Page 1

Planning Guide for Beta Test

Scan-Thru

™

Platform

Proximity Deactivator

ZBSTP-PK-1 Power Pack

ZBSTP-PP Power Pad Antenna

Contents

About this Guide.................................................... 1

About the Deactivator............................................ 2

IMPORTANT SAFEGUARDS...............................5

Pre-Install Preparation ..........................................5

Specifications........................................................9

Declarations ........................................................ 10

About this Guide

This guide explains installation configurations,

requirements, and specifications for the Scan-Thru

Platform (STP) proximity deactivator. Other related

documents are:

• Installation Guide, 8000-2599-02

• Setup and Service Guide, 8000-2599-11

Note: The exact placement of the deactivator will

depend on customer requirements. See your

Sensormatic representative for this information.

If you need assistance...

Call Sensormatic Customer Support at:

1-800-543-9740

Scan-Thru, Sensormatic, and the Sensormatic logo are

registered trademarks of Sensormatic Electronics Corporation.

Other product names (if any) mentioned herein may be

trademarks or registered trademarks of other companies.

No part of this guide may be reproduced in any form without

written permission from Sensormatic Electronics Corporation.

© Copyright 1998. All rights reserved.

MDR 12/98

8000-2599-01, Rev. A (10 pages) DEACTIVATION PRODUCTS 1

Page 2

STP POWER PAD DEACTIVATOR

8000-2599-01, Rev. A

About the Deactivator

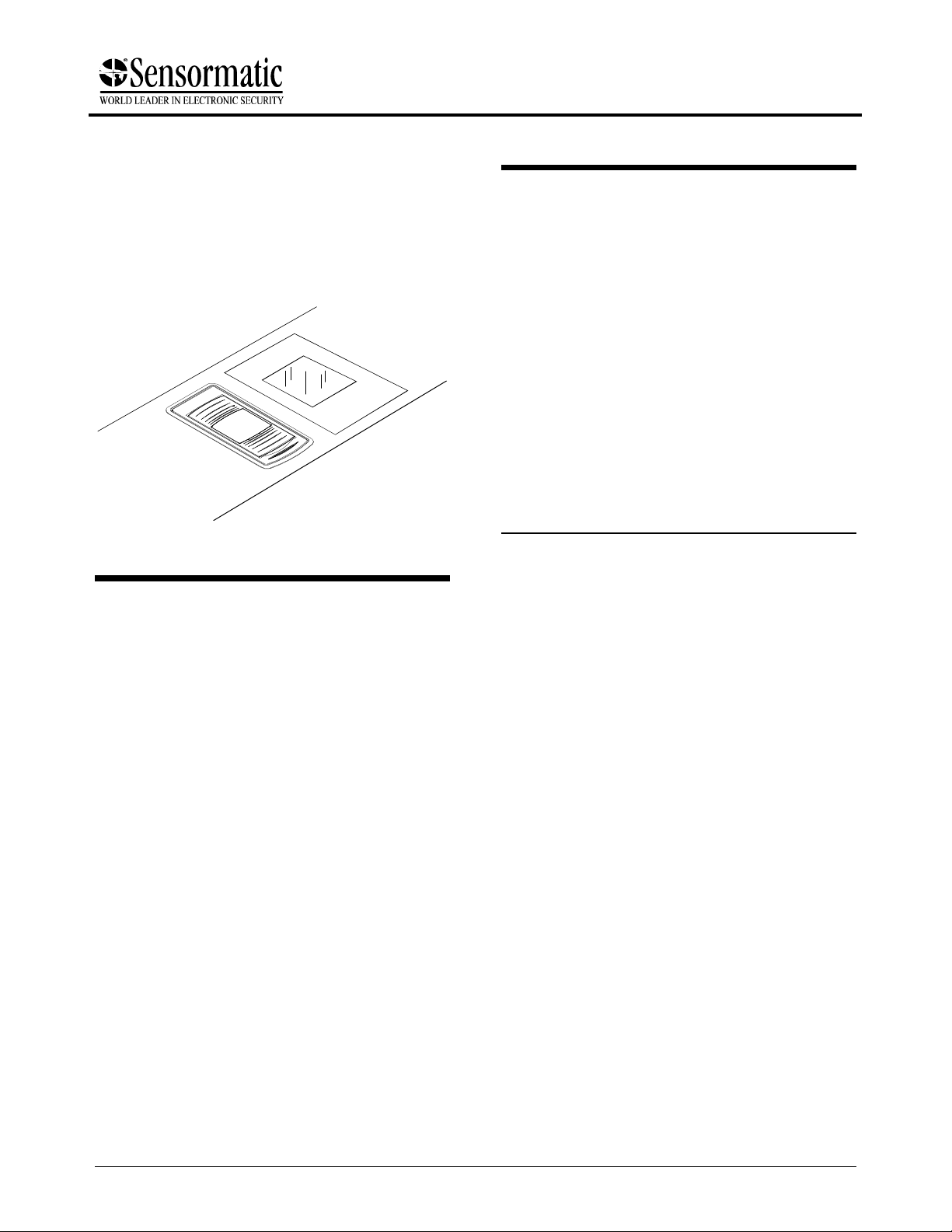

The STP Deactivator (Figure 1) reliably deactivates

Sensormatic UltraStrip II and Ultrastrip III security

labels during the bar-code scanning process when:

• Installed immediately downstream from

the bar-code scanner.

• UltraStrip II and III security labels are properly

applied to items

• Labeled items are moved properly across the

antenna on their way to the bag well or bagging

station.

The deactivator consists of a hidden power pack, a

countertop antenna with interconnect cable.

• ZBSTP-PK-1 power pack controls antenna

operation. At the rear of the pack is an ac

receptacle for an 3m (10') power cord. In front

is a power on LED; connections for the

interconnect cable, an optional remote LED

board or remote indicator module (see options),

a laptop configurator, POS integration, and

RS485 port; and DIP switches (SW1) for phase

and sensitivity adjustments. A bracket enables

the pack to attach to the underside of a

countertop.

• ZBSTP-PP Power Pad antenna generates a

15cm (6") (???-to be verified) high by 20cm (8")

wide magnetic field above its surface to detect

and deactivate UltraStrip II security labels.

The antenna can be placed on the countertop, or

using various brackets, mounted flush with the

countertop, under the countertop, or when

counter space is not available, over or on the

side of the bagwell.

The attached 2.5m (8') interconnect cable carries

the label signal to the pack and the deactivate

pulse to the antenna.

Figure 1. STP deactivator

Power Pack

Status LEDs

Antenna

Magnetic Media Safe Mode

The magnetic field can be reduced before passing

labeled magnetic media over the antenna, thus

protecting the media from the deactivation field.

This can be done manually using an optional

footswitch. Status LEDs do not indicate when the

field is reduced.

CAUTION: The antenna cannot deactivate through

metal. Do not place the antenna on, under, or

near ferrous metal or cold-rolled steel.

Optional status LEDs on the antenna indicate

power on (green), security label deactivation

(orange), and errors (red). An adjustable audio

tone provides additional feedback that

deactivation occurred. A second cable carries

deactivator status signals to the LEDs in the

antenna, or to a remote alarm, if used.

2 PLANNING GUIDE FOR BETA TEST

Page 3

Options

The following options can be ordered:

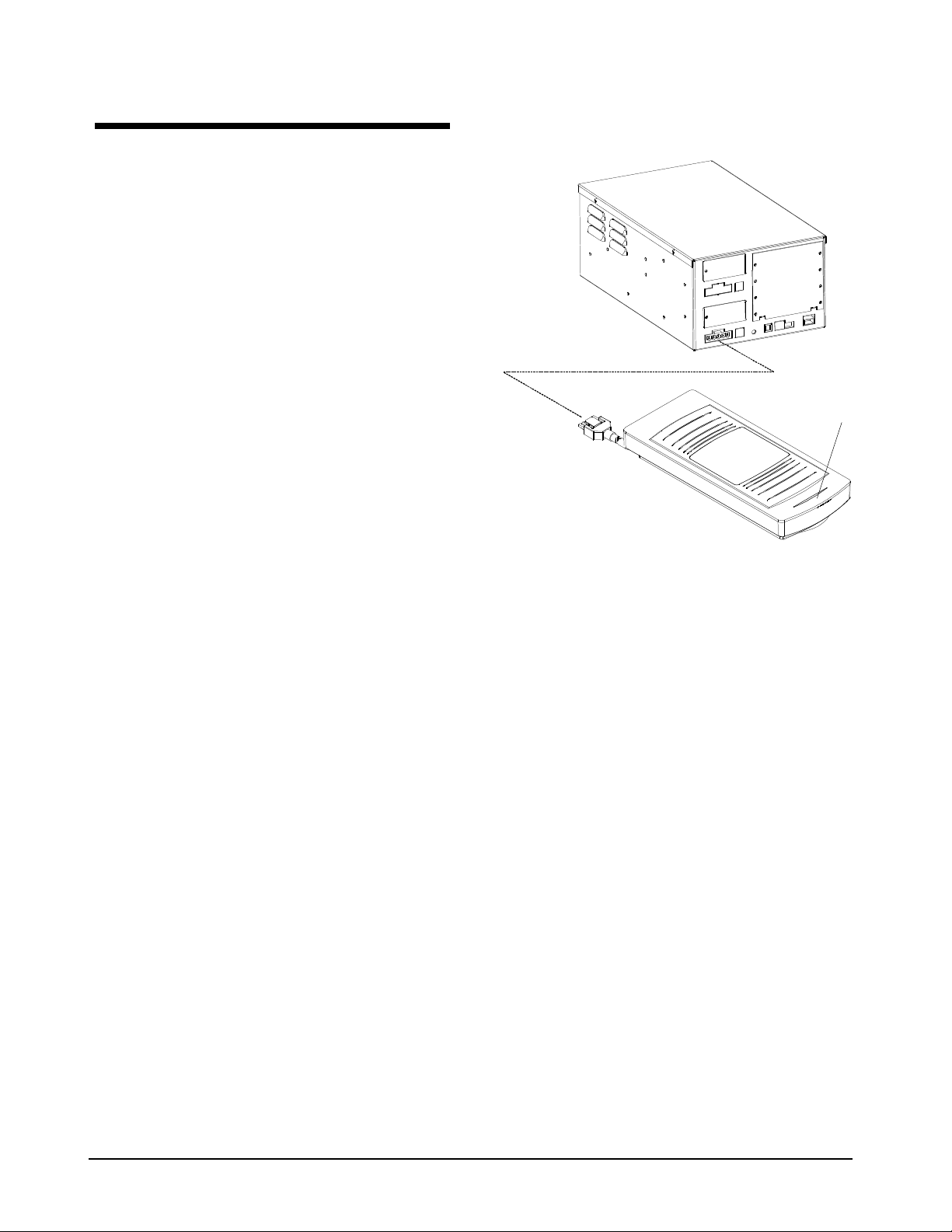

ZBSTP-PK-B power pack mounting bracket

(Figure 2) enables the power pack to attach to the

underside of a countertop.

Figure 2. Power pack mounting bracket

ZBSTP-PP-IB indicator board (Figure 3) plugs

into the bottom of the antenna to provide an

audio/visual indication of operation. LEDs are

visible through the top of the antenna. A cable

connects the board to the power pack.

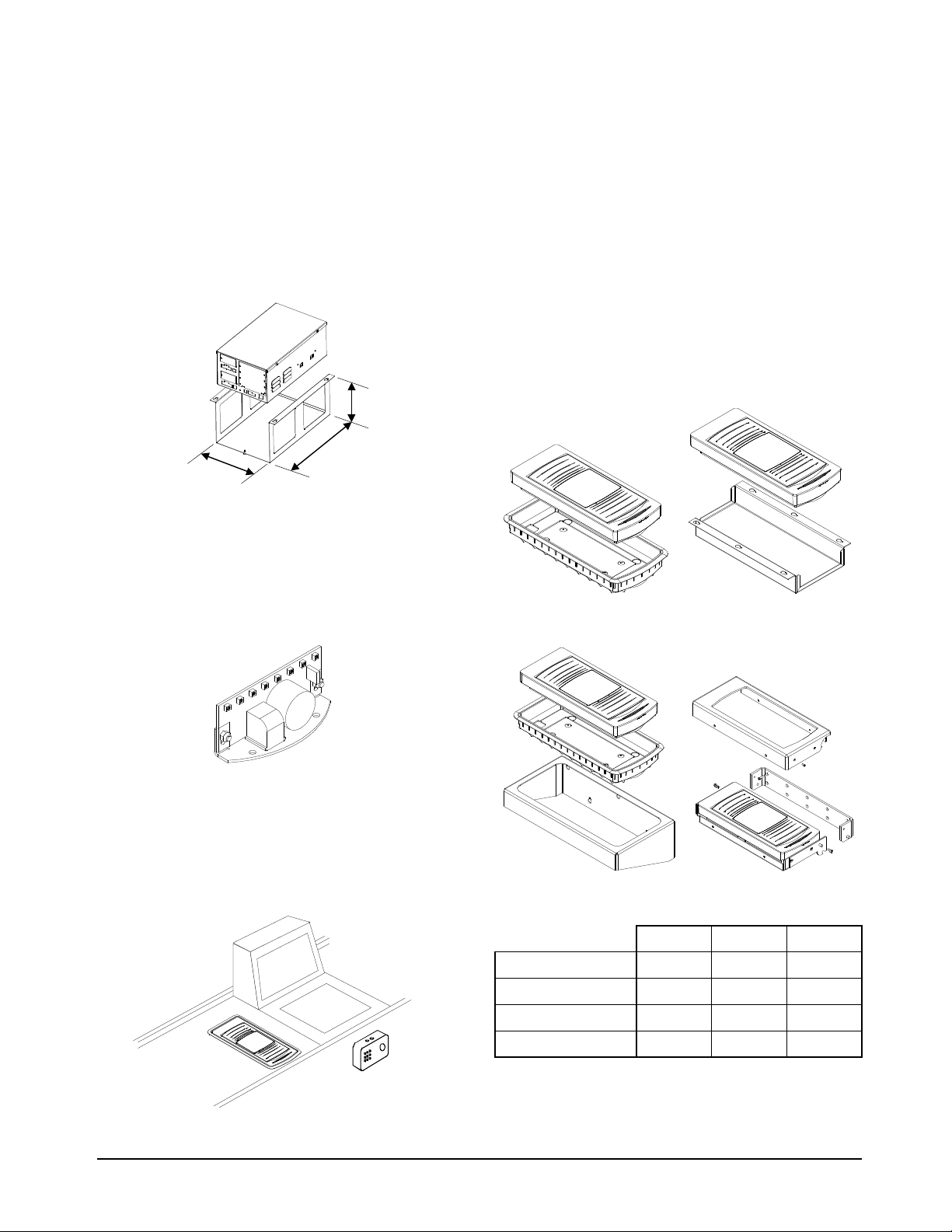

Antenna mounting brackets (Figure 5) are used

to mount the antenna flush with the countertop,

under the countertop, or when counter space is not

available, over or on the side of the bagwell.

These brackets are as follows:

− ZBSTP-PP-B1 flush mount tray

− ZBSTP-PP-B2 under counter bracket

− ZBSTP-PP-B3 cantilever bracket (for bagwell)

− ZBSTP-PP-B4 flip bracket (for bagwell)

Note: Countertop mounting requires no

additional bracketry.

Figure 5. Antenna mounting brackets

Figure 3. Indicator board

Remote Alarm Module (Figure 4) replaces the

indicator board to position status LEDs closer to

the operator. A cable connects the module to the

power pack.

Figure 4. Remote indicator module

Under Counter BracketFlush Mount Tray

Cantilever Bracket

Flush Mount Tray 430mm 201mm 56mm

Under Counter Brkt 397mm 226mm 57mm

Cantilever Bracket 451mm 236mm 125mm

Flip Down Bracket 425mm 195mm 54mm

Flip Down Bracket

L W H

STP POWER PAD DEACTIVATOR

8000-2599-01, Rev. A

PLANNING GUIDE FOR BETA TEST 3

Page 4

STP POWER PAD DEACTIVATOR

8000-2599-01, Rev. A

Component Description

ZBSTPPK1 power pack (Figure 6). The pack

contains the following components:

a. AC input. Automatically adjusts for any input

voltage from 100 to 250Vac and for 50/60Hz.

b. On/Off switch. Turns power on and off.

c. P16. Deactivation cable receptacle.

d. P15. Indicator board receptacle.

e. DS1. Power on indicator.

f. P12. RS-232 software configurator port.

g. P9. Scan Link I/O port.

h. SW1. DIP switches for ac phase and gain

adjustments.

i. TB1. RS485 port.

j. Antenna tuning jumpers. Inside the box.

Power Pad Antenna (Figure 7). Is a nonserviceable iron core assembly inside a plastic

shell. The bottom of the antenna contains a well for

the optional audio/visual indicator board and a

receptacle for the deactivation cable.

Figure 7. Power Pad antenna

Upper Housing

Antenna Winding

and Core

Figure 6. Power pack components

b

a

e

d

c

2.5m (8')

Antenna Cable

j

Lower Housing

i

h

g

f

4 PLANNING GUIDE FOR BETA TEST

Page 5

IMPORTANT SAFEGUARDS

Please observe the following safeguards before

you begin installation or service.

o Hazardous areas.

DO NOT install deactivator in hazardous areas

where highly combustible or explosive products

are stored or used.

o RISK OF ELECTRIC SHOCK!

Keep the power cord and interconnect cable

away from cash drawers and other items whose

operation may pinch or otherwise damage

them. Failure to do so can result in damage to

equipment or injury to people nearby.

o Interference with magnetic readers and CRT

monitors.

− Antenna fields may affect the operation of

magnetic check and card readers (alone or

in keyboards).

− Antenna fields may cause CRT images

within 1.8m (6') to quiver. LCD and LED

displays are not affected.

Note: If antenna fields cause interference, ask

the customer if they accept it. If not, move

the antenna to eliminate the interference. If

this cannot be done, contact your Sensormatic technical support specialist for guidance.

o Ac source must be:

− Isolated from neon signs, motors,

computers, cash registers, terminals, or

data communications equipment

− Unswitched with less than 0.5Vac between

neutral and ground

− Within 1.8m (6') of power pack to accommodate 3m (10') long power cord.

Each power pack requires its own electrical

outlet.

o Interference with nearby metal and

electronic equipment.

− Fields emitted by the antenna cannot pass

through metal. Also, ferrous metal surrounding the antenna can distort the field and

reduce detection range.

Note: If you must place the antenna on

ferrous metal, then place an aluminum plate

behind the antenna to minimize absorption

of the field.

− Computer monitors, TVs, switching power

supplies and neon displays can affect

deactivator operation. Keep the antenna

away from these devices whenever

possible.

Pre-Install Preparation

To ensure the deactivator performs reliably:

o Have electrical work comply with latest national

electrical code, national fire code, and all

applicable local codes and ordinances.

o Coordinate work with other trades to avoid

interference.

o Verify existing site conditions and coordinate

with the owner’s representative and appropriate

utilities as required.

o Obtain copies of all related plans, specifi-

cations, shop drawings and addenda to

schedule and coordinate related work.

o Thoroughly review the project to ensure that all

work meets or exceeds the above requirements. Bring alleged discrepancies to the

attention of Sensormatic Electronics.

Also, follow procedures listed next in this

document:

• Perform a site survey

• Note maximum pedestal separation at exits

• Ensure label application guidelines are followed

• Ensure scanning/deactivation guidelines are

followed.

STP POWER PAD DEACTIVATOR

8000-2599-01, Rev. A

PLANNING GUIDE FOR BETA TEST 5

Page 6

STP POWER PAD DEACTIVATOR

8000-2599-01, Rev. A

Site Survey

Placing the antenna immediately downstream from

the bar-code scanner (Figure 8) places the

deactivation field in line with the checker’s natural

arm movement.

Figure 8. Deactivator antenna location

• The 2.3m (7.5') power cord cannot interfere

with the operation of cash drawers or conveyor

belts or interfere with operation, maintenance or

removal of equipment.

Forward this information to Corporate Technical

Support to establish a library of installations and to

facilitate support.

Note: If the mounting brackets available cannot be

used, consider a custom solution. A custom

solution involves a process that usually takes two

to three months from initial request to delivery, and

is as follows:

Bar-Code Scanner

Deactivator

Antenna

To determine the best mounting solution, do the

following:

• Obtain a drawing showing the dimensions of

the checkstand.

• Describe the checkout process. If possible,

videotape the process for clarification.

• Photograph the antenna in its installed position.

Also note the following:

• If shelf or countertop is adjacent to the barcode scanner, install the antenna under or flush

in the countertop.

• Is the countertop made of ferrous metal? If it is,

and you must install the antenna on the

countertop, then place an aluminum plate

behind the antenna to minimize absorption of

the field.

• If installing the antenna in a bagwell, ensure the

prongs holding the bag will not shift and the bag

will be as close to the antenna as possible.

If wall of bagwell is steel, use 3/4-inch plywood

(not provided) to stiffen it and to provide a solid

anchor for bracket’s mounting screws (you may

have to remove the scanner to do this).

Plywood should be at least 22.9cm (9") wide.

Determine its length by measuring from top of

mounting bracket to base of wall inside counter.

• Metal around the antenna can deflect or distort

the deactivate field. Try pre-installing the

antenna to see the effects.

1. You initiate a request for a custom solution and

send site-specific data to Corporate Technical

Support.

2. Development team analyzes photographs of

the checkstand (videos are extremely helpful to

demonstrate merchandise handling).

3. In some cases, representatives from the team

conduct an on-site analysis to evaluate initial

proposals and gather additional data.

4. A Request for Product Modification (RFM) is

generated, formally requesting the development

of a new installation kit.

5. Engineering Design and Procurement acquires

a working prototype.

6. Development and field teams test the

prototype.

7. Design modifications occur based on test

results.

8. If necessary, a revised prototype is developed

and tested.

9. Start-up production includes finalizing documentation, placing orders, and first article

approval.

Note: The most effective installation integrates

deactivation with the scanning process. However, if

circumstances do not allow sufficient lead time for

developing a custom solution, consider integrating

deactivation with another step in the normal

product flow.

6 PLANNING GUIDE FOR BETA TEST

Page 7

Maximum Detector Separation

Label Application Guidelines

The Ultrastrip II Label is used with Ultra•Max EAS

detectors. Maximum pedestal separation for use

with the UltraStrip II label is as follows:

Ultra•Max Detector

Pro•Max 2.3m (8')

Pro•Max II 2.3m (8')

EuroPro•Max III 2.3m (8')

Ultra•Post 1.8m (6')

StandAlone/Euro•Max 1.3m (4.5')

MAX Checkout (2 pedestals) 1.1m (3.6')

Pedestal

Separation

To ensure reliable deactivation, follow these

guidelines when applying UltraStrip II labels:

• Always place label on a flat, clean, dry surface,

as close to UPC bar-code as possible, but no

more than 5cm (2") from bar-code.

• Apply the label to same surface as the barcode

whenever possible.

• Do not cover any part of the bar code or its

numbers.

• Do not cover any text printed on the item such

as directions, ingredients, lot numbers, or

expiration dates.

• Do not bend or pinch the label. Discard all bent

or damaged labels.

• Do not apply the label to a curved surface.

However, the label can be applied parallel to

cylindrical items at least 76mm (3") in diameter.

Never apply the label to these items diagonally

or horizontally.

• Do not apply the label to vinyl or leather. The

label’s adhesive can damage these items.

• Use an offset label when applying directly to

ferro-magnetic metallic items such as metal fan

blades and light fixtures.

• Do not apply the label near strong magnets

such as those in loudspeakers, or within 13mm

(0.5") of small magnets.

About source tagging...

Source tagging is the process of applying labels

during the manufacturing process, typically inside

product packaging. All standard source tagging

guidelines apply for this deactivator. For more

information, contact your Sensormatic account

manager.

STP POWER PAD DEACTIVATOR

8000-2599-01, Rev. A

PLANNING GUIDE FOR BETA TEST 7

Page 8

STP POWER PAD DEACTIVATOR

8000-2599-01, Rev. A

Scanning/Deactivation

Guidelines

Reliable label deactivation depends on a good

scanning technique. Read the following guidelines

for routine scanning/deactivation and scanning/

deactivation of pre-recorded magnetic media.

Routine Scanning/Deactivation

To help cashiers develop a proper scanning

rhythm, select ten “labeled” items that represent a

cross section of the store’s most frequently sold

items. Cashiers should practice scanning and

deactivating these items using the steps listed

below.

1. Locate the scanner’s the sweet spot. The sweet

spot provides optimal scanning recognition.

Some scanners have markings such as arrows

or tightly spaced lines to identify this spot.

2. Position items before presenting them to the

scanner. Cashiers should use both hands to

position heavy or bulky items. For tall items,

they should keep their wrists straight to avoid

tipping the item and lifting the bar code out of

the scan zone. This technique also eliminates

wrist stress.

3. Both the scanner’s sweet spot and the

antennas’s magnetic field are aligned to the

cashier’s normal scanning motion. The

antenna’s field extends 15cm (6") above its

surface. Move merchandise horizontally along

the scan/ deactivation pathway (Figure 9),

keeping the label and barcode within 15cm (6")

of the countertop; do not lift items away from

the scanner.

4. Avoid wasted motion. Avoid turning or repositioning items during scanning/deactivation.

5. Verify deactivation. Have the cashier position

the item so that the bar code is close to the

antenna surface. If the label was correctly

deactivated, the LED will remain green. If the

LED turns red, the label was not deactivated

initially, but has been deactivated during this

verification process.

Note: Use this step for training purposes only.

Once a consistent scanning/deactivation

technique is developed, cashiers can be

confident of reliable label deactivation on the

first pass.

6. Repeat the process. Cashiers should practice

until a smooth rhythm is developed and they

should become familiar with bar code location

on high volume items.

Note: A ZKWACT ActivatorWand or ZKCDACT

Activator Pad can be used during training to

reactivate the label. You can obtain it by contacting

your Sensormatic Customer Support Specialist.

A special note about bagwells:

If the antenna is to be located within the bagwell,

follow these special steps to ensure deactivation:

1. Position the bag rack so the bag lines up with

the antenna (Figure 10).

2. If the bag rack is removeable, check its

alignment periodically since it might be moved.

Figure 10. Bag alignment

Figure 9. Scanning/Deactivation pathway

Bar-Code Scanner

Deactivator

Antenna

Remember: When a label is detected, the

antenna’s green LED turns red and it emits a

8 PLANNING GUIDE FOR BETA TEST

Page 9

Scanning/Deactivation and

ZK30 Hand Stamp Deactivator

Pre-Recorded Magnetic Media

Specifications

The antenna’s magnetic field can affect prerecorded magnetic media such as videotapes,

audiotapes, computer hardrives, software on

floppy disks, and credit cards. Use the following

guidelines to reduce the possibility of affecting prerecorded media:

• Do not place credit cards near the antenna

during the deactivation process. Be sure that

customers do not place or hold cards near the

antenna.

• Do not place laptop computers on the antenna.

• If not using the magnetic media safe mode,

then use a contact deactivator to deactivate

pre-recorded items—before they are scanned.

Examples of contact deactivators are shown in

Figure 11.

Figure 11. Examples of contact deactivators

ZK252 Contact

Deactivator

ZBMMECD Contact

Deactivator

Electrical

AC line input ...................... 100–250V~ (50/60Hz)

AC line current................... 15Arms (short term

operation, 1

deactivation every sec)

2.0Arms (long term

avg, 1 deactivation

every 12 sec)

Transmitter

Output................................ Pulsed, synchronized

to AC line

Current............................... 0.5Apk (nominal)

Operating frequency.......... 58 kHz

Receiver

Center frequency............... 58 kHz

Deactivation

Output................................ Line resonant @ 50Hz

or 60Hz (?)

Pulse width ........................ 250ms (?)

Current............................... 7Arms (+10/-15%)

50Hz (?)

15Arms (+10/-15%)

60Hz (?)

Line Synchronization

50Hz Settings .................... 75Hz (phase A,B,C)

60Hz Settings .................... 90Hz (phase A,B,C)

Zero line crossing.............. ±4000µs from center

RS232 Communication Port:

Settings .......................... 9600, 8, N, 1

Connector....................... Four position modular

phone jack

STP POWER PAD DEACTIVATOR

8000-2599-01, Rev. A

PLANNING GUIDE FOR BETA TEST 9

Page 10

STP POWER PAD DEACTIVATOR

8000-2599-01, Rev. A

Auxiliary I/O

This I/O port is user configurable for internal power

or external drive options. Vcc and Ground are

available at the port pins.

Inputs (two).........................Opto-coupled diode

10mA, typical /60mA

max drive

Output.................................Opto-coupled transistor

max capacity 150mA

Connector...........................8-position modular

phone jack

RS485 ................................(?)

Environmental

Operating temperature.......0°C to 50°C

(32°F to 122°F)

Non-operating temp. ..........–40°C to 70°C

(–40°F to 158°F)

Relative humidity................0 to 90% non-

condensing

Mechanical

Power pack:

Weight.............................4 kg (9 lbs)

Length.............................38 cm (14.9")

Width...............................22.6 cm (9")

Height..............................14.4 cm (5.5")

Power cord.........................3 m (10')

Power Pad Antenna:

Weight.............................10 kg (22 lbs)

Length.............................39.3 cm (15.5")

Width...............................17 cm (6.75")

Height..............................5.6 cm (2.2")

Remote Indicator Module:

Length.............................82.5mm (3.3")

Width...............................59mm (2.3")

Depth ..............................30mm (1.2")

Declarations

Regulatory Compliance

Emissions.......................... 47 CFR, Part 15,

Class A

ETS 300 330

ETS 300 683

Bapt 222 (Germany)

EN61000-3-2

EN61000-3-3

VDE 0848

Safety................................. UL1950

CSA C22.2 No 950

EN 60 950

FCC COMPLIANCE: This equipment complies with Part 15

of the FCC rules for intentional radiators and Class A digital

devices when installed and used in accordance with the

instruction manual. Following these rules provides reasonable

protection against harmful interference from equipment

operated in a commercial area. This equipment should not be

installed in a residential area as it can radiate radio frequency

energy that could interfere with radio communications, a

situation the user would have to fix at their own expense.

EQUIPMENT MODIFICATION CAUTION: Equipment

changes or modifications not expressly approved by

Sensormatic Electronics Corporation, the party responsible

for FCC compliance, could void the user's authority to operate

the equipment and could create a hazardous condition.

Other Declarations

WARRANTY DISCLAIMER: Sensormatic Electronics

Corporation makes no representation or warranty with respect

to the contents hereof and specifically disclaims any implied

warranties of merchantability or fitness for any particular

purpose. Further, Sensormatic Electronics Corporation

reserves the right to revise this publication and make changes

from time to time in the content hereof without obligation of

Sensormatic Electronics Corporation to notify any person of

such revision or changes.

LIMITED RIGHTS NOTICE: For units of the Department of

Defense, all documentation and manuals were developed at

private expense and no part of it was developed using

Government Funds. The restrictions governing the use and

disclosure of technical data marked with this legend are set

forth in the definition of "limited rights" in paragraph (a) (15)

of the clause of DFARS 252.227.7013. Unpublished - rights

reserved under the Copyright Laws of the United States.

10 PLANNING GUIDE FOR BETA TEST

Loading...

Loading...