Page 1

High Performance Series Fryer

Model F-ID-20x17

Operation Instructions

FOR YOUR SAFETY

Do not store or use gasoline or other flammable vapors or

liquids in the vicinity of this or any other appliance.

Purchaser to post in a prominent location instructions to be

followed in the event the user smell gas.

This information shall be obtained by consulting the local gas

supplier.

302 Spencer Lane • P.O. Box 5369 San Antonio, Texas 78201

(800) 525-8130 • (210) 731-5000 • Fax: (210) 731-5099

www.ultrafryer.com

WARNING

Improper installation, adjustment, alteration, service, or

maintenance can cause property damage, injury, or death.

Read the installation, operating, and maintenance instructions

thoroughly before installing or servicing this equipment.

1 30A268 May 2016 Rev A

Page 2

PREFACE

This manual was written and published by the Ultrafryer Systems Engineering Department for use by personnel who

will operate a Model F-ID-20x17 Premix Gas Fryer equipped with an Ultrastat 23 Computer in a commercial cooking

environment. Proper use of a manual will allow store employees to operate, clean, and maintain equipment properly,

thereby reducing service call expenses.

This appliance is intended for professional use and is to be operated by qualified personnel.

The manual is to be retained for future reference.

Throughout this manual, NOTE, NOTICE, WARNING, CAUTION and DANGER are used to alert the operator to items of

special circumstances. These items are identified as follows:

NOTE: Adequate clearances must be provided for servicing and proper operation.

NOTICE: Programming of an Ultrastat 23 Cooking Computer should only be preformed by a store manager or area

supervisor.

WARNING: DISCONNECT THE ELECTRICAL POWER TO THE FRYER.

CAUTION: DO NOT ALLOW ANY CLEANING SOLUTION OR WATER TO SPLASH INTO A VESSEL

OF HOT COOKING OIL, AS IT WILL CONTAMINATE THE OIL AND MAY CAUSE THE

OIL TO SPLATTER, CAUSING SEVERE BURNS.

DANGER: THE FRYER MUST BE CONNECTED TO THE TYPE OF GAS IDENTIFICATION ON THE

RATING PLATE

This manual is intended as a guide for all Model F-ID-20x17 Premix Gas Fryers, regardless of configuration and

2

30A268 May 2016 Rev A

Page 3

TABLE OF CONTENTS

GENERAL INFORMATION

Warranty ............................................................................................................................................ 5

Safety ................................................................................................................................................. 6

Description ......................................................................................................................................... 6

Specifications ..................................................................................................................................... 7

Operating Controls ............................................................................................................................. 7-8

Automatic Safety Features .................................................................................................................. 9

Rating Plate ........................................................................................................................................ 9

Inlet Gas Line Sizing .......................................................................................................................... 9-10

PRE-INSTALLATION

General ............................................................................................................................................... 11

Standards ............................................................................................................................................ 11

Air Supply and Ventilation ................................................................................................................. 11

RECEIVING AND INSTALLING

Unpacking .......................................................................................................................................... 14

Installing ............................................................................................................................................ 14

Leveling ............................................................................................................................................. 14

Gas Connection .................................................................................................................................. 15

Electrical Connection ........................................................................................................................ 15

ULTRASTAT 23

Computer Panel Key Descriptions ...................................................................................................... 16-17

Programming Guide ........................................................................................................................... 18

Start-up and Cooking Operation .......................................................................................................... 19-21

PREVENTIVE MAINTENANCE AND TROUBLESHOOTING

Preventive Maintenance ..................................................................................................................... 23

Troubleshooting .................................................................................................................................. 24

Troubleshooting Chart ........................................................................................................................ 24-25

CLEANING

Daily ................................................................................................................................................... 27

Weekly ............................................................................................................................................... 27

TECHNICAL ASSISTANCE & ORDERING INFORMATION

Technical Assistance .......................................................................................................................... 28

Ordering Information .......................................................................................................................... 28

RECOMMENDED SPARE PARTS

Spare Parts Listing ................................................................................................................................ 31

PARTS IDENTIFICATON

Parts Identification .............................................................................................................................. 33-36

SERVICE PROCEDURE AND ADJUSTMENTS

Harmonic Tone ................................................................................................................................... 38

Gas Valve ........................................................................................................................................... 38

Infrared Burner Spark Ignitor and Temperature Probe Settings.......................................................... 39

Ground Wire Connection .................................................................................................................... 39

Premix Gas Blower (PWM) Settings .................................................................................................. 40

Delay On Make Settings ..................................................................................................................... 40

Temperature Probe Settings ................................................................................................................ 41

Hi Limit Probe Settings ...................................................................................................................... 41

LADDER / SCHEMATIC DIAGRAM

Ladder Diagram .................................................................................................................................. 43

Schematic Diagram............................................................................................................................. 44

3

30A268 May 2016 Rev A

Page 4

GENERAL INFORMATION

4

30A268 May 2016 Rev A

Page 5

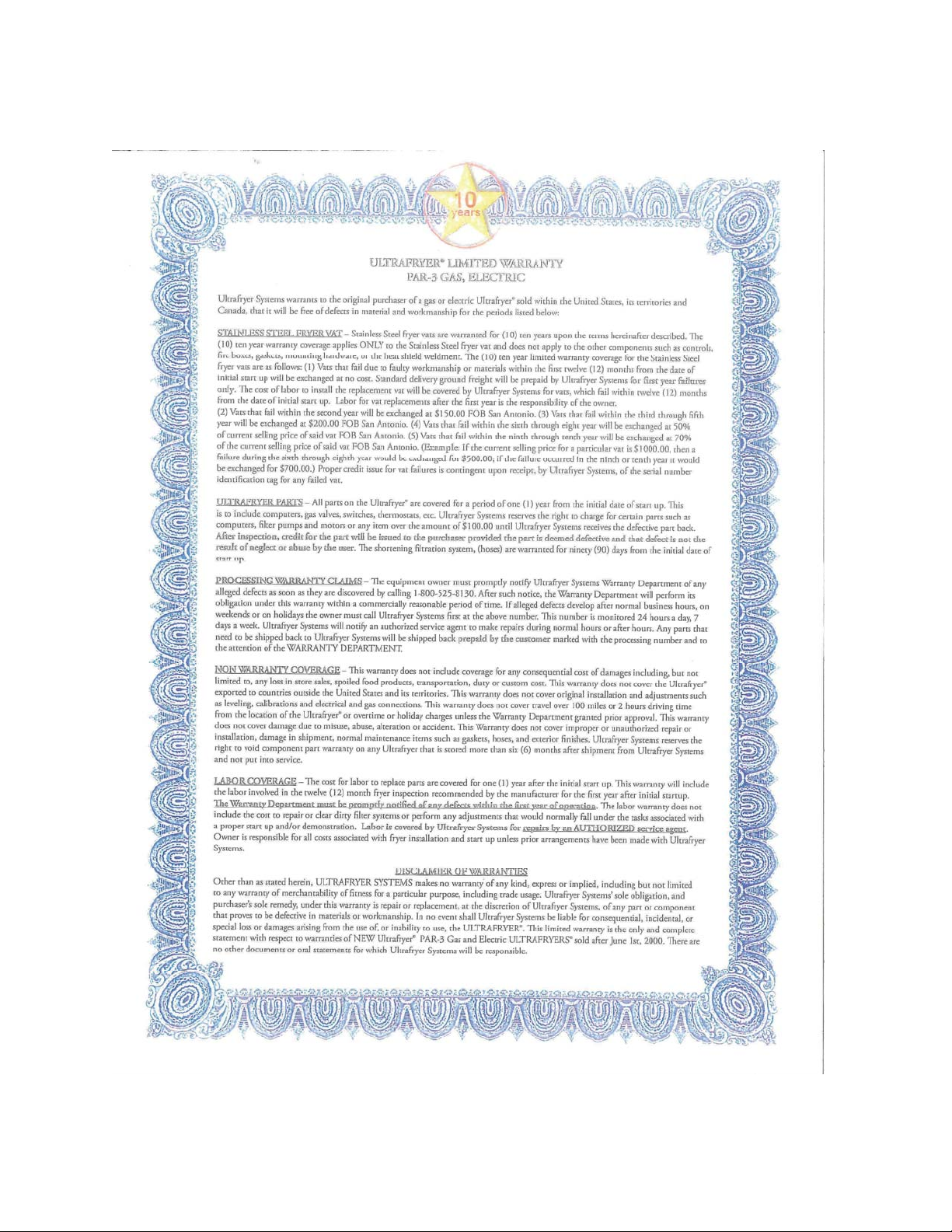

A. WARRANTY

5

30A268 May 2016 Rev A

Page 6

B. SAFETY

The major safety concern associated with the Ultrafryer Premix Gas fryer is burns from hot shortening.

In order to prevent serious burns, good housekeeping habits are required. The floor in front of and the area around the fryer

should be kept clean and dry. Whenever anything is placed into a fryer vat, care should be used not to splash the hot shortening.

Product should always be “PLACED” into the shortening, not thrown. Safety goggles, neoprene insulated gloves, and an apron

must be worn while boiling-out a fryer vat. Electrical controls used in the gas fryer operate on 120 volts single phase electrical

power, and no adjustments or replacement of electrical controls should ever be attempted without first disconnecting electrical

power. The fryer should never be operated with wet hands or while standing in water. To do so can result in serious electrical

shock or death.

C. DESCRIPTION

ULTRAFRYER ID 20x17 PREMIX GAS FRYER

The Ultrafryer 20"x17” (508mm x 432mm) ID premix gas fryer was designed by Ultrafryer Systems® to operate as an energyefficient, gas-fired fryer and is design-certified by the Canadian Standards Association (CSA) and the National Sanitation Foundation (NSF). It is manufactured to operate on either NATURAL or PROPANE gas according to the following Operational

Requirements. Each fryer is shipped completely assembled with the accessories packed inside the fryer vat, and each fryer has

been adjusted, tested and inspected prior to shipment. This gas fryer is designed to be used in a commercial food preparation

environment after it is properly installed as outlined in this manual.

6

30A268 May 2016 Rev A

Page 7

D. SPECIFICATIONS

SPECIFICATION ITEM 20”x17” ID

MODEL 20”x17” (508mm x 432mm) ID PREMIX GAS FRYER

OPERATIONAL REQUIREMENTS

Overall Width 21.375” (543mm)

Overall Depth 33.49” (850mm)

Work Height 34.95” (888mm)

Oil Capacity

High Level

Low Level

100 lbs (45.4 liters)

78 lbs (35.8 liters)

Vat Container Size 20.00” x 17.375” (508mm x 441mm)

Gas Pressure (inlet to fryer)

Natural Gas

Propane

Gas Rating

Natural Gas

Propane

7” (178mm) W.C.

14” (356mm) W.C.

150,000 BTU/hr (158.15 MJ/hr)

150,000 BTU/hr (158.15 MJ/hr)

Shipping Cube 29” x 42” x 45” (74mm x 107mm x 114mm)

Shipping Weight 412 lbs (186.9 kgs)

Power Input 120 Volt, 15 Amp, 60Hz, 1 Phase

FT3 / HR (M3 / HR) VALUES May vary due to heating value and specific gravity of gas supplied by local Gas Company

NOTE:

Test Start-Up, Operation, Cooking, Filtering and Boil Out Procedures of a 20”x17” Model ID Premix Gas Fryer in the

manual are based on the Ultrastat 23 Cooking Computer.

Refer to Manual P/N 30A216 to perform these functions in a fryer equipped with this controller.

E. OPERATING CONTROLS

The fryer is equipped with an Ultrastat 23 Cooking Computer as shown on the next page. Operating instructions for the

Ultrastat 23 Cooking Computer (P/N 30A216) will be provided with the fryer. Operating controls on the fryer include the

Ultrastat 23 Cooking Computer and the Red Heating Indicator Lamp, these controls are mounted on the Controller Door. The

Temperature Probe and Hi-Limit Switch, these controls are located inside the vat. The Drain Ball Valve and Red Hi-Limit

Reset Switch, these controls are located behind the Service Access Door. These controls were identified in the illustrations

shown on the next page.

7

30A268 May 2016 Rev A

Page 8

F. OPERATING CONTROLS LOCATION

Ultrastat 23

Cooking Computer

Service Access Door

Controller Door

Red Heating

Indicator Lamp

Hi Limit Probe

Drain Ball Valve

Electrical Control

Box Assembly

Temperature Probe

Hi Limit Reset Switch

8

30A268 May 2016 Rev A

Page 9

G. AUTOMATIC SAFTEY FEATURES

))

(

N

1. High Limit thermostat to shut off gas to the main burners by opening a solenoid –activated safety valve in the

combination gas control valve.

2. Combination gas control valve which includes a built-in pressure regulator.

3. Air pressure switch to open the 24 volt electrical circuit to th e gas control v alve, w hich turns off th e gas to the fryer OFF if a

Blower Motor becomes inoperable.

4. Sensing Circuit within the spark ignitor module to which turns gas to the fryer OFF if a burner FLAME OUT occurs.

5. A Current Sensor and Air Pressure Switch which, combined, provide an air Proof System for the fryer.

H. RATING PLATE

The Rating Plate is located on the inside of the Service Access door and contains the following information: the model and

serial numbers, BTU/HR input rating of the burners, gas manifold pressure in inches W.C. , minimum inlet gas required, and

gas type. This data is essential for proper identification when communicating with ULTRAFRYER SYSTEMS or requesting

special parts or information.

DANGER:

THE FRYER MUST BE CONNECTED ONLY TO THE TYPE OF GAS IDENTIFICATION

ON THE RATING PLATE !

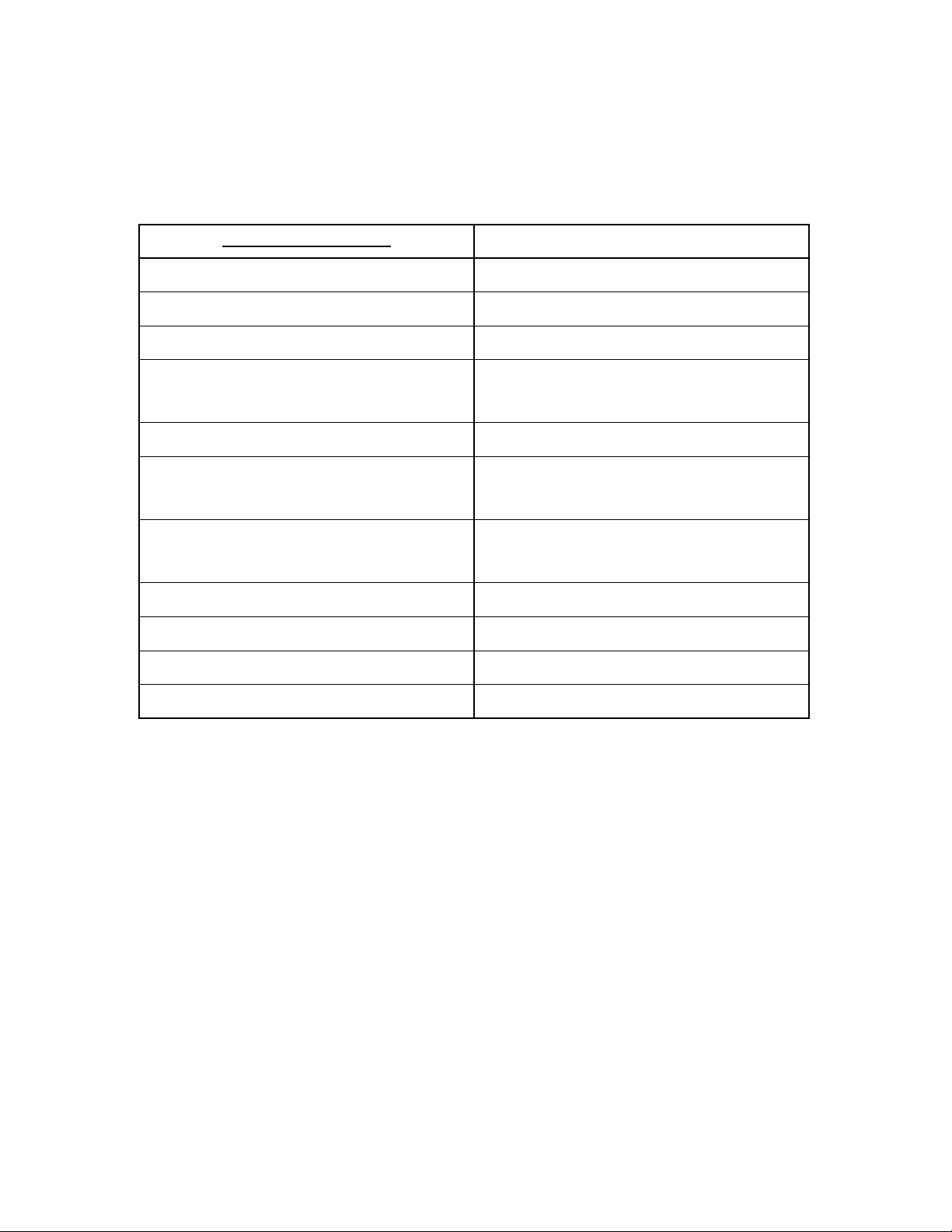

I. INLET GAS LINE SIZING

The table below is to be utilized to calculate the size (diameter) of the inlet gas line from the building regulator to the fryer

manifold.

PIPE

LENGTH

Peet

(Meters) (13 mm) (19mm) (25mm) (32mm) (38mm) (51mm) (64 mm) (76mm) (102mm)

15 62 170 350 620 960 2,000 3,500 5,400 11,200

(4.6) (1.7) (4.7) (9.8) (17.4) (26.9) (56.0) (98.0) (151.2) (313.6)

30 43 120 245 430 680 1,400 2,450 3,800 7,900

(9.1) (1.2) (3.4) (6.9) (12.0) (19.0) (39.2) (68.6) (106.4) (221.2)

45 35 98 200 355 530 1,150 2,000 3,200 7,900

(13.7) (1.0) (2.7) (5.6) (9-9) (14.8) (32.2) (56.0) (89.6) (182.0)

60 30 84 175 310 480 1,000 1,760 2,700 5,600

(18.3) (0.8) (2.4) (4-9) (8.7) (13.4) (28.0) (49.3) (75.6) (156.8)

75 27 76 155 275 430 890 1,560 2,450 5,000

(22.9) (0.8) (2.1) (4.3) (7.7) (12.0) (24.9) (43.7) (68.6) (140.0)

90 25 70 145 250 395 810 1,430 2,260 4,550

(27.4) (0.7) (2.0) (4.1) (7.0) (11.1) (22.7) (40.0) (63.3) (127.4)

105 23 64 132 232 370

(32.0) (0.6) (1.8) (3.7) (6.5) (10.4) (21.0) (36.4) (58.8) (117.6)

120 21 60 125 215 340 700 1,200 1,950 4,000

(36.6) (0.6) (1*7) (3.5) (6.0) (9.5) (19.6) (33.6) (54.6) (112.0)

150 19 54 no 195 310 630 1,080 1,750 3,550

(45.7) (0.5) (1.5) (3.1) (5.5) (8.7) (17.6) (30.2) (49.0) (99.4)

180 17 49 100 175 280 570 960 1,600 3,200

(54.9) (0.5) (1.4) (2.8) (4-9) (7.8) (16.0) (26.9) (44.8) (89.6)

210 16 44 94 165 260 530 890 1,450 3,000

(64.0) (0.4) (1.2) (2.6) (4-6) (7.3) (14.8) (24.9) (40.6) (84.0)

240 15 43 88 155 240 500 840 1,350 2,800

(73.2) (0.4) (1.2) (2.5) (4.3) (6-7) (14.0) (23.5) (37.8) (78.4)

270 14 40 83 145 230 470 780 1,300 2,650

(82.3) (0.4) (1.1) (2.3) (4.1) (6.4) (13.2) (21.8) (36.4) (74.2)

300 14 38 79 138 215 440 750 1,250 2,500

(91.4) (0.4) (1.1) (2.2) (3.9) (6.0) (12.3) (21.0) (35.0) (70.0)

450 11 31 64 112 176 360 630 1,000 2,050

(137.2) (0.3) (0.9) (1.8) (3.1) (4-9) (10.1) (17.6) (28.0) (57.4)

600 10 27 56 97 152 315 530 860 1,750

(182.9) (0.3) (0.8) (1.6) (2.7) (4.3) (8.8) (14.8) (24.1) (49.0)

OTE: 1) FT3/HR (M

2) To determine the inlet gas line diameter for the distance between the fryer and main gas regulator, locate the FT3/HR (M3/HR) of gas required for the fryer and pipe length and read the

pipe diameter on the top row. For example, a 14” PD fryer operating on NATURAL GAS requires 105 FT3/HR (3.0 M3/HR) of gas at the fryer’s inlet gas manifold. If the fryer bank is

located 60 feet from the building gas regulator, a 1” (25mm) diameter gas line MUST be installed between the manifold and regulator.

3

/HR) values may vary due to heating value and specific gravity of gas supplied by local companies.

1/2”

INLET GAS LINE REQUIREMENTS

PIPE DIAMETERS (inches & (mm equivalents

Maximum Allowable Flow (Shown in ft3/hr (M3/hr))

1”

1¼”

1½”

2”

750 1,300 2,100 4,200

2½” 3” 4”

10

30A268 May 2016 Rev A

Page 10

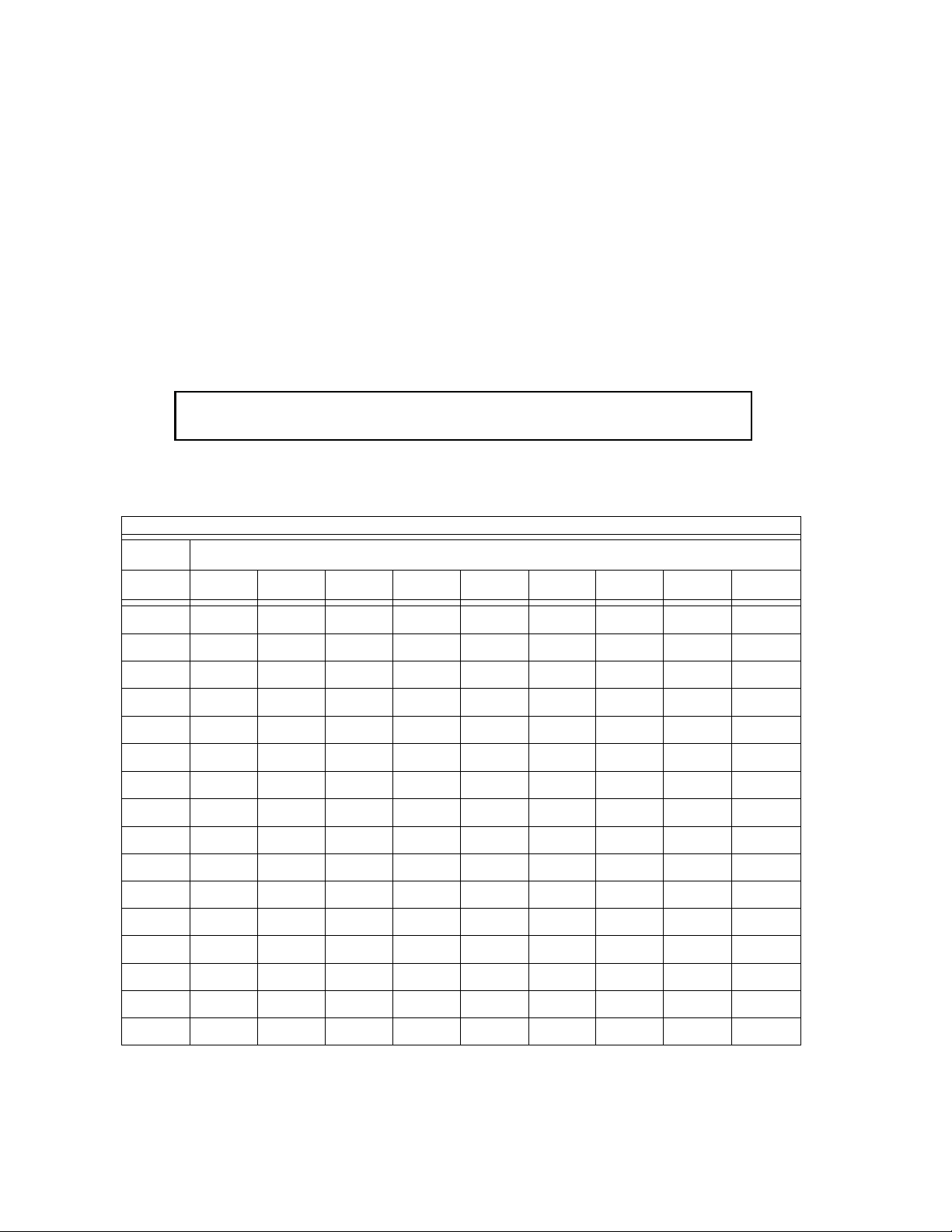

J. FLEXIBLE GAS LINE LENGTHS

The Flexible Gas Line used to connect the gas manifold to the building gas supply line must be rated for the BTU/Hr (MJ/Hr)

designated for the Fryer. Flexible gas lines and their ratings stocked by Ultrafryer Systems are listed below:

FLEXIBLE GAS LINES STOCKED BY ULTRAFRYER SYSTEMS

NUMBER DESCRIPTION

24322

24323

24456

¾“ (19mm) Diameter Flexible Gas Line (w/quick connect couplings)

48” (1219mm) long. Connect-It SSGC75-48-UCQ

1” (25mm) Diameter Flexible Gas Line (w/quick connect couplings) 48”

(1219mm) long. Connect-It SSGC100-48-UCQ

1V” (32mm) Diameter Flexible Gas Line (w/quick connect couplings)

48” (1219mm) long. Connect-It SSGC125-48-UCQ

RATING BTU/HR (MJ/HR)

225,000 (238)

435,000 (459)

875,000 (924)

10

30A268 May 2016 Rev A

Page 11

PRE-INSTALLATION

11

30A268 May 2016 Rev A

Page 12

A. GENERAL:

Safe and satisfactory operation of a Model F-ID 20x17 premix gas fryer depends on its proper installation. Installation must

conform to local codes or, in the absence of local codes, with the current National Fuel Gas Code ANSI Z223.1/NFPA 54

(latest edition). In Canada, gas installation shall be in accordance with the current CSA B 149.1 and .2 installation codes and/or

local codes. Each Model F-ID 20x17 premix gas fryer should be installed as follows:

1. Placed beneath a properly designed exhaust hood

2. Installed by a licensed plumber.

3. Connected to the type gas for which the unit was fabricated as shown on the rating plate.

4. Connected to the proper size pressure regulator installed in the gas supply line and adjusted to the proper manifold

pressure.

5. Connected to the main gas supply line with the proper size supply line.

6. Restrained by use of a restraining device to avoid splashing of hot liquid and to assure tension cannot be placed on the

flexible gas line or fittings. CLEARANCES: The appliance must be kept free and clear of all combustibles. The minimum clearance from combustible and non-combustible construction is 6" (152 mm) from the sides, and 6" (152 mm)

from rear. The fryer may be installed on combustible floors.

NOTE: Adequate clearances must be provided for servicing and proper operation.

B. STANDARDS: Installation must be planned in accordance with all applicable state and local codes, taking into account

the following standards:

1. The fryer and its individual shut-off valve must be disconnected from the gas supply piping system during any pressure

testing of that system at pressures in excess of 1⁄2 psi (3.45kPa). In Canada, gas installation shall be in accordance with the

current CSA B 149.1 and .2 installation codes and/or local codes.

2. The fryer must be isolated from the gas supply piping system by closing its individ ual manual shut- off valve during an y

pressure testing of the gas supply piping system at pressures equal to or less than 1⁄2 psig (3.45kPA).

3. When installed the fryer must be electrically grounded in accordance with local codes, or in the absence of local codes, in

accordance with the current National Electrical code ANSI/NFPA 70 (latest edition). In Canada electrical installation must

be in accordance with the current CSA C22.1 Canadian Electrical Code and/or local codes.

4. Other applicable nationally recognized inst allation s tandards such as:

a. National Fuel Gas Code ANSI Z223.1/NFPA 54 (latest edition)

American Gas Association

1515 Wilson Blvd.

Arlington, VA 22209

b. NFPA Standards #54, #94 and #221 (latest edition)

National Fire Protection Association

470 Atlantic Avenue

Boston, MA 02110

c. ANSI Z21.69/CSA-6.16 AND ANSI Z21.41/CSA 6.9

5. Exhaust vent hood, when installed must conform to the current NFPA 54-1 and Canadian Standards (latest edition).

NOTE: Local building codes will usually not permit a fryer with its open tank of hot oil to be installed immediately next to an

open flame of any type, whether a broiler or an open burner or range. Check local codes before beginning installation.

C. AIR SUPPLY AND VENTILATION: The area around the appliance must be kept clear of any combustible or flammable

products and avoid any obstruction to the flow of ventilation air as well as for ease of maintenance and service. NOTHING

is to be stored in the interior of the fryer’s cabinet.

1. A means must be provided for any commercial, heavy duty-cooking appliance to exhaust combustion wastes outside of

the building. It is essential that a fryer be set under a powered exhaust vent hood or that an exhaust fan be provided in the

wall above the unit, as exhaust temperatures are in the vicinity of 400˚F (204˚C).

NOTE: Strong exhaust fans in a hood or in the overall air conditioning system can produce slight air drafts in the room, which

can interfere with burner performance and be hard to diagnose. Air movement should be checked during installation and if

burner problems persist, make-up air openings or baffles may have to be provided in the room.

2. Exhaust temperature, in addition to the open tank of hot oil, make the storage of anything on shelving over or behind the

fryer unsafe.

3. Filters and drip troughs should be part of any industrial hood, but consult local codes before constructing and installing

any hood.

4. Provisions must be made for an adequate supply of fresh air and adequate clearance must be maintained for air openings

into the combustion chamber.

12

30A268 May 2016 Rev A

Page 13

RECEIVING AND INSTALLING

13

30A268 May 2016 Rev A

Page 14

A. UNPACKING: Check that the container is upright. Use an outward prying motion – DO NOT USE A HAMMER - to

remove the carton. Check the fryer for visible damage; if such damage has occurred do not refuse shipment, but contact the

carrier and file the appropriate freight claims.

B. INSTALLING: Roll the assembled fryer into the building, to its operating location.

WARNING: IMPROPER INSTALLATION, ADJUSTMENT, ALTERATION, SERVICE, OR MAINTENANCE CAN

CAUSE PROPERTY DAMAGE, INJURY, OR DEATH. READ THE INSTALLATION, OPERATING

AND MAINTENANCE INSTRUCTIONS THOROUGHLY BEFORE INSTALLING OR SERVICING

THIS EQUIPMENT.

C. LEVELING:

1. When the fryer is placed in its operating location, check to be sure it is l evel. If not, loosen the cast er s and insert the a pp ro-

priate number of shim plates between leg and caster plates then retighten the caster bolts.

2. If the floor is smooth and level, adjust to the high corner and measure with a spirit level. If the floor is uneven or has a

decided slope, level the unit with metal shims.

NOTE: A caster may not return exactly to the same position after being moved, which may require re-leveling after each move.

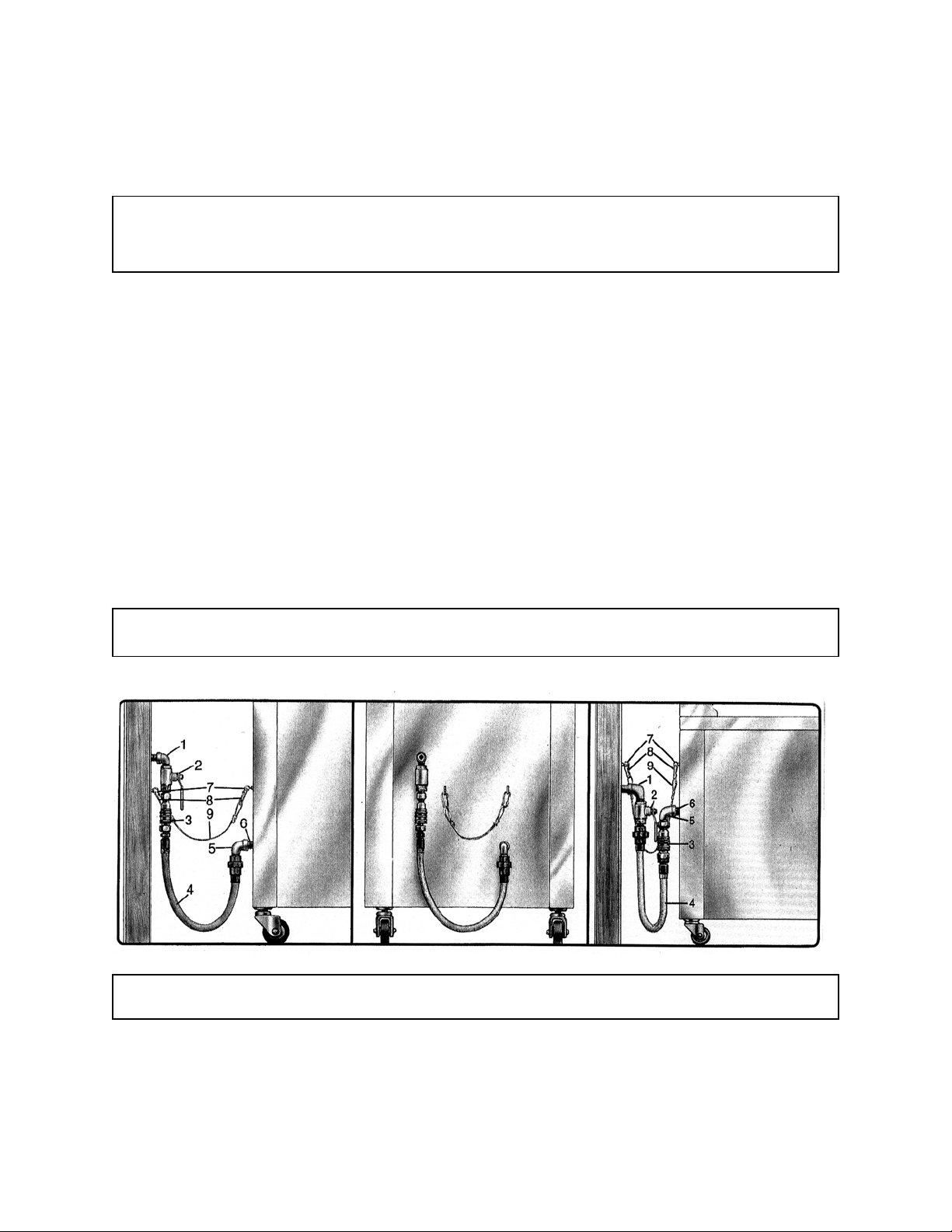

3. Connect the gas manifold to the building gas supply line by means of a CSA Group APPROVED flexible gas line as

shown in the figure below.

NOTE: CONNECT-IT Inc. 3⁄4" (19mm), 1" (25mm) and 1 1⁄4" (32mm) flexible gas hose 4 feet long (1219mm) with a quick

disconnect coupling on one end is available from Ultrafryer Systems under PN 24322 (3⁄4" (19mm) hose), PN 24323

(1" (25mm) hose) and PN 24456 (1 1⁄4" (32mm) hose). These hoses are equipped with a fusible link, which melts at

361°F (183ºC) that will SHUT OFF the gas supply when it melts. Reference Installation Instructions sheet provided

with hose for additional information. A 44" (1119mm) long restraining device is also available under PN 24324. Install

as shown below between the wall and the fryer using existing mounted hardware or add hardware to the wall and fryer

making a secure connection at each ends.

CAUTION: THE BUILDING GAS SUPPLY LINE MUST BE SIZED TO PROVIDE THE VOLUME OF GAS

REQUIRED FOR PROPER OPERATION AS EXPLAINED ON THE PREVIOUS PAGE.

TYPICAL GAS CONNECTION

1. BUILDING GAS SERVICE LINE 6. APPLIANCE MANIFOLD/

WARNING: THE RESTRAINT DEVICE (ITEM 9) MUST BE INSTALLED TO ASSURE TENSION CANNOT BE

PLACED ON THE FLEXIBLE GAS LINE OR FITTING.

NIPPLE

2. MAIN GAS CUT-OFF VALVE 7. EYELET FASTENERS

3. CONNECT-IT QUICK-DISCONNECT 8. SPRING HOOK

4. FLEX-CON CONNECTOR 9. RESTRAINING CHAIN

5. ELBOW

14

30A268 May 2016 Rev A

Page 15

D. GAS CONNECTION: The gas supply (service) line must be the same size or greater than the inlet line of the appliance.

THE GAS SUPPLY LINES MUST BE SIZED TO ACCOMMODATE ALL THE GAS FIRED EQUIPMENT

THAT MAY BE CONNECTED TO THAT SUPPLY. Refer to the Inlet Gas Line Sizing Table and inlet gas require-

ments.

NOTE: Sealant used on all pipe joints must be resistive to natural and propane gas.

1. Manual shut off valve: This supplier-installed valve must be installed in the gas service line ahead of the appliance and in

a position where it can be reached quickly in the event of an emergency.

2. Pressure regulator: All commercial cooking equipment must have a pressure regulator on the incoming service line for

safe and efficient operation, because service pressure may fluctuate with local demand. External regulators are not required on this fryer, as that function is performed by a combination gas control valve, however if the incoming pressure is

in excess of 1⁄2 psig, a step-down regulator will be required.

3. Natural gas: Natural gas fryers require 7” (178mm) water column (W.C.) “inlet” pressure to the fryer’s combination gas

control valve for proper operation, when all gas units are operating simultaneously. Propane gas fryers require

14" (356 mm) water column (W.C.) “inlet” pressure to the fryer’s combination gas control valve for proper operation,

when all gas units are operating simultaneously. This “inlet” pressure MUST be checked with a manometer PRIOR to

WARNING: IF THE “INLET” GAS PRESSURE AT THE FRYER’S COMBINATION GAS CONTROL VALVE

“EXCEEDS” 1⁄2 lb/in2 (.035 kg/cm2) OR APPROXIMATELY 11” (280mm) W.C., AN EXTERNAL

REGULATOR MAY BE NEEDED TO PREVENT DAMAGE TO THE COMBINATION GAS VALVE

AND VOIDING OF WARRANTY. FAILURE TO ADDRESS THIS COULD RESULT IN AN EXPLOSION OR A FIRE.

placing the fryer in operation.

4. Combination gas control valve: The correct combination gas control valve and orifice is installed at the factory for

NATURAL and PROPANE units based on each Purchase Order. This valve should be CHECKED/ADJUSTED by

qualified service personnel using proper test equipment for the following “OUTLET” gas pressure PRIOR to start-up of

a fryer. NATURAL GAS FRYERS 7" (178mm) W.C. PROPANE FRYERS 14" (356mm) W.C.

5. Rigid connections: Check any installer-supplied intake pipe(s) visually and/or blow them out with compressed air to clear

dirt particles, threading chips or any other foreign matter before connecting to the service line as these particles may clog

the orifice when gas pressure is applied. All connections must be tested with a soapy solution before lighting the fryer.

DO NOT USE AN OPEN FLAME TO CHECK FOR LEAKS! Putting an open flame beside a new connection is not

only dangerous, but will often miss small leaks that a soapy solution would find.

6. Flexible Couplings and Connectors: The installation is to be made with a connector that (1) complies with the Standard

for Connectors for Movable Gas Appliances, ANSI Z21.69 (CSA 6.16), and a quick-disconnect device that complies

with the Standard for Quick-Disconnect Devices for Use With Gas Fuel, ANSI Z21.41 (CSA 6.9) (2) adequate means

must be provided to limit the movement of the appliance without depending on the connector and the quick dis- connect

device or its associated piping to limit the appliance movement and (3) the location(s) where the restraining means may

be attached to the appliance shall be specified. DOMESTIC CONNECTORS ARE NOT SUITABLE!!!

7. Fryer Service: The fryer is equipped with swivel casters. To service th e fr yer:

a) Remove / unplug power supply from fryer

b) Turn “OFF” gas supply at the supply source.

b) Disconnect the flexible gas line quick-disconnect

c) Disconnect restraint means and roll fryer out for rear service access.

d) When the fryer is re-positioned, be sure to reconnect the restraint and level the fryer.

E. ELECTRICAL CONNECTION: The MAXIMUM current draw per vat at Initial Start-up or during a Warm-up Cycle will

be 3 Amperes at 120 Volts. When running the Filter System simultaneously allow for an additional 3 Amperes. Refer to the

wiring diagram attached to the inside of the Service Access door for internal electrical connections.

WARNING: (ELECTRICAL GROUNDING INSTRUCTIONS)

THIS APPLIANCE IS EQUIPPED WITH A THREE-PRONG (GROUNDING) PLUG FOR YOUR PROTECTION

AGAINST SHOCK HAZARD AND SHOULD BE PLUGGED DIRECTLY INTO A PROPERLY GROUNDED

THREE-PRONG RECEPTACLE. DO NOT CUT, REMOVE, OR OTHERWISE BYPASS THE GROUNDING

PRONG ON THIS PLUG!

15

30A268 May 2016 Rev A

Page 16

F. Ultrastat 23 Cooking Computer

The Ultrastat 23 Cooking Computer is a high performance, microprocessor-based electronic controller designed for use in

commercial appliance temperature and timing control applications. Utilizing a microcontroller board, membrane switch front

panel with a digital LED readout and display board, the Ultrastat 23 Cooking Computer has been customized for Ultrafryer

Systems applications by the addition of up to 10 stage cooking profiles for each of the 10 product keys; features can be

programmed to cook products under “Flex” or “Straight” timing modes. Operation of the Ultrastat 23 Cooking Computer is

covered in its Instruction Manual PN 30A216 provided with the Fryer.

1 2 3 4 5

15 14

6 8 9 10

11 12

13

7

16

30A268 May 2016 Rev A

Page 17

COMPUTER PANEL KEY DESCRIPTIONS

1. HOLD LAMP

When lit (bright) indicates a product hold time is being tracked.

2. HEAT LAMP

When lit (bright) indicates the computer is calling for heat.

3. DISPLAY

Displays modes, functions and operations of the computer.

4. MELT LAMP

When lit (bright) indicates the computer is in the melt cycle.

5. PROGRAM LAMP

When lit (bright) indicates the computer is in the program mode.

6. ON/OFF KEY

Turns the computer ON and OFF when the fryer power switch is in the ON position and the drain valve lever is in the

closed UP position.

7. PROGRAM KEY

a. In “operating” mode, allows access to the programming mode.

b. In “programming” mode, allows access to the operating mode and general navigation function.

8. SCAN KEY

a. In “operating” mode, displays the remaining cook time on every product currently in a cook cycle and lights the re-

spective products “LED” for 2 seconds.

b. In “programming” mode, steps to the next function to be programmed.

9. ENTER EXIT FILTER KEY

This key will force the fryer into the filter mode. This key is an optional feature.

10. TEMP/TOGGLE CLEAR KEY

a. In “operating” mode, displays the actual temperature followed by the programmed “set” tem perature.

b. In “programming” mode, will “clear” values from a data field.

11. HOLD KEY

a. In “operating” mode, used to view remaining hold times.

12. SET BACK

a. In operating mode forces setback . Display will show “setback” and appliance will be controlled to setback tempera-

ture instead of set point temperature.

13. EXIT/MELT KEY

a. In “operating” mode, used to manually exit the shortening melt cycle.

14. PRODUCT LED

a. When lit (bright) in the “operating” mode, identifies the product data being displayed.

b. When lit (bright) in the “programming” mode, identifies the product being programmed.

15. PROGRAMMING AND PRODUCT COOK KEY

a. In “operating” mode, used to start and stop a product’s cook cycle.

b. In “programming” mode, used to enter numerical values 1 to 10.

17

30A268 May 2016 Rev A

Page 18

y

Ultrastat 23 Programming Guide

Turn Toggle ON/OFF switch to ON position and

amber power indicator lamp will illuminate.

Then press power ON/OFF key.

Push and hold the "P" key for 3 seconds to enter PROGRAMMING MODE.

PROGRAM will appear in display.

Push “P" key the second time to display CODE. Enter

“1724" and push the "P" key. RECIPE will display.

Push °P" key and “PRODUCT” will

display. Hit product key you want to

Display shows ‘‘ALL”. Push “P” key to program

each function and "NAME" appears. To change

hit the “DOWN ARROW’ and scroll to find the

word you want in the library. Then push the “P”

ke

to enter it and go to the next item.

'TIME 1" will display. To change the time hit "TOGGLE CLEAR”

index the time you want on the number pad and press the “P*

"

"

"TEMP 1" will display. To change hit “TOGGLE CLEAR”

and key in the amount you v/ant and hit the “P” key.

"FLEX" or "STRAIGHT'1 time will appear. To change from one to

the other, hit the left arrow key. Then hit the “P" key to save it.

Display shows “TIME 2". Repeat steps 6, 7, and 8 for

each profile. After the last profile, display will show

“

To change "ALARM TIME 1" hit “TOGGLE CLEAR" and

index what you want on the number keys and hit the “P”

To change “ALARM NAME” hit “DOWN ARROW’ and

scroll until you find the name you want. Then hit the “P"

Display will show “HOLD TIME 1”. For most applications this

is not used so exit at this point. To exit press the “DOWN

ARROW' key repeatedly until "EXIT'' shows on the display.

Then hit the "P" key. “PRC DUCT" will show on the display.

Then hit the “UP ARROW* key and display will show “EXIT".

Hit the “P" key and display shows “RECIPE”. Hit the "UP

ARROW again then hit "P” key and "PREHEAT'* or “READY”

should appear. You are now out of program mode and ready

to operate with the latest changes.

"

"

”

18

30A268 May 2016 Rev A

Page 19

ULTRASTAT 23 START-UP AND COOKING COMPUTER OPERATION

NOTICE:

1) The computer will keep the fryer in the MELT CYCLE until the EXIT MELT button is manually depressed.

2) The computer CANNOT be taken out of the SHORTENING MELT MODE until the shortening temperature

reaches the MELT LIMIT TEMPERATURE. The Melt Limit Temperature is factory set for a HIGH exit

temperature (135˚F / 57˚C) or a LOW exit temperature (100º F/38ºC).

The following are abbreviated operating procedures for a fryer equipped with an Ultrastat 23 Cooking Computer. The attached

Ultrastat 23 Ultrafryer Computer Operating Instructions, Manual PN 30A216, contains DETAILED Operating, Filtering, BoilOut, and Programming Instructions.

START-UP and COOKING

ULTRASTAT 23 START-UP - Safely start-up an gas fryer equipped with an Ultrastat 23 Cooking computer as follows:

STEP ACTION RESPONSE

1 ENSURE the drain valve lever on the fryer

is in the CLOSED position, shortening is at

A. The fryer heat exchanger will power up and begin to heat the

shortening.

the proper level, then turn the computer ON

by depressing the computer ON/OFF

button.

CAUTION:

PRIOR TO PROCEEDING TO NEXT STEP, VISUALLY CHECK THAT THE HEAT

EXCHANGER IS COVERED WITH AT LEAST 2” (51mm) OF SHORTENING

2 Turn the Computer ON by depressing the

computer ON/OFF button.

3 Once the Melt Limit Temperature is

reached depress the EXIT MELT BUTTON on the computer to cancel the

SHORTENING MELT MODE.

4 When “READY” appears in the Computer

display indicating the SET-POINT TEMPERATURE of the shortening has been

reached, a COOK cycle can be initiated.

ULTRASTAT 23 COOKING COMPUTER PROGRAMMING

Program the Ultrastat 23 Cooking Computer according to the Computer Operating Instructions Manual

(PN 30A216) provided with the Fryer.

Programming of an Ultrastat 23 Cooking Computer should only be preformed by a store manager or

area supervisor.

A. The MELT lamp will LIGHT to indicate the computer is in

the SHORTENING MELT MODE.

B. The HEAT lamp on the computer and the RED heat mechanism

indicator lamp on the fryer will cycle ON and OFF indicating

the heat mechanism is periodically being turned ON and OFF to

gen- tly heat the shortening.

A. “HEATING” will appear in the computer display indicating

shortening temperature is more than 10˚F (5˚C) below the setpoint temperature.

B. The HEAT lamp on the computer and the RED heat mechanism

indicator lamp will remain ON until the set-point temperature is

reached.

A. Stir the shortening several times to ensure that all the shortening

has reached the set point temperature.

NOTICE:

19

30A268 May 2016 Rev A

Page 20

GENERAL COOKING

Most products should be cooked with a shortening temperature about 350˚F (177˚C); however, each product should be

cooked at the LOWEST temperature that produces a high quality product while obtaining maximum usage of the shortening.

WARNING:

I – DO USE A HIGH QUALITY SHORTENING TO ACHIEVE A CONSISTENT

QUALITY PRODUCT AND LONG TERM SAVINGS

II – DO NOT SALT PRODUCTS OVER THE FRYER AS SALT QUICKLY DETERIORATES

THE SHORTEN ING AND FLAVORS OTHER PRODUCTS COOKED IN THE SAME

SHORTENING

III – DO FILTER SHORTENING AFTER THE LUNCH AND DINNER RUSH AND MORE OF-

TEN IN A HIGH SALE VOLUME STORE; AND BOIL-OUT THE FRYER EVERY 7 DAYS

NOTICE:

Startup steps 1, 2, 3, and 4 will have to be repeated each time any of the following occurs:

DRAIN VALVE IS OPEN. FRYER ON/OFF SWITCH IS TURNED OFF TO FILTER

SHORTENING OR BOIL-OUT A FRYER. FRYER ON/OFF SWITCH IS TURNED OFF AT

CLOSING OR ANY OTHER REASON.

POWER FAILURE

This fryer cannot be operated during power failures. DO NOT attempt to bypass safety and manually operate fryer.

CAUTION:

THE FRYER HAS A RESTRAINT ATTACHED TO THE WALL TO LIMIT MOVEMENT AND

TIPPING IN ORDER TO AVOID SPLASHING OF HOT LIQUID.

MOVING THE FRYER WITH HOT COOKING OIL IN THE VESSEL MAY CAUSE SPLASHING OF

THE HOT LIQUID CAUSING SEVERE BURNS.

IF MOVING THE FRYER IS REQUIRED FOR CLEANING OR SERVICING.

TAKE THE REQUIRED STEPS OF REMOVING THE RESTRAINT, POWER AND GAS

CONNECTIONS BEFORE MOVING THE FRYER AND MAKE SURE THE COOKING OIL IN THE

VESSEL IS COLD OR HAS BEEN REMOVED FROM THE VESSEL TO LIMIT ACCIDENTAL

BURNS OR DAMAGE TO THE FRYER.

20

30A268 May 2016 Rev A

Page 21

When the Computer is taken out of the SHORTENING MELT MODE each morning, shortening in the fryer vat will be

heated to its SETPOINT temperature, “HEATING” will appear in the display to indicate the shortening temperature is

MORE than 20˚F (-6.6˚C) BELOW the set point temperature. When shortening temperature rises to the SETPOINT temperature, “READY” will appear in the display indicating a COOK CYCLE can be started.

STARTING A COOK CYCLE

To start a cook cycle simply press the product key for the product you wish to cook. Cooking time will be displayed

“3:00” (example) and this time will immediately start to count down in minutes and seconds. It will count down to “ :00”

followed by a beeping signal. To turn this signal OFF and reset the Computer, press the same product key used to start the

COOK CYCLE.

CANCELLING A COOK CYCLE

If a cook cycle was inadvertently started it may be cancelled two (2) ways:

1) Press and hold the same product key used to start the cook cycle for 4 SECONDS. This prevents an accidental start of a

cook cycle while a product is being cooked.

2) A cook cycle can be CANCELLED at any time by turning the fryer ON/OFF Switch to the OFF position.

Press and Hold

Product Key

ON/OFF Switch

21

30A268 May 2016 Rev A

Page 22

PREVENTIVE MAINTENANCE AND TROUBLESHOOTING

22

30A268 May2016 Rev A

Page 23

PREVENTIVE MAINTENANCE

Minimal maintenance is required on the fryer because of its design and materials used in the manufacturing process.

However some preventive maintenance and inspection must be performed periodically to prevent breakdowns which could

curtail food sales. Any preventive maintenance or inspection should be accomplished with CAUTION while the fryer is in

operation since HOT liquid shortening could cause severe burns. If service or repairs are required, all electrical power and gas

MUST BE TURNED OFF PRIOR TO preforming that service or repair.

PREVENTIVE MAINTENANCE SCHEDULE

DAILY

ITEM INSPECT FOR

Grease Filters Clean grease filters in the exhaust vent hood every evening and

allow them to dry overnight.

WEEKLY

ITEM INSPECT FOR

Drain Valve Handle Determine if the Drain Valve Handle is securely attached to the

drain valve and that the valve can be easily opened and closed.

Temperature Sensing Probes During boil-out of the fryer, inspect the temperature and hi limit

sensing probes for any visible damage.

23

30A268 May2016 Rev A

Page 24

TROUBLESHOOTING

A. GENERAL: The problems and possible solutions listed in the troubleshooting chart below are typical problems that are

frequently encountered. ONLY qualified repairmen are to use the troubleshooting chart to repair this fryer. In the event a main

burner malfunction occurs, perform the following checks PRIOR to contacting a repairman:

1. Check that the fryer electrical plug is connected to an electrical receptacle.

2. Ensure the applicable Circuit Breaker is in the ON position and that the fryer ON/OFF switch is in the ON position.

3. Ensure the applicable fryer control has been placed in the EXIT MELT mode.

4. Ensure the gas supply line quick-disconnect coupling is SEATED on the gas manifold fitting.

5. Determine that the blower is operating.

B. TROUBLESHOOTING CHART: Should a problem occur that cannot be corrected after performing the above CHECKS,

contact an AUTHORIZED repairman and/or Ultrafryer Systems Customer Service 1-800-525-8130 and provide the information acquired while performing these checks.

ITEM PROBLEMS POSSIBLE SOLUTIONS

1 Ignition Lockout 1.) Harness connection to gas valve

2.) Gas valve or gas pressure

3.) All harness connections

4.) Electrode

5.) Interconnecting wiring malfunction

6.) Ignition module malfunction

8.) Grounding Status

2 No spark, No blower 1.) Harness connections

2.) Probe lead wires

3.) Open probe

4.) Controller

3 “Puffing” during normal start up 1.) Incorrect gas pressure

2.) Cracked electrode

3.) Electrode gap exceeded

4 Burner lights but will not maintain flame 1.) Igniter / flame sense misalignment

2.) Insufficient gas pressure

5 Excessive Heat 1.) Incorrect temperature offset selected

2.) Set Temperature exceeding 400 deg F

3.) Temperature probe malfunction

4.) Cooking control malfunction

5.) Interface board malfunction

6.) Gas pressure incorrect

6 Low heat 1.) Incorrect temperature offset selected

2.) Cooking control malfunction

3.) Temperature probe malfunction

4.) High limit tripped

5.) Interface board malfunction

6.) Gas pressure incorrect

7 Intermittent problems 1.) High ambient temperatures

2.) Wiring connections loose

8 No power to cooking control,

fryer does not heat

1.) Should display “OFF” when powered

2.) Main circuit breaker off

3.)Transformer inoperative

4.) Interconnecting wiring malfunction

24

30A268 May2016 Rev A

Page 25

TROUBLESHOOTING CHART CONTINUED:

Should a problem occur that cannot be corrected after performing the above CHECKS, contact an AUTHORIZED repairman

and/or Ultrafryer Systems Customer Service 1-800-525-8130 and provide the information acquired while performing these

checks.

ITEM PROBLEMS POSSIBLE SOLUTIONS

9 High limit thermostat shutting down sys-

tem

10 Excessive time to melt shortening 1.) Melt cycle timing incorrect

11 Dry fire fry tank 1.) No shortening in vat

1.) Shortening level below minimum fill line

2.) Probe malfunction

3.) Controller malfunction

2.) Insufficient gas pressure

3.) Probe malfunction

4.) Control malfunction

2.) Control malfunction

3.) Probe malfunction

CAUTION: ENSURE REPAIRMEN ARE ADVISED THAT FRYER RESTRAINTS MUST BE DISCONNECTED/

RECONNECTED. IF A FRYER IS TO BE MOVED DURING MAINTENANCE OR REPAIR, AND

THAT ELECTRICAL POWER AND GAS MUST BE TURNED OFF PRIOR TO PERFORMING ANY

MAINTENANCE OR REPAIR.

25

30A268 May2016 Rev A

Page 26

CLEANING

26

30A268 May 2016 Rev A

Page 27

GENERAL CLEANING

Any item of equipment operates and lasts longer when kept clean and properly maintained, and the Ultrafryer is no exception.

In order for this fryer to provide years of trouble-free service, it must be CLEANED and MAINTAINED according to the

instructions listed below.

DAILY

1) Clean the fryer surfaces periodically during operating hours with a solution of sanitizer and hot water, and at closing with

stainless steel cleaner. If necessary, use a dampened type 7447 RED or 7440 BROWN (heavy duty) Scotch brite pad to

remove encrusted material. DO NOT use steel wool, abrasive cloths, cleaners, powders, metal knife, spatula or any metal

object to scrape stainless steel! Scratches on stainless steel are almost impossible to remove.

2) Filter the shortening in each fryer once a day or according to Company Policy.

CAUTION:

DO NOT ALLOW ANY CLEANING SOLUTION / WATER TO SPLASH INTO THE VESSEL OF HOT COOKING

OIL AS IT WILL CONTAMINATE THE OIL AND MAY CAUSE THE OIL TO SPLATTER, CAUSING SEVERE

BURNS

WEEKLY

1) BOIL-OUT the fryer vat using Boil Out Compound according to procedures in the cleaning manual provided by the

chemical provider.

2) Perform steps 1 and 2 listed above under the Daily Cleaning.

27

30A268 May 2016 Rev A

Page 28

TECHNICAL ASSISTANCE, ORDERING INFORMATION

28

30A268 May 2016 Rev A

Page 29

A. TECHNICAL ASSISTANCE - Contact an authorized service agent or the Customer Service Department,

Ultrafryer Systems at 1-800-525-8130 for technical assistance.

E-Mail technical assistance at: techserv@ultrafryer.com

B. ORDERING INFORMATION:

1. REPLACEMENT PARTS - Provide the following information when ordering replacement parts by phone, fax or mail:

Your company name and phone number

Your company purchase order number

Bill-to address

Ship-to address

Quantity desired

Part number and description of the desired-item Your name or signature of authorized-buyer

Phone in order to: 1-800-525-8130

FAX order to: 1-210-731-5061

Mail order to: Ultrafryer Systems

Order Entry Office

P.O. Box 5369

San Antonio, TX 78201

E-Mail your order to: custserv@ultrafryer.com

2. TERMS - Net 30 days for customers on approved accounts. Past due balances will be charged 1% per month (12% per an-

num) until full balance is paid.

3. DAMAGES - Ultrafryer Systems is not responsible for damage occurring in transit. All deliveries must be inspected for

damage to shipping containers prior to departure of the delivering carrier. Any damage must be notated on the receiving document to facilitate filing of freight claims. Carriers must be notified immediately and freight inspections must be requested

from the carrier. Ultrafryer Systems can and will gladly assist you in preparing and processing of the necessary claims only if

proper notification has been accomplished on the carrier delivery document. Damaged equipment and or containers must be

available for the claims inspector to inspect.

4. RETURNS - Ultrafryer Systems cannot guarantee credit for items returned without proper authorization. All returns must

have prior Ultrafryer Systems Customer Service or Warranty department approval. An assigned number will be issued by the

approval authority. Please print the assigned number on all returned packages and corresponding paperwork. Returned goods

are subject to a l5% restocking charge. Ultrafryer Systems is not responsible for freight charges on returned goods unless

authorized by Customer Service and or Warranty personnel. Ultrafryer Systems does not receive freight collect or C.O.D.

shipments.

28

30A268 May 2016 Rev A

Page 30

RECOMMENDED SPARE PARTS

30

30A268 May 2016 Rev A

Page 31

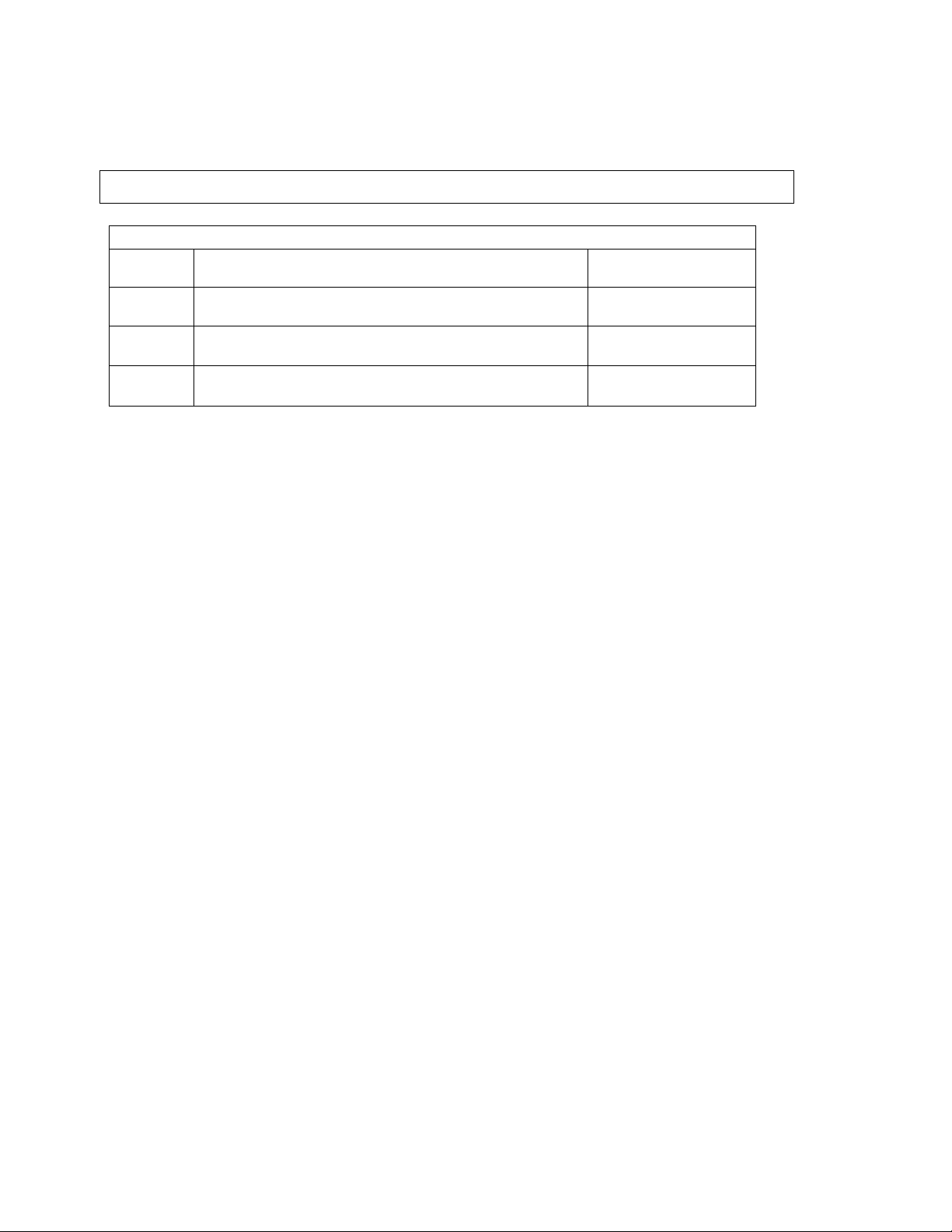

A. RECOMMENDED SPARE PARTS

To minimize downtime on the premix gas fryer upon failure of a component part, at least one (1) of the following items should

be kept as a spare part in a local area:

PREMIX GAS FRYER

RECOMMENDED SPARE PARTS LISTING

DESCRIPTION PN

Computer, Cook U23 22A651

Blower Premix 5.0 Power Burner and Gas Valve 17A031

Gasket, Blower Motor / Manifold IDE 22A810

Burner Infrared 1x3x8 W/ Mounting Plate 22A807

Rod, Ignitor Infrared Burner F/ 22A807 18610

Gasket, Mount Infrared Burner IDE 20in 22A811

Module, Ignitor Spark Dual Infrared 18A384

Transformer, Step Down 110V to 24V

18180

Transformer, FAST Wiring Harness 18A047

Relay, 24V DC 10 AMP SPDT Computer 23A023

Relay, 24V AC Flange Mounted 18A034

Relay, 24V AC DELAY ON MAKE 18A102

Control, 24VAC Universal Gas Blower (PWM) 23A462

Switch, Air Pressure 18A291

Switch, HI Limit 19B782

Probe, Temp Thermistor 18A006

Snap Light, Red Neon 125V 1/3 Watt 23043

31

30A268 May 2016 Rev A

Page 32

PARTS IDENTIFICATION

32

30A268 May 2016 Rev A

Page 33

MODEL F-ID-20X17 PREMIX GAS FRYER

CONTROL PANEL

1

2

ITEM DESCRIPTION PN

1

Computer, Cook U23 22A651

2

Snap Light, Red Neon 125V 1/3 Watt 23043

33

30A268 May 2016 Rev A

Page 34

MODEL F-ID-20X17 PREMIX GAS FRYER

FRONT VIEW

123

10

4

5

6

7

8

4

5

6

7

8

9

ITEM DESCRIPTION PN

1

Probe, Temp Thermistor 18A006

2

Fitting, Compression Male 3/8 NPT 24A270

3

Switch, HI Limit 19B782

4

Box Mount, Infrared Burner 19C991

5

Burner Infrared 1x3x8 W/ Mounting Plate 22A807

6 Rod, Ignitor Infrared Burner

7

Gasket, Blower / Box IDE 22A803

8 Baffle, Agitator 20in IDE Front

9 Valve, Ball 1 1/2in Full W/ Lock Mech

10

Box, Assy IDE Electrical Control 12D111

34

30A268 May 2016 Rev A

22A807

19C993

24A204

Page 35

MODEL F-ID-20X17 PREMIX GAS FRYER

REAR VIEW

1

2

3

4

5

6

ITEM DESCRIPTION PN

1

Box, W/ Flue F/ 20in IDE 19C992

2

Gasket, Blower / Box IDE 20in 22A803

3

Baffle, Agaitor 20in IDE Rear 19C994

4

Blower, Premix 5.0 Power Burner and Gas Valve 17A031

5

Gasket, Blower Motor / Manifold IDE 22A810

6 Switch, Air Pressure

18A291

35

30A268 May 2016 Rev A

Page 36

BOX ASSEMBLY, IDE ELECTRICAL CONTROL

5

1

2

3

4

7

ITEM DESCRIPTION PN

6

1

Control, 24VAC Universal Gas Blower (PWM) 23A462

2

Relay, 24V AC Flange Mounted 18A034

3

Relay, 24V DC 10 AMP SPDT Computer 23A023

4

Relay, 24V AC DELAY ON MAKE 18A102

5

Transformer, FAST Wiring Harness 18A047

6 Module, Ignitor Spark Dual Infrared

7

Transformer, Step Down 110V to 24V 18180

18A384

36

30A268 May 2016 Rev A

Page 37

SERVICE PROCEDURES AND ADJUSTMENTS

37

30A268 May 2016 Rev A

Page 38

HARMONIC TONE

Harmonic Tone (hum) at First Start, fryer will begin heating in low fire and a few seconds later go to high fire. There will be a

harmonic tone that is NORMAL to hear. As fryer continues to heat, harmonic tone will dissipate and become less noticeable.

GAS VALVE

WARNING:

DISCONNECT THE ELECTRICAL POWER TO THE FRYER.

WARNING:

SHUT OFF THE GAS BEFORE SERVICING THE FRYER.

WARNING:

ALL GAS JOINTS DISTURBED DURING SERVICING MUST BE CHECKED FOR LEAKS.

CHECK WITH A SOAP AND WATER SOLUTION (BUBBLES).

DO NOT USE AN OPEN FLAME

The gas valve is considered part of the Blower Premix 5.0 Power Burner and Gas Valve assembly. If the gas valve fails and

needs to be replaced, you must order a complete blower / gas valve assembly (burner). The reason for this is every blower / gas

valve assembly (burner) is set up at the factory to operate at the most efficient level possible. This set up procedure can not be

duplicated inn the field.

MODULATING GAS VALVE ADJUSTMENTS

WARNING:

DISCONNECT THE ELECTRICAL POWER TO THE FRYER.

WARNING:

SHUT OFF THE GAS BEFORE SERVICING THE FRYER.

WARNING:

ALL GAS JOINTS DISTURBED DURING SERVICING MUST BE CHECKED FOR LEAKS.

CHECK WITH A SOAP AND WATER SOLUTION (BUBBLES).

DO NOT USE AN OPEN FLAME

The modulating gas valve is adjustable at the factory and requires no adjustments. If the modulating gas valve needs to be

replaced, the new gas valve from the factory will be adjusted properly and will only need to have the gas pressure verified

coming into the gas valve.

38

30A268 May 2016 Rev A

Page 39

INFRARED BURNER SPARK IGNITOR AND TEMP PROBE SETTINGS

SENSOR ROD

.158 GAP

SPARK AND GROUND ROD

.275 GAP

GROUND ROD

GROUND WIRE CONNECTION

Ground Wire Connection

39

30A268 May 2016 Rev A

Page 40

CONTROL, 24VAC UNIVERSAL GAS BLOWER (PWM) SETTINGS

Dip Switch Settings

#1 = OFF

#2 = OFF

#3 = OFF

#4 = ON

Low Fire Setting = A

High Fire Setting = D

DELAY ON MAKE SETTING

Setting = 2 Second

40

30A268 May 2016 Rev A

Page 41

TEMPERATURE PROBE SETTING

Vat

Temp Probe

HI LIMIT PROBE SETTING

Heat Exchanger

Heat Exchanger

Vat

Hi Limit Probe

41

30A268 May 2016 Rev A

Page 42

WIRING DIAGRAM

42

30A268 May 2016 Rev A

Page 43

43

30A268 May 2016 Rev A

Page 44

44

30A268 May 2016 Rev A

Loading...

Loading...