETTING

FOR

SIX

OR

EIGHT

STITCHES

(continued)

When

possible

hold

24

to

(A,

Fig.

stitch

the

screw

will

in

lever

or

32

5)

(F).

have to

setting

relation

down,

(D)

stitches,

to

the

adjusting

should

It

be

for

Fio’.5

front.

knob

re-cycled

6

to

raise

HO

the

be

or

the

machine

(A)

at

3,

or

lever

latch

F

If

the

and move

the

once

or

12

(D).

(C)

must

machine

bottom

to

bring

as

16

be

it

as

stitches,

make

To

high

stitches,

position

(A,

the

the

Gap

in

is

to

the

shown

screw

the

latch(C)

this

adjustment,

will

SIXTEEN

changing

the

with

towards

5)

adjusting

of

now

FOR

6

or

of

Fig.

proper

go,

machine

the

its

8

stitch

its

5.

as

it

SETTING

When

Fig.

stitch

bottom

will

(B)

SETTING

THIRTY

Whenchangingfrom6or

position

stop

in

the

bottom

in

into

(F)

must

and

FOR

STITCHES

from

stitch

the

knob

slot

closed,

be

TWENTY

TWO

with

slot.

it

If

position.

be

loosen

retighten

TWELVE

6

or8to

must

adjusting

front.

(A)

as

shown

STITCHES

stitch

position,

Check

is

not,

set

as

screw

screw

OR

be

Pull

and

move

in

FOUR

8,

or

adjusting

pull

position

the

high

12

or

in

stop

knob

out

it

Fig.

OR

12

or

knob

out

machine

as

(E),

(E).

16

on

to

5.

16,

on

of

Loosen

If,

properly,

adjusted.

(C).

corner

is

latch

Run

nut

lines

pair

pair.

complete

line

which

lower

clamp

clamp

Turn

at

the

(C)

screw(G)

(L).

Whenusingshortneedles,

on

of

Take

With

of

length

edge

To

screw

must

after

the

To

pulley

of

gap

top.

down

the

timing

machine

revolutions

the

each

raise

screw(E)

of

adjustment,

this

position

do

this,

in

is

(H)

Raise

against

lightly

ADJUSTING

needle

lines;

outofstop

needle

of

the

or

(C),

of

needle

needle

lower

move

against

pair

rest

andmovelatch(C)

of

the

loosen

operating

lever

screw

in

needle

bar

the

against

NEEDLE

for

extra

operating

its

in

lines

is

used,

bar

the

under

down

bar;

for

bar

timing

the

stop

screws

direction

roller

against

(D)

(F),

use

long

long

position,

lowest

(A,

bushing.

bar,

to

desired

needle

machine

(J)

and

lever(D)

BAR

the

upper

needles,

needles,

direction.

position,

Fig.

should

loosen

bar

downas

screw

(E

until

and

lever

tighten

and

6),

be

height,

clamp.

faras

does

and

use

turnpulley

not

(G)

G)

outside

the

screw

(K),

screw

lock

and

pair

the

use

the

the

depending

even

needle

must

in

of

with

and

it

cycle

latch

front

move

(E).

with

timing

middle

lower

two

upper

the

bar

retightcn

willgo.

be

(F)

on

clamp

Retightenscrew

.0

—

/

r

screw

screws.

(E).

B

L

6

and

The

—

‘H

take-up

take-up

rr

T’

Fig.

(B)

slot

The

in

needle

the

needle

bar

bar

is

correctly

bushing

positioned

freely,

when

10

the needle

set

screw

(D)

enters

the

Page 11

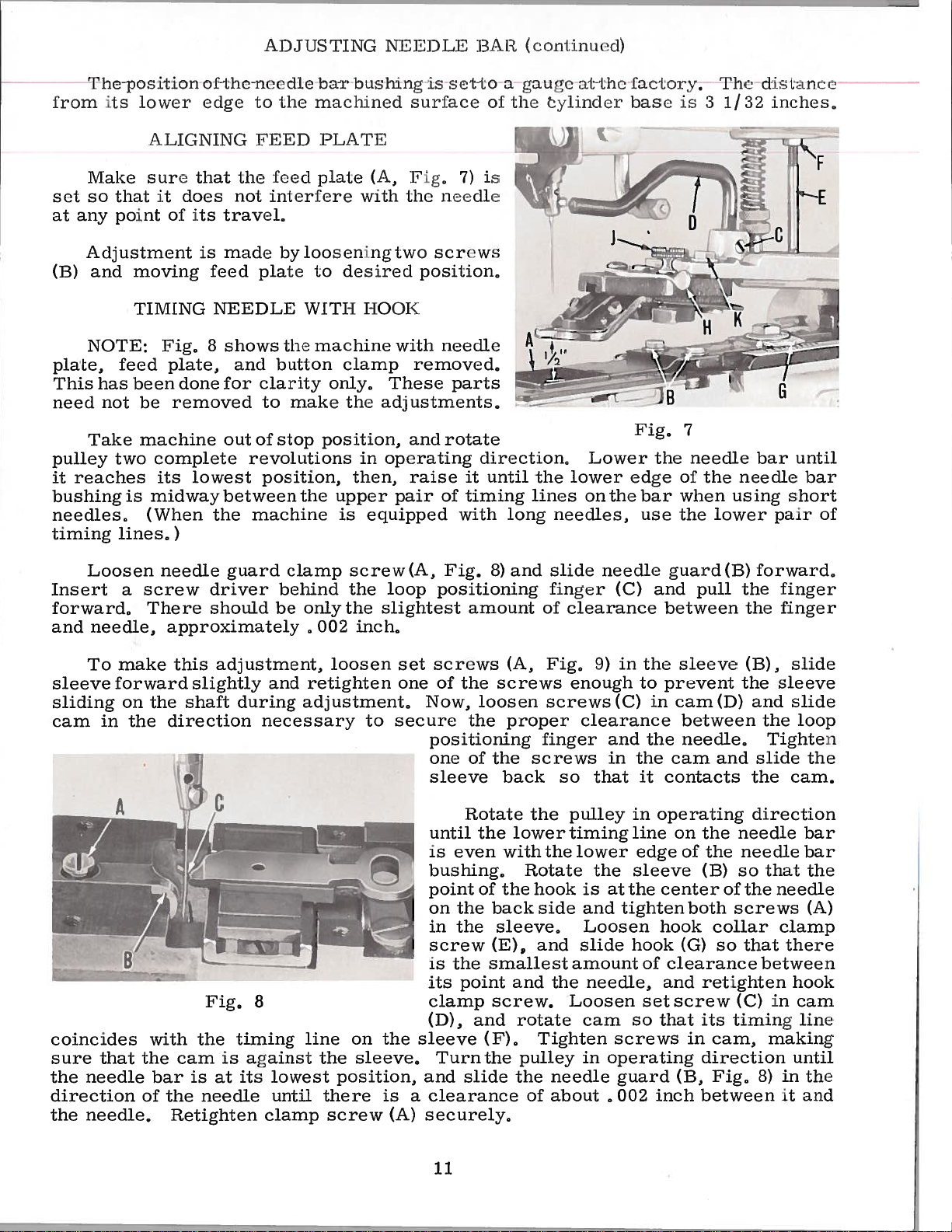

AI)I

IISTIN(1

NIII)IJ

HAH,

(lLiiuu(I)

rrta

-

rII1

Icom

iViakesnrc

so

set

at

any

Adj

and

(B)

NOTE:

plate,

This

neec[

Take

pulley

reaches

it

bushing

needles,

timing

LLS

has

not

position

iowei’

that

ponL

ustm

moving

TIM

feed

been

be

machine

two

is

lines,)

A

I

d(;

it

ilocs

of

cut

[NG

Vig,

plate,

done

removed

complete

its

midway

(When

ol.

edge

N1NG

that

its

is

feed

NEED

3

lowest

the

the

needle

to

i’iII)

the

not

tn:avel,

made

pLate

shows

and

clarity

for

to

out

of

revolutions

position,

between

machine

Line

Iced

mt,erlere

l.oos

by

Wirf.[I

Ii

the

button

make

stop

the

ha

hush

lliaeIniliu(l

PT

plate

with

cuing

desired

to

machine

clamp

only,

the

position,

in

then,

upper

is

iing

surl’aue

(A,

i

the

two

JQQ

with

removed,

These

adjustments,

and

operating

raise

pair

equipped

is

setto

1g.

7)

ineedte

sc

cc

position,

needle

parts

rotate

of

with

of

is

ws

direction,

until

it

timing

a

the

long

cylinder

the

lines

needles,

I.

Lower

lower

on

Line

the

au

hase

i.

edge

bar

use

tory,

the

is

7

needle

01

when

the

3

the

lower

Tine

1/32

using

distatien

bar

needle

innulics,

I

until

bar

short

pair

of

Loosen

Insert

forward,

and

needle,

To

sleeve

sliding

cam

coincides

sure

the

needle

direction

the

needle,

a

make

forward

on

in the

that

needle

screw

There

approximately

this

slightly

the

shaft

direction

cam

bar

the

Retighten

the

is

with

the

of

guard

driver

should

adjustment,

during

t1j

Fig.

timing

is

against

at

its

needle

clamp

behind

be

and

necessary

8

lowest

until

clamp

screw(A,

the

the

only

002

,

inch,

loosen

retighten

adjustment,

to

-—Z4

on

line

the

sleeve,

position,

there

screw

loop

slightest

set

one

secure

the

sleeve

is

a

(A)

Fig.

positioning

amount

screws

of

the

Now,

loosen

the

positioning

one

of

sleeve

Rotate

until

is

the

even

bushing,

point

on

of

the

in the

screw

is

the

its

point

clamp

and

(D),

Turn

and

slide

clearance

securely,

and

8)

(A,

screws

proper

the

back

lower

with

the

backside

sleeve.

(E)

9

smallest

and

screw.

rotate

(F),

pulley

the

the

slide

finger

of

clearance

Fig,

enough to

screws

clearance

finger

screws

so

the pulley

timing

the

lower

Rotate

hook

is

and

Loosen

and

slide

amount

the

Loosen

cam

Tighten

in

needle

of

about,002

needle

(C)

in

9)

(C)

and

in

that

the

at

needle,

screws

operating

guard

guard

and

between

the

sleeve

prevent

in

cam(D)

between

the

needle,

the

cam

it

contacts

in

operating

line

on

of

edge

sleeve

the

center

tightenboth

hook

hook

of

(G)

clearance

and

setscrew

so

that

(B,

inch between

pull

and

the

the

(B)

collar

so

ret

its

in

cam,

direction

Fig,

(B)

the

the

(B),

the

needle

needle

so

of

the

screws

that

ighten

(C)

timing

forward,

finger

finger

slide

sleeve

and

slide

the

Tighten

slide

the

cam.

direction

that

needle

clamp

there

between

hook

in

making

until

in

8)

it

loop

the

bar

bar

the

(A)

cam

line

the

arid

11

Page 12

buLi

a(Ijus

\V

id

Lnicnt,

ith

or

CL\\IP

distance

be

lower

1/

2

inch

rod

between

(i’ig,

(D),

7),

the

bottom

make

To

of’

t.Iit

this

OV

plate

and

13LTTON

normal

the

should

raise

iiIICil’I’

position,

stop

m

p

loosen

ulilno

lu

Liii’

c

in

the

set

in

Lop

of

screw

the

teed

(C),

L

[tetu:i’n

pi.n

stop

the

neec[lc

clearance

re-cycle,

to

On

button

mately

the

of

desired

(E,

Styles

clamp,

1/2

clamp

height,

6

the

Vig.

will

between

Too

200—16.

the

inch

canbe

Fig,

ichine

m

7).

not

tacking

between

The

9

to

purpose

Its

strike

the

stop

much

200-17,

changed

clampholder

A

A

stop

button

the

pin

clearance

clamp

it

and

byloosening

C

position,

is

and

which

should

feeciplate

the

will

to

or

prevent

any

the

will

are

turn

clamp

At

between

(A,

roller

screw

affect

relation

described,

2

1/

and

and

other

button

cause

equipped

set

be

lock

have

Take

pulley

this

Pig,

(13),

inch,

roller

check

overthrow

so

with

nut

to

be

in

is

point,

(C)

the

to

part

clamp

the

that

machine

and

i.nachLne

in

operating

furthest

its

the

and

10)

Adjustment

and

moving

height

the

but

interference

no

will

the

the

of

holder

button

with

there

turning

removed

out

there

button

the

feed

for

occur,

position

of

button

tacking

a

is

in

to

of

the

the

will

to

a

stop

clamp

make

of

stop

direction

Ltion

pos

must

clamp

button

macic

is

(A)

rod

the

plate

normal

between

of

button

clamp,

cause

strike

clamp

distance

position,

be

up.

button

as

the

clamp

rod

this

position,

until

to

the

clearance

lifting

clamp

loosening

by

This

clamp

previously

setting

lifting

button

Insufficient

machine

the

the

instead

approxi

of

Position

or

in

adjustment.

button

rcai’,

lifting

will

clamp

that

so

needle,

of

out

mid

rod

in

oF

rod

a

to

The

drop the

to

FOR

FOUR

Accurately

holes

the

indicator

(A,

Fig.

distance

the

to

With

button

the

stop

the

that

so

(J)

jaws.

Take

needle

the

be

shifted

to

adjustment,

The

necessary

pin,

stop

feed

HOLE

of

the

Fig,

(G,

the

to

11)

between

machine

the

inthe

lever

(I-I,

the

machine

the

enters

slightly

graduations

to

deviate

corresponding

plate

holder

POSITIONING

BUTTONS

measure

button,

7)

and

graduations

the

in

jaws

button

of

Fig,

is

out

center

the

to

on

slightly

the

stop

the

7)

holes

held

of

the

off

distance

and

spring

position,

clamp,

means

by

stop

of

secure

indicator

the

from

to(E,

latch

AND

Fig.

when

ADJUSTING

between

the

set

indicator

corresponding

button,

the

in

insert

adjust

and

screw

of

loosely

by

position,

this

hole

condition,

each

scales

them,

pivot

the

and

in

7),

the

the

shouldbe

machine

BUTTON

turn

button,

are

slowly

Loosen

only

onlyas

set

reached

has

CLAMP

Fig,

hand

by

button

The

screws

approximate,

10

low

to

(K)

stop

make

clamp

and

as

to

necessary

position,

sure

may

make

may

it

that

have

the

be

12

Page 13

POSITIONING

AND

LAM

A

HUTTON

C

P

(continued)

FOR

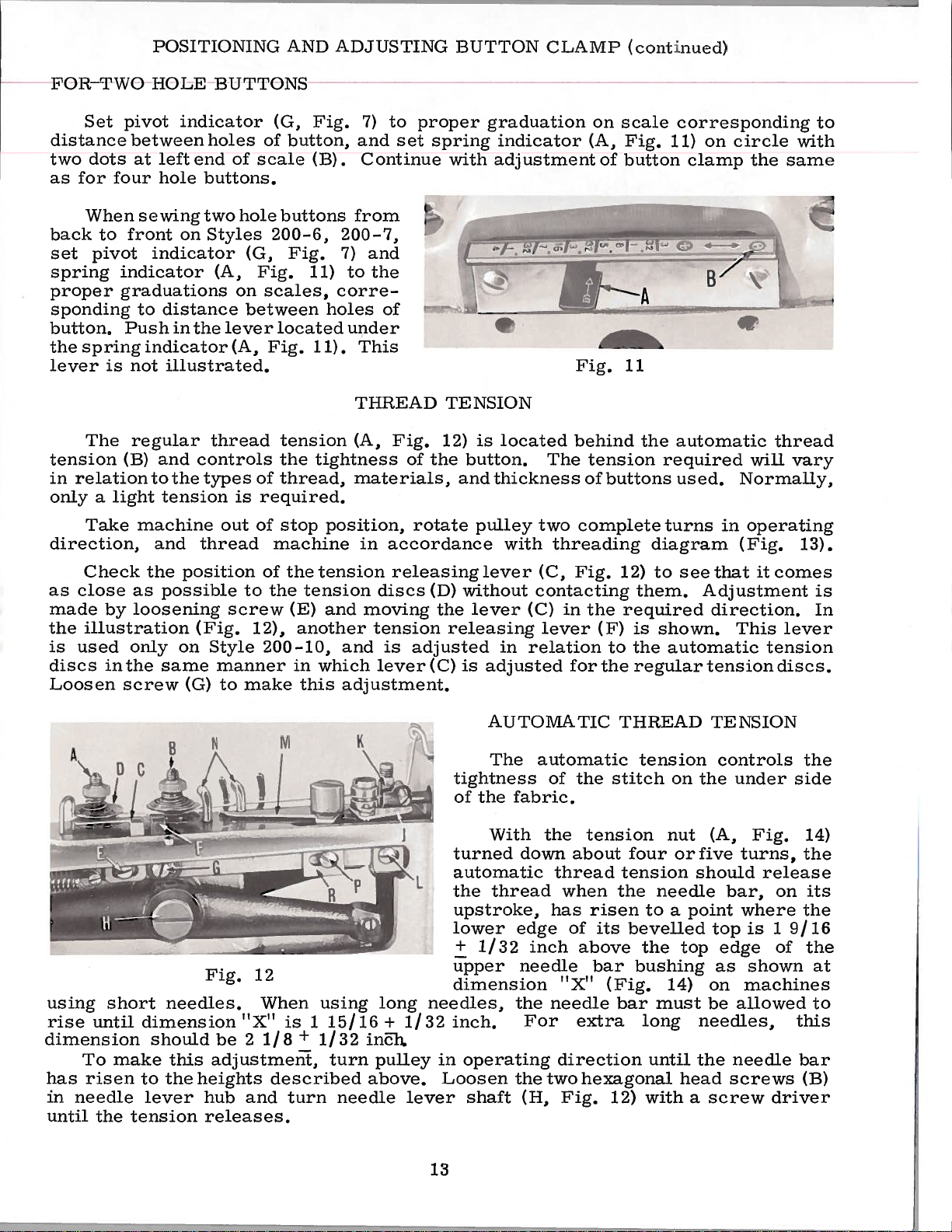

Set

clista!lce

two

clots

br

as

When

back

pivot

set

spring

proper

sponcling

button,

the

spring

lever

The

tension

in

relation

only

a

Take

direction,

Check the

as

close

made

the

illustration

is

used

discs

Loosen

TWO

pvoL

between

at

Four’

sewing

to

front

indicator

graduations

to

Push

is

not

regular

(B)

light

machine

as

loosening

by

only

inthe

screw

hOLE

Lndicator

leFt

hole

on

indicator

distance

in

indicator

illustrated.

and

to

the

tension

and

position

possible

on

same

(G)

BUTTONS

holes

end

buttons.

two

Styles

(A,

the

thread

controls

types

thread

(Fig.

Style 200-10,

manner

of

on

lever

(A,

is

out

screw

to

of

scale

hole

(G,

Fig.

scales,

between

Fig.

of

required.

of

of

to

12),

make

(G,

button,

buttons

200-6,

Fig.

located

tension

the

thread,

stop

machine

the

the

tension

(E)

another

in

this

I’ig.

.

(B)

200—7,

7)

to

11)

corre

holes

under

11).

tightness

position,

tension

and

and

which

adjustment.

to

7)

and

set

Continue

from

and

the

of

This

THREAD

Fig.

(A,

materials,

in

accordance

releasinglever

discs

moving

tension

is

lever(C)

peoper graduation

sprlng

I

12)

of

the

rotate

(D)

the

adjusted

with

TENSION

releasing

adjustment

•f

is

button.

and

thickness

pulley

without

lever

is

adjusted

indicator

located

with

in

Fig.

behind

The

complete

two

threading

Fig,

(C,

contacting

in

(C)

lever

relation

for

on

(A,

of

tension

of

buttons

the

(F)

to

the

scale

Iig,

button

11

12)

required

corresponding

on

11)

(-

the

automatic

required

used.

turns

diagram

to

see

them. Adjustment

is

shown.

the

automatic

regular

circle

clamp

—

in

that

direction,

This

tension

the

same

I.

thread

will

vary

Normally,

operating

(Fig.

it

comes

lever

tension

discs.

to

with

13).

is

In

1

1I

using

rise

until

dimension

To

has

risen

in

needle

until

the

short

make

B

I

needles.

dimension

should

this

to

the

lever

tension

N

Fi

g.

be

2

adjustment,

heights

and

hub

releases,

M

‘

2

12

When

XI

1/8

described

is

+

turn

mE

R

using

1

15/16

1/32

turn

needle

K

in1i,

pulley

above.

long

+

I

1/32

lever

tightness

of

automatic

the

upstroke,

lower

+

upper

dimension

needles,

inch.

operating

in

Loosen

shaft

13

AUTOMATIC THREAD

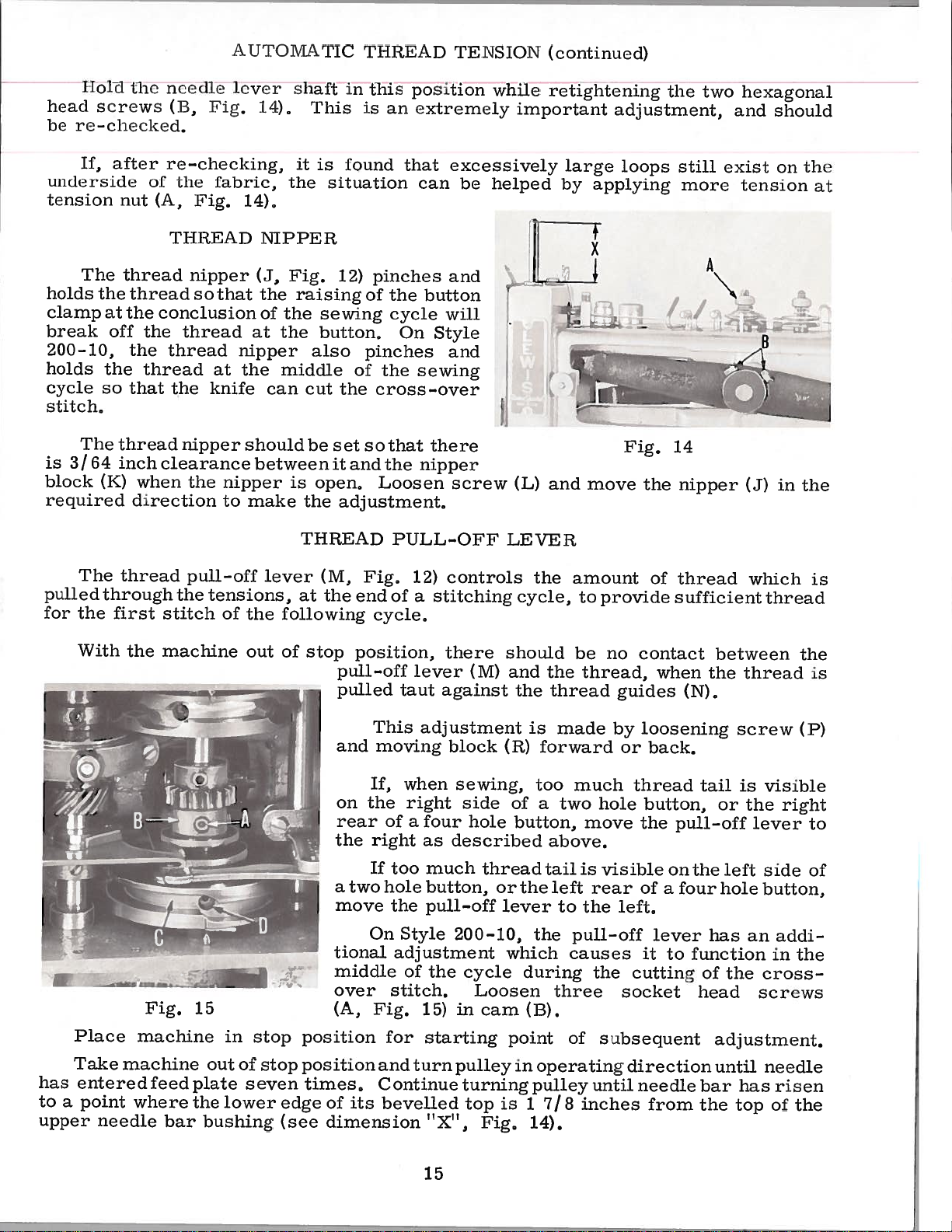

The

the

With

thread

1/32

automatic

fabric.

the

edge

inch

needle

the

For

the

(H,

the

of

thread

when

has

of

above

‘X’

T

needle

extra

direction

two

Fig.

stitch

tension

tension

the

risen

its

bevelled

bar

bushing

(Fig.

bar

hexagonal

12)

tension controls

to

the

long

until

with

on

nut

needle

a

top

14)

must

head

TENSION

the

(A,

should

point

top

edge

as

on

be

needles,

the

a

screw

under side

Fig.

release

bar,

where

is

shown

machines

allowed

needle

screws

on

1

9/16

of

driver

the

14)

its

the

the

at

to

this

bar

(B)

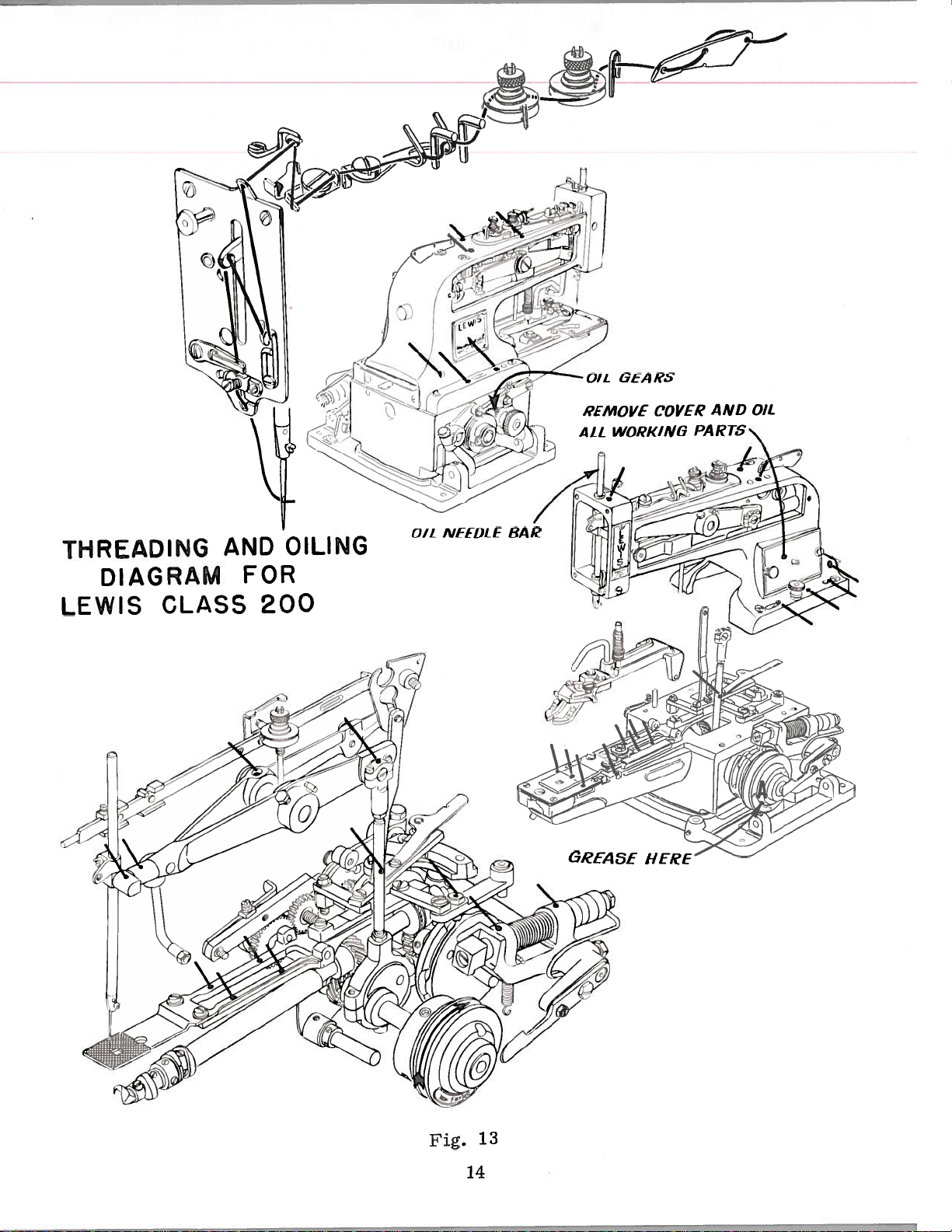

Page 14

O1L

GEARS

REMOVE

WORKING

ALL

COVER

AND

PARTS

OIL

THREADING

DIAGRAM

LEWIS

CLASS

AND

FOR

200

OILING

OIL

NEEDLE

BAR

HERE

Fig.

13

14

Page 15

I

head

be

ru—checked,

11,

node

tension

101(1

screws

iiiter

ide

rs

nut

thu

iuud1.e

(K,

re—checking,

of.

(A,

tie

I

‘ig.

A

1i’I)\’IATlC

luvu

‘ig,

fabric,

11).

V

1.1).

shaft

it

the

This

is

situation

‘[‘H

in

is

[ound

this

READ

position

an

that

TES1O

extremely

excessively

can

be

while

important

helped

(continued)

retighitening

adjustment,

large

by

loops

applying

the

still

moore

two

hexagotia

and

exist

tension

sh1ohI)(I

on

the

at

The

holds

clamp

break

200—10,

holds

The

is

3/

block

required

The

pulled

for

the

With

the

at

off

the

so

thread

64

mcli

(K)

through

first

thread

thread

the

the

the

thread

that

when

direction

thread

the

Tl[ItEAD

nipper

so

conclusion

thread

thread

at

the

knife

nipper

clearance

the

pull-off

the

tensions,

stitch

machine

that

nipper

the

nipper

to

of

N1PPE

(J,

the

of

at

can

should

between

make

lever

the

out

It

[ig.

raising

the

sewing

the

button,

also

middle

cut

be

is

open,

the

THREAD

(M,

at

the

following

of

stop

pinches

12)

of

pinches

of

the

the

cross—over

set

so

that

and

it

the

Loosen

adjustment.

Fig,

end

cycle,

position,

pull-off

pulled

and

the

button

On

will

Style

cycle

and

sewing

there

nipper

PULL-OFF

controls

12)

of

stitching

a

there

lever

taut

against

screw

(M)

-

(L)

LEVER

the

cycle,

should

and

the

the

and

amount

be

thread

1

move

to

provide

no

thread,

—

Fig.

the

contact

guides

14

of

thread

sufficient

when

nipper

(N),

between

thread

the

B

(J)

which

thread

in

1

the

is

the

is

,—

has

to

a

upper

Place

Take

entered

point

needle

Fig.

machine

machine

feed

where

bar

15

out

plate

the

bushing

in

of

seven

lower

stop

stop

edge

(see

and

on

rear

the

a

move

tional

middle

over

(A,

position

position

times,

of

dimension

two

its

This

moving

If,

the

of

right

If

too

hole

the

On

Style

adjustment

stitch.

Fig.

for

and

Continue

bevelled

adjustment

when

right

a

four

as

much

button,

pull-off

the

of

15)

starting

turn

“X”,

15

block

sewing,

side

hole

described

thread

or

200-10,

cycle

Loosen

in

cam

pulley

turning

top

Fig.

(R)

of

button,

the

lever

which

during

point

in

is

is

made

forward

too

two

a

above.

tail

left

to

the

three

(B).

operating

pulley

1

7/

14).

much

move

is

rear

the

pull-off

causes

the

of

until

inches

8

loosening

by

or

back.

thread

hole

button,

the

visible

of

left,

lever

it

cutting

socket

subsequent

direction

needle

from

pull-off

on

the

a

four

to

function

screw

is

tail

or

the

left

hole

has

of

the

head

adjustment.

until

has

bar

top

the

visible

lever

side

button,

an

cross

screws

needle

right

addi

in

risen

of

(P)

to

of

the

the

Page 16

the

Ti1

urn

p

roj

cam

ection

(K,

on

the

Vig,

nipper

III

ItHAD

15)

Ph

to

the

operating

IL—Oi’

right,

link,

V

as

and

LVVE

you

retighten

it

Lice

(continued)

it,

three

until

the

socket

lobe

head

stops

screws

aga

Lust

(A)

hi____

N

To

subsequent

complete

lay

and

cam

in

machine

until

right

to

securely,

Fig,

make

revolutions

machine

(C,

to

A

16

corrections

adjustment.

on

Fig,

is

speed

15)

again

its

comes

up

in

side,

in

knife

The

is

controlled,

to

the

If

loosen

easier

On

stitch

Take

operating

times,

the

to

should

knife

to

Take

operating

Turn

into

position,

stop

timing,

length

pull—oLE

much

too

screws

access

Style

the

at

machine

direction

Continue

top

snap

timing,

machine

direction,

pulley

view,

and

of

on

lever,

200—10,

middle

of

its

out

out

and

and

thread

Style

thread

(A,

link,

to

turning

stroke,

of

place

in

loosen

loosen

the

to

200—10,

tail

Fig,

TIMING

the

the

of

of

out

until

operating

machine

stop

of

Loosen

operating

this

left

tails

is

16)

remove

THE

knife

cycle.

stop

needle

pulley

At

position

screw.

screw(D),

to

on

the

by

visible

and

right

KNIFE

should

position

has

until

exactly

position,

in

knurled

direction

retard

an

raise

entered

stop

and

it,

front

additional

on

the

the

side

cut

and

needle

this

position

turn

base

until

Continue

Turn

Tighten

holes

right

link

cover,

cross-over

the

turn

feed

bar

point,

for

the

clamping

first

the

to

(A)

cam

buttons

of

adjustment

(B).

pulley

has

the

starting

slightly

hole,

eight

risen

knife

screw

screw

pulley

screws

front

plate

pulley

turn

all

Vor

in

two

The

effect

On

The

position

within

the

in

Changes

manner

To

Fig,

on

Style

1/16

cycle,

17),

slight

previous

200-15,

knife

when

inch

to

described

as

POSITIONING

position

and

amount

should

the

of

timing

move

timing

the

needle

the

knife,

bar

of

knife

snap

top

are

for

(B)

adjustment

the

of

should

out

bar

the

of

made

THE

in

200-10,

or

Style

loosen

cams

of

has

last

in

KNIFE

screws

out,

required

described

the

cut

operating

risen

up-stroke

same

the

16

thread

to

(A,

for

this

on

Page

at

setting

the

9

end

will

of

Fig,

have

the

17

no

stitching

noticeable

cycle,

Page 17

ILLUSTRATIONS

ORDERING

REPAIR

PARTS

various

of

actual

listing

a

required

position

ordering

cated

Example:

45

46

47

48

49

50

ed.

so

the

This

Numbers

The

catalog

position

of

in

of

parts.

Component

indenting

by

4124—49

It

will

reason

complete

sections

the

the

in

that

parts

18—968

18—730

18—925

666—19

137—19

be

has

been

of

the

the

first

their

that

machine.

with

in

use

sub—assemblies

of

in

replacement

in

parts

particular

the

part

Always

noted

is

sub—assembly

arranged

mechanism

their

view

column

illustration.

the

the

descriptions

Ball

Joint,

Spot

Set

Screw

Oil

Oil

above example

the

should

On

part

being

are

part

Screw

Wick

Wick

to

are

the

reference

number

lower,

Screw

of

be

simplify

shown

page

number,

shown.

which

under

Retainer

these

ordered.

so

opposite

description

numbers

Reference

listed

can

the

complete

that

parts

ordering

that

numbers

in

be

furnished

description

eccentric

the

individually

the

the

only,

the

repair

parts

illustration

and

and

second

of

parts.

may

the

merely

should never

column.

for

the

and

is

be

number

repairs

main

strap

not

Exploded

will

recommended,

views

seen

are

in

their

be

found

pieces

of

indicate

be

used

indi

are

sub—assembly.

not

list

the

in

1

1

1

2

1

1

in

this

only

numbers

SPECIAL

and

authorized

tific

bility

warded

directed.

At

the

book.

part

the

Where

represent

Success

Repair

principles,

are

Prices

f.o.b.

back

number

the

in the

assured.

are

shipping

A

charge

of

the

This

will

is

construction

the

operation

Parts

distributors.

net

as

and

cash

is

book

known.

same

furnished

are

and

point.

made

will

facilitate

permits,

part,

USE

made

subject

to

be

found

locating

IDENTIFYING

each

regardless

GENUINE

of

these

the

by

They

are

with

Parcel

cover

utmost

TERMS

to

Post

postage

a

PARTS

part

REPAIR

machines

Union

designed

precision.

change

shipments

numerical

the

is

of

catalog

PARTS

can

Special

according

without

and

illustration

stamped

be

are

insurance.

index

in

secured

Corporation,

Maximum

notice.

with

which

to

insured

of

the

all

description

and

its

they

only

most

efficiency

All

unless

the

parts

part

number.

appear.

with

its

subsidiaries

approved

shipments

otherwise

genuine

and

shown

when

scien

dura—

are

Part

UNION

for

17

Page 18

I,’

/7

-

p4

I

Page 19

BASE,

COVERS,

BUSHINGS

Ref.

No.

4

7

8

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

Part

No.

1

2

3

5

6

432-306

432-305

12957

1220

16-291

E

L

16-412

16—289

16-292

9

32—192

21—295

CS337

16-334

144-25

16-288

16-398

32-191

45-333

787

L

L

L

L

L

1235

1160

1158

1009

50-215

21-321

131—Cl

63—2

141-4

1005

L

Arm

Arm

Washe

Screw

Needle

Cam

Pulley

Looper

Cover,

Spring

Screw

Looper

Felt

Pulley

Cam

Stop

Stop

Screw

Stop

Nut

Screw

Nut

Bracket

Spring

M5h1

Machine

18—738

1003 L

14-399

186—16

4

16-297

16-411

4119-86

Hinge

Button

Needle

Needle

Thread

Pad

Motion

Motion

Screw

Chain

—7,

Cover,

Cover,

Lever

Shaft

Shaft

Shaft

left

Shaft

Shaft

Shaft

Set

Screw

Set

Shaft

Tray,

—8,

Bar

Bar

Cutting

Description

left

right

Bushing,

Bushing,

Bushing,

Bushing,

Bushing,

Bushing,

and

Trip

Hook

Sub-Bas

Screw

Screw

complete,

—10,

—9,

Bushing,

Bushing,

Shaft

Pulley

Knife,

Bushing

Leve

—25,

left

left

front

rca

right

right

Cover,

for

—26,

lower

uppe

complete,

Styles

—27

right

for

200—1,

Styles

—2,

200-10

—6,

—15

—15

for

—15

—15

-15

bottom,

Styles

top,

for

for

Styles

200-10,

Styles

-15

200-10,

46-182

4

CS337

46-181

22—255

21—96

6-183

18-1035

Spring

Spring,

Thread

200—10,

Thread

Screw,

Screw,

Thread

Pin,

for

Cutting

Cutting

for

for

Cutting

for

Styles

—15

Styles

Styles

Styles

Lever

Cam

200—10,

200-10,

Lever

200—10,

200—10,

Link,

Link,

Link,

—15

45-426

75-267

Thread

Needle

Cutting

Bar

Guard

Knife

Lever,

for

Styles

200-10,

-15

Amt.

Req.

1

1

2

2

1

1

1

1

1

2

4

1

1

1

1

1

1

1

1

1

2

1

1

1

1

1

1

2

2

2

1

1

1

1

2

1

1

1

5

2

1

1

1

19

Page 20

£

‘

77cJq

1

iI

CYjJ!

y

1’

@j

I

‘

‘C

/

09

9

91/

oimic

(paJqwoss)

oz

p

p

Page 21

NR

RD1J’

1)RIV

N,

CLIJ’I’CI

—

I,

5101

I\I(

)‘l’i(

)NI‘A

RI’S

11(1.

No,

1

2

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40