Page 1

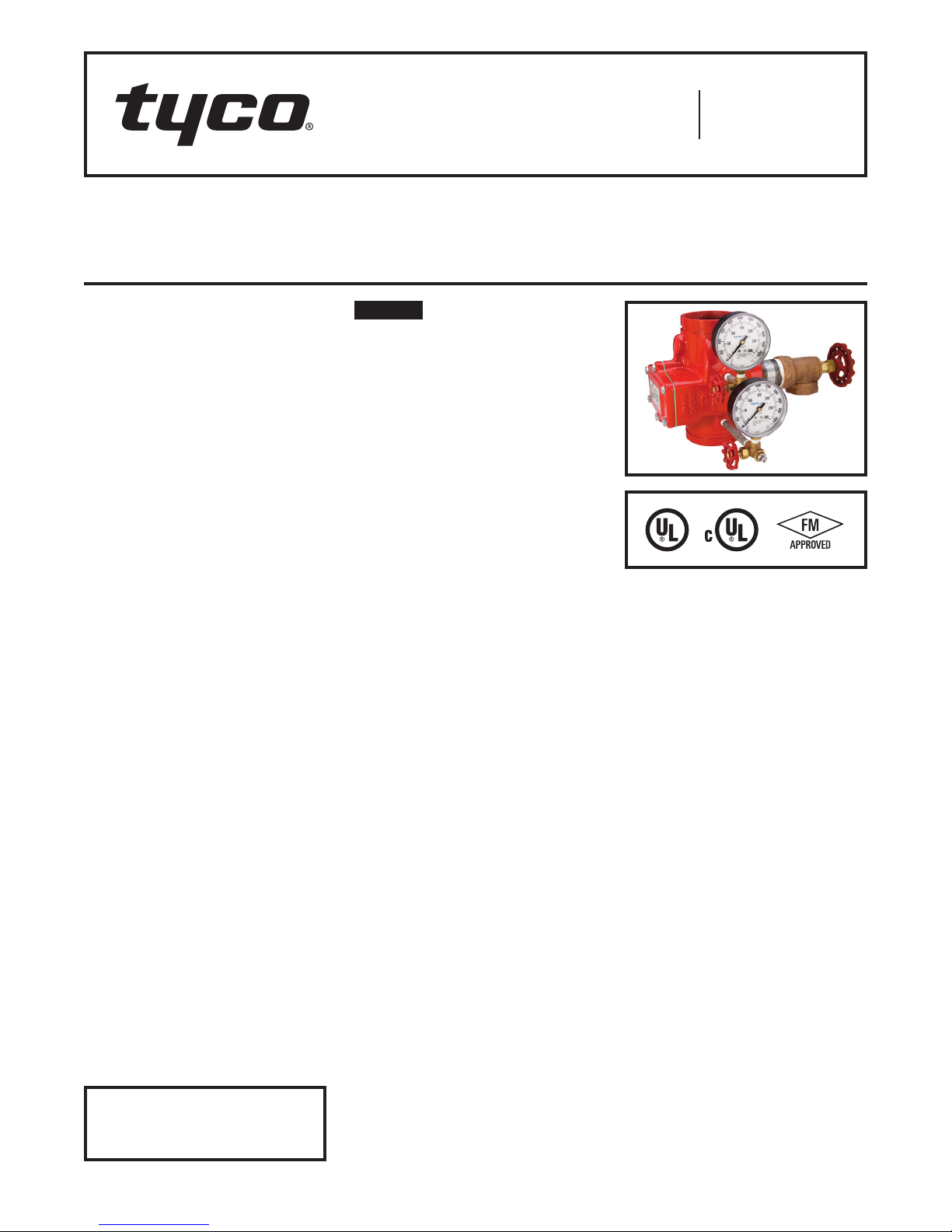

Model CV-1FR Grooved-End

Riser Check Valves

2 Inch to 12 Inch (DN50 to DN300)

Worldwide

Contacts

www.tyco-fire.com

General

Description

The TYCO Model CV-1FR GroovedEnd Riser Check Valve is a compact

and rugged swing-type unit that allows

water flow in one direction and prevents flow in the opposite direction.

A resilient elastomer seal facing on

the spring-loaded clapper ensures a

leak-tight seal and non-sticking operation. The Model CV-1FR Riser Check

Valves are designed to minimize water

hammer caused by flow reversal.

The Model CV-1FR Riser Check Valve

is furnished with grooved ends and

can be installed using GRINNELL

Grooved Couplings or GRINNELL

Figure 71 Flange Adapters. The Model

CV-1FR Riser Check Valves have been

designed with a removable cover for

ease of field maintenance. These valves

can be installed horizontally (with cover

in the upward position) or vertically with

the flow in the upward direction. Refer

to Figure 6.

To facilitate their use in wet-type automatic sprinkler system risers, the

Model CV-1FR Riser Check Valves are

provided with threaded outlets for pressure gauges and a drain connection.

They provide a more compact and economical alternative to an alarm check

valve where a water motor alarm is not

required. Provisions must be made for

a local alarm using an approved flow

switch (not included).

The Model CV-1FR Riser Check Valve

is also Listed for use in conjunction

with the TYCO DV-5 Deluge Valve in

Preaction Systems under air pressure

without the use of prime water.

The Model CV-1FR Riser Check Valves

are a redesign for the Central Figure

590FR and GRINNELL Figure 590FR.

NOTICE

The Model CV-1FR Riser Check Valve

described herein must be installed

and maintained in compliance with

this document and with the applicable

standards of the NATIONAL FIRE PROTECTION ASSOCIATION, in addition to

the standards of any authorities having

jurisdiction. Failure to do so may impair

the performance of this device.

Never remove any piping component

nor correct or modify any piping deficiencies without first de-pressurizing

and draining the system. Failure to do

so may result in serious personal injury,

property damage, and/or impaired

device performance.

The owner is responsible for maintaining their fire protection system and

devices in proper operating condition.

Contact the installing contractor or

manufacturer with any questions.

Technical

Data

Approvals

UL, C-UL Listed

FM Approved

Sizes

2 in. to 12 in. (DN50 to DN300)

Maximum Working Pressure

300 psi (20,7 bar)

Valve Assembly Finish

Red, non-lead paint

Installation

The Model CV-1FR Riser Check Valves

are to be installed in accordance with

this section:

1. The arrow cast on the Body must

point in the direction of the flow.

2. Valves installed vertically must

be positioned with the flow in the

upward direction.

3. Valves installed horizontally must be

positioned with the Cover facing up.

Refer to Figure 6.

4. Grooved-end pipe couplings used

with the Model CV-1FR Riser Check

Valve must be installed in accordance

with manufacturer’s instructions.

NOTE: Valves should be installed a

reasonable distance downstream from

pumps, elbows, expanders, reducers,

or other similar devices to extend the

valve life. Standard piping practices

call for a minimum of five times the pipe

diameter for general use.

Refer to Technical Data Sheet

TFP2300 for warnings pertaining to

regulatory and health information.

IMPORTANT

Page 1 of 4 AUGUST 2018 TFP950

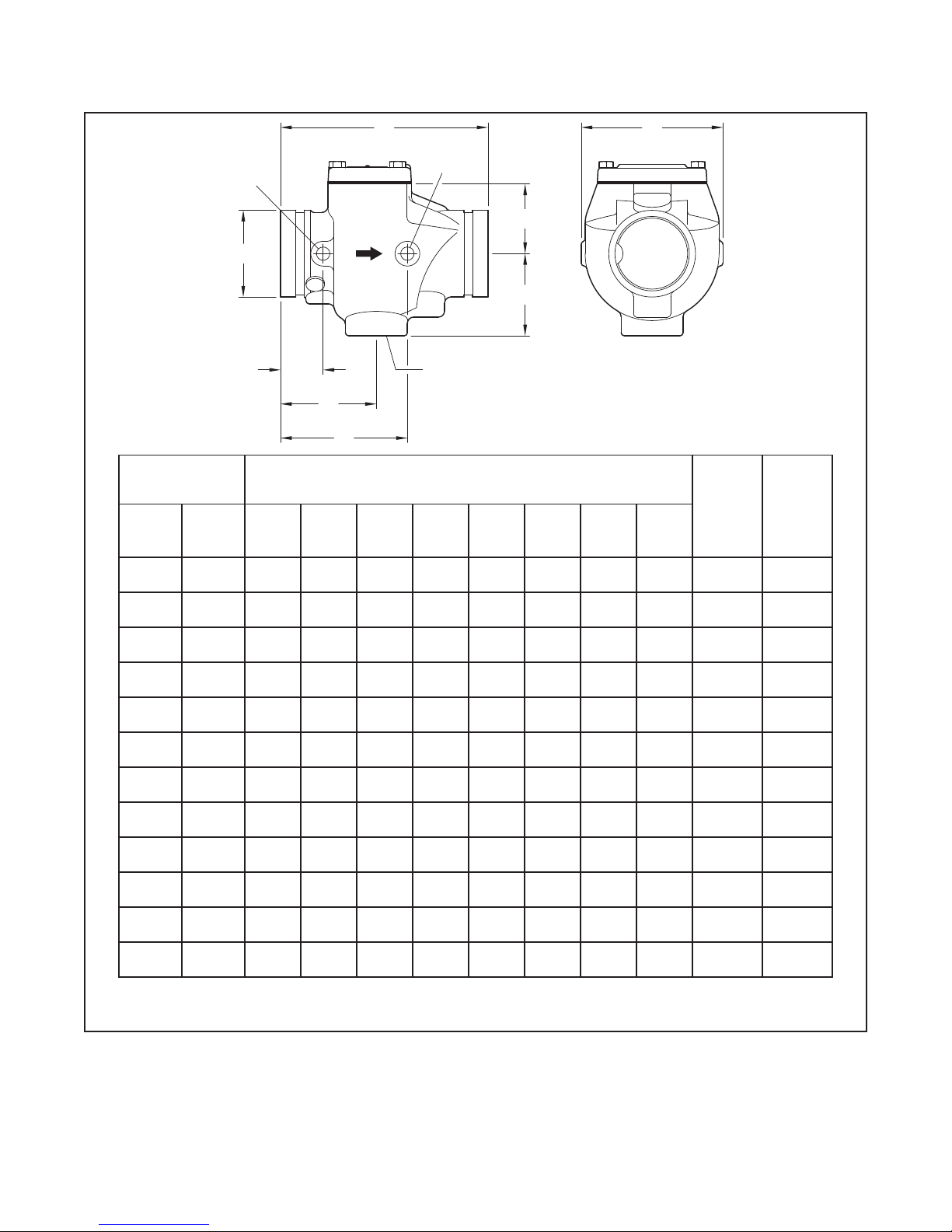

Page 2

TFP950

Page 2 of 6

1/4"

NPT

O.D.

BA

1/4"

NPT

C

D

Nominal Pipe Size

ANSI

Inches

DN

2

DN50

2-1/ 2

DN65

76 ,1

DN65

3

DN80

4

DN10 0

139.7

DN125

5

DN125

16 5 .1

DN15 0

6

DN15 0

8

DN200

10

DN250

12

DN300

O.D.

Inches

(mm)

2.375

(60,3)

2.875

(73,0)

-

(76 ,1)

3.500

(88,9)

4.500

(114, 3 )

-

(139,7)

5.563

(141,3)

-

(165,1)

6.625

(168 ,3)

8.625

(219,1)

10.750

(27 3 ,1)

12.75 0

(323,9)

J

E

F

A B C D E F J

6.75

(171, 5)

8.00

(203,2)

8.00

(203,2)

8.37

(212,6)

9.63

(245,6)

10.50

(266,7)

10.50

(266,7)

11. 5 0

(292,1)

11. 5 0

(292,1)

14.00

(355,6)

18.00

(457,2)

21.0

(533,4)

4.38

(111,3)

5.38

(136 ,7 )

5.38

(136 ,7 )

5.72

(145, 3)

6.68

(169,7)

7.40

(188 ,0 )

7.40

(188 ,0 )

8.00

(203,2)

8.00

(203,2)

10 .14

(257, 6 )

12.38

(314, 5)

14. 28

(362,7)

1.9 6

(49,8)

2.63

(66,8)

2.63

(66,8)

2.81

(71,4)

3.80

(96,5)

4.46

(113,2)

4.46

(113,2)

4.62

(117, 4)

4.62

(117, 4)

6.67

(169,4)

8.62

(218,9)

9.93

(252,2)

K

Nominal Dimensions

Inches

(mm)

2.57

(65,3)

3.09

(78,5)

3.09

(78,5)

3.31

(84,1)

3.63

(92,2)

4.1 3

(104,9)

4.1 3

(104,9)

4.50

(114,3)

4.50

(114,3)

5.52

(140,2)

6. 41

(162,8)

7. 27

(184,7)

3.25

(82,3)

3.87

(98,3)

3.87

(98,3)

3.87

(98,3)

4.53

(115,4)

4.90

(124,5)

4.90

(124,5)

5.00

(12 7, 0 )

5.00

(12 7, 0 )

5.46

(138 ,7 )

7.5 0

(190,5)

7.62

(193, 5)

4.37

(111,0)

5.12

(130 ,0 )

5.12

(130 ,0 )

5.12

(130 ,0 )

5.78

(146, 8)

7.0 0

(177, 8 )

7.0 0

(177, 8 )

7. 2 5

(184 ,2)

7. 2 5

(184 ,2)

10.50

(266,7)

10.75

(27 3 ,1)

10.0 0

(254,0)

FIGURE 1

MODEL CV-1FR RISER CHECK VALVES

NOMINAL DIMENSIONS

1.5 6

(39,6)

1.73

(43,9)

1.72

(43,7)

1.72

(43,7)

2.12

(53,8)

2.09

(53,1 )

2.09

(53,1 )

2.00

(50,8)

2.00

(50,8)

2.43

(61,7)

3.38

(85,9)

3.13

(79,5)

K

Inches

NPT

1

1-1/4

1-1/4

1-1/4

2

2

2

2

2

2

2

2

Cover

Bolt

Torque

ft-lb

(Nm)

18

(25)

39

(54)

39

(54)

39

(54)

50

(69)

39

(54)

39

(54)

60

(82)

60

(82)

120

(164)

130

(178)

130

(178)

Approx.

Weight

lb

(kg)

9.0

(4,5)

10.0

(4,5)

10.0

(4,5)

11. 0

(5,0)

25.0

(11,3)

29.0

(13,2)

29.0

(13,2)

47. 0

(21,3)

47. 0

(21,3)

66.0

(30,0)

109.7

(49,4)

151.0

(68,0)

Page 3

TFP950

IN POUNDS PER SQUARE INCH (PSI)

NOMINAL PRESSURE DROP

NOMINAL PRESSURE DROP IN BAR

Page 3 of 6

8

16

4,15

2

3

1

Detail Part Material Qty. Detail Part Material Qty. Detail Part Material Qty.

1 Body Ductile Iron 1 6

2 Cover Ductile Iron 1 7 Spring

3

4

5

Cover

Gasket

Hex Cap

Screw

Clapper

2˝ - 8˝

(DN50-200)

Clapper

10˝ - 12˝

(DN250-300)

Nitrile Rubber 1 8

Steel, Zinc

Ductile Iron 13

SEE

VIEW A

Plated

Stainless

Steel

17

AR 9

1

11

Clapper

Facing

Hinge

Shaft

Retaining

Ring

Retention

Bolt

Retaining

Disc

9

2

SEE

DETAIL B

EPDM

Grade “E”

Stainless

Steel

Stainless

Steel

Stainless

Steel

Stainless

Steel

Stainless

Steel

2" - 8"

(DN50-DN200)

5

11

2" - 8"

(DN50-DN200)

1 14 Locknut

1 15 Adhesive

1 16 Nameplate Aluminum 1

AR 17 Rivet Steel 2

1 18 Spacer

1

5

7

DETAIL B

8

9

VIEW A

13

14,15

6

5

(DN250 - DN300)

2

10" - 12"

(DN250 - DN300)

13

10" - 12"

6

Stainless

Steel

Thread

Sealer

Stainless

Steel

7

11,15

18

1

AR

1

FIGURE 2

MODEL CV-1FR RISER CHECK VALVES

AS SEM B LY

5

5.0

500

4.0

3.0

2.0

1.0

0.9

0.8

0.7

0.6

0.5

100

FLOW RATE IN LITRES PER MINUTE (LPM)

700 1000 2000 3000 5000 7000 10000 20000 30000

2 INCH (DN50)

2-1/2 INCH (DN65)

3 INCH (DN80)

4 INCH (DN100)

200 300 400 600 1000 2000 3000 4000 6000 10000

FLOW RATE IN GALLONS PER MINUTE (GPM)

(1 GPM = 3,785 LPM)

5 INCH (DN125)

6 INCH (DN150)

8 INCH (DN200)

10 INCH (DN250)

12 INCH (DN300)

FIGURE 3

MODEL CV-1FR RISER CHECK VALVES

PRESSURE LOSS DATA

50000

0,30

0,20

0,10

0,09

0,08

0,07

0,06

0,05

0,04

15000

(1 PSI = 0,06895 BAR)

Page 4

TFP950

Page 4 of 6

A

C

E

B

D

Nominal Pipe Size

ANSI

Inches

DN

2

DN50

2-1/ 2

DN65

76 ,1

DN65

3

DN80

4

DN10 0

139,7

DN125

5

DN125

16 5 ,1

DN15 0

6

DN15 0

8

DN200

10

DN250

12

DN300

O.D.

Inches

(mm)

2.375

(60,3)

2.875

(73,0)

(76 ,1)

3.500

(88,9)

4.500

(114, 3 )

(139,7)

5.563

(141,3)

(165,1)

6.625

(168 ,3)

8.625

(219,1)

10.750

(27 3 ,1)

12.75 0

(323,9)

A B C D

6.75

(171,5)

8.00

(203,2)

–

–

–

8.00

(203,2)

8.37

(212,6)

9.63

(244,6)

10.50

(266,7)

10.50

(266,7)

11. 5 0

(29 2 ,1)

11. 5 0

(29 2 ,1)

14.00

(355,6)

18.00

(4 57, 2)

21.0 0

(533,4)

Nominal Dimensions

Inches

(mm)

5.87

(149,1)

6.66

(169,2)

6.66

(169,2)

6.88

(174 , 8)

7.6 3

(193 ,7)

8.13

(206,4)

8.13

(206,4)

8.50

(215,8)

8.50

(215,8)

9.52

(241,7)

10. 41

(264,3)

11. 2 7

(28 6 ,1)

3.25

(82,6)

3.87

(98,3)

3.87

(98,3)

3.87

(98,3)

4.53

(115,1)

4.90

(124, 5)

4.90

(124,5)

5.00

(1 2 7, 0 )

5.00

(1 2 7, 0 )

5.46

(138 ,7 )

7.5 0

(190,5 )

7.62

(193 ,5 )

9.52

(241,9)

10.80

(2 74 ,3)

10.80

(2 74 ,3)

11. 0 2

(279,9)

11. 9 2

(302,7)

12.42

(315,4)

12.42

(315,4)

12.79

(324,8)

12.79

(324,8)

13.81

(350,7)

14.70

(373,3)

15.56

(395,2)

E

Inches

NPT

1

1-1/4

1-1/4

1-1/4

2

2

2

2

2

2

2

2

FIGURE 4

MODEL CV-1FR RISER CHECK VALVE WITH TRIM COMPONENT S

NOMINAL DIMENSIONS

Page 5

P/N 59-591-1-020

2 Inch (DN50)

NO.

DESCRIPTION P/N

1

300 psi/ 2000 kPa

Water Pressure Gauge

2

3

1/4" Plug CH

4

5

1/4" x 2" Nipple CH

6

1/4" x 5" Nipple CH

7

1" x 3" Nipple CH

2-1/2 Inch (DN65) through 3 Inch (DN80)

NO.

DESCRIPTION P/N

1

300 psi/ 2000 kPa

Water Pressure Gauge

2

3

1/4" Plug CH

4

5

1/4" x 2" Nipple CH

6

1/4" x 5" Nipple CH

7

1-1/4" x 3" Nipple CH

. . . . . . . . . . . . .

. . . . . . . . .

. . . . . . . . . .

P/N 59-591-1-030

. . . . . . . . . . . . .

. . . . . . . .

. . . . . . . .

. . . . . .

. . . . . . . .

. . . . . . . .

. . . . . . .

QTY.

. .

. .

QTY.

. .

. .

2

2

2

1

1

1

1

2

2

2

1

1

1

1

92-343-1-005

46-005-1-0021/4" Gauge Test Valve

46-048-1-0061" Angle Valve

92-343-1-005

46-005-1-0021/4" Gauge Test Valve

46-048-1-0071-1/4" Angle Valve

NOTES:

All Fittings and Nipples are

1.

galvanized (Standard Order).

CH: Common Hardware.

2.

TFP950

Page 5 of 6

MAIN

DRAIN VALVE

(NORMALLY

CLOSED)

7

SYSTEM

PRESSURE

1

2

5

3

4

GAUGE

SUPPLY

PRESSURE

GAUGE

4 Inch (DN100) through 12 Inch (DN300)

NO.

DESCRIPTION P/N

1

300 psi/ 2000 kPa

Water Pressure Gauge

2

3

1/4" Plug CH

4

5

1/4" x 2" Nipple CH

6

1/4" x 5" Nipple CH

7

2" x 3" Nipple CH

P/N 59-591-1-080

QTY.

. .

. .

. . . . . . . . . . . . .

. . . . . . . . .

. . . . . . . .

. . . . . . . .

. . . . . . . . . .

COVER

2

2

2

1

1

1

1

MODEL CV-1FR

RISER CHECK

92-343-1-005

46-005-1-0021/4" Gauge Test Valve

46-048-1-0092" Angle Valve

VALVE

FIGURE 5

MODEL CV-1FR RISER CHECK VALVES

TRIM PARTS LIST

OUTLET

FLOW

INLET

COVER

FLOW

1

6

OUTLETINLET

2

3

HORIZONTAL ORIENTATIONVERTICAL ORIENTATION

FIGURE 6

MODEL CV-1FR RISER CHECK VALVES

INSTALLATION

Page 6

TFP950

Page 6 of 6

TFP950

Page 6 of 6

Care and

Maintenance

Before closing a fire protection system

main control valve for maintenance

work on the fire protection system

that it controls, obtain permission to

shut down the affected fire protection

system from the proper authorities

and notify all personnel who may be

affected by this decision.

After placing a fire protection system

in service, notify the proper authorities

and advise those responsible for monitoring proprietary and/or central station

alarms.

The owner is responsible for the

inspection, testing, and maintenance of

their fire protection system and devices

in compliance with this document, as

well as with the applicable standards

of the NATIONAL FIRE PROTECTION

ASSOCIATION (e.g., NFPA 25), in addition to the standards of any authority

having jurisdiction. Contact the installing contractor or product manufacturer

with any questions. Any impairments

must be immediately corrected.

Automatic sprinkler systems are recommended to be inspected, tested,

and maintained by a qualified Inspection Service in accordance with local

requirements and/or national codes.

Limited

Warranty

For warranty terms and conditions, visit

www.tyco-fire.com.

Ordering

Procedure

Contact your local distributor for availability. When placing an order, indicate

the full product name and Part Number

(P/N).

Model CV-1FR Check Valves

Specify: Size and P/N (below):

2 in. (DN50) .............P/N 59-590-1-020

2-1/2 in. (DN65) ..........P/N 59-590-1-025

76,1 mm (DN65) ......... P/N 59-590-1-076

3 in. (DN80) .............P/N 59-590-1-030

4 in. (DN100) ............P/N 59-590-1-040

139,7 mm (DN125) ....... P/N 5 9-59 0 -1-139

5 in. (DN125) ............P/N 59-590-1-050

165,1 mm (DN150) ....... P/N 59-5 9 0 -1-16 5

6 in. (DN150) ............P/N 59-590-1-060

8 in. (DN200) ............P/N 59-590 -1-080

10 in. (DN250) ...........P/N 5 9-59 0 -1-100

12 in. (DN300) ........... P/ N 5 9 - 590 -1-120

Model CV-1FR

Riser Check Valve Trim Assembly

Specify: Size and P/N (below).

2 in. (DN50) ............. P/N 59 -591-1-020

2-1/2 in. (DN65) .......... P/N 59 -5 91-1-0 30

76,1 mm (DN65) ......... P/N 59 -591-1-030

3 in. (DN80) ............. P/N 59- 591-1- 03 0

4 in. (DN100) ............ P/N 59 -591-1-080

139,7 mm (DN125) ....... P/N 59 -591-1-080

5 in. (DN125) ............ P/N 59 -591-1-08 0

165,1 mm (DN150) ....... P/N 59 -591-1-0 80

6 in. (DN150) ............ P/N 59 -591-1-080

8 in. (DN200) ............ P/N 5 9- 591-1-080

10 in. (DN250) ...........P/N 59 -591-1-080

12 in. (DN300) ........... P/N 59 -591-1-080

1400 Pennbrook Parkway, La nsdale, PA 194 46 | Telep hone +1-215- 362- 0700

© 2018 John son Control s. All right s reserved. A ll specifica tions and ot her informa tion shown wer e current as o f document rev ision date an d are subject t o change wit hout notice.

NATIONAL FIRE P ROTECTION ASSOCIATIO N and NFPA are register ed trademarks of N ational Fire Protec tion Associati on;

Loading...

Loading...