Page 1

Technical Services: Tel: (800) 381-9312 / Fax: (800) 791-5500

Model B-1 — 3.0 K-factor

Upright and Pendent

Foam-Water Sprinklers

tection Association, in addition to the

General

Description

The Model B-1 Upright and Pendent

Foam-Water Sprinklers are air-aspirating foam discharge outlets designed for use in foam-water deluge

systems. They are designed for flammable liquidrisks where it is desired to

apply foam from overhead sprinklers

(either upright or pendent) and where

follow-upwith plain waterina standard

spraysprinkler patternis necessaryas

in the case of NFPA 16, “Standard for

the Installation of Foam-Water Sprinkler and Foam-WaterSpray Systems”.

Itis recommended thattheend user be

consultedwith respecttothe suitability

of thematerials of construction for any

given corrosive environment. The effects of ambient temperature, concentration of chemicals,and gas/chemical

velocity, should be considered, at a

minimum, along with the corrosive nature to which the sprinklers may be

exposed.

The Model B-1 Foam-Water Sprinkler

is a redesignation for the Gem Issue

B-1 and Star Model B-1.

WARNINGS

TheModel B-1Foam-WaterSprinklers

describedherein mustbeinstalled and

maintained in compliance with this

document, as well as with the applicable standards of the National Fire Pro-

IMPORTANT

Always refer to Technical Data

Sheet TFP700 for the “INSTALLER

WARNING” that provides cautions

with respect to handling and installation of sprinkler systems and components. Improper handling and installation can permanently damage

a sprinkler system or its components and cause thesprinkler to fail

tooperate ina fire situationor cause

it to operate prematurely.

standardsof anyother authoritieshaving jurisdiction. Failure to do so may

impair the performance of thesedevices.

The owneris responsible formaintaining theirfire protectionsystem and devices in proper operating condition.

The installing contractor or sprinkler

manufacturer should be contacted

with any questions.

Technical

Data

Approvals

The M odel B-1 Upright and Pendent

Foam-Water Sprinklers are UL and

ULC Listed. (Discharge outlets and

foam concentrates are Listed for use

together. Refer to the individual foam

concentrate Listing for operating limitations and compatibility with the B-1

Foam-Water Sprinklers as providedin

the UL Fire Protection Equipment Directory.)

The M odel B-1 Upright and Pendent

Foam-Water Sprinklers meet the requirements of MIL-S-901C for lightweight Grade A shock proof equipment.

The Model B-1 Pendent Foam-Water

Sprinklers meet the requirements of

MIL-H-24146.

Maximum Working Pressure

175 psi (12,1 bar)

Discharge Coefficient

K=3.0GPM/psi

Thread Connection

1/2 inch NPT

Finishes

Natural Bronze

Physical Characteristics

Body . . . . . . . . . . . . . . Bronze

Deflector............ Brass

Agitator ............ Brass

1/2

(43,2 LPG/bar

1/2

Operation

TheModel B-1 Foam-WaterSprinklers

are designed with a unique venturi

style body. As foam solution (water

and foam concentrate mixture) flows

through the inlet of the body, air is

drawn into thebody through the openings adjacent to the wrenching area.

The foam solution and air mix is then

agitated to create an air-aspirated

foam.

The B-1 Foam-Water Sprinklers are

designed to discharge foam in a predetermined discharge pattern, as well

as to discharge water similar to standard spray sprinklers. To meet the intent of NFPA 16, foam-water sprinklers must be able to sufficiently

)

distribute water after depletion of the

foam concentrate.

Page 1 of 4 TFP840

MARCH, 2006

Page 2

Page2of4

TFP840

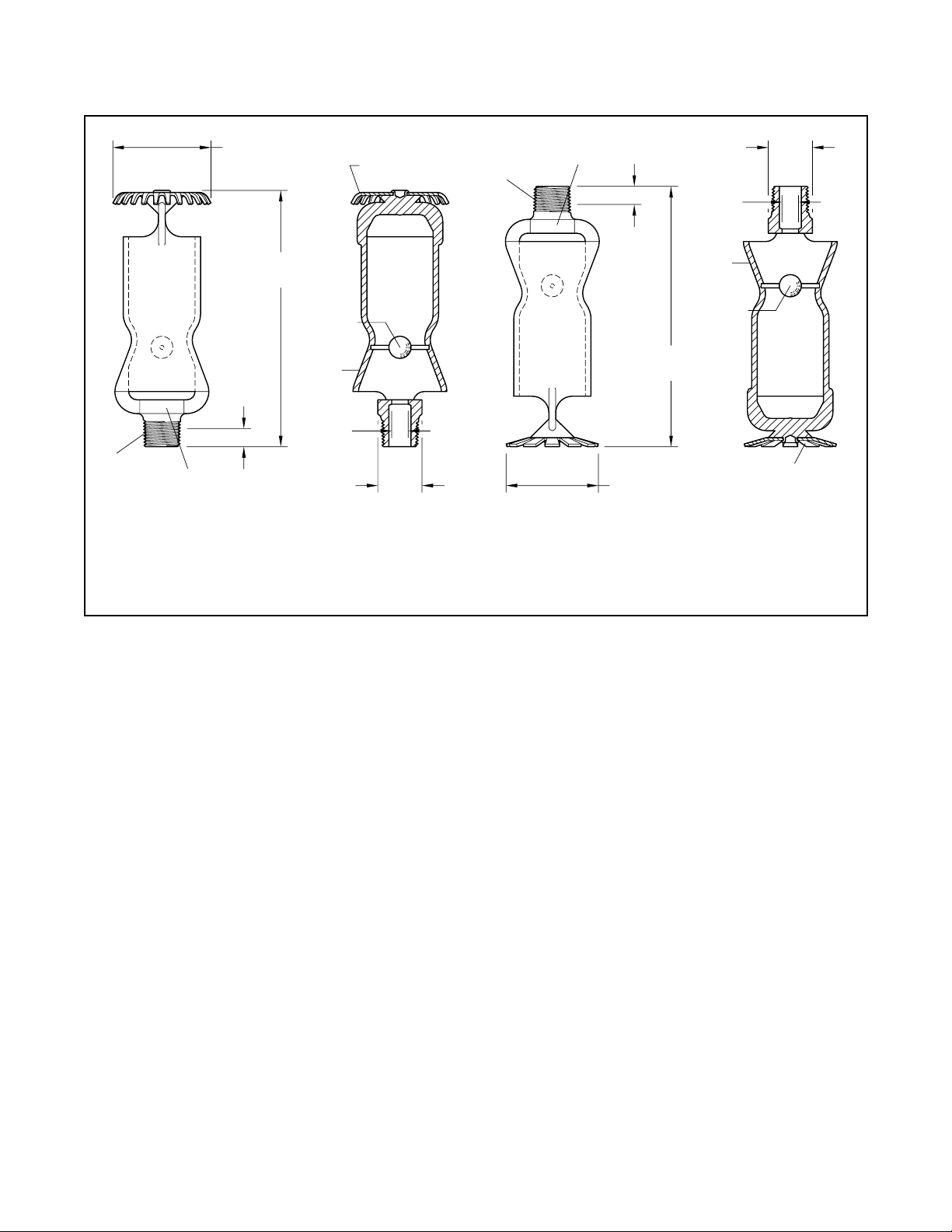

1/2"

NPT

(11,1 mm)

NOMINAL

MAKE-IN

WRENCHING

AREA

2-1/8" DIA.

(54,0 mm)

5-13/16"

(147,6 mm)

7/16"

UPRIGHT

AGITATOR

BODY

3/8" DIA.

(9,5 mm)

1" (25,4 mm)

ACROSS

WRENCH

FLATS

DEFLECTOR

1/2"

NPT

WRENCHING

AREA

7/16"

(11,1 mm)

NOMINAL

MAKE-IN

5-15/16"

(150,8 mm)

2-1/8" DIA.

(54,0 mm)

PENDENT

FIGURE 1

MODEL B-1 UPRIGHT AND PENDENT FOAM-WATER SPRINKLERS

NOMINAL DIMENSIONS

1" (25,4 mm)

ACROSS

WRENCH

FLATS

3/8" DIA.

(9,5 mm)

BODY

AGITATOR

DEFLECTOR

Design

Criteria

The M odel B-1 Upright and Pendent

Foam-Water Sprinklers are intended

for fire protection systems designed in

accordance with the standard installation rules for foam-water sprinklers

systems recognized by the applicable

Listing agency (e.g., UL Listing is

basedon the requirementsofNFPA13

and 16).

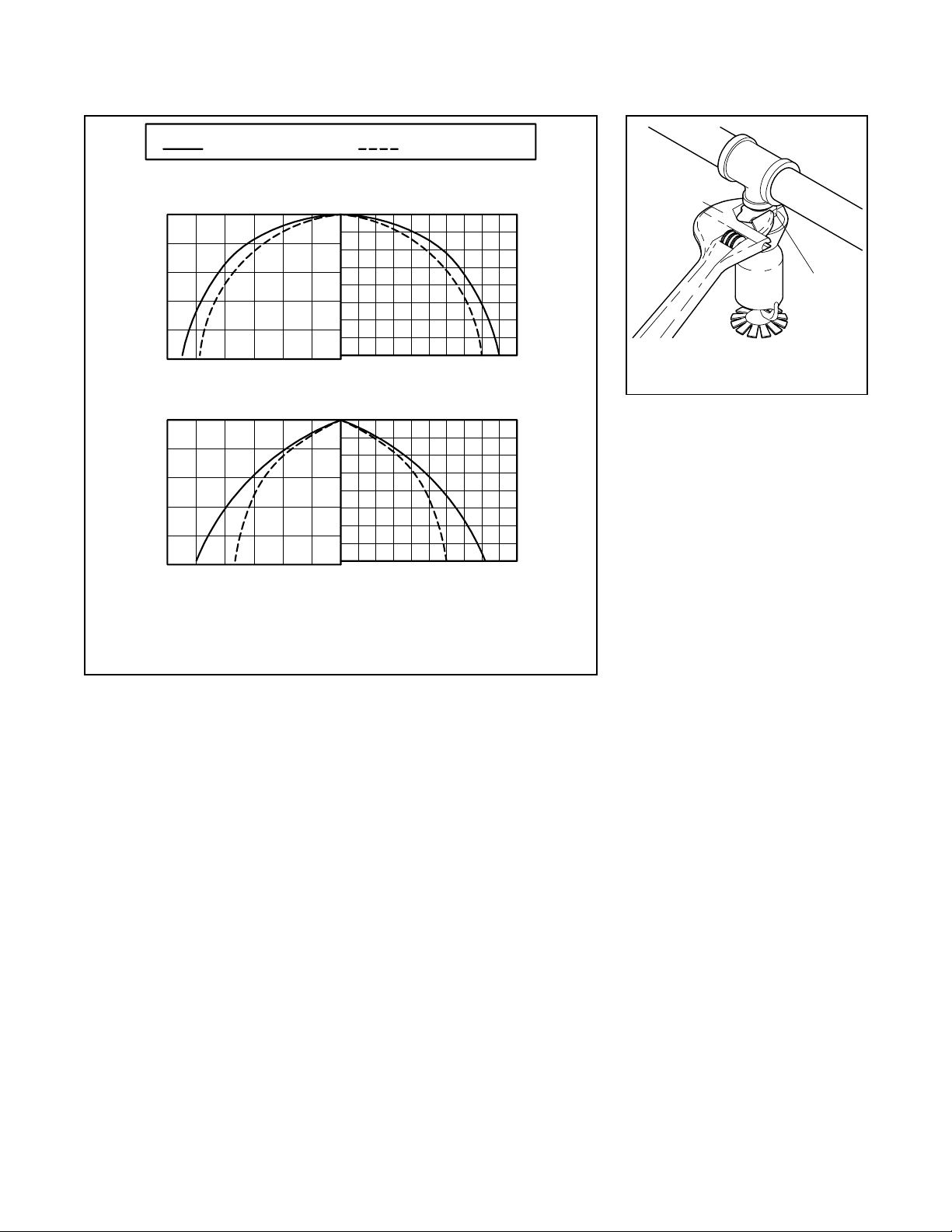

Figure 2 provides the nominal discharge patterns for reference use.

NOTE

The discharge patterns shown in Figure 2 are not to be used for design

purposes or to disregard standard installation rules.

Not l ess tha n two foam-wat er spri nklers are to be installed in any area,

regardless of size, in order to obtain

pattern overlap.

The applied density (flow per unit of

area) of foam solution must meet the

requirements of the Authority Having

Jurisdiction for the type flammable liquidand occupancy.Per NFPA 16,coverage density must not be less than

0.16 GPM/ft2(6,52 mm/min) of floor

area with a resulting minimu m dischargepressure ofnot less than30 psi

(2,1 bar).

Foam-water sprinkler spacing must

not exceed the requirements of NFPA

13 for extra hazard occupancies and

the system must be hydraulically calculated to obtain the required density

and discharge pressure.

NOTE

Discharge outlets and foam concentrates are Listed for use together. Refer to the individual foam concentrate

Listing for operating limitations and

compatibility withthe B-1 Foam-Water

Sprinklers as provided in the UL Fire

Protection Equipment Directory.

Installation

TheModel B-1 Foam-WaterSprinklers

must be installed in accordance with

the following instructions:

NOTE

A leak tight1/2 inchNPT sprinklerjoint

should be obtained with a torque of 7

to 14 ft.lbs. (9,5 to 19,0 Nm). A maximum of 21 ft. lbs. (28,5 Nm) of torque

may be used to install sprinklers with

1/2 NPT connections. Higher levels of

torque may distort the sprinkler inlet

and causeimpairment of the sprinkler.

Step 1. Pendent sprinklers are to be

installed in the pendent position, and

upright sprinklersare to be installedin

the upright position.

Step 2. With pipe thread sealant applied to the pipe threads, hand tighten

the sprinkler into the sprinkler fitting.

Step 3. Tighten the sprinkler into the

sprinkler fitting using an 8 or 10 inch

adjustable Crescent wrench. With reference to Figures 1 and 3, the adjustable Crescent wrench is only to be

applied to the wrench flats of the

wrenching area.

Page 3

TFP840

Page 3 of 4

CEILING, METRES

DISTANCEBELOW

CEILING, METRES

DISTANCEBELOW

0

0,5

1,0

1,5

2,0

2,5

0

0,5

1,0

1,5

2,0

2,5

RADIUS, METRES

RADIUS, METRES

3,0 2,0

DATAKEY

FOAM DISCHARGEWATER DISCHARGE

RADIUS, FEET

024868

UPRIGHT

RADIUS, FEET

01,0 246810

PENDENT

8 OR 10 INCH

101,02,03,0

0

2

4

6

CEILING, FEET

DISTANCEBELOW

ADJUSTABLE

WRENCH

APPLYTO

WRENCH

FLATS

ONLY

FIGURE 3

WRENCH FLATS

0

2

4

6

CEILING, FEET

DISTANCEBELOW

8

FIGURE 2

NOMINAL DISCHARGE PATTERNS

(Shown for reference only — Not suitable for design purposes)

Frequent visual inspections are rec-

Care and

ommendedtobeinitiallyperformedfor

sprinklersinstalled inpotentially corro-

Maintenance

siveatmospheres toverify the integrity

ofthe materialsof constructionas they

TheModel B-1 Foam-WaterSprinklers

must be maintained and serviced in

accordance with the following instructions:

NOTE

Before closinga fire protection system

main control valve for maintenance

work on thefire protection system that

itcontrols, permission toshutdownthe

affectedfire protection systemmustbe

obtained from the proper authorities

and all personnel who may be affected

by this action must be notified.

Model B-1 Foam-Water Sprinklers

must never be painted, plated, coated

or altered in any way after leaving the

factory; otherwise, the spray performance may be impaired.

Care must be exercised to avoid damage to the sprinklers - before, during,

and after installation. Sprinklers damaged by droppin g, s triking, wrench

may be affected by the corrosive conditions present for a given installation.

Thereafter, annual inspections per

NFPA 25 are required.

The owner is responsible for the inspection, testing, and maintenance of

their fire p rotection system and devices in compliance with this document, as well as with the applicable

standards of the National Fire Protection Association (e.g., NFPA 25), in

addition to the standards of any other

authorities having jurisdiction. The installing contractor or sprinkler manufacturer should be contacted relative

to any questions.

It is rec ommen ded that foam-water

sprinkler systems be inspected,

tested, and maintained by a qualified

Inspection Service in accordance with

local requirements and/or national

codes.

twist/slippage, or the like, must be replaced.

Page 4

Page4of4

TFP840

Limited

Warranty

Products manufactured byTyco Fire&

Building Products ( TFBP) ar e warranted solely to the original Buyer for

ten (10) years againstdefects inmaterial and workmanship when paid for

and properly installed and maintained

under normal use and service. This

warranty will expire ten (10) years

from date of shipment by TFBP. No

warranty is given for products or components manufactured by companies

not affiliated by ownership with TFBP

or forproducts and componentswhich

havebeen subject tomisuse,improper

installation, corrosion, or which have

not been installed, maintained, modified orrepaired in accordance with applicable Standards of theNational Fire

Protection Ass ociation, and/or the

standards of any other Authorities

Having Jurisdiction. Materials found

by TFBP to bedefective shall be either

repaired or replaced, at TFBP’s sole

option. TFBP neither assumes, nor

authorizesany persontoassumefor it,

any otherobligation inconnection with

the sale of products or parts of products.TFBP shallnot be responsiblefor

sprinkler systemdesign errorsor inaccurate or incomplete information supplied by Buye r or Buy er’s representatives.

In no event shall TFBP be liable, in

contract, tort, strict liability or under

any other legal theory, for incidental,

indirect,special or consequentialdamages, including but not limited to labor

charges, regardless of whether TFBP

was informed about the possibility of

such damages, and in no event shall

TFBP’s liability exceed an amount

equal to the sales price.

Theforegoingwarrantyismadeinlieu

of any and all other warranties, express or implied, including warranties

ofmerchantabilityand fitnessfor a particular purpose.

This limited warranty sets forth theexclusive remedy for claims based on

failure of or defect in products, materials or components, whether the claim

is made in contract, tort, strict liability

or any other legal theory.

This warranty will apply to the full extent permittedby law. The invalidity, in

whole or part, of any portion of this

warranty will not affect the remainder.

Ordering

Procedure

Whenplacing an order,indicatethefull

product name. Refer to the Price List

for complete listing of Part Numbers.

Contact your local distributor for availability.

Upright Foam-Water Sprinklers:

Specify: Model B-1 Upright FoamWater Sprinkler, P /N 49-210-1-001 .

Pendent Foam-Water Sprinklers:

Specify: Model B-1 Pendent FoamWater Sprinkler, P /N 49-211-1-001 .

TYCO FIRE & BUILDING PRODUCTS,451 North Cannon Avenue, Lansdale, Pennsylvania 19446

Loading...

Loading...