Page 1

Ultra Low Flow AQUAMIST Nozzles

Type ULF AM27

Automatic (Closed)

Worldwide

Contacts

www.tyco-fire.com

General

Description

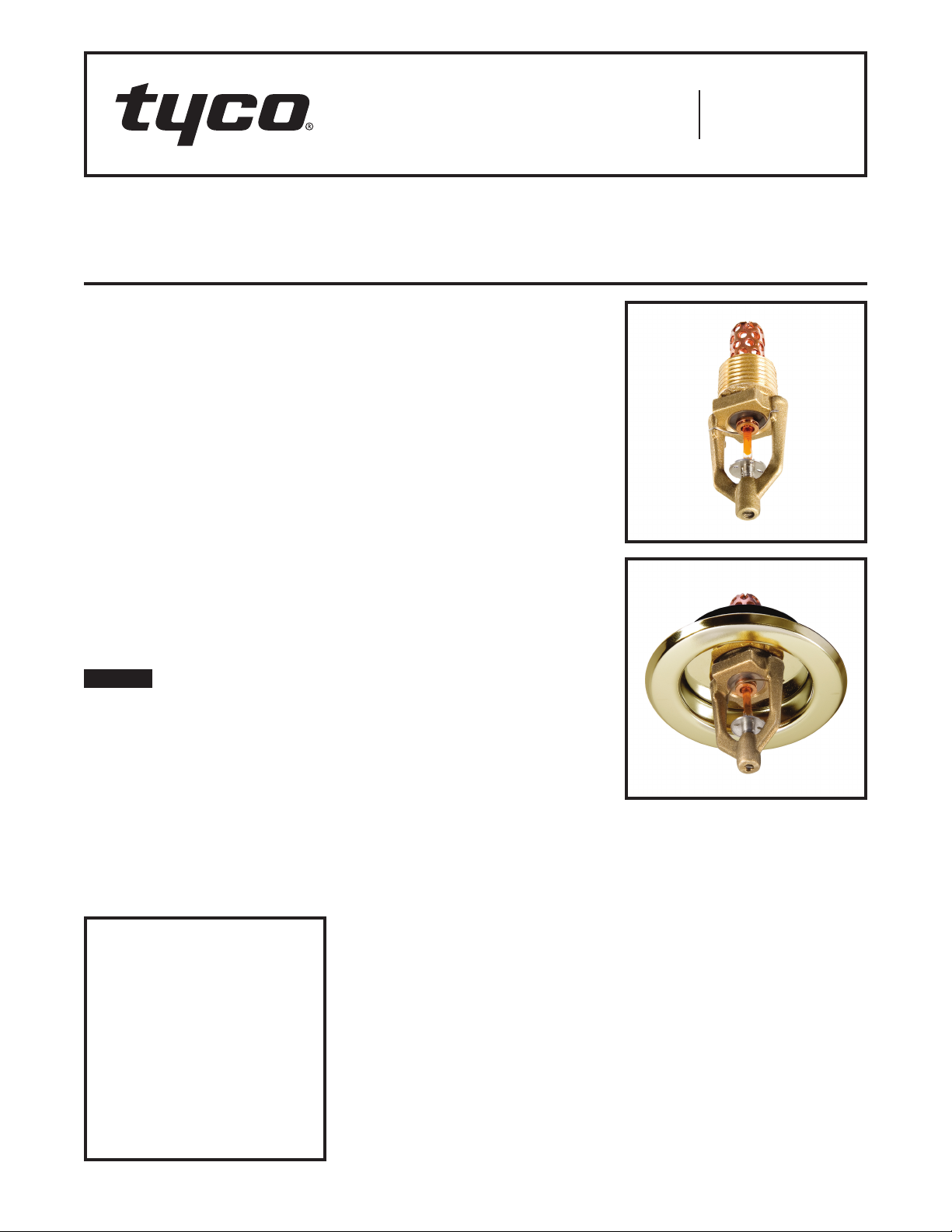

The TYCO Ultra Low Flow AQUAMIST

Nozzles Type ULF AM27 are closed

(automatic) nozzles intended for use

with engineered, water-mist systems.

They are low-pressure nozzles that

utilize a single fluid jet impinging on a

diffuser to produce a spray having a

range of water droplet sizes suitable

for the control of Class A fires.

It is recommended that the end user be

consulted with respect to the suitability of the materials of construction and

finish for any given corrosive environment. The effects of ambient temperature, concentration of chemicals, and

gas/chemical velocity should be considered, at a minimum, along with the

corrosive nature to which the nozzles

may be exposed.

NOTICE

The Type ULF AM27 AQUAMIST

Nozzles de scribed herein must be

installed and maintained in compliance

with this document and with the applicable standards of the NATIONAL FIRE

PROTECTION ASSOCIATION (NFPA),

in addition to the standards of any

authorities having jurisdiction. Failure

to do so may impair the performance

of these devices.

The design of individual water mist

systems can vary considerably,

depending on the characteristics and

nature of the hazard and the basic

IMPORTANT

Refer to Technical Data Sheet

TFP2300 for warnings pertaining to

regulatory and health information.

Always refer to Technical Data

Sheet TFP700 for the “INSTALLER

WARNING” that provides cautions

with respect to handling and installation of sprinkler systems and components. Improper handling and

installation can permanently damage

a sprinkler system or its components and cause the sprinkler to fail

to operate in a fire situation or cause

it to operate prematurely.

purpose of the water mist system.

Because of these variations, the design

of water mist systems for fire protection must only be performed by experienced designers who thoroughly

understand the limitations as well as

capabilities of such systems.

The owner is responsible for maintaining their fire protection system

and devices in proper operating condition. Contact the installing contractor or product manufacturer with any

questions.

Approvals

The TYCO Type ULF AM27 AQUAMIST Nozzles in a 57°C (135°F) temperature rating and in a natural brass

finish are Factory Mutual Approved

when used as part of an engineered,

wet pipe water mist system. In particular, the FM Approval testing was performed in accordance with FM Class

5560, Approval Standard for Water Mist

Systems.

Technical

Data

Discharge Coefficient

K = 11,7 LPM/bar½

(K = 0.81 GPM/psi½)

Thread Connection

1/2 inch NPT

Finish

Natural Brass

Chrome Plated

White Coated

Temperature Ratings

Refer to Table A

Physical Characteristics

Frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Brass

Strainer . . . . . . . . . . . . . . . . . . . . . . . . . . Copper

Orifice Insert . . . . . . . . . . . . . . . . . . . . . . .Bronze

Button . . . . . . . . . . . . . . . . . . . . . . . . . . . .Bronze

Sealing Assembly ..Beryllium Nickel w/TEFLON

Ejection Spring . . . . . . . . . . . . . . Stainless Steel

Bulb . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Glass

Diffuser/Loading Screw . . . . . . . Stainless Steel

The smallest waterway (orifice) diameter of the Orifice Insert is nominally 4,3

mm (0.169 inches). The diameter of the

Inlet Strainer perforations is nominally

3,2 mm (0.125 inches).

Design

Criteria

Obtain guidance for the design of a

water-mist system that utilizes the

TYCO Type ULF AM27 AQUAMIST

Nozzles from the Technical Services

department.

Page 1 of 4 AUGUST 2018 TFP2227

Page 2

TFP2227

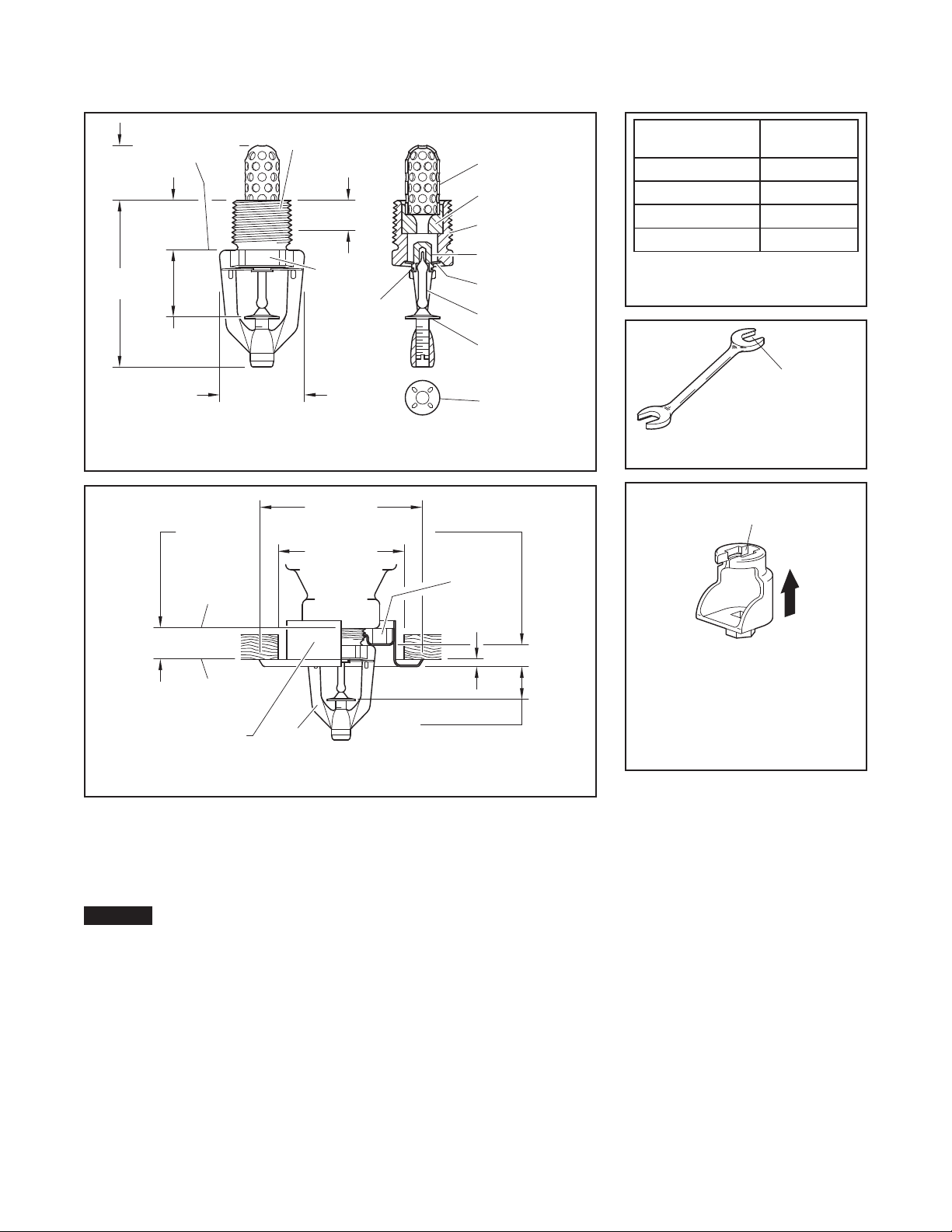

Assembly

Components:

SHAPE

ESCUTCHEON

20,6 mm

61,9 mm

(2-7/16")

11,1 mm

1/2"

AM27

73,0 mm

CLOSURE

WRENCH RECESS

WRENCH

WRENCHING AREA

Page 2 of 4

(13/16")

PLATE SEATING

SURFACE

17,5 mm

(11/16")

25,4 mm

(1")

TYPE ULF AM27 AQUAMIST NOZZLE

11,1±3,2 mm

(7/16±1/8")

FACE OF

NOZZLE

FITTING

(7/16")

NPT

NOMINAL

MAKE-IN

WRENCH

FLATS

8

31,0 mm

(1.22")

FIGURE 1

NOMINAL DIMENSIONS

(2-7/8") DIA.

57,2 mm

(2-1/4") DIA.

1

2

3

4

5

6

7

DIFFUSER

12,7 mm (1/2")

6,4 mm (1/4")

MOUNTING

PLATE

3,2 mm

(1/8")

1

2

3

4

5

6

7

8

-

Strainer

-

Orice

Insert

-

Frame

-

Button

-

Sealing

-

Bulb

-

Diffuser/

Loading

Screw

-

Ejection

Spring

Temperature

Rating

57° C/13 5°F Orange

68°C/155° F Red

79 °C/175° F Yel low

93°C/200°F Green

Bulb Fluid

Color

TABL E A

TE M PE R ATU R E R ATIN GS

SELECTION

(USE ONLY

END "A")

FIGURE 3

W-TYPE 6 WRENCH

RECESS

MOUNTING

SURFACE

TYPE ULF AM27 AQUAMIST NOZZLE

WITH STYLE 20 RECESSED ESCUTCHEON

Installation

The TYCO Type ULF AM27 AQUAMIST

Nozzles must be installed in accordance with this section.

NOTICE

Do not install any bulb-type nozzle if

the bulb is cracked or there is a loss

of liquid from the bulb. With the nozzle

held horizontally, a small air bubble

should be present. The diameter of

the air bubble is approximately 1,6 mm

(1/16 inch) for the 57°C (135°F) to 2,4

mm (3/32 inch) for the 93°C (200°F)

temperature ratings.

Obtain a leak-tight 1/2 inch NPT nozzle

joint by applying a minimum-to-maximum torque of 9,5 to 19,0 Nm (7 to

14 ft.-lbs.). Higher levels of torque

can distort the nozzle inlet and cause

leakage or impairment of the nozzle.

FIGURE 2

Do not attempt to compensate for

insufficient adjustment in the escutcheon plate by under or over-tightening

the nozzle. Re-adjust the position of the

nozzle fitting to suit.

Type ULF AM27

The Type ULF AM27 AQUAMIST

Nozzles must be installed in accordance with the following instructions.

Step 1. Install the Type ULF AM27

in the pendent position as shown in

Figure 1.

Step 2. With pipe-thread sealant

applied to the pipe threads, handtighten the nozzle into the nozzle fitting.

Step 3. Tighten the nozzle into the

nozzle fitting using only the W-Type 6

Wrench (Ref. Figure 3). With reference

to Figure 1, apply the W-Type 6 Wrench

to the Wrench Flats.

17,4 mm (11/16")

11,1 mm (7/16")

PUSH WRENCH

IN TO ENSURE

ENGAGEMENT

WITH SPRINKLER

FIGURE 4

W-TYPE 7

RECESSED WRENCH

Type ULF AM27 Recessed

The Type ULF AM27 AQUAMIST

Recessed Nozzles must be installed

in accordance with the following

instructions.

Step 1. Install the Recessed Type ULF

AM27 in the pendent position as shown

in Figure 2.

Step 2. After installing the Style 20

Mounting Plate, as applicable, over

the nozzle threads and with pipe-thread

sealant applied to the pipe threads,

hand-tighten the nozzle into the nozzle

fitting.

Step 3. Tighten the nozzle into the

nozzle fitting using only the W-Type 7

Recessed Wrench (Ref. Figure 4). With

reference to Figure 1, apply the W-Type

7 Recessed Wrench to the nozzle

Wrench Flats.

Step 4. After the ceiling has been

in stalled or the finish coat has been

Page 3

TFP2227

Page 3 of 4

applied, slide on the Style 20 Closure

over the Type ULF AM27 Nozzle and

push the Closure over the Mounting

Plate until its flange comes in contact

with the ceiling.

Care and

Maintenance

The TYCO Type ULF AM27 AQUAMIST

Nozzles must be maintained and serviced in accordance with this section.

Before closing a fire protection system

main control valve for maintenance

work on the fire protection system

that it controls, obtain permission to

shut down the affected fire protection

system from the proper authorities

and notify all personnel who may be

affected by this action.

Absence of an escutcheon, which is

used to cover a clearance hole, can

delay the time to nozzle operation in a

fire situation.

Absence of an escutcheon, which is

used to cover a clearance hole, can

delay the time to nozzle operation in a

fire situation.

The owner must assure that the sprinklers are not used for hanging any

objects and that the sprinklers are only

cleaned by means of gently dusting

with a feather duster; otherwise, nonoperation in the event of a fire or inadvertent operation may result.

Sprinklers which are found to be

leaking or exhibiting visible signs of

corrosion must be replaced.

Automatic sprinklers must never be

painted, plated, coated, or otherwise altered after leaving the factory.

Modified sprinklers must be replaced.

Sprinklers that have been exposed to

corrosive products of combustion, but

have not operated, should be replaced

if they cannot be completely cleaned

by wiping the sprinkler with a cloth or

by brushing it with a soft bristle brush.

Care must be exercised to avoid

damage to the sprinklers - before,

during, and after installation. Sprinklers damaged by dropping, striking,

wrench twist/slippage, or the like, must

be replaced. Also, replace any sprinkler that has a cracked bulb or that has

lost liquid from its bulb. (Ref. Installation Section.)

The owner is responsible for the

inspection, testing, and maintenance of

their fire protection system and devices

in compliance with this document, as

well as with the applicable standards

of the NATIONAL FIRE PROTECTION

ASSOCIATION - for example, NFPA 20,

25, and 750 - in addition to the standards of any other authorities having

jurisdiction. Contact the installing contractor or product manufacturer with

any questions.

Water-mist fixed systems should be

inspected, tested, and maintained by

a qualified Inspection Service in accordance with local requirements and/or

national codes.

Limited

Warranty

For warranty terms and conditions, visit

www.tyco-fire.com.

Ordering

Procedure

Contact your local distributor for availability. When placing an order, indicate

the full product name and Part Number

(P/N).

Type ULF AM27

AQUAMIST Nozzles

Specify: Type ULF AM27 AQUAMIST

Nozzle with (type of) finish and (specify)

tem perature rating, P/N (specify):

Natural Brass

57° C (135°F ) ..................49 -212-1-135

68°C (15 5°F ) ..................49 -212-1-155

79°C (175°F ) ..................49 -212-1-175

93°C (200°F) ..................49-212-1-200

Chrome Plated

57° C (135°F ) ..................49-212-9-135

68°C (15 5°F ) ..................49-212-9-155

79°C (175°F ) ..................49-212-9-175

93°C (200°F) ..................49 -212-9-200

Signal White* (RAL 9003)

57° C (135°F ) ..................49-212- 4-135

68°C (15 5°F ) ..................49 -212-4-15 5

79°C (175°F ) ..................49-212-4-175

93°C (200°F) ..................49 -212-4-200

Pure White** ( RAL 9 010)

57° C (135°F ) ..................49-212-3-135

68°C (15 5°F ) ..................49 -212-3-15 5

79°C (175°F ) .................49-212-3-175

93°C (200°F) .................49-212-3-200

* Previou sly known a s Bright Wh ite

** Eastern Hemis phere sales only

Recessed Escutcheon

Specify: Style 20 Recessed Escutcheon with (specify*) finish, P/N (specify*).

* Refer to Technical Data Sheet TFP770.

Nozzle Wrench

Specify: W-Type 6 Wrench,

P/N 56-000-6-387

Specify: W-Type 7 Recessed Wrench,

P/N 56-850-4-001

Page 4

TFP2227

Page 4 of 4

1400 Pennbrook Parkw ay, Lansd ale, PA 194 46 | Teleph one +1-215-362-070 0

© 2018 John son Control s. All right s reserved. A ll specifica tions and ot her informa tion shown wer e current as o f document rev ision date an d are subject t o change wit hout notice.

NATIONAL FIRE P ROTECTION ASSOCIATIO N and NFPA are register ed trademarks of N ational Fire Protec tion Associati on;

TEFLON is a regi stered tradema rk of DuPont

Loading...

Loading...