Page 1

Company Confidential

AMS-9040 Controller

Installation and Service Guide

Contents

To the Installer....................................................... 1

About the Product.................................................. 2

Operation ...........................................................2

Device Connections........................................... 3

Installation Features........................................... 7

Service Features................................................ 8

Installation............................................................. 9

Installation Requirements .................................. 9

Installation Procedure ...................................... 10

Power Connections.......................................... 13

Sample Hookups.............................................. 14

Troubleshooting................................................... 15

System Status Alert Codes..............................15

Laptop/Modem Connections............................ 16

Fuse Replacement........................................... 17

Specifications...................................................... 18

Declarations ........................................................ 18

To the Installer

This installation and service guide explains how to

install, setup, and service the AMS-9040 controller.

Parts required to install this system are:

- AMS-9040 Controller (ZEAISLEPP)

- Digital AM antennas (various)

- Extension bracket 0500-9792-01 (optional)

- AMS-9040 Controller Keyswitch (optional)

Other documents that may be required for

installation are:

- Planning Guide, 8200-0367-01

- Antenna Installation Guide (various)

- Antenna Controller Keyswitch, 8200-0367-04

Note:

- Because customer requirements dictate the

placement of system components, your

Sensormatic representative will supply this

information separately.

- If this product was installed in a European

Union or European Free Trade Association

member state, please give the Declaration of

Conformity included with this product to the

manager or user. By law, this information must

be provided to the user.

- There may be restrictions on the installation of

certain antennas in certain countries. Please

see the antenna installation guides for

documentation of the restriction.

Appendix A: About Auto Sync........................... 19

© 2004 Sensormatic

AMS-9040 CONTROLLER 8200-0367-02, REV. 9

INSTALLATION AND SERVICE GUIDE

1 of 20

Page 2

Company Confidential

(

)

About the Product

The AMS-9040 controller is part of a

four-channel EAS detector used to detect EAS

tags/labels at store exit(s). The controller:

- Supports transceiver (Tx/Rx) antennas, auxiliary

receiver antennas, and noise coils in any

combination up to the maximum specified.

- Supports controller-assisted tuning of Digital AM

antennas.

- Can power and control up to two remote alarms.

Also supports externally powered alarm devices

and beacon lamps, an alarm management

device, and a Sensormatic Sync Link wireless

sync device.

- Has four relays used to trigger externallypowered alarm devices.

- Supports RS485 networking.

- Has connections for hardwired sync and

transmit inhibit functions.

- Can be placed on a shelf or mounted to a wall.

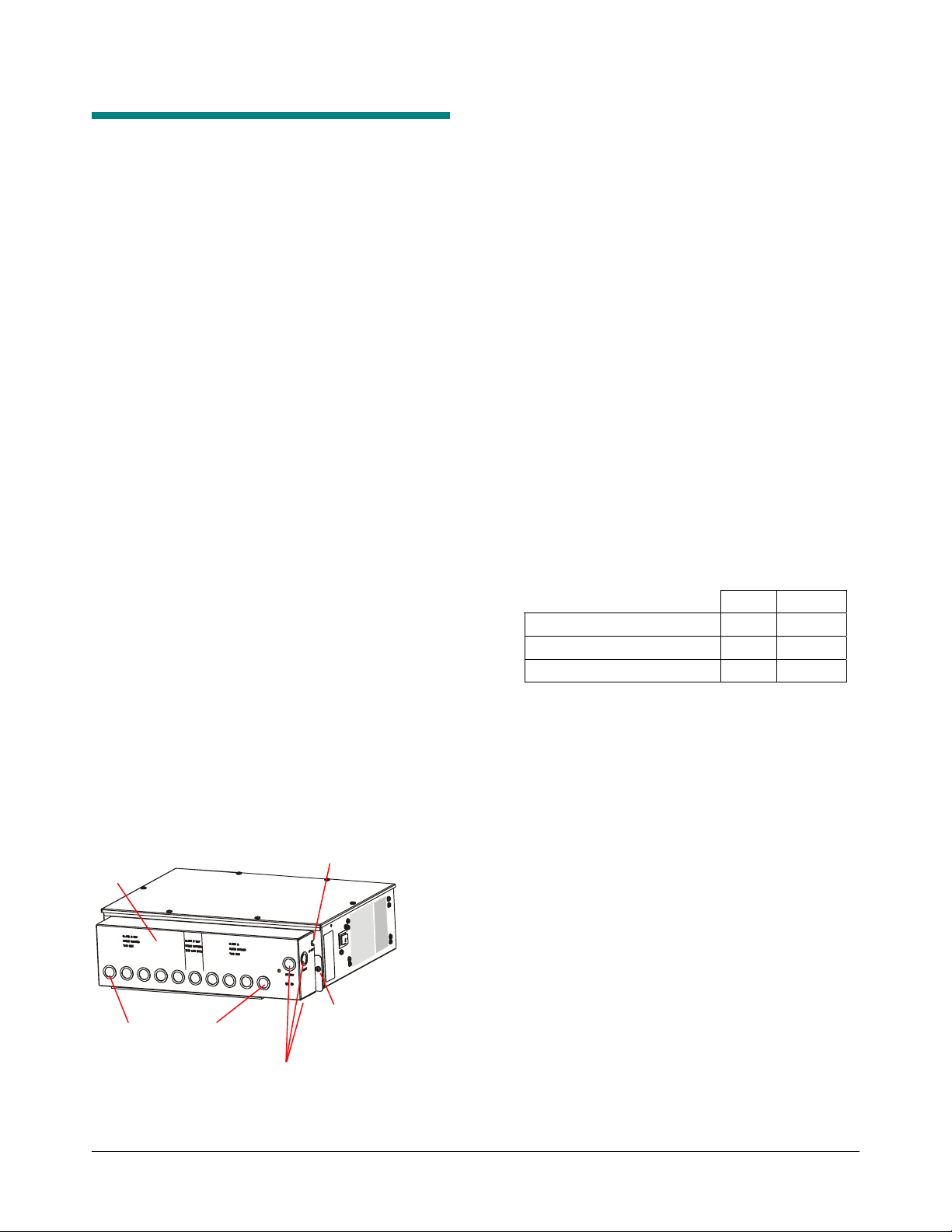

- Consists of an integral cable tray/mounting

bracket assembly and a controller housing that

attaches to it. Two captive ¼-turn fasteners in

the tray secure it to the controller.

- Nineteen knockouts in the cable tray support

exposed cables or cables in conduit. There are

designated knockouts for Class 2 wiring from

low voltage devices, Class 2 “wet” wiring from

an alarm management device, and Class 3

wiring from a transmit antenna.

- Three knockouts in the tray support an exposed

ac cable or the cable in conduit. A U-shaped

opening in the side of the tray allows access for

a power cord, if used instead of the ac cable.

Cable Tray

U-shaped opening for power cord

Operation

The controller deters theft by activating an alarm

when it detects the unique response of an active

Ultra•Max hard plastic tag or disposable label.

To detect a tag, the antenna(s) connected to the

controller emit a magnetic field close to the

tag/label’s natural frequency causing it to vibrate or

“ring” at the frequency of the field. When the field is

removed, energy in the tag/label dissipates causing

an exponential ring down.

The controller processes signal inputs picked up by

the antennas to determine if they are indicative of

ring down. If they are, then the controller activates

an alarm.

Audible and visual indicators located on top of

each antenna indicate an active tag/label is

between the antennas. Alternately, the controller

can trigger a remote alarm module, or double-pole

double-throw relay, one for each antenna. The

controller can also trigger externally powered

devices such as a security camera.

- Antenna coils can be set to aiding or figure-8.

Maximum operating current is as follows for

each coil configuration:

Aiding Figure 8

Non-European 16A 16A

European (except Germany) N/A 12A

Germany N/A 10A

- Maximum cable length between antennas and

controller is 15.2m (50ft). Longer cables can

reduce performance and operating current.

19 knockouts for cables

(1 on side, 8 on underside)

3 knockouts for hardwired AC

(1 on underside)

AMS-9040 CONTROLLER 8200-0367-02, REV. 9

INSTALLATION AND SERVICE GUIDE

Tray to controller

captive ¼-turn fastener

one at each end

2 of 20

Page 3

Company Confidential

Device Connections

Connector pin assignments are listed on pages 4

and 5. Device connections are as follows:

- Transceiver antenna connections (4) and

antenna communication connections (4)

- General-purpose connections (4) for auxiliary

receive antennas and/or noise coils*

- Remote alarm connections (2)

- Beacon lamp connections (2)

- Relay connections (4)

- Alarm management device connection (1)

- RS485 connection (1)

- Wired Tx sync connection (1)

- Tx inhibit connection (1)

- Wireless ac synchronization (Sync Link)

connection (1)

- Service connection (1).

* Only certain inputs support noise coils.

Transceiver (Tx/Rx) Antenna and

Antenna Communication Connections

Transceiver antenna connectors and antenna

communication connectors support the following

transceiver antennas and families:

- Digital Door-Max*

- Digital Floor-Max*

- Digital Pro-Max*

- Digital Euro Pro-Max*

- Ultra•Loop

* Controller-assisted tuning applies. See page 7.

Transceiver connectors (P1, P24, P4, P35). Four

connectors support transceiver antennas

designated A, B, C, and D.

- Tx/Rx antenna A connects to connector P1.

- Tx/Rx antenna B connects to connector P24.

- Tx/Rx antenna C connects to connector P4.

- Tx/Rx antenna D connects to connector P35.

Antenna communication connectors (P5, P25,

P6, P36). Four connectors support controller-

assisted tuning of digital antennas.

- Com for antenna A connects to connector P5.

- Com for antenna B connects to connector P25.

- Com for antenna C connects to connector P6.

- Com for antenna D connects to connector P36.

General-Purpose Connections

(P27, P29, P31, P33)

Four connectors accept auxiliary receive antennas

such as Rangers, Digital Pro-Max, Sky•Max, and

Satellite receivers, and/or noise coils up to the

maximum allowed.

- These connectors default to Rx function with no

auto detection or support for noise canceling

coil support.

- To support noise cancellation, use the service

configurator to set these connectors to noise

canceling mode. Adjustments to default settings

must be saved in the controller for use on the

next power cycle or system reset.

Auxiliary receive antennas or noise coils connected

to the general-purpose inputs are designated A, B,

C, and D.

- Antenna/Coil A connects to connector P27.

- Antenna/Coil B connects to connector P29.

- Antenna/Coil C connects to connector P31.

- Antenna/Coil D connects to connector P33.

IMPORTANT! Each general-purpose connector

has a Coil 1 input and a Coil 2 input. Noise coils

can only connect to the Coil 1 input.

More about noise coils:

- A noise coil is used to cancel specific noise

interfering with detector operation.

- Only “Coil 1’ of a receive antenna can be used

as a noise coil.

- To accept a noise coil, the Coil 1 part of each

general-purpose input must be reconfigured to

noise canceling mode using the service

configurator.

- By moving a noise coil around while monitoring

power levels on the service configurator, field

personnel find the location where noise

cancellation is best. This is where the coil is

likely to be installed.

- The location for noise coil installation must be

practical as well as yield satisfactory results.

Continued on page 6

AMS-9040 CONTROLLER 8200-0367-02, REV. 9

INSTALLATION AND SERVICE GUIDE

3 of 20

Page 4

Company Confidential

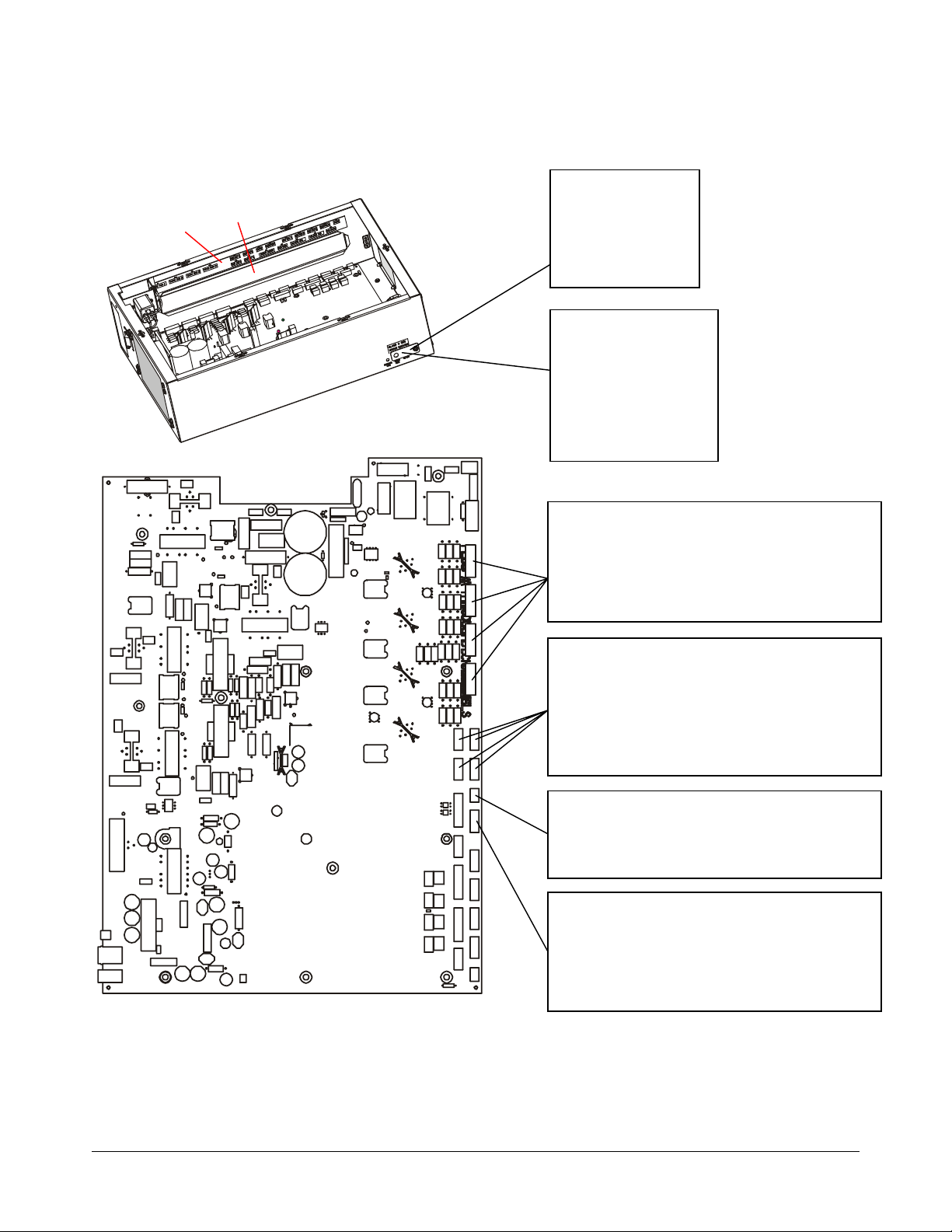

A

A label inside the controller identifies connectors.

Cables pass into enclosure

through here.

Label

AMS-9040 Controller

AMS-9040 Circuit Board

SERVICE (RS232)

(Behind Cover)

Pin 1 - Rx

Pin 2 - Tx

Pin 3 - Ground

Pin 4 - Ground

SYNC LINK

(Behind Cover)

Pin 1 - Ground

Pin 2 - Sync Link out

Pin 3 - Sync Link in

Pin 4 - Ground

Pin 5 - Ground

Pin 6 - Vbus

Tx/Rx: PED A (P1), B (P24), C (P4), D (P35)

Pin 1 - Black (Bottom coil return)

Pin 2 - Red (Bottom coil)

Pin 3 - Green (Top coil return)

Pin 4 - White (Top coil)

Pin 5 - White with an 'X' (Shield)

Continued, next page

GENERAL-PURPOSE AUX. RECEIVE

(P27), B (P29), C (P31), D (P33)

Pin 1 - Black (Coil 1)

Pin 2 - Red (Coil 1 return)

Pin 3 - Green (Coil 2 return)

Pin 4 - White (Coil 2)

Pin 5 - White with an 'X' (Shield)

ULTRA LINK ALARM MANAGEMENT (P41)

Pin 1 - Black

Pin 2 - Red

Pin 3 - White with an 'X' (Shield)

BEACON LAMP (P10)

Pin 1 - Black (Lamp A)

Pin 2 - Red (+12V signal lamp A)

Pin 3 - Black (Lamp B)

Pin 4 - Red (+12V signal lamp B)

Pin 5 - White with an 'X' (Shield lamp A/B)

AMS-9040 CONTROLLER 8200-0367-02, REV. 9

INSTALLATION AND SERVICE GUIDE

4 of 20

Page 5

Continued from previous page

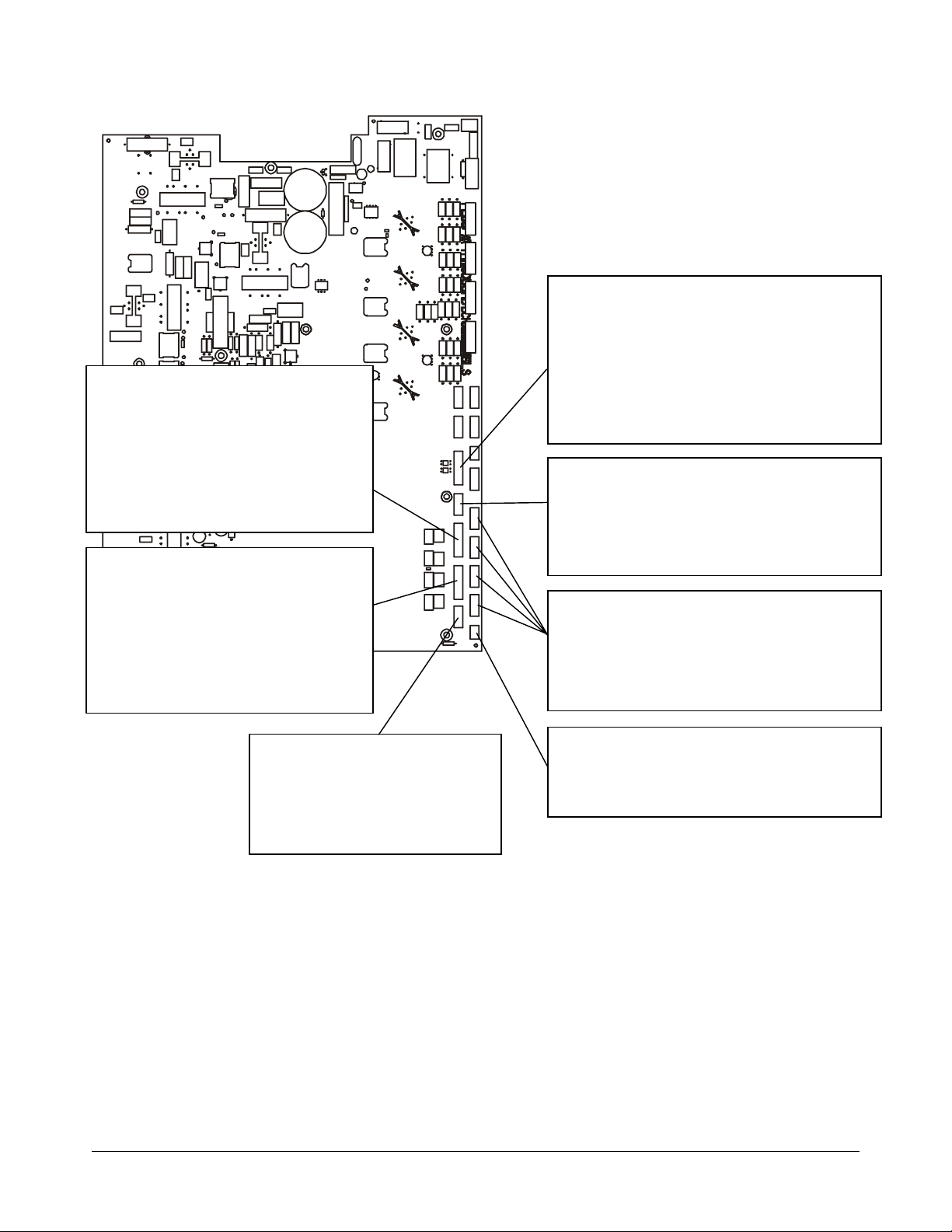

A

RELAYS C-D (P9)

Pin 1 - C (Relay C)

Pin 2 - NC (Relay C)

Pin 3 - NO (Relay C)

Pin 4 - White with an 'X' (Relay C Shield)

Pin 5 - C (Relay D)

Pin 6 - NC (Relay D)

Pin 7 - NO (Relay D)

Pin 8 - White with an 'X' (Relay D Shield)

RELAYS A-B (P12)

Pin 1 - C (Relay A)

Pin 2 - NC (Relay A)

Pin 3 - NO (Relay A)

Pin 4 - White with an 'X' (Relay A Shield)

Pin 5 - C (Relay B)

Pin 6 - NC (Relay B)

Pin 7 - NO (Relay B)

Pin 8 - White with an 'X' (Relay B Shield)

Company Confidential

REMOTE ALARMS (P7)

Pin 1 - 12V return

Pin 2 - 12V alarm

Pin 3 - Alarm 0

Pin 4 - 12V return

Pin 5 - 12V alarm

Pin 6 - Alarm 1

Pin 7 - Shield (Alarm 0/1)

Pin 8 - NC

WIRED Tx SYNC (P2)

Pin 1 - Black (Tx Burst High)

Pin 2 - Red (Tx Burst Low)

Pin 3 - Green (Arm High)

Pin 4 - White (Arm Low)

Pin 5 - White with an 'X' (Shield)

NT COM: PED A (P5), B (P25), C (P6), D (P36)

Pin 1 - Black (12V Return)

Pin 2 - Brown (RS485 Low)

Pin 3 - Red (RS485 High)

Pin 4 - Orange (12V Alarm)

Pin 5 - White with an 'X' (Shield)

PED INHIBIT (P26)

Pin 1 - Black (Ped A)

Pin 2 - Red (Ped B)

Pin 3 - Green (Ped C)

Pin 4 - White (Ped D)

Pin 5 - White with an 'X' (Shield)

AMS-9040 CONTROLLER 8200-0367-02, REV. 9

INSTALLATION AND SERVICE GUIDE

5 of 20

RS485 (P8)

Pin 1 - Black (RS485 Low)

Pin 2 - Red (RS485 High)

Pin 3 - White with an 'X' (Shield)

Page 6

Company Confidential

Remote Alarm Connections (P7)

This connector can power and control up to two

remote alarms, such as a ZC30 or ZC35.

Beacon Lamp Connections (P10)

This connector can power and control up to two

beacon lamps, supplying up to 12V at 1A for each

lamp.

Relay Connections (P9, P12)

The controller has four double pole double throw

(DPDT) relays, each programmed independently.

These relays are used to trigger devices such as

externally powered remote alarms and beacon

lamps, time lapse VCRs, and security cameras,

one device per detection zone.

Each relay requires three wires and a shield. Cable

shields share one pin on the connector.

Alarm Management and RS485

Connections (P41, P8)

Wireless AC Sync Connection

(On Controller)

Protected by a cover plate, this connector receives

a cable from a Sync Link device which, when

connected, is automatically used as the timing

reference for system functions. See “Automatic AC

Line Synchronization” on page 7. Also, see

Appendix A.

RS232 Service Connection

(On Controller)

Protected by a cover plate, this RJ22 connector

receives the cable from a modem or laptop

computer used to communicate with the controller.

Ped (Tx) Inhibit Connection (P26)

This connector has a maximum of four Tx Inhibit

pins, each configurable using the service

configurator. Each pin, when grounded, turns off a

specified transmitter.

“Ultra” connector P41 powers a Sensormatic alarm

management device. Connector P8 supports

RS485 communication to the device.

Wired Tx Sync Connection (P2)

This connector is used to wire two AMS-9040

controllers together to synchronize them so they do

not interfere with each other.

Note: The controller also provides for a slower

sequencer level synchronization to allow two

Digital Floor-Max antennas to be placed next to

each other when driven by different controllers.

AMS-9040 CONTROLLER 8200-0367-02, REV. 8

INSTALLATION AND SERVICE GUIDE

6 of 20

Page 7

Company Confidential

Installation Features

Installation features are as follows:

- Automatic detect and setup functions

- Controller-assisted antenna tuning

- Transmitter current control

- Wall mounted controller. Requires mounting

bracket with extension.

Automatic Detect and Setup Functions

Device Detect. The controller automatically

detects digital AM antennas, when they are

connected to the controller and the controller is

powered on. Once these antennas are autodetected, the controller sets them up as

transceivers and sets their sequence of operation

to “simultaneous-alternating” as shown below.

ANTENNA SEQUENCE

Digital Pro*Max Simultaneous–Alternating

Digital Door*Max Simultaneous–Alternating

Digital Euro Pro*Max Simultaneous–Alternating

Digital Floor*Max Alternating maximum

repetition rate is 45Hz.

Unknown Alternating maximum

repetition rate is 45Hz

(60Hz), or 37.5Hz (50Hz).*

* When an antenna without device identification, such

as an Ultra*Post secondary antenna, is detected,

the repetition rate does not exceed this value due to

de-rating of capacitors on the capacitor tuning circuit

board.

The controller also detects a SyncLink device,

when connected. See page 6.

Automatic ac line synchronization. Upon power

up or system reset, the controller automatically

adjusts its operation to the ac input’s frequency

and voltage.

Also, to avoid interference from nearby EAS

detectors, upon power up or system reset, the

controller automatically adjusts the ac-derived

timing of its transmit and receive functions to that

of nearby EAS transmitters, if detected. Auto sync

status is displayed on the service configurator.

Note: If a Sync Link device is connected to the

controller, the controller automatically uses its

signal as the timing reference instead. The service

configurator indicates that Sync Link is active.

Controller-Assisted Antenna Tuning

A series of LEDs on the tuning circuit board of a

digital AM antenna indicate to field personnel when

and where tuning jumpers are to be placed for

optimum antenna performance. For specific

information, see the installation guide supplied with

the antenna.

Note: Proper AC line delay must be selected

before performing controller-assisted tuning.

Transmitter Current Control

The controller allows transmit current to be

adjusted to the maximum allowed for the region of

use.

- The controller checks current in each transmitter

and the antenna coil configuration: aiding or

figure-8.

- If current reaches a pre-determined level, a

signal is sent to software that indicates current

is excessive and which antenna is affected. The

controller also shuts down the transmitter for

one second before operation resumes.

Mounting the Controller

DO NOT mount the controller with its fan

!

Using the mounting bracket supplied, the controller

can be mounted as follows:

- On a shelf.

- On a wall. If required, use the extension bracket

provided to enable mounting screws to thread

into wall studs. DO NOT mount the controller

with its fan facing up!

- To a ceiling. Secure a piece of plywood larger

than the mounting bracket to the ceiling

structure that holds the drywall. Then attach the

bracket to the plywood.

facing up!

AMS-9040 CONTROLLER 8200-0367-02, REV. 8

INSTALLATION AND SERVICE GUIDE

7 of 20

Page 8

Company Confidential

Service Features

Service features are as follows:

- Laptop computer service configurator

- Internal diagnostics

- LED status indicator

- Remote diagnostics via modem, Ethernet, or

RS485 network. Must have external converter

to support Ethernet.

Service Configurator

A service configurator downloaded to a laptop

computer is required to setup and troubleshoot the

controller. The service configurator allows you to:

- Set antenna coil configuration as aiding or

figure-8

- Customize detection for each antenna

- Monitor transmit and noise levels from each

antenna

- Monitor transmit current from each antenna

- Customize alarm setup

- Turn off transmitters (via pedestal inhibit port)

- Monitor temperature inside the controller

- Download new software features/updates to

flash memory

- Provide a system error report

- Separate a problem into one of three

categories: controller, environment, or the

device connected to the controller, such as

antennas or remote alarms.

Note: Special tools are not required when installing

the controller as long as antennas are installed in a

reasonable noise environment and local

transmitters are properly adjusted.

Note: If default settings are changed, you do not

need to turn the controller off and on to store them.

®

Operating software required: Windows

2000, or XP.

95, 98,

Internal Diagnostics

The controller provides the following internal

diagnostics:

- The service configurator displays operating

current for each antenna.

- The service configurator displays ambient

temperature within the controller.

- The service configurator enables the controller

to be reset remotely after a software download.

- The controller has runaway software protection.

- Board diagnostics.

LED System Status Indicator

An LED system status indicator on the controller

indicates the following:

- Green flashing (system on and okay)

- Yellow flashing (performance downgraded;

service recommended)

- Red flashing in a particular sequence (fault

detected, call for service).

The number of red flashes identifies a digit in a

two-digit alert code (for example, four flashes is

the number four). The start of an alert code is

indicated by a long LED interval. Then the first

digit of the code occurs, followed by a short

delay, followed by the second digit.

Alert codes are listed on page 15.

Remote Diagnostics

Remote diagnostics enables the use of a computer

at another location to troubleshoot problems and

change controller parameters.

- The controller must be connected to a properly

programmed modem and telephone line, or to

an Ethernet or RS485 network.

- An external adapter is required.

AMS-9040 CONTROLLER 8200-0367-02, REV. 8

INSTALLATION AND SERVICE GUIDE

8 of 20

Page 9

Installation

Installation Requirements

Verifying Equipment and Unpacking

- Verify that all equipment has arrived. Ensure the

system configuration is the right one for the

installation site.

- Unpack major components in a back room. At

the install site, lay out parts in the order you will

need them. Do not clutter the aisle or cause a

trip hazard.

Installer/Contractor

- Have electrical work comply with the latest

national electrical code, national fire code, and

all applicable local codes and ordinances.

- Coordinate work with other trades to avoid

interference.

- Verify existing site conditions and coordinate

with the owner’s representative and appropriate

utilities as required.

- Obtain copies of all related plans, specifications,

shop drawings and addenda to schedule and

coordinate related work.

- Thoroughly review the project to ensure that all

work meets or exceeds the above requirements.

Bring alleged discrepancies to the attention of

Sensormatic Electronics.

Controller Requirements

If using conduit:

- In the cable tray part of the cable tray/mounting

bracket assembly, there are three ½” or ¾”

knockouts for hardwired ac power and nineteen

½" or ¾" knockouts for antenna and other

cables.

- Select knockouts closest to cable connectors.

- DO NOT route more cables through conduit

than regulation allows.

Company Confidential

Mounting limitations are as follows:

- The wall must support 29.2kg (64.6 lbs) or four

times the weight of the controller assembly.

- Mounting options are mounting directly to two

metal or wood wall studs, mounting indirectly to

a wood board attached to two metal or wood

studs, mounting to drywall using suitable

hardware that can support the weight, or placing

the controller on a shelf.

- When mounting to wall studs, if holes in the

controller’s integral cable tray/mounting bracket

assembly do not align with the two wall studs,

use the extension bracket supplied to achieve

alignment.

- Do not mount controller with its fan facing up.

WARNING! Do not install this product

!

Antenna Requirements

See antenna installation guide for antenna

installation requirements.

Equipment Required

Basic setup requires the following equipment:

• Antenna controller

• Digital AM antennas (installation instructions are

supplied with the antenna)

• Hard tag (non-deactivateable Ultra•Max tag)

• Ultra•Max low energy labels.

Advanced setup requires the following additional

equipment:

• Laptop with Windows

operating software

• RS232 Ultra•Max programming cable

• Service configurator.

where highly combustible or explosive

products are stored or used.

WARNING—RISK OF ELECTRIC

SHOCK! During installation, if the

antenna must be left unattended, turn off

the power or cover high voltage

components to prevent unauthorized

access to hazardous voltages.

®

95, 98, 2000, or XP

Parts Required

Bracket, extension 1 0500-9792-01

Tray, cable 1 0404-0175-01

AMS-9040 CONTROLLER 8200-0367-02, REV. 8

INSTALLATION AND SERVICE GUIDE

9 of 20

Page 10

Company Confidential

A

Installation Procedure

This section describes installation procedures for

when the controller is to rest on a shelf, or be

attached to a wall or ceiling.

When Controller Rests on a Shelf

1. Remove the cover from the top of the controller,

then detach the integral cable tray/mounting

bracket assembly from the controller. Two

captive ¼-turn fasteners secure the assembly.

Controller

Bracket

ssembly

¼-turn fasteners (2)

2. Of the 19 knockouts in the cable tray dedicated

to cables, remove the ones closest to the

connectors they are associated with. DO NOT

remove the three knockouts used to access the

ac connection area. Observe Class 2, Class 2

“wet”, and Class 3 requirements silkscreened

on the cable tray.

3. Thread cable clamps into the holes. Run cables

(except power) through the cable clamps

leaving about 30cm (12in) of excess on the

other side. Tighten the clamps.

4. Attach connectors supplied to the cables, route

cables through the rectangular opening in the

controller housing, and referring to the diagrams

on pages 4 and 5, plug them into the

appropriate circuit board connectors:

a. Transceiver antenna(s)

b. Antenna communication line(s)

c. Auxiliary receive antenna(s), if required

d. Remote alarm(s), if required

e. Beacon lamp(s), if required

f. External alarm(s) or other triggered device, if

required

g. Wired Sync, if required

h. Sync Link, if required

i. RS485 network, if required

j. Alarm management device, if required.

5. Connect ac power (see page 13).

6. Attach the controller to the cable tray/mounting

bracket assembly using the two ¼-turn

fasteners.

19 knockouts for cables

(1 on side, 8 on underside)

3 knockouts for hardwired AC

(1 on underside)

AMS-9040 CONTROLLER 8200-0367-02, REV. 8

INSTALLATION AND SERVICE GUIDE

10 of 20

Page 11

Company Confidential

A

Wall Mounting

1. Remove the cover from the top of the controller,

then detach the integral cable tray/mounting

bracket assembly from the controller. Two

captive ¼-turn fasteners secure the assembly.

2. Place the bracket part of the assembly on the

wall, level it, and mark mounting hole locations.

WARNING! The wall must be able to

support 29.2kg (64.6 lbs).

Controller

Bracket

ssembly

¼-turn fasteners (2)

WARNING! Mounting hole locations

must align with two wall studs. If not,

use the extension bracket supplied.

5. If using cable clamps: Thread cable clamps

into the holes. Run cables (except power)

through the cable clamps leaving about 30cm

(12in) of excess on the other side. Tighten the

clamps.

If using conduit: Attach conduit to the cable

tray and run cables to the controller.

6. Attach connectors supplied to the cables, route

cables through the rectangular opening in the

controller housing, and referring to the diagrams

on pages 4 and 5, plug them into the

appropriate circuit board connectors:

a. Transceiver antenna(s)

b. Antenna communication line(s)

c. Auxiliary receive antenna(s), if required

d. Remote alarm(s), if required

e. Beacon lamp(s), if required

f. External alarm(s) or other triggered device, if

required

g. Wired Sync, if required

h. Sync Link, if required

i. RS485 network, if required

j. Alarm management device, if required.

Ensure mounting

holes align with

wall studs.

3. Secure the cable tray/mounting bracket

assembly to each of two wall studs.

4. Of the 19 knockouts in the cable tray dedicated

to cables, remove the ones closest to the

connectors they are associated with. DO NOT

remove the three knockouts used to access the

ac connection area. Observe Class 2, Class 2

“wet”, and Class 3 requirements.

7. Connect ac power (see page 13).

8. Attach the controller to the cable tray/mounting

bracket assembly using the two ¼-turn

fasteners.

Note: If mounting with the cable tray vertical,

hook the metal flange attached to the bottom of

the controller onto the mounting bracket to hold

the controller in place while you slide it into

position.

Flange

19 knockouts for cables

(1 on side, 8 on underside)

3 knockouts for hardwired AC

(1 on underside)

AMS-9040 CONTROLLER 8200-0367-02, REV. 8

INSTALLATION AND SERVICE GUIDE

11 of 20

Page 12

Company Confidential

A

Ceiling Mounting

1. Remove the cover from the top of the controller,

then detach the integral cable tray/mounting

bracket assembly from the controller. Two

captive ¼-turn fasteners secure the assembly.

2. Cut a piece of plywood larger than the mounting

bracket and large enough to attach two ceiling

beams that support the drywall or hard ceiling.

Secure the plywood to the beams using suitable

hardware.

3. Place the bracket part of the assembly on the

plywood and mark mounting hole locations.

Then secure the cable bracket to the plywood.

WARNING! The ceiling must be able to

support 29.2kg (64.6 lbs).

Controller

Bracket

ssembly

¼-turn fasteners (2)

4. Of the 19 knockouts in the cable tray dedicated

to cables, remove the ones closest to the

connectors they are associated with. DO NOT

remove the three knockouts used to access the

ac connection area. Observe Class 2, Class 2

“wet”, and Class 3 requirements.

19 knockouts for cables

(1 on side, 8 on underside)

3 knockouts for hardwired AC

(1 on underside)

5. If using cable clamps: Thread cable clamps

into the holes. Run cables (except power)

through the cable clamps leaving about 30cm

(12in) of excess on the other side. Tighten the

clamps.

If using conduit: Attach conduit to the cable

tray and run cables to the controller.

7. Attach connectors supplied to the cables, route

cables through the rectangular opening in the

controller housing, and referring to the diagrams

on pages 4 and 5, plug them into the

appropriate circuit board connectors:

Ensure mounting

holes align with

wall studs.

a. Transceiver antenna(s)

b. Antenna communication line(s)

c. Auxiliary receive antenna(s), if required

d. Remote alarm(s), if required

e. Beacon lamp(s), if required

f. External alarm(s) or other triggered device, if

required

g. Wired Sync, if required

h. Sync Link, if required

i. RS485 network, if required

j. Alarm management device, if required.

8. Connect ac power (see page 13).

9. Attach the controller to the cable tray/mounting

bracket assembly using the two ¼-turn

fasteners.

MS-9040 CONTROLLER 8200-0367-02, REV. 8

A

INSTALLATION AND SERVICE GUIDE

12 of 20

Page 13

Company Confidential

A

A

Power Connections

Ac power connects to the controller using a power

cord or hardwired cable.

- The power source can be 100-120Vac

or 220-240Vac.

- The controller automatically senses the voltage

so no jumper settings are required.

Power Cord

WARNING—RISK OF ELECTRIC

SHOCK! The ac power cord could be

carrying 120Vac or 240Vac.

CAUTION: When using a power cord, a

socket-outlet must be installed near the

controller and in an easily accessible

location.

Für Installationen mit einem Stromkabel muß

die Steckdose an einem Standort installiert

werden, welcher einfachen Zugang erlaubt.

CAUTION: A 6A, 2 pole, ganged

disconnect device, which also provides

short circuit and overload protection, and

has a minimum 3mm open circuit

clearance, in accordance with the

National Electric Code and applicable

local codes must be installed by a

licensed electrician at a location readily

accessible to the equipment.

Ein 6A, 2-poliges, gekoppeltes

Ausschaltgerät, welches auch über einen

Kurzschluß- sowie Überbelastungsschutz

verfügt, und einen minimum 3mm offenen

Schaltabstand aufweist, nach

Übereinstimmung mit den Nationalen

Elektrischen Regelungen sowie lokalen

Regeln, muß an einem Standort installiert

werden, welcher einfachen Zugang zum

Gerät erlaubt.

Hardwired Cable

CAUTION: Use only copper wire.

Referring to the figure below:

1. Remove one of the three knockouts accessing

the ac connection area in the cable tray. Thread

a cable clamp into the hole.

2. Route the ac cable through a cable clamp,

leaving about 15.2cm (6in) out the other side.

Tighten the clamp around the cable.

3. Expose about 5cm (2in) of insulated wire s: hot,

common, and ground.

4. Using a small screwdriver, connect ac wires to

the two-pin connector: white wire to N (neutral);

black wire to L (line). Connect the green wire to

ground on the controller chassis.

5. Plug the short power cord into the IEC320

receptacle in the controller housing.

6. Return to the installation procedures beginning

on page 10.

U-Shaped Opening

IEC320

Receptacle

Referring to the figure opposite:

1. Route the power cord through the U-shaped

opening accessing the ac connection area in

the cable tray. DO NOT remove the three

knockouts used to access the ac connection

area.

C

Knockouts

(3)

Cable Plug

2. Plug the cord into the IEC320 receptacle in the

controller housing.

C Connections

3. Return to the installation procedure beginning

on page 10.

AMS-9040 CONTROLLER 8200-0367-02, REV. 8

INSTALLATION AND SERVICE GUIDE

13 of 20

Page 14

Sample Hookups

Because antennas and equipment can be

connected to the controller in various ways based

on the number of store exits involved, security

zones required, coverage desired, and customer

preferences, system configurations are too

numerous to describe in this document. Instead,

study the sample systems shown in this section to

provide a feel for how to connect these devices.

(TBD)

Company Confidential

AMS-9040 CONTROLLER 8200-0367-02, REV. 8

INSTALLATION AND SERVICE GUIDE

14 of 20

Page 15

Troubleshooting

System Status Alert Codes

Fault Condition Monitoring

The controller generates alert codes. Software

reads the codes, reports them, and takes

corrective action if possible depending on the code

received. The following critical faults are backed up

with hardware support and provide the necessary

action when encountered.

- Current fault 1 per channel

- Fan fault

- Ambient temperature fault.

- Primary current fault

- Secondary current fault

- Last resort current fault to maintain Class 2

wiring requirements.

Alert codes require different actions: critical,

severe, hardware, and warning. These codes

repeat until the condition is resolved.

1. Critical. Critical and Fatal System Alerts are

displayed on the System Alert LED until a timer

resets the system. If the timer is not enabled, a

unique LED sequence indicates that this

condition has occurred and repeats

continuously.

2. Severe. Severe System Alert codes are

displayed by the System Alert LED and result

in the software recovering from the error in a

deterministic and reliable method.

3. Hardware. Hardware System Alert codes are

displayed by the System Alert LED and result

in the software and hardware working together

to recover from the error in a deterministic and

reliable method when the Alert is resolved.

4. Warning. Warning System Alert codes are

displayed by the System Alert LED and result

in the software recovering from the error in a

deterministic and reliable method.

Company Confidential

When a status alert occurs, the LED indicator

changes color and pattern. Red is used for serious

or critical system alerts while yellow is for less

serious alerts and warnings.

- The number of red flashes identifies a digit in a

two-digit error code (for example, four flashes is

the number four). The start of an error code is

indicated by a long LED interval. Then the first

digit of a two-digit error code occurs, followed by

a short delay, followed by the second digit.

- An alert code does not necessarily mean action

is taken; it simply is a notification that the

system is performing some operation. Most alert

conditions are automatically resolved.

- Up to 80 alert codes are displayed by the Status

LED, except codes that begin or end with a zero

such as 0-9 and 10, 20, 30, 40, 50, 60, 70, 80

and 90. Codes not displayed on the LED may

be accessed only via the service configurator.

- Alert codes are stored in RAM and lost when

the controller is reset. Code storage has a time

stamp in days, hours, minutes, seconds,

milliseconds/ ticks of when the system alert

occurred.

Alert Codes

Alert codes are as follows:

Illegal Instruction

11

Unimplemented Interrupt

12

NVM Write Failed

13

Invalid Device

14

Sequence Table Error

15

Out of Memory

16

Undecided: No Split

17

Watchdog: Task Reset

18

AntA S/W Current Fault

21

AntB S/W Current Fault

22

AntC S/W Current Fault

23

AntD S/W Current Fault

24

H/W Current Fault

25

AntA Current Sense Fault

26

AntB Current Sense Fault

27

AntC Current Sense Fault

28

AntD Current Sense Fault

29

Ped A Not Tuned

31

Ped B Not Tuned

32

Ped C Not Tuned

33

Ped D Not Tuned

34

Ped A Tuning TX Off

35

Ped B Tuning TX Off

36

AMS-9040 CONTROLLER 8200-0367-02, REV. 8

INSTALLATION AND SERVICE GUIDE

15 of 20

Page 16

Ped C Tuning TX Off

37

Ped D Tuning TX Off

38

Sequence Table Mismatch

39

Missing Zero Crossing

41

Wired Sync: Missing Signal

42

Temperature Fault

43

S/W Temperature Fault

44

PWM Fault

45

Fan Fault

46

Realtime Error

49

Autosetup Owner Timeout

51

Autosetup Release W/O Lock

52

Autosetup Buffer Overrun

53

Autosetup Mailbox Full

54

55

Notch Select Timeout

56

Window Select Timeout

57

Autosetup Illegal Owner

58

Detector Overrun

61

Alarm Mailbox Full

62

Host Comm Mailbox Full

63

Host Comm Mailbox Full

64

Host Comm Mailbox Full

71

Company Confidential

Laptop/Modem Connections

A modem enables you to use your computer to

dial-up the controller for remote service.

Hardware required is as follows:

• External modem

• DB25 male to RJ12/RJ11 female connector

• RJ11 male to RJ10 male cable

Procedure

1. Prepare the DB25 to RJ12/RJ11 null modem

connector.

RJ12/RJ11

Inside View

1

2

3

4

5

6

Signal RJ12 DB25

Rx Pin 2 Pin 3

Tx Pin 3 Pin 2

Gnd Pin 4 Pin 7

Controller-Assisted Tuning Disabled

If configurator-assisted tuning cannot be

performed, a message indicating the cause will be

posted on the service configurator. Causes the

software recognizes are:

- Tx set to off in the service configurator.

- Tx inhibit active.

- Auto line delay not ready.

- Key switch turned to off (locked).

Once the CE has turned the transmitter on,

controller-assisted tuning can be performed.

DB25

2

3

7

2. Connect the DB25 connector to the modem.

3. Connect the RJ11 connector to the DB25 to

RJ12/RJ11 connector.

S-9040 CONTROLLER 8200-0367-02, REV. 8

AM

INSTALLATION AND SERVICE GUIDE

16 of 20

Page 17

Fuse Replacement

The controller contains two 5A, 250V, slow-blow

fuses. To replace the fuse(s) in the controller, do

the following:

Fuses (2)

Company Confidential

1. Detach the controller from the cable tray. Two

screws secure the tray, one on each side.

2. On the controller, pry the rectangular cover

plate from the IEC320 receptacle using a small

slotted screwdriver. Two spring-loaded fuses

should pop out.

3. Replace the blown fuse (or fuses) with 5A,

250V slow-blow fuses (P/N 5111-0028-11).

4. Reattach the cover plate to the receptacle.

5. Attach the controller to the cable tray using two

screws previously removed.

AMS-9040 CONTROLLER 8200-0367-02, REV. 8

INSTALLATION AND SERVICE GUIDE

17 of 20

Page 18

Company Confidential

Specifications

Electrical

Power Supply

Primary input ............................100-120Vac or

220-240Vac @ 50–60Hz

Primary power fuse...................5A, 250V, slo-blow,

hi-breaking

Current draw.............................4.0Arms @ 120Vac

Input power...............................<400W

Transmitter

Operating frequency.................58 kHz (±200Hz)

Transmit burst duration.............1.6ms

Transmit current maximum.......16A peak

Burst Repetition Rate:

Based on 50Hz ac ....................75Hz or 37.5Hz

Based on 60Hz ac ....................90Hz or 45Hz

Receiver

Center frequency......................58 kHz

Receive coil resistance.............1.6 ohms (±5%)

Alarm

Declarations

Regulatory Compliance

EMC.............................. 47 CFR, Part 15

EN 300330-1 U1.3.2 (2002)

ETSI EN 300330-2 V1.1.1

(2001-06)

ETSI EN 301489-3 V 1.2.1

(2000-08)

ETSI EN 301489-1 V 1.2.1

(2000-08)

RSS210

Safety............................ UL 60950

CSA C22.2 No 60950

EN 60950

FCC COMPLIANCE: This equipment complies with Part 15

of the FCC rules for intentional radiators and Class A digital

devices when installed and used in accordance with the

instruction manual. Following these rules provides reasonable

protection against harmful interference from equipment

operated in a commercial area. This equipment should not be

installed in a residential area as it can radiate radio frequency

energy that could interfere with radio communications, a

situation the user would have to fix at their own expense.

EQUIPMENT MODIFICATION CAUTION: Equipment

changes or modifications not expressly approved by

Sensormatic Electronics Corporation, the party responsible for

FCC compliance, could void the user's authority to operate the

equipment and could create a hazardous condition.

Alarm relay output.....................DPDT contacts

Contact switching current .........1.0A max.

Contact switching voltage.........28V max.

Lamp/Audio duration.................1–30 sec.

(1 sec. increments)

Environmental

Ambient temperature................0°C to 50°C

(32°F to 122°F)

Relative humidity ......................0 to 90%

non-condensing

Mechanical

Length.......................................50.8cm (20in)

Width with bracket ....................43.4cm (17.1in)

Width without bracket ...............32.2cm (14.3in)

Height.......................................15cm (5.9in)

Weight ......................................7.3kg (16.1lbs.)

Other Declarations

WARRANTY DISCLAIMER: Sensormatic Electronics

Corporation makes no representation or warranty with respect

to the contents hereof and specifically disclaims any implied

warranties of merchantability or fitness for any particular

purpose. Further, Sensormatic Electronics Corporation

reserves the right to revise this publication and make changes

from time to time in the content hereof without obligation of

Sensormatic Electronics Corporation to notify any person of

such revision or changes.

LIMITED RIGHTS NOTICE: For units of the Department

of Defense, all documentation and manuals were developed at

private expense and no part of it was developed using

Government Funds. The restrictions governing the use and

disclosure of technical data marked with this legend are set

forth in the definition of “limited rights” in paragraph (a) (15)

of the clause of DFARS 252.227.7013. Unpublished - rights

reserved under the Copyright Laws of the United States.

TRADEMARK NOTICE: Sensormatic is a registered

trademark of Sensormatic Electronics Corporation. Other

product names mentioned herein may be trademarks or

registered trademarks of Sensormatic or other companies.

No part of this guide may be reproduced in any form without

written permission from Sensormatic Electronics Corporation.

MDR 04/04

AMS-9040 CONTROLLER 8200-0367-02, REV. 8

INSTALLATION AND SERVICE GUIDE

18 of 20

Page 19

Company Confidential

Appendix A:

About Auto Sync

Note: Auto Sync is expected to be only about 80%

reliable due to external environmental issues.

Initialization Phase

Auto sync initialization occurs during power up or

system reset. During initialization, auto sync can

have four different outcomes depending on

whether or not nearby EAS transmitters are

detected, whether they are properly aligned with

the ac-derived functions of the controller, and

whether too much ambient noise exists

No transmitters detected. During initialization, the

controller determines if EAS transmitters are

nearby. If none are found, transmitter delay is set

to zero if this is the initial power on, or set to the

value stored in NVM if this is not the initial power

on. The service configurator displays "No Signal”

and normal operation proceeds.

Transmitters detected and aligned. During

initialization, the controller determines if EAS

transmitters are nearby. If transmitters are found,

and are correctly aligned, transmitter delay is

calculated and set to that value, and the value is

stored in the controller for reference. The service

configurator displays “Locked” and normal

operation proceeds.

Transmitters detected and unaligned. During

initialization, the controller determines if EAS

transmitters are nearby. If transmitters are found,

and are not correctly aligned, transmitter delay is

set to zero if this is the first power on of the

controller, or if not, the delay value is set according

to the value retrieved from the controller and the

service configurator displays “Too Many Signals”.

Operation continues as normal. The user is

advised that system performance might be

compromised. The yellow LED flashes to indicate

system performance is downgraded.

Too much ambient noise. During initialization, the

controller determines if EAS transmitters are

nearby. If noise in the environment prevents the

location other transmitters and if this is the first

power on of the controller, the delay is set to zero.

If this is not the first power on of the controller, the

zero crossing delay is retrieved from storage within

the controller and the service configurator displays

“Too Much Noise”. Operation continues as normal.

The user is advised that the system performance

might be compromised. The status LED flashes

yellow to indicate system performance is

downgraded.

Note: The controller stores the zero crossing delay

for the instance when, during subsequent power

cycles, the controller could not determine a reliable

lock. Instead of using zero for the delay, the

controller uses the zero crossing delay stored.

Sync Link Detection

The Sync Link port is scanned for activity. If activity

is found, the controller automatically switches over

to using the Sync Link signal as the timing

reference. The service configurator indicates that

the Sync Link is active.

Note: If the Sync Link device does not receive the

timing reference signal, it will add up to 60

additional pulses (±100µs). If the controller stops

receiving the required pulse signals, it will measure

the delay from the zero crossing to the SYNCB

signal and start transmitting at that delay until it

reacquires the Sync Link pulse.

AMS-9040 CONTROLLER 8200-0367-02, REV. 8

INSTALLATION AND SERVICE GUIDE

19 of 20

Page 20

Company Confidential

AMS-9040 CONTROLLER 8200-0367-02, REV. 8

INSTALLATION AND SERVICE GUIDE

20 of 20

Loading...

Loading...