Page 1

WORLD LEADER IN ELECTRONIC SECURITY

Installation Guide

1 ADS Floor•Max

Antennas

Abou t this Guid e

This installation guide explains how to install ADS

Floor•Max antennas. Ot her related docume nts

are:

Planning Guide, 8000- 2693- 01

•

Insta llat ion G uid e , ADS 2 16 Power Pa c k,

•

8000-2693-02

Setup and Service Guide, 8000-2693-xx

•

Reference G uide, 8000-2693-xx

•

Because placement of antenna components

Note:

depends on architect ural a nd customer requirements, your Sensormatic representative will supply

this information separately.

If you need assistan ce...

Call Sensormatic Custo mer Suppor t at :

1-800-543-9740

Limitation of Warranty

Contents

About this Guide................................................1

Limitation of Warranty........................................1

Antenna Overview.............................................2

Installation Requirements...................................3

Installi ng ADS Floor•Max Antennas.................... 7

Connecting Cond uit and Cables....................... 11

Antenna Tuning............................................... 15

Pouring the Concrete.......................................16

Specifications.................................................. 18

Declarations.................................................... 19

PREL IMINARY – 0 1/31/00

Any deviations from the materials or pr ocedures

spec ified herein shall void S ensormatic's war ranty

with the owner/buyer. In no event sha ll Sensormatic be liable for loss or damage caused by the

use of materials or procedures that do not meet

Sensormatic's specificat io ns .

Ultra•Max, Floor•Max, Sensormatic,

logo

are registered trademarks of Sensormatic Electronics

Corporation. Other product names (if any) mentioned herein

may be trademarks or registered trademarks of other

companies.

No part of this guide may be reproduced in any form without

written permission from Sensormatic Electronics Corporation.

© Copyright 2000. All rights reserved.

DOJ 01/00

and the

Sensormatic

8000-2693-04, R ev. A (19 pages)

ULTRA•MAX PRODUCTS 1

Page 2

S

A

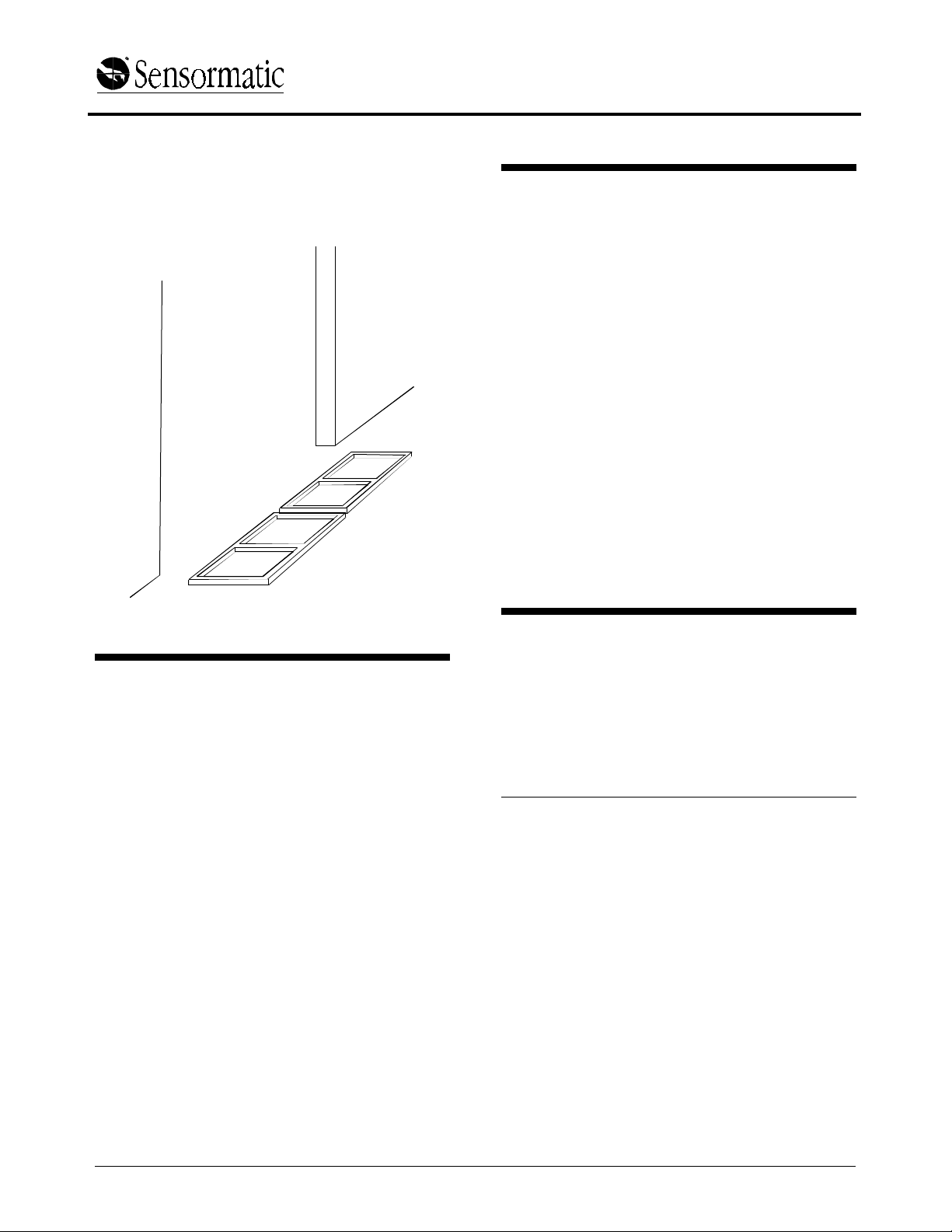

Antenna Overview

ADS Floor•Max antennas, positioned at an exit,

are part of an Ultra•M ax security label detector that

deters t heft . One or two ADS Floor•Max in-floor

antennas are attac hed to a power pac k through a

capacitor boar d enclosure.

Figure 1. ADS Floor•M ax Det ect or

Component Part Nu mbers

ADS Floor•Max 6' System

1 ADS Floor•Max Ante nna (ZSFLORMX-

−

ANT)

ADS Enc losure Ass e mbly (ZPF LORMX-

−

ENC)

RS232 Assembly (ZPFLO RMX- 232)

−

ADS Power Pack (ZEADS2 16 )

−

Power

pack

Cap board

enclosure

RS232

plate

ADS Floor•Max 12' System

2 ADS Floor•Max Ante nnas (ZSFLORMX-

−

ANT)

ADS Enc losure Ass e mbly (ZPF LORMX-

−

ENC)

Optional

remote

alarm

RS232 Assembly (ZPFLO RMX- 232)

−

ADS Power Pack (ZEADS2 16 )

−

ADS Floor•Max Antenna (ZSFLORMX-ANT)

In-floor

antennas

Install kit (0351-1696- 01)

−

Capacitor board ( 0301- 1536- 01)

−

Antenna (0300-2289-01)

−

ADS Floor•M ax Shield (ZPFLORMX-SH)

Shield tray - left (0300-9219- 01

−

Shield tray - right (0300- 9219- 02)

−

Shield tiles (0500-9216- 01)

−

2 INSTALLATION GUIDE

ADS FLO OR•MAX ANTENNA

8000-2693-04, REV.

Page 3

In st allation Requiremen ts

Verifying Equipment and Unpacking

Verify that all equipment has arri ved. Mak e

❑

sure the system configuration is the right one

for the installation site.

Unpack major components i n a back room. At

❑

the install site, lay out parts in the order you will

need them. Do not clutter the aisle or cause a

trip hazard.

The capacitor board is in a cardboard

Note:

sleeve taped to t he bottom of the ante nna

shipping box. The PVC leveli ng legs are inside

one of the cardboard support r ibs on the end of

the box.

Installer/Contractor

Shall have electrical work comply with the

❑

latest national electr ical code, national f ire

code, and all applicable local codes and

ordinances.

Shall coordi nate all work with other trades to

❑

avoid interfer ence.

Shall verify existing site conditions and

❑

coordinate w ith the owner’s representative and

appropriate utilit ies as requir ed.

Shall obtain copies of all related pla ns,

❑

specificatio ns, shop dr aw ings and addenda to

schedule and coordinate relat ed w or k .

Shall thoroughly re view the project t o ensure

❑

that all work meets or exceeds the above

requirements. Any alleged discrepa ncies shall

be brought to the attentio n of Sensormatic

Electronics.

Chemical Interaction

WARNING!

!

Do not install this product in hazardous

areas where highly combustible or

explosive products are stored or used.

Antenna Placement and Cabling

Whenever possible, keep t he antennas at least

❑

2.4m (8') away from noise sources suc h as

computer monitors, TV’s, switching power

supplies, a nd neon displays.

Maximum cable distance from the antennas to

❑

the capacitor board enclosure is 12.2m (40').

DO NOT splice antenna cables.

Maximum cable dista nce from the power pac k

❑

to the cap board enclosure is 2m (7').

WARNING!

!

DO NOT compromise the structural

integrity of the floor by cutting or removing

rebar. Contractors must obtain approval for

all proposed structural changes. All

structural changes must meet national and

local requirements.

CAUTION:

cost t o the in- floor instal lation, check detector per formance and label detection height at the exact

installation s ite. Do this BEFORE cutting the floor

and again BEFORE pouring the concrete.

❏

Loca te panels i nside the facilit y and as c lo s e to

exit doors as possible.

❏

To provide 1.8m (6') of coverage widt h per

panel, space panels no more than 25-30c m

(10-12") apar t. Spacing of 25cm (10") is

recommended.

❏

For On Grade installatio ns, the pane ls must be

between 3cm (1.25") and 5cm (2") below t he

surface of t he finished floor.

❏

For Off Grade installation, the pa nels must be

1.25cm (.5") below the surface of the finished

floor.

❏

For On Grade installatio ns, no metal such as

rebar or wire mesh should be located under or

adjacent to t he antenna. If metal is required, it

must be spaced great er than 21cm (8") from

the bottom and 31cm (12") in all other

directio ns from the antenna.

❏

For conduit runs, use 3/4-inch Electrical Metal

Tub i ng (EMT) or rigid conduit (

the maximum run not to exceed 10.5m (35') t o

allow adequate cable length for system

connectio ns. Some local codes requir e r igid

conduit instead of EMT for concrete burial.

Some local codes require steel hardwar e in

concrete to be coat ed by tape or paint before

burial.

❏

Use two separ at e conduit runs for each

antenna. Conduit r un must be a minimum of

20cm (8") fr om the antennas. Conduit ca nnot

cross above or below t he antenna. It must be

routed around the perimeter .

To avoid adding sig nificant time a nd

not plastic

) with

ADS FLO OR•MAX ANTENNAS

8000-2693-04, Rev . A

INSTALLATION GUIDE 3

Page 4

S

A

❏

All conduit fittings must be rain/concrete tight. A

3/4-inch EMT fitting is s upplied with the

antenna. A rigid 3/4-i nch rain/concrete tight

fitt ing may be substituted. Wrap t hreads w ith

four turns of Teflon pipe tape.

❏

Minimize underground conduit couplings to

prevent moisture i ntrusion.

❏

Hi gh stre ngth, non-me tallic, non-shrink

mortar/ concret e w it h a compressive strength of

5000 psi is required.(For example, FX- 228

mortar mix and FX-752 bondi ng agent by Fox

Industries)

❏

Mort ar cure time depends on the mix and

temperature of t he mortar ingredients.

❏

Avoid walking on antenna cables duri ng

installation.

❏

Heavy forklifts can pass over the mortar after

24 hours, provided the mortar is protected by

3/4-inch steel plates.

Have on hand tools and equipment necessary

❑

to place the mortar once it is mixed.

Enclosure

❏

Mount the cap board enclosure as close to t he

power pack as possible. M aximum dista nce

from the power pack to the enclosure is 2m (7').

Install a heater in enclosures i n sub-fr eezing

❑

environments.

If conduit is not used, use Romex connectors

❑

wherever cables enter the power pack and

capacitor boar d enclosure.

Tools and Equipmen t Required

For all ADS Floor•Max system inst al latio ns:

6 mil (minimum) plastic sheeting ( t o pr ot ect

•

nearby items from dust)

Chalk or red permanent marker

•

Floor saw

•

PVC pipe cutter or hacksaw

•

Hammer dr ill with 6.5mm (1/ 4" ) and 9. 6 m m

•

(3/8") masonry d rill bit s

Pow er dr ill wit h 1. 6mm ( 1 /16"), 6.5mm (1 /4") ,

•

and 9.6 mm (3/8") d rill bit s

Hammer

•

Phillips and slotted screwdrivers

•

14-16 AWG and 16-22 AWG wire strippers

•

Ratchet a nd socket set

•

Vacuum and broom

•

Wet vacuum

•

Level

•

Electrical tape

•

Teflon pipe tape

•

Caution tape

•

Duct tape

•

4 INSTALLATION GUIDE

ADS FLO OR•MAX ANTENNA

8000-2693-04, REV.

Page 5

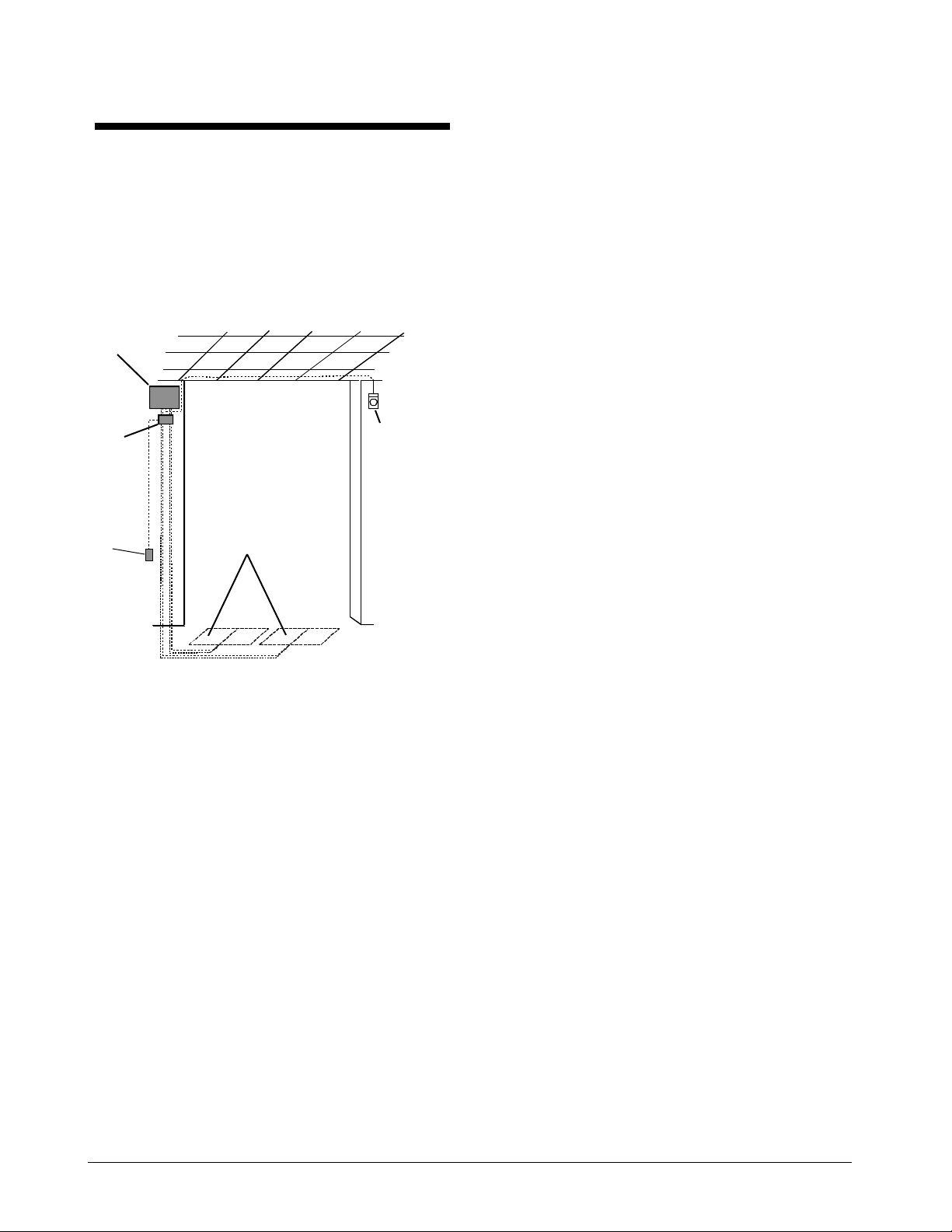

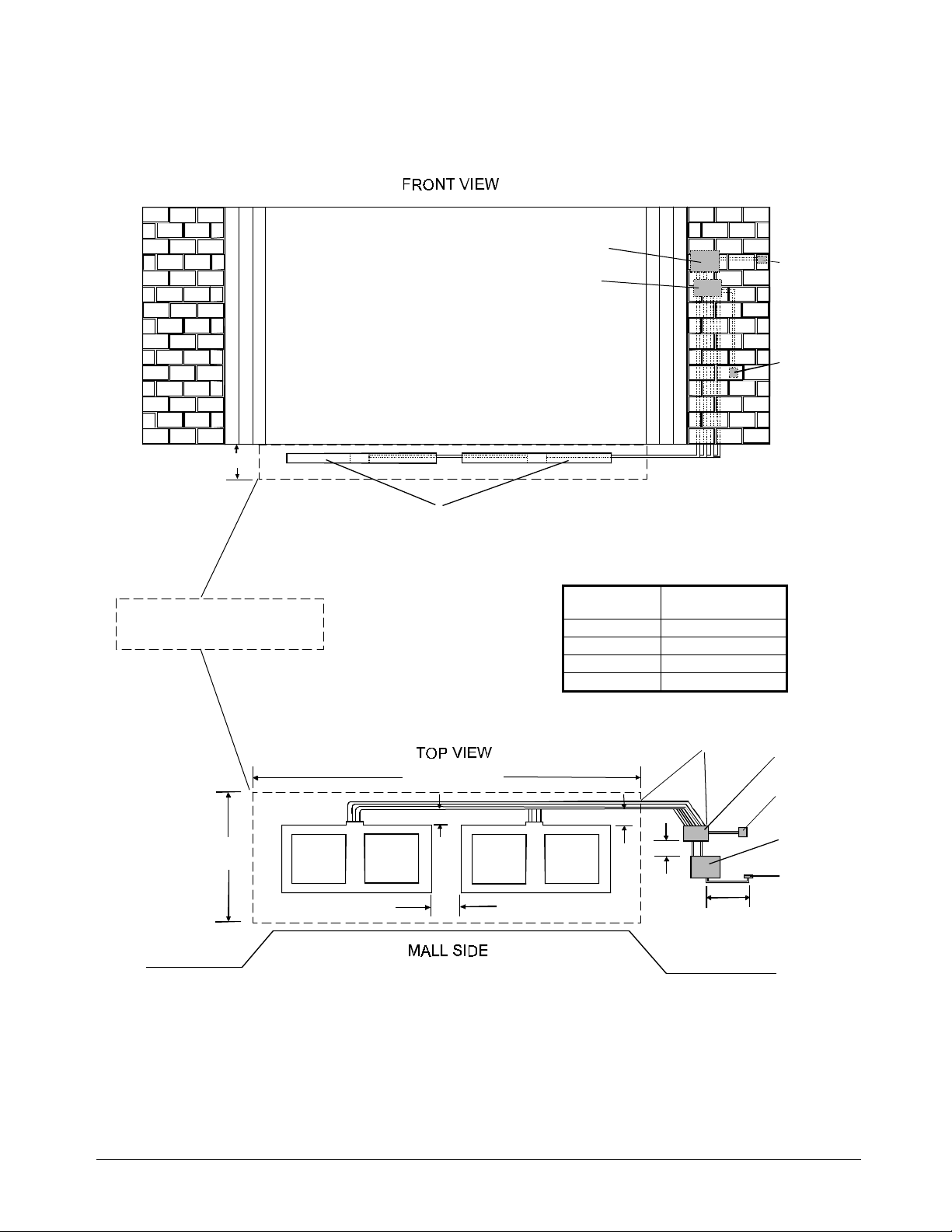

Figure 2. “O n G r ade” inst allation diagr am

25cm (10")

Power pack

Cap board

enclosure

Remote

alarm

RS232

plate

(3cm (1.25") min to 5cm (2") max below surface of floor)

No metal rebar or wire mesh

within 21cm (8") of bottom and

31cm (12") of sides of antenna

1.29m

(4' 3")

Antennas

3.98m (13' 1")

[a]

[c]

No. of

antennas

Length of

excavation

1 2.18m (7' 2")

2 3.98m (13' 1")

3 5.80m (19' 0")

4 7.61m (24' 11")

Conduit run

10.5m (35') max

[a]

[b]

7.5m (25') max

[a] - 20cm (8") min

[b] - 2m (7') max

[c] - 25cm (10")

Cap board

enclosure

RS232

plate

Power

pack

Remote

alarm

ADS FLO OR•MAX ANTENNAS

8000-2693-04, Rev . A

INSTALLATION GUIDE 5

Page 6

S

A

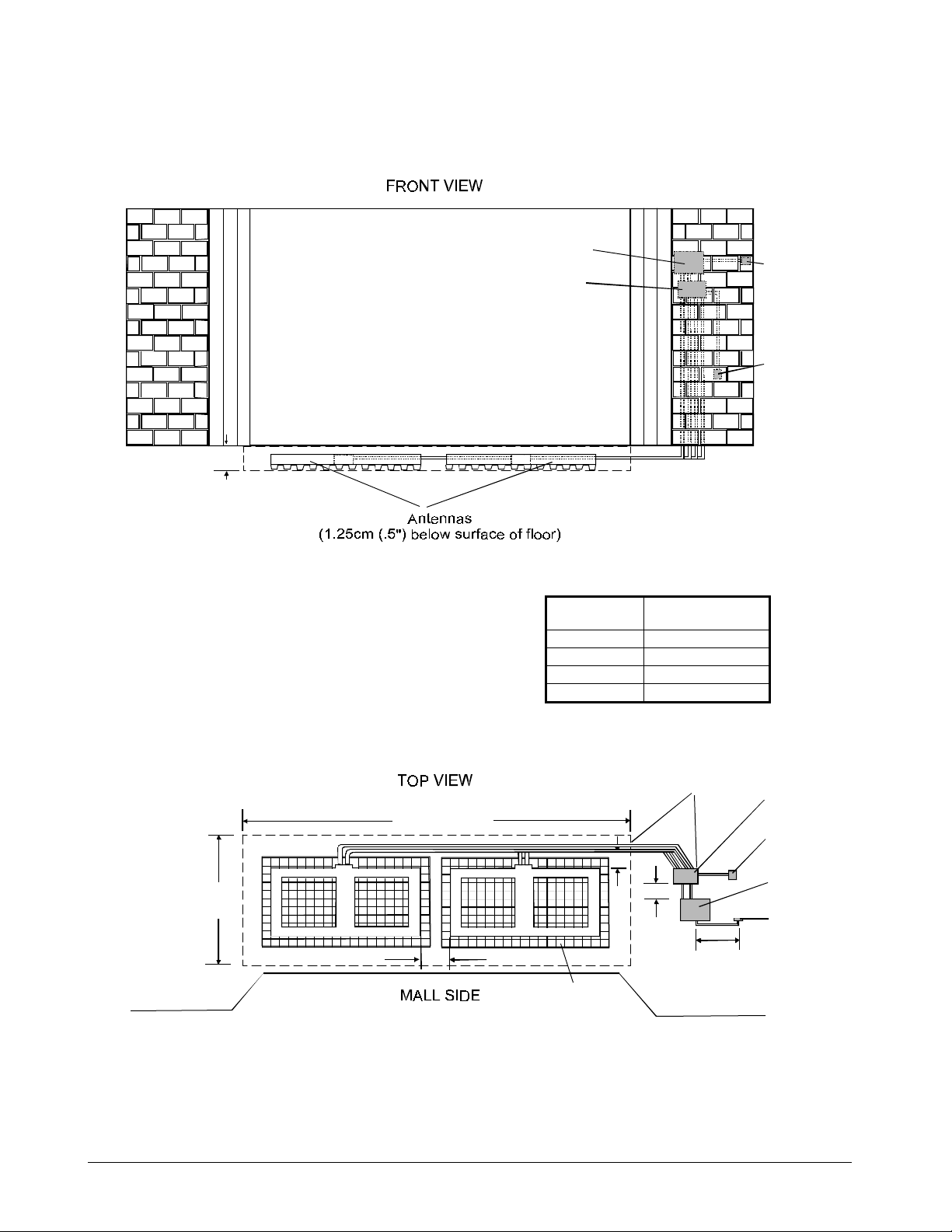

Figure 3. “O f f Gr ade” installation d iagram

5cm (2")

Power pack

Cap board

enclosure

Remote

alarm

RS232

plate

No. of

antennas

Length of

excavation

1 1.91m (6' 3")

2 3.93m (12' 11")

3 5.95m (19' 6")

4 7.96m (26' 2")

Conduit run

10.5m (35') max

Cap board

3.93m (12' 11")

enclosure

RS232

plate

Power

pack

Remote

1.14m

(3' 9")

[a]

[b]

alarm

[c]

7.5m (25') max

[a] - 20cm (8") min

Shield

tiles

[b] - 2m (7') max

[c] - 25cm (10")

6 INSTALLATION GUIDE

ADS FLO OR•MAX ANTENNA

8000-2693-04, REV.

Page 7

In st alling ADS Floor•Max

Antennas

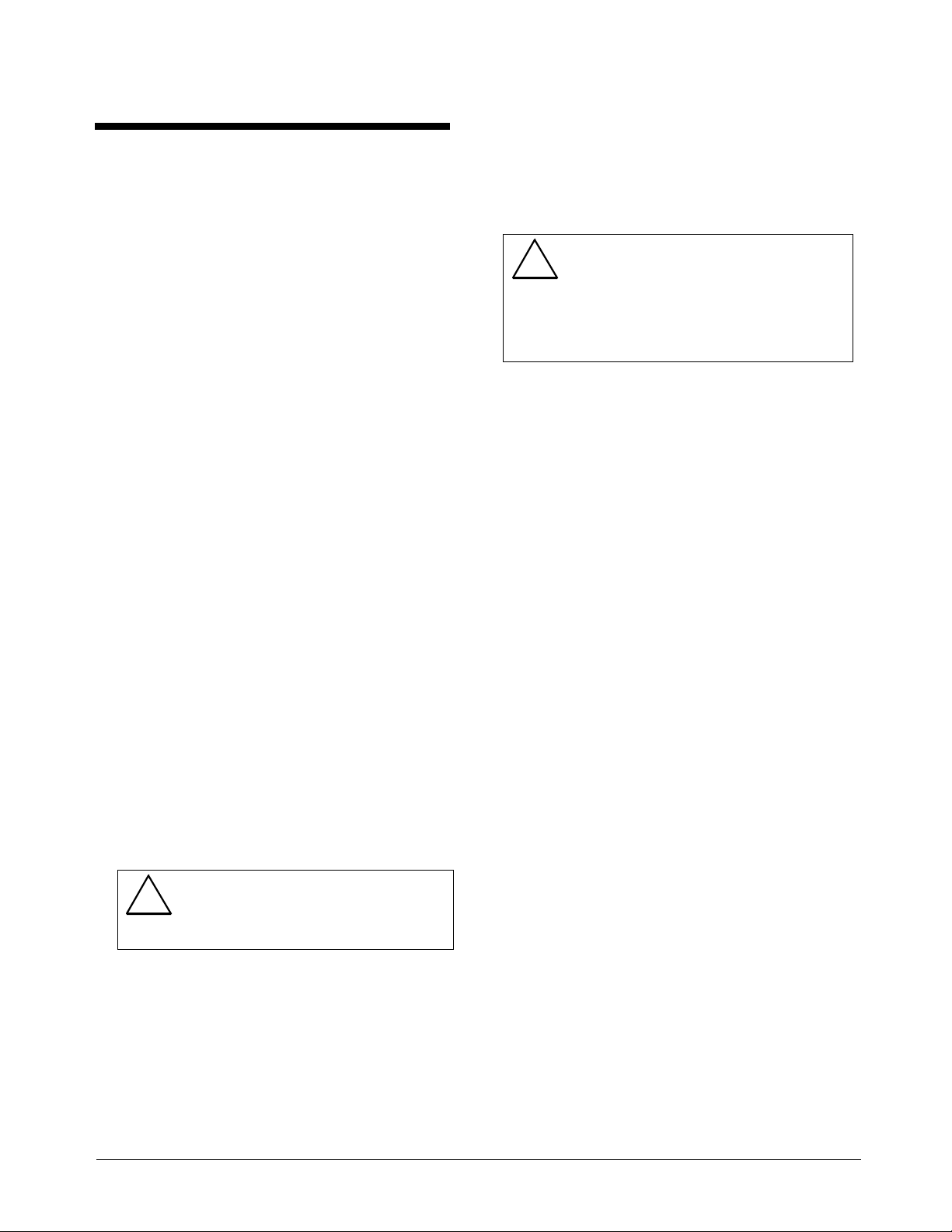

1. Lay out ADS Floor •M ax ant ennas as shown

for proper ant e nna phasing (Figure 4) .

Loca te panels i nside the facilit y and as c lo s e to

exit doors as possible.

DO NOT space antennas more than 25-30c m

(10-12") apar t. Spacing of 25cm (10") is

recommended.

The flat side of the cable entry neck must face

up.

Figure 4. ADS Floor•M ax ant e nna

orientation for pr oper phasin g

Front view of antenna

showing flat side of

neck facing up.

2. Det er mine t he place ment of conduit runs

(Figure 5).

Two separat e conduit r uns ar e r equired f or

each antenna.

Conduit must ter minate at the capacitor

board enclosur e f or pr oper gr ounding.

Figure 5. Antenna w ith conduit att ached

Top view

Ant. 2

CAUTION:

Ant. 1

To avoid adding sig nificant time a nd

cost t o the in- floor instal lation, check detector per formance and label detection height at the exact

installation s ite. Do this BEFORE cutting the floor

and again BEFORE pouring the concrete.

ADS FLO OR•MAX ANTENNAS

8000-2693-04, Rev . A

INSTALLATION GUIDE 7

Page 8

S

A

3. Mark excavation locati on on f loor. Ref er t o

Figure 2 or Figure 3 for r ecommended

length and width of excavat ion.

a. With each antenna in place, use a chalk

line or wide tip red per manent marker to

trace an outline around the outside of t he

antenna and conduit. Also tr ac e the conduit

route from the antenna back to the cap

board enclos ure (Fig ure 6).

b. Remove the antennas.

c. Spray all floor markings with clear lacquer

to prevent erasure during t he floor

excavation process (next).

4. Excavat e t he f loor ( Figure 7) .

a. Usi ng a concret e saw , cut along the

outline.

For “On Grade” installation, cut down to grade.

For “Off Grade” installation, cut to a minimum

depth of 5cm (2").

WARNING!

!

DO NOT compromise the structural

integrity of the floor by cutting or

removing rebar. Contractors must obtain

approval for all proposed structural

changes. All structural changes must

meet national and local requirements.

Figure 6. Mar king the excavat ion lo cat ion

b. Usi ng the specified chipping hammer,

break up the floor and remove the

concrete.

Fiberglass reinfor ced plast ic (FRP) r ebar

Note:

can be used in the excavati on to prevent

cracking and settling. Drill 9/ 16" diameter holes

and dowel the rebar into the sides of the

exca vat ion. Do wels sho u ld be insta lled in the

holes using concrete adhesive. Refer to

Figure 8.

c. Remove all debris fr om the c hannels usi ng

water and a wet vacuum.

Figure 7. Excavatin g t he f loor

8 INSTALLATION GUIDE

ADS FLO OR•MAX ANTENNA

8000-2693-04, REV.

Page 9

Figure 8. FRP rebar instal lat io n

“On Grade” installation

For “Of f G rade” installations, pr oceed t o “Off

Grade” Installati on on page 10

Existing slab

Existing deck

Existing steel beam

31cm

(12")

min

“Off Grade” installation

31cm

(12")

min

25cm

(10")

FRP reinforcing bars

spaced at 31cm (12") on center

25cm

(10")

FRP reinforcing bars

spaced at 31cm (12") on center

Floor•Max

antenna

Floor•Max

antenna

“On Grad e” Installatio n

5. Assemble the antenna suppor t s, if needed.

(Figure 9).

Insert eight support rods into the antenna

support holes in the antenna.

Figure 9. Antenna w it h support rods

Support

rod

6. Level the gr ound under neath t he ant enna

and place the antenna wit h suppor t r ods

into the pit.

The antenna must be a minimum of 3cm (1.25")

and a maximum of 5c m (2") below t he surface

of the finished floor.

Figure 10. Placing supp or t s and assemb ly

31cm (12")

on center

ADS FLO OR•MAX ANTENNAS

8000-2693-04, Rev . A

Top view

31cm

25cm

(12")

(10")

min

INSTALLATION GUIDE 9

Page 10

S

A

7. If necessar y, cut the ant enna suppor t r ods

so that t he ant enna is level (Figure 11).

a. For each support rod, measure the depth of

the excavation from the s urface of the

finished floor.

b. Cut the suppor t r od to t he lengt h of t he

depth of the excavation minus the dept h of

the antenna (3cm (1.25") t o 5cm (2")).

Figure 11. Cutt ing the suppor t r ods

“Off Grade” Installation

5. Smooth the surface in the bottom of the pit.

Remove any peaks or valleys in the bottom of

the pit s o that the tr a y will be s uppor ted firmly.

6. Assemble the tray.

Place the two halves of the tray toget her and

secure with duct tape on the outside of the

bottom of the tray.

Length of rod =

depth of excavation

minus depth of

antenna

Finished floor

Depth of

excavation

Proceed to “Connecti ng Conduit and Cables”

on page 11.

7. Place the tray in the pit.

Orient the tray so that the cutout is on the side

where the cond uit attaches to the antenna.

8. Place ti les on tr ay.

Completely cover the bottom of the tray with

closely packed tiles. Begin placi ng t iles alo ng

the center line of the tray . Work fr om the center

to the outside of the tray. Refer to Figure 12.

9. Place the ant enna on t ile s.

Place the antenna on the tiles so that the

conduit ho using is over the cutout in the tray

and the antenna is centered over the tiles.

Figure 12. Placing til es on t r ay

Center line

10 INSTALLATION GUIDE

ADS FLO OR•MAX ANTENNA

8000-2693-04, REV.

Page 11

Connecting Conduit and

Cables

d. Insert Tx/Rx cable for panel A into

pluggable terminal block Tx/Rx A; insert

transmit cable for panel B into pluggable

terminal block Tx/Rx B.

1. Attach conduit to t he ant enna and pull the

antenna cables ( Figure 5) .

a. Lay out 3/4-inch EMT or rigid conduit from

the antenna to the cap board enclosure.

Two separat e conduit r uns ar e r equired

for each ant enna.

Conduit must ter minate at the capacitor

board enclosur e f or pr oper gr ounding.

b. For DIY installatio ns, lay out conduit from

the power pack t o the capacitor board

enclosure. M aximum conduit r un from the

power pack to the enclosure is 2m (7').

c. Pull t he antenna cables fr om the antenna

to the enclosure.

d. Label the cables indicating the location of

the attached in-floor panel for future

servicing.

e. Attach all conduit and tighten all conduit

connectors. Use only rai n/concrete t ight

EMT or rigid connectors.

f. Ground the conduit t o an earth ground by a

code-approved method suc h as a clamp.

WARNING—RISK OF ELECTRIC

SHOCK!

Failure to ground correctly could cause

shock risk.

2. Connect Tx/ Rx cables (5 conductor ) t o t he

power pack (Figure 15).

WARNING:

the power pack bef or e connecting cables.

a. Install Romex-type connect or s or conduit

fittings in knockouts on pack.

b. Route each Tx/Rx cable through knocko ut.

c. Using a small screw dr iver, attach Tx/Rx

cables to connectors 2109- 0351- 05

accordi ng to the followi ng table:

Do NOT hot plug cables. Turn off

Pin 1 - Black

Pin 2 - Red

Pin 3 - Green

Pin 4 - White

Pin 5 - Shield

3. Connect Com cables (10 conduct or) t o t he

power pack.

a. Route each Com cable through knockout.

b. Usi ng a small screw dr iver, at t ach

connectors 2109-0510-10 to each Com

cable following the color- coded label.

Pin 1 - Black

Pin 2 - Brown

Pin 3 - Red

Pin 4 - Ora nge

Pin 5 - Yellow

Pin 6 - Green

Pin 7 - Blue

Pin 8 - Violet

Pin 9 - Gr ay

Pin 10 - Shield

c. Insert connectors i nto pluggable t er mi nal

blocks on the power pack. Connect panel A

to Com A; connect panel B to Com B.

CAUTION:

cables for a panel are attac hed to

corresponding connectors. Incorrect

connecti ons w ill c ause i nco r rect alarm

signaling.

4. Determine whether the capacitor board

enclosure will be mounted ver t ica lly or

horizontally. Refer t o Figure 13. Identif y

correct knockout locations for ant enna

conduit and connect io n to power pack.

5. Mount cap board enclosure cl ose t o power

pack.

Mount with 3/16" Tapco ns® on masonry wall or

#10 self-t apping screws with anchors o n

drywa l l. Mountin g ha rd ware i s not supp lied.

6. M ount capacit or boar ds in enc losure and

pull cables from pack t o enclosure.

7. M ount RS232 plate and pull cable from

enclosure t o RS232 plate.

The RS232 plate can be mounted on the side

of the cap board enclosure or remotely usi ng a

standard duplex junction box.

Be sure the Tx/Rx and Com

ADS FLO OR•MAX ANTENNAS

8000-2693-04, Rev . A

INSTALLATION GUIDE 11

Page 12

S

A

8. Connect RS2 32 cable to cap boar d and

RS232 plate.

a. Connect the 8 conductor cable to P3 - cap

board A and the 2 conductor cable to P4 cap board B.

b. Cut cable to length leaving sufficie nt slack

to connect to RS232 plate.

c. Remove 6" to 8" of the outer jacket. Strip

all conductors 1/8". Insert shrink tub ing

over drain wire to pr event shorting of

printed circuit board.

d. Connect to connector 2109-0510- 10 in t he

RS232 plate following t he color-coded

label.

Pin 1 - Black

Pin 2 - Brown

Pin 3 - Red

Pin 4 - Ora nge

Pin 5 - Yellow

Pin 6 - Green

Pin 7 - Blue

Pin 8 - Violet

Pin 9 - Gr ay

Pin 10 - Shield

Pin 1 is on t he right end of the connector as

you look at the rear of the RS232 plate.

9. Connect power pack com cable to cap

board.

a. Route cable through knockout.

b. Usi ng a small screw dr iver, at t ach

connectors 2109-0510-10 to each Com

cable following the color- coded label.

Pin 1 - Black

Pin 2 - Brown

Pin 3 - Red

Pin 4 - Ora nge

Pin 5 - Yellow

Pin 6 Green

Pin 7 Bl ue

Pin 8 V iole t

Pin 9 G ray

Pin 10 Shield

c. Insert connectors i nto pluggable t er mi nal

blocks on cap board. Co nnect panel A to

P2 on cap board A; connect panel B to P2

on cap board B.

10. Connect antenna coil cables to cap board.

Use a separate conduit and knockout f or

each coil start and f inish pair (t wo per

antenna). Refer to Figure 15.

a. Route each antenna cable pair thro ugh

knockout and secure away f r om cap board

with cable cla mps located on partition and

sidewall.

b. Attach panel A to TB1-TB4 on cap board A;

attach panel B to TB1-TB4 on cap board B.

Attach using the followi ng table:

TB1 - Bottom coil start ( black)

TB2 - Bottom coil finish (white)

TB3 - Top coil start ( black)

TB4 - Top coil fi nish (white )

CAUTION!

!

For proper operation and reliability,

connect the large diameter, white, coilfinish cables to TB2 and TB4 only.

c. Att ach ground w ires from enclosure

chassis to TB5 on cap boards A and B.

11. Connect power pack T x/ Rx cable to cap

board.

a. Route each Tx/Rx cable through knocko ut

and secure away fr om cap board with cable

clamps located on partitio n and sidewal l.

b. Usi ng a small screw dr iver, at tach Tx/Rx

cables to connectors 2109- 0254- 04

according to the following table:

Pin 1 - Black

Pin 2 - Red

Pin 3 - Green

Pin 4 - White

Pin 5 Shield

c. Insert Tx/Rx cable for pane l A into

pluggable ter minal block P1 o n cap board

A; insert Tx/Rx cable for panel B into

pluggable ter minal block P1 o n cap board

B.

Proceed to “Antenna Tuning” on page 15.

12 INSTALLATION GUIDE

ADS FLO OR•MAX ANTENNA

8000-2693-04, REV.

Page 13

Figure 13. Cap board enclosure

V

ertically mounted

F

B

C

H

E

J

Horizontally mounted

A

C

B

F

H

G

E

I

A

D

I

J

A - Mounting holes

G

B - Power pack Tx/Rx cable entry

C - Power pack Com cable entry

D - Antenna coil cable entry

D

E - RS232 plate mounting location

F - Power pack Tx/Rx and Com cable

entry to other compartment

G - Antenna Tx/Rx cable entry to other

compartment

H - RS232 cable entry to other

compartment

I - Cable supports

J - Ground wire (connect to TB5)

Figure 14. Capacit or boar d 0301- 1536- 01

Tuning jumpers

JW1 – JW7

ADS FLO OR•MAX ANTENNAS

8000-2693-04, Rev . A

TB1 TB2 TB4 TB3

Bottom Bottom Top Top

Start Finish Finish Start

P1 - TB5

Tuning jumpers Tuning jumper LEDS

JW8 – JW14 DS1 – DS7 DS8 – DS14

P4

P2 –

Com

P3

Tx Off Check

LED Tuning button

INSTALLATION GUIDE 13

Page 14

S

A

Figure 15. Wiring d iagram

)

(Cap

)

(Cap

)

(Cap

)

(Cap

)

P8

ADS

Alarm

ADS Power Pack

P2

10 9 8 7 6 5 4 3 2 1

SHLD

GRY

VIO

BLU

P1

SHLD

WHT

GRN

RED

1 2 3 4 5

BLK

P14

RS485

GRN

YEL

P10

Noise

Coil B

ORG

RED

BRN

Noise

Coil A

BLK

Cap Box

P4

P2

P3

A

TB5 TB5

TB3

TB4

P1

TB2

TB1

P17

P9

Option

1

P2

P4 P3

B

TB3

TB4

P1

TB2

TB1

P18

Option

2

P12

Option

3

P11

Ferrite

P13

Relay

A-B

1 2 3 4 5 6 7 8 9 10

BLK

BRN

RED

P4

2 1

SHLD

GRY

P3

8 7 6 5 4 3 2 1

VIO

BLU

GRN

YEL

ORG

RED

BRN

. Board B

P2

. Board B

P7

Tx/Rx

Com

Ped. B

Ped. B

Com

ORG

YEL

GRN

BLU

VIO

GRY

P3

(Cap. Board A)

(Cap. Board B)

1 2 3 4 5 6 7 8 9 10

BLK

BLK

P1

P2

. Board A

P5

P6

Com

Ped. A

SHLD

P4

2109-0510-10

BRN

RED

ORG

YEL

GRN

P1

. Board A

P4

Tx/Rx

Ped. A

Tx/Rx

1 2 3 4 5

BLK

RED

GRN

RS232

Plate

BLU

VIO

GRY

WHT

SHLD

SHLD

Bottom Coil Start

Bottom Coil Finish

To p Coil Start

To p Coil Finish

A

14 INSTALLATION GUIDE

TB1 (Cap. Board A

TB2 (Cap . Boa rd A)

TB3 (Cap . Boa rd A)

TB4 (Cap . Boa rd A)

Floor•

Max

Bottom Coil Start

Bottom Coil Finish

To p Coil Start

To p Coil Finish

Floor•

B

Max

TB1 (Cap . Boa rd B)

TB2 (Cap . Boa rd B)

TB3 (Cap . Boa rd B)

TB4 (Cap . Boa rd B)

ADS FLO OR•MAX ANTENNA

8000-2693-04, REV.

Page 15

Antenna Tuning

The antenna is shipped with default settings that

are acceptable f or most installations. However, the

antenna may require tuning to adjust f or conditions

at the installation site.

The antenna is tuned by changing jumper set t ings

on the capacitor boards in the enclos ure. The

power pack assist s tuning by lighting LEDs to

indicate the correct jumper settings.

To tune the antenna, do the following for eac h

antenna:

1. If necessar y, turn off the power pack.

6. Change the ju mpers on t he capacitor board

to the set t ings indicated by the yellow LE Ds

on the capacitor board. Refer t o Figure 14.

WARNING—RISK OF ELECTRIC

SHOCK!

The green Tx Off LED on the capacitor

board must be ON before changing

jumpers. It indicates there are no high

voltages on the board.

If a yellow jumper LED is on, place the

corresponding jumper in the 1-2 position.

If a yellow jumper LED is off, place the

corresponding jumper in the 2-3 position.

2. Access the capacitor boar d i n t he

enclosure.

3. M ake sur e t he jumpers are set t o the

defaults.

JW1 -

JW2 -

JW3 -

JW4 -

JW5 -

JW6 -

JW7 -

JW8 -

JW9 -

JW10 -

JW11 -

JW12 -

JW13 -

JW14 -

7. Pr ess t he Check T uning but t on on t he

capacitor board and ret ur n t o st ep 5.

After repeating steps 5 and 6 several times, the

antenna should be tuned with t he green status

LED on continuously. If not, c onta ct

Sensormatic Customer Service.

4. Turn on the power pack.

5. Check the gr een st at us LED on the RS232

plate.

If the green st at us LED is ON continuousl y,

the antenna is tuned.

If the green st at us LED is blinking, the

antenna needs tunin g. Pr oceed t o st ep 6.

ADS FLO OR•MAX ANTENNAS

8000-2693-04, Rev . A

INSTALLATION GUIDE 15

Page 16

S

A

Pouring the Concrete

Figure 16. Adding t he f inal layer

CAUTION:

To avoid adding sig nificant time a nd

cost t o the in- floor instal lation, check detector per formance and label detection height at the exact

installation s ite. Do this BEFORE cutting the floor

and again BEFORE pouring the concrete.

1. Prepare the high-str engt h mort ar mix. FX-

228 by Fox Industries is recom men ded but

not required.

Fox products may be replaced by other mortar

materials as long as they have a compressi ve

strength of 5000 psi and contai n no ferrous

metal. For product specif icat io ns, call Tec hnical

Support.

CAUTION:

Work t ime is greatly reduced at

temperatures abo ve 80°F. Comp lete mort ar

placement w ithin the time specified.

2. Rough up the surface and work mortar int o

the sawed face of t he concr et e to promote

bonding and hand sho vel mort ar ar ound all

support r ods bef or e f illing the rest of th e

pit.

CAUTION:

Bottom of ante nnas must be 100%

supported by mortar— NO VOIDS! Do not lift

antenna assemblies o nce they have been

placed in the mortar.

3. Complete ly fil l the pit with additional

mortar. Apply the final layer by t r oweling it

into place (Figure 16) .

CAUTION:

Use only a small amo unt of water

when trow eling the final top surface to avoid

potential shrinkage cracks. Do not over trow el doi ng so will entra p air or le ave b lis ters in the

mortar.

16 INSTALLATION GUIDE

ADS FLO OR•MAX ANTENNA

8000-2693-04, REV.

Page 17

4. Using a garden sprayer, t hor oughly coat the

surface of t he concr et e with curing

compound (ref er back t o Figure 16) .

Wait five minutes for the compound to set.

5. Protect the installation f or at least 72 hour s.

After the initial set, cover mortar with 1.3cm

(1/2") plyw ood in retail installations and 2cm

(3/4") steel plates in DIY installatio ns.

NOTE:

the installation to warn of potential trip hazards.

After 24 hours

installation can be opened to pedest r ia n traf fic.

After 72 hours

plastic sheeti ng. The floor is now ready for the

desired floor coveri ng (tile, car pet , wood, etc. ).

Figure 17. Protecting the installatio n

Place signs and cautio n tape around

—The wood prot ec t ed

—Remove the steel plate a nd

Use caution tape

on edges of

wood or steel trip

hazard

STOP!

Wai t at least 24 hour s before

allowi n g fo rklift tr affic o ver the

steel plates.

Wai t 72 hour s before removing

the plates.

ADS FLO OR•MAX ANTENNAS

8000-2693-04, Rev . A

INSTALLATION GUIDE 17

Page 18

S

A

Specifications

Electrical

Power Supply (Non-European Power Pack)

Primary Input: ...................100-120Vac or

220-240Vac

@ 50–60Hz

Primary Power Fuse:.........5A, 250V slo-blow

Current Draw:...................2.0A peak

Input Power:.....................<180W

Transmitter

Outputs:............................2 ports (two antennas,

multiplexed)

Operating Frequency:........58 or 60kHz (±200Hz)

Transmit Burst Duration.....1.6ms

Transmit Current: ..............16A peak

Burst Repetition Rate:

Based on 50Hz ac.............37.5Hz (Normal)

75 Hz ( Va lidatio n)

Based on 60Hz ac.............45Hz (Normal)

90 Hz ( Va lidatio n)

Environmental

Amb ient Temperature:.......0°C to 50°C

(32°F to 122° F)

Relative Humi dity:............. 0 to 90%

non-condensing

Mechanical

ADS Floor•Ma x Pane l

Length..............................156cm (61 ¼")

Width................................67cm (26 ½")

Depth...............................2cm (.9")

Weig ht..............................kg (lbs.)

Antenna Shield

Length..............................180cm (71")

Width................................91cm (36")

Depth...............................3cm (1.3")

Weig ht..............................kg (lbs.)

Capacitor Board Enclosure

Length..............................47.5cm (18.7")

Width................................37.8cm (14.9")

Depth...............................8.5cm (3.3")

Weig ht..............................kg (lbs.)

Receiver

Inputs:..............................2 ports (two antennas,

multiplexed)

Center Frequency:.............58 or 60kHz

Receive Coil Resistance:...1.6 ohms (±5%)

Alarm

Alarm Relay Output...........DPDT contacts

Contact Switching Current .1.0A max.

Contact Sw itching Voltage .28V max.

Lamp/Audio Duration.........1–30 sec.

(1 sec. increments)

RS232 Plate

Height .............................. 11.5cm (4.5")

Width................................7cm (2.7")

Depth...............................1.7cm (.7")

Weig ht..............................kg (lbs.)

18 INSTALLATION GUIDE

ADS FLO OR•MAX ANTENNA

8000-2693-04, REV.

Page 19

Declarations

Regulatory Compliance (NonEuropean Power Pack)

Safety:............................UL 1950

Can/ CSA C22.2

No. 950

EMC:..............................47 CFR, Part 15

FCC COMPLIANCE:

15 of the FCC rules for intentional radiators and Class A

digital devices when installed and used in accordance with the

instruction manual. Following these rules provides reasonable

protection against harmful interference from equipment

operated in a commercial area. T his equipment should not be

installed in a residential area as it can radiate radio frequency

energy that could interfere with radio communications, a

situation the user would have to fix at their own expense.

EQUIPMENT MODIFICATION CAUTION:

changes or modifications not expressly approved by

Sensormatic Electronics Corporation, the party responsible for

FCC compliance, could void the user's authority to operate the

equipment and could create a hazardous condition.

This equipment complies with Part

Equipment

Other Declarations

WARRANTY DISCLAIMER:

Corporation makes no representation or warranty with respect

to the contents hereof and specifically disclaims any implied

warranties of merchantability or fitness for any particular

purpose. Further, Sensormatic Electronics Corporation

reserves the right to revise this publication and make changes

from time to time in the content hereof without obligation of

Sensormatic Electronics Corporation to notify any person of

such revision or changes.

LIMITED RIGHTS NOTICE:

of Defense, all documentation and manuals were developed at

private expense and no part of it was developed using

Government Funds. The restrictions governing the use and

disclosure of technical data marked with this legend are set

forth in the definition of "limited rights" in paragraph (a) (15)

of the clause of DFARS 252. 227.7013. Unpublished - rights

reserved under the Copyright Laws of the United States.

Sensormatic Electronics

For units of the Department

ADS FLO OR•MAX ANTENNAS

8000-2693-04, Rev . A

INSTALLATION GUIDE 19

Loading...

Loading...