Page 1

Preliminary

r

AMS-3000 Antenna

with Digital 216

Controller

Installation Guide

About this Guide

This installation guide explains how to install the

antennas and capacitor box for AMS-3000 systems

that use a Digital 216 controller. Other related

documents are:

• Planning Guide, 8200-0179-01

• Installation Guide, AMS-3000 Antenna with

Ultra*Post Plus Controller, 8200-0179-03

Note: Because customer requirements dictate the

placement of system components, your

Sensormatic representative will supply this

information separately.

About the Product

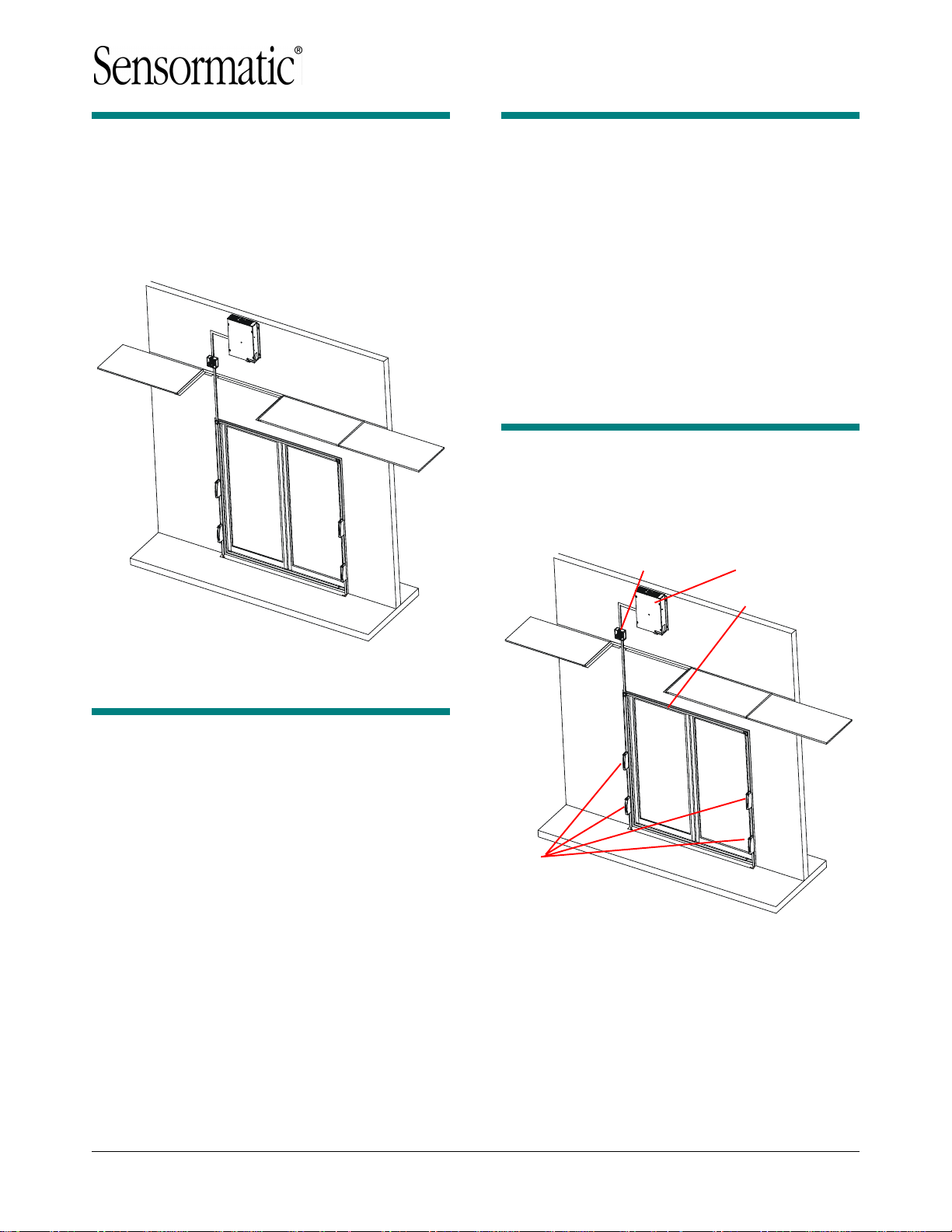

The AMS-3000 system consists of an antenna

cable, three metal extrusions to house the cable, a

capacitor (cap) box, various connecting hardware,

and a set of receiver antennas.

Cap box

Controller

ZSLOOP

Contents

About this Guide ................................................ 1

About the Product .............................................. 1

Installation Requirements .................................. 2

Tools and Equipment Required .................. 3

Installation.......................................................... 3

Planning the installation .............................. 3

Installing the controller ................................ 4

Installing the equipment in the floor ............ 4

Preparing the extrusions ............................. 6

Mounting extrusions .................................... 9

Installing the cap box .................................. 9

Connect antenna and receiver wires to

controller.................................................... 10

Connecting the remote alarm.................... 10

Configuring, tuning, and testing ................ 10

Declarations..................................................... 12

Regulatory Compliance............................. 12

Other Declarations .................................... 12

© Sensormatic 2002

Loop antenna

Receive

Antennas

AMS-3000 ANTENNA INSTALLATION GUIDE (8200-0179-02, REV. 0)

1 of 12

Page 2

Installation Requirements

Verifying Equipment and Unpacking

❑ Verify that all equipment has arrived. Make sure

the system configuration is the right one for the

installation site.

❑ Unpack major components in a back room. At

the install site, lay out parts in the order you will

need them. Do not clutter the aisle or cause a

trip hazard.

Note: The capacitor board is in a cardboard

sleeve taped to the bottom of the cardboard

antenna sleeve. The PVC leveling legs are

inside an envelope with the antenna.

Installer/Contractor

❑ Shall have electrical work comply with the

latest national electrical code, national fire

code, and all applicable local codes and

ordinances.

❑ Shall coordinate all work with other trades to

avoid interference.

❑ Shall verify existing site conditions and

coordinate with the owner’s representative and

appropriate utilities as required.

❑ Shall obtain copies of all related plans,

specifications, shop drawings and addenda to

schedule and coordinate related work.

❑ Shall thoroughly review the project to ensure

that all work meets or exceeds the above

requirements. Any alleged discrepancies shall

be brought to the attention of Sensormatic

Electronics.

WARNING!

Do not install this product in hazardous

!

areas where highly combustible or

explosive products are stored or used.

WARNING—RISK OF ELECTRIC

SHOCK!

If the equipment must be left unattended

during installation, turn off the power or

cover high voltage components so that

no unauthorized person has access to

hazardous voltages.

Preliminary

❑ Maximum cable distance from the AMS-3000

antenna to the capacitor board enclosure is

1.2m (4’). DO NOT splice antenna cables.

❑ Maximum cable distance from the controller to

the cap board enclosure is 12m 40’)

❑ Maximum cable distance from the receiver

antennas to the controller is 12m(40”)

WARNING!

DO NOT compromise the structural

!

integrity of the floor by cutting or removing

rebar. Contractors must obtain approval for

all proposed structural changes. All

structural changes must meet national and

CAUTION: To avoid adding significant time and

cost to the in-floor installation, check detector performance and label detection height at the exact

installation site. Do this BEFORE pouring the

concrete.

❑ All electrical work must comply with the

latest national electrical code, national fire

code, and all applicable local codes and

ordinances.

❑ High strength, non-metallic, non-shrink

mortar/concrete with a compressive strength of

5000 psi is required. (For example, FX-228

mortar mix and FX-752 bonding agent by Fox

Industries).

❑ Mortar cure time depends on the mix and

temperature of the mortar ingredients.

❑ Avoid walking on antenna cables during

installation.

❑ Heavy forklifts can pass over the mortar after 24

hours, provided the mortar is protected by

1.9cm (3/4") steel plates.

❑ Have on hand tools and equipment necessary

to place the mortar once it is mixed.

Cap Board Box

❑ Mount the cap board box as close to the

controller as possible. Maximum distance from

the controller to the cap box is 12m(40”)

❑ If conduit is not used for the cables between the

cap box and controller, use Romex connectors

wherever cables enter the controller and

capacitor board enclosure.

local requirements.

Antenna Placement and Cabling

❑ Whenever possible, keep the antennas at least

2.4m (8') away from noise sources such as

computer monitors, TVs, switching power

supplies, and neon displays.

AMS-3000 ANTENNA INSTALLATION GUIDE (8200-0179-02, REV. 0)

2 of 12

Page 3

Preliminary

Tools and Equipment Required

For all system installations:

• Plastic sheeting at least 0.15mm (6-mil) thick (to

protect nearby items from dust)

• Chalk or red permanent marker

• Floor saw

• PVC pipe cutter or hacksaw

• Hammer drill with 6.5mm (1/4") and 9.6mm

(3/8") masonry drill bits

• Power drill with 1.6mm (1/16"), 6.5mm (1/4"),

and 9.6mm (3/8") drill bits

• Hammer

• Phillips and slotted screwdrivers

• 14-16 AWG and 16-22 AWG wire strippers

• Ratchet and socket set

• Vacuum and broom

• Wet vacuum

• Level

• Electrical tape

• Teflon pipe tape

• Caution tape

• Duct tape

• Clear lacquer spray

Installation

To install the AMS-3000 antenna, perform the

following steps.

I. Plan the installation.

II. Perform a “tape up” to ensure system can

be installed.

III. Install the controller.

IV. Dig trench, install floor conduit, and feed

wires.

V. Prepare extrusions (drill holes, cut

extrusions, feed wires, and attach

Rangers).

VI. Attach extrusions and corner pieces

VII. Mount cap box, 1x1 channel (if necessary),

and route wires.

VIII. Connect antenna and receiver wires to

power pack and cap box.

IX. Mount remote alarm and connect.

X. Configure, tune, and test.

Planning the installation

Plan the placement of the controller, cap box,

receivers (Rangers), and the loop. See Planning

Guide for all details.

Controller restraints

• Determine whether the controller can be visible

to customers. If it must be hidden it can go

above a drop ceiling or in another room.

• Ensure the ranger cables will be long enough

to reach the controller.

• Ensure the transmitter (loop) cables will be

long enough to reach the controller.

• If you have multiple loops near each other,

resolve all antenna issues: one pack or two,

placement of controller to reach both antennas.

• Ensure the controller will be near a power

outlet.

Cap box restraints

• Determine whether the cap box will go above

the antenna or off to the side near the floor.

• Determine if the cap box can be visible or must

be hidden. If it must be hidden it can either go

above a drop ceiling or be mounted in a wall

off to the side of the antenna.

• Locate a suitable mounting surface (stud

location, grout lines).

• Ensure the cap box is within 1.2m(4ft) of the

loop.

Ranger restraints

• Ensure that the height of rangers does not

obstruct the operation of the door.

Loop restraints

• Determine whether the extrusions will go on

the store side of the doorframe or within the

arch of the doorframe.

• The only allowable configuration for the loop

antenna is an “L” shape, so ensure the

antenna can be routed in the floor in this way.

• Measure the height and width of the doorframe

to determine extrusion lengths.

• Keep loops on separate packs several feet

apart.

AMS-3000 ANTENNA INSTALLATION GUIDE (8200-0179-02, REV. 0)

3 of 12

Page 4

Preliminary

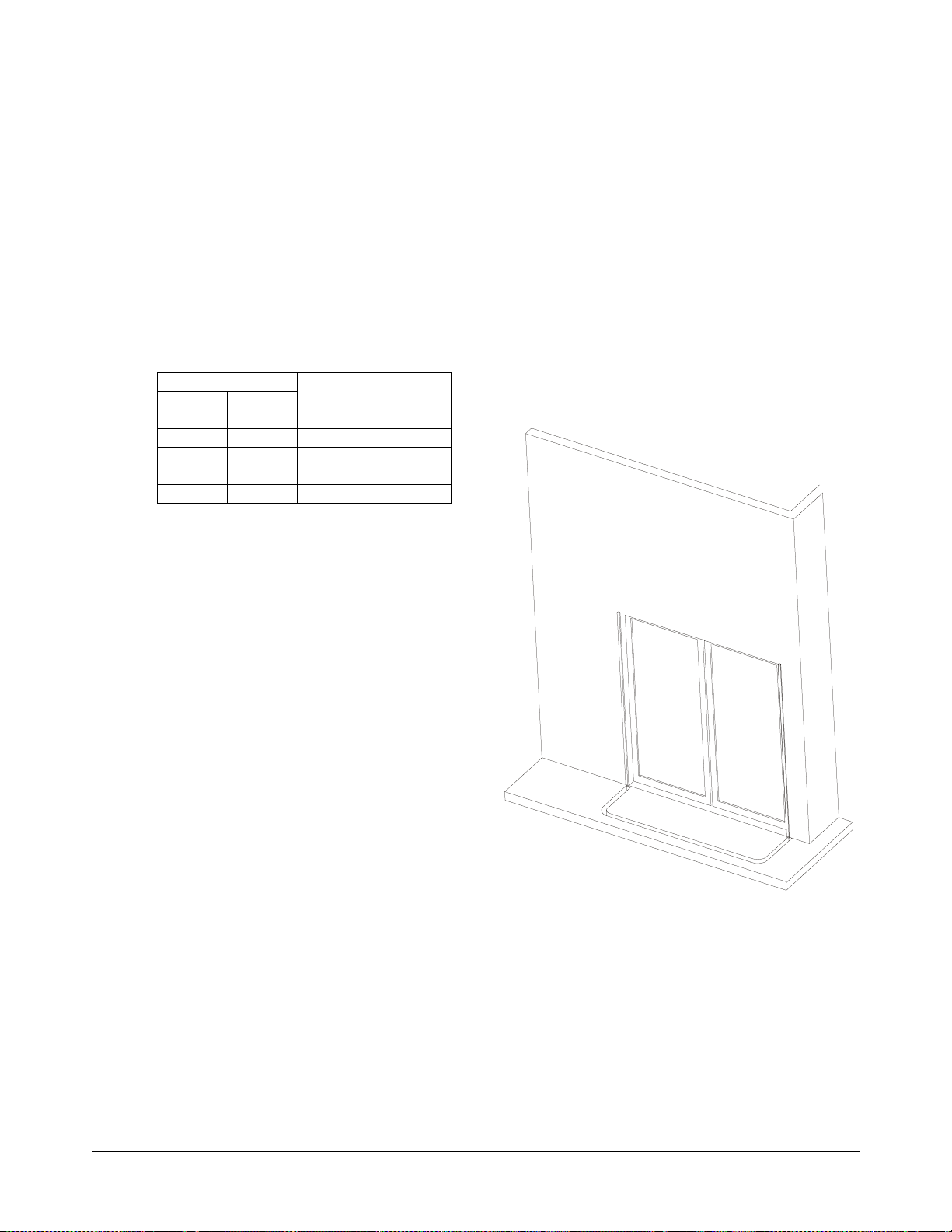

• The dimensions of the exit door affect the

maximum amount of current in the loop and

the strength of the field it will generate. In

general, a smaller door can generate a

stronger B-field without exceeding regulatory

limits. Because larger door openings require a

stronger field to maintain pick ratios, you must

determine if the loop will work adequately for

an installation. Use the table below to

determine if the field strength will be sufficient

to give you the pick rate you need for the exit.

You may need to tape up an antenna before

installing the extrusions to help predict detector

performance.

Loop Size

Width Height

5.5ft 9ft 12.9 A/m

6ft 8ft 13.1 A/m

5ft 8ft 17.6 A/m

3ft 8ft 17.9 A/m

6ft 7ft 14.6 A/m

Maximum Allowed

Field Strength

Installing the controller

frames. If contact is made, make sure to

isolate such contacts.

3. Prepare the bottom run of loop cable. The

route of the cable depends on where the cap

box will be located and whether the antenna

goes on the store side of the doorframe or the

inside the arch of the doorframe.

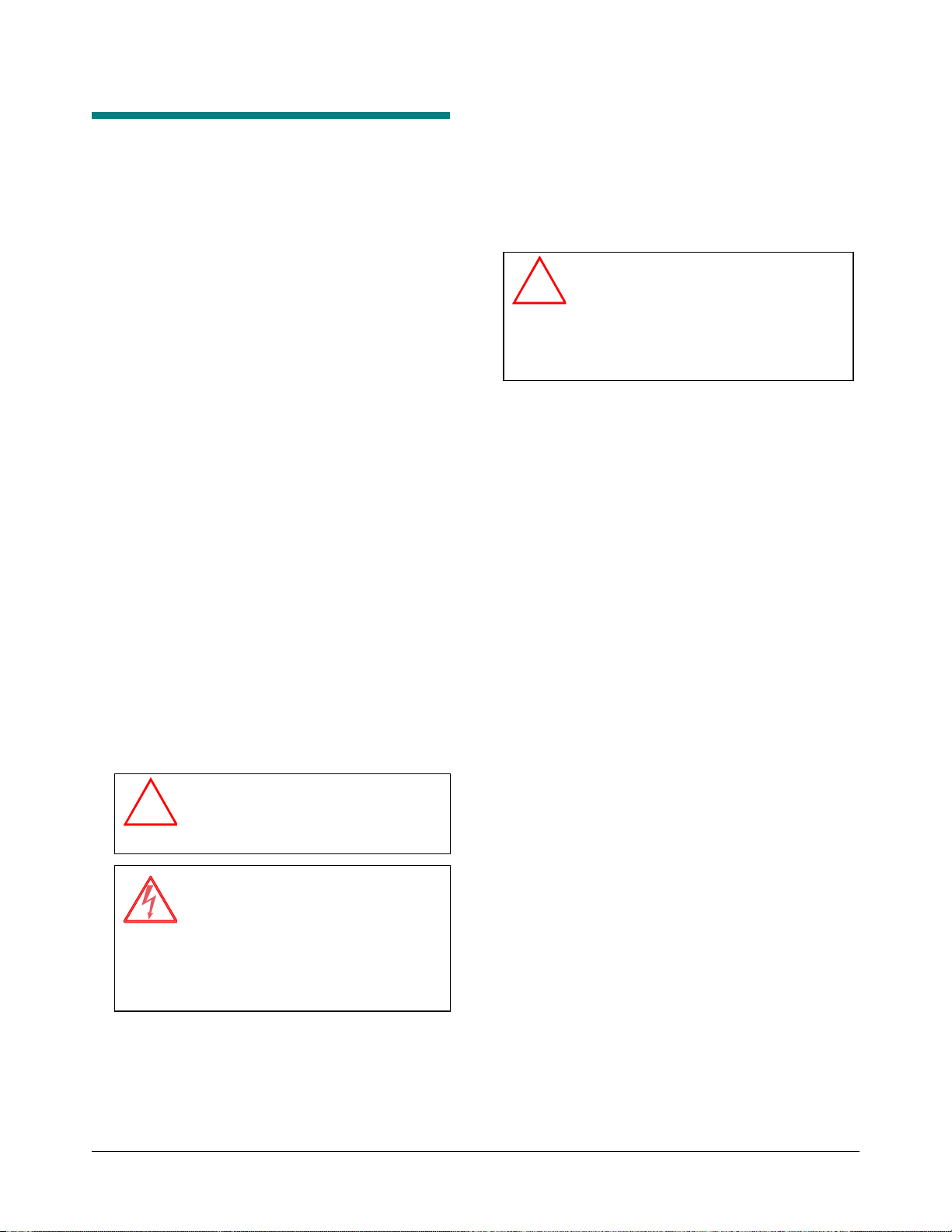

• If the cap box will be above the door

and the antenna goes on the store side

of the doorframe, assemble the floor

conduit and trace an outline on the floor as

shown below. Use a floor saw and chisel to

cut the 32mm (1.25”) deep trench in the

floor that is wide enough to accept 1/2”

conduit. Note that (½”) conduit measures

2.13cm (.84”) in outside diameter.

Refer to the appropriate controller installation

manual for instructions on installing the controller.

Performing a tape-up

It may be necessary to tape the antenna cable

around the door in the intended configuration prior

to installation to check for performance issues. This

is especially true for installations requiring a large

antenna loops or with metal doorframes. You

should tape the antenna cable in the intended

configuration, connect it to the controller, and then

check the current or field strength.

Installing the conduit in the

floor

The loop cable is installed beneath the surface of

the floor in ½” conduit. Note that ½” conduit

measures 2.13cm (.84”) in outside diameter.

1. If the doorframe and threshold are metal and

have no gap, remove the threshold and cut

6mm from the length of the threshold with a

saw.

2. Ensure there are no brackets underneath that

make contact to the threshold and the side

AMS-3000 ANTENNA INSTALLATION GUIDE (8200-0179-02, REV. 0)

4 of 12

Page 5

Preliminary

• If the cap box will be above the door

and the antenna goes inside the

archway of the doorframe, assemble the

floor conduit and trace an outline on the

floor as shown below. Use a floor saw and

chisel to cut the 32mm (1.25”) deep trench

in the floor that is wide enough to accept

1/2” conduit. Note that (½”) conduit

measures 2.13cm (.84”) in outside

diameter.

• If the cap box will be installed near the

floor, the trenching pattern is different.

Assemble the floor conduit, including the

section that routes the cable off to the side.

Trace an outline of the conduit on the floor.

Use a floor saw and chisel to cut the 31mm

(1.25”) deep trench in the floor that is wide

enough to accept 1.27cm (1/2”) conduit.

Note that ½” conduit measures 2.13cm

(.84”) in outside diameter. See the picture

below for an example of what the trench

looks like for an installation with the cap

box near the floor and the antenna

mounted on the store side of the

doorframe.

4. Reinstall the threshold if it was removed. Fill

the gap with RTV. Put ½” conduit in the

trenches.

5. Connect the conduit runs using the elbows

provided.

6. Connect the ½” conduit-to-extrusion adapters

to the ends of the conduit near the extrusions.

7. If the antenna will not be installed until a later

date, insert a dummy wire into the conduit to

facilitate antenna routing later. You should use

Yellow 77 or a similar wire-pulling lubricant to

ensure the wire can be pulled easily.

AMS-3000 ANTENNA INSTALLATION GUIDE (8200-0179-02, REV. 0)

5 of 12

Page 6

Preliminary

Preparing the extrusions

1. Determine on which edge the Rangers will line

up: inside edge, outside edge, or on side of

extrusion. Lining up on the inside edge of the

doorframe is preferred. If a nearby wall or other

object prevents this, line the Rangers up on the

outside edge of the doorframe. Ensure that

arrows on all the Rangers point in the up

direction.

tape indicating hole locations. Score the tape

before cutting.

4. To facilitate marking the extrusions for drilling,

a label has been provided in the extrusion to

show location and size of holes.

5. Prepare the right extrusion.

Note the two template labels at the bottom of

the extrusions. Use a center punch and punch

the center of the holes marked for the right

side “R”. Then drill through one surface with

drill size that comes closest to the hole

diameter on the template.

6. Prepare the left extrusion.

Same as right side, drill through holes marked

for left side “L”.

7. Prepare the top extrusion.

Cut the top extrusion to the proper length: the

width of the door minus .5”.

8. Install Rangers (ZKRANGER-2 only).

a. Find 91cm (36”) supplied wire in the kit.

(The interconnect wire included with the kit

is not long enough.)

2. Measure length of vertical extrusion needed.

Remember to allow for length necessary for

insertion into corner piece in floor.

3. Cut extrusions to length. Make sure you cut the

bottom of the extrusion, not the end with the

AMS-3000 ANTENNA INSTALLATION GUIDE (8200-0179-02, REV. 0)

6 of 12

Page 7

Preliminary

ger

b. Run wire from lower ranger to upper

ranger lower hole. Note that you may have

to route wire through hole in Ranger to get

to other side.

h. Remove backing from adhesive, align

Ranger to correct edge of extrusion, and

stick Ranger to extrusions.

Wire

routed

through

Ran

c. Connect wires to bottom and top Ranger

per instructions in kit. (Bottom four-wire

connector on bottom to top two-wire

connectors on top).

d. Align notches for wires and edge of

Ranger with edge of extrusion.

e. Run wire from top of extrusion to top hole.

f. Connect wires to top Ranger.

g. Remove labels and using towelette, clean

surface of extrusions.

AMS-3000 ANTENNA INSTALLATION GUIDE (8200-0179-02, REV. 0)

7 of 12

Page 8

Preliminary

i. Drill two 2.0mm(3/32”) holes through each

Ranger at each of the smaller notches.

j. Install two 8mm M4 screws through

Ranger and into extrusion. Do not use

screws in Ranger kit; they are too long.

k. Repeat steps for Rangers on other

extrusion. Note that notches for screws

may not be available and you will need to

drill hole in Ranger.

9. If the cap box will be installed above the door,

route the loop cable through the conduit in the

floor. Ensure that the adapter is in place at the

ends of the conduit. Also note that the section

of the loop cable coming out of the side

nearest the cap box should be shorter than the

section coming out the other side.

10. Route the loop cable through the left

extrusions.

11. Put the covers on the Rangers at the very end.

AMS-3000 ANTENNA INSTALLATION GUIDE (8200-0179-02, REV. 0)

8 of 12

Page 9

Preliminary

Mounting extrusions

Extrusions can be mounted to painted steel,

aluminum, wood, drywall, or glass surfaces.

1. Clean all surfaces where extrusions will go with

towelette. Allow surfaces to dry.

2. Route the loop cable through the right

extrusion.

3. Remove the backing from the adhesive tape.

4. Insert the bottom of the left extrusion into the

corner piece and shove downward. If

necessary, strike top of extrusion with hammer

to ensure extrusion enters corner piece.

5. Press the extrusion against the doorframe.

6. Measure the width of the doorframe and cut

the top extrusion to that length minus 13mm

(.5”).

7. If this is a wood or drywall doorframe drill a

6mm (1/4”) hole through the extrusion for the

screw. Use a 10mm (3/8”) bit to drill through

the front side of the extrusion for the screw

head to fit through. If this is a drywall

doorframe, drill a hole for a #10 anchor or

molly and insert the anchor. Secure at the end

with supplied wood screw. Note that the photo

below shows the hole being drilled while the

extrusion is on the floor.

8. Route the loop cable and Ranger wires

through the top extrusion.

9. Use towelette to clean mating surface and

position top extrusion.

10. Remove adhesive backing from top extrusion

(including for wood and dry wall surfaces).

11. Press top extrusion against surface.

12. Remove the backing from the adhesive tape

on the right extrusion

13. Insert the bottom of the left extrusion into the

corner piece and shove downward. If

necessary, strike top of extrusion with hammer

to ensure extrusion enters corner piece.

14. Press the extrusion against the doorframe.

15. See the above steps for wood.

Installing the cap box

The cap box can be installed near the top of the

door, above a suspended ceiling, or inside a wall

next to the antenna. Antenna performance

degrades as you move the cap box further away

from the loop; the maximum separation distance is

4 feet.

1. Route the loop cable and receiver wires from

the extrusions to the cap box.

a. Measure the length of 1”x1” channel you

will need and cut the channel if necessary.

b. Cut a 1x1 square hole in the ceiling above

the adapter piece on the top corner of the

extrusion.

c. Feed the two ends of the loop cable and

the receiver wires through the channel.

d. Put channel through hole in ceiling.

e. Check the alignment of the 1x1 channel

and the antenna by attaching the adapter

piece to the extrusions and inserting the

1x1 channel. Do not peel the adhesive

backing on the adapter yet.

f. Peel the adhesive backing from the

channel and attach the 1x1 channel to the

wall.

g. Wipe the tops of the extrusions and

channels with a towelette.

h. Attach the adapter to the top of the 1x 1

channel. Tighten the screw on the adapter

to secure the channel.

AMS-3000 ANTENNA INSTALLATION GUIDE (8200-0179-02, REV. 0)

9 of 12

Page 10

Preliminary

i. The adapter may be attached directly to

the cap box or a short run of ¾” conduit

may be used between them. The total

distance from the extrusion to the cap box

may not exceed 1.2m (4 ft).

2. Install the cap box. The cap box is rated for

installation above the ceiling. The cap box

should be mounted directly above the corner

piece or in the wall next to the antenna.

a. Orient cap box one orientation only to

ensure screws go into stud and for ease of

reading tuning jumpers.

b. Fit cap box onto the adapter and screw in

fitting to hold cap box in place.

c. Mount the cap box to the wall using two

screws. Cover any open holes.

d. Install the cap board in the cap box.

e. The receiver wires pass through the cap

box but must be dressed in tie wraps

along the sides of the cap box.

3. Connect the loop cable to the cap box.

Pin P1-P2

1 Black

2 Red

3 Green

4 White

5 Ground

Connect antenna and receiver

wires to controller

The wires between the controller and the cap box

are Class 2 and Class 3 signaling wires. This

means they do not require conduit, but conduit or

Wiremold may be used to dress the cables.

1. Run the transmitter cable from the cap box to

the controller. Conduit may be used.

2. Connect the transmitter cable to the cap box.

Pin P3

1 Black

2 Red

3 Ground

3. Connect the conduit (if used) from the cap box

to the controller.

Connecting the remote alarm

The antenna requires either the remote alarm

(ZC30) or the message unit (ZC35). Mount the

remote alarm or message unit and connect it to the

controller. Refer to the appropriate controller

installation manual for information on mounting and

connecting these devices.

Configuring, tuning, and testing

When you tune the antenna, the goal is to have the

highest B field strength without exceeding the legal

limit. The B field strength is decreased by the

presence of metal (especially metal loops) in the

vicinity of the antenna. To compensate for this loss,

you can increase the field strength by increasing

the current in the antenna. Their are two ways to

increase the current in the antenna; you can adjust

the amount of capacitance on the cap board to

bring the antenna closer to resonance or you can

use the lap top configurator to change the output

current. Depending on the configuration of the

antenna and the environment, you may be able to

resonate the antenna and be within the legal limits

for the B-field or you may need to stop short of

resonance to avoid going over the limit.

The tuning process depends on whether you have

a B field meter.

• If you do not have a B field meter, you will

need to look up your antenna size and

configuration in the table below and then

tune the capacitor board until you reach

AMS-3000 ANTENNA INSTALLATION GUIDE (8200-0179-02, REV. 0)

10 of 12

Page 11

Preliminary

the maximum allowable current in the

antenna.

• If you have a B field meter, you will tune

the capacitor board until the B field

reaches its maximum allowable strength.

Because this is a more direct

measurement of the B field strength, you

should be able to put more current through

the antenna (and therefore get better pick)

than using the table.

The procedure below describes how to tune the

capacitor board.

WARNING: RISK OF ELECTRIC

SHOCK! Cap box contains high

!

1. Turn on the controller.

Configure controller to proper transmit/receive

mode for the AM Loop system

2. At the cap box, start the tuning procedure with

all of the capacitors out of the circuit.

voltage components. Avoid

touching other components when

moving the jumpers during tuning.

3) By removing jumpers, find the

combination that results in the

maximum current as displayed in the

configurator. The system is now tuned.

4) Find the loop size in the table below

that most closely matches the size of

your antenna and find out what is the

maximum allowable current.

5) Adjust the current using the

configurator and/or re-tune the Cap

PCB to arrive at the maximum

allowable current.

Loop Size

Width Height

5.5ft 9ft TBD

6ft 8ft TBD

5ft 8ft TBD

3ft 8ft TBD

6ft 7ft TBD

4. Test the system with a tag or label.

Maximum

allowable current

3. Tune the cap box by using either the B field

meter or the configurator.

a. If you have a B field meter, follow the

procedure below:

1) Set the current level in the configurator

to lowest setting.

2) Make sure all jumpers in the capacitor

board are in the “in” position.

3) By removing jumpers, find

combination that results in the

maximum current as displayed in the

configurator. The system is now tuned.

4) Look at the B-field meter reading in

the table below for the respective door

size. Adjust the current in the

configurator and/or re-tune the Cap

PCB as necessary to arrive at the Bfield meter reading required.

b. If you do not have a B field meter:

1) Set the current level in the configurator

to lowest setting.

2) Make sure all jumpers in the capacitor

board are in the “in” position.

AMS-3000 ANTENNA INSTALLATION GUIDE (8200-0179-02, REV. 0)

11 of 12

Page 12

Declarations

Regulatory Compliance

Emissions .......................... 47 CFR, Part 15

RSS 210

Safety UL1950

CSA C22.2 No 950

EN 60 950

FCC COMPLIANCE: This equipment complies with Part 15

of the FCC rules for intentional radiators and Class A digital

devices when installed and used in accordance with the

instruction manual. Following these rules provides reasonable

protection against harmful interference from equipment

operated in a commercial area. This equipment should not be

installed in a residential area as it can radiate radio frequency

energy that could interfere with radio communications, a

situation the user would have to fix at their own expense.

EQUIPMENT MODIFICATION CAUTION: Equipment

changes or modifications not expressly approved by

Sensormatic Electronics Corporation, the party responsible for

FCC compliance, could void the user's authority to operate the

equipment and could create a hazardous condition.

Preliminary

Other Declarations

WARRANTY DISCLAIMER: Sensormatic Electronics

Corporation makes no representation or warranty with respect

to the contents hereof and specifically disclaims any implied

warranties of merchantability or fitness for any particular

purpose. Further, Sensormatic Electronics Corporation

reserves the right to revise this publication and make changes

from time to time in the content hereof without obligation of

Sensormatic Electronics Corporation to notify any person of

such revision or changes.

LIMITED RIGHTS NOTICE: For units of the Department

of Defense, all documentation and manuals were developed at

private expense and no part of it was developed using

Government Funds. The restrictions governing the use and

disclosure of technical data marked with this legend are set

forth in the definition of “limited rights” in paragraph (a) (15)

of the clause of DFARS 252.227.7013. Unpublished - rights

reserved under the Copyright Laws of the United States.

TRADEMARK NOTICE: Sensormatic and the Sensormatic

logo are trademarks or registered trademarks of Sensormatic

Electronics Corporation. Wiremold is a registered trademark

of the Wiremold Company. Other product names mentioned

herein may be trademarks or registered trademarks of

Sensormatic or other companies.

No part of this guide may be reproduced in any form without

written permission from Sensormatic Electronics Corporation.

RWH 07/02

AMS-3000 ANTENNA INSTALLATION GUIDE (8200-0179-02, REV. 0)

12 of 12

Loading...

Loading...