Page 1

C•CURE® Watch

Installation and Service Guide

8000-2803-01 A

Page 2

Page 3

Access Systems

C•CURE Watch

Installation and Service Guide

COPYRIGHT 2001

All rights reserved.

No part of this manual may be reproduced in any form without written permission

from Sensormatic Electronics Corporation.

8000-2803-01, Rev. 0/A

SHF 5/01

Page 4

WARNING

Do not install this product in hazardous areas where highly combustible or explosive products

are stored or used.

WARNING

The C•CURE Watch installation must be performed by qualified service personnel and should

conform to all local codes. The reader/controller enclosure does not contain user serviceable

parts. Contact Technical Support at 1-800-392-2873 for help in resolving system performance

issues.

FCC COMPLIANCE

FCC COMPLIANCE: This equipment complies with Part 15 of the FCC rules for Class A digital devices

when installed and used in accordance with the instruction manual. Following these rules provides

reasonable protection against harmful interference from equipment operated in a commercial area. This

equipment should not be installed in a residential area as it can radiate radio frequency energy that

could interfere with radio communications, a situation the user would have to fix at their own expense.

DISCONNECT DEVICE

A 20A max., disconnect device, which also provides short circuit and overload protection, and has a

minimum 3mm open circuit clearance, in accordance with the National Electric Code and applicable

local codes must be installed at a location readily accessible to the equipment.

EQUIPMENT MODIFICATION CAUTION

Equipment changes or modifications not expressly approved by Sensormatic Electronics Corporation,

the party responsible for FCC compliance, could void the user's authority to operate the equipment and

could create a hazardous condition.

WARRANTY DISCLAIMER

Sensormatic Electronics Corporation makes no representation or warranty with respect to the contents

hereof and specifically disclaims any implied warranties of merchantability or fitness for any particular

purpose. Further, Sensormatic Electronics Corporation reserves the right to revise this publication and

make changes from time to time in the content hereof without obligation of Sensormatic Electronics

Corporation to notify any person of such revision or changes.

LIMITED RIGHTS NOTICE

For units of the Department of Defense, all documentation and manuals were developed at private

expense and no part of it was developed using Government Funds. The restrictions governing the use

and disclosure of technical data marked with this legend are set forth in the definition of “limited rights” in

paragraph (a) (15) of the clause of DFARS 252.227.7013. Unpublished - rights reserved under the

Copyright Laws of the United States.

C•CURE, Sensormatic, and the Sensormatic logo are registered trademarks of Sensormatic Electronics

Corporation. Other product names (if any) mentioned herein may be trademarks or registered

trademarks of other companies.

Page 5

Error! Bookmark not defined.

Table of Contents ........................................................................................................ 1

Chapter 1 ................................................................................................................... 1-1

Introduction............................................................................................................... 1-1

Chapter 2 ................................................................................................................... 2-1

Basic Functionality................................................................................................... 2-1

Chapter 3 ................................................................................................................... 3-1

Planning..................................................................................................................... 3-1

Table of Contents

Product Overview................................................................................................. 1-2

Access Badges and Asset Tags .......................................................................... 1-2

Handheld Reader ................................................................................................. 1-2

RF Readers.......................................................................................................... 1-2

Antennas........................................................................................................ 1-2

RF Controller ................................................................................................. 1-3

RF Reader Configuration............................................................................... 1-3

Specifications ....................................................................................................... 1-4

Electrical ........................................................................................................ 1-4

Environmental................................................................................................ 1-5

Regulatory ..................................................................................................... 1-5

Basic System Operation ...................................................................................... 2-2

RF Controller Block .............................................................................................. 2-3

Synchronization Circuitry............................................................................... 2-3

Communications Interfaces........................................................................... 2-3

RF Passage Reader Configurations .................................................................... 3-2

Single-Antenna Configurations...................................................................... 3-2

Multiple-Antenna Configurations ................................................................... 3-2

Application-Specific Configuration Requirements ......................................... 3-2

C•CURE Watch Installation and Service Guide 1

Page 6

Coordinating with Software Features................................................................... 3-3

Configuration Requirements ................................................................................ 3-3

RF Passage Antennas................................................................................... 3-3

RF Controllers ............................................................................................... 3-4

Inputs ............................................................................................................. 3-4

Outputs .......................................................................................................... 3-4

Host Panel ..................................................................................................... 3-4

RF Controller Power Supply .......................................................................... 3-4

External Power (to Power Supply) ................................................................ 3-4

Cabling........................................................................................................... 3-5

Asset Tag ...................................................................................................... 3-6

Access Control Badge ................................................................................... 3-6

Tools and Equipment ........................................................................................... 3-6

Chapter 4 ................................................................................................................... 4-1

Installation................................................................................................................. 4-1

Installation Checklist ............................................................................................ 4-2

Phase 1: Hardware Installation ..................................................................... 4-2

Phase 2: System Activation and Test............................................................ 4-2

Install Cable Runs ................................................................................................ 4-2

Install RF Passage Antennas............................................................................... 4-2

Prepare for Installation .................................................................................. 4-2

Install brackets and Mount Antennas ............................................................ 4-3

Install Wire Loop for Antenna Pairs ............................................................... 4-3

Connect RF Controller Cables ...................................................................... 4-4

Install Finishing Hardware ............................................................................. 4-5

Install RF Controller ............................................................................................. 4-5

Prepare for Installation .................................................................................. 4-5

Mount the RF Controller Enclosure ............................................................... 4-5

Connect RF Antenna Cables......................................................................... 4-6

Connect Inputs and Outputs.......................................................................... 4-8

Connect Communications Cable................................................................... 4-9

Connect Sync Cable ...................................................................................... 4-9

Connect RF Reader at Panel............................................................................. 4-10

Connect Power to RF Controller ........................................................................ 4-10

Connect Model CW-RID-1 to AC Power ..................................................... 4-10

Inspect Installation ............................................................................................. 4-12

Apply Power ....................................................................................................... 4-12

Verify System Operation .................................................................................... 4-12

Functional Test ............................................................................................ 4-12

Full System Test.......................................................................................... 4-13

Chapter 5 ................................................................................................................... 5-1

Service ....................................................................................................................... 5-1

2 8000-2803-01, Rev. 1/A Table of Contents

Page 7

Parts List .............................................................................................................. 5-2

RFID 56 Format ................................................................................................... 5-2

Tune RF Passage Antennas ................................................................................ 5-2

DIP Switch Settings.............................................................................................. 5-4

Troubleshooting Tips ........................................................................................... 5-5

Appendix A................................................................................................................A-1

Asset Tag Installation ..............................................................................................A-1

Overview ..............................................................................................................A-2

Applying Adhesive Tape ......................................................................................A-2

Applying 3M 4475 Plastic Adhesive.....................................................................A-2

Positioning Guidelines ......................................................................................... A-3

Appendix B................................................................................................................B-1

Managing RF Passage Antenna Performance.......................................................B-1

Performance Overview......................................................................................... B-2

Environmental Conditions Affecting Performance ...............................................B-2

Cable/Line Interference .................................................................................B-2

Antenna Loading ...........................................................................................B-2

Antenna Interference .....................................................................................B-2

Antenna Performance ..........................................................................................B-3

One Antenna, .9m (3ft).................................................................................. B-3

One Antenna, 1.8m (6ft)................................................................................ B-3

Two Antennas, .9m (3ft) ................................................................................B-3

Two Antennas, 1.8m (6ft) ..............................................................................B-3

Before You Begin ................................................................................................. B-4

Investigating Performance ...................................................................................B-4

Check for Obvious Sources of Interference ..................................................B-4

Check for Antenna Loading........................................................................... B-4

Investigate Antenna Interference .................................................................. B-4

Troubleshooting Tips ..................................................................................... B-5

Improve Performance .......................................................................................... B-5

Control Cable/Line Interference .................................................................... B-5

Control Antenna Loading ............................................................................... B-5

Control Antenna Interference ........................................................................B-5

Troubleshooting Procedures................................................................................ B-6

Isolate an Antenna.........................................................................................B-6

Use a Communications Receiver ..................................................................B-6

Install Cancellation Coils ...............................................................................B-7

C•CURE Watch Installation and Service Guide 3

Page 8

4 8000-2803-01, Rev. 1/A Table of Contents

Page 9

Introduction

In This Chapter

Product Overview ....................................................................................................... 1-2

Access Badges and Asset Tags................................................................................. 1-2

Handheld Reader ....................................................................................................... 1-2

RF Readers ................................................................................................................ 1-2

Antennas .............................................................................................................. 1-2

RF Controller........................................................................................................ 1-3

RF Reader Configuration ..................................................................................... 1-3

Specifications ............................................................................................................. 1-4

Electrical............................................................................................................... 1-4

Environmental ...................................................................................................... 1-5

Regulatory............................................................................................................ 1-5

Chapter 1

C•CURE Watch Installation and Service Guide 1-1

Page 10

Product Overview

Handheld Reader

C•CURE Watch products use RFID (radio

frequency identification) technology to gather

unique identification data from access control

badges and asset tags. This information is sent to

the C•CURE 800/8000 Access Control System

(host) for customized event handling and database

storage.

The components of a C•CURE Watch solution

include:

• Access badges and asset tags

• Handheld reader

• RF Readers

Access Badges and Asset Tags

C•CURE Watch badges and tags are small,

passive devices that contain a transponder

encoded with unique data. This data is detected

and decoded by RF readers and sent to the host

for processing.

A handheld reader is available for initializing

assets. Asset tags must be initialized before they

can be assigned to specific assets in the host

system.

RF Readers

A C•CURE Watch RF reader is different from a

typical access control reader. It is a “virtual”

component that is comprised of two different

C•CURE Watch components: one or more

antennas and an RF controller. RF antennas can

be connected to an RF controller in a variety of

configurations that represent from one to four RF

readers.

An RF reader protects a door or portal up to six

feet wide by establishing an interrogation zone.

When an access badge or asset tag enters this

zone, its identification data is captured and sent to

the host for processing.

Each RF reader is recognized as a separate door

or portal by the host system.

Access badges identify individuals. When a

C•CURE Watch RF reader detects an access

badge, identification data is sent to the host system

which decides whether to open the door or initiate

other actions based on the privileges assigned to

that individual.

Asset tags are permanently affixed to assets that

the user wants to manage. When a C•CURE

Watch RF reader detects an asset tag,

identification data is sent to the host system which

responds based on the privileges assigned to that

asset.

Antennas

C•CURE Watch products include two types of

antenna which can be configured as part of an RF

reader: RF passage antenna and RF proximity

antenna (not yet available).

Under the direction of an RF controller, RF

antennas transmit and receive radio signals that

enable them to gather data from badges and tags.

This data is sent to the RF controller for decoding

and transmission to the host.

RF Passage Antenna

The RF passage antenna is designed to detect

both access badges and asset tags by establishing

1-2 8000-2803-01, Rev. 1/A Introduction

Page 11

an extended interrogation zone that makes badge

y

y

and tag detection practically transparent to users. It

does not require line of sight and operates without

any special presentation effort.

RF passage antennas can be installed at doors or

portals to monitor badges and/or assets. A portal is

any location where access is not restricted such

as: halls, passageways, and doors that are not

controlled by the host.

RF Reader Configuration

The RF controller provides a flexible foundation for

configuring RF readers. Each RF reader must

include at least one antenna connected to an RF

controller. However, the RF controller provides

connections for up to four antennas enabling a

single RF controller to represent multiple RF

readers to the host.

RF passage antennas are available in two models:

A and B. Model A RF passage antennas are

designed for hands-free access control

applications. Model B RF passage antennas work

in conjunction with model A RF passage antennas

for applications that monitor assets.

There are many ways to configure an RF reader

using RF passage antennas. The number and type

of antennas and their placement at the door or

portal depends on the size of the opening and the

security goals of the customer. For more

information about configuring RF readers with RF

passage antennas, see RF Reader Configuration

on page 1-3.

RF Proximity Antenna

The RF proximity antenna is not yet available.

The RF proximity antenna is designed to detect

only access badges. It establishes a limited

interrogation zone.

RF Controller

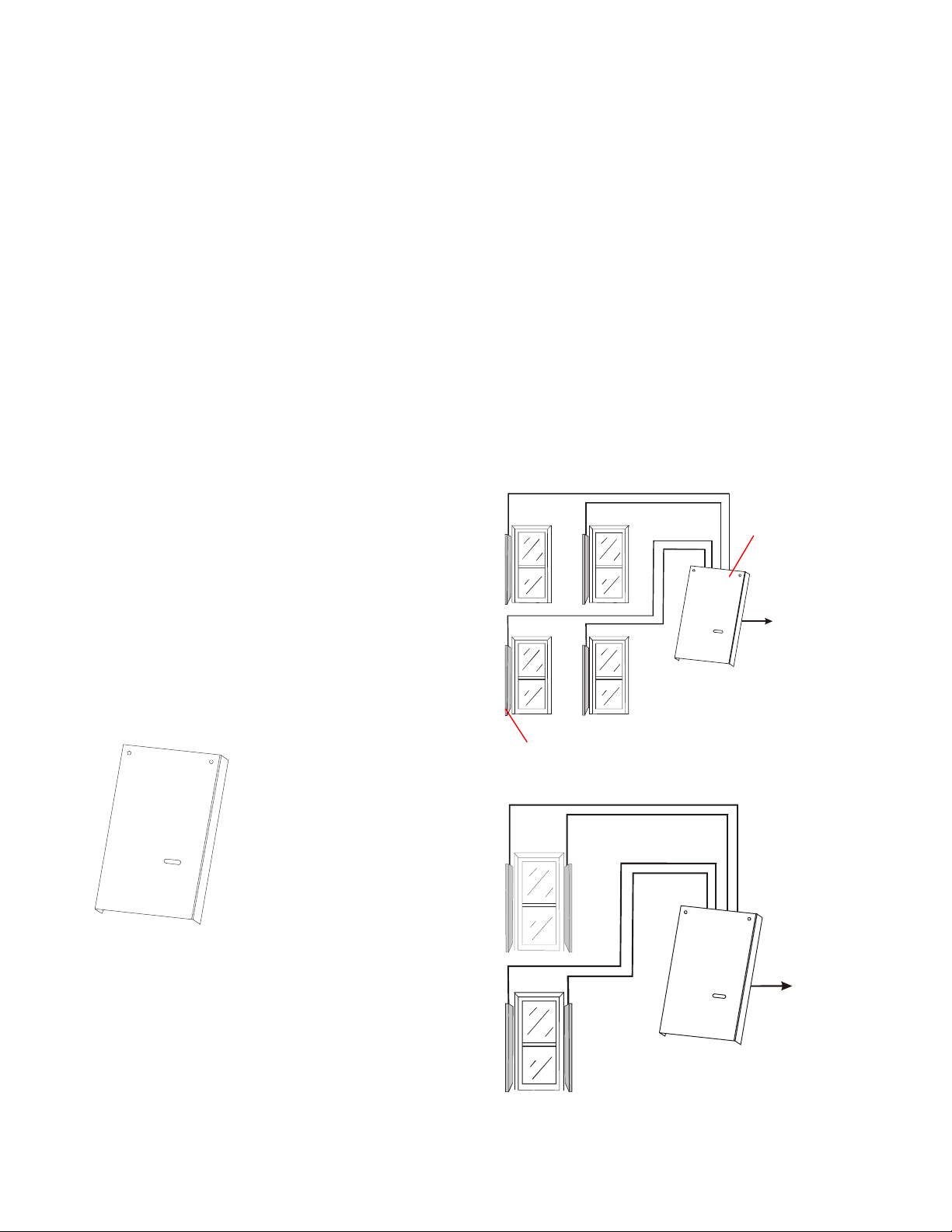

RF Passage Antenna Configurations

RF passage antennas can be configured in a

variety of ways depending on application

requirements and the size of the door/portal.

When four RF antennas are connected to an RF

controller, they may represent one, two, three, or

four RF readers depending on the address settings

selected.

RF Controller

Recognized b

Host as Four

RF Readers

RF Passage

Antenna

Every RF reader configuration includes an RF

controller. The RF controller directs the RF

antenna’s transmission and reception of radio

signals, conditions and decodes signals from the

antennas, and communicates with the host.

Each RF controller provides connections for up to

Recognized b

Host as Two

RF Readers

four antennas. These connections can represent

from one to four RF readers depending on antenna

type and board settings.

C•CURE Watch Installation and Service Guide 1-3

Page 12

Recognized b

y

Host as One

RF Reader

The number of RF passage antennas required for

a particular door/portal depend on the size of the

opening being protected and whether the RF

reader is to recognize assets. The following

configurations are recommended:

Door/Portal

Width

Up to

.9m (3ft)

.9m (3ft) –

1.8m (6ft)

Tags Only Badges

1 Model A

and 1

Model B

2 Model A

and 2

Model B

Only

1 Model A

2 Model A 2 Model A and

Optimum

Performance

2 Model A and

2 Model B

2 Model B

RF Proximity Antenna Configurations

RF proximity antennas are not available at this

time.

Specifications

Electrical

Transponder

Type: ..................................Passive, TIRIS® ,

read/write

...........................................(64-bit usable data

max.)

Style: ..................................Asset tag or access

control badge

Antennas

Input Requirements: ...........16V nominal @ 4A

peak

Type: ..................................Tunable passage

antenna

RF Controller

Input Requirements: ...........15V nominal @ 8A

peak

Power Fuse: .......................5A, 250V manufactured

by Semko or equivalent

Outputs:..............................10V @ 10 mA,

12V open circuit

Transmitter/Receiver

Operating Frequency: ........134.2kHz

Transmit/Receive Cycle: ....70ms

Transmit Time: ...................50ms

Receive Time: ....................20ms

Receiver Data Format: .......52-bit

1-4 8000-2803-01, Rev. 1/A Introduction

Page 13

External Power Supply for RF Controller

North America:......Requires a nominal 15Vdc @

8A peak Class 2 linear power

supply. (Not investigated by

UL).

EU: This product runs on 15Vdc

linear power supply. In the EU,

it is intended to be powered

from a Limited Power Source.

A limited power source is a

certified source of SELV, and if

inherently limited, with 8A

maximum output current, and

a maximum of 100VA

available; or if not inherently

limited, fused with a maximum

value of 3.3 Amps, meeting

section 2.11 of IEC950, and a

maximum of 250VA available.

The power supply can be

obtained through Sensormatic

or through another source

where the provider can furnish

the verification. This is

required to assure electrical

safety in the product. (Not

investigated by UL).

Regulatory

Emissions: ..........................FCC Part 15

ETS 300330

ETS 300683

Safety: ................................UL 294

External Power Supply: ......Listed Class 2

EN60950 (CE) LPS

UL 294

Inputs and Outputs

System Inputs: ................... 2 auxiliary inputs

System Outputs: ................ 2 auxiliary outputs: 10V

@ 10mA / 12V open

circuit

1 RS-422 sync output

1 RS-485

communications

interface

Environmental

Ambient Temperature: ....... 0°C to 50°C

(32°F to 122°F)

Storage Temperature:........ –30°C to 70°C

(–22°F to 158°F)

Relative Humidity: .............. 0 to 90% non-

condensing

C•CURE Watch Installation and Service Guide 1-5

Page 14

1-6 8000-2803-01, Rev. 1/A Introduction

Page 15

Basic Functionality

In This Chapter

Basic System Operation ............................................................................................. 2-2

RF Controller Block .................................................................................................... 2-3

Synchronization Circuitry ..................................................................................... 2-3

Communications Interfaces ................................................................................. 2-3

Chapter 2

C•CURE Watch Installation and Service Guide 2-1

Page 16

Basic System Operation

The C•CURE Watch system consists of three

major parts: transponder (embedded in tag or

card), antenna, and RF controller.

To read data from a tag/card, the RF controller

transmits a 134.2kHz charging field for

approximately 50ms to an antenna connected to

the RF controller. The electromagnetic field

generated by the antenna charges the tag/card.

The tag/card stores this charge in a capacitor.

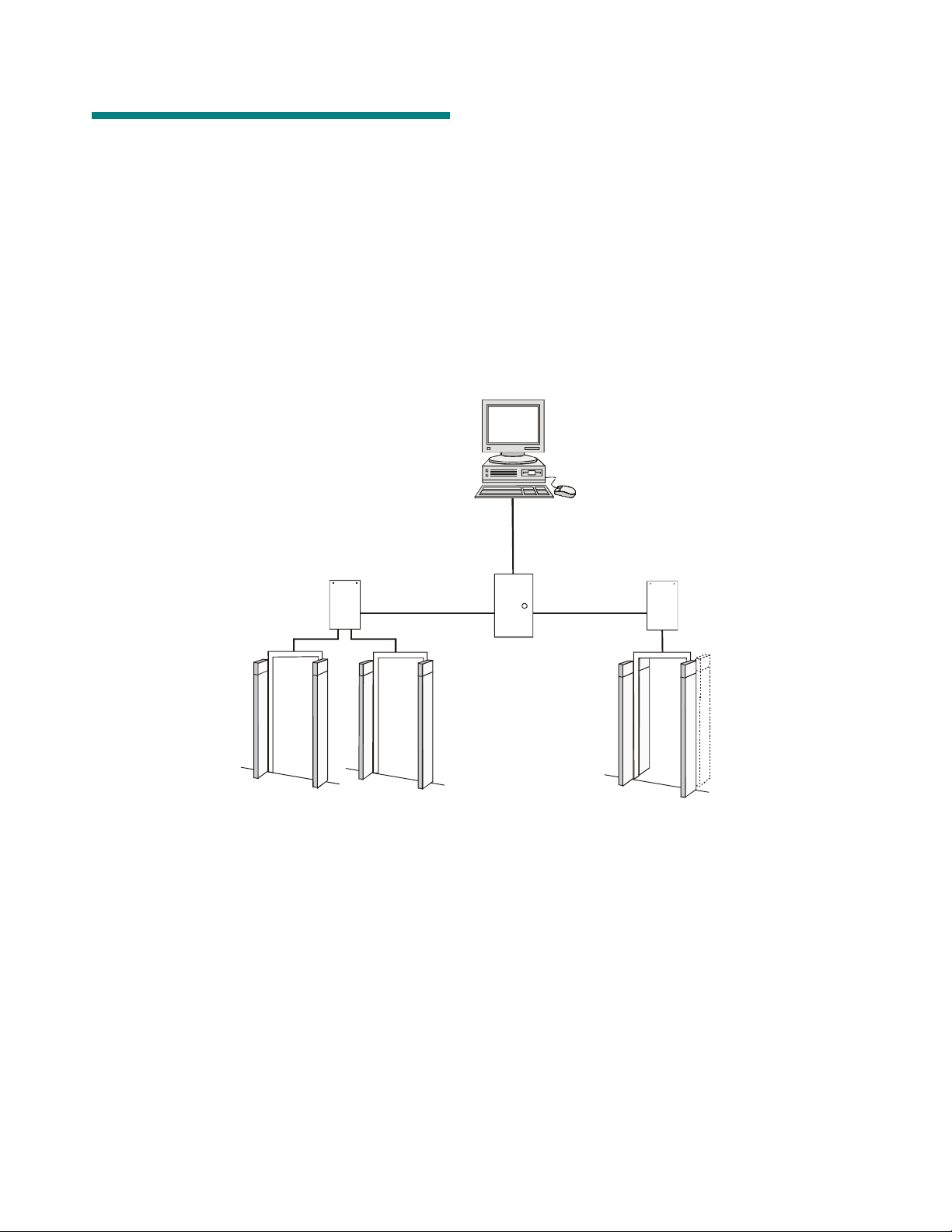

Figure 1. C•CURE Watch System Configuration

After the 50ms charging period ends, the tag/card

immediately transmits its pre-programmed data for

20ms, using the energy stored in the capacitor as

its power source. Once all the data is transmitted,

the storage capacitor is discharged, and the

transponder is reset, readying it for the next power

pulse.

C•CURE 800 Host

RF Controller

2-RF Antenna

Configuration

2-RF Antenna

Configuration

RF Controller

Panel

4-RF Antenna

Configuration

2-2 8000-2803-01, Rev. 1/A Basic Functionality

Page 17

RF Controller Block

synchronization signal and sends it to the next

RF controller (if any).

• Secondary controller operation

Synchronization Circuitry

The synchronization circuitry (7) consists of one

input and one output channel using the RS-422

differential communications protocol. This circuitry

prevents interference from other RFID components

in the area by synchronizing transmit/receive

signals.

Synchronization establishes a daisy-chain

connection between RF controllers operating in

close physical proximity to each other. Every RF

controller operating within 152m (500ft) of another

RF controller must be included in the wiring

configuration (even if they are part of a separate

C•CURE 800 system).

The wiring configuration establishes the first RF

controller in the daisy chain as the primary

controller. The first RF controller in the chain is

identified based on the lack of an input

synchronization signal at the synchronization port

(7). All other RF controllers in the synchronization

daisy chain operate as secondary controllers.

Synchronization circuitry operates automatically

based on installation configuration and system

status:

• RF controller offline

When the RF controller is not powered on or is

being reset, the synchronization signal is

passed straight through to other RF controllers

in the system.

If initialization establishes the RF controller as

a secondary controller, it synchronizes

operation of this RF controller and sends the

synchronization signal to the next RF controller

(if any).

Communications Interfaces

The communications interfaces include the

following:

• RS-485

The RS-485 communications interface controls

the flow of information between the apC and

the CID controller. The half-duplex interface

limits communication to one direction at a time.

The RS-485 interface currently is set by the

system software to operate at 9600 baud, eight

data bits, no parity, no flow control, and one

stop bit.

• On-board Digital Signal Processor (DSP) LEDs

DS1—Flickers when a valid detection occurs.

DS4–Flickers when a partial detection occurs.

A partial detection may be caused by

interference.

• RF controller initialization

When an offline or reset RF controller begins

operating, the synchronization signal continues

to be passed through to other RF controllers

while the system monitors the input signal.

The monitoring process enables the hardware

to determine whether this RF controller is a

primary or secondary controller.

The RF controller checks for proper

synchronization polarity. If synchronization

wiring is incorrect, the RF controller locks up

and the on-board status LEDs flash an error

code.

• Primary controller operation

If initialization establishes the RF controller as

the primary controller, it generates a

C•CURE Watch Installation and Service Guide 2-3

Page 18

2-4 8000-2803-01, Rev. 1/A Basic Functionality

Page 19

Planning

In This Chapter

RF Passage Reader Configurations........................................................................... 3-2

Single-Antenna Configurations ............................................................................ 3-2

Multiple-Antenna Configurations.......................................................................... 3-2

Application-Specific Configuration Requirements................................................ 3-2

Coordinating with Software Features ......................................................................... 3-3

Configuration Requirements....................................................................................... 3-3

RF Passage Antennas ......................................................................................... 3-3

RF Controllers ...................................................................................................... 3-4

Inputs ................................................................................................................... 3-4

Outputs................................................................................................................. 3-4

Host Panel............................................................................................................ 3-4

RF Controller Power Supply................................................................................. 3-4

External Power (to Power Supply)....................................................................... 3-4

Cabling ................................................................................................................. 3-5

Asset Tag ............................................................................................................. 3-6

Access Control Badge ......................................................................................... 3-6

Tools and Equipment.................................................................................................. 3-6

Chapter 3

C•CURE Watch Installation and Service Guide 3-1

Page 20

RF Passage Reader Configurations

An RF passage reader protects a door or portal by

detecting badges and/or tags. An RF reader is

represented by a combination of hardware

components: an RF controller and one or more RF

passage antennas.

Since an RF controller accepts input from up to

four antennas, one RF controller can represent up

to four RF readers. Some RF readers use a single

RF antenna while others consist of one or two

antenna pairs.

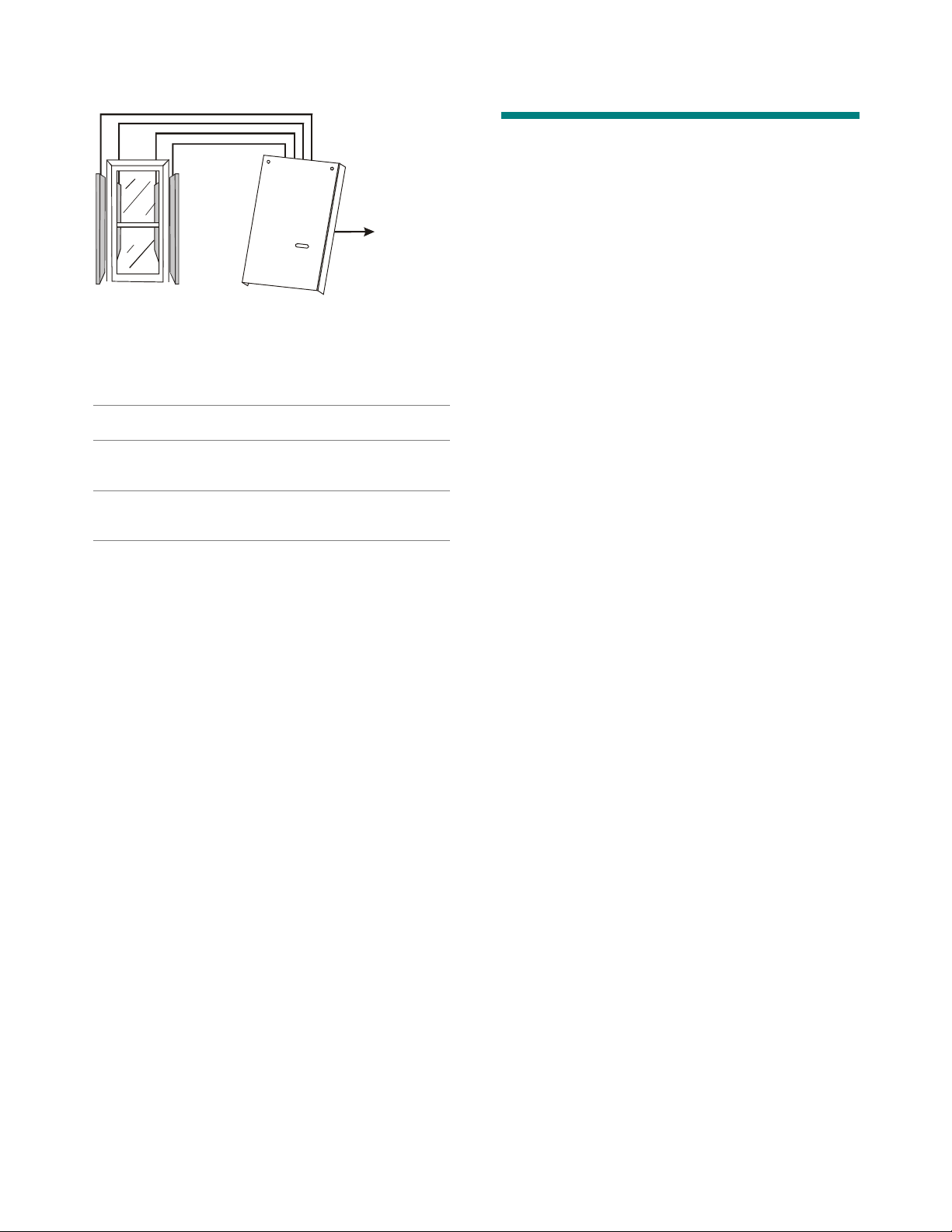

Single-Antenna Configurations

In some circumstances, a single RF antenna can

be used to protect a door. In this configuration, one

RF controller can represent one, two, three, or four

RF readers.

In many configurations, antennas in an antenna

pair are connected above and below the door to

form a wire loop.

Wire Loop

Two RF passage antenna models are available to

maximize performance for multiple-antenna

configurations: Model A antennas and Model B

antennas. Model A antennas are optimized to

detect badges and Model B antennas are

optimized to detect tags. Antenna pairs are always

configured with two antennas of the same model. A

pair cannot be configured using one Model A and

one Model B antenna.

Antenna

Multiple-Antenna Configurations

In many cases, more than one RF passage

antenna is required to protect a door/portal.

Multiple antennas are always installed in pairs—

one on the left side of the door/portal and one on

the right side. Users pass between the antennas in

a pair when they walk through the door/portal. In

multiple-antenna configurations, one RF controller

can represent one or two RF readers.

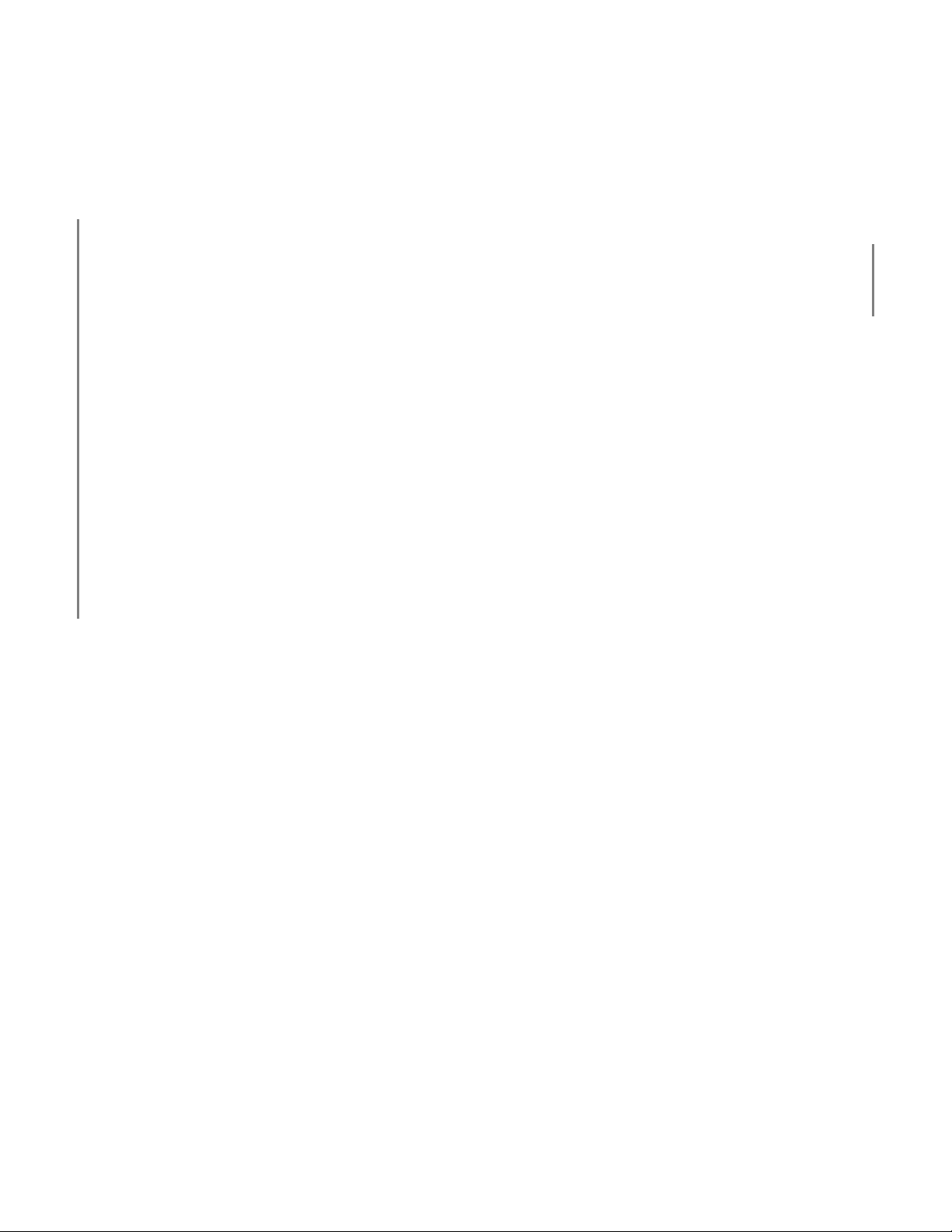

Application-Specific Configuration Requirements

The number, model, and placement of RF passage

antennas varies based on whether or not the

system is to be used for asset management.

Hands-Free Access Control

Requirements

Hands-free access control systems do not detect

assets. The following requirements apply:

• A single Model A RF passage antenna may be

used to protect doors up to .9m (3ft).

A

• A pair of Model A RF passage antennas may

be used to protect doors up to .9m (3ft). The

wire loop is optional for this configuration.

AA AA

Antenna Pair

3-2 8000-2803-01, Rev. 1/A Planning

Page 21

• A pair of Model A RF passage antennas is

A

A

A

required to protect doors between .9m (3ft) and

1.8m (6ft). The wire loop is required for this

configuration.

A A

Coordinating with Software Features

The C•CURE 800/8000 application provides

several features that require specific hardware

components or configurations including:

Asset Management Requirements

RF passage readers that detect assets (whether

they detect assets and badges or assets only) are

always configured in multiple-antenna

configurations that include one pair of Model A

antennas and one pair of Model B antennas to

protect doors/portals up to 1.8m (6ft).

Secured

Area

B

A A

Model A Antennas Outside Secured Area

B

at Doors Controlled by Badges

B B

A

When a door that detects assets also secures an

area through the use of access control badges, the

Model A antenna pair is installed outside the

secured area. For doors/portals that detect assets

only (badges are not detected), it does not matter

which side has Model A and which side has Model

B antennas.

B

B

Secured

Area

• Asset/badge linking requires that systems be

configured with four RF passage antennas at

secured doors/portals.

• Check out feature requires that RF readers be

configured with PIR or other exit detection

devices.

Configuration Requirements

Configuration requirements provide information

needed when selecting hardware components and

planning the installation. Requirements are

provided for the following:

• RF passage antennas

• RF controllers

• Host panel (apC or iStar)

• RF controller power supply

• External power

• Cabling

• Asset tag

• Access control badge

A A

Placement of Model A and Model B

Antennas Not Critical if Opening Not

Controlled by Badges

B

B

RF Passage Antennas

• See Cabling on page 3-5 for maximum cable

distance between RF passage antennas and

RF controller.

A wire loop is required for doors/portals greater

than .9m (3ft) wide. At doors/openings that are .9m

(3ft) or less, a wire loop is optional.

• A wire loop is recommended for antenna pairs

when they are installed at doors/portals greater

than .9m (3ft) wide. A wire loop is optional for

antenna pairs installed at doors/portals that are

.9m (3ft) or less.

Note: The wire loop generally enhances RF

antenna performance. Occasionally,

environmental noise conditions can cause the

wire loop to degrade performance.

C•CURE Watch Installation and Service Guide 3-3

Page 22

• Check installation sites for potential noise

sources:

– Whenever possible, remove noise sources

such as computer monitors, TVs, switching

power supplies, and neon displays from

within 1.8m–2.4m (6ft–8ft) of antennas.

– Whenever possible, remove large metal

office furniture such as desks, filing

cabinets, book shelves, and waste baskets

from within .6m–.9m (2ft–3ft) of antennas.

– Avoid installing passage antennas where

metal construction materials (recessed

door frames, corner beading) are adjacent

and parallel to flat side of antenna.

Outputs

The outputs provide 12V open circuit or 10V at

10mA. These outputs are automatically associated

with antenna 1.

Host Panel

• Connect to a dedicated line controlled by an

easily accessible power switch.

• Maximum cable distance from the panel to an

RF controller is 305m (1000ft).

RF Controller Power Supply

RF Controllers

• The enclosure must be mounted in a protected

location such as: above ceiling tiles, in a utility

room, or in a basement. The RF controller

must be installed within the following cable

distances from other system components:

– 61m (200ft) of RF passage antennas

– 30m (100ft) of power supply

– 305m (1000ft) of host panel

Note: Cable specifications vary based on the

distance between components. Select the

correct cable for each installation.

• Select a mounting location that provides

adequate space for installation and service.

The enclosure is approximately 28cm (11in)

high, 22.5cm (8.9in) wide, and 5.4cm (2.2in)

deep.

– When possible, select an installation site

that DOES NOT impede traffic during

installation and servicing.

– Select an installation site that enables

direct conduit runs and cable runs, without

causing cable routing problems. All cables

except power enter the enclosure from the

top.

Note: External power supply not evaluated by UL

(see electrical specifications in Chapter 1:

Introduction.

• For external power sources, 15Vdc linear

power supply is recommended.

• Maximum distance from power supply to RF

controller is approximately 30m (100ft) (see

Cabling on page 3-5).

• North America: requires a nominal 15V Class

2 linear power supply.

• EU: This product runs on 15Vdc linear power

supply. In the EU, it is intended to be powered

from a Limited Power Source. A limited power

source is a certified source of SELV, and if

inherently limited, with 8 amps maximum

output current, and a maximum of 100VA

available; or if not inherently limited, fused with

a maximum value of 3.3 Amps, meeting

section 2.11 of IEC950, and a maximum of

250VA available. The power supply can be

obtained through Sensormatic or through

another source where the provider can furnish

the verification. This is required to assure

electrical safety in the product.

External Power (to Power Supply)

– Power cables must enter enclosure from

the bottom knockout.

Inputs

Two supervised inputs are provided. These inputs

are automatically associated with antenna 1.

3-4 8000-2803-01, Rev. 1/A Planning

The ac source to the RF controller power supply

must be unswitched with less than 0.5Vac between

neutral and ground. DO NOT share the ac source

with neon signs, motors, computers, cash

registers, terminals, or data communications

equipment.

DO NOT use orange-colored outlets dedicated for

computer equipment.

Page 23

Cabling

General cabling guidelines:

• apC/iStar RS-485 cable runs of exceptional

distance may require Belden 9842, which IS

NOT plenum rated.

• A single common ground is required for all

system components.

• All wiring that runs through a plenum area

must be plenum rated.

• RF controller cabling should not share conduit

with mains line power cabling.

• All exposed wiring must be concealed with

raceway or similar cabling protection.

Wire Use Wire Type Specification Star

RF Controller Sync to

common terminal block

(add’l wire may be needed

between terminal blocks)

RS-485 between panel and

RF controller (are there

differences between apC

and istar?)

RF Controller to RF

Passage Antenna

(Signal/Control)

RF Controller to RF

Passage Antenna (Power)

Wire Loop for RF Passage

Antenna Pairs

RF Controller to Inputs 2 conductor / 22 AWG, shielded Belden 82761 or equiv. N/A N/A 305m (1000ft)

RF Controller to Outputs 2 conductor / 18 AWG, shielded Belden 82760 or equiv. N/A N/A 305m (1000ft)

RF Controller to External

Power Supply

RF Controller ac Power

Cord

Chassis Ground Wire multi-stranded / 16AWG 250V 1.8m (6ft)

2 or 4 conductor / 22 AWG,

shielded

2 conductor / 22 AWG, shielded Belden 82761 or equiv. Yes

8 conductor / 22AWG, shielded

8 conductor / 18AWG, shielded 23m (75ft)

8 conductor / 16AWG, shielded 38m (125ft)

8 conductor / 14AWG, shielded 61m (200ft)

2 conductor / 20AWG, shielded 15m (50ft)

2 conductor / 18AWG, shielded 23m (75ft)

2 conductor / 16AWG, shielded 38m (125ft)

2 conductor / 14AWG, shielded 61m (200ft)

1 conductor / 18 AWG, DO NOT

use shielded wire, cable jacket must

be composed of a fluoropolymer

with a thickness of .3mm (.015in.)

2 conductor / 20AWG, shielded 6m (20ft)

2 conductor / 18AWG, shielded 11m (35ft)

2 conductor / 16AWG, shielded 18m (60ft)

2 conductor / 14AWG, shielded 30m (100ft)

Type SJ or SJT / 18AWG 250V

rated (power cord connection not

evaluated by UL)

• Synchronization cabling is required for RF

controllers located within 152m (500ft) of each

other, even when they are not connected to the

same system.

• Passage antenna wire loop may be exposed to

corrosive cleaning fluids; cable jacket MUST

be composed of a fluoropolymer such as FEP

Teflon or Kynar with a thickness of .3mm

(.015in.).

Con.

Belden 82723 or equiv. No Yes 305m (1000ft)

N/A N/A 3m (10ft)

Daisy

Chain

Multi

Drop

Maximum

Distance

305m (1000ft)

1.8m (6ft)

minimum

Note: To maintain UL Listing, field wiring shall not be less than 22AWG.

C•CURE Watch Installation and Service Guide 3-5

Page 24

Asset Tag

Note: Asset tags have not been evaluated by UL.

Allow two hours for the adhesive to set, ensuring a

bond to the asset’s surface that will not be easily

compromised. Complete application instructions

are provided in

Installation.

Appendix A: Asset Tag

Access Control Badge

Access control badges and badge format

(RFID 56) must be defined in the host system

before use.

Tools and Equipment

The installation process may vary based on

construction materials and hardware components.

The following tools and equipment may be required

to install this system:

• Digital voltmeter (DVM)

• Drill with 6.4mm (1/4in.) and 9.5mm (3/8in.)

bits

• Fish tape (snake)

• Hammer

• Hammer drill and masonry drill bits

• Hand vacuum and broom

• Hacksaw

• Jig saw (hand-held)

• Laptop computer running Microsoft

• Level

• Permanent ink marker

• Plastic sheeting (to protect environment from

dust)

• Pliers, small needlenose

• PVC pipe-cutting tool

• Ratchet and socket set

• RJ-6/telephone crimping tool

• Saw (with diamond blade) for cutting floor

trench

• Screwdrivers (including Phillips screwdrivers)

• Wire crimper

• Wire cutters

• Wire stripper

®

Windows

®

3-6 8000-2803-01, Rev. 1/A Planning

Page 25

Installation

In This Chapter

Installation Checklist ................................................................................................... 4-2

Phase 1: Hardware Installation ............................................................................ 4-2

Phase 2: System Activation and Test .................................................................. 4-2

Install Cable Runs ...................................................................................................... 4-2

Install RF Passage Antennas ..................................................................................... 4-2

Prepare for Installation ......................................................................................... 4-2

Install brackets and Mount Antennas................................................................... 4-3

Install Wire Loop for Antenna Pairs ..................................................................... 4-3

Connect RF Controller Cables ............................................................................. 4-4

Install Finishing Hardware.................................................................................... 4-5

Install RF Controller .................................................................................................... 4-5

Prepare for Installation ......................................................................................... 4-5

Mount the RF Controller Enclosure...................................................................... 4-5

Connect RF Antenna Cables ............................................................................... 4-6

Connect Inputs and Outputs ................................................................................ 4-8

Connect Communications Cable ......................................................................... 4-9

Connect Sync Cable ............................................................................................ 4-9

Connect RF Reader at Panel ................................................................................... 4-10

Connect Power to RF Controller............................................................................... 4-10

Connect Model CW-RID-1 to AC Power............................................................ 4-10

Connect Model CW-RID-XPS to External Power SupplyError! Bookmark not

defined.

Inspect Installation .................................................................................................... 4-12

Apply Power.............................................................................................................. 4-12

Verify System Operation........................................................................................... 4-12

Functional Test................................................................................................... 4-12

Full System Test ................................................................................................ 4-13

Chapter 4

C•CURE Watch Installation and Service Guide 8000-2803-01, Rev. 1/A 4-1

Page 26

Installation Checklist

This check list provides an overview of the steps

required to install C•CURE Watch components.

Since order of installation can vary somewhat

based on site requirements, the check list

establishes guidelines concerning the relative order

in which they may be completed.

Site planning should be completed before

beginning the installation.

G Activate the system, page x.

– Tune RF passage antennas, page x

– Configure C•CURE 800 software, page x

G Verify system operation, page x.

Install Cable Runs

Tag all wire bundles and run cables.

WARNING: Do not install this product in

hazardous areas where highly

!

combustible or explosive products are

stored or used.

Phase 1: Hardware Installation

G Install cable runs.

– Cable requirements overview, page x

– RF passage antenna cabling, page x

– RF controller cabling, page x

G Install RF antennas, RF controllers, door

hardware (door latch relay, door sense

monitor, request to exit, passive infrared

detector).

G Install RF controller, page x.

– Mount RF controller enclosure, page x

– Connect power supply cables, page x

– Connect RF antenna cables, page x

– Connect inputs and outputs, page x

– Connect communications cables, page x

– Connect synchronization cables, page x

G Connect to host panel (apC or I-Star), refer to

installation instructions supplied with panel.

G Connect power to RF controller, page x.

Phase 2: System Activation and Test

All steps in Phase 1 must be completed before

beginning Phase 2. Complete these steps in the

order presented.

Pull a little extra wire to place less strain at the

connection points (excess wire can be coiled into

the wall space).

Required cable runs include:

• RF controller to door/portal being protected.

• Host panel to RF controller.

• RF controller to RF controller (for

synchronization).

• Power to RF controller.

Refer to Chapter 3: Planning for more specific

cable specifications.

Install RF Passage Antennas

Installing RF passage antennas includes the

following:

• Prepare for installation

• Install brackets and mount antennas

• Install wire loop (for antenna pairs)

• Connect RF controller cables

• Install finishing hardware

Prepare for Installation

The following items are required before installation

begins:

• Site plan indicating model of each RF passage

antenna and its mounting location.

• Two cables run between RF antenna mounting

location and RF controller mounting location:

control cable and power cable.

G Inspect the installation, page x.

4-2 8000-2803-01, Rev. 1/A8000-2803-01, Rev. 1/A8000-2803-01, Rev. 1/A8000-2803-01, Rev. 1/A Installation

Page 27

RF Passage Antenna Kit (0351-2180-01)

Description Qty. Part No.

Top Bracket, Passage Antenna 1 0500-5026-01

Butt Splice, FULLINS, 22-16 2 2141-0003

Screws, SDRL 8 x 1/2, PHP, S304 16 2816-7669-01

Anchors, MLY, 8-10, W/PH SCR, 7/8”L 16 2880-0097-01

Wire, HK, 18G, 19x30, TFE, Black 8 6018-0012-01

Install brackets and Mount Antennas

1. With bracket tabs facing up, press bracket

against door frame or wall with bottom of

bracket 17cm (6.75in.) above floor.

Position bracket perpendicular to floor.

Antennas that comprise a pair must be

mounted parallel to each other on opposite

sides of door/opening.

2. Mark and drill mounting screw holes.

Note: Mount bracket using holes adjacent to

mounting tabs. Holes at top and bottom of

mounting bracket are not used at this time (you

may want to pre-drill for later use).

3. Mount antenna bracket using appropriate

mounting hardware from install kit.

Mounting Bracket

4. With antenna’s mounting surface facing

bracket, align three openings over bracket

tabs, press antenna against bracket (1), then

slide antenna down (2) until it is secure.

5. Determine where cables will exit wall/ceiling

and drill holes. Fish required cables through

appropriate holes.

Install Wire Loop for Antenna Pairs

Installation of a wire loop is optional. Check with

project manager to determine if wire loop is

required.

Mounting Tab

Each RF passage antenna includes a loop wire

that runs the length of the antenna, exiting at the

top and bottom (near the mounting bracket). A wire

loop is created when the loop wires of an antenna

pair are connected to each other above and below

the door/portal.

Connecting Wire

Completes Wire Loop

Loop Wire

in Passage

Antenna

Connecting Wire

Completes Wire Loop

Loop Wire

in Passage

Antenna

Exposed wire loop wiring may be concealed with

raceway and/or placed under the doorway

threshold. In some cases it may be necessary to

conceal the lower connecting wire within a floor

trench.

C•CURE Watch Installation and Service Guide 8000-2803-01, Rev. 1/A 4-3

Page 28

1. Remove door threshold, and determine if there

is adequate clearance to place connecting wire

under it without cutting a floor trench.

2. If necessary, cut floor trench (0.3cm [1/8in.]

wide by 1.2cm [1/2in.] deep).

3. Locate ends of loop wire tucked into frame at

top and bottom of each antenna.

Loop Wire

Note: Remove bottom cap to retrieve wire

loop, feed through opening in cap, and reinstall cap.

4. Cut two pieces of wire to complete wire loop

above and below door/portal (connecting

wires).

5. Run top connecting wire above door/portal and

connect to antenna wire at top of each

antenna.

6. Run bottom connecting wire under doorway.

Conceal by replacing threshold or sealing

trench being careful not to pinch wire.

7. Connect to antenna loop wire at bottom of

each antenna.

The wire loop is installed and ready to operate.

2. Connect terminal block to control connector P2

(pin 1 is at outside edge of board).

1: RX–

2: RX+

3: Green LED

4: Amber LED

5: Red LED

6: LED Ground

7: TX

8: N/C

3. Connect 2-conductor power cable to terminal

block as follows:

Pin Function

Pin 1 +16Vdc

Pin 2 Return

Pin 3 Unused

Pin 4 Unused

4. Connect terminal block to power connector P1

(pin 1 is at bottom).

4: Unused

Connect RF Controller Cables

3: Unused

2: Return

1: Vcc

WARNING: RISK OF ELECTRIC

SHOCK! Read manual before

!

servicing.

1. Connect 8-conductor control cable from RF

controller to terminal block on the RF antenna

board as follows:

Pin Function

Pin 1 RX–

Pin 2 RX+

Pin 3 Red LED

Pin 4 Amber LED

Pin 5 Green LED

Pin 6 LED Ground

Pin 7 TX

Pin 8 N/C

Note: See Chapter 5: Service for information

about verifying and optimizing antenna

performance.

4-4 8000-2803-01, Rev. 1/A8000-2803-01, Rev. 1/A8000-2803-01, Rev. 1/A8000-2803-01, Rev. 1/A Installation

Page 29

Install Finishing Hardware

Prepare for Installation

1. Insert stabilizing brackets as shown below, one

at top and one at bottom of antenna. Attach to

mounting bracket with two screws.

Stabilizing Bracket

Mounting Bracket

2. Install antenna top cap.

Place top cap over antenna interface board

starting at front. Position LED window over

LEDs. A pin inside cap front seats in antenna

cover beneath LEDs. Secure at sides with two

screws.

DO NOT leave antenna components exposed

for extended periods.

The following items are required before installation

begins:

• Site plan indicating:

– Installation site of RF controller

– Installation sites of RF antennas and

associated reader addresses

– Inputs and outputs associated with

antenna 1 (optional)

– Installation site of host panel

– Installation site of power supply enclosure

– Optional inputs and outputs are to be

connected to antenna 1.

– Installation site of common terminal block

for RF controller synchronization.

• Two cables (one control and one power) run

between RF antennas and RF controller.

• Optional — cable run between each required

input and output and RF controller.

RF Controller Install Kit (0351-2160-01)

3. Install raceway to conceal exposed wiring.

Install RF Controller

Installing RF controller includes the following:

• Prepare for installation

• Mount the RF controller enclosure

• Connect RF antenna cables

• Connect inputs and outputs

• Connect power supply cable

• Connect communications cable

• Connect sync cable

Verify contents of kit before beginning installation.

Description Qty. Part No.

Plastic Anchors, 10-12, 1”L, w/scr 4 2880-0098-01

Template, C•CURE Watch RFID Contrlr 1 8000-2820-01

Install and Service Guide 1 8000-2803-01

Mount the RF Controller Enclosure

1. Remove screws that secure enclosure cover.

Remove cover by pulling forward slightly at top

and slip cover straight up until cover is free of

the retaining tab at bottom of enclosure.

C•CURE Watch Installation and Service Guide 8000-2803-01, Rev. 1/A 4-5

Page 30

2. Verify that On/Off switch is in off position.

2. Connect terminal block to appropriate antenna

control connector (pin one is solid).

Antenna 1Antenna 2

Mounting

Holes

NL

On/Off Switch

3. Hold enclosure in its mounting location and

mark position of mounting screws (4) at

openings in back of enclosure.

4. Drill holes for screws and install wall anchors if

required. Insert top screws and tighten until

almost flush with wall.

5. Slip enclosure over screws and slide down to

lock screws in keyhole openings.

6. Tighten top screws. Insert bottom screws and

tighten.

Connect RF Antenna Cables

RF antenna cable connections differ depending on

whether RF proximity or RF passage antennas are

used.

Connecting RF Proximity Antenna Cables

RF proximity antennas are not available at this

time.

Connecting RF Passage Antenna Cables

The following steps must be completed for each

RF antenna connected to this RF controller.

1. Connect 8-conductor control cable from RF

antenna to 9-pin terminal block on RF

controller as follows:

Pin Function

Pin 1 Shield

Pin 2 RX–

Pin 3 RX+

Pin 4 Red LED

Pin 5 Amber LED

Pin 6 Green LED

Pin 7 LED Ground

Pin 8 TX

Pin 9 N/C

Antenna 3

Antenna 4

NL

Note: The RF controller provides two

channels. One channel is associated with

antenna connectors 1 and 2 and the other

channel is associated with antenna connectors

3 and 4.

Always connect the two antennas that

comprise a pair to the same channel.

Antenna Connector Channel

Antenna 1 First Channel

Antenna 2 First Channel

Antenna 3 Second Channel

Antenna 4 Second Channel

3. Connect 2-conductor power cables from RF

antennas to 4-pin terminal blocks as follows.

Always combine antennas 1 and 2 on one

connector and antennas 3 and 4 on the other.

Pin Function Connector Antenna

Pin 1 Return P24

Pin 2 +16Vdc P23

Pin 1 Return P22

Pin 2 +16Vdc P21

Antenna 1 or 2

Antenna 3 or 4

4-6 8000-2803-01, Rev. 1/A8000-2803-01, Rev. 1/A8000-2803-01, Rev. 1/A8000-2803-01, Rev. 1/A Installation

Page 31

4. Connect Connect terminal block to appropriate

antenna power connector.

CAUTION: System failure may

!

result if antennas are not connected

as specified below.

Return

NL

Power

P21 / Antenna 4

5. Set antenna address switches. Multiple RF

passage antennas configured as part of the

same RF reader must have corresponding

address switches set to same address.

Important: Set address switches for

unconnected antennas to 0.

Antenna 4

Antenna 3

Antenna 2

Antenna 1

Return

Power

Return

Power

Return

Power

P22 / Antenna 3

P23 / Antenna 2

P24 / Antenna 1

NL

C•CURE Watch Installation and Service Guide 8000-2803-01, Rev. 1/A 4-7

Page 32

Connect Inputs and Outputs

The RF controller provides connections for two

inputs and two outputs. These inputs and outputs

must be associated with the opening/portal

connected to the Antenna 1 connector.

+12Vdc

P20

NL

Output 1

Output 2

+12Vdc

Output

1

Output

2

Output 1

Output 2

Return 2

P19

Input 2

Return 1

Input 1

Inputs must be supervised. All inputs and outputs

are configured from the host system. Inputs must

be wired as shown below.

Circuit protected

outside dotted line.

Circuit protected

outside dotted line.

1K

1K

1K

Supervised,

1K

Normally Closed

Supervised,

Normally Open

The output connector provides internal power for

both outputs. These must be wired in series.

Outputs provide 10 milliamps at 10V and 12V open

circuit.

4-8 8000-2803-01, Rev. 1/A8000-2803-01, Rev. 1/A8000-2803-01, Rev. 1/A8000-2803-01, Rev. 1/A Installation

Page 33

Connect Communications Cable

The RF controller provides two RS-485 connectors

for configuration flexibility. RF controllers may be

daisy-chained to the host panel. In addition to RF

controllers, input/output boards may also be

included in the daisy chain.

1. Connect 2-conductor or 4-conductor, shielded

cable to 5-pin terminal block.

Pin Function

Pin 1 TX/RX

Pin 2 TX/RX

Pin 3 RX

Pin 4 RX

Pin 5 Shield

Note: Connection depends on RS-485

implementation. For 2-conductor, half-duplex

mode connect to TX/RX pins. This mode

operates at 9600 baud. For 4-conductor, fullduplex mode use the TX/RX pins for transmit

and the RX pins for receive.

2. Connect communications cable from panel,

another RF controller, or input/output board to

connector P18 or P36.

RX

RX

TX/RX

TX/RX

Shield

3. Do one of the following:

– If another device, is to be connected to this

RF controller, connect additional

communication cable to 5-pin terminal

block and connect to the available RS-485

connector (P18 or P36).

– If a connection terminates at this RF

controller, the shield must be connected to

a chassis ground instead of the RS-485

connector (P18 or P36).

In addition, pins one and two must be

jumpered on the associated termination

jumper.

Connector Jumper Terminated Unterminated

P18 P10 Pins 1 / 2 Pins 3 / 4

P36 P17 Pins 1 / 2 Pins 3 / 4

Connect Sync Cable

RS-422 synchronization (sync) cabling coordinates

transmit and receive signals on a system-wide

basis to eliminate system-generated interference.

ALL RF controllers must be installed with sync

cabling, even if they are associated with different

host systems. Call Technical Support for

synchronization guidelines regarding RF controllers

installed in separate buildings.

Sync cabling establishes a single daisy-chain

connection for all RF controllers. The daisy chain is

installed through one or more common terminal

blocks.

P18 P36

P10 (Shown

Terminated)

P17 (Shown

Unterminated)

NL

C•CURE Watch Installation and Service Guide 8000-2803-01, Rev. 1/A 4-9

Page 34

Sync cabling establishes one RF controller as

primary and all others as secondary. The first RF

controller in the sync cabling daisy chain becomes

the primary RF controller.

Out +

Out –

Shield

In +

In –

Open

Connect RF Reader at Panel

Connect the RF Reader to the host panel using

instructions provided by the manufacturer.

Note: Shield in RS-485 cable must be connected

to chassis ground at panel.

Connect Power to

P34

NL

The following guidelines must be observed:

• Sync cabling connects to P34.

• Input terminals are not connected on primary

RF controller. Output terminals are not

connected on last secondary RF controller in

daisy chain.

RF Controller

The RF Controller is available in two models:

• Model CW-RID-1 is hard-wired to ac power. It

includes a universal power supply (Eos model

VLT 130-1002).

• Model CW-RID-XPS requires an external

power supply.

WARNING: RISK OF

ELECTRIC SHOCK! Be sure

!

Connect Model CW-RID-1 to AC Power

This model may be hard wired or connected using

a line cord.

Chassis

Ground Wire

power is off before connecting

components.

• Polarity MUST BE strictly observed (output– to

input– and output+ to input+).

To connect sync cable to RF controller:

1. Remove jacket and metal shielding from end of

sync cable, leaving enough to connect to P34.

2. Connect wires to 6-pin terminal block that

mates to P34 on RF controller.

Pin Signal

Pin 1 Open

Pin 2 Input, –

Pin 3 Input, +

Pin 4 Shield

Pin 5 Output, –

Pin 6 Output, +

3. Connect terminal block to P34.

4-10 8000-2803-01, Rev. 1/A8000-2803-01, Rev. 1/A8000-2803-01, Rev. 1/A8000-2803-01, Rev. 1/A Installation

Hard Wired Connection

This step must be performed by a licensed

electrician in accordance with National Electric

Code and applicable local codes.

PE

Neutral

Line

NL

NL

On/Off Switch

Page 35

CAUTION: A 10A, 2 pole, ganged

disconnect device, which also provides

!

short circuit and overload protection, and

has a minimum 3mm open circuit

clearance, in accordance with the

National Electric Code and applicable

local codes must be installed by a

licensed electrician at a location readily

accessible to the equipment.

Ein 10A, 2-poliges, gekoppeltes

Ausschalt-gerät, welches auch über

einen Kurzschluß- sowie

Überbelastungsschutz verfügt, und einen

minimum 3mm offenen Schaltabstand

aufweist, nach Übereinstimmung mit den

Nationalen Elektrischen Regelungen

sowie lokalen Regeln, muß an einem

Standort installiert werden, welcher

einfachen Zugang zum Gerät erlaubt.

Cord Connection

Use one of the following installation kits.

Power Cord (NA)

Description Qty. Part No.

Txxx 1 0xxx-xxxx-01

Txxx 1 0xxx-xxxx-01

Power Cord (EU)

Description Qty. Part No.

Txxx 1 0xxx-xxxx-01

Txxx 1 0xxx-xxxx-01

CAUTION: For installation using a line

cord, the socket-outlet must be installed

!

near the equipment and at a location

which is easily accessible.

Für Installationen mit einem Stromkabel

muß die Steckdose an einem Standort

installiert werden, welcher einfachen

Zugang erlaubt.

1. Verify that RF controller is turned off.

2. Use knockout at bottom left corner of

enclosure to access the power connector.

3. Connect incoming ac wires to the connector for

115Vac or 230Vac operation based on the

following:

NAa Europe Pin Function

Green/Yellow Green/Yellow PE Ground

White Blue N Neutral

Black Brown L Line

4. For FCC compliance, a chassis ground wire is

required. Connect chassis ground wire from a

building ground (such as pipes or conduit) to

the chassis ground terminal in the RF

controller enclosure. Use 16AWG 250V multistranded wire with maximum length 1.8m (6ft).

1. Verify that RF controller is turned off.

2. Tighten strain relief into conduit knockout at

bottom of enclosure.

3. Thread power cord through strain relief and

secure.

4. Connect incoming ac wires to the connector for

115Vac or 230Vac operation based on the

following:

NA Europe Pin Function

Green/Yellow Green/Yellow PE Ground

White Blue N Neutral

Black Brown L Line

5. For FCC compliance, a chassis ground wire is

required. Connect chassis ground wire from a

building ground (such as pipes or conduit) to

the chassis ground terminal in the RF

controller enclosure. Use 16AWG 250V multistranded wire with maximum length 1.8m (6ft).

C•CURE Watch Installation and Service Guide 8000-2803-01, Rev. 1/A 4-11

Page 36

Inspect Installation

Verify System Operation

A final inspection of the installation should be

conducted before applying power to the system.

1. Verify that the RF controller power switch is

turned Off.

NL

2. Inspect RF controller, host panel, power supply

enclosures, and wiring connections:

– Remove metal shavings and other

installation debris from enclosures.

– Verify that all connections are secure.

On/Off Switch

There are two levels of system verification:

• Functional test of RF controller and RF

antenna does not require connection to panel.

• Full system test requires connection to panel

and configuration of host system.

Functional Test

The functional test consists of an RF antenna LED

test and a signal detection test.

RF Antenna LED Test

1. Verify that rotary switches have been set for

this antenna configuration.

2. Record rotary switch settings.

3. Change rotary switches to 9-1-1-9.

4. Turn RF controller Off, then On to activate test

mode. It may take a short time for the test to

begin.

Green, amber, and red LEDs on all antennas

connected to this controller should light in

sequence.

Apply Power

1. Provide power to the RF controller.

2. Turn the RF controller power switch On.

5. Set rotary switches back to original

configuration or to setting for signal detection

test.

6. Turn RF controller Off, then On for settings to

take effect.

RF Antenna Signal Detection Test

1. Verify that rotary switches have been set for

this antenna configuration.

2. Record rotary switch settings.

3. Change rotary switches to 9-1-0-9.

4. Turn RF controller Off, then On to activate test

mode. It may take a short time for the test to

begin.

The RF antenna LEDs should remain off until a

badge or tag is detected. Detection of a badge

or tag should activate the amber LED. Blinking

of the LED indicates a weak detection.

5. Set rotary switches back to original

configuration.

6. Turn RF controller Off, then On for settings to

take effect.

4-12 8000-2803-01, Rev. 1/A8000-2803-01, Rev. 1/A8000-2803-01, Rev. 1/A8000-2803-01, Rev. 1/A Installation

Page 37

Full System Test

The full system test requires configuration of the

C•CURE 800/8000. To add an RF reader to the

host system, refer to the C•CURE 800/8000

Administrator’s Guide (UM-028) and the C•CURE

800/8000 Asset Manager User’s Guide (UM-033).

To verify system operation you must configure the

following software parameters:

• Configure C•CURE Watch readers.

• Define tag and card formats.

• Define tags and cards to be tested.

Based on system configuration, test each opening

with tags and/or badges. Verify that system

identifies and responds as expected based on

system configuration. Be sure to test the following:

• Detection of tags and/or badges.

• Read range of reader extends at least .9m (3ft)

in front of antennas.

• C•CURE 800 recognizes and reports detected

tags and badges.

• Inputs and outputs operate correctly.

Chapter 5: Service provides information on

troubleshooting system and antenna read range

problems.

C•CURE Watch Installation and Service Guide 8000-2803-01, Rev. 1/A 4-13

Page 38

4-14 8000-2803-01, Rev. 1/A8000-2803-01, Rev. 1/A8000-2803-01, Rev. 1/A8000-2803-01, Rev. 1/A Installation

Page 39

Service

In This Chapter

Parts List..................................................................................................................... 5-2

RFID 56 Format .......................................................................................................... 5-2

Tune RF Passage Antennas ...................................................................................... 5-2

DIP Switch Settings .................................................................................................... 5-4

Troubleshooting Tips .................................................................................................. 5-5

Chapter 5

C•CURE Watch Installation and Service Guide 5-1

Page 40

Parts List

Description Product Code

C•CURE Watch RF Controller

with universal power supply CW-RID-1

RF Passage Antenna, Model A CW-ANT-PA

RF Passage Antenna, Model B CW-ANT-PB

C•CURE Watch Programmed Badge CW-FBRW-1

RFID 56 Format

Tune RF Passage Antennas

WARNING: RISK OF

!

To optimize system performance, each RF

passage antenna must be tuned. The tuning

process uses six tuning jumpers to peak antenna

voltage.

ELECTRIC SHOCK! When

powered, high voltage exists on

the antenna board and at

tuning jumpers.

The RFID 56 card format must be selected in the

Card Format window of C•CURE 800/8000. If it is

not an available choice, the following information

should be entered:

Identification

Name: RFID 56

Card Characteristics

Format Usage: Select Access control if this is

an access only installation.

Select Asset tracking if this is

an asset and access or an

asset only installation.

Type: Proximity

Field List

Field Type

Start

Length

Compl.

P. Start

P. Length

Shift

Facility Code 17 16 No 0 0 0

Card Number 33 24 No 0 0 0

Tuning Guidelines

RF passage antennas located within 4.6m (15ft) of

an antenna being tuned may interfere with the

tuning process (other passage antennas connected

to the same RF controller as antenna being tuned

DO NOT interfere with tuning). Interference is

possible even if antenna is connected to another

system or not connected to any system. Follow

these guidelines to eliminate the possibility of

interference:

• If interfering passage antenna can be moved,

place it further than 4.6m (15ft) from antenna

being tuned.

Tuning Procedure