Page 1

Technical Services

800-381-9312 | +1-401-781-8220

www.tyco-fire.com

Series DS-1 Dry-Type Sprinklers

Quick Response, Standard Coverage

5.6 K-factor, 3/4 and 1-Inch NPT

General

Description

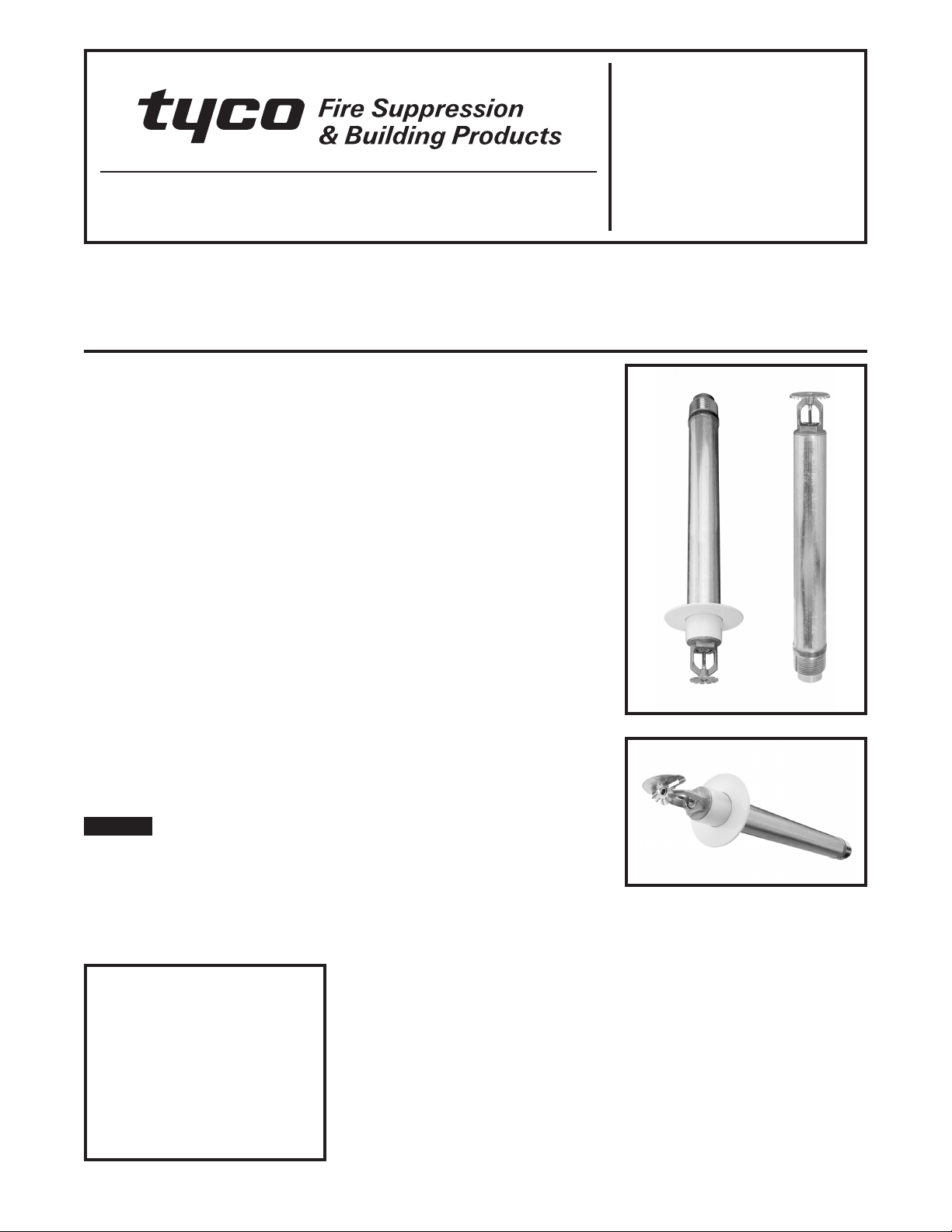

The TYCO Series DS-1, 5.6 K-factor,

3/4 and 1-Inch NPT, Quick Response,

Standard Coverage, Dry-Type Sprinklers are decorative, 3-mm glass bulb

automatic sprinklers de signed for commercial use. Dry-Type Sprinklers are

typically used where:

•

pendent sprinklers are re quired on

dry pipe systems that are exposed to

freezing tempera tures; for example,

sprinkler drops from un heated portions of buildings.

•

sprinklers and/or a portion of the connecting piping are exposed to freezing

temperatures; for example, sprinkler

drops from wet sys tems into freezers,

sprinkler sprigs from wet systems into

unheated attics, or horizontal piping

extensions through a wall to protect an

unheated areas such as loading docks,

overhangs, and building exteriors.

•

sprinklers are used on sys tems that are

seasonally drained to avoid freezing;

for example, vacation areas.

jurisdiction. Failure to do so may impair

the performance of these de vices.

Owners are responsible for maintain ing

their fire protection system and de vices

in proper operating condition. The installing contractor or sprinkler manufacturer should be contacted with any

questions.

The Series DS-1 Dry-Type Sprinklers

must only be installed in fittings that

meet the requirements of the Design

Criteria section.

Model/Sprinkler

Identification

Numbers (SINs)

3/4-Inch NPT:

TY3935 - Pendent

TY3735 - Horizontal Sidewall

1-Inch NPT:

TY3235 - Pendent

TY3135 - Upright

TY3335 - Horizontal Sidewall

NOTICE

The Series DS-1 Dry-Type Sprinklers

described herein must be installed

and maintained in compliance with this

document, as well as with the applicable standards of the National Fire

Protection Association, in addition to

the standards of any authorities hav ing

Always refer to Technical Data

Sheet TFP700 for the “INSTALLER

WARNING” that provides cautions

with respect to handling and installation of sprinkler systems and

components. Improper handling and

installation can permanently damage a sprinkler system or its components and cause the sprinkler to fail

to operate in a fire situation or cause

it to operate prematurely.

IMPORTANT

Page 1 of 10 OCTOBER 2010 TFP510

Page 2

TFP510

Page 2 of 10

3/4-INCH NPT

TY3935 Pendent

with Standard

Recessed Escutcheon

(Figure 4)

TY3935 Pendent

with Standard Escutcheon

(Figure 3)

with Deep Escutcheon

(Figure 5)

without Escutcheon

(Figure 6)

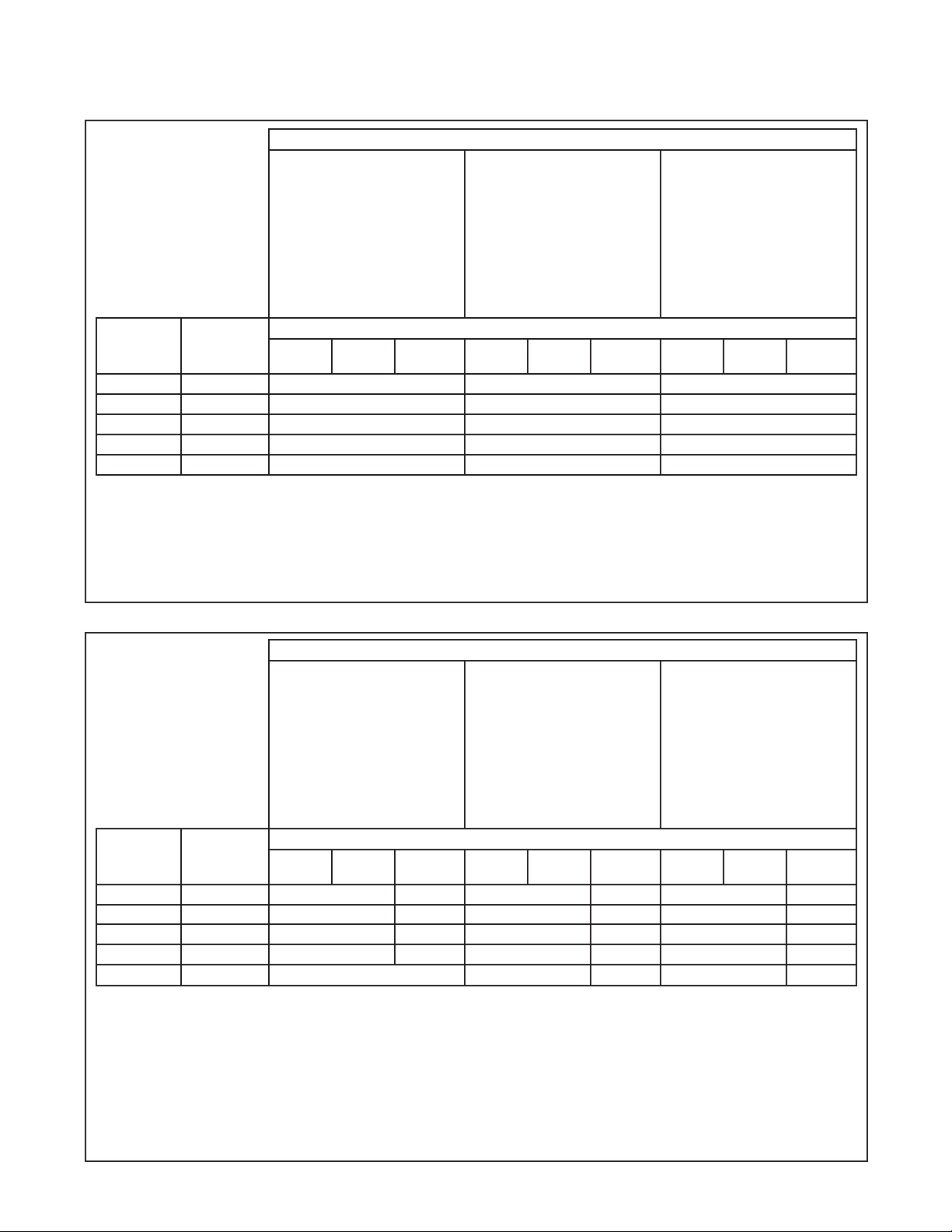

TY3735 Horizontal Sidewall

with Top of Deflec tor-to-Ceiling

Dist ance of 4 to 12 inches

(100 to 30 0 mm)

with Standard Escutcheon

(Figure 8)

with Deep Escutcheon

(Figure 9)

without Escutcheon

(Figure 10)

Temperature

Rating

Bulb

Color Code

Natural

Bras s

Chrome

Plate d

White

Polyester

Natural

Bras s

Finish

Chrome

Plate d

White

Polyester

Natural

Bras s

Chrome

Plate d

135°F (57°C) Orange 1, 2 1, 2 1*, 2*

155°F (68°C) Red 1, 2 1, 2 1*, 2*

175°F (79°C) Yellow 1, 2 1, 2 1*, 2*

200°F (93°C) Green 1, 2 1, 2 1*, 2*

286°F (141°C) Blue N/A 1, 2 1*, 2*

Notes:

1. Listed by Underwriters Laboratories, Inc.

(maximum order length of 48 inches).

2. Listed by Underwriters Laboratories for use in

Canada (maximum order length of 48 inches).

* Light and Ordinary Hazard Occupancies Only / N/A - Not Available

TABLE A

3/4-INCH NPT, SERIES DS-1 QUICK RESPONSE, STANDARD COVERAGE DRY-TYPE SPRINKLERS

LABORATORY LISTINGS AND APPROVALS

White

Polyester

1-INCH NPT

Temperature

Rating

Bulb

Color Code

TY3235 Pendent

with Standard

Recessed Escutcheon

(Figure 4)

Natural

Bras s

Chrome

Plate d

White

Polyester

TY3235 Pendent

with Standard Escutcheon

(Figure 3)

with Deep Escutcheon

(Figure 5)

without Escutcheon

(Figure 6)

TY3135 Upright

without Escutcheon

(Figure 7)

Finish

Natural

Bras s

Chrome

Plate d

White

Polyester

TY3335 Horizontal Sidewall

with Top of Deflec tor-to-Ce iling

Dist ance of 4 to 12 inches

(100 to 30 0 mm)

with Standard Escutcheon

(Figure 8)

with Deep Escutcheon

(Figure 9)

without Escutcheon

(Figure 10)

Natural

Bras s

Chrome

Plate d

White

Polyester

135°F (57°C) Orange 1, 2, 3 1, 2 1, 2, 3 1, 2 1*, 2*, 3** 1*, 2*

155°F (68°C) Red 1, 2, 3 1, 2 1, 2, 3 1, 2 1*, 2*, 3** 1*, 2*

175°F (79°C) Yellow 1, 2, 3 1, 2 1, 2, 3 1, 2 1*, 2*, 3** 1*, 2*

200°F (93°C) Green 1, 2, 3 1, 2 1, 2, 3 1, 2 1*, 2*, 3** 1*, 2*

286°F (141°C) Blue N/A 1, 2, 3 1, 2 1*, 2*, 3** 1*, 2*

Notes:

1. Listed by Underwriters Laboratories, Inc.

(maximum order length of 48 inches).

3. Approved by Factory Mutual Research Corporation

(maximum order length of 48 inches).

2. Listed by Underwriters Laboratories for use in Canada

(maximum order length of 48 inches).

4. The Upright Sprinkler without an Escutcheon (TY3135)

is available in 1-Inch NPT only.

* Light and Ordinary Hazard Occupancies Only / ** Light Hazard Occupancies Only / N/A - Not Available

1-INCH NPT AND ISO 7-R1, SERIES DS-1 QUICK RESPONSE, STANDARD COVERAGE DRY-TYPE SPRINKLERS

TABLE B

LABORATORY LISTINGS AND APPROVALS

Page 3

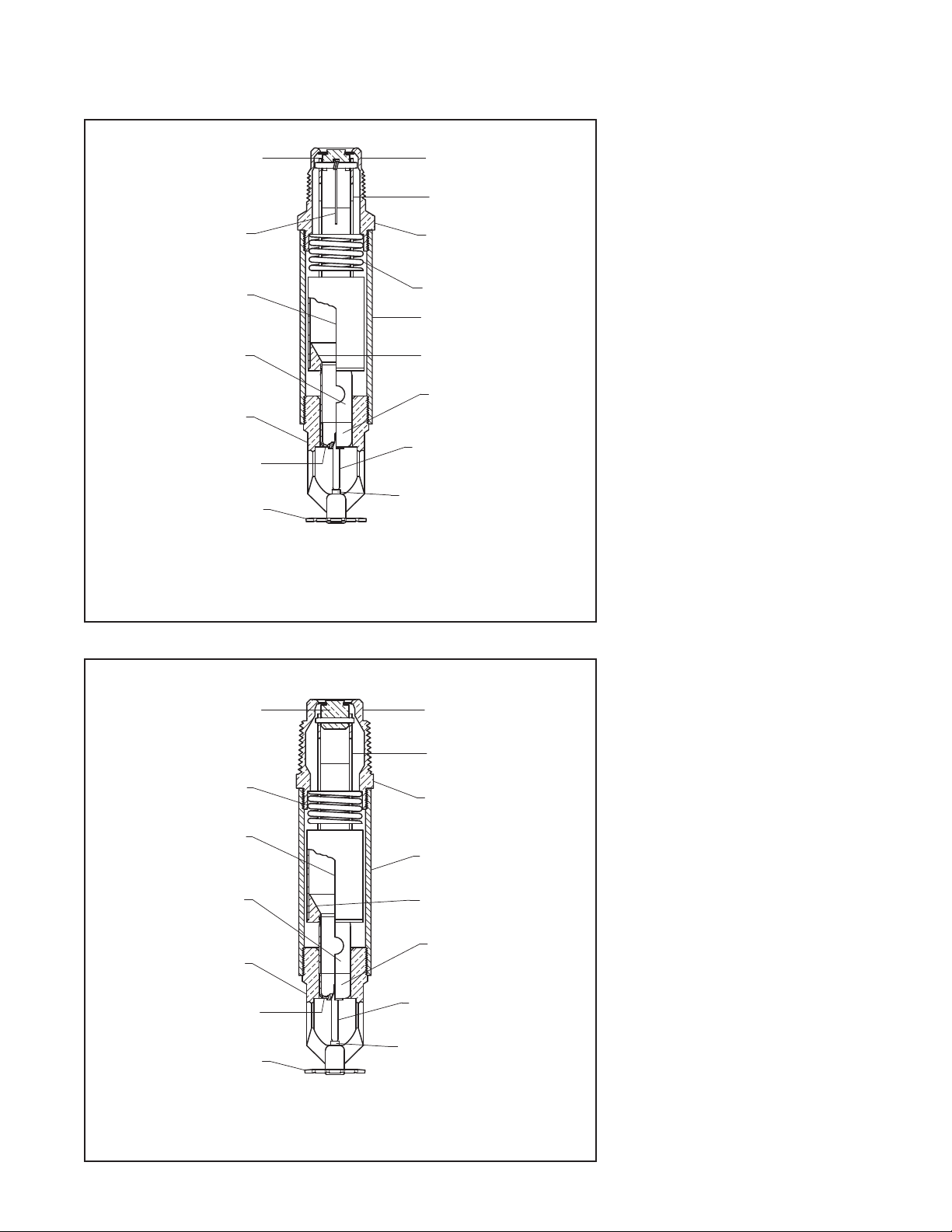

PLUG WITH

SEALING

ASSEMBLY

PLUG

SPRING

INLET

YOKE

INLET

BAND

TFP510

Page 3 of 10

Technical

Data

Approvals

UL and C-UL Listed

FM Approved

Refer to Tables A and B.

WATER

TUBE

GUIDE

TUBE

FRAME

VENT HOLE

DEFLECTOR

SPRING

CASING

INSERT

BULB

SEAT

3 mm BULB

COMPRESSION

SCREW

FIGURE 1

SERIES DS-1, 3/4-INCH NPT, QUICK RESPONSE

DRY-TYPE SPRINKLER ASSEMBLY

PLUG WITH

SEALING

ASSEMBLY

SPRING

WATER

TUBE

GUIDE

TUBE

FRAME

INLET

YOKE

INLET

BAND

CASING

INSERT

BULB

SEAT

Maximum Working Pressure

175 psi (12,1 bar)

Inlet Thread Connection

3/4-Inch NPT

1-Inch NPT or ISO 7-R1

Discharge Coefficient

K = 5.6 GPM/psi

(80,6 LPM/bar

1/2

1/2

)

Temperature Ratings

Refer to Tables A and B.

Finishes

Sprinkler: Natural Brass, Chrome

Plated, White Polyester

Escutcheon: White Coated, Chrome

Plated, Brass Plated

Physical Characteristics

Inlet. . . . . . . . . . . . . . . . . . . . . Copper

Plug . . . . . . . . . . . . . . . . . . . . Copper

Yoke . . . . . . . . . . . . . . Stainless Steel

Casing . . . . .Galvanized Carbon Steel

Insert . . . . . . . . . . . . . . . . . . Bronze

Bulb Seat . . . . . . . . . . .Stainless Steel

Bulb . . . . . . . . . . . . . . . . . . . . . . Glass

Compression Screw . . . . . . . . Bronze

Deector . . . . . . . . . . . . . . . . Bronze

Frame . . . . . . . . . . . . . . . . . . . Bronze

Guide Tube . . . . . . . . . Stainless Steel

Water Tube . . . . . . . . .Stainless Steel

Spring . . . . . . . . . . . . .Stainless Steel

Plug Spring*. . . . . . . . .Stainless Steel

Sealing Assembly . . . . . . . . Beryllium

Nickel w/Teon**

Escutcheon . . . . . . . . . Carbon Steel

Patents

U.S.A. Patent No. 5,188,185

**Registe red trademark of DuPont

*For 3/4- Inch NPT only

VENT HOLE

DEFLECTOR

3 mm BULB

COMPRESSION

SCREW

FIGURE 2

SERIES DS-1, 1-INCH NPT AND ISO 7-R1, QUICK RESPONSE

DRY-TYPE SPRINKLER ASSEMBLY

Page 4

TFP510

Page 4 of 10

SPRINKLER FITTING

(REFER TO DESIGN

CRITERIA SECTION)

FACE OF

SPRINKLER

FITTING

ORDER LENGTHS:

2-3/4" to 48"

(69,9 to 1219,2 mm)

IN 1/4" (6,4 mm)

INCREMENTS

FACE OF

CEILING

2-3/16" ± 1/8"

(55,6 ± 3,2 mm)

1-3/4" DIA.

(44,5 mm)

3" DIA.

(76,2 mm)

FIGURE 3

TY3235 AND TY3935 PENDENT

WITH STANDARD ESCUTCHEON

SPRINKLER FITTING

(REFER TO DESIGN

CRITERIA SECTION)

FACE OF

SPRINKLER

FITTING

ORDER LENGTHS:

3-3/4" to 48"

(95,3 to 1219,2 mm)

IN 1/4" (6,4 mm)

INCREMENTS

FACE OF

CEILING

1-3/8" ± 1/8"

(34,9 ± 3,2 mm)

2-1/4" DIA.

(57,2 mm)

2-7/8" DIA.

(73,0 mm)

FIGURE 4

TY3235 AND TY3935 PENDENT

WITH STANDARD RECESSED

ESCUTCHEON

SPRINKLER FITTING

(REFER TO DESIGN

CRITERIA SECTION)

FACE OF

SPRINKLER

FITTING

ORDER LENGTHS:

1/2" to 46"

(12,7 to 1168,4 mm)

IN 1/4" (6,4 mm)

INCREMENTS

FACE OF

CEILING

4-1/4" ± 1/8"

(108,0 ± 3,2 mm)

3-1/2" DIA.

(88,9 mm)

2-1/2" DIA.

(63,5 mm)

FIGURE 5

TY3235 AND TY3935 PENDENT

WITH DEEP ESCUTCHEON

SPRINKLER FITTING

(REFER TO DESIGN

CRITERIA SECTION)

FACE OF

SPRINKLER

FITTING

ORDER LENGTHS:

5" to 48"

(127,0 to 1219,2 mm)

IN 1/4" (6,4 mm)

INCREMENTS

MINIMUM

1-3/4" (44,5 mm)

DEFLECTOR

TO CEILING

FIGURE 6

TY3235 AND TY3935 PENDENT

WITHOUT ESCUTCHEON

TOP OF

DEFLECTOR

ORDER LENGTHS:

5" to 48"

(127,0 to 1219,2 mm)

IN 1/4" (6,4 mm)

INCREMENTS

FACE OF

SPRINKLER

FITTING

SPRINKLER FITTING

(REFER TO DESIGN

CRITERIA SECTION)

FIGURE 7

TY3135 UPRIGHT

WITHOUT ESCUTCHEON

— 1-INCH NPT ONLY —

Page 5

TFP510

Page 5 of 10

ORDER LENGTHS:

2-3/4" to 48" (69,9 to 1219,2 mm)

IN 1/4" (6,4 mm) INCREMENTS

FACE OF

SPRINKLER

FITTING

SPRINKLER FITTING

(REFER TO DESIGN

CRITERIA SECTION)

FACE OF

MOUNTING

SURFACE

FIGURE 8

TY3335 AND TY3735 HORIZONAL SIDEWALL

WITH STANDARD ESCUTCHEON

ORDER LENGTHS: FACE OF

1/2" to 45-3/4" (12,7 to 1162,1 mm)

IN 1/4" (6,4 mm) INCREMENTS

FACE OF

SPRINKLER

FITTING

SPRINKLER FITTING

(REFER TO DESIGN

CRITERIA SECTION)

FIGURE 9

TY3335 AND TY3735 HORIZONAL SIDEWALL

WITH DEEP ESCUTCHEON

ORDER LENGTHS:

5-1/2" to 48" (139,7 to 1219,2 mm)

IN 1/4" (6,4 mm) INCREMENTS

FACE OF

SPRINKLER

FITTING

SPRINKLER FITTING

(REFER TO DESIGN

CRITERIA SECTION)

FIGURE 10

TY3335 AND TY3735 HORIZONAL SIDEWALL

WITHOUT ESCUTCHEON

1-3/4" DIA.

(44,5 mm)

CENTERLINE

OF WATERWAY

MOUNTING

SURFACE

2-1/2" DIA.

(63,5 mm)

CENTERLINE

OF WATERWAY

4" ± 1/8"

(101,6 ± 3,2 mm)

3.5°

(7,9 mm)

4-13/16" ± 1/8"

(122,2 ± 3,2 mm)

3.5°

(7,9 mm)

2-1/4" (57,2 mm)

DEFLECTOR TO

CENTERLINE

OF WATERWAY

3" DIA.

(76,2 mm)

5/16"

3-1/2" DIA.

(88,9 mm)

5/16"

MINIMUM

MOUNTING

SURFACE

3.5°

(7,9 mm)

5/16"

Operation

When the TYCO Series DS-1 Dry-Type

Sprinkler is in service, water is prevented from entering the assembly by the

Plug with Sealing Assembly in the Inlet

of the Sprinkler. See Figures 1 and 2.

The glass Bulb contains a uid that expands when ex posed to heat. When the

rated tem perature is reached, the uid

expands sufciently to shatter the glass

Bulb, and the Bulb Seat is released.

The compressed Spring is then able

to ex pand and push the Water Tube as

well as the Guide Tube outward. This

action simultaneously pulls inward on

the Yoke, withdrawing the Plug with

Sealing Assembly from the Inlet and

allowing the sprin kler to activate and

ow water.

Design

Criteria

The TYCO Series DS-1 Sprinklers are

intended for use in re sprinkler systems designed in accordance with the

standard installation rules recognized

by the applicable Listing or Approval

agency; for example, UL Listing is

based on NFPA 13 requirements.

Sprinkler Fittings

Install the 3/4 or 1-inch NPT Series

DS-1 Dry-Type Sprinklers in the 3/4 or

1-inch NPT outlet or run of the following ttings:

•

malleable or ductile iron threaded tee

ttings that meet the dimensional requirements of ANSI B16.3 (Class 150)

•

cast iron threaded tee ttings that

meet the dimensional requirements

of ANSI B16.4 (Class 125).

Do not install the DS-1 Sprinklers into

an elbow ttings. The Inlet of the sprinkler can contact the interior of the elbow, potentially damaging the Inlet

seal.

The unused outlet of the threaded tee is

plugged as shown in Figures 12 and 13.

You can also install the Series DS-1

Dry-Type Sprinklers in the 3/4 or 1-inch

NPT outlet of a GRINNELL Figure 730

Mechanical Tee. However, the use of

the Figure 730 Tee for this arrangement

is limited to wet pipe systems.

The conguration shown in Figure 12

is only applicable for wet pipe systems

where the sprinkler tting and waterlled pipe above the sprinkler tting are

not subject to freezing and where the

length of the Dry-Type Sprinkler has the

minimum exposure length depicted in

Figure 11. Refer to the Exposure Length

section.

Page 6

TFP510

Page 6 of 10

For wet pipe system installations of

the 1-inch NPT Series DS-1 Dry-Type

Sprinklers connected to CPVC piping,

use only the following TYCO CPVC

ttings:

•

1" x 1" NPT Female Adapter (P/N 80145)

•

1" x 1" x 1" NPT Sprinkler Head Adapter

Tee (P/N 80249).

For wet pipe system installations of

the the 3/4-inch NPT Series DS-1

Sprinklers connected to CPVC piping, use in the 3/4" x 3/4" NPT Female

Adapter (P/N 80142).

For dry pipe system installations, use

only the side outlet of maximum 2-1/2inch reducing tee when locating the

Series DS-1 Sprinklers directly below

the branch line. Otherwise, use the conguration shown in Figure 13 to assure

complete water drainage from above

the Series DS-1 Dry-Type Sprinklers

and the branch line. Failure to do so

may result in pipe freezing and water

damage.

NOTICE

Do not install the Series DS-1 Dry-Type

Sprinkler into any other type fitting

without first consulting the Technical

Services Department. Failure to use the

appropriate fitting may result in one of

the following:

•

Failure of the sprinkler to operate properly due to formation of ice over the

inlet Plug or binding of the Inlet Plug.

•

Insufficient engagement of the Inlet

pipe threads with consequent leakage.

Drainage

In accordance with the minimum

requirements of the National Fire

Protection Association for dry pipe

sprinkler systems, branch, cross, and

feed-main piping connected to Dry

Sprinklers and subject to freezing temperatures must be pitched for proper

drainage.

Exposure Length

When using Dry Sprinklers in wet pipe

sprinkler systems to protect areas subject to freezing temperatures, use Table

C to determine a sprinkler’s appropriate

exposed barrel length to prevent water

from freezing in the connecting pipes

due to conduction. The exposed bar-

rel length measurement must be taken

from the face of the sprinkler tting to

the surface of the structure or insulation that is exposed to the heated area.

Refer to Figure 11 for an example.

Clearance Space

In accordance with Section 8.4.9.2

of the 2010 edition of NFPA 13, when

connecting an area subject to freezing and an area containing a wet pipe

sprinkler system, the clearance space

around the sprinkler barrel of Dry-Type

Sprinklers must be sealed. Due to temperature differences between two areas, the potential for the formation of

condensation in the sprinkler and subsequent ice build-up is increased. If

this condensation is not controlled, ice

build-up can occur that might damage

the dry-type sprinkler and/or prevent

proper operation in a re situation.

Use of the Model DSB-2 Dry Sprinkler

Boot, described in technical data sheet

TFP591 and shown in Figures 14 and

15, can provide the recommended seal.

Ambient Temperature

Exposed to Discharge End of

Sprinkler

40°F (4°C) 0 0 0

30°F (-1°C) 0 0 0

20°F (-7°C) 4 (100) 0 0

10°F (-12°C) 8 (200) 1 (25) 0

0°F (-18°C) 12 (305) 3 (75) 0

-10°F (-23°C) 14 (355) 4 (100) 1 (25)

-20°F (-29°C) 14 (355) 6 (150) 3 (75)

-30°F (-34°C) 16 (405) 8 (200) 4 (100)

-40°F (-40°C) 18 (455) 8 (200) 4 (100)

-50°F (-46°C) 20 (510) 10 (255) 6 (150)

-60°F (-51°C) 20 (510) 10 (255) 6 (150)

Notes:

(a) For protected area temperatures that occur between values listed above, use the next cooler temperature.

(b) These lengths are inclusive of wind velocities up to 30 mph (18,6 kph).

40°F (4°C) 50°F (10°C) 60°F (16°C)

Minimum Exposed Barrel Length, Inches (mm)

Temperatures for Heated Area

(a)

(b)

TABLE C

MINIMUM RECOMMENDED LENGTHS OF EXPOSED SPRINKLER BARRELS

IN WET PIPE SYSTEMS

Page 7

FACE OF

SPRINKLER

FITTING

HEATED

AREA

DSB-2

INTENDED

FOR FREEZER

STRUCTURES

EXPOSURE

LENGTH

(SEE DESIGN

CRITERIA

SECTION)

TO WET

SYSTEM

HEATED

AREA

DSB-2

INTENDED

FOR FREEZER

STRUCTURES

SIDE

OUTLET

PLUGGED

SPRINKLER

FITTING

(SEE DESIGN

CRITERIA

SECTION)

TO DRY

SYSTEM

AREA

SUBJECT

TO

FREEZING

TFP510

Page 7 of 10

RUN

OUTLET

PLUGGED

SPRINKLER

FITTING

(SEE DESIGN

CRITERIA

SECTION)

DSB-2

INTENDED

FOR FREEZER

STRUCTURES

FIGURE 11

EXPOSURE LENGTH

MODEL DSB-2 SPRINKLER

BOOT WITH PENDENT SERIES

DS-1 DRY SPRINKLER

SHOWN WITH

ESCUTCHEON

FIGURE 14

FIGURE 12

SPRINKLER FITTING IN

HEATED AREA

STRAP TIES

(ENDS ON

OPPOSING

SIDES OF

BOOT)

DSB-2 BOOT

ADHESIVE

1-3/4" DIA.

(44,5 mm)

CLEARANCE

HOLE

INSULATED

FREEZER

STRUCTURE

DS-1

STANDARD

SPRINKLER FITTING IN

UNHEATED AREA

1-3/4" DIA.

(44,5 mm)

CLEARANCE

HOLE

ADHESIVE

DSB-2

BOOT

STRAP TIES

(ENDS ON

OPPOSING

SIDES OF

BOOT)

INSULATED

FREEZER

STRUCTURE

DS-1

SHOWN WITH

STANDARD

ESCUTCHEON

FIGURE 15

MODEL DSB-2 SPRINKLER

BOOT WITH SIDEWALL SERIES

DS-1 DRY SPRINKLER

FIGURE 13

Page 8

TFP510

Page 8 of 10

Installation

The T YCO Series DS-1 Dry-Type

Sprinklers must be installed in accordance with the following instructions.

NOTICE

The Series DS-1 Dry-Type Sprinkler

must only be installed in fittings that

meet the requirements of the Design

Criteria section. Refer to the Design

Criteria section for other important requirements regard ing piping design

and sealing of the clearance space

around the Sprinkler Casing.

Do not install any bulb type sprinkler

if the bulb is cracked or there is a loss

of liquid from the bulb. With the sprinkler held horizontally, a small air bubble

should be present. The diameter of the

air bubble is approximately 1/16 inch

(1,6 mm) for the 135°F (57°C) rating to

1/8 inch (3,2 mm) for the 286°F (141°C)

rating.

•

Obtain a leak-tight 3/4-inch NPT sprinkler joint by applying a minimum-tomaximum torque of 10 to 20 ft. lbs.

(13,4 to 26,8 Nm).

• Obtain a leak-tight 1 inch NPT sprinkler joint by applying a minimum-tomaximum torque of 20 to 30 ft. lbs.

(26,8 to 40,2 Nm).

Higher levels of torque can distort the

sprinkler Inlet with consequent leakage

or impairment of the sprinkler.

Do not attempt to compensate for

insufcient adjustment in an

Escutcheon Plate by under or overtightening the Sprinkler. Re-adjust the

position of the sprinkler tting to suit.

1.

Install pendent sprinklers only in the

pendent position, and install upright

sprinklers only in the upright position. The deector of a pendent or

upright sprin kler must be parallel to

the ceiling.

Install horizontal sidewall sprinklers in the horizontal position with

their centerline of waterway perpendicular to the back wall and parallel to the ceiling. Ensure the word

“TOP” on the De ector faces the

ceiling.

2.

With a non-hardening pipe-thread

sealant such as Teon1 tape applied

to the Inlet threads, hand-tighten the

sprinkler into the sprinkler tting.

3.

Wrench-tighten the sprinkler using

either:

•

a pipe wrench on the Inlet Band or

the Casing (Figures 1 and 2)

•

the W-Type 7 Sprinkler Wrench on

the Wrench Flat (Figure 16).

1 Registered trademark of DuPont

Apply the Wrench Recess of the

W-Type 7 Sprinkler Wrench to the

Wrench Flat.

Note: If sprinkler removal becomes

necessary, remove the sprinkler

using the same wrenching method noted above. Sprinkler removal is easier when a non-hardening

sealant was used and torque guidelines were followed. After removal,

inspect the sprinkler for damage.

4.

After installing the ceiling or wall and

applying a celing nish, slide on the

outer piece of the Escutcheon until

it comes in contact with the ceiling

or wall. Do not lift the ceiling panel

out of its normal position.

When using the Deep Escutcheon,

hold the outer piece in contact with

the mounting surface (ceiling or

wall). Then rotate the inner piece

approximately 1/4 turn with respect

to the outer piece, to hold the Deep

Escutcheon rmly together.

Care and

Maintenance

The T YCO Series DS-1 Dry-Type

Sprinklers must be maintained and serviced in accordance with the following

instructions.

NOTICE

Before closing a fire protection system

main control valve for maintenance

work on the fire protection system that

it controls, obtain permission to shut

down the affected fire protection systems from the proper authorities and

notify all personnel who may be affected by this action.

Absence of the outer piece of an escutcheon, which is used to cover a

clearance hole, can delay the time to

sprinkler operation in a re situation.

A Vent Hole is provided in the Bulb Seat

(Figures 1 and 2) to indicate if the DryType Sprinkler is remaining dry. Evidence of leakage from the Vent Hole indicates potential leakage past the Inlet

seal and the need to remove the sprinkler to determine the cause of leakage;

for example, an improper installation

or an ice plug. Close the re protection system control valve and drain the

system before removing the sprinkler.

Exercise care to avoid dam age before,

during, and after instal lation. Never

paint, plate, coat, or otherwise alter

automatic sprinklers after they leave

the factory.

Never repaint factory-painted Cover

Plates. When necessary, replace cover plates with factory-painted units.

Non-factory applied paint can adversely delay or prevent sprinkler operation

in the event of a re.

Replace sprinklers that:

• were damaged by dropping, striking,

wrench twisting, wrench slippage, or

the like.

• were modied or over-heated.

•

have cracked bulbs or have lost liquid

from the bulbs. Refer to the Installation

Section in this data sheet.

• are leaking or exhibiting visible signs

of corrosion.

Responsibility lies with owners for the

in spection, testing, and maintenance of

their re protection system and devices

in compliance with this document, as

well as with the applicable standards of

the National Fire Protec tion Association

(for example, NFPA 25), in addition to

the standards of any other authorities

having jurisdiction. The installing contractor or sprinkler manufacturer should

be contacted relative to any questions.

Automatic sprinkler systems are recommended to be inspected, tested, and

maintained by a qualied Inspection

Service in accordance with local requirements and/or national codes.

WRENCH

RECESS

WRENCH

FLAT

PUSH WRENCH

IN TO ENSURE

ENGAGEMENT

WITH SPRINKLER

WRENCHING AREA

W-TYPE 7 SPRINKLER WRENCH

FIGURE 16

Page 9

TFP510

Page 9 of 10

Limited

Warranty

Products manufactured by Tyco Fire

Suppression & Building Products

(TFSBP) are war ranted solely to the

original Buyer for ten (10) years against

defects in mate rial and workmanship when paid for and properly installed and maintained under normal

use and service. This warranty will expire ten (10) years from date of shipment by TFSBP. No warranty is given

for products or com ponents manufactured by companies not afliated

by ownership with TFSBP or for products and components which have

been subject to misuse, improper installation, corrosion, or which have

not been installed, maintained, modied or repaired in accordance with applicable Standards of the National Fire

Protection Association, and/or the standards of any other Authorities Having

Jurisdiction. Materials found by TFSBP

to be defective shall be either repaired

or replaced, at TFSBP's sole option.

TFSBP neither assumes, nor authorizes

any person to assume for it, any other

obligation in connection with the sale of

products or parts of prod ucts. TFSBP

shall not be responsible for sprinkler

system design errors or inac curate or

incomplete information sup plied by

Buyer or Buyer’s repre sentatives.

In no event shall TFSBP be liable, in

contract, tort, strict liability or under

any other legal theory, for incidental,

indirect, special or consequential damages, including but not limited to labor

charges, regardless of whether TFSBP

was informed about the possibility of

such damages, and in no event shall

TFSBP's liability exceed an amount

equal to the sales price.

The foregoing warranty is made in lieu

of any and all other warranties, express

or implied, including warranties of merchantability and tness for a particular

purpose.

This limited warranty sets forth the exclusive remedy for claims based on failure of or defect in products, materi als

or components, whether the claim is

made in contract, tort, strict liability or

any other legal theory.

This warranty will apply to the full extent permitted by law. The invalidity, in

whole or part, of any portion of thiswarranty will not affect the remainder.

Ordering

Procedure

Contact your local distributor for availability. When placing an order, indicate

the full product name and Part Number

(P/N).

Dry-Type Sprinklers

Specify this dry-type sprinkler as

follows:

• Model/SIN from Page 1

•

Quick Response, Standard Cover age,

Dry-Type Sprinkler

• Deector Style

• 5.6 K-Factor

• Order Length

Dry-Type Sprinklers are furnished

based upon Order Length as measured per Figures 3 through 10. After

taking the measurement, round it to

the nearest 1/4 inch increment.

•

Inlet Connection: 3/4-inch NPT,

1-inch NPT, or ISO 7-R1

• Temperature Rating

• Sprinkler Finish

•

Escutcheon Style and Finish, as

applicable

• Part Number (P/N) from Table C

The Upright Sprinkler without an

Escutcheon ( TY3135) is available in

1-Inch NPT only.

Part Numbers are for 3/4-inch and

1-inch NPT stand ard order sprinklers. Orders for all other sprinkler

assemblies must be accompanied

by a complete description. Refer to

the Price List for a complete listing of

Part Numbers.

Sprinkler Wrench

Specify: W-Type 7 Sprinkler Wrench,

P/N 56-850-4-001.

Sprinkler Boot

Specify: Model DSB-2 Dry Sprinkler

Boot, P/N 63-000-0-002.

This Part Number includes one Boot,

two Strap Ties, and 1/3 oz. of Adhesive.

The quantity of adhesive is sufcient for

installing one Boot.

Page 10

TFP510

Page 10 of 10

P/N 60 – XXX – X – XXX

Pendent with Standard

01

Escutcheon (3/4" NPT)

Pendent with Deep

02

Escutcheon (3/4" NPT)

Pendent with Standard Recessed

03

Escutcheon (3/4" NPT)

Pendent without

04

Escutcheon (3/4" NPT)

Sidewall with Standard

05

Escutcheon (3/4" NPT)

Sidewall with Deep

06

Escutcheon (3/4" NPT)

Sidewall without

07

Escutcheon (3/4" NPT)

Pendent with Standard

36

Escutcheon (1" NPT)

Pendent with Deep

33

Escutcheon (1" NPT)

Pendent with Standard Recessed

37

Escutcheon (1" NPT)

MODEL/SIN

TY3935

(Figure 3)

TY3935

(Figure 5)

TY3935

(Figure 4)

TY3935

(Figure 6)

TY3735

(Figure 8)

TY3735

(Figure 9)

TY3735

(Figure 10)

TY3235

(Figure 3)

TY3235

(Figure 5)

TY3235

(Figure 4)

SPRINKLER

FINISH

1 NATURAL BRASS WHITE

4 WHITE POLYESTER WHITE

9 CHROME PLATED CHROME

0 CHROME PLATED WHITE

2 NATURAL BRASS BRASS PLATED

TEMPERATURE

RATINGS (2)

0 135°F (57°C)

1 155°F (68°C)

2 175°F (79°C)

3 200°F (93°C)

4 286°F (141°C)

ESCUTCHEON

FINISH (1)

055 5.50”

082 8.25”

180 18.00”

187 18.75”

372 37.25”

480 48.00”

SAMPLE ORDER

LENGTHS (3)

Pendent without

32

Escutcheon (1" NPT)

TY3235

(Figure 6)

NOTES

Sidewall with Standard

34

Escutcheon (1" NPT)

Sidewall with Deep

43

Escutcheon (1" NPT)

Sidewall without

44

Escutcheon (1" NPT)

Upright without

38

Escutcheon (1" NPT)

TY3335

(Figure 8)

TY3335

(Figure 9)

TY3335

(Figure 10)

TY3135

(Figure 7)

(1). Escutcheon Finish applies to sprinklers provided with

escutcheons.

(2). 286°F (141°C) temperature rating applies to non-recessed

sprinkler assemblies.

(3). Dry-Type Sprinklers are furnished based upon “Order Length”

as measured per Figures 3 through 10, as applicable, and

for each individual sprinkler where it is to be installed. After

the measurement is taken, round it to the nearest 1/4 inch

increment.

TABLE C

PART NUMBER SELECTION

SERIES DS-1, 3/4 AND 1-INCH NPT, QUICK RESPONSE, STANDARD COVERAGE, DRY-TYPE SPRINKLERS

(Use Prefix “I” for ISO 7-R1 Connection; for example, I-60-361-1-180)

Copyright © 200 9 - 2010 Tyco Fire Suppression & Building Products

. All rights reserved.

Loading...

Loading...