Page 1

Preliminary

AMS-1140 Detectors

Setup and Service Guide

ZA1140-D

Contents

About this Guide .................................................... 1

Detector Service Features ..................................... 1

Circuit Board Pinouts ............................................. 3

Service Procedures ............................................... 3

Field Replaceable Units .................................. 3

Replacing the Secondary Cap Board .............. 3

Replacing the Interconnect Cable ................... 4

Installing the Pedestal Installation Kit .............. 5

Replacing the Alarm Board and Lens ............. 6

Replacing the Fuse ......................................... 7

Inhibiting the Transmitter ................................. 7

Using the Software Configurator ..................... 7

Connecting to AC Power ................................. 8

Tuning the Pedestals ...................................... 9

Troubleshooting ................................................... 10

Checking Detector Operation ........................ 10

Dead system/Low sensitivity ......................... 10

False Alarms ................................................. 11

Understanding Error Codes .......................... 11

Interpreting LED Indicators ........................... 12

Specifications ....................................................... 15

Declarations ......................................................... 15

About this Guide

This guide explains how to tune, service, and

troubleshoot AMS-1140 detectors. Related

documents are:

• Installation Guide, AMS-1140 Detector, 82002684-01

Detector Service Features

AMS-1140 detectors have the following servicerelated features:

• Power on self-test. Upon power up or

hardware reset, detector software runs a selftest to ensure it functions.

• Diagnostics. You use a laptop computer and

configuration software to set up and configure

the detector, and to determine its operational

status. The detector also has an LED (DS5)

inside the primary pedestal that flashes an error

code if system software should fail.

• Alarm indication. The top cap of the primary

pedestal contains flashing LEDs; the base

cover of the primary pedestal contains a piezo

for an audio alarm. The volume of the audio

alarm is controlled with a pot (RV3) on the main

circuit board in the primary base cover.

• Transmit inhibit. The base of the primary

pedestal has a hole that provides access to a

transmit-inhibit pushbutton.

• Tags Too Close indication. If this feature is

enabled by the configurator, the pedestal will

flash a unique alarm pattern when a nondeactivated label or tag is left in the detection

field of the detector for awhile.

• Adjacent transmitter interference reduction.

This feature allows service to adjust the Energy

Trim Level to decrease the impact of electronic

noise from nearby anti-theft systems.

• Backfield reduction. If enabled by the

configurator, the detector will reduce the size of

the detection field behind the pedestals.

• Simplified design. AMS-1140 detectors are a

simplified design and do not support the

following features or options: people-counting,

relays, auto-phase, wired sync, jammer detect,

auxiliary receivers, remote alarms and external

alarm counters.

© 2010 Sensormatic Electronics LLC

AMS-1140 DETECTORS 8200-2684-02, REV. 0

SETUP AND SERVICE GUIDE

1 of 15

Page 2

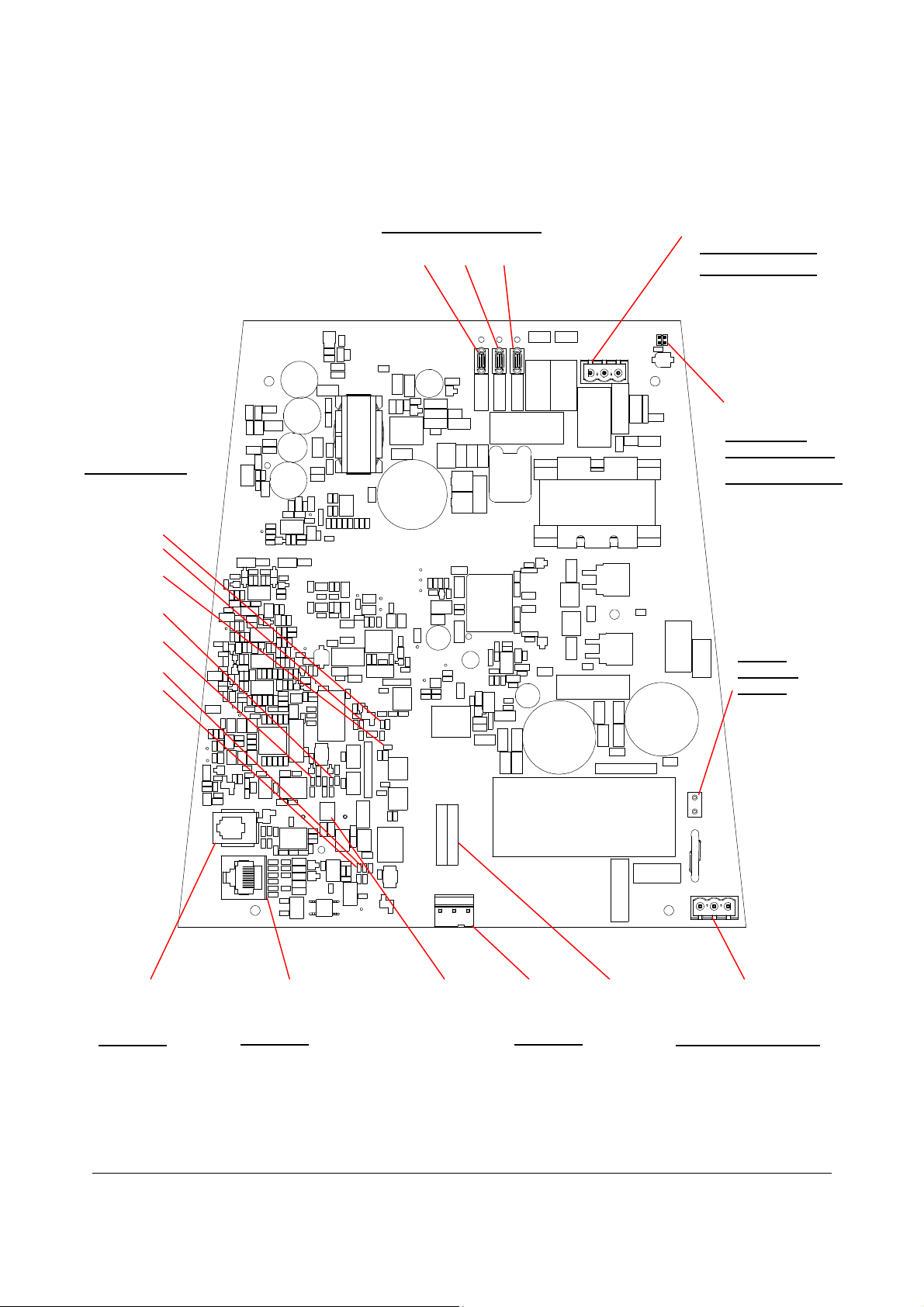

Figure 1. Primary pedestal main circuit board (0312-3072-01) pinouts

J4 J3 J2

Status Jumpers

(See Figure 5 for

close-up).

DS4

DS5

DS3

DS1

DS2

DS7

DS6

Primary Tuning Jumpers

P5

Tx Coil Connector

Pin Signal Color

1 TX White

2 GND Shield

3 TX RET Black

1

1

P3

Alarm Board

Cable Connector

Pin Signal Color

1 GND Shield

2 ALARM Black

3 Unused

4 +12V Red

J1

Voltage

Selection

Jumper

1

J5 RV3

Pin Signal

1 RS-232 RX

2 RS-232 TX

3 GND

4 GND

J6

Pin Signal

1 RS-485 HI *

2 RS-485 LO *

3 SYNC HI

4 NOT USED

Piezo

Volume

Pot

1

Pin Signal

1 NEUTRAL

2 GND

3 LINE

P4

F1

Fuse Line Input

Interconnect Connector RS-485 Network Port Service Port

Pin Signal Color

1 TX White

2 GND Shield

3 TX RETURN Black or Red

P6

5 NOT USED

6 SYNC LO

7 GND

8 GND

AMS-1140 DETECTORS 8200-2684-02, REV. 0

SETUP AND SERVICE GUIDE

2 of 15

Page 3

Circuit Board Pinouts

The AMS-1140 pedestals each have a circuit

board in their bases. Figure 1 and Figure 2 show

the location of connectors, LEDS, jumpers, and

fuses, as well as pinouts for the connectors.

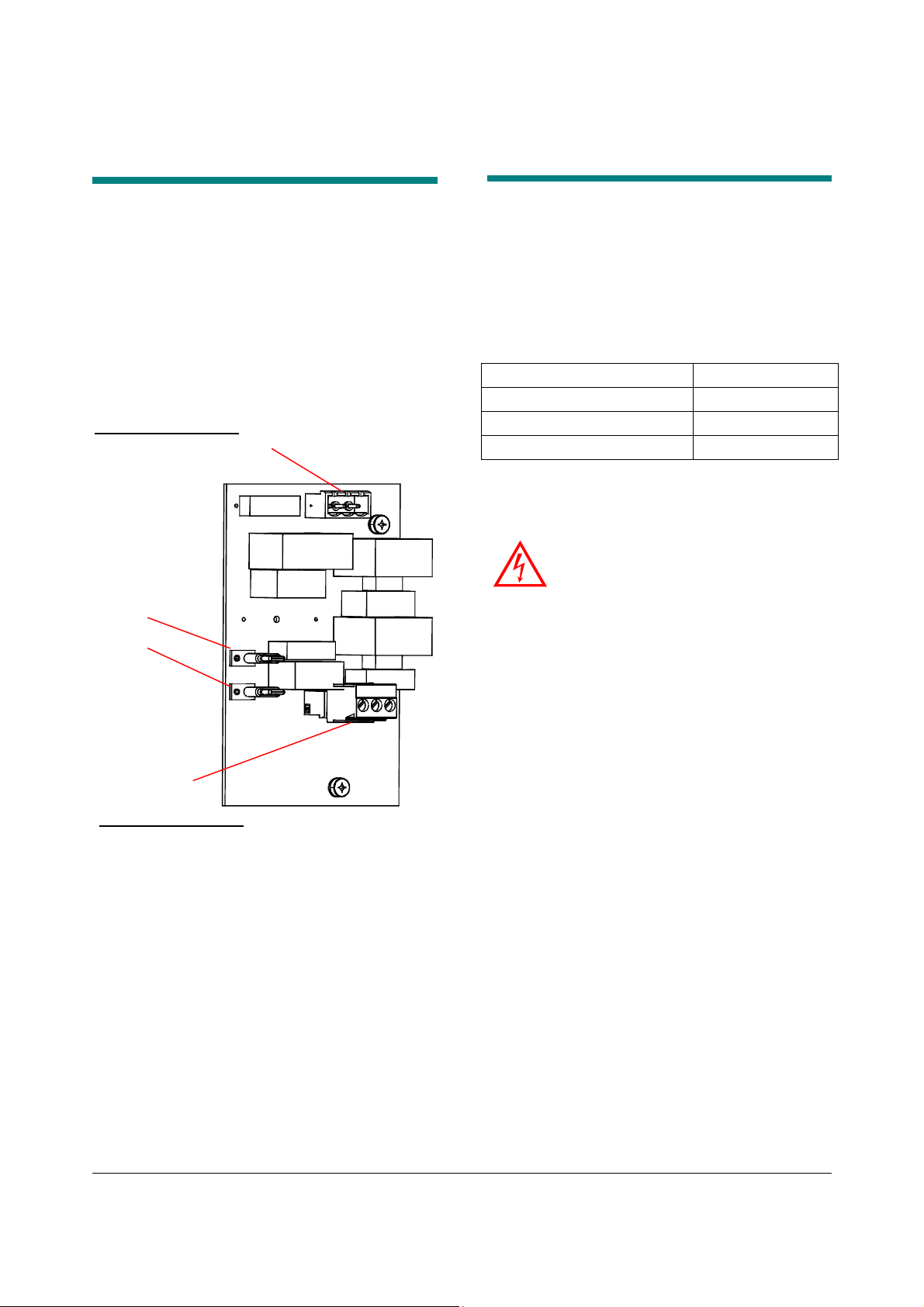

Figure 2. Secondary pedestal capacitor board

(0312-3075-01) pinouts

P2

Tx Coil Connector

Pin Signal Color

1 TX White

2 GND Shield

3 TX RETURN Black

1

Secondary

Tuning jumpers

J1

J2

1

Service Procedures

This section covers the setup and service of the

AMS-1140 detector.

Field Replaceable Units

The AMS-1140 has the following Field

Replaceable Units (FRU):

Secondary capacitor board 0312-3075-01

Interconnect cable 0652-0506-01

Pedestal installation kit 0352-0444-01

Alarm lens installation kit 0352-0444-02

Replacing the Secondary Cap

Board

1. Turn off power to the pedestal at the circuit

2. Remove the cover from the exit side of the

WARNING—RISK OF ELECTRIC

SHOCK! Disconnect AC power when

servicing.

breaker.

secondary pedestal. To do this: loosen the four

fasteners at the base of the cover, and then lift

the bottom of the cover up and then off the

base.

P1

Interconnect

cable connector

Pin Signal Color

1 TX White

2 GND Shield

3 TX RETURN Red or Black

3. On the secondary board, disconnect the Tx Coil

cable from connector P1 and the primary

pedestal from connectors P2. Pull on the

connectors, not the wires.

4. Loosen two fasteners securing the capacitor

board and remove it from the base cover.

Retain the insulator for the replacement board.

5. Use the two fasteners to secure the new

capacitor board to the base cover.

6. Reconnect the two cables to the capacitor

board.

7. Put the cover back on the base, ensuring that

you do not pinch any cables.

8. Tighten the four screws holding the base cover.

AMS-1140 DETECTORS 8200-2684-02, REV. 0

SETUP AND SERVICE GUIDE

3 of 15

Page 4

White

Black or Red

Ground

White

Red or Black

Ground

cable

cable

Replacing the Interconnect Cable

Interconnect cable

entry hole

Interconnect

cable

Trench

1. Route the interconnect cable through the

interconnect cable entry hole on each pedestal.

The end of the cable that has been stripped

and has heat shrink goes to the primary

pedestal; the other end goes to the secondary.

2. Route the interconnect cable through the

Interconnect cable entry port on the primary

pedestal. Make sure you have the end of the

cable that has been stripped and has heatshrink tubing.

CAUTION: Do not coil any cable inside

the base of the primary pedestal.

3. Connect the interconnect cable to the

connector plugged into P6 on the main board.

4. Cut the interconnect cable to the proper length,

allowing 15cm (6in) of extra cable for future

servicing. Strip the ends of the interconnect

cable wires.

P2

P1

Transmitter

Pin 3

P6

Pin 2

Interconnect cable

entry port

Pin 1

Pin 3

Pin 2

Pin 1

Interconnect

CAUTION: Do not coil any cable inside

the base of the secondary pedestal.

5. Connect the interconnect cable to the

connector plugged into P1 on the capacitor

board in the secondary pedestal. Unlike some

other detectors, the secondary pedestal must

be connected to the primary in order for the

system to work properly.

ULTRA•POST DETECTORS WITH SWITCHED MODE TRANSMITTER 8000-2595-07, REV. E

SETUP AND SERVICE GUIDE

4 of 15

Page 5

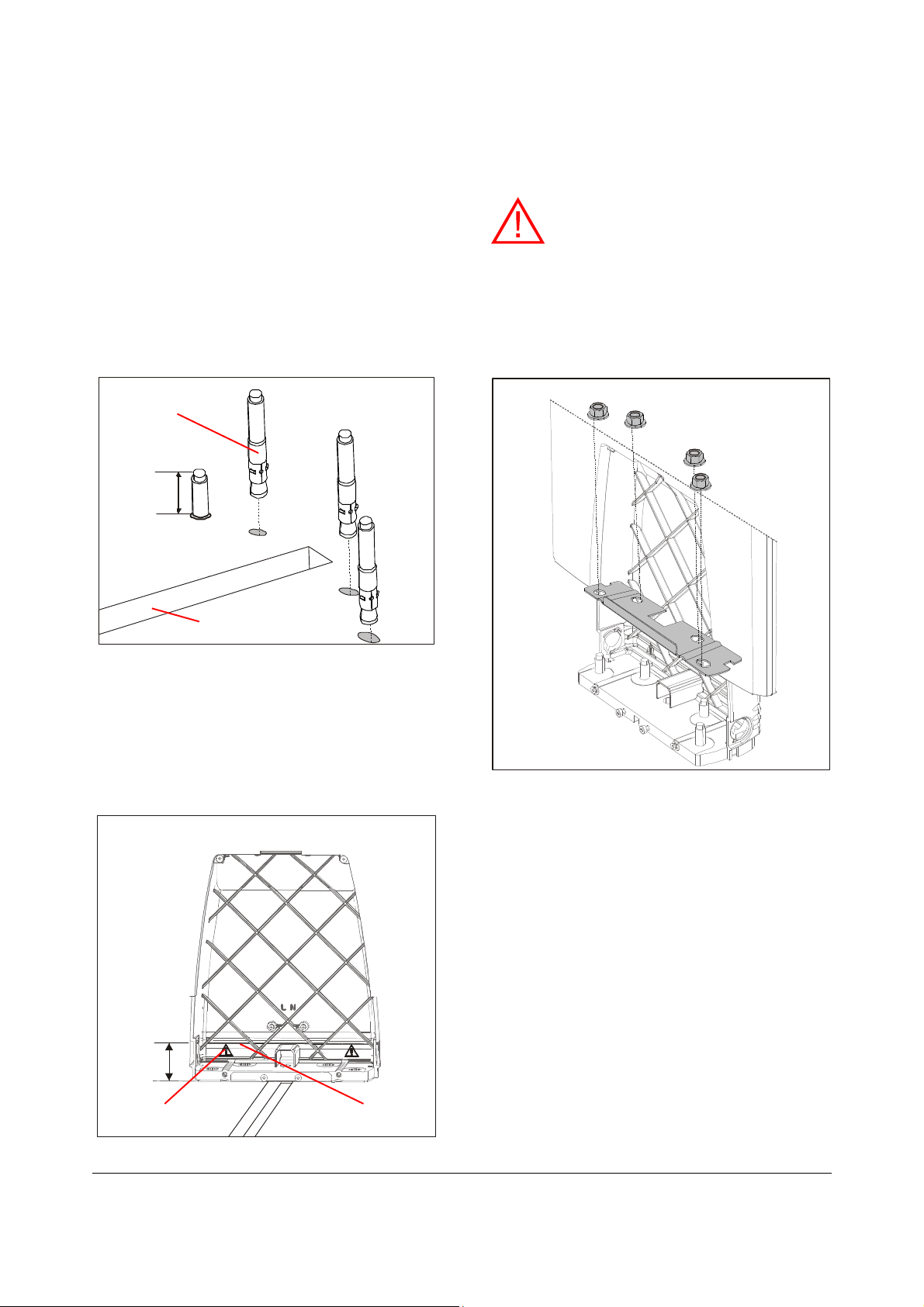

Installing the Pedestal

Installation Kit

The pedestal installation kit contains eight wedge

anchors to secure the pedestals to a concrete

floor, four hole plugs, two metal plates, one voltage

selection jumper, and three conduit clamps.

Installing the wedge anchors and metal

plate

Mounting bolt

2.5cm

(1in)

Cable trench

1. Insert the mounting bolts into holes for each

base with the threaded end up. The exposed

portion of the bolt should be about 2.5cm (1in)

in length but must not exceed 3.4cm (1 3/8in).

Exposed portion of bolts should be measured

from the top of the floor surface (for example,

carpeting or wood).

2. Put each pedestal on its bolts.

WARNING: The tops of the bolts must

not be higher than the interference line

that appears above the alert symbol

(shown above) that is on the back of the

compartment. If the bolts are higher than

the line they will interfere with the main

circuit board when you install the primary

base cover.

3. Gently hit the top of each bolt with a hammer

to set the anchor.

4. Put a metal plate, which is in the pedestal

installation kit, over the bolts in each pedestal.

5. Secure the pedestals to the floor with the nuts

and washers from the pedestal installation kit.

3.45cm

(1 3/8in)

Interference line Alert symbol

AMS-1140 DETECTORS 8200-2684-02, REV. 0

SETUP AND SERVICE GUIDE

5 of 15

Page 6

Installing the hole plugs and conduit

clamps

Hole plug

Conduit clamp

The hole plug and conduit clamps are installed in

the side of the pedestal base.

WARNING! DO NOT run the power

cable and the Interconnect cable in the

same conduit or raceway.

Installing the voltage selection jumper

You must set the voltage selection jumper (J1) on

the lower right side of the main circuit board to the

proper setting. Refer to Figure 1. The default

setting is for 240Vac.

WARNING—RISK OF ELECTRIC

SHOCK! Disconnect AC power when

servicing.

• For 120Vac operation, install the jumper

on J1. The jumper is in the pedestal

installation kit.

Replacing the Alarm Board and

Lens

The alarm lens installation kit (0352-0444-02)

contains two alarm lens (one for each pedestal),

the alarm board, and six screws. You use four of

the screws for the two alarm lens. The other two

screws are for the grounding plate in the base;

they are not needed.

1. Remove the two screws on the top of the alarm

2. Lift the alarm lens.

3. Disconnect the alarm cable from the alarm

4. Connect the alarm board to the alarm cable

5. Remove the adhesive backing and stick the

WARNING—RISK OF ELECTRIC

SHOCK! Disconnect AC power when

servicing.

lens.

board.

CAUTION: The alarm board is fragile;

use caution when handling it.

connector on the top of the primary pedestal

alarm board to the center of the top of the

pedestal. Make sure you align the arrow on the

alarm board with the groove on the top of the

pedestal. Note: the pedestal top has a slight

depression for the alarm board but the alarm

board overlaps it when the arrow on the alarm

board is properly aligned with the groove.

• For 240Vac operation, remove the jumper

from J1 if it is installed.

CAUTION: If you install the jumper for

120Vac and connect the pedestal to a

240Vac supply, the system will be

damaged.

If you set a pedestal to 240Vac and connect it to

120Vac power, the system will not operate

properly. Also, the system will generate a low

current error condition message (error number 21)

that can be read with the service configurator

software.

ULTRA•POST DETECTORS WITH SWITCHED MODE TRANSMITTER 8000-2595-07, REV. E

SETUP AND SERVICE GUIDE

6 of 15

Page 7

inhibit

pushbutton

hole

Replacing the Fuse

1. Turn off power to the pedestal at the circuit

2. Remove the cover from the exit side of the

3. Remove the cover over the fuse at F1. See

4. Replace blown fuse F1 with the type and rating

5. Replace the fuse cover.

6. Secure the base cover back on the pedestal.

WARNING—RISK OF ELECTRIC

SHOCK! Disconnect AC power when

servicing.

breaker.

primary pedestal. To do this: loosen the four

fasteners at the base of the cover, and then lift

the bottom of the cover up and then off the

base.

Figure 1 for the location of the fuse.

marked on the board.

Inhibiting the Transmitter

Use the transmit-inhibit circuit to determine the

cause of unexplained alarms. If the alarm

continues when the transmitter is disabled,

interference is the likely cause. If the alarm stops

when the transmitter is disabled, tags placed too

close to the detector are the likely cause.

The transmitter can be inhibited by pressing

pushbutton S2 through the hole in front of the base

cover on the primary antenna. See the procedure

below for instructions on how this works.

2. Press S2 once to disable the transmitter for 30

seconds (the power LED at the center of the

board will flash rapidly).

3. Press S2 a second time within 30 seconds to

disable both transmitter and alarm circuits

indefinitely (power LED stays on continuously).

This prevents continuous alarms until the

detector can be serviced.

4. Press S2 a third time to return the detector to

routine operation (power LED flashing once per

second).

Using the Software Configurator

An AMS-1140 detector can be serviced using the

AMS-1140 configurator, which is a software

program that runs on a portable (laptop) computer.

You can use the configurator at initial installation to

modify some aspects of the system’s operation per

a customer’s request, but the configurator is

usually used to find out why a system is not

working properly and to make adjustments to it to

get it working again.

Figure 4. Configurator setup panel

Figure 3. Tx-inhibit pushbutton access hole

Tx-

You can make the following adjustments to modify

1. Using a pointed instrument such as a

straightened paper clip, press the pushbutton.

Note: A beep occurs each time S2 is pressed.

The software configurator can disable this

feature.

AMS-1140 DETECTORS 8200-2684-02, REV. 0

SETUP AND SERVICE GUIDE

7 of 15

the system for a customer:

• Modify how long the LEDs flash and the audio

alarm sounds

• Enable the system to work with Active Tags,

which is a battery-powered tag that emits its

own alarm

Page 8

Conduit clamp

• Enable (or disable) the Tags Too Close feature

so the pedestals silently alarm when a tag is left

nearby

• Enable (or disable) the reduction of the size of

the detection field behind the pedestals

You can use the configurator to find out the

following information to troubleshoot problems:

• How many times the system has alarmed

• The temperature of the air around the main

circuit board

• The current in the transmitter coils

• The status of the transmitter

• The amount of electronic noise the antenna

sees and the strength of a tag signal

• The frequency of the tag signal

• A report of past and current system errors and

runtime information

You can use the configurator to make the following

changes to the detector:

• Download software upgrades into the detector

• Disable the transmitter temporarily to check for

the source of false alarms

• Modify the Energy Trim level to decrease the

impact of electronic noise from nearby anti-theft

systems

• Adjust some operating parameters (Polarity,

Minimum Threshold, Sensitivity, and the Nulling

Pot) to reduce the effect of electronic noise the

antenna receives from the environment

Connecting to AC Power

1. Set the voltage selection jumper (J1) on the

2. Remove the cover from the exit side of the

Wires go to

primary base

cover

WARNING: RISK OF ELECTRIC

SHOCK! Make sure the primary pedestal

is disconnected from its power source

before you proceed.

lower right side of the main circuit board to the

proper setting. Refer to Figure 1 for the location

of the jumper. The default setting is for 240Vac

(no jumper). For 120Vac operation, install the

jumper in J1. The jumper is in the pedestal

installation kit.

CAUTION: If you install the jumper for

120Vac and connect the pedestal to a

240Vac supply, the system will be

damaged.

If you set a pedestal to 240Vac and connect it

to 120Vac power, the system will not operate

properly. Also, the system will generate a low

current error condition message (error number

21) that can be read with the service

configurator software.

primary pedestal. To do this: loosen the four

fasteners at the base of the cover, and then lift

the bottom of the cover up and then off the

base.

• Enable (or disable) the Phase Lock Loop

feature to adjust for noise on the power line

• Change how the system synchronizes to the

power line

Note: Refer to the online help provided with the

configurator for a complete description of

configurator operation.

Grounding plate

3. Use two screws from the alarm lens installation

kit to attach the grounding plate to the primary

pedestal. Do not unplug the cable from the

main circuit board on the base.

ULTRA•POST DETECTORS WITH SWITCHED MODE TRANSMITTER 8000-2595-07, REV. E

SETUP AND SERVICE GUIDE

8 of 15

Page 9

Line

Ground

4. Install the hole plug supplied in the pedestal

installation kit in the conduit access hole that

will not be used.

5. Install the steel conduit clamp supplied in the

pedestal installation kit.

Neutral

WARNING! DO NOT run the power

cable and the Interconnect cable in the

same conduit or raceway.

6. Have a licensed electrician wire the primary

pedestal to power. The locations of where the

Line, Neutral, and Ground wires connect to the

grounding plate are shown above.

Tuning the Pedestals

Tuning the pedestals is not a standard part of initial

installation; the system should be left at the factory

default setting of minimum capacitance (all

jumpers out). If the pedestals are placed near a lot

of metal, however, the current in the system may

be reduced and the performance can be reduced.

If the performance is unacceptable and the

maximum burst current is not at least 30A, you can

use the following procedure to optimize the tuning

until maximum peak current is achieved.

1. Remove the base covers on both pedestals

and locate the tuning jumpers on the main

circuit board on the primary pedestal and the

secondary capacitor board. See Figure 1.

3. Adjust the tuning jumpers on the primary

pedestal up one step (for example, from Step

0 to Step 1).

4. Check the current.

• If the current is less than before you adjust

the capacitance, you are detuning the

pedestal. Return to the default setting. You

are done.

• If the current goes up, you are tuning the

pedestal in the correct direction. Keep

adding capacitance until you find the peak

current.

5. If you get to step 8 in Table 1 (all jumpers in)

and the current is still increasing, go to the

secondary pedestal and increase the

capacitance one step. Then go back to the

primary pedestal, set it back to step one (all

jumpers removed) and start adding

capacitance on the primary one step at a time.

Table 1. AMS-1140 Tuning Table (Primary)

Step # J4 JW3 JW2

1* 0 0 0

2 0 0 1

3 0 1 0

4 0 1 1

5 1 0 0

6 1 0 1

7 1 1 0

8 1 1 1

* Default

Table 2. AMS-1140 Tuning Table (Secondary)

Step # J2 J1

1* 0 0

2 0 1

3 1 0

4 1 1

* Default

• Primary tuning jumpers: J2, J3, J4

• Secondary tuning jumpers: J1, J2

2. Ensure the tuning jumpers are set to their

default values. See Table 1 (primary) or

Table 2 (secondary).

AMS-1140 DETECTORS 8200-2684-02, REV. 0

SETUP AND SERVICE GUIDE

9 of 15

Page 10

Statu

s Problem/Action

Troubleshooting

Checking Detector Operation

DO NOT perform the following

!!!!

1. Verify all boards are properly seated and all

2. Turn on the circuit breaker.

3. Connect the laptop computer to J5 on the main

4. Close the base cover and verify the transmit

5. Check the following:

6. Disconnect the laptop cable. Detector operation

procedure until you have thoroughly

reviewed configurator software settings.

cables are securely plugged in.

circuit board and load the configurator.

Note: After power is applied the detector

passes its power-up test, the power

on/heartbeat LED (DS2) should start flashing

once per second. If it does not flash, check for

an error condition using either the laptop

computer or by observing LED DS5 on the

board. Refer to Figure 5 for the location of DS2

and DS5. Refer to the section entitled

“Understanding Error Codes” on page 11 for

interpretation of the codes.

current is at least 25A. If it is less than 25A, go

to the section “Tuning the Pedestal” on page 9.

• If validations occur with no tags/labels

nearby, increase the Minimum Threshold or

change the Sensitivity in 1dB increments

until validations cease.

• If this Ultra•Max detector is causing another

to constantly alarm or not detect, or vice

versa, check the System Noise Average

screen. If the bar meters are constantly

reaching the maximum values, then adjust

the Zero Crossing Delay.

• Check the vicinity for tags or labels.

• If a lot of noise is entering the detector but it

is lower when the Polarity of the detector is

set to “Figure-8” than when it is set to

Aiding, set the Polarity to “Figure-8”.

• Set audio and LED durations.

has now been verified.

Dead system/Low sensitivity

A detector that is dead or has low sensitivity may

be without power, in the wrong mode, or affected

by noise from an electronic device such as a TV

set or PC monitor, or from certain fluorescent,

halogen, or neon lamps. To diagnose the problem,

you use the Mode LED (DS2) inside the primary

base cover. Refer to Figure 6 for the location of

DS2.

1. Observe the Mode LED (DS2). In what state is

the lamp?

• Off - No power

• Steady (not flashing) – Service Mode

• Flashing twice a second – Hidden Tag Mode

• Flashing once a second – Normal Mode

2. Use the following table to determine the

problem/action to take.

Off The detector has no power.

1. Ensure the detector is connected

to the AC power source.

2. Check the circuit breaker in the

store’s breaker box. If the

breaker tripped, reset it and

check system performance. If the

breaker will not stay on, call

maintenance. If the breaker is

OK, the detector needs service.

Call for assistance.

Flashing twice

per second

On steady (not

flashing)

Flashing once An electronic device or a lamp may

Detector is in Hidden Tag Mode.

1. Wait 30 seconds for the detector

to revert to Normal Mode.

2. Use a tag to test the system for

sensitivity. If the detector still has

low sensitivity, see “Flashing

once per second” below.

Detector is in Service Mode.

1. To change detector to normal

mode, insert a paper clip into the

Tx-inhibit pushbutton access hole

(

Figure 3

once.

2. Test the detector for sensitivity

with the tag/label. If the detector

still has low sensitivity, see

“Flashing once per second”

below.

be causing interference. One at a

) and press the switch

ULTRA•POST DETECTORS WITH SWITCHED MODE TRANSMITTER 8000-2595-07, REV. E

SETUP AND SERVICE GUIDE

10 of 15

Page 11

per second time, turn off each device or lamp

within 3m (10ft) of the pedestals and

use a tag to test sensitivity. If

sensitivity improves when a device is

turned off, that is the interference

source. Leave the device off or move

it away from the receiver antennas. If

sensitivity does not improve, call for

assistance.

False Alarms

Nearby electronic devices or hidden tags/labels

can cause the detector to false alarm.

1. To help diagnose the problem, the detector has

a Mode LED DS2 (Figure 5). In what state is

the lamp?

• Flashing once a second – Normal Mode

• Steady (not flashing) – Service Mode

• Flashing twice a second – Hidden Tag

Mode

2. Does pedestal alarm constantly or just

sometimes—twice a minute or less?

• Sometimes. Go to step 3.

• Constantly. Go to step 4.

3. Move all store products 3m (10ft) from

pedestal. Do alarms stop?

• Yes. One or more moved products have a

tag/label. Find and remove it, you are done.

• No. Look for tags/labels within 3m (10ft) of

pedestals. If no tags/labels are found and

problem persists, go to step 6.

4. Place the alarming pedestal in Hidden Tag

Mode by inserting the end of a paper clip into

the Tx-inhibit access hole (Figure 3) and

pressing the switch once. The pedestal should

emit a three second tone and enter Hidden Tag

Mode and the mode LED DS2 should flash

rapidly. (If not, this feature has been disabled.

Go back to step 3.) After 30 seconds, Hidden

Tag Mode reverts to Normal Mode.

Do alarms occur during the 30 seconds Hidden

Tag Mode is on?

• No. Go to step 5.

• Yes. Go to step 6.

5. After the Hidden Tag Mode completes, do

alarms resume?

• Yes. One or more tags/labels are still in the

area. Find and remove them, you are done.

• No. Ensure you waited 30 seconds and

then check mode light to ensure pedestal is

not in Service Mode. If it is in Service Mode,

press the mode switch once more to return

to Normal Mode and go back to step 1. If it

is not in Service Mode, wait until the system

false alarms again before performing this

procedure.

6. A nearby device such as a TV set or computer,

or a neon or halogen lamp may be causing

false alarms. One at a time, turn off each

device or lamp within 3m (10ft). Do alarms stop

when the device or lamp is off?

• Yes. That device or lamp is the source of

the false alarms. Leave the device or lamp

off or move it away from the receiver

antennas. If you cannot, see “No” below.

• No. Call for assistance. Place the pedestal

in Service Mode to stop the alarm until

service arrives by inserting the end of a

paper clip into the Tx-inhibit switch access

hole (Figure 3). If the pedestal is in the

Normal Mode, press the mode switch twice;

otherwise, press the mode switch once.

The mode LED should stay on

continuously.

Understanding Error Codes

When the system encounters an error, it generates

one of two types of error codes:

• Recoverable – these errors are not as

serious as fatal errors. The system

continues to transmit but an error code is

stored in a log in RAM memory. If the

system shuts down, the error codes will be

lost.

• Fatal – this type of error is more serious

than the recoverable errors. The system

stops transmitting, displays the error three

times on the system error LED (DS5), and

logs the error code in a log in non-volatile

memory (NVM). The system usually tries

to reset itself but it may be unsuccessful.

The list of error codes is shown in Table 3. These

codes are displayed on the System Error LED

(DS5). A history of the errors can viewed using the

configurator.

AMS-1140 DETECTORS 8200-2684-02, REV. 0

SETUP AND SERVICE GUIDE

11 of 15

Page 12

Interpreting LED Indicators

LED indicators on the receiver board can be used

for diagnostic purposes. During the power-on selftest, all LEDs flash simultaneously to test their

function, then they light in sequence to indicate the

progress of the power on self-test. Figure 5 shows

the location of the status LEDs.

Figure 5. LED locations

DS4

DS5

DS3

DS1

DS2

DS7

DS6

• DS1 (red) is the alarm indicator.

• DS2 (green) is the mode/power/heartbeat

indicator, which shows that the board is

powered and what mode the system is in

(Normal/Hidden Tag/Service).

• DS3 (red) is the frequency rejection indicator. If

this LED is lit, the pedestal has detected an outof-frequency label, such as a deactivated or

wounded label, in the vicinity.

• DS4 (red) is unused.

• DS5 (yellow) is the validation/system error

indicator. This LED flashes in a coded

sequence whenever the board fails the power

on self test, or run-time diagnostic tests, or

when a serious failure interrupt occurs. To

indicate an error code, the DS5 error LED on

the receiver board will flash a number of times,

pause, then flash again a number of times. For

example: DS5 flashing three times, pausing,

then flashing two times indicates error code 32.

Error codes are listed in Table 3.

• DS6 (green) indicates that data is being

received on the Network RS-485 port.

• DS7 (red) indicates that data is being

transmitted on the Network RS-485 port.

ULTRA•POST DETECTORS WITH SWITCHED MODE TRANSMITTER 8000-2595-07, REV. E

SETUP AND SERVICE GUIDE

12 of 15

Page 13

Table 3. AMS-1140 error codes

Alert Code Action

11 Illegal Instruction Not applicable

12 Unimplemented Interrupt Not applicable

13 NVM Write Failed Fatal error. Replace main circuit board

14 Invalid Device Fatal error. Replace main circuit board

15 Sequence Table Error Not applicable

16 Out of Memory Not applicable

17 Undecided: No Split Not applicable

18 Watchdog: Task Reset Recoverable. First, try resetting the NVM to its defaults. If problem

persists, reinstall application software. If problem persists, replace main

circuit board.

21 Current Sense Antenna A Recoverable. Retune antennas

22 Current Sense Antenna B Not applicable

23 Power Supply Overtemp

Recoverable. Replace main circuit board.

Fault

24 Transmitter Failsafe

Recoverable. Replace main circuit board.

Fault, Burst Too Long

25 Receiver samples

Recoverable. Reinstall application software

exceeded the Receiver

buffer

26 TX PWM Fault Fatal error. Check for large amounts of metal in vicinity of the pedestals.

If this is not the cause and error keeps occurring, replace the main circuit

board.

27 HW Current Fault Fatal error. If the error keeps occurring, replace the main circuit board.

28 Tx Shutdown Not used.

29 SW Current Fault Fatal error. This error is caused by an over-current condition. This is

probably caused by hardware. This could be caused by a damaged main

circuit board or a short in the coil wiring, for example.

31 Missing Zero Crossing

Signal

32 Missing External Zero

Crossing Signal

Recoverable. Check the AC line quality. If it is OK, replace the main

circuit board.

Recoverable. This occurs when Universal Sync has been selected as the

Sync source in the configurator but no signal is received. Check the

connection on the RS-485 connectors on the receiver board and the

signal source.

33 Invalid Line Frequency at

Power/Up

34 Invalid Power Supply

Recoverable. This can be caused by noise on the AC power line. Check

the AC line quality.

Not applicable

Type at Powerup

35 Wired Sync: Missing

Not applicable

Signal

36 Unknown Voltage ID

Fatal. Replace main circuit board.

selection assuming

58kHz

37 Line PLL Unlocked Recoverable. This can be caused by noise on the AC power line. Check

AMS-1140 DETECTORS 8200-2684-02, REV. 0

SETUP AND SERVICE GUIDE

13 of 15

Page 14

the AC line quality.

41 Jammer Event Detected Not applicable

44 Host Communication

Mailbox Full

Recoverable. Reload the application software. If error is not eliminated,

replace the main circuit board.

45 LDM Power Save Active Not applicable

46 LDM Power Save Inactive Not applicable

51 No Reference Not applicable

52 Invalid Alarm Type from

Not applicable

detector

53 NVM Checksum Error Recoverable.

54 NVM Reset Recoverable.

55 NVM Revision Change Recoverable.

56 People Counter Blocked

Not applicable

Sensor Detected

57 Invalid Wired Sync

Not applicable.

Command Received

ULTRA•POST DETECTORS WITH SWITCHED MODE TRANSMITTER 8000-2595-07, REV. E

SETUP AND SERVICE GUIDE

14 of 15

Page 15

Specifications

Power Supply

Primary Input ........................................ 100-120Vac

or 200-240Vac @ 50-60Hz

Primary power fuse ........................... One 2A, 250V,

slo-blo, hi-breaking,

5mmx20mm fuse

Current draw .............. less than 0.5Arms @ 120Vac

Input power ....................................... less than 44W

Transmitter

Operating frequency ...................... 58kHz (+200Hz)

Transmit Burst Duration ................................. 1.6ms

Transmit Current (in Tx coil) ..................... 42A peak

Transmit Current (in Interconnect cable) .. 17A peak

Burst Repetition Rate:

Based on 50Hz ac .................................. 37.5Hz

Based on 60Hz ac ..................................... 45Hz

Antenna Coil Resistance ................ .25 ohms (±5%)

Receiver

Center Frequency .......................................... 58kHz

Alarm

Audio level ..................................................... 83dBA

Environmental

Ambient Temperature .. 0°C to 40°C (32°F to 104°F)

Relative Humidity .............0 to 90% non-condensing

Enclosure .......................................................... IPx0

Mechanical

Height .............................................. 137.1cm (54in)

Width ................................................. 35.8cm (14in)

Depth (base) ....................................... 8.6cm (3.4in)

Declarations

Regulatory Compliance

EMC ............................................... 47 CFR, Part 15

EN 300 330

EN 301 489

RSS 210

Safety .................................................... UL 60950-1

CSA C22.2.60950-1

EN 60950-1

REGULATORY PRODUCT NAME:

ZA1140-D = TYPE: AMS-1140

FCC ID: BVCAMS1140

FCC COMPLIANCE: This equipment complies with Part 15 of the

FCC rules for intentional radiators and Class A digital devices when

installed and used in accordance with the instruction manual.

Following these rules provides reasonable protection against harmful

interference from equipment operated in a commercial area. This

equipment should not be installed in a residential area as it can

radiate radio frequency energy that could interfere with radio

communications, a situation the user would have to fix at their own

expense.

EQUIPMENT MODIFICATION CAUTION: Equipment changes

or modifications not expressly approved by Sensormatic Electronics

Corporation, the party responsible for FCC compliance, could void

the user's authority to operate the equipment and could create a

hazardous condition.

Other Declarations

WARRANTY DISCLAIMER: Sensormatic Electronics

Corporation makes no representation or warranty with respect to the

contents hereof and specifically disclaims any implied warranties of

merchantability or fitness for any particular purpose. Further,

Sensormatic Electronics Corporation reserves the right to revise this

publication and make changes from time to time in the content hereof

without obligation of Sensormatic Electronics Corporation to notify

any person of such revision or changes.

LIMITED RIGHTS NOTICE: For units of the Department of

Defense, all documentation and manuals were developed at private

expense and no part of it was developed using Government Funds.

The restrictions governing the use and disclosure of technical data

marked with this legend are set forth in the definition of "limited

rights" in paragraph (a) (15) of the clause of DFARS 252.227.7013.

Unpublished - rights reserved under the Copyright Laws of the

United States.

TRADEMARK NOTICE: Ultra•Max and Sensormatic are

registered trademarks of Sensormatic Electronics Corporation. Other

product names (if any) mentioned herein may be trademarks or

registered trademarks of other companies.

No part of this guide may be reproduced in any form without written

permission from Sensormatic Electronics Corporation.

RWH 01/2010

AMS-1140 DETECTORS 8200-2684-02, REV. 0

SETUP AND SERVICE GUIDE

15 of 15

Loading...

Loading...