Page 1

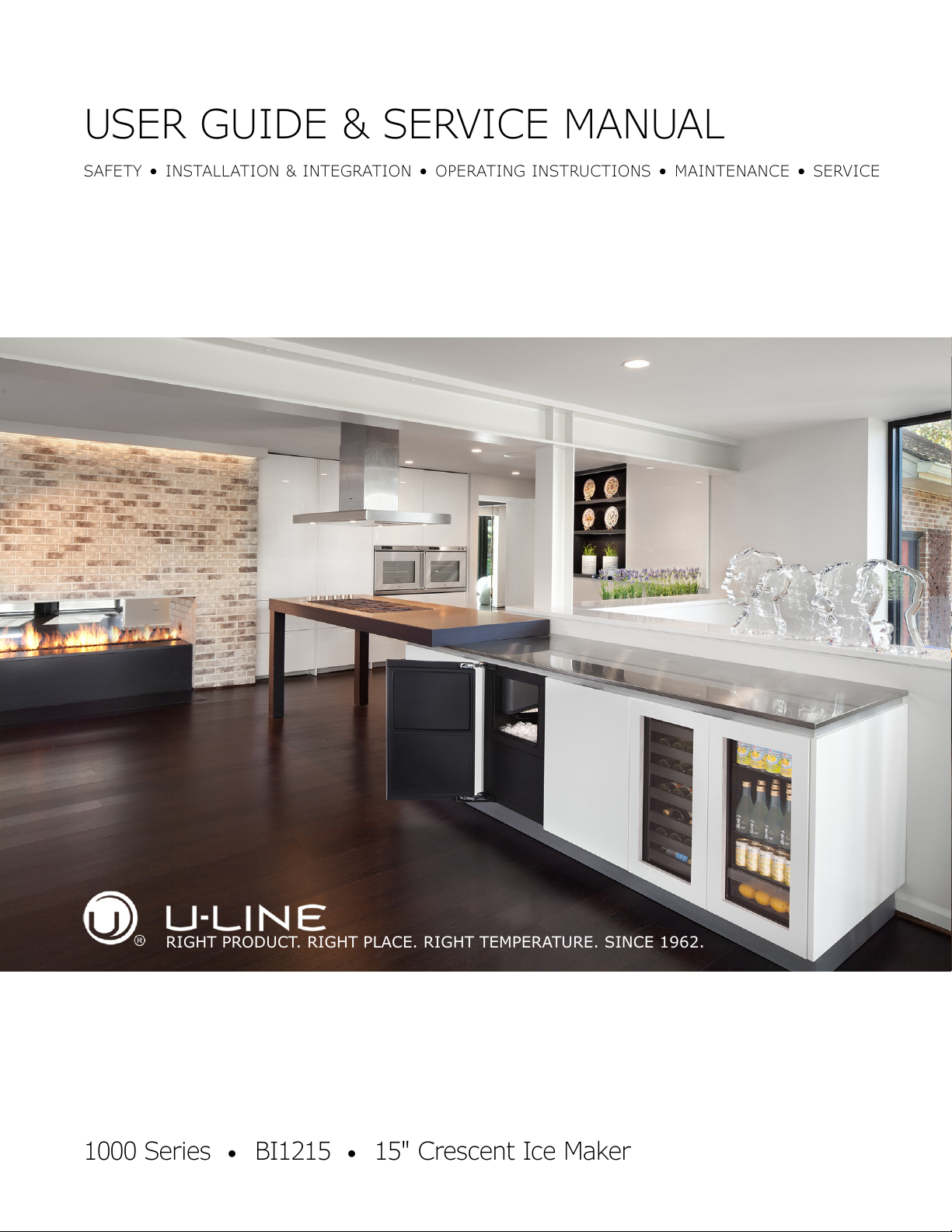

USER GUIDE & SERVICE MANUAL

SAFETY • INSTALLATION & INTEGRATION • OPERATING INSTRUCTIONS • MAINTENANCE • SERVICE

RIGHT PRODUCT. RIGHT PLACE. RIGHT TEMPERATURE. SINCE 1962.

1000 Series • BI1215 • 15" Crescent Ice Maker

Page 2

USER GUIDE

u-line.com

Contents

SAFETY • INSTALLATION & INTEGRATION • OPERATING INSTRUCTIONS • MAINTENANCE • SERVICE

Intro

Service

Safety

Safety and Warning

Disposal and Recycling

Installation

Environmental Requirements

Electrical

Cutout Dimensions

Product Dimensions

Side by Side Installation

Water Hookup

Anti-Tip Bracket

General Installation

Integrated Panel Dimensions

Integrated Panel Installation

Troubleshooting

Warranty

Service Extended

Wire Diagram

Product Liability

Warranty Claims

Parts

Ordering Replacement Parts

System Diagnosis Guide

Compressor Specifications

Troubleshooting Extended

Defrost

Replace Ice Maker

Grille / Plinth Installation

Door Swing

Door Stop

Door Adjust

Operating Instructions

First Use

Ice

Airflow and Product Loading

Maintenance

Cleaning

Cleaning Condenser

Extended Non-Use

Page 3

USER GUIDE

u-line.com

WELCOME TO U-LINE

Congratulations on your U-Line purchase. Your product comes from a company with over five decades of premium modular

ice making, refrigeration, and wine preservation experience. U-Line continues to be the American leader, delivering versatility

and flexibility for multiple applications including residential, light commercial, outdoor and marine use. U-Line’s complete

product collection includes Wine Captain

Door Refrigerators, Drawer Models, Freezers, Combo® Models, and more.

U-Line has captivated those with an appreciation for the finer things with exceptional functionality, style, inspired innovations

and attention to even the smallest details. We are known and respected for our unwavering dedication to product design,

quality and selection. U-Line is headquartered in Milwaukee, Wisconsin and has shipped product to five continents for over

two decades and is proud to have the opportunity to ship to you.

PRODUCT INFORMATION

Looking for additional information on your product? User Guides, Spec Sheets, CAD Drawings, Compliance Documentation,

and Product Warranty information are all available for reference and download at u-line.com.

®

Models, Beverage Centers, Clear Ice Machines, Crescent Ice Makers, Glass & Solid

PROPERTY DAMAGE / INJURY CONCERNS

In the unlikely event property damage or personal injury is suspected related to a U-Line product, please take the following

steps:

1. U-Line Customer Care must be contacted immediately at +1.800.779.2547.

2. Service or repairs performed on the unit without prior written approval from U-Line is not permitted. If the unit has been

altered or repaired in the field without prior written approval from U-Line, claims will not be eligible.

GENERAL INQUIRIES

U-Line Corporation

8900 N. 55th Street

Milwaukee, Wisconsin 53223 USA

Monday - Friday 8:00 am to 4:30 pm CST

T: +1.414.354.0300

F: +1.414.354.7905

Email: sales@u-line.com

u-line.com

SERVICE & PARTS ASSISTANCE

Monday - Friday 8:00 am to 4:30 pm CST

T: +1.800.779.2547

F: +1.414.354.5696

Service Email: onlineservice@u-line.com

Parts Email: onlineparts@u-line.com

CONNECT WITH US

Designed, engineered and assembled in WI, USA

Introduction 1

Page 4

USER GUIDE

NOTICE

u-line.com

SAFETY • INSTALLATION & INTEGRATION • OPERATING INSTRUCTIONS • MAINTENANCE • SERVICE

Safety and Warning

Please read all instructions before installing,

operating, or servicing the appliance.

Use this appliance for its intended purpose only and follow

these general precautions with those listed throughout this

guide:

SAFETY ALERT DEFINITIONS

Throughout this guide are safety items labeled with a

Danger, Warning or Caution based on the risk type:

DANGER

!

Danger means that failure to follow this safety

statement will result in severe personal injury or

death.

WARNING

!

Warning means that failure to follow this safety

statement could result in serious personal injury

or death.

CAUTION

!

Caution means that failure to follow this safety

statement may result in minor or moderate

personal injury, property or equipment damage.

Safety and Warning 1

Page 5

USER GUIDE

u-line.com

SAFETY • INSTALLATION & INTEGRATION • OPERATING INSTRUCTIONS • MAINTENANCE • SERVICE

Disposal and Recycling

DANGER

!

RISK OF CHILD ENTRAPMENT. Before you throw

away your old refrigerator or freezer, take off

the doors and leave shelves in place so children

may not easily climb inside.

If the unit is being removed from service for disposal,

check and obey all federal, state and local regulations

regarding the disposal and recycling of refrigeration

appliances, and follow these steps completely:

1. Remove all consumable contents from the unit.

2. Unplug the electrical cord from its socket.

3. Remove the door(s)/drawer(s).

Disposal and Recycling 1

Page 6

USER GUIDE

u-line.com

SAFETY • INSTALLATION & INTEGRATION • OPERATING INSTRUCTIONS • MAINTENANCE • SERVICE

Environmental Requirements

This model is intended for indoor/interior applications only

and is not to be used in installations that are open/

exposed to natural elements.

This unit is designed to operate between 50°F (10°C) and

100°F (38°C). Higher ambient temperatures may reduce

the unit’s ability to reach low temperatures and/or reduce

ice production on applicable models.

For best performance, keep the unit out of direct sunlight

and away from heat generating equipment.

In climates where high humidity and dew points are

present, condensation may appear on outside surfaces.

This is considered normal. The condensation will

evaporate when the humidity drops.

CAUTION

!

Damages caused by ambient temperatures of

40°F (4°C) or below are not covered by the

warranty.

Environmental Requirements 1

Page 7

USER GUIDE

NOTICE

u-line.com

SAFETY • INSTALLATION & INTEGRATION • OPERATING INSTRUCTIONS • MAINTENANCE • SERVICE

Electrical

WARNING

!

SHOCK HAZARD — Electrical Grounding

Required. Never attempt to repair or perform

maintenance on the unit until the electricity has

been disconnected.

Never remove the round grounding prong from

the plug and never use a two-prong grounding

adapter.

Altering, cutting or removing power cord,

removing power plug, or direct wiring can cause

serious injury, fire, loss of property and/or life,

and will void the warranty.

Never use an extension cord to connect power to

the unit.

Always keep your working area dry.

Electrical installation must observe all state and

local codes. This unit requires connection to a

grounded (three-prong), polarized receptacle

that has been placed by a qualified electrician.

The unit requires a grounded and polarized 115 VAC,

60 Hz, 15A power supply (normal household current). An

individual, properly grounded branch circuit or circuit

breaker is recommended. A GFCI (ground fault circuit

interrupter) is usually not required for fixed location

appliances and is not recommended for your unit because

it could be prone to nuisance tripping. However, be sure

to consult your local codes.

See CUTOUT DIMENSIONS for recommended receptacle

location.

Electrical 1

Page 8

USER GUIDE

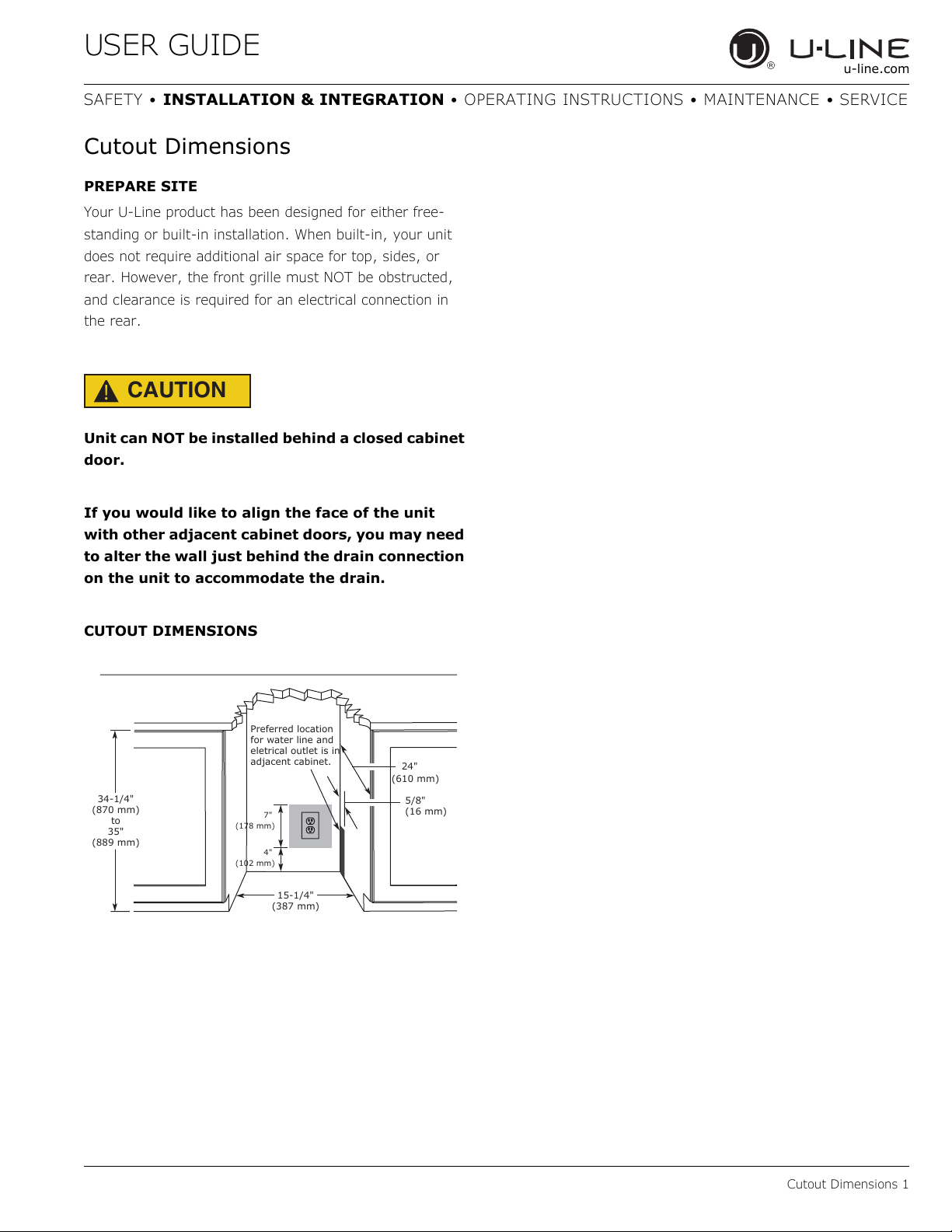

34-1/4"

(870 mm)

to

35"

(889 mm)

15-1/4"

(387 mm)

24"

(610 mm)

4"

(102 mm)

7"

(178 mm)

5/8"

(16 mm)

Preferred location

for water line and

eletrical outlet is in

adjacent cabinet.

u-line.com

SAFETY • INSTALLATION & INTEGRATION • OPERATING INSTRUCTIONS • MAINTENANCE • SERVICE

Cutout Dimensions

PREPARE SITE

Your U-Line product has been designed for either free-

standing or built-in installation. When built-in, your unit

does not require additional air space for top, sides, or

rear. However, the front grille must NOT be obstructed,

and clearance is required for an electrical connection in

the rear.

CAUTION

!

Unit can NOT be installed behind a closed cabinet

door.

If you would like to align the face of the unit

with other adjacent cabinet doors, you may need

to alter the wall just behind the drain connection

on the unit to accommodate the drain.

CUTOUT DIMENSIONS

Cutout Dimensions 1

Page 9

USER GUIDE

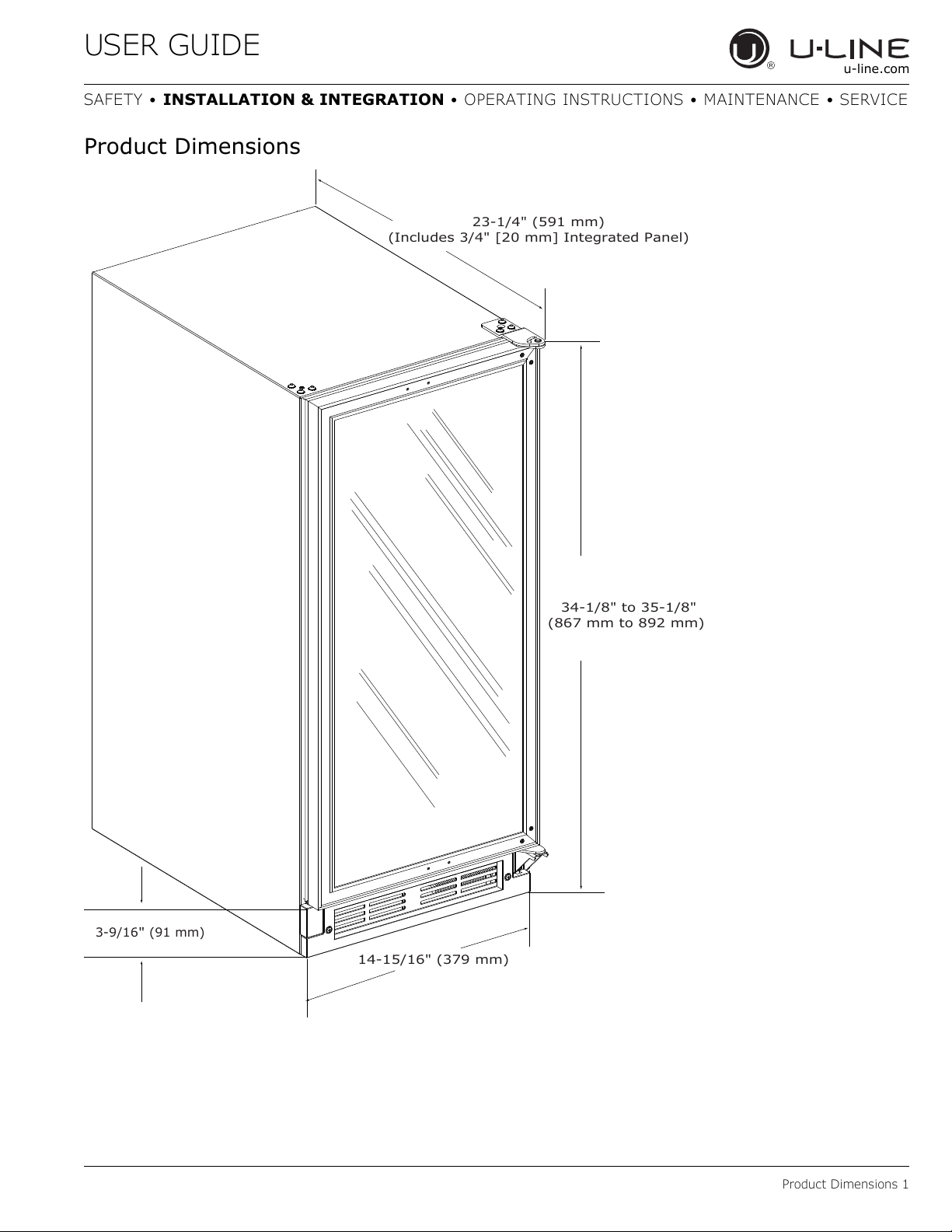

23-1/4

" (591 mm)

(Includes

3/4

" [20 mm] Integrated Panel)

34-1/8" to 35-1/8"

(867 mm to 892 mm)

14-15/16" (379 mm)

3-9/16" (91 mm)

u-line.com

SAFETY • INSTALLATION & INTEGRATION • OPERATING INSTRUCTIONS • MAINTENANCE • SERVICE

Product Dimensions

Product Dimensions 1

Page 10

USER GUIDE

u-line.com

SAFETY • INSTALLATION & INTEGRATION • OPERATING INSTRUCTIONS • MAINTENANCE • SERVICE

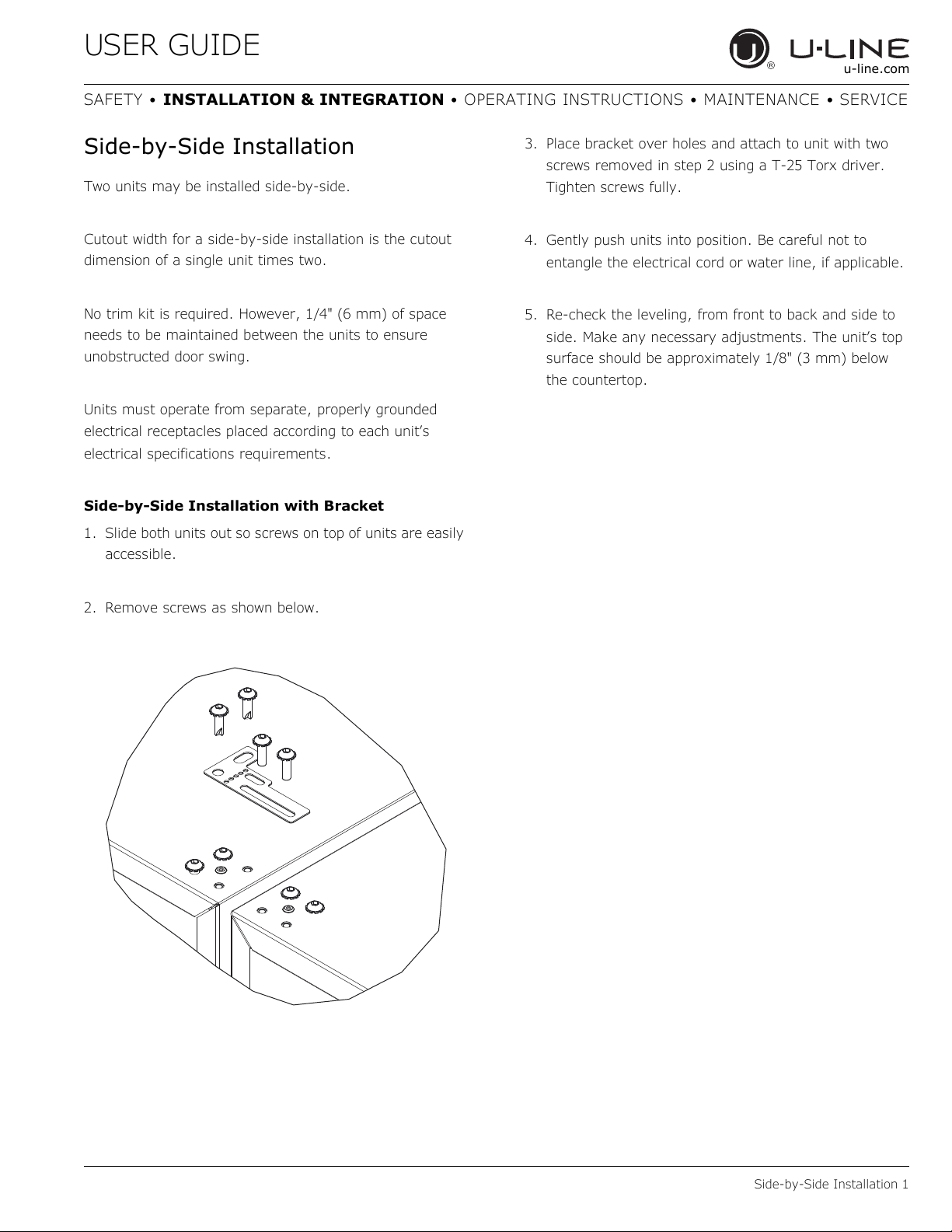

Side-by-Side Installation

Two units may be installed side-by-side.

Cutout width for a side-by-side installation is the cutout

dimension of a single unit times two.

No trim kit is required. However, 1/4" (6 mm) of space

needs to be maintained between the units to ensure

unobstructed door swing.

Units must operate from separate, properly grounded

electrical receptacles placed according to each unit’s

electrical specifications requirements.

Side-by-Side Installation with Bracket

1. Slide both units out so screws on top of units are easily

accessible.

3. Place bracket over holes and attach to unit with two

screws removed in step 2 using a T-25 Torx driver.

Tighten screws fully.

4. Gently push units into position. Be careful not to

entangle the electrical cord or water line, if applicable.

5. Re-check the leveling, from front to back and side to

side. Make any necessary adjustments. The unit’s top

surface should be approximately 1/8" (3 mm) below

the countertop.

2. Remove screws as shown below.

Side-by-Side Installation 1

Page 11

USER GUIDE

u-line.com

SAFETY • INSTALLATION & INTEGRATION • OPERATING INSTRUCTIONS • MAINTENANCE • SERVICE

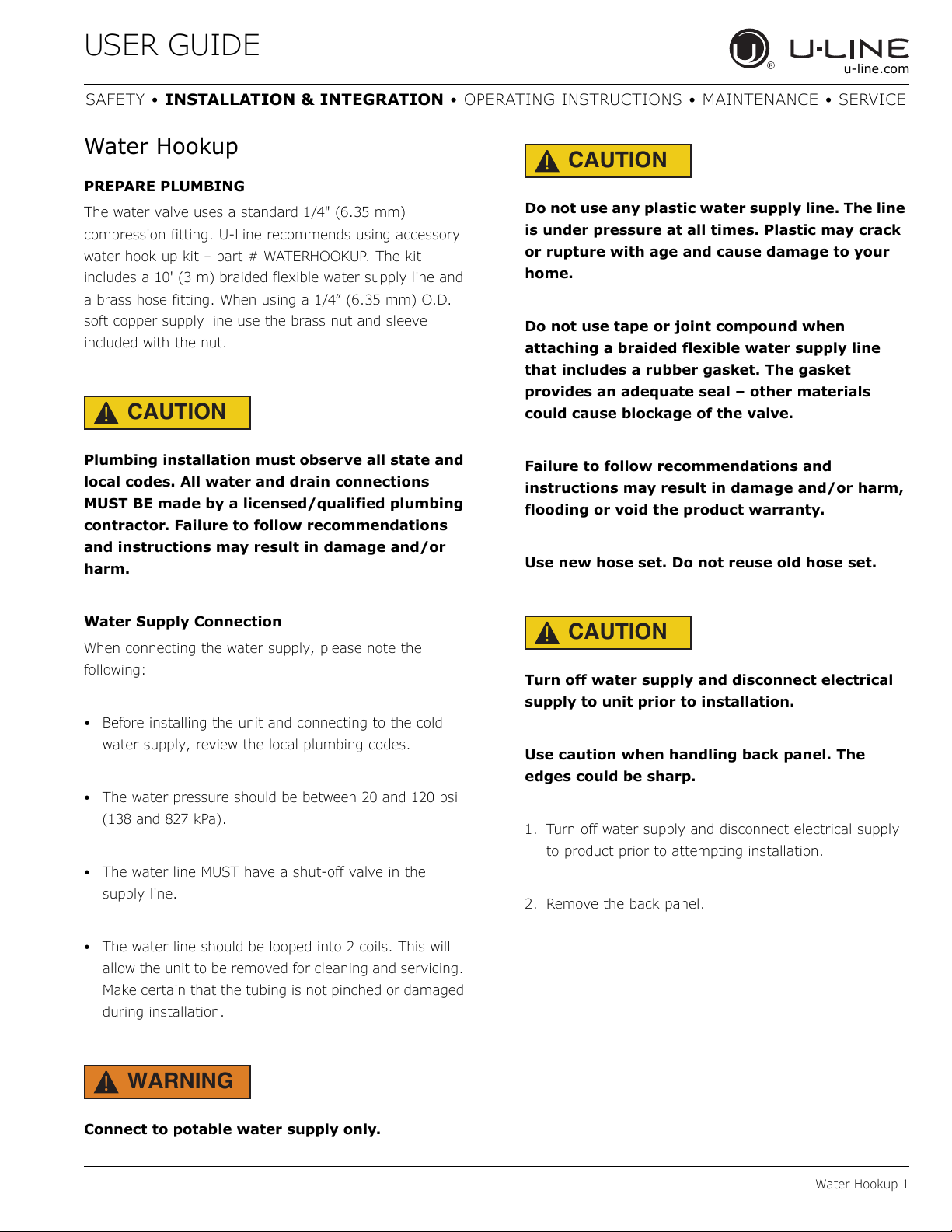

Water Hookup

PREPARE PLUMBING

The water valve uses a standard 1/4" (6.35 mm)

compression fitting. U-Line recommends using accessory

water hook up kit – part # WATERHOOKUP. The kit

includes a 10' (3 m) braided flexible water supply line and

a brass hose fitting. When using a 1/4” (6.35 mm) O.D.

soft copper supply line use the brass nut and sleeve

included with the nut.

CAUTION

!

Plumbing installation must observe all state and

local codes. All water and drain connections

MUST BE made by a licensed/qualified plumbing

contractor. Failure to follow recommendations

and instructions may result in damage and/or

harm.

CAUTION

!

Do not use any plastic water supply line. The line

is under pressure at all times. Plastic may crack

or rupture with age and cause damage to your

home.

Do not use tape or joint compound when

attaching a braided flexible water supply line

that includes a rubber gasket. The gasket

provides an adequate seal – other materials

could cause blockage of the valve.

Failure to follow recommendations and

instructions may result in damage and/or harm,

flooding or void the product warranty.

Use new hose set. Do not reuse old hose set.

Water Supply Connection

When connecting the water supply, please note the

following:

• Before installing the unit and connecting to the cold

water supply, review the local plumbing codes.

• The water pressure should be between 20 and 120 psi

(138 and 827 kPa).

• The water line MUST have a shut-off valve in the

supply line.

• The water line should be looped into 2 coils. This will

allow the unit to be removed for cleaning and servicing.

Make certain that the tubing is not pinched or damaged

during installation.

CAUTION

!

Turn off water supply and disconnect electrical

supply to unit prior to installation.

Use caution when handling back panel. The

edges could be sharp.

1. Turn off water supply and disconnect electrical supply

to product prior to attempting installation.

2. Remove the back panel.

WARNING

!

Connect to potable water supply only.

Water Hookup 1

Page 12

USER GUIDE

Remove

ZLWKɠDW

screwdriver

u-line.com

SAFETY • INSTALLATION & INTEGRATION • OPERATING INSTRUCTIONS • MAINTENANCE • SERVICE

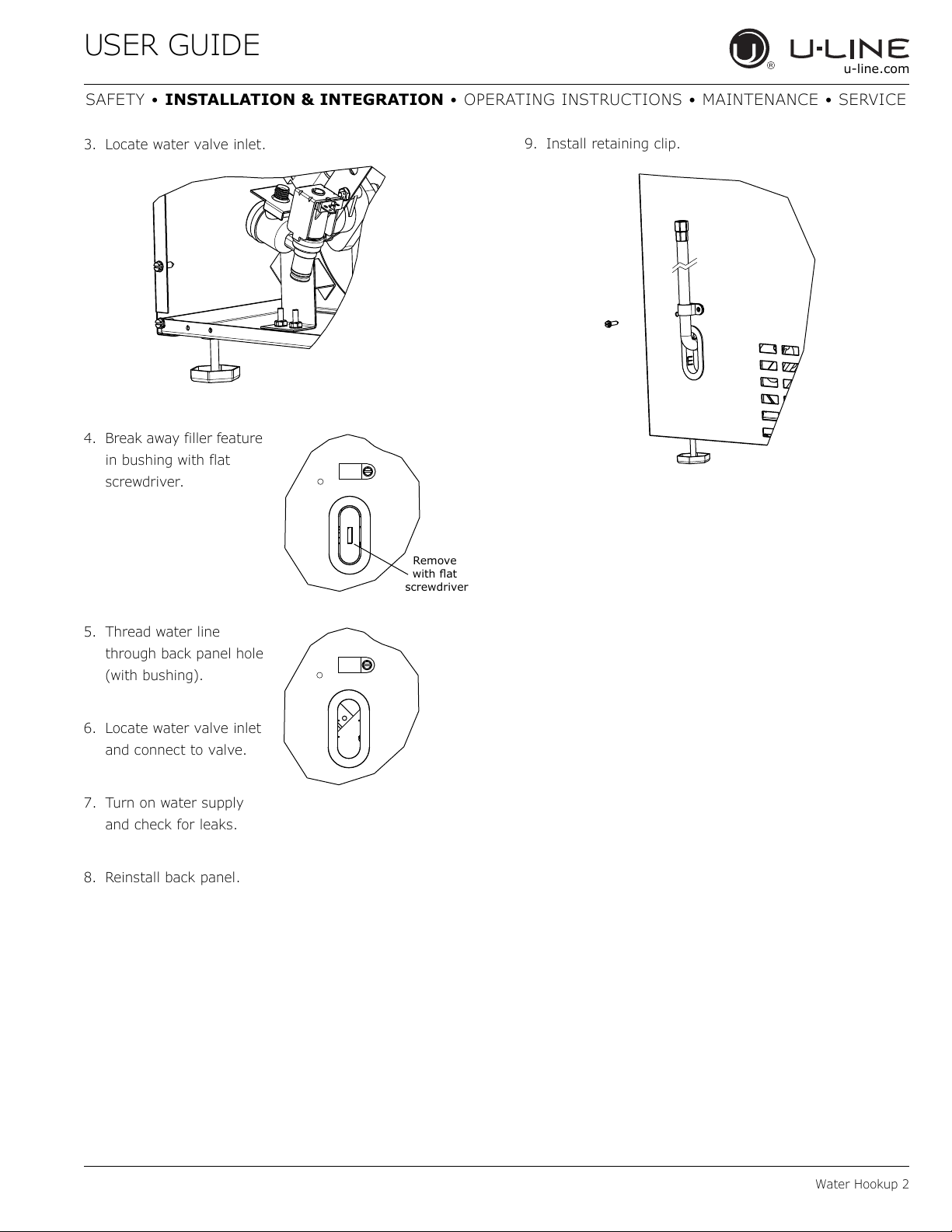

3. Locate water valve inlet.

4. Break away filler feature

in bushing with flat

screwdriver.

9. Install retaining clip.

5. Thread water line

through back panel hole

(with bushing).

6. Locate water valve inlet

and connect to valve.

7. Turn on water supply

and check for leaks.

8. Reinstall back panel.

Water Hookup 2

Page 13

USER GUIDE

u-line.com

SAFETY • INSTALLATION & INTEGRATION • OPERATING INSTRUCTIONS • MAINTENANCE • SERVICE

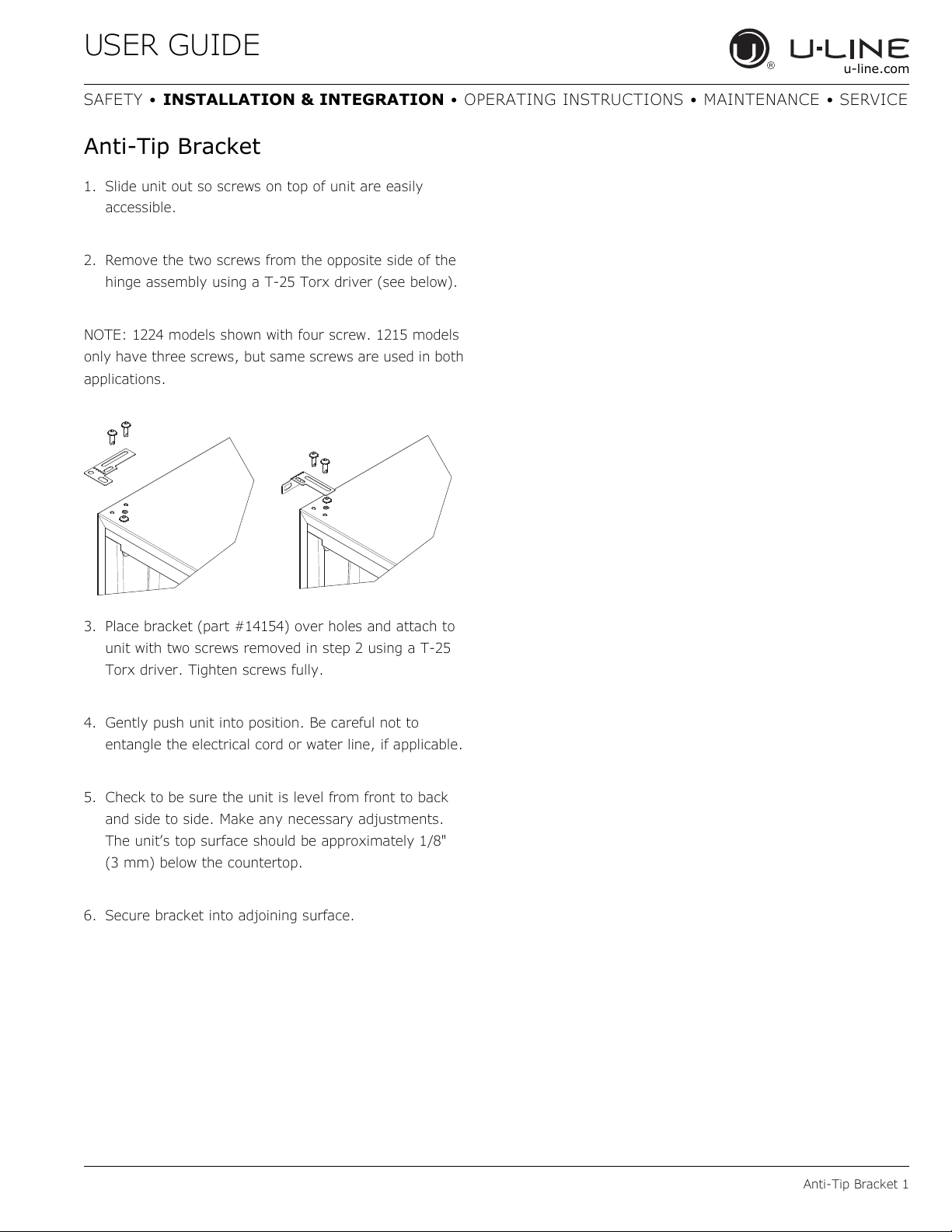

Anti-Tip Bracket

1. Slide unit out so screws on top of unit are easily

accessible.

2. Remove the two screws from the opposite side of the

hinge assembly using a T-25 Torx driver (see below).

NOTE: 1224 models shown with four screw. 1215 models

only have three screws, but same screws are used in both

applications.

3. Place bracket (part #14154) over holes and attach to

unit with two screws removed in step 2 using a T-25

Torx driver. Tighten screws fully.

4. Gently push unit into position. Be careful not to

entangle the electrical cord or water line, if applicable.

5. Check to be sure the unit is level from front to back

and side to side. Make any necessary adjustments.

The unit’s top surface should be approximately 1/8"

(3 mm) below the countertop.

6. Secure bracket into adjoining surface.

Anti-Tip Bracket 1

Page 14

USER GUIDE

Turn to Adjust

u-line.com

SAFETY • INSTALLATION & INTEGRATION • OPERATING INSTRUCTIONS • MAINTENANCE • SERVICE

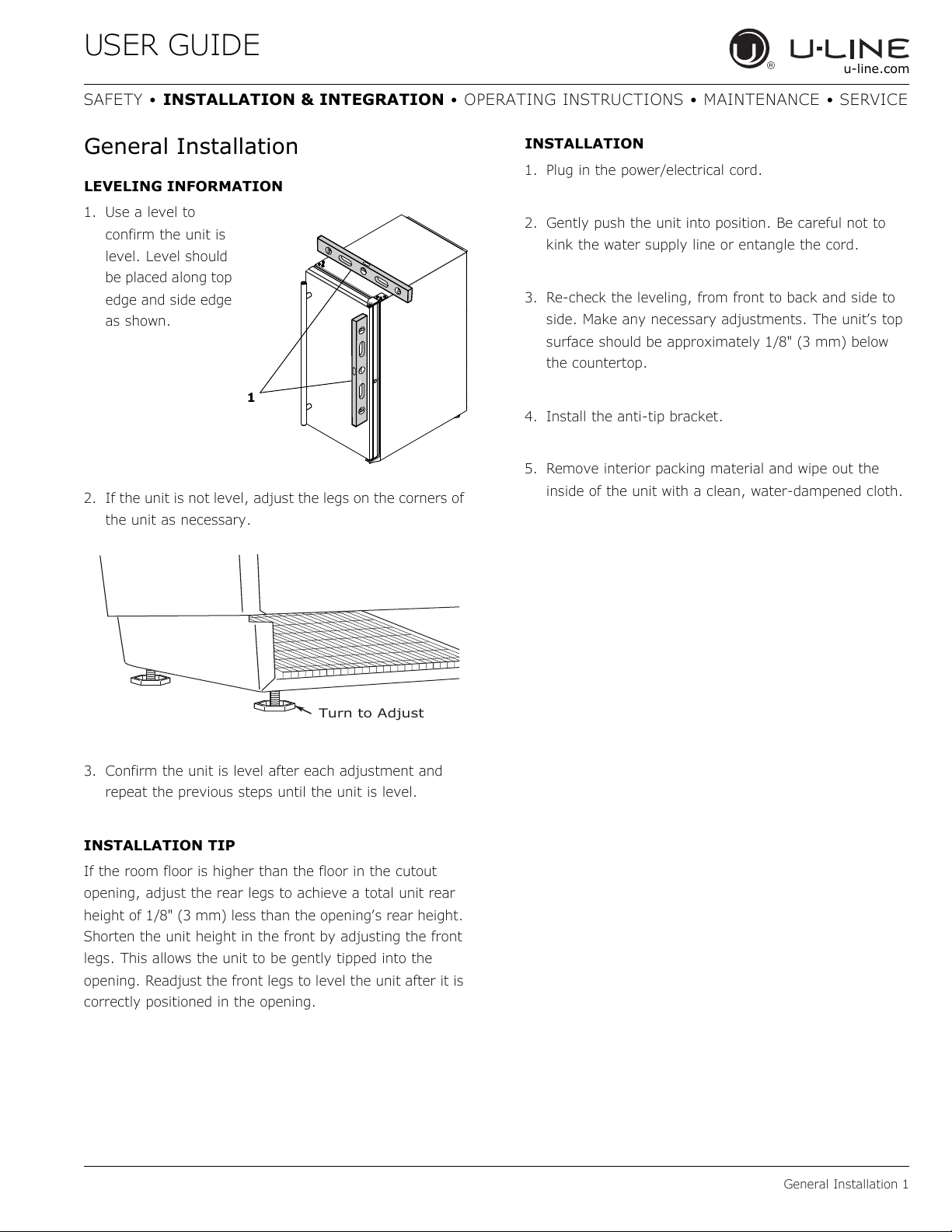

General Installation

LEVELING INFORMATION

1. Use a level to

confirm the unit is

level. Level should

be placed along top

edge and side edge

as shown.

1

2. If the unit is not level, adjust the legs on the corners of

the unit as necessary.

INSTALLATION

1. Plug in the power/electrical cord.

2. Gently push the unit into position. Be careful not to

kink the water supply line or entangle the cord.

3. Re-check the leveling, from front to back and side to

side. Make any necessary adjustments. The unit’s top

surface should be approximately 1/8" (3 mm) below

the countertop.

4. Install the anti-tip bracket.

5. Remove interior packing material and wipe out the

inside of the unit with a clean, water-dampened cloth.

3. Confirm the unit is level after each adjustment and

repeat the previous steps until the unit is level.

INSTALLATION TIP

If the room floor is higher than the floor in the cutout

opening, adjust the rear legs to achieve a total unit rear

height of 1/8" (3 mm) less than the opening’s rear height.

Shorten the unit height in the front by adjusting the front

legs. This allows the unit to be gently tipped into the

opening. Readjust the front legs to level the unit after it is

correctly positioned in the opening.

General Installation 1

Page 15

USER GUIDE

NOTICE

BACK SURFACE MUST HAVE AMPLE FLAT SURFACE

TO MOUNT OVERLAY PANEL FLAT AND WITHOUT

INTERFERENCE

3/4"

(20 mm)

Integrated Panel

14-3/4"

(375 mm)

30-1/4"

(768 mm)

u-line.com

SAFETY • INSTALLATION & INTEGRATION • OPERATING INSTRUCTIONS • MAINTENANCE • SERVICE

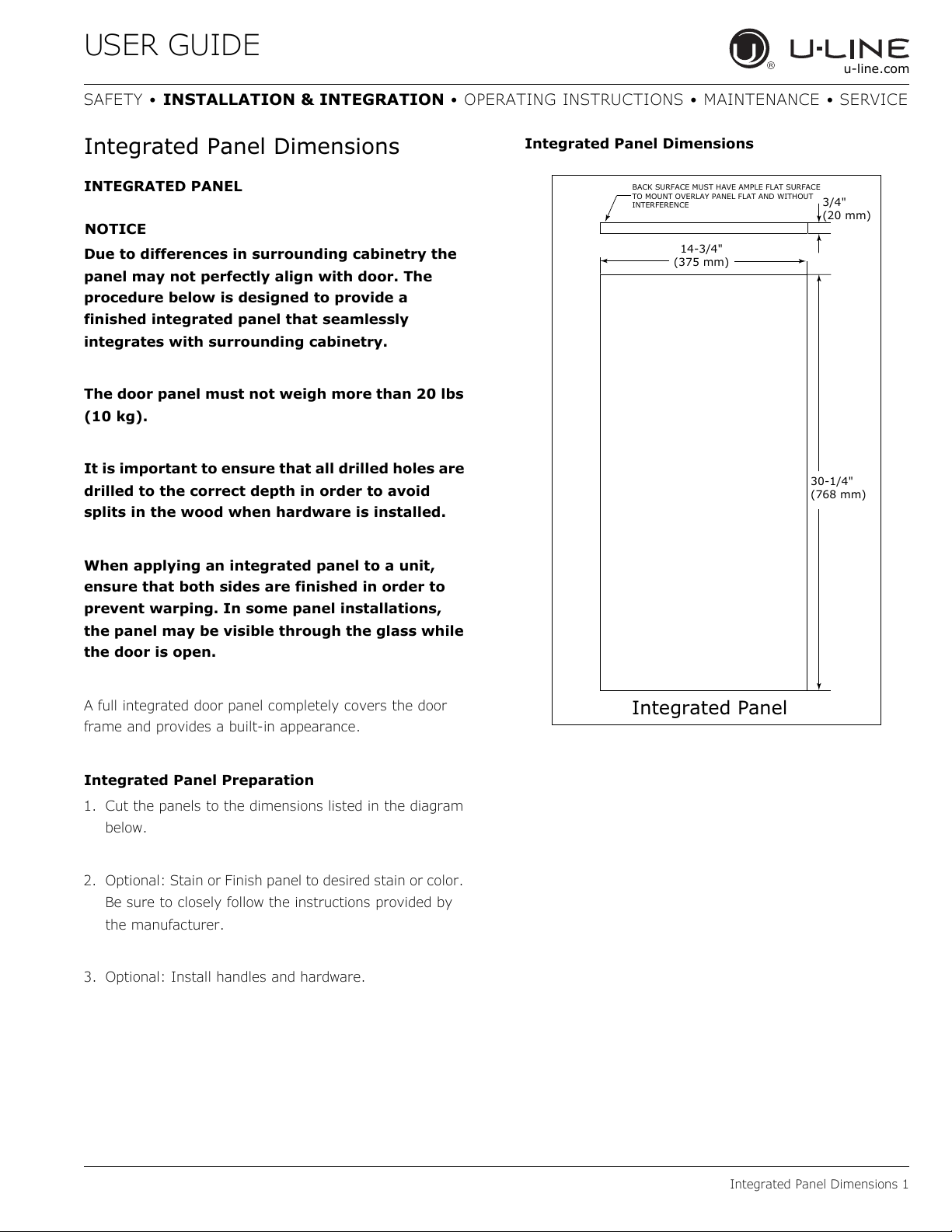

Integrated Panel Dimensions

INTEGRATED PANEL

Due to differences in surrounding cabinetry the

panel may not perfectly align with door. The

procedure below is designed to provide a

finished integrated panel that seamlessly

integrates with surrounding cabinetry.

The door panel must not weigh more than 20 lbs

(10 kg).

It is important to ensure that all drilled holes are

drilled to the correct depth in order to avoid

splits in the wood when hardware is installed.

When applying an integrated panel to a unit,

ensure that both sides are finished in order to

prevent warping. In some panel installations,

the panel may be visible through the glass while

the door is open.

Integrated Panel Dimensions

A full integrated door panel completely covers the door

frame and provides a built-in appearance.

Integrated Panel Preparation

1. Cut the panels to the dimensions listed in the diagram

below.

2. Optional: Stain or Finish panel to desired stain or color.

Be sure to closely follow the instructions provided by

the manufacturer.

3. Optional: Install handles and hardware.

Integrated Panel Dimensions 1

Page 16

USER GUIDE

NOTICE

NOTICE

Align Panel

Against

Door/Drawer

Edge First

Align Top Of Panel With Highest Point Of Door/Drawer

Door

Panel

Integrated Panel

Integrated Panel

u-line.com

SAFETY • INSTALLATION & INTEGRATION • OPERATING INSTRUCTIONS • MAINTENANCE • SERVICE

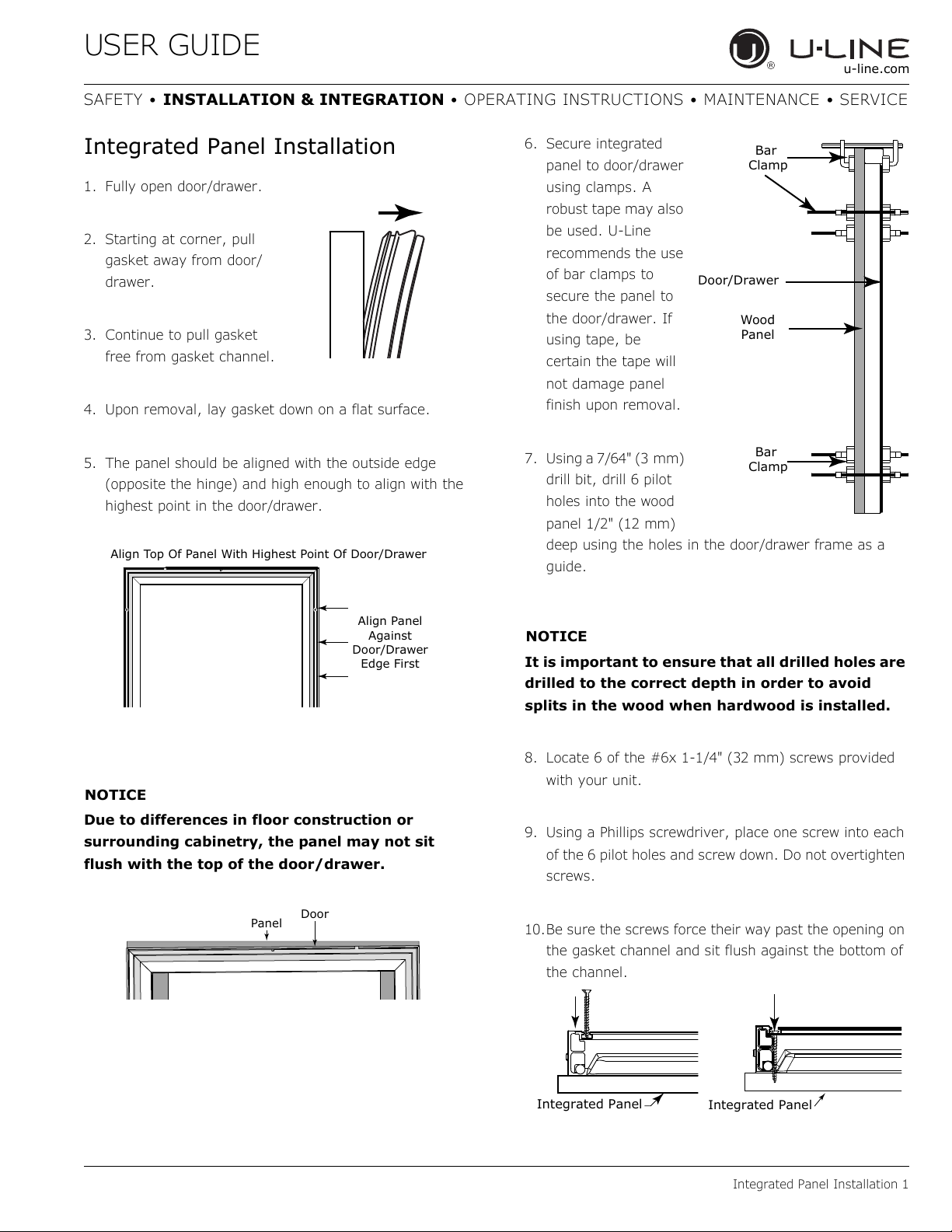

Integrated Panel Installation

1. Fully open door/drawer.

2. Starting at corner, pull

gasket away from door/

drawer.

3. Continue to pull gasket

free from gasket channel.

4. Upon removal, lay gasket down on a flat surface.

5. The panel should be aligned with the outside edge

(opposite the hinge) and high enough to align with the

highest point in the door/drawer.

6. Secure integrated

panel to door/drawer

Bar

Clamp

using clamps. A

robust tape may also

be used. U-Line

recommends the use

of bar clamps to

Door/Drawer

secure the panel to

the door/drawer. If

using tape, be

Wood

Panel

certain the tape will

not damage panel

finish upon removal.

7. Using a 7/64" (3 mm)

Bar

Clamp

drill bit, drill 6 pilot

holes into the wood

panel 1/2" (12 mm)

deep using the holes in the door/drawer frame as a

guide.

Due to differences in floor construction or

surrounding cabinetry, the panel may not sit

flush with the top of the door/drawer.

It is important to ensure that all drilled holes are

drilled to the correct depth in order to avoid

splits in the wood when hardwood is installed.

8. Locate 6 of the #6x 1-1/4" (32 mm) screws provided

with your unit.

9. Using a Phillips screwdriver, place one screw into each

of the 6 pilot holes and screw down. Do not overtighten

screws.

10.Be sure the screws force their way past the opening on

the gasket channel and sit flush against the bottom of

the channel.

Integrated Panel Installation 1

Page 17

USER GUIDE

NOTICE

u-line.com

SAFETY • INSTALLATION & INTEGRATION • OPERATING INSTRUCTIONS • MAINTENANCE • SERVICE

11.Remove clamps from door/drawer.

If panel requires additional adjustment after

removing clamps, slightly loosen each screw and

adjust panel as necessary. Tighten screws upon

completion.

12.Starting at the corners, re-install the gasket into the

gasket channel in the frame. Make sure the gasket is

fully seated. This may take some force.

Integrated Panel Installation 2

Page 18

USER GUIDE

2

1

3

4

u-line.com

SAFETY • INSTALLATION & INTEGRATION • OPERATING INSTRUCTIONS • MAINTENANCE • SERVICE

Grille - Plinth Installation

REMOVING AND INSTALLING GRILLE

WARNING

!

Disconnect electric power to the unit before

removing the grille.

When using the unit, the grille (plinth strip/base

fascia) must be installed.

WARNING

!

DO NOT touch the condenser fins (4). The

condenser fins are SHARP and can be easily

damaged.

Removing the grille

1. Disconnect power to the unit.

2. Loosen the two screws (1).

3. Remove grille (2) and grille cap (3) from unit.

5

Installing the grille

1. Make sure grille cap (3) is behind grille in slots (2)

provided in grille before attaching grille to unit.

2. Align cabinet and grille holes and secure, but do not

over tighten grille screws (1).

3. Reconnect power to the unit.

Grille - Plinth Installation 1

Page 19

USER GUIDE

Wall Wall

90

Door Swing

90

Door Swing

2-1/8" Min.

(54 mm)

1/4" Min.

(6 mm)

u-line.com

SAFETY • INSTALLATION & INTEGRATION • OPERATING INSTRUCTIONS • MAINTENANCE • SERVICE

Door Swing

Units have a zero clearance for the door to open 90°,

when installed adjacent to cabinets.

Stainless Steel and black and white models require 2-1/8"

(54 mm) door clearance to accommodate the handle if

installed next to a wall.

Integrated models require 1/4" (6 mm) clearance if

installed next to a wall. Allow for additional space for any

knobs or pulls installed on the integrated panel/frame.

Door Swing 1

Page 20

USER GUIDE

NOTICE

NOTICE

u-line.com

SAFETY • INSTALLATION & INTEGRATION • OPERATING INSTRUCTIONS • MAINTENANCE • SERVICE

Door Stop

Your U-Line unit was shipped to you with the optional

90° pin(s). (Models that are 15" wide include 1 pin. Models

that are 24" wide include 2 pins.) The unit’s door will open

freely without a fixed opening angle limitation. If you

would like the door stop at 90° follow these instructions.

The pin is designed to stop the door at 90° under

normal operating conditions. It is not designed

for excessive force. Do not use the door to move

the unit in/out of the cutout during installation.

If your unit is already undercounter, it might

need to be moved out/forward to access the

hinge.

1. Locate the threaded pin.

3. On 24" models, a second pin is included for the bottom

hinge. Repeat steps above for second hinge.

NOTE: Threaded pin will be inserted from the bottom.

4. Carefully slide your unit back in place.

2. With the door between 0° (closed) and 90° and using a

3/32" hex driver, install the threaded pin through the

hinge.

The pin can be removed to return the door swing

back to its original state by unscrewing the

threaded pin.

Door Stop 1

Page 21

USER GUIDE

NOTICE

u-line.com

SAFETY • INSTALLATION & INTEGRATION • OPERATING INSTRUCTIONS • MAINTENANCE • SERVICE

Door Adjustments

DOOR ALIGNMENT AND ADJUSTMENT

Align and adjust the door if it is not level or is not sealing

properly. If the door is not sealed, the unit may not cool

properly, or excessive frost may form in the interior.

Properly aligned, the door’s gasket should be

firmly in contact with the cabinet all the way

around the door (no gaps). Carefully examine

the door’s gasket to ensure that it is firmly in

contact with the cabinet. Also make sure the

door gasket is not pinched on the hinge side of

the door.

To align and adjust the door:

1. Loosen (do not remove) top and bottom hinge screws

using a Torx T-25 screwdriver on the top and a 1/4”

socket on the bottom.

2. Align door squarely with cabinet.

TO REVERSE THE DOOR

Remove grille:

Remove the grille (see GRILLE-PLINTH INSTALLATION

section of this guide).

Remove top hinge and door:

1. Hold door to keep it from falling.

3. Make sure gasket is firmly in contact with cabinet all

the way around the door (no gaps).

4. Tighten bottom hinge screws.

5. Tighten top hinge screws.

REVERSING THE DOOR

Location of the unit may make it desirable to mount the

door on the opposite side of the cabinet.

The hinge hardware will be removed and reinstalled on the

opposite side of the cabinet.

2. Remove top hinge from cabinet using a Torx T-25

screwdriver to remove three screws. Set aside and

save for possible future use.

Door Adjustments 1

Page 22

USER GUIDE

u-line.com

SAFETY • INSTALLATION & INTEGRATION • OPERATING INSTRUCTIONS • MAINTENANCE • SERVICE

3. Remove door by tilting forward and lifting door off

bottom hinge. Retain shoulder washers; they will

be reused.

4. Remove three screws from hinge holes on the opposite

side. Reinstall into holes where the hinge was

removed. Take care not to scratch cabinet.

Remove bottom hinge:

1. Remove bottom hinge from cabinet using 1/4” socket.

Install top hinge and door:

1. Use alternate hinge supplied with unit and reinstall the

screws. Do not tighten..

2. Rotate door 180° to reverse and set the door onto the

bottom hinge.

3. Align flat edge of the hinge with the outer edge of the

unit.

4. Tighten three screws.

2. Remove corresponding screws on opposite side of

cabinet. On some models there may be a nut behind

one or both screws on either side.

Install bottom hinge:

Install two or three screws, depending on model. Replace

nuts if used.

Align and adjust the door:

Align and adjust the door (see DOOR ALIGNMENT AND

ADJUSTMENT).

Install grille:

Install the grille.

Door Adjustments 2

Page 23

USER GUIDE

NOTICE

OFF

ON

u-line.com

SAFETY • INSTALLATION & INTEGRATION • OPERATING INSTRUCTIONS • MAINTENANCE • SERVICE

First Use

All U-Line controls are preset at the factory. Initial startup

requires no adjustments.

U-Line recommends discarding the ice produced

during the first two to three hours of operation

to avoid possible dirt or scale that may dislodge

from the water line.

To turn the unit on or off:

Press the rocker switch located inside the door on the

front panel, or behind the grille.

First Use 1

Page 24

USER GUIDE

NOTICE

NOTICE

OFF

ON

u-line.com

SAFETY • INSTALLATION & INTEGRATION • OPERATING INSTRUCTIONS • MAINTENANCE • SERVICE

Ice

ICE MAKER OPERATION

When the ice bucket is full, the ice making mechanism will

shut off. However, the refrigeration system will continue

to cool and maintain the ice supply.

Do not place cans or bottles in the ice

compartment because they will freeze.

CAUTION

!

NEVER use an ice pick, knife or other sharp

instrument to separate cubes. Shake the ice

bucket instead.

During periods of limited use or high ambient

temperatures, it is common for cubes to fuse together.

Gently shake the bucket to break apart cubes. If not using

the ice maker regularly, empty the ice bucket periodically

to ensure fresh cubes.

It is normal for cubes to appear cloudy. The cause is air

trapped in the water because of fast freezing. It is not

caused by the health, taste or chemical make up of the

water. It is the same air that is in every glass of water you

drink.

Remove the ice bucket for emptying and cleaning. To

remove the ice bucket, raise the bin arm and remove the

bucket from the ice compartment. Use the ice bucket for

ice storage only.

To turn off ice production: Raise the bin arm into

an upright and locked position. The unit will preserve

temperature for ice storage.

If not intending to use the ice maker, turn the

water supply valve off. It is also important to

raise the bin arm of the ice maker (see above).

Failure to raise the bin arm may result in damage

to the water valve.

Certain sounds are normal during the unit’s operation. You

may hear the compressor or fan motor, the water valve,

or ice dropping into the ice bucket.

Ice 1

Page 25

USER GUIDE

1

2

C

O

L

D

E

R

Warmer Colder

3

u-line.com

SAFETY • INSTALLATION & INTEGRATION • OPERATING INSTRUCTIONS • MAINTENANCE • SERVICE

ICE MAKER ADJUSTMENT

Ice Cube Thickness Adjustment

Interval - As Required

On ice maker equipped models, adjust the cube size by

changing water amount injected into the ice maker

assembly as follows:

3. Turn the adjusting screw toward the minus (-) sign

(clockwise) for smaller cubes or toward the plus (+)

sign (counterclockwise) for larger cubes.

4. Install the ice maker assembly cover.

ADJUSTING ICE HARVEST

1. Remove the front grille (see GRILLE-PLINTH

INSTALLATION).

2. Using a flat tip screwdriver, turn the adjusting screw

(3) a small increment clockwise for a COLDER setting

(slower ice production) or counterclockwise for a

WARMER setting (faster ice production).

1. Remove the ice maker assembly cover (1).

2. Find the adjusting screw on the ice maker assembly

control box (2). The adjusting screw is just below the

minus (-) and plus (+) signs on the control box.

CAUTION

!

Too large of an adjustment to the screw can

cause the water to overflow the ice maker and

can cause property damage.

1

3. Reinstall the front grille (two screws).

2

Ice 2

Page 26

USER GUIDE

NOTICE

u-line.com

SAFETY • INSTALLATION & INTEGRATION • OPERATING INSTRUCTIONS • MAINTENANCE • SERVICE

Airflow and Product Loading

The unit requires proper airflow to perform at its

highest efficiency. Do not block the front grille at

any time, or the unit will not perform as

expected. Do not install the unit behind a door.

Airflow and Product Loading 1

Page 27

USER GUIDE

u-line.com

SAFETY • INSTALLATION & INTEGRATION • OPERATING INSTRUCTIONS • MAINTENANCE • SERVICE

Cleaning

EXTERIOR CLEANING

Vinyl Clad (Black or White) Models

Clean surfaces with a mild detergent and warm water

solution. Do not use solvent-based or abrasive cleaners.

Use a soft sponge and rinse with clean water. Wipe with a

soft, clean towel to prevent water spotting.

Clean any glass surfaces with a non-chlorine glass

cleaner.

Stainless Models

Stainless door panels, handles and frames can discolor

when exposed to chlorine gas, pool chemicals, saltwater

or cleaners with bleach.

Keep your stainless unit looking new by cleaning with a

good quality all-in-one stainless steel cleaner and polish

monthly. For best results use Claire

Polish and Cleaner. Comparable products are acceptable.

Frequent cleaning will remove surface contamination that

could lead to rust. Some installations may require cleaning

weekly.

Do not clean with steel wool pads.

®

Stainless Steel

If any surface discoloring or rusting appears, clean it

quickly with Bon-Ami

and a nonabrasive cloth. Always clean with the grain.

Always finish with Claire

Cleaner or comparable product to prevent further

problems.

Using abrasive pads such as ScotchBrite™ will

cause the graining in the stainless to become

blurred.

Rust not cleaned up promptly can penetrate the

surface of the stainless steel and complete

removal of the rust may not be possible.

Integrated Models

To clean integrated panels, use household cleaner per the

cabinet manufacturer’s recommendations.

INTERIOR CLEANING

Disconnect power to the unit.

Clean the interior and all removed components using a

mild nonabrasive detergent and warm water solution

applied with a soft sponge or non-abrasive cloth.

®

or Barkeepers Friend Cleanser®

®

Stainless Steel Polish and

Do not use stainless steel cleaners or polishes on

any glass surfaces.

Clean any glass surfaces with a non-chlorine glass

cleaner.

Do not use cleaners not specifically intended for

stainless steel on stainless surfaces (this

includes glass, tile and counter cleaners).

Rinse the interior using a soft sponge and clean water.

Do not use any solvent-based or abrasive

cleaners. These types of cleaners may transfer taste to

the interior products and damage or discolor the interior.

Cleaning 1

Page 28

USER GUIDE

NOTICE

u-line.com

SAFETY • INSTALLATION & INTEGRATION • OPERATING INSTRUCTIONS • MAINTENANCE • SERVICE

DEFROSTING

Manual Defrost Models

This unit is a manual defrost model and will require

occasional defrosting. When there is build-up of 1/4"

(6 mm) or more of frost, manually defrost the unit.

CAUTION

!

DO NOT clean ice bucket using a dishwasher. The

bucket is not dishwasher safe and will be

damaged.

10.When the interior is dry, reconnect power and turn unit

on.

DO NOT use an ice pick or other sharp

instrument to help speed up defrosting. These

instruments can puncture the inner lining or

damage the cooling unit. DO NOT use any type of

heater to defrost. Using a heater to speed up

defrosting can cause personal injury and

damage to the inner lining.

To defrost:

1. Disconnect power to the unit.

2. Remove ice bucket and discard ice.

3. Place towel or other absorbent material on bottom of

ice bin.

4. Fill the ice bucket half full with warm, not hot water.

This will help the unit defrost faster.

NOTE: To safeguard against contaminates in ice, discard

first three batches of ice after defrosting.

5. Place the ice bucket back into the unit on top of the

towel or other absorbent material.

6. Prop the door in an open position (2 in. [50 mm]

minimum).

7. After about 1 hour remove the ice bin and discard

water.

8. Allow the frost to melt naturally.

9. After the frost melts completely clean the interior and

all removed components. (See INTERIOR CLEANING).

Cleaning 2

Page 29

USER GUIDE

NOTICE

Condenser

u-line.com

SAFETY • INSTALLATION & INTEGRATION • OPERATING INSTRUCTIONS • MAINTENANCE • SERVICE

Cleaning Condenser

INTERVAL - EVERY SIX MONTHS

To maintain operational efficiency, keep the front grille

free of dust and lint, and clean the condenser when

necessary. Depending on environmental conditions, more

or less frequent cleaning may be necessary.

WARNING

!

Disconnect electric power to the unit before

cleaning the condenser.

WARNING

!

DO NOT touch the condenser fins. The condenser

fins are SHARP and can be easily damaged.

DO NOT use any type of cleaner on the

condenser unit.

1. Remove the grille. (See GRILLE-PLINTH

INSTALLATION).

2. Clean the condenser coil using a using a soft brush

with a “combing” action or vacuum cleaner. Do not

touch the condenser coil.

3. Install the grille.

Cleaning Condenser 1

Page 30

USER GUIDE

u-line.com

SAFETY • INSTALLATION & INTEGRATION • OPERATING INSTRUCTIONS • MAINTENANCE • SERVICE

Extended Non-Use

VACATION/HOLIDAY, PROLONGED SHUTDOWN

The following steps are recommended for periods of

extended non-use:

1. Remove all consumable content from the unit.

2. Disconnect the power cord from its outlet/socket and

leave it disconnected until the unit is returned to

service.

3. Turn off the water supply.

4. If ice is on the evaporator, allow ice to thaw naturally.

5. Clean and dry the interior of the cabinet. Ensure all

water has been removed from the unit.

6. Disconnect the water and drain line (if applicable)

making sure all water is removed from the lines.

For questions regarding winterization, please

call U-Line at +1.800.779.2547.

CAUTION

!

Damage caused by freezing temperatures is not

covered by the warranty.

Do not put anti-freeze in your unit.

7. The door must remain open to prevent formation of

mold and mildew. Open door a minimum of 2"

(50 mm) to provide the necessary ventilation.

WINTERIZATION

If the unit will be exposed to temperatures of 40°F (5°C)

or less, the steps above must be followed. In addition, P60

drain pumps in clear ice machines must be drained

according to the following procedure:

1. Remove the drain pump from the ice machine.

2. Drain the water in the pump’s reservoir by turning the

pump upside down and allowing the water to drain

through the pump’s inlet and vent tube fittings.

3. After water is drained, reinstall the drain pump and

reattach all connections.

Extended Non-Use 1

Page 31

USER GUIDE

u-line.com

SAFETY • INSTALLATION & INTEGRATION • OPERATING INSTRUCTIONS • MAINTENANCE • SERVICE

Troubleshooting

BEFORE CALLING FOR SERVICE

If you think your U-Line product is malfunctioning, read

the CONTROL OPERATION section to clearly understand

the function of the control.

If the problem persists, read the NORMAL OPERATING

SOUNDS and TROUBLESHOOTING GUIDE sections below

to help you quickly identify common problems and

possible causes and remedies. Most often, this will resolve

the problem without the need to call for service.

IF SERVICE IS REQUIRED

If you do not understand a troubleshooting remedy, or

your product needs service, contact U-Line Corporation

directly at +1.414.354.0300

When you call, you will need your product Model and

Serial Numbers. This information appears on the Model

and Serial number plate located on the upper right or rear

wall of the interior of your product.

NORMAL OPERATING SOUNDS

All models incorporate rigid foam insulated cabinets to

provide high thermal efficiency and maximum sound

reduction for its internal working components. Despite this

technology, your model may make sounds that are

unfamiliar.

Normal operating sounds may be more noticeable because

of the unit’s environment. Hard surfaces such as cabinets,

wood, vinyl or tiled floors and paneled walls have a

tendency to reflect normal appliance operating noises.

• Evaporator: Refrigerant flowing through an evaporator

may sound like boiling liquid.

• Condenser Fan: Air moving through a condenser may

be heard.

• Automatic Defrost Drain Pan: Water may be heard

dripping or running into the drain pan when the unit is

in the defrost cycle.

TROUBLESHOOTING GUIDE

DANGER

!

ELECTROCUTION HAZARD. Never attempt to

repair or perform maintenance on the unit

before disconnecting the main electrical power.

Troubleshooting - What to check when problems occur:

Problem Possible Cause and Remedy

Light Remains

on When Door

Is Closed.

Unit Develops

Frost on

Internal

Surfaces.

Unit Develops

Condensation

on External

Surfaces.

Product Is

Freezing.

Turn off light switch if equipped.

Check reed switch.

Frost on the rear wall is normal and will melt

during each off cycle.

If there is excessive build-up of 1/4" or more,

manually defrost the unit.

Ensure the door is closing and sealing

properly.

High ambient temperature and excessive

humidity can also produce frost.

The unit is exposed to excessive humidity.

Moisture will dissipate as humidity levels

decrease.

Because product in contact with the rear wall

may freeze, ensure no product is touching the

rear wall.

Adjust the temperature to a warmer set point.

Listed below are common refrigeration components with a

brief description of the normal operating sounds they

make. NOTE: Your product may not contain all the

components listed.

• Compressor: The compressor makes a hum or pulsing

sound that may be heard when it operates.

Troubleshooting 1

Page 32

USER GUIDE

u-line.com

SAFETY • INSTALLATION & INTEGRATION • OPERATING INSTRUCTIONS • MAINTENANCE • SERVICE

Problem Possible Cause and Remedy

Product is Not

Cold Enough.

Air temperature does not indicate product

temperature. See CHECKING PRODUCT

TEMPERATURE below.

Adjust the temperature to a cooler set point.

Ensure unit is not located in excessive

ambient temperatures or in direct sunlight.

Ensure the door is closing and sealing

properly.

Ensure the interior light has not remained on

too long.

Ensure nothing is blocking the front grille,

found at the bottom of the unit.

Ensure the condenser coil is clean and free of

any dirt or lint build-up.

CHECKING PRODUCT TEMPERATURE

Causes which affect the internal temperatures of

the cabinet include:

• Temperature setting.

• Ambient temperature where installed.

• Installation in direct sunlight or near a heat source.

• The number of door/drawer openings and the time the

door/drawer is open.

• The time the internal light is illuminated. (This mainly

affects product on the top rack or shelf.)

• Obstruction of front grille or condenser.

To check the actual product temperature in the

unit:

1. Partially fill a plastic (nonbreakable) bottle with water.

2. Insert an accurate thermometer.

3. Tighten the bottle cap securely.

4. Place the bottle in the desired area for 24 hours.

5. Avoid opening the unit during the testing period.

6. After 24 hours, check the temperature of the water. If

required, adjust the temperature control in a small

increment (see CONTROL OPERATION).

Troubleshooting 2

Page 33

USER GUIDE

u-line.com

SAFETY • INSTALLATION & INTEGRATION • OPERATING INSTRUCTIONS • MAINTENANCE • SERVICE

U-Line Corporation (U-Line) Limited Warranty

One Year Limited Warranty

For one year from the date of original purchase, this U-Line product warranty covers all parts and labor to repair or replace any part of the

product that proves to be defective in materials or workmanship. For products installed and used for normal residential use, material

cosmetic defects are included in this warranty, with coverage limited to 60 days from the date of original purchase. All service provided by U-

Line under the above warranty must be performed by U-Line factory authorized service, unless otherwise specified by U-Line. Service

provided during normal business hours.

Available Second Year Limited Warranty

Beyond the standard one year warranty outlined above, U-Line offers an extension of the one year warranty coverage for an additional

second year from the date of purchase, free of charge. To take advantage of this second year warranty, you must register your product with

U-Line within two months from the date of purchase at u-line.com providing proof of purchase.

Five Year Sealed System Limited Warranty

For five years from the date of original purchase, U-Line will repair or replace the following parts, labor not included, that prove to be

defective in materials or workmanship: compressor, condenser, evaporator, drier, and all connecting tubing. All service provided by U-Line

under the above warranty must be performed by U-Line factory authorized service, unless otherwise specified by U-Line. Service provided

during normal business hours.

Terms

These warranties apply only to products installed in any one of the fifty states of the United States, the District of Columbia, or the ten

provinces of Canada. The warranties do not cover any parts or labor to correct any defect caused by negligence, accident or improper use,

maintenance, installation, service, repair, acts of God, fire, flood or other natural disasters. The product must be installed, operated, and

maintained in accordance with the U-Line User Guide.

The remedies described above for each warranty are the only ones that U-Line will provide, either under these warranties or under any

warranty arising by operation of law. U-Line will not be responsible for any consequential or incidental damages arising from the breach of

these warranties or any other warranty, whether express, implied, or statutory. Some states do not allow the exclusion or limitation of

incidental or consequential damages, so the above limitation or exclusion may not apply to you. These warranties give you specific legal

rights, and you may also have other rights which vary from state to state.

Any warranty that may be implied in connection with your purchase or use of the product, including any warranty of merchantability or any

warranty fit for a particular purpose is limited to the duration of these warranties, and only extends to five years in duration for the parts

described in the section related to the five ye ar limited warranty above. Some states do not all ow limitations on how long an implied warranty

lasts, so the above limitations may not apply to you.

• The warranties only apply to the original purchaser and are non-transferable.

• The second year and five year warranties cover products installed and used for normal residential or designated marine use only.

• The warranties apply to units operated outside only if designed for outdoor use by model and serial number.

• Replacement water filters, light bulbs, and other consumable parts are not covered by these warranties.

• The start of U-Line’s obligation is limited to four years after the shipment date from U-Line.

• In-home instruction on how to use your product is not covered by these warranties.

• Food, beverage, and medicine loss are not covered by these warranties.

• If the product is located in an area where U-Line factory authorized service is not available, you may be responsible for a trip charge

or you may be required to bring the product to a U-Line factory authorized service location at your own cost and expense.

• Units purchased after use as floor displays

no coverage is provided for cosmetic defects.

• Signal issues related to Wi-Fi connectivity are not covered by these warranties.

, and/or certified reconditioned units, are covered by the limited one year warranty only and

For parts and service assistance, or to find U-Line factory authorized service near you, contact U-Line:

8900 N. 55th Street, Milwaukee, WI 53223 • u-line.com • onlineservice@u-line.com • +1.800.779.2547

Copyright © 2014/2017 U-Line Corporation. All Rights Reserved. | Publication Number 30379 | 10/2017 Rev. L

Warranty 1

Page 34

42312_C WIRING DIAGRAM

NEUTRAL

BLACK

RELAY

EMBRACO

COMPRESSOR

GREEN or

GREEN W/ YELLOW

GROUND:

OVERLOAD

CAP

EMU

ONLY

MANUAL CONTROL ICEMAKER & COMBO

ROCKER

SWITCH

COND

FAN

WATER

VALV E

SEE COMPRESSOR

DIAGRAMS

BROWN

BLUE

BLUE

WHITE

BLACK

BLACK

WHITE

BIN

SW

NONCC

WATER

SW

NC

NO

C

HOLD

SW

NO

NC

C

CAM

3 RPM

MOTOR

LIMIT

SW

MOLD HEATER

YELLOW

RED

WHITE

BROWN

BLACK

RED

YELLOW

BROWN

BLACK

BROWN

ORANGE

OR BLUE

BLACK

OR BLUE

OR

ALL OTHER MODELS

ICEMAKER

BI1215 ONLY

CONTROL

POWER CORD ASSEMBLY

GROUND:

GREEN or GREEN W/ YELLOW

115

VOLT

PLUG

220-240 VOLT

PLUG

BLACK-HOT

(SMOOTH)

BLACK-NEUTRAL

(RIBBED)

BLACK

WHITE

RED

YELLOW

BROWN

WHITE

BLACK

1

3

6

4

4

1

532

6

41532

6

USER GUIDE

u-line.com

SAFETY • INSTALLATION & INTEGRATION • OPERATING INSTRUCTIONS • MAINTENANCE • SERVICE

Wire Diagram

Wire Diagram 1

Page 35

USER GUIDE

u-line.com

SAFETY • INSTALLATION & INTEGRATION • OPERATING INSTRUCTIONS • MAINTENANCE • SERVICE

Product Liability

Field service technicians are authorized to make an initial

assessment in the event of reported damages. If there are

any questions about the process involved, the technician

should call U-Line for further explanation.

While inspecting for defects or installation issues, photos

should be taken to document any damages or issues

found.

During the assessment, if the service technician is able to

find the source of the damage and it can be resolved by

replacement of a part, the servicer is authorized to

replace the part in question. The part that caused the

damage must be returned to U-Line in its entirety. The

part must be clearly labeled with the serial number of the

unit it was removed from, the date, and the servicer who

removed the part.

If the service technician determines the damage is the

result of installation issues (water connection/drain, etc.),

the consumer would be notified and the issues shall be

resolved at the direction of the consumer.

If damage is evident and the service technician is unable

to find the source, U-Line must be contacted at 1-800-

799-2547 for further direction

8900 N. 55th Street • Milwaukee, WI 53223

T: +1.414.354.0300 • F: +1.414.354.354.5696

Website: www.u-line.com

Right product. Right place.

Right temperature Since 1962.

Product Liability 1

Page 36

USER GUIDE

14 30911 1 2 XXXX

Year

Month

u-line.com

SAFETY • INSTALLATION & INTEGRATION • OPERATING INSTRUCTIONS • MAINTENANCE • SERVICE

Warranty Claims

The following information defines the parameters for filing

a warranty claim:

• Valid serial number needed

• Valid model number needed

• Narda (or equivalent) form or submitted online at

www.u-line.com

• 60 day submittal deadline from date of completed

service

• Only one repair or unit per warranty claim

• Refrigerant should be labeled and included on the labor

submittal

warranty status. We also accept the following

information to verify warranty status:

• New Construction Occupancy Documents

•Closing Paperwork

• Final Billing – Remodel

Noting all of the following on the warranty claim will be

considered proof of purchase, hard copy will not be

required:

• Name of the selling Dealer

• Date of purchase/installation

• Order or Invoice number (if available)

• Door and water level adjustments are covered 30 days

from install date.

Serial Number Requirements:

A typical serial number is shown above. The first two

digits of the first segment, 14, represents the production

year. The number between the dashes, 12, represents the

production month. In most cases, warranty status can be

verified by the production date information within the

serial number.

• Description of document reviewed (i.e. store receipt,

closing paperwork, etc)

Parts and labor claims are paid separately. Indicate part

numbers and description for parts used in the warranty

repair. Include the purchase invoice and name of the parts

supplier used to procure the parts.

• Alternatively, a Proof of Purchase (or equivalent) may

submitted with the warranty claim to document

Warranty Claims 1

Page 37

Parts

2

27 20

19

24

21

14

1

13

18

U-BI1215INT-00B

Item Description U-Line P/N

1 Anti tip brackets w/screws 80-54221-00

2 Back panel 80-54392-00

3 Compression nut/sleeve 80-54355-00

4 Compressor electricals only 80-54377-00

5 Compressor w/electricals 80-54376-00

6 Condenser assembly 80-54293-00

7 Condenser fan 80-54378-00

8 Condenser fan blade 80-54379-00

9 Control assembly 80-54381-00

10 Control knob 80-54382-00

11 Door assembly w/hinges 80-54390-00

12 Drier 80-54055-00

13 Evap/cabinet assembly 80-54393-00

14 Front panel w/screws 80-54371-00

15 Gasket, door 80-54235-00

16 Gasket, Horizontal 80-54391-00

17 Grille w/ screws 80-54230-00

18 Hinges (2) w/screws 80-54233-00

19 Ice bucket 80-54386-00

20 Ice maker assembly 80-54372-00

21 Leg Levelers (4) 80-54201-00

22 Packaging 80-54238-00

23 Power cord 80-54380-00

24 Rocker switch 80-54105-00

25 Water line assembly 80-54383-00

26 Water valve assembly 80-54356-00

27 Faceplate 115V 80-54523-00

17

15

16

11

5

12

4

9

7

10

26

6

8

Parts 1

Page 38

USER GUIDE

NOTICE

u-line.com

SAFETY • INSTALLATION & INTEGRATION • OPERATING INSTRUCTIONS • MAINTENANCE • SERVICE

Ordering Replacement Parts

If you have a purchasing account, please utilize our

service website to order parts.

Orders may also be placed by Fax or phone. See our

contact information below:

www.U-LineService.com (with service login)

FAX Number: +1.414.354.5696

Phone Number: +1.800.779.2547

Use only genuine U-Line replacement parts. The

use of non-U-Line parts can reduce speed of ice

production, cause water to overflow from ice

maker mold, damage the unit, and void the

warranty.

Warranty parts will be shipped at no charge after U-Line

confirms warranty status. Please provide the model, serial

number, part number and part description. Some parts

will require color or voltage information.

If U-Line requires the return of original parts, we will

inform you when the parts order is taken. This

requirement will be noted on your packing list. A prepaid

shipping label will be included with the replacement part.

Please enclose a copy of the parts packing list and any

labor claims with your return. Please be sure the model

and serial numbers are legible on the paperwork. Tag the

part with the reported defect.

When ordering a non-warranty part, you will need an open

account and tax exemption on file at U-Line. Another

option would be to visit www.u-line.com to locate an

authorized parts distributor in your area.

Ordering Replacement Parts 1

Page 39

USER GUIDE

u-line.com

SAFETY • INSTALLATION & INTEGRATION • OPERATING INSTRUCTIONS • MAINTENANCE • SERVICE

System Diagnosis Guide

REFRIGERATION SYSTEM DIAGNOSIS GUIDE

System

Condition

Normal Normal Slightly below

Overcharge Higher than

Undercharge Lower than

Partial

Restriction

Complete

Restriction

No Gas 0 PSIG to 25" Room

Suction

Pressure

normal

normal

Somewhat

lower than

normal vacuum

In deep

vacuum

Suction

Line

room

temperature

Very cold may

frost heavily

Warm-near

room

temperature

Warm - near

room

temperature

Room

temperature

(cool)

temperature

(cool)

Compressor

Discharge

Very hot Very hot Warm Cold Normal

Slightly warm

to hot

Hot Warm Warm Extremely cold

Very hot Top passes

Room

temperature

(cool)

Cool to hot Room

Condenser Capillary

Hot to warm Cool Cold Higher than

warm - Lower

passes cool

(near room

temperature)

due to liquid

Room

temperature

(cool)

temperature

(cool)

Tube

Room

temperature

(cool) or

colder

Room

temperature

(cool)

Room

temperature

(cool)

Evaporator Wattage

normal

Lower than

near inlet -

Outlet below

room

temperature

Extremely cold

near inlet -

Outlet below

room

temperature

backing up

No refrigeration Lower than

No refrigeration Lower than

normal

Lower than

normal

normal

normal

System Diagnosis Guide 1

Page 40

USER GUIDE

ULIN_0576_AW

RS

C

OVERLOAD PROTECTOR

STARTING RELAY

RELAY COVER

u-line.com

SAFETY • INSTALLATION & INTEGRATION • OPERATING INSTRUCTIONS • MAINTENANCE • SERVICE

Compressor Specifications

DANGER

!

Electrocution can cause death or serious injury.

Burns from hot or cold surfaces can cause

serious injury. Take precautions when servicing

this unit.

Disconnect the power source.

Do not stand in standing water when working

around electrical appliances.

Make sure the surfaces you touch are not hot or

frozen.

Do not touch a bare circuit board unless you are

wearing an anti-static wrist strap that is

grounded to an electrical ground or grounded

water pipe.

Handle circuit boards carefully and avoid

touching components.

Refrigerant R134a

Voltage 115 VAC

Frequency 60 Hz

Run Cap n/a

Start Winding 12.1 Ohm at 77°F

Run Winding 3.9 Ohm at 77°F

LRA 18.0 A

FLA 2.0 A

Starting Device 213514105

Overload 4TM757KFBYY-53

* All resistance readings are ±10%

EM150HER

To measure the start winding resistance, measure across

the C and S pins.

To measure the run winding resistance, measure across

the C and R pins.

Also check S to R and you should get the sum of the run

and start windings.

To ensure the windings are not shorted, check the S and R

to ground.

Compressor Specifications 1

Page 41

USER GUIDE

u-line.com

SAFETY • INSTALLATION & INTEGRATION • OPERATING INSTRUCTIONS • MAINTENANCE • SERVICE

Troubleshooting - Extended

SPECIFIC ERRORS & ISSUES

CAUTION

!

Never attempt to repair or perform maintenance

on the unit until the main electrical power has

been disconnected from the unit.

TROUBLESHOOTING GUIDE

Concern Potential Causes Suggested Remedy

Will not eject ice

(water frozen).

Will not fill with

water.

Will not stop

making ice.

Water will not

stop filling.

Ejector blades

will not stop

turning.

Low ice

production.

Not freezing

(compressor

and fan motors

operating).

Not freezing

(compressor not

operating - fans

operating).

Control setting too cold. Adjust control warmer (counterclockwise).

Control inoperable (1-2 contacts open) Replace control.

Bin switch inoperable. Replace bin switch.

Limit switch defective (open). Replace limit switch.

Ice maker assembly motor stalled. Replace motor.

Broken wire in ice maker circuit. Repair or replace wiring.

Water soaked cabinet insulation. Replace foamed cabinet assembly.

Dirty condenser. Clean condenser.

Water supply valve closed. Open water supply valve.

Water switch inoperable (open). Replace water switch.

Solenoid valve inoperable. Replace solenoid valve.

Fill tube outlet frozen. Defrost fill tube.

Broken wire in water fill circuit. Repair or replace wiring.

Bin switch inoperable (closed). Replace bin switch.

Bin arm binding. Lubricate bin arm pivot points or loosen bin arm lever screw.

Water switch inoperable (closed). Replace water switch.

Solenoid valve inoperable. Replace solenoid valve.

Stalled ice maker motor. Replace motor.

Temperature control inoperable. Ice maker is in

continuous harvest cycle (contacts 1-2 closed).

Control inoperable (1-2 contacts will not open). Replace control.

Hold switch inoperable. Replace hold switch.

Broken wiring. Repair or replace wiring.

Short in mold heater. Replace heater.

Control set too cold. Adjust control warmer (counterclockwise).

Fan motor stalled. Replace fan motor.

Ice cubes too large. Lower water fill adjustment.

Dirty condenser. Clean condenser.

Bypass valve stuck open (Frost Free units only). Replace bypass valve (Frost Free units only).

Little or no frost pattern on evaporator. Check for sealed system leak or restriction.

Bypass valve stuck open (Frost Free units only). Replace bypass valve (Frost Free units only).

Relay inoperable. Replace relay.

Overload inoperable (open). Replace overload.

Compressor inoperable. Replace compressor.

Replace temperature control.

Troubleshooting - Extended 1

Page 42

USER GUIDE

u-line.com

SAFETY • INSTALLATION & INTEGRATION • OPERATING INSTRUCTIONS • MAINTENANCE • SERVICE

Concern Potential Causes Suggested Remedy

Not freezing

(compressor

and fans not

operating).

Compressor

overheating.

Compressor will

not stop

operating.

Water leak

(under unit).

Water leak

(inside unit).

Excessive frost

buildup.

Noisy. Copper refrigeration tube touching cabinet. Carefully adjust tubing.

Ice buildup in

drain trough or

drainage

problem.

Unit will not

defrost (Frost

Free units only).

Fresh food

temperature too

cold.

Power cord not plugged in. Plug in power cord.

On/Off switch in off position. Turn switch to on position.

On/Off switch inoperable (open). Replace On/Off switch.

Hold switch inoperable (open). Replace hold switch.

Control inoperable (2-3 contacts open). Replace control.

Broken wire in freeze circuit. Repair or replace wiring.

Ejector blades not in freeze position (12:00) Manually advance ejector blades to the 12:00 position (test ice

Condenser air flow restricted. Remove restriction (clean condenser and grille).

Condenser fan blade obstructed. Remove blade restriction.

Condenser fan motor stalled. Replace fan motor.

Compressor inoperable. Replace compressor.

Control set too cold. Adjust control warmer (counterclockwise).

Control inoperable (2-3 contacts will not open). Replace control.

Control sensing bulb not sensing mold

temperature.

Evaporator fan stalled (Frost Free units only). Remove obstruction or replace motor.

Water supply line leaking at solenoid valve inlet. Tighten fitting or replace fitting gasket and/or fitting.

Water line leaking at solenoid valve outlet. Replace water line and fitting.

Water line leaking at fill tube. Tighten clamp or replace fill tube assembly.

Defrost drain line not in drain pan. Position drain line in drain pan.

Crack in water line. Replace water line.

Ice maker assembly fill cup obstructed. Remove obstruction.

Fill ice cup and fill tube out of alignment. Align fill tube and fill cup.

Water level too high. Adjust water level.

Defrost drain plugged (Frost Free units only). Ice in drain trough (Frost Free units only) (see below).

Door gasket not sealing properly. Adjust door hinges or replace door gasket.

Door out of alignment. Adjust door hinges.

Water soaked cabinet insulation. Replace foamed cabinet assembly.

Light stays on when door is closed. Repair or adjust light bracket.

Fan blade touching shroud. Adjust fan mounting or shroud.

Fan blade obstruction (wiring, foam insulation,

packaging material).

Obstructed drain cup or tube. Clear obstruction.

Drain trough heater failed (Frost Free units only). Replace drain trough heater (Frost Free units only).

Kinked drain tube. Align drain trough and drain cup.

Drain trough spout and drain cup not aligned. Reroute drain tube.

Bypass coil inoperable. Replace bypass valve.

Defrost timer inoperable. Replace defrost timer.

Bypass valve inoperable. Replace bypass valve.

Temperature control set too cold. Adjust control to warmer setting (counterclockwise).

Bin/Freezer door not closing. Adjust or replace door.

Ice bucket not fully inserted. Check for ice behind bucket and push ice bucket in place.

maker and limit switch).

Fully insert bulb into ice maker tube. Rout bulb away from

compressor discharge tube.

Remove obstruction.

Troubleshooting - Extended 2

Page 43

USER GUIDE

DOES THE UNIT REFRIGERATE?

Sealed System Leak

Electrical Failure

Compressor Failure

Fan Motor Failure

Defrost System Failure

Low Voltage

Voltage Drop

Wiring

Temperature Control Failure

Water Adjustment

Bin Switch Failure

NO

NO

EVERYWHERE

INTERMITTENT

AT 3:00

YES

NO

AT 12:00

DOES THE UNIT HARVEST ICE

IF THE EJECTOR BLADES ARE

MOVED BY HAND OR WITH A

WRENCH ?

WHERE DO THE

EJECTOR BLADES

STOP?

Mold Heater Failure

Solenoid Valve Failure

Ice Motor Failure

Hold Switch Failure

Limit Switch Failure

Binding Cam/Ejector

Water Switch Failure

IS THERE VOLTAGE AT THE

SOLENOID VALVE TERMINALS

DURING HARVEST?

UL183-11

YES

YES

u-line.com

SAFETY • INSTALLATION & INTEGRATION • OPERATING INSTRUCTIONS • MAINTENANCE • SERVICE

ICE MAKER DIAGNOSIS FLOW CHART

Troubleshooting - Extended 3

Page 44

USER GUIDE

SWITCH

LIMIT

orange

black

black

black

MOTOR

MAKER

ICE

MOLD HEATER

WATER

SWITCH

FILL

C

NC

MOTOR

FAN

LOAD

OVER

black

RELAY

START

COMP.

SWITCH

OFF

ON

black

black

blue

black

CONTROL

TEMP.

NC

black

orange

3

yellow

2

orange

SWITCH

BIN

red

NO

1

C

NO

brown

black

white

C

SWITCH

HOLD

VALVE

WATER

ground

UL183-4

u-line.com

SAFETY • INSTALLATION & INTEGRATION • OPERATING INSTRUCTIONS • MAINTENANCE • SERVICE

ICE MAKER OPERATING CYCLES

Freeze Cycle

• Temperature control terminals 2 and 3 are closed.

• Power to the condenser.

• Power to the condenser fan.

Figure 1. Freeze Cycle

Troubleshooting - Extended 4

Page 45

USER GUIDE

SWITCH

LIMIT

orange

black

black

black

MOTOR

MAKER

ICE

MOLD HEATER

WATER

SWITCH

FILL

C

NC

MOTOR

FAN

LOAD

OVER

black

RELAY

START

COMP.

SWITCH

OFF

ON

black

black

blue

black

CONTROL

TEMP.

NC

black

orange

3

yellow

2

orange

SWITCH

BIN

red

NO

1

C

NO

brown

black

white

C

SWITCH

HOLD

VALVE

WATER

ground

UL183-5

u-line.com

SAFETY • INSTALLATION & INTEGRATION • OPERATING INSTRUCTIONS • MAINTENANCE • SERVICE

Harvest-1 Cycle

• Temperature control terminals 2 and 3 are open - 2 and

1 close.

• No power to the compressor or condenser fan.

• If bin arm is down, power goes through bin arm switch

to the ice maker motor. If bin arm is up, the ice maker

will not harvest.

Figure 2. Harvest-1 Cycle (Hold Switch in Normal Position)

Troubleshooting - Extended 5

Page 46

USER GUIDE

SWITCH

LIMIT

orange

black

black

black

MOTOR

MAKER

ICE

MOLD HEATER

WATER

SWITCH

FILL

C

NC

MOTOR

FAN

LOAD

OVER

black

RELAY

START

COMP.

SWITCH

OFF

ON

black

black

blue

black

CONTROL

TEMP.

NC

black

orange

3

yellow

2

orange

SWITCH

BIN

red

NO

1

C

NO

brown

black

white

C

SWITCH

HOLD

VALVE

WATER

ground

UL183-6

u-line.com

SAFETY • INSTALLATION & INTEGRATION • OPERATING INSTRUCTIONS • MAINTENANCE • SERVICE

HARVEST-2 CYCLE

• Ice maker ejector blades reach approximately 2:00

position and cam depresses the hold switch. Power

goes through the hold switch to the ice maker motor

and mold heater.

• Ejector blades stall on ice and ice maker motor

pulsates until mold heater warms and ice releases.

Figure 3. Harvest-2 Cycle (Hold Switch in Switched Position)

Troubleshooting - Extended 6

Page 47

USER GUIDE

SWITCH

LIMIT

orange

black

black

black

MOTOR

MAKER

ICE

MOLD HEATER

WATER

SWITCH

FILL

C

NC

MOTOR

FAN

LOAD

OVER

black

RELAY

START

COMP.

SWITCH

OFF

ON

black

black

blue

black

CONTROL

TEMP.

NC

black

orange

3

yellow

2

orange

SWITCH

BIN

red

NO

1

C

NO

brown

black

white

C

SWITCH

HOLD

VALVE

WATER

ground

UL183-7

u-line.com

SAFETY • INSTALLATION & INTEGRATION • OPERATING INSTRUCTIONS • MAINTENANCE • SERVICE

WATER FILL CYCLE

• Ice maker ejector blades reach approximately 10:00

position and cam depresses the water fill switch.

• Power to the water valve. Ice maker mold fills.

EJECT CYCLE

• Ejector blades push ice into bucket and stop at 12:00

position.

• Temperature control terminals 2 and 3 have closed

during harvest cycle.

• Next freeze cycle begins with power to the compressor

and condenser fan.

Figure 4. Water Fill Cycle

Troubleshooting - Extended 7

Page 48

USER GUIDE

YELLOW WIRE

CONNECTION

RED WIRE

CONNECTION

BLUE/BLACK WIRE

CONNECTION

ICE MAKER CONTROL

2

1

3

183-8

22

1

3

1

3

FREEZE POSITION ICE HARVEST POSITION

CYCLE

CLOSED

CIRCUIT

OPEN

CIRCUIT

FREEZE 2 - 1 2 - 3

HARVEST 2 - 3 2 - 1

183-9

u-line.com

SAFETY • INSTALLATION & INTEGRATION • OPERATING INSTRUCTIONS • MAINTENANCE • SERVICE

TEMPERATURE CONTROL SPECIFICATIONS

Double Throw Ice Maker Thermostat Numbers

4548, AR-19-12, 2636, 2690, 2691, 2717, 2783,

2782-S, 2763-S, 2780, 80-26005-02

These temperature controls are double throw, single pole

controls. The sensing tube is inserted into the ice maker

mold and senses mold temperature. After ice is sensed in

the mold, the 2-3 contacts open (stopping the

compressor) and the 2-1 contacts are closed (starting the

ice maker motor). The 2-3 contacts close (2-1 contacts

open) before the end of the ice harvest cycle.The hold

switch prevents power going back to the compressor. This

prepares the control for the next cycle.

.

Figure 5. Temperature Controls - Manual Defrost Ice Makers

Troubleshooting - Extended 8

Page 49

USER GUIDE

28.12

3.00

183-10

u-line.com

SAFETY • INSTALLATION & INTEGRATION • OPERATING INSTRUCTIONS • MAINTENANCE • SERVICE

LIMIT SWITCH SPECIFICATIONS

• Normally closed Bi-metal switch

• Open temperature: 104°F

• Close temperature: 83°F

The function of this switch is to open in the event of an

overheating condition. This bi-metal thermostat is

normally closed and does not initiate the ice harvest

cycle. The ice harvest cycle is initiated by a double throw,

single pole temperature located remotely from the ice

maker assembly.

Figure 6. Limit Switch

Troubleshooting - Extended 9

Page 50

USER GUIDE

u-line.com

SAFETY • INSTALLATION & INTEGRATION • OPERATING INSTRUCTIONS • MAINTENANCE • SERVICE

REPLACING ICE MAKER ASSEMBLY (CO29F

ONLY)

1. Unplug the unit from the main power source.

2. Disconnect ice maker wire harness at plug (1).

3. Remove control capillary tube from sensing tube on ice

maker assembly (2).

4. Remove water inlet tube.

5. Remove front cover (3).

6. Advance the ejector blade to the 3 o’clock position by

turning the 5/16" hex head on the small brass gear

counterclockwise (4).

7. Remove three screws from wall of freezer housing (5).

8. Remove ice maker assembly.

9. Place new ice maker assembly into position and secure

with three screws (5).

10.Reconnect wire harness at plug.

11.Insert control capillary tube into ice maker sensing

tube.

12.Insert water inlet tube.

13.Apply Permagum

14.Install back panel.

15.Plug in unit and test.

®

to all exit holes.

Figure 7. Ice Maker Assembly

Troubleshooting - Extended 10

Page 51

USER GUIDE

u-line.com

SAFETY • INSTALLATION & INTEGRATION • OPERATING INSTRUCTIONS • MAINTENANCE • SERVICE

REPLACING ICE MAKER ASSEMBLY (ALL MODELS

EXCEPT CO29F)

1. Remove back panel.

2. Disconnect all wires at bell connectors (5 wires-Models

BI95, BI98 or SP18; or Plug-Models).

3. Remove capillary tube from sensing tube on ice maker

assembly (2).

4. Remove water inlet tube.

5. Remove front cover (3)

6. Advance ejector blades to the 3:00 position by turning

the 5/16" hex head on the small brass gear

counterclockwise (4).

7. Remove two screws from the side wall of evaporator

(5).

8. Remove screws from the bottom of the evaporator

plate.

9. Remove ice maker assembly from evaporator shelf.

10.Clean alumilastic from evaporator shelf.

11.Apply 1/4" layer of fresh alumilastic to heater side of

new ice maker.

17.Mount the back panel.

18.Plug in unit and test.

220 Volt Conversion List

All models listed in this manual are equipped to run on

110/115 volt. This document is a conversion list for the

applicable 220 volt parts for the following models:

•SP18

•BI95

•BI98

• SS1095

110V P/N 220V P/N Description

5263-S 5195 Fan Motor

80-39015-00 628109 I.M. motor (ice makers)

402 619 Ice maker assembly -

Models SP18, BI95, BI98

and model SS1095

402-29/1175 620 Ice maker assembly -

Models SP18, BI95, BI98

and model SS1095

2552A 2555A Water valve

5402-S 5404-S Compressor (ice makers)

150 650 Faceplate assembly

5414 5418 Relay

5413 5417 Overload

12.Replace parts in reverse order of removal.

13.Reconnect all wires.

14.Insert capillary tube into ice maker sensing tube.

15.Insert water inlet tube.

16.Apply permagum to all exit holes. Mount back panel.

Troubleshooting - Extended 11

Page 52

USER GUIDE

u-line.com