Page 1

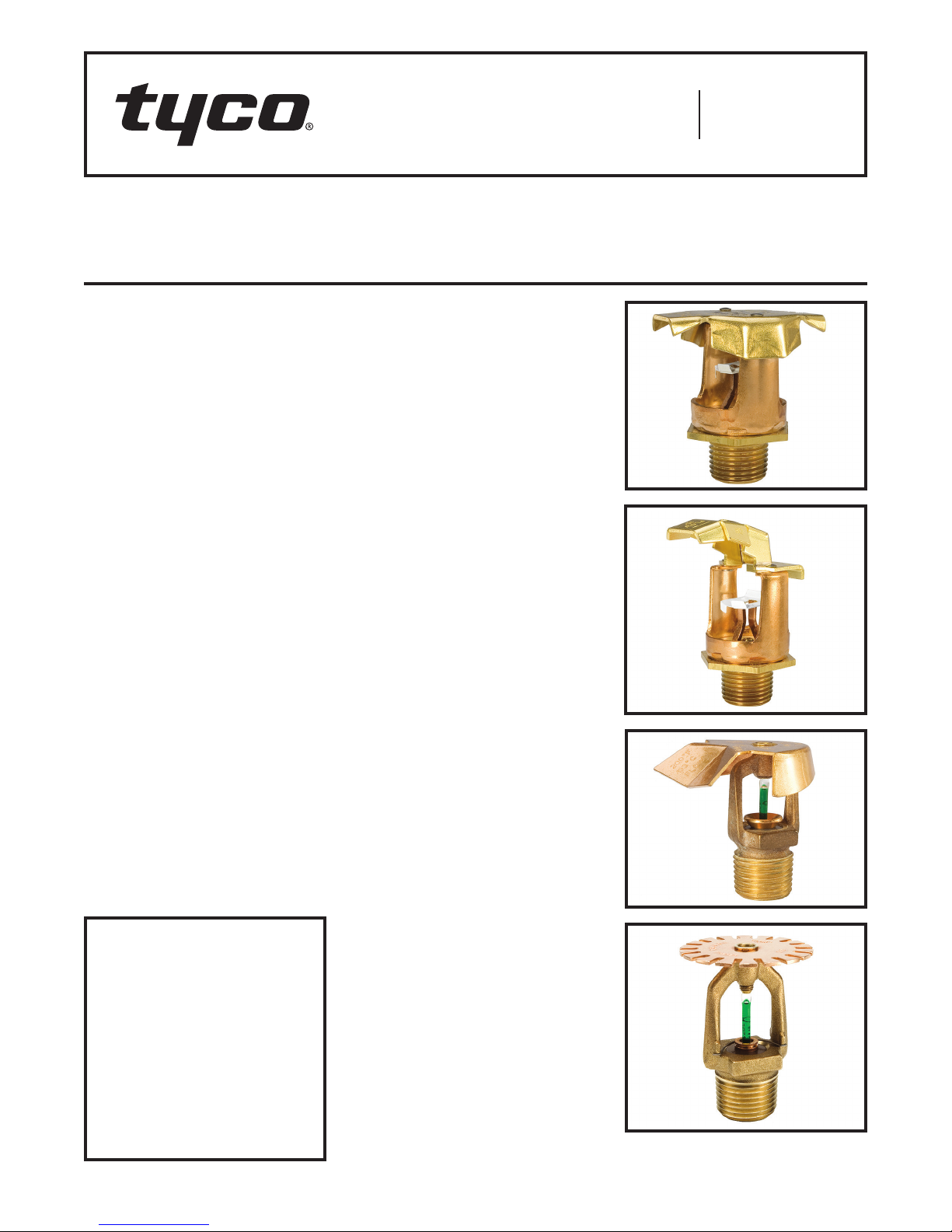

Models BB, SD, HIP, and AP

Specific Application Sprinklers

For Protecting Attics

Worldwide

Contacts

www.tyco-fire.com

General

Description

The TYCO Models Back to Back Dual

Directional (BB), Single Directional (SD),

HIP, and Attic Plus (AP) Specific Application Attic Sprinklers for Protecting

Attics are fire sprinklers for combustible and non-combustible sloped attic

spaces.

While Models BB, SD, and HIP are

specific application attic sprinklers,

the Model AP is a specific application

combustible concealed-space sprinkler with specific application criteria

for use with Models BB, SD, and HIP

in attic spaces.

Specific Application Attic Sprinklers

provide superior fire protection in attic

spaces. When compared to Standard Spray Sprinklers, cost savings

are achieved by eliminating branchline

materials and the associated installation labor.

Specific Application Attic Sprinklers for

Protecting Attics have undergone the

most extensive fire testing ever performed for sloped attic spaces. They

are UL Listed with their specific application guidelines for use as special

sprinklers as defined by the NATIONAL

FIRE PROTECTION ASSOCIATION

(NFPA).

Specific Application Attic Sprinklers

provide an extended coverage spacing

alternative to the restricted spacing of

Standard Spray Sprinklers.

IMPORTANT

Refer to Technical Data Sheet

TFP2300 for warnings pertaining to

regulatory and health information.

Always refer to Technical Data

Sheet TFP700 for the “INSTALLER

WARNING” that provides cautions

with respect to handling and installation of sprinkler systems and components. Improper handling and

installation can permanently damage

a sprinkler system or its components and cause the sprinkler to fail

to operate in a fire situation or cause

it to operate prematurely.

The Specific Application Attic Sprinklers are the first sprinklers to be:

• Listed for extended coverage in combustible construction

• Full-scale fire tested in both wet and

dry system scenarios

• Full-scale tested for use in wood

truss construction

• Listed for specific roof slopes (Ref.

Table A )

The Specific Application Attic Sprinklers provide cost control with the

best level of protection by eliminating the need for additional sprinklers

and branchline piping. In many cases,

an attic can be entirely protected with

just one line of piping located below the

peak of the roof using Model BB Sprinklers. If Model SD Sprinklers or Model

HIP Sprinklers are needed, one line of

either at each area being covered is

sufficient.

For example, while using Standard

Spray Sprinklers, a system in a 60 ft

(18,3 m) wide attic with up to a 12:12

roof pitch designed to NFPA 13, could

require seven branchlines to cover the

main portion of the attic and several

additional branchlines to cover the hip

areas. With Specific Application Attic

Sprinklers, the required coverage can

be obtained with just one branchline

running below the peak and one down

each slope of the hip beam. This would

result in approximately 90% less pipe

needed for installation. This reduction

in the number of branchlines saves the

cost of the pipe, fittings, hangers, and

associated labor by eliminating up to

five branchlines.

Another important aspect of the Specific Application Attic Sprinkler technology, which also allows for cost savings,

is the reduction in system volume. This

volume reduction may result in reducing the size of a dry pipe valve and air

compressor, and possibly allows for

quicker water delivery times, eliminating the need for an accelerator.

Page 1 of 28 AUGUST 2018 TFP610

Page 2

TFP610

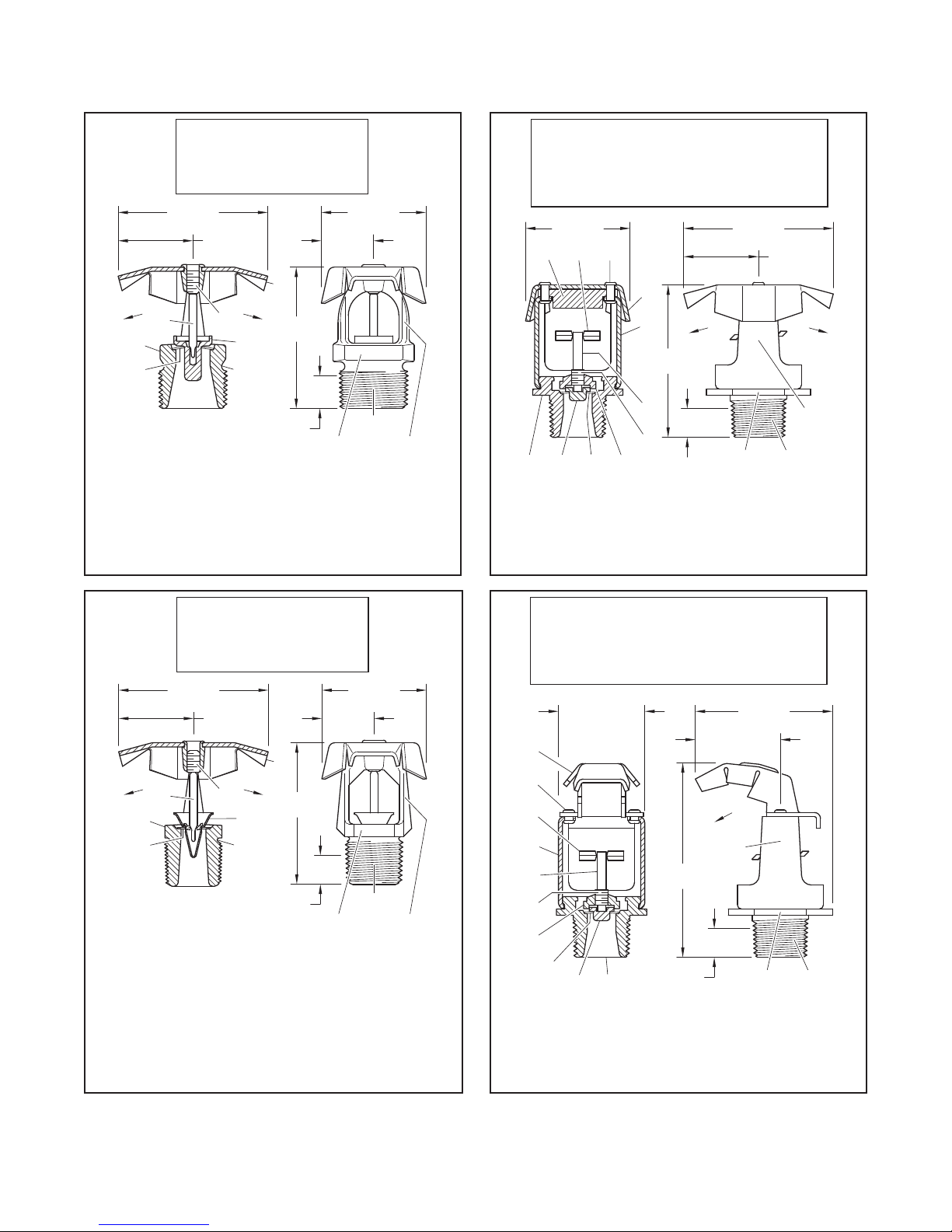

SECTION ELEVATION

ELEVATION

SECTION

1

ELEVATION

SECTION

FRAME

FLOW

SECTION ELEVATION

10

Page 2 of 28

Components:

-

Frame

1

-

Button

2

-

Sealing

3

Assembly

2-1/4"

(57,2 mm)

1-1/8"

(28,6 mm)

FLOW FLOW

4

1

3

CROSS

5

THREAD

1/2" (12,7 mm)

(54,0 mm)

2

RELIEF

NOMINAL

MAKE-IN

-

Bulb

4

-

Compression

5

Screw

-

Deector

6

6

2-1/8"

13/16"

(20,6 mm)

WRENCH

FLATS

1-5/8"

(41,3 mm)

3/4" NPT

FRAME

ARMS

FIGURE A

MODELS BB1, BB2, AND BB3 WITH 8.0 K-FACTOR

SPECIFIC APPLICATION ATTIC SPRINKLERS

Components:

-

1

-

2

-

3

-

4

1-9/16"

(39,7 mm)

10

2

CROSS

Body

Cap

Sealing

Assembly

Saddle

11

3

-

Compression

5

Screw

Lever

6

-

Deector

7

Frame

9

8

FLOW FLOW

7

2-1/2"

(63,5 mm)

6

5

4

(11,1 mm)

NOMINAL

MAKE-IN

7/16"

WRENCH

8

9

10

11

2-1/4"

(57,2 mm)

HEX

-

Deector

-

Rivet

--

Diffuser

-

Link

Assembly

1-1/8"

(28,6 mm)

1/2"

NPT

FRAME

ARMS

FIGURE B

MODELS BB1, BB2, AND BB3 WITH 5.6 K-FACTOR

SPECIFIC APPLICATION ATTIC SPRINKLERS

Components:

-

Frame

1

-

Button

2

-

Sealing

3

Assembly

2-1/4"

(57,2 mm)

1-1/8"

(28,6 mm)

4

1 2

3

CROSS

5

7/16" (11,1 mm)

FLOW

THREAD

(54,0 mm)

RELIEF

NOMINAL

MAKE-IN

-

Bulb

4

-

Compression

5

Screw

-

Deector

6

6

2-1/8"

13/16"

(20,6 mm)

WRENCH

FLATS

1-5/8"

(41,3 mm)

1/2" NPT

ARMS

FIGURE C

MODELS BB1, BB2, AND BB3 WITH 4.2 K-FACTOR

SPECIFIC APPLICATION ATTIC SPRINKLERS

Components:

(54,0 mm)

1-5/16"

WRENCH

-

8

-

9

--

10

2-1/8"

HEX

Deector

Rivet

Link

Assembly

1/2"

NPT

8

9

7

6

5

4

-

1

-

2

-

3

-

4

3

Body

Cap

Sealing

Assembly

Saddle

1-5/16"

(33,3 mm)

2 1

CROSS

-

Compression

5

Screw

Lever

6

-

Deector

7

Frame

3"

(76,2 mm)

7/16" (11,1 mm)

NOMINAL

MAKE-IN

(33,4 mm)

FLOW

FRAME

ARMS

FIGURE D

MODELS SD1, SD2, AND SD3 WITH 5.6 K-FACTOR

SPECIFIC APPLICATION ATTIC SPRINKLERS

Page 3

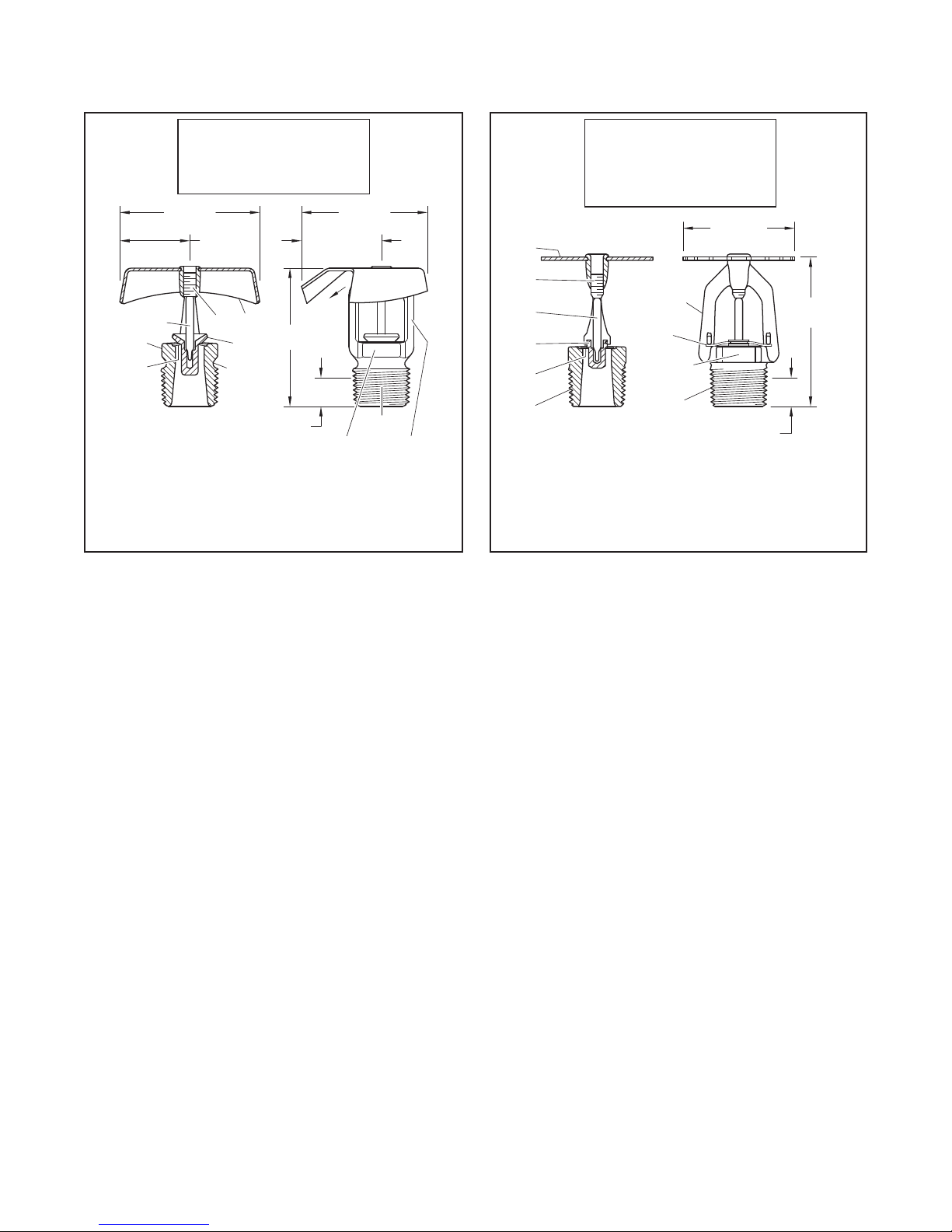

TFP610

SECTION ELEVATION

SECTION ELEVATION

2

1

3

4

5

6

(57,2 mm)

Page 3 of 28

Components:

1

3

2-1/8"

(54,0 mm)

4

CROSS

-

Frame

1

-

Button

2

-

Sealing

3

Assembly

1-1/16"

(27,0 mm)

5

2

THREAD

RELIEF

7/16" (11,1 mm)

4

5

6

6

2-1/8"

(54,0 mm)

NOMINAL

MAKE-IN

-

Bulb

-

Compression

Screw

-

Deector

1-1/4"

(31,8 mm)

FLOW

WRENCH

FLATS

2"

(50,8 mm)

1/2" NPT

FRAME

ARMS

FIGURE E

MODEL HIP WITH 5.6 K-FACTOR

SPECIFIC APPLICATION ATTIC SPRINKLERS

MODEL AP WITH 4.2 OR 5.6 K-FACTOR SPECIFIC

APPLICATION COMBUSTIBLE CONCEALED

Components:

-

1

-

2

-

3

-

4

CROSS

Frame

Sealing

Assembly

Button

Bulb

SPRINKLER

FRAME

ARMS

WRENCH

FLATS

1/2" NPT

FIGURE F

-

Compression

5

Screw

-

Deector

6

-

Ejection

7

Spring

1-11/16"

(42,9 mm)

7

7/16" (11,1 mm)

NOMINAL MAKE-IN

2-1/4"

SPACE SPRINKLERS

Another cost reduction is the Listing of

BLAZEMASTER CPVC for use in attic

spaces to feed the wet system Specific

Application Attic Sprinklers for Protecting Attics, as well as to feed the wet

system sprinklers below the ceiling.

Traditionally, BLAZEMASTER CPVC

has been used on the lower floors in

the joist space above a ceiling that

do not require sprinklers. The cost of

using CPVC on those floors can now

be translated to the upper floor even if

sprinklers are required in the attic.

There are four models of the Specific

Application Attic Sprinklers used for

protecting attics: BB, SD, HIP, and AP.

The Model BB and Model SD Sprinklers

have three separate versions used for

different roof pitches. The pitches, as

applicable, can vary from a minimum of

3:12 to a maximum of 12:12. For more

information, refer to Table A.

BB Sprinkler

(Back to Back Dual Directional)

The Model BB Specific Application

Attic Sprinkler, as seen in Figure A,

B and C, throws a narrow and long

pattern. The narrow spacing along

the ridge serves two purposes: the

response time is reduced by placing

the sprinklers no farther than 6 ft

(1,8 m) apart, and the spray can be

concentrated in the throw direction to

obtain a pattern that will cover up to

30 ft (9,1 m) in each direction when

measured horizontally.

There are three different models that

account for different roof slopes: BB1,

BB2, and BB3. Each model is provided

in one of three different orifice sizes:

K=4.2, 5.6, or 8.0.

SD Sprinkler (Single Directional)

The Model SD Specific Application

Attic Sprinkler, as seen in Figure D,

throws a narrow but long pattern like

the Model BB. However, unlike the

Model BB, the Model SD only throws

in one direction.

Model BB Sprinklers are primarily used

where shear walls or draft curtains have

been installed within an attic space.

Model BB Sprinklers are also used

when the framing direction is parallel

with the outside wall in the hip area.

For more information, refer to Figure

13. In this case, the SD Model Sprinkler

would be used on one side of the slope

and AP Sprinklers or Standard Spray

Sprinklers would be used to protect the

other side.

The Model SD Sprinklers must be

installed in a vertical upright orientation

and not angled with the slope. Achieving the vertical upright orientation may

require the use of a swing joint if the

SD Sprinklers are being fed from a line

running along and parallel to the roof

hip.

There are three different models that

account for different roof slopes: SD1,

SD2, and SD3.

HIP Sprinkler

The Model HIP Specific Application

Attic Sprinkler, as seen in Figure E,

covers the area of the hip in the attic.

This is a slightly different concept than

the BB Model or SD Model Sprinklers.

The HIP Sprinkler is located along

the slope running down the hip, and

throws a 90° pattern toward the outside

eaves. This pattern allows the water to

“corner” and control the fire.

The HIP does not throw much water

directly up or down the hip, but rather it

throws most of the pattern out to each

side (90°) down the slope of the roof.

This sprinkler is typically spaced 6 ft

(1,8 m) to 3 ft (0,9 m) on center down

the slope.

To use the HIP Sprinkler, the framing

must be perpendicular to the outside

wall (refer to Figure 12) and the

maximum throw cannot exceed 28 ft

(8,5 m) measured horizontally. The HIP,

unlike the BB Model and SD Model, is

installed with the deflector parallel with

the slope. There is only one model with

flows and pressures for two different

spacings.

Page 4

TFP610

Page 4 of 28

AP Sprinkler (Attic Plus)

The AP Specific Application Attic Sprinkler are to be installed in the upright

orientation with their deflector parallel

to the roof. The Model AP Sprinklers,

as seen in Figure F, are intended to

be used to provide protection of attic

areas outside the scope of applications for the BB, SD, or HIP Sprinklers.

The AP Sprinklers must only be used in

conjunction with other Specific Application Attic Sprinklers (BB, SD, and

HIP), or as permitted in other sections

of this document. The AP Sprinklers

will provide a hydraulic advantage over

Standard Spray Sprinklers for the protection of attic areas outside the scope

of application for the BB Model, SD

Model, or HIP Model Sprinklers.

NOTICE

The Specific Application Attic Sprinklers for Protecting Attics described

herein must be installed and maintained

in compliance with this document, as

well as with the applicable standards

of NFPA, in addition to the standards of

any other authorities having jurisdiction.

Failure to do so may impair the performance of these devices.

The owner is responsible for maintaining their fire protection system

and devices in proper operating condition. Contact the installing contractor or product manufacturer with any

questions.

Sprinkler

Identification

Number (SIN)

TY4180* BB1 K= 8.0

TY4181* BB2 K= 8.0

TY4182* BB3 K= 8.0

TY3180* BB1 K= 5.6

TY3181* BB2 K = 5.6

TY3182* BB3 K = 5.6

TY2180 BB1 K= 4.2

TY2181 BB2 K=4. 2

TY2182 BB3 K=4.2

TY3183* SD1 K= 5.6

TY3184* SD2 K= 5.6

TY3185* SD3 K= 5.6

TY3187* HIP K= 5.6

TY3190 AP K= 5.6

TY2190 AP K= 4.2

* The “TY” prefix is a re-designation of

the previous “C” prefix. For example,

TY4180 is a re-designation for C4180.

Technical

Data

Approvals

UL and C-UL Listed

These Approvals only apply to the service

conditions indicated in the Design Criteria

section on Page 6 and the Design Guidelines

section on Page 8.

Pipe Thread Connection

1/2 inch NPT for K= 4.2 and 5.6

3/4 inch NPT for K= 8.0

Discharge Coefficient

K = 4.2 GPM/psi½ (60,5 LPM/bar½)

K = 5.6 GPM/psi½ (80,6 LPM/bar½)

K = 8. 0 GPM /psi½ (115,5 LPM/bar½)

Temperature Rating

Intermediate Temperature as follows:

–200°F ( 93°C) for BB (K4.2 and K8.0),

H I P, A P

–212°F (100°C) for BB ( K5.6), SD

Finish

Natural Brass

Physical Characteristics

(Figures A, C and E)

Frame . . . . . . . . . . . . . . . . . . . . . . . . . . . .Bronze

Button .....................Bronze/Copper

Sealing Assembly ..Ber yllium Nickel w/TEFLON

Bulb .....................Glass (3 mm dia.)

Link . . . . . . . . . . . . . . . . . . . . . . . . . . . . . MONEL

Compression Screw . . . . . . . . . . . . . . . . . .Brass

Deflector . . . . . . . . . . . . . . . . . . . . Brass /Bronze

Physical Characteristics

(Figures B and D)

Body . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Brass

Cap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Bronze

Sealing Assembly ..Ber yllium Nickel w/TEFLON

Saddle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Brass

Link Assembly . . . . . . . . . . . . . . . . . . . . . . Nickel

Compression Screw . . . . . . . . . . . . . . . . . .Brass

Deflector . . . . . . . . . . . . . . . . . . . . Brass /Bronze

Lever .....................Bronze Deflector

Frame . . . . . . . . . . . . . . . . . . . . . . . . . . . .Bronze

Diffuser . . . . . . . . . . . . . . . . . . . . . . . . . . . .Brass

Rivet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Brass

Physical Characteristics

(Figure F)

Frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Brass

Button . . . . . . . . . . . . . . . . . . . . . . . . . . . .Bronze

Sealing Assembly ..Ber yllium Nickel w/TEFLON

Bulb .....................Glass (3 mm dia.)

Compression Screw . . . . . . . . . . . . . . . . . .Brass

Deflector . . . . . . . . . . . . . . . . . . . . . . . . . .Bronze

Operation

BB (K=8.0 and 4.2), HIP (K=5.6) and

AP (5.6 and 4.2)

The glass bulb contains a fluid that

expands when exposed to heat. When

the rated temperature is reached, the

fluid expands sufficiently to shatter the

glass bulb, allowing the sprinkler to

activate and water to flow.

BB (K=5.6) and SD (K=5.6)

The fusible link assembly is comprised

of two link halves which are joined by

a thin layer of solder. When the rated

temperature is reached, the solder

melts and the two link halves separate,

allowing the sprinkler to activate and

water to flow.

Page 5

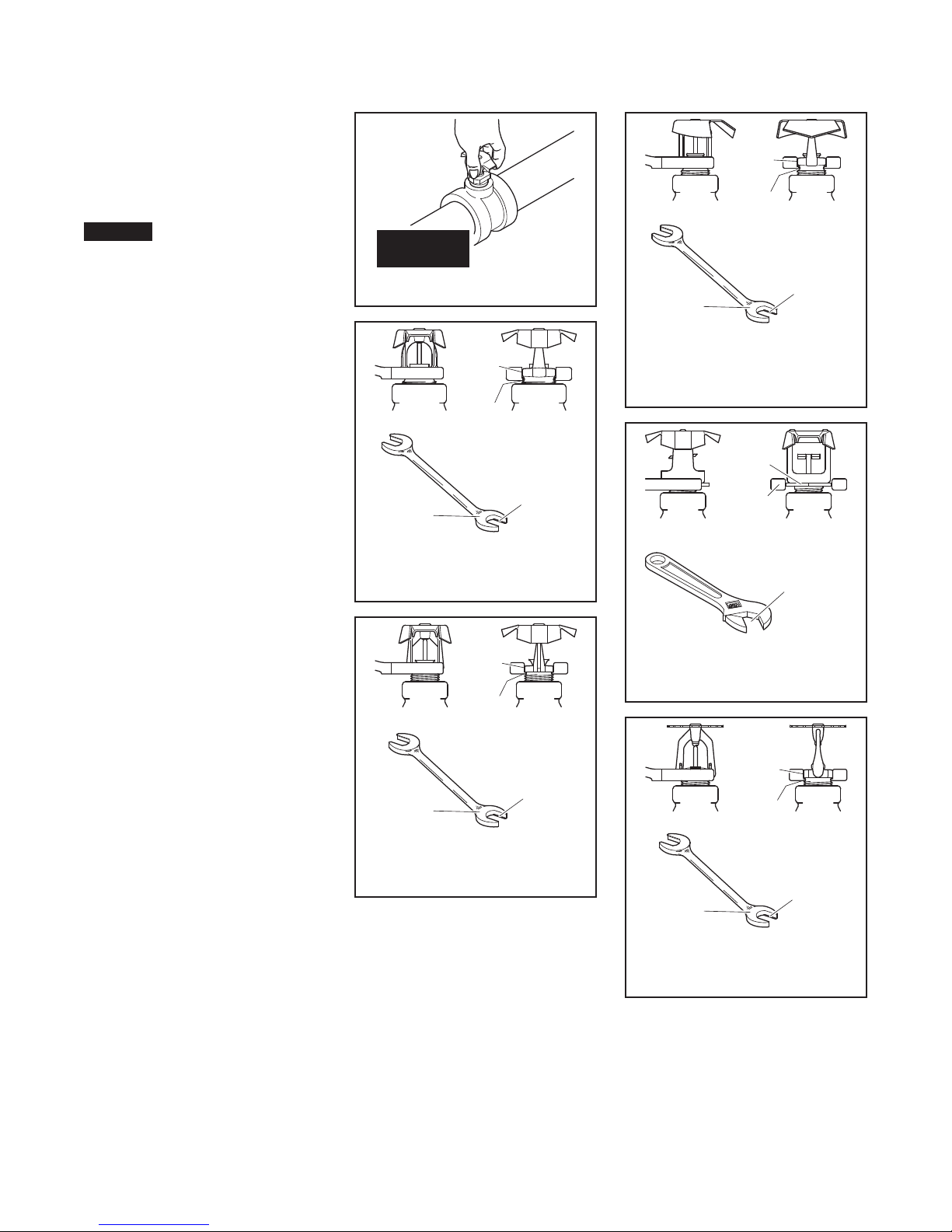

Installation

"A" ONLY

"A" ONLY

"A" ONLY

"A" ONLY

The TYCO Specific Application Attic

Sprinklers for Protecting Attics must

be installed in accordance with this

section.

NOTICE

Do not install any bulb-type sprinkler

if the bulb is cracked or there is a loss

of liquid from the bulb. With the sprinkler held horizontally, a small air bubble

should be present. The diameter of the

air bubble is approximately 1/16 inch

(1,6 mm) for the 155°F (68°C) and 3/32

inch (2,4 mm) for the 200°F (93°C) temperature ratings.

A leak-tight 1/2 inch NPT sprinkler joint

should be obtained by applying a minimum-to-maximum torque of 7 to 14

lb-ft ( 9,5 to 19,0 N·m). Higher levels of

torque can distort the sprinkler inlet

with consequent leakage or impairment

of the sprinkler.

To install the Specific Application Attic

Sprinklers, complete the following:

Step 1. Sprinklers must be oriented

correctly as follows:

• Model BB Sprinklers are to be

installed in the upright vertical position with the flow arrows on the

deflector pointing down the two

opposing slopes.

• Model SD Sprinklers are to be

installed in the upright vertical position with the flow direction arrow

on the deflector pointing down the

slope.

• The Model HIP Sprinklers are to be

installed with the deflector at the top,

the sprinkler centerline perpendicular

to the ridge of the hip roof, and the

flow direction arrows on the deflector pointing down the two opposing slopes. Unlike the Model BB and

Model SD, the Model HIP is installed

angled so that its deflector is parallel with the slope of the hip ridge line.

• The Model AP Sprinklers are to be

installed in the upright position with

the deflector parallel to the roof

slope. There are no flow arrows on

the deflector to consider; however, a

good piping practice is to position all

the Model AP Sprinklers so that their

frame arms are in the same direction.

DO NOT

DO NOT GRASP DEFLECTOR

USE END

MARKED

W-TYPE 3 SPRINKLER WRENCH

BB (K=8.0) SPRINKLERS’

USE END

MARKED

W-TYPE 6 SPRINKLER WRENCH

Step 2. With pipe thread sealant

applied to the pipe threads, handtighten the sprinkler into the sprinkler

fitting.

Note: With reference to Figure G, do

not grasp the sprinkler by the deflector.

Step 3. Wrench-tighten the sprinkler using only the wrenches shown

in Figures H through M. Wrenches

are only to be applied to the sprinkler wrench flats or wrench hex, as

applicable.

FIGURE G

WRENCH

FLATS

ENGAGE

SPRINKLER

THREAD RELIEF

WITH WRENCH

JAW FLANGES

WRENCH

JAW FLANGE

FIGURE H

FOR USE WITH

WRENCH

FLATS

ENGAGE

SPRINKLER

THREAD RELIEF

WITH WRENCH

JAW FLANGES

WRENCH

JAW FLANGE

FIGURE J

For Use with

BB (K= 4.2) Sprinklers

TFP610

Page 5 of 28

WRENCH

FLATS

ENGAGE

SPRINKLER

THREAD RELIEF

WITH WRENCH

JAW FLANGES

WRENCH

HEX

WRENCH JAW

TO FIT WRENCH

WRENCH

FLATS

ENGAGE

JAW FLANGE

ADJUST

HEX

WRENCH

JAW FLANGE

USE END

MARKED

FIGURE K

W-T Y P E 2 0

SPRINKLER WRENCH

For Use with

HIP (K= 5.6) Sprinklers

WRENCH

APPLY

WRENCH

TO WRENCH

HEX ONLY

FIGURE L

ADJUSTABLE WRENCH

For Use with BB ( K= 5.6) and

SD (K= 5.6) Sprinklers

SPRINKLER

THREAD RELIEF

WITH WRENCH

JAW FLANGES

USE END

MARKED

FIGURE M

W-TYPE 6 SPRINKLER WRENCH

For Use with

AP (K= 4.2 and 5.6) Sprinklers

Page 6

TFP610

Page 6 of 28

Design

Criteria

Area of Use

The TYCO Specific Application Attic

Sprinklers are designed for use in

roof structures and combustible and

non-combustible sloped attic spaces,

including wood joist/rafters and wood

trussed attics with a ceiling below.

System Type for

BB, SD, HIP, or AP Sprinklers

Wet using CPVC pipe

Wet or dry using steel pipe

Note: Use of the 4.2 K sprinklers in dry

pipe systems is permitted by NFPA 13

where piping is corrosion resistant or

internally galvanized.

Hazard

Light Hazard.

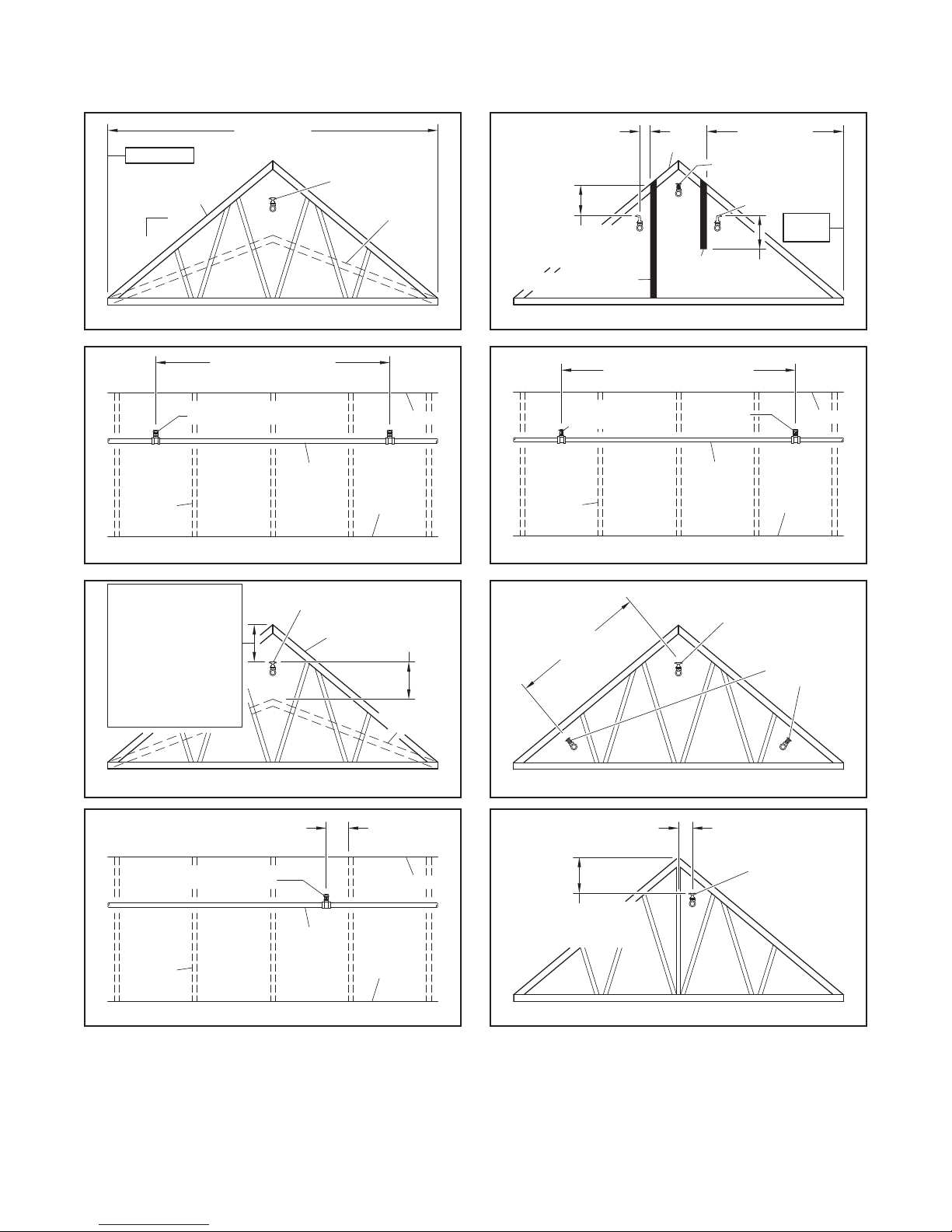

BB, SD, or HIP Allowable Roof Span

(Coverage) and Roof Pitch

Refer to Table A for allowable roof

spans and roof pitches, and for the

associated minimum sprinkler flows

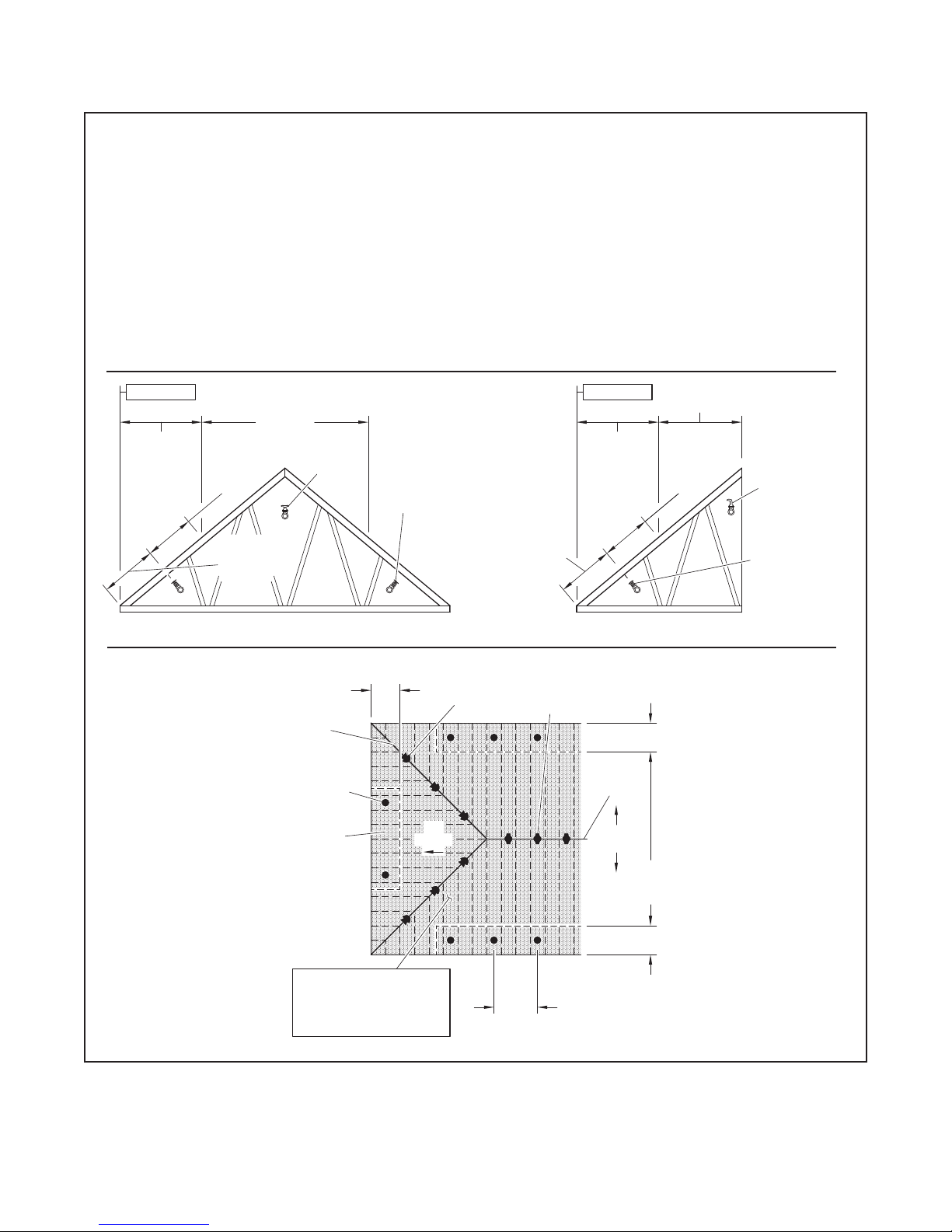

and pressures. Figures 1, 2, 11 and 12

illustrate where the roof span is to be

measured.

Coverage Beyond BB, SD or HIP

Allowable Roof Spans

Up to 10 ft (3,1 m) of coverage at the

eave(s) beyond the allowable roof

spans for BB, SD, or HIP Sprinklers

may be obtained by using a single row

of AP Sprinklers. For more information,

refer to Figure 14A, 14B, and 15.

BB, SD, HIP, or AP Minimum

Distance Between Sprinklers

4 ft (1,2 m) as measured along the

branchline for BB and SD. For more

information, refer to Figure 3.

3 ft (0,9 m) as measured along the

branchline for HIP. For more information, refer to Figure 12.

7 ft (2,1 m) between AP Sprinklers.

BB, SD, HIP, or AP Maximum

Distance Between Sprinklers

6 ft (1,8 m) on center along the branchline for BB, SD, and HIP. For more information, refer to Figure 3 and 12.

For AP, the maximum spacing is

10 ft (3,1 m) perpendicular to slope and

12 ft (3,6 m) parallel to slope. When

there is more than one row of AP Sprinklers, the sprinklers must be staggered

as seen in Figure 20-B-3.

BB, SD, HIP, or AP Minimum

Distance to AP Sprinklers or

Standard Spray Sprinklers

As measured along the peak/ridge

direction, 6 ft (1,8 m) from BB, SD, and

HIP to Standard Spray Sprinklers. For

more information, refer to Figure 4.

As measured along the peak/ridge

direction, 7 ft (2,1 m) from AP to Standard Spray Sprinklers. For more information, refer to Figure 4.

In the slope direction, 26 ft (7,9 m) from

BB or HIP Sprinklers to AP Sprinklers

or Standard Spray Sprinklers. For more

information, refer to Figure 6.

BB, SD, or HIP Deflector Installation

Position Below Peak/Ridge or Deck

For roof pitches of 4:12 (33%) to 12:12

(100%), 22 in. (558,8 mm) maximum

and 16 in. (406,4 mm) minimum. For

more information, refer to Figure 2 and

5.

For roof pitches of 3:12 (25%) up to

4:12 (33%), (only 4.2K Model BB),

12 in. (304,8 mm) maximum below the

peak and a minimum of 1 in. (25,4 mm)

below the bottom of the top chord or

solid wood rafter.

AP Deflector Position and

Roof Pitch

1 to 3 in. (25,4 to 75,6 mm) below the

bottom of the top chord or bottom of

solid wood rafter, where the roof pitch

is 3:12 to 12:12 and the top chord or

solid wood rafter is a nominal 12 in.

(600 mm) or less.

BB or SD Deflector Installation

Position Above Scissor Truss

18 in. (457,2 mm) minimum. For more

information, refer to Figure 5.

BB, SD, or HIP Minimum Distance

Away from Trusses

Attic Sprinklers must be installed

6 in. (152,4 mm) away from the face of

trusses. For more information, refer to

Figure 7.

SD Distance from Shear Wall or

Draft Curtain

4 to 6 in. (101,6 to 152,4 mm) from face,

and a minimum of 8 in. (203,2 mm)

above the bottom of the draft curtain.

For more information, refer to Figure 2.

Draft Curtains

Draft curtains installed to permit the

installation of Attic Sprinklers shall be

constructed so as to not allow heat

to escape through or above the draft

curtain. The draft curtain may be constructed of 1/2 in (12,7 mm) plywood.

BB or HIP Maximum Distance from

the Center Line of the Ridge

6 in. (152,4 mm) with the deflector

located 16 to 22 in. (406,4 mm to 558,8

mm) from the peak. For more information, refer to Figure 8.

Use of UL Listed BLAZEMASTER

CPVC Piping with Specific

Application Attic Sprinklers for

Protecting Attics (Wet Systems

Only)

BLAZEMASTER CPVC piping may

be used in a combustible concealed

attic space requiring sprinklers when

installed in accordance with the following guidelines:

Note: Where the use of non-combustible insulation is specified, verify

with the insulation manufacturer as to

the non-combustibility of the insulation. The non-combustible insulation

(fiberglass) may be faced or unfaced.

Where faced, the facing need not be

non-combustible. The insulation is to

have a flame spread index of not more

than 25.

Verify chemical compatibility of the

insulation with BLAZEMASTER CPVC

by consulting www.lubrizol.com.

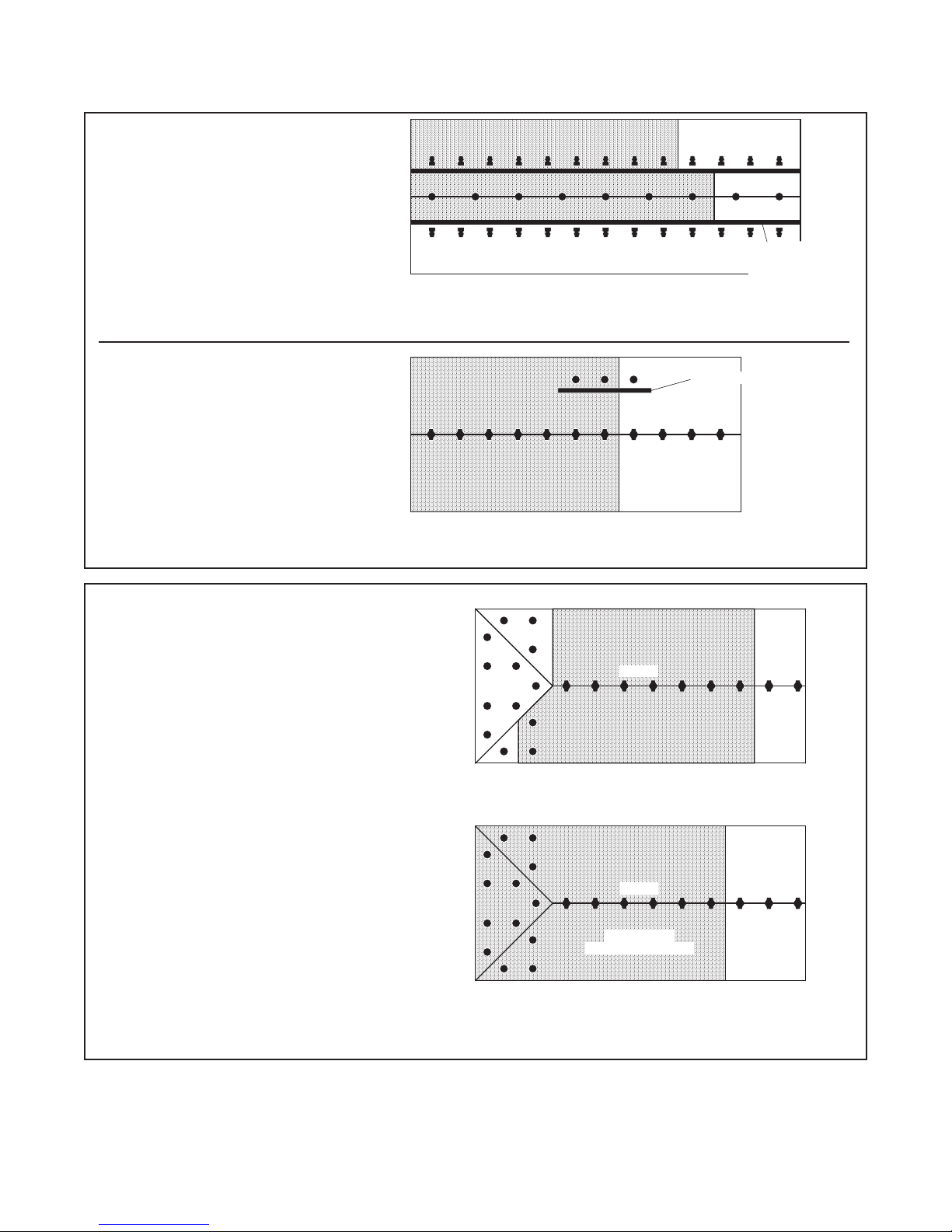

• BLAZEMASTER CPVC may be used

to feed the wet system ceiling sprinklers on the floor below. There must

be 6 in. (152,4 mm) of non-combustible insulation covering the horizontal or vertical pipe extending 12 in.

(304,8 mm) on each side away from

the centerline of the pipe. Refer to

Figures 9A, 9B, and 9C. The area

above the pipe must be protected

by BB, SD, HIP, or AP Sprinklers. For

more information, refer to Figure 9A.

If the pipe is located inside the ceiling joist, the joist channel must be

covered or filled with 6 in. (152,4 mm)

of non-combustible insulation on top

of the pipe and the area above must

be protected by BB, SD, HIP, or AP

Sprinklers. For more information,

refer to Figure 9B. Insulation is for re

protection purposes. It is not freeze

protection. BLAZEMASTER CPVC

must be installed in accordance with

the BLAZEMASTER installation guide

instructions.

• With reference to Figure 19, BLAZEMASTER CPVC may be used

exposed to feed wet system BB, SD,

or HIP Sprinklers where:

•

Risers are vertical and protected

by BB, SD, or HIP Sprinklers located at a maximum lateral distance

of 12 in. (304,8 mm) from the riser

centerline.

•

BB, SD, or HIP Sprinklers are directly mounted on the branchline.

•

BB, SD, or HIP Sprinklers are on

arm-overs and located at a maximum lateral distance of 6 in.

(152,4 mm) from the branchline

centerline.

•

BB, SD, or HIP Sprinklers are on

vertical sprigs attached to the

branchline.

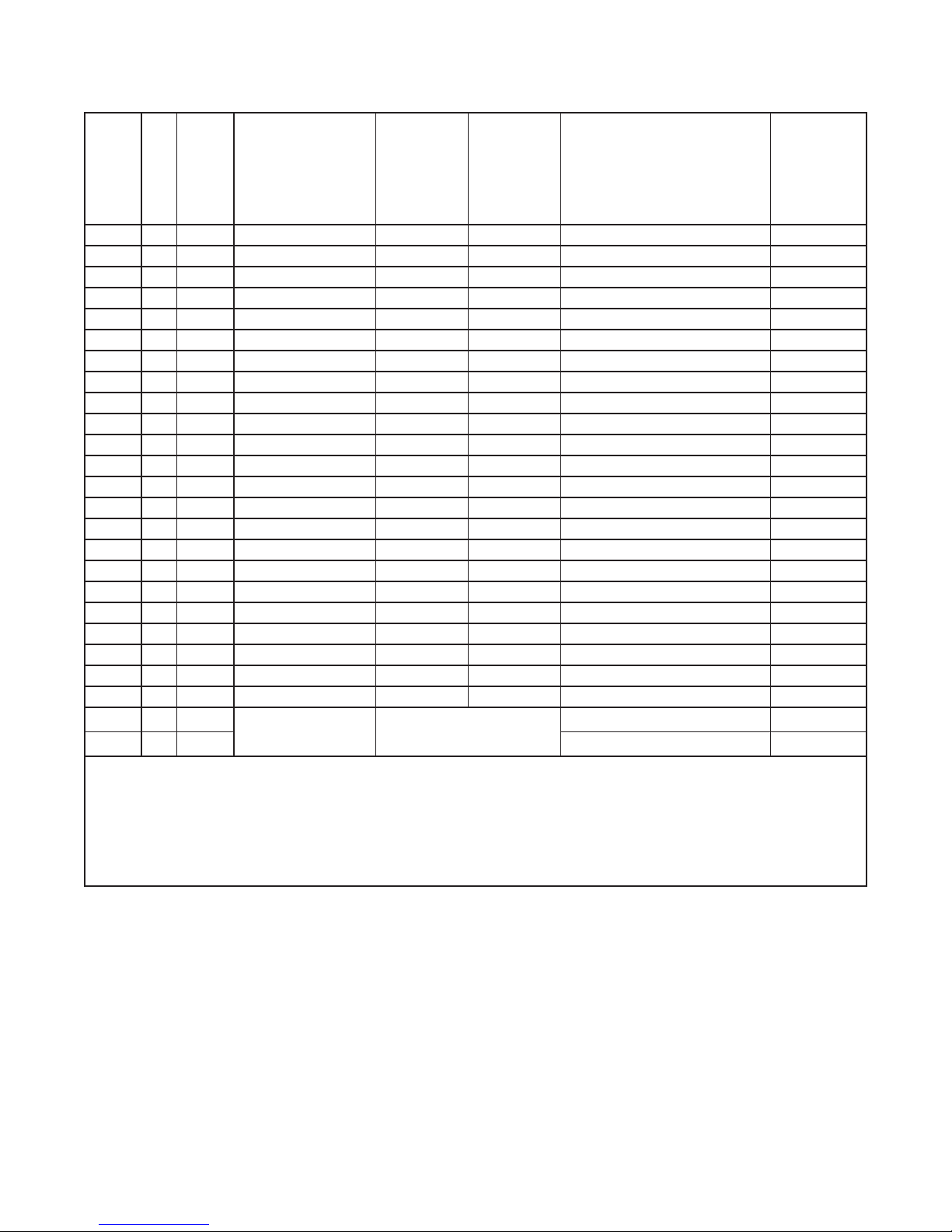

Page 7

Page 7 of 28

DRY PIPE

SYSTEM

MAXIMUM

WATER

DELIVERY

Seconds

MODEL K SIN

ALLOWABLE

ROOF SPAN,

(a) (b) (e)

Feet (m)

MINIMUM

FLOW,

GPM (LPM)

MINIMUM

PRESSURE,

psi (bar)

PITCH,

Rise Over Run (%)

BB1 8.0 T Y4180 ≤60 (18,3) 38 (14 4) 22.6 (1,5) 4:12 (33) to less than 7:12 (58) (c)

BB2 8.0 TY4181 ≤60 (18,3) 38 (144 ) 22.6 (1,5) 7:12 (58) to less than 10:12 (83) (c)

BB3 8.0 T Y4182 ≤60 (18,3) 40 (152) 25.0 (1,7 ) 10:12 (83) to 12:12 (100) (c)

BB1 5.6 T Y3180 >40 (12,2) to ≤60 (18,3) 38 (14 4) 46.0 (3,2) 4:12 (33) to less than 7:12 (58) (c)

BB2 5.6 TY3181 >40 (12,2) to 60 (18,3) 38 ( 144) 46.0 (3,2) 7:12 (58) to less than 10:12 (83) (c)

BB3 5.6 T Y3182 >40 (12,2) to 60 (18,3) 38 (144) 46.0 (3,2) 10:12 (83) to 12:12 (100) (c)

BB1 5.6 T Y3180 ≤40 (12,2) 25 (95) 20.0 (1,4) 4:12 (33) to less than 7:12 (58) (c)

BB2 5.6 TY3181 ≤40 (12,2) 25 (95) 20.0 (1,4) 7:12 (58) to less than 10:12 (83) (c)

BB3 5.6 T Y3182 ≤40 (12,2) 25 (95) 20.0 (1,4) 10:12 (83) to 12:12 (100) (c)

BB1 4.2 T Y2180 ≤20 (6,1) 13 (4 9) 9.6 (0,7) 3:12 (25) to less than 7:12 (58) 45 (d)

BB2 4.2 T Y2181 ≤20 (6,1) 13 (49) 9.6 (0,7) 7:12 (58) to less than 10:12 (83) 45 (d)

BB3 4.2 T Y2182 ≤20 (6,1) 13 (4 9) 9.6 (0,7) 10:12 (83) to 12:12 (100) 45 (d)

SD1 5.6 T Y318 3 >30 (9,1) to ≤40 (12,2) 35 (132) 39.0 (2,7) 4:12 (33) to less than 7:12 (58) (c)

SD2 5.6 T Y3184 >30 (9,1) to ≤40 (12,2) 35 (13 2) 39.0 (2,7 ) 7:12 (58) to less than 10:12 (83) (c)

SD3 5.6 T Y3185 >30 (9,1) to ≤40 (12,2) 35 (132) 39.0 (2,7 ) 10:12 (83) to 12:12 (100) (c)

SD1 5.6 T Y318 3 >10 (3,0) to ≤30 (9,1) 25 (95) 20.0 (1,4) 4:12 (33) to less than 7:12 (58) (c)

SD2 5.6 T Y3184 >10 (3,0) to ≤30 (9,1) 25 (95) 20.0 (1,4) 7:12 (58) to less than 10:12 (83) (c)

SD3 5.6 T Y3185 >10 (3,0) to ≤30 (9,1) 25 (95) 20.0 (1,4) 10:12 (83) to 12:12 (100) (c)

SD1 5.6 T Y318 3 ≤10 (3,0) 19 (72) 11.5 (0,8) 4:12 (33) to less than 7:12 (58) (c)

SD2 5.6 T Y3184 ≤10 (3 ,0) 19 ( 72) 11.5 (0,8) 7:12 (58) to less than 10:12 (83) (c)

SD3 5.6 T Y3185 ≤10 (3,0) 19 ( 72) 11.5 (0,8) 10:12 (83) to 12:12 (100) (c)

HIP 5.6 T Y3187 >20 (6,1) to ≤28 (8,5) 3 4 (129 ) 36.9 (2,5) 4:12 (33) to 12:12 (100) (c)

HIP 5.6 T Y3187 ≤20 (6,1) 25 (95) 20.0 (1,4) 4:12 (33) to 12:12 (100) (c)

AP 5.6 TY319 0

AP 4.2 TY219 0 3:12 (25) to 12:12 (100) 60 (d)

NOTES

a. T he BB and S D roof spa n is measured ho rizont ally (no t along th e slope) a s shown in F igure 1 an d Figure 2.

b. The HIP roof span is mea sured h orizontally as shown in Fi gure 2.

c. R efer to NFPA 13.

d. Maximum water delive ry tim e for all sy stem size s.

e. T he AP roo f span is measured along the slop e. Maxi mum 10 ft (3, m) p erpendicul ar to slop e by maxi mum 12 ft (3,6 m) p arall el to slop e.

10 (3,1) x 12 (3,6)

-See note (e)

Minimum 7 psi (0,48 bar)

Minimum 0.10 gpm/ft2

(4,1 mm/min.) Design Density

3:12 (25) to 12:12 (100) 60 (d)

TFP610

TIME,

ALLOWABLE ROOF SPAN, FLOW, PRESSURE, AND PITCH FOR

SPECIFIC APPLICATION SPRINKLERS FOR PROTECTING ATTICS

TABL E A

Page 8

TFP610

Page 8 of 28

•

BB, SD, or HIP Sprinklers are on

arm-over or angled sprigs, and located at a maximum lateral distance of 6 in. (152,4 mm) from the

branchline centerline.

•

A minimum lateral distance of

18 in. (450 mm) is maintained between the CPVC pipe and a heat

producing device such as heat

pumps, fan motors, and heat

lamps.

• BLAZEMASTER CPVC may be used

exposed to provide wet system, vertical or angled, sprigs to AP Sprinklers (refer to Figures 17A and 17B)

where:

• The exposed portion of an angled

sprig is a maximum length of 3 ft

(0,9 m), the sprig is supported adjacent to the AP Sprinkler, and vertical restraint is provided using the

CPVC hanger support for horizontal pipe runs.

•

Vertical sprigs have a maximum

exposed length of 10 ft (3,05 m),

the AP Sprinkler is located at a

maximum lateral distance of 12 in.

(3304,8 mm) from the sprig centerline, and the sprig is supported at

the swing joint to the AP Sprinkler.

•

A minimum 6 in. (152,4 mm) deep

of non-combustible insulation extending 12 in. (304,8 mm) on each

side away from the centerline of

the CPVC branchline feeding the

AP sprigs (refer to Figure 17A). If

the CPVC branchline is located inside the ceiling joist, the joist channel must be covered or lled with a

minimum of 6 in. (152,4 mm) deep

of noncombustible insulation on

top of the branchline feeding the

AP sprigs (refer to Figure 17B). Insulation is for re protection purposes. It is not freeze protection.

Additional depth of non-combustible insulation may be added to reduce the exposed length of the AP

sprigs.

•

A minimum lateral distance of

18 in. (450 mm) is maintained between the CPVC pipe and a heat

producing device such as heat

pumps, fan motors, and heat

lamps.

Mismatched Slopes

Refer to Figure 10.

Obstructions

For BB, SD, and HIP, refer to Figure 16.

For AP Sprinklers, refer to Figure 18.

BB, SD, HIP, and AP Sprinklers may

be installed directly on maximum 2-1/2

inch NPS (DN65) branch lines without

the need for sprigs. See NFPA 13 for

requirements when installed on pipe

greater than 2-1/2 inch NPS (DN65).

Hydraulic Requirements

Refer to Figure 20.

Determine the Correct Flow and

Pressure

For BB, SD, or HIP Sprinklers, determine the roof span (measured horizontally) and the slope of the roof, and then

refer to Table A. There is no interpolation of the flow and pressure shown.

Round all cases to the next higher

spacing. For example, a 45 ft (13,7 m)

span with the BB1 (K=8.0) would be

calculated at the 60 feet (18,3 m) span.

For the AP Sprinklers, the minimum

design pressure is 7 psi, and

the minimum design density is

0.10 gpm/ft² (4,1 mm/min). The NFPA

13, 20 psi (1,4 bar) minimum operating

pressure for Standard Spray Sprinkler

spacings parallel to the ridge that are

above 8 ft (2,4 m) does not apply to the

A P.

Coverage Area

• Coverage area for the BB Sprinklers

is determined by twice the distance

of the furthest throw measured along

the slope multiplied by the distance

along the branchline. The maximum

distance along branchline is 6 ft

(1,8 m) regardless of the length of the

throw.

Note: The distance along the branchline may have to be reduced to less

than the maximum of 6 ft (1,8 m) to

remain under 400 ft² (37,2 m²) maximum

depending on the slope and the span.

In no case can the span exceed 60 ft

(18,3 m) without additional Standard

Spray Sprinklers.

• Coverage area for the SD (Single

Directional) Sprinklers is the distance

along the branchline multiplied by

the distance of the throw down the

slope. Regardless of the throw, the

maximum distance along the branchline is 6 ft (1,8 m), the maximum

throw measured horizontally is 40 ft

(12,2 m), and the maximum coverage

per sprinkler is 400 ft² (37,2 m²).

• Coverage area for the HIP Sprinklers

is the distance down the larger slope

multiplied by two, and multiplied by

the distance between the sprinklers

as measured along the slope of the

hip.

• Coverage area for the AP (Attic Plus)

Sprinklers is the distance along the

branchline multiplied by the distance

between the branchlines. The maximum spacing is 10 ft (3,1 m) perpendicular to the slope and 12 ft

(3,6 m) parallel to slope, and as measured on the slope. When there is

more than one row of AP Sprinklers,

the sprinklers must be staggered per

Figure 20-B-3. The maximum spacing per sprinkler is 120 ft² (11,1 m²).

Design

Guidelines

To design a project with the TYCO Specific Application Attic Sprinklers, use

these steps as a guideline:

• Determine if single, dual directional

or hip sprinkler is needed.

• Determine the roof slope is between

3:12 to 12:12. If more than one slope

is being used on a project, select the

correct sprinkler for each area.

• Follow the guidelines for each type

of sprinkler.

• Calculate the sprinkler system in

accordance with the appropriate flow

and pressure information provided in

Table A, as well as Figure 20. There

is no interpolation of the flows and

pressures shown on the chart.

For BB Sprinklers

(Back to Back Dual Directional)

• Verify the framing direction is perpendicular to the outside wall (refer

to Figure 12). If not, cover that area

with AP Sprinklers or Standard Spray

Sprinklers (refer Figure 13).

• Determine the throw needed. For

more information, see the spacing requirements in Table A. If over

20 ft (6,1 m) and up to 60 ft (18,3 m)

is required, use the 8.0 K-factor, BB

Sprinklers to reduce the pressure

required. If pressure is not a concern,

use the 5.6 K-factor, BB Sprinklers to

minimize over discharge.

• If less than 20 ft (6,1 m) is required,

use the 4.2 K-factor, Back to Back

Dual Directional to minimize pressure

and flow requirements.

• Determine the distance along the

slope. If the distance is not equal,

use the longer side. Multiply the longer side by two to determine the

spacing down the slope. Four hundred divided by this value will determine the maximum spacing along

the ridge. The maximum distance

is 6 ft (1,8 m). For example, a 12:12

slope at the maximum span of 60 ft

(18,3 m) will produce a slope length

of approximately 42.5 ft (13,0 m).

That number multiplied by two produces an 85 ft (25,9 m) throw. A

400 ft² maximum divided by an

85 ft (25,9 m) throw only allows a

4 ft 8 in. (1,4 m) spacing along the

ridge. Using the maximum spacing,

space the sprinklers along the ridge.

• Avoid obstructions as shown in Figure 16. If necessary, add Model AP

Sprinklers or Standard Spray Sprinklers to maintain coverage around

obstructions.

Page 9

TFP610

Page 9 of 28

For SD Sprinklers

(Single Directional)

• Determine the throw needed.

• As the 400 ft² (37,2 m²) is not a factor

with the SD Sprinklers, the maximum

spacing is 6 ft (1,8 m) and the minimum is 4 ft (1,2 m). For more information, refer to Figures 2 and 11. The

reason 400 ft² is not an issue with

the single directional is because, at

its maximum spacing, 6 ft (1,8 m) on

center / covering 40 ft (12,2 m) flat /

a 12:12 slope / and the throw being

56.5 ft (17,2 m), the 400 ft² (37,2 m²)

maximum would not be exceeded.

• Avoid obstructions as shown in Figure 16. If necessary, add Model AP

Sprinklers or Standard Spray Sprinklers to maintain coverage around

obstructions.

For HIP Sprinklers

• Verify framing direction is perpendicular to outside wall (refer to Figure

12). If not, cover that area with AP

Sprinklers or Standard Spray Sprinklers (refer to Figure 13).

• From the intersection of the top of

the hip and the ridge, the maximum

distance down the slope of the hip is

3 ft (0,9 m). Start the layout with the

first sprinkler as close to that point as

possible, but no further, while staying

6 in. (152,4 mm) away from the face

of the trusses. Remember the slope

of the hip is not equal to the slope

of the roof from the ridge to the outside wall. Continue to space sprinklers down the hip at a maximum of

6 ft (1,8 m) on center as measured

along the slope of the hip. When the

bottom of the hip is encountered, the

last sprinkler must be within 7-1/2 ft

(2,3 m) of the outside wall as measured flat (plan view). If this pipe is

“cut to fit”, remember to account for

the different slopes of the hip and the

roof, as well as distances measured

along the slope verses horizontal in

plan view must be accounted for.

• Avoid obstructions as shown in Figure 16. If necessary, add Model AP

Sprinklers or Standard Spray Sprinklers to maintain coverage around

obstructions.

Care and

Maintenance

The TYCO Specific Application Attic

Sprinklers for Protecting Attics must

be maintained and serviced in accordance with this section.

Before closing a fire protection system

main control valve for maintenance

work on the fire protection system

that it controls, obtain permission to

shut down the affected fire protection system from the proper authorities

and notify all personnel who may be

affected by this action.

The owner is responsible for the

inspection, testing, and maintenance of

their fire protection system and devices

in compliance with this document, as

well as with the applicable standards of

the NFPA, such as NFPA 25. In addition

to the standards of any other authorities having jurisdiction. Contact the

installing contractor or product manufacturer with any questions.

Automatic sprinkler systems should be

inspected, tested, and maintained by a

qualified Inspection Service in accordance with local requirements and/or

national code.

Sprinklers that are found to be leaking

or exhibiting visible signs of corrosion

must be replaced.

Automatic sprinklers must never be

painted, plated, coated, or otherwise

altered after leaving the factory. Modified sprinklers must be replaced.

Over-heated solder type sprinklers

must be replaced. Bulb-type sprinklers that have been exposed to corrosive products of combustion, but

have not operated, should be replaced

if they cannot be completely cleaned

by wiping the sprinkler with a cloth or

by brushing it with a soft bristle brush.

Care must be exercised to avoid

damage to the sprinklers before,

during, and after installation. Sprinklers damaged by dropping, striking,

wrench twist/slippage, or the like, must

be replaced. Also, replace any sprinkler

that has a cracked bulb or that has lost

liquid from its bulb. For more information, refer to the Installation Section.

Limited

Warranty

For warranty terms and conditions, visit

www.tyco-fire.com.

Ordering

Procedure

Contact your local distributor for availability. When placing an order, indicate

the full product name and Part Number

(P/N).

Sprinkler Assemblies with

NPT Thread Connections

Specify: Model (specify), K-factor

(specify), SIN (specify), Specific Application Attic Sprinkler, P/N (specify):

BB1 (K=8.0),

T Y418 0 . . . . . . . . . . . . . . . . . . . . . . 51-62 3-1-2 00

BB2 (K=8.0),

T Y418 1 ...................... 51-6 21-1-20 0

BB3 (K=8.0),

T Y418 2 ......................51-6 22-1-200

BB1 (K=5.6),

TY3180 ......................50 -601-1-212

BB2 (K=5.6),

TY3181 ......................50 - 602 -1-212

BB3 (K=5.6),

TY3182 ......................50- 6 0 3 -1-212

BB1 (K=4. 2),

TY2180 ......................50-620-1-200

BB2 (K=4.2),

TY2181 ......................50- 621-1-2 00

BB3 (K=4. 2),

TY2182 ......................50 - 6 22 -1-20 0

SD1 (K= 5.6),

TY3183 ......................50 -611-1-212

SD2 (K=5.6),

TY3184 ......................50- 612-1-212

SD3 (K=5.6),

TY3185 ......................50 - 613-1-212

HIP (K=5.6),

TY3187 ......................51-620-1-2 00

AP (K= 5.6),

TY3190 ......................5 0-62 5 -1-20 0

AP (K= 4.2),

TY2190 ......................5 0 - 624 -1-20 0

Sprinkler Wrench

Specify: W-Type 3 Sprinkler Wrench,

P/ N 5 6 -895-1- 001

Specify: W-Type 20 Sprinkler Wrench,

P/ N 5 6 -00 0 -1-10 6

Specify: W-Type 6 Sprinkler Wrench,

P/N 56-000-6-387

Page 10

TFP610

ROOF SPAN

6" (152,4 mm) MAX.

ROOF SPAN

6'-0" (1,83 m) MAXIMUM

RIDGE

7'-0" (2,1 m) MIN. FOR AP SPRINKLERS

RIDGE

22" (558,8 mm) MAX.

BB, SD or HIP ATTIC

BB, SD or HIP

6" (152,4 mm)

6" (152,4 mm)

Page 10 of 28

SEE FIG. 11

12

4-12

TRUSS

STANDARD

TRUSS

BB or SD ATTIC

SPRINKLERS

(COVERAGE)

BACK TO BACK

SPRINKLER

SCISSOR

TRUSS

4" (101,6 mm) MIN.

FROM WALL

22" (558,8 mm) MAX.

16" (406,4 mm) MIN.

BOTTOM OF SHEATHING

FULL WALL TO DECK

FIGURE 1 FIGURE 2

4'-0" (1,22 m) MINIMUM

BRANCH

LINE

CEILING

TRUSS CEILING

6'-0" (1,8 m) MINIMUM FOR

STANDARD SPRAY SPRINKLERS

AP or STANDARD

SPRAY SPRINKLER

FIGURE 3 FIGURE 4

DECK

DRAFT

CURTAIN

TO DECK

(COVERAGE)

AP or STANDARD

SPRAY SPRINKLER

SINGLE DIRECTIONAL

SPRINKLERS

8" MIN.

(203,2 mm)

ATTIC

SPRINKLER

BRANCH

LINE

SEE

FIG. 11

16" (406,4 mm) MIN.

-or-

FOR A ROOF PITCH

LESS THAN 4:12 (33%),

12" (304,8 mm) MAXIMUM

BELOW PEAK AND 1"

(25,4 mm) MINIMUM

BELOW BOTTOM OF

TOP CHORD OR

RAFTER

BB, SD or HIP

SPRINKLER

TRUSS

SPRINKLER

FIGURE 5

MINIMUM

BRANCH

STANDARD

LINE

TRUSS

18" MIN.

(457,2 mm)

SCISSOR

TRUSS

RIDGE

CEILING

26'-0" (7,92 m)

MINIMUM

MAXIMUM

22" (558,8 mm) MAX.

16" (406,4 mm) MIN.

BOTTOM OF SHEATHING

FIGURE 6

FIGURE 7 FIGURE 8

ATTIC

SPRINKLER

BB or HIP

SPRINKLER

AP or

STANDARD

SPRAY

SPRINKLERS

ATTIC

Page 11

TFP610

PROTECTION

12" MIN.

12" MIN.

SPRINKLER

& FITTINGS

SPRINKLER

& FITTINGS

NON-COMBUSTIBLE INSULATION

OPTION A

CEILING

ATTIC

PROTECTED

(152,4 mm)

NON-COMBUSTIBLE INSULATION

FOR FIRE PROTECTION OF CPVC PIPE,

ATTIC

CEILING

NOT EQUAL ANGLE "B"

SINGLE DIRECTIONAL

AP or STANDARD

INSULATION

OR TOP CHORD

Page 11 of 28

CEILING

(304,8 mm)

NON-COMBUSTIBLE

INSULATION FOR FIRE

PROTECTION OF CPVC

ATTIC

SPRINKLER

PROTECTED

SPACE

CEILING

JOIST

CPVC PIPE

(304,8 mm)

FIGURE 9A

FOR FIRE PROTECTION OF CPVC PIPE,

NOT FREEZE PROTECTION

OPTION B

6" MIN.

(152,4 mm)

CPVC PIPE

CEILING

JOIST

FIGURE 9B

6" MIN.

(152,4 mm)

PIPE, NOT FREEZE

SPRINKLER

SPACE

SPRINKLERS AS

APPROPRIATE FOR

RESPECTIVE SLOPE

DRAFT CURTAIN

(SHOWN)

OR FULL WALL

TO ROOF DECK

A B

WHEN ANGLE "A" DOES

8" MIN.

(203,2 mm)

FIGURE 10

PERMITTED USE OF ATTIC SPRINKLERS

FOR MISMATCHED SLOPES

SPRAY SPRINKLER

COVERAGE ON SLOPE

BB, SD or HIP

COVERAGE ON

HORIZONTAL

NOT FREEZE PROTECTION

CEILING

CEILING

ELEVATION

CHANGE

NON-COMBUSTIBLE INSULATION

FOR THE PROTECTION OF CPVC PIPE

FIGURE 9C

FIGURE 9

SPRINKLER

PROTECTED

SPACE

VERTICAL

RISE

CPVC PIPE

& FITTINGS

6" MIN.

JOIST

MAXIMUM

2" (50 mm) VENT

PERMITTED

TOP OF

INSULATION

NON-COMBUSTIBLE

CEILING

JOIST

ROOF JOIST

OR TOP CHORD

AP or STANDARD

SPRAY SPRINKLER

COVERAGE ON SLOPE

BB, SD or HIP

COVERAGE ON

HORIZONTAL

ROOF JOIST

FIGURE 11

COVERAGE STARTING POINT AT EAVE

Page 12

TFP610

7'-6" (2,3 m) MAX. HORIZONTAL

ON HIP SLOPE

HIP SLOPE

28'-0" (8,5 m)

HORIZONTAL

SPRINKLERS

6'-0" (1,8 m) MAX.6'-0" (1,8 m) MAX.

TRUSSES IN HIP SLOPE AREA

PARALLEL TO OUTSIDE WALL

6'-0" (1,8 m) MAX.

HIP RIDGES

Page 12 of 28

SEE FIG. 11

HIP ROOF INSTALLATION

FIGURE 12

WITH RAFTERS FRAMED

PERPENDICULAR TO

OUTSIDE WALL

(SHOWN WITH HIP

SPRINKLERS PROTECTING

HIP SLOPE AND ADJACENT

AREAS TO HIP SLOPE )

FIGURE 13A

HIP ROOF INSTALLATION

WITH TRUSSES FRAMED

PARALLEL TO OUTSIDE WALL

(SHOWN WITH STANDARD

SPRAY OR AP SPRINKLERS

IN HIP SLOPE)

WHERE AN AREA

(SHOWN NON-SHADED)

IS PROTECTED

WITH AP SPRINKLERS,

CPVC MAY BE

USED FOR CEILING

PROTECTION BELOW

(SEE PAGE 6)

HIP SPRINKLERS

PROTECT AREA ON

BOTH SIDES OF

RAFTERS IN HIP SLOPE

AREA PERPENDICULAR

TO OUTSIDE WALL

MAXIMUM

SEE FIG. 11

STANDARD SPRAY

SPRINKLERS INSTALLED

PER NFPA 13 IN HIP SLOPE

AREA WHEN TRUSSES

ARE FRAMED PARALLEL

TO OUTSIDE WALL

TRUSSES IN HIP SLOPE AREA

PARALLEL TO OUTSIDE WALL

MAXIMUM

40'-0" (12,2 m)

HORIZONTAL

ROOF SPAN

(COVERAGE)

OUTSIDE WALL

SINGLE

DIRECTIONAL

SPRINKLERS

HIP RIDGES

HIP RIDGE

OUTSIDE

WALL

HIP

RIDGES

6'-0" (1,8 m) MAX.

HIP

SLOPE

3'-0" (0,9 m) MIN.

HIP

SLOPE

3'-0" (0,9 m)

MAX. ON

TO BACK

RIDGE LINE

BACK

TO BACK

SPRINKLERS

ROOF

SLOPE

RIDGE LINE

3'-0" (0,9 m)

MAX. ON

HIP SLOPE

BACK

ROOF

SLOPE

HIP ROOF INSTALLATION

WITH TRUSSES FRAMED

PARALLEL TO OUTSIDE WALL

(SHOWN WITH STANDARD

SPRAY OR AP SPRINKLERS IN

HIP SLOPE AND ADJACENT

AREAS TO HIP SLOPE )

FIGURE 13B

3'-0" (0,9 m)

MAX. ON

HIP SLOPE

STANDARD SPRAY

SPRINKLERS INSTALLED

PER NFPA 13 IN HIP SLOPE

AREA WHEN TRUSSES

ARE FRAMED PARALLEL

TO OUTSIDE WALL

OUTSIDE WALL

WHERE AN AREA

(SHOWN NON-SHADED)

IS PROTECTED

WITH AP SPRINKLERS,

CPVC MAY BE

USED FOR CEILING

PROTECTION BELOW

(SEE PAGE 6)

CPVC PIPE MAY BE USED IN SHADED AREA ONLY

FOR CEILING PROTECTION BELOW (SEE PAGE 6)

BACK

TO BACK

SPRINKLERS

HIP

SLOPE

CPVC PIPE MAY BE USED IN SHADED AREA ONLY

FOR CEILING PROTECTION BELOW (SEE PAGE 6)

ROOF

SLOPE

RIDGE LINE

Page 13

TFP610

6'-0" MAX.

SPRINKLERS

10'-0" (3,0 m)

(TABLE A)

BACK

AT THE EAVES

Page 13 of 28

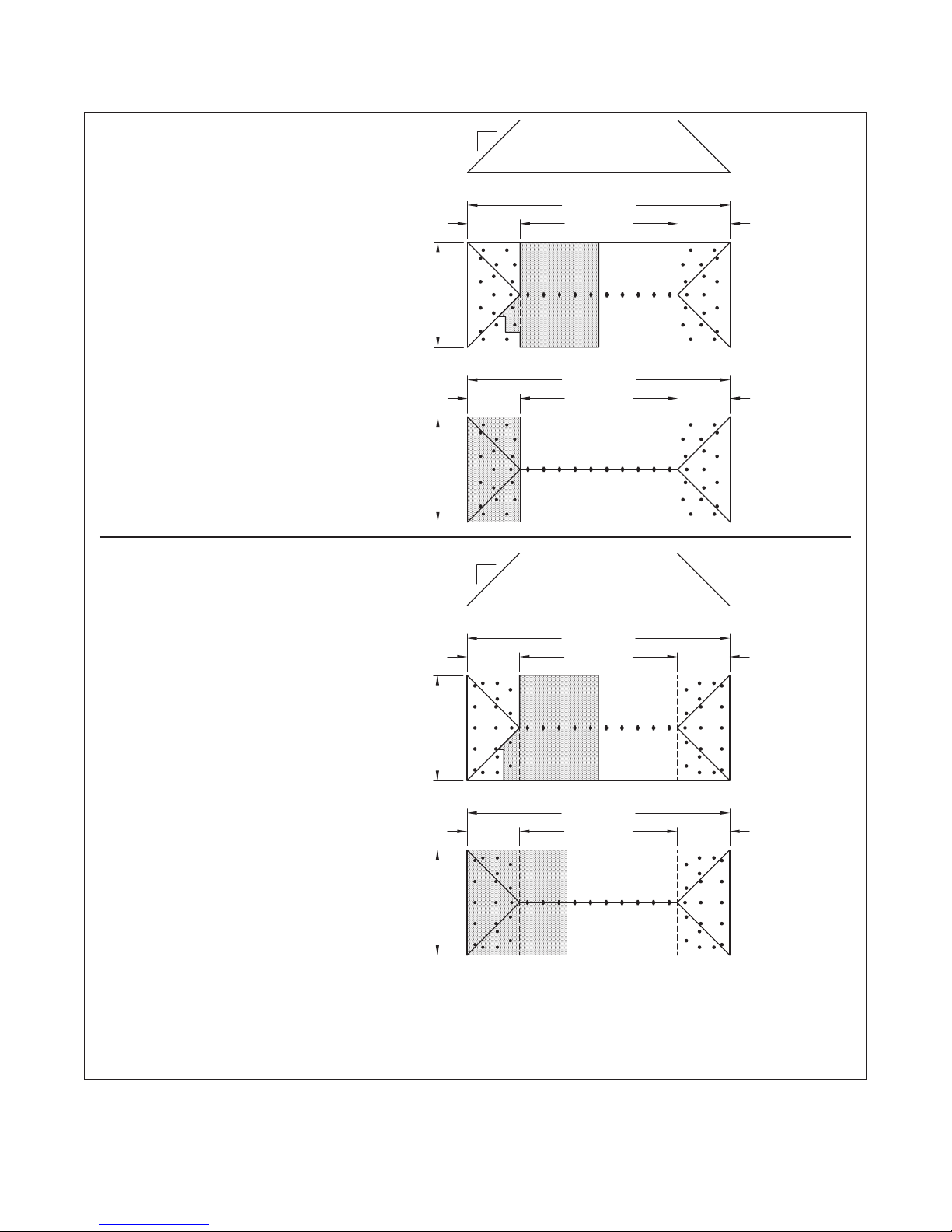

Attic Spaces Greater Than 60 ft (18,3m) up to 80 ft (24,4m) Wide, (refer to Figures 14 and 15).

Only 8.0 K, BB Sprinklers in conjunction with AP Sprinklers or Standard Spray Sprinklers can be used to protect attics up

to 80 ft (24,4 m) wide.

NOTES:

•

Attics over 80 ft (24,4 m) wide must use Standard Spray Sprinklers throughout because Attic Sprinklers have not been

tested in this scenario.

•

For single ridge construction (refer to Figure 14A and 14B), use 8.0K, BB Sprinklers to protect the center portion. AP

Sprinklers (refer to Figure 14A) or Standard Spray Sprinklers (refer to Figure 14B) are then used to protect up to 10 ft

(3,1 m) of width at the eaves beyond the maximum allowable 60 ft (18,3 m) span of the 8.0K, BB Sprinklers.

•

For hip roof construction (refer to Figure 15), use 8.0K, BB Sprinklers in the center portion and HIP Sprinklers can be

located down the entire hip. AP Sprinklers or Standard Spray Sprinklers are then used to protect up to 10 ft (3,1 m) of

width at the eaves beyond the maximum allowable 60 ft (18,3 m) span of the 8.0K, BB Sprinklers, and the maximum

allowable horizontal coverage of the HIP Sprinklers.

SEE FIG. 11

10'-0" MAX.

(3,05 m)

AP

SPRINKLER

COVERAGE

BB SPAN

(TABLE A)

6'-0"

(1,83 m)

MAX.

6'-0" MAX.

(1,83 m)

4'-0" MIN.

(1,22 m)

FIGURE 14A

SPRINKLERS

PERIMETER

PROTECTION

BB ATTIC

SPRINKLER

10'-0"

(3,0 m)

HIP

RIDGES

AP

AREA

AP

SPRINKLERS

SPACED

7'-0" (1,8 m)

TO

10'-0" (3,0 m)

ON CENTER

HIP

SLOPE

HIP

SPRINKLERS

(1,83 m)

4'-0" MIN.

(1,22 m)

TO BACK

SPRINKLERS

SEE FIG. 11

10'-0" MAX.

(3,05 m)

AP SPRINKLER

COVERAGE

FIGURE 14B

10'-0"

(3,0 m)

RIDGE

LINE

ROOF

SLOPE

BB

SPAN

SD SPAN

(TABLE A)

6'-0"

(1,83 m)

MAX.

SD ATTIC

SPRINKLER

AP

SPACED

7'-0" (1,8 m)

TO

ON CENTER

CPVC PIPE MAY

BE USED IN SHADED

AREA FOR CEILING

PROTECTION BELOW

(SEE PAGE 6)

FIGURE 15

10'-0"

(3,0 m)

7'-0" to 10'-0"

(2,1 m to 3,0 m)

ON CENTER FOR

AP SPRINKLERS

Page 14

TFP610

BB ATTIC

BB ATTIC

BB ATTIC

LESS THAN

BB ATTIC

Page 14 of 28

NO

ADDITIONAL

SPRINKLER

REQUIRED

3-1/2" MIN.

(88,9 mm)

AIR SPACE

SPRINKLER

36" MIN.

(914,4 mm)

6" MAX.

(152,4 mm)

GREATER

THAN 6"

(152,4 mm)

ANY

DISTANCE

SPRINKLER

ADDITIONAL AP

OR STANDARD SPRAY

SPRINKLER REQUIRED

(LOCATE PER FIGURE

14A OR 14B)

FIGURE 16A FIGURE 16B

There can be a maximum of a 6 in. (152,4 mm) high Horizontal Obstruction as long as it is 36 in. (914,4 mm), measured

vertically, below the Attic Sprinkler. If the obstruction is closer or larger, there must be a sprinkler on the other side of the

obstruction. Refer to Figures 16A and 16B. This criteria does not limit the top chord of the trusses or the depth of the rafter, but does limit the obstructions that run across the trusses or rafters.

6" (152,4 mm)

NO

ADDITIONAL

SPRINKLER

REQUIRED

ADDITIONAL AP

OR STANDARD SPRAY

SPRINKLER(S)

REQUIRED (LOCATE

PER FIGURE

14A OR 14B)

MINIMUM

6" (152,4 mm)

SPRINKLER

4'-0" (1,2 m)

MAXIMUM

FIGURE 16C

SPRINKLER

36" (914,4 mm)

MINIMUM

36" (914,4 mm)

MINIMUM

Dimension A

Maximum

Horizontal

Dimension of

Obstruction

All Vertical Obstructions

1/2"-1" (12,7 mm-25,4 mm)

1"-4" (25,4 mm-101,6 mm)

4"-8" (101,4 mm-203,2 mm)

8"-10" (203,2 mm-254,0 mm)

10"-20" (254,0 mm-508,0 mm)

20"-30" (508,0 mm-762,0 mm)

30"-40" (762,0 mm-1016,0 mm)

40"-48" (1016,0 mm-1219,2 mm)

> 48" (1219,2 mm)

Distance B

Minimum

Horizontal

Distance to

Obstruction

< 6" (152,4 mm)

6" (152,4 mm)

12" (304,8 mm)

24" (609,6 mm)

5'-0" (1,52 m)

10'-0" (3,05 m)

15'-0" (4,57 m)

20'-0" (6,10 m)

25'-0" (7,62 m)

Any Distance

Additional

Sprinkler

Required

Beyond

Obstruction

YES

NO

NO

NO

NO

NO

NO

NO

NO

YES

GREATER THAN

4'-0" (1,2 m)

FIGURE 16D

If the Horizontal Obstruction is below the sprinkler, there

must be 6 in. (152,4 mm) clearance over the top of the

obstruction, and the obstruction must be 4 ft (1,2 m) or

less in width to allow water to pass both over and under

the obstruction. The clearance is measured perpendicular to and from the bottom of the rafter. If there is not

6 in. must be located on the other side of the obstruction. If the obstruction is greater than 4 ft (1,2 m) in width,

a sprinkler must be added below the obstruction. Refer

to Figures 16C and 16D, where the maximum spacing for

AP Sprinklers is 12 ft (3,7 m) and Standard Spray Sprinklers is 15 ft (4,6 m).

OBSTRUCTIONS TO WATER DISTRIBUTION — BB, SD AND HIP

DIMENSION B

PER TABLE

For Vertical Obstructions, the maximum dimension of the

obstruction is its width and the horizontal distance away

from the obstruction is measured horizontally.

FIGURE 16 (1 OF 2 )

ADDITIONAL AP

OR STANDARD SPRAY

SPRINKLER REQUIRED

(LOCATE PER FIGURE

FIGURE 16E

DIMENSION A

PER TABLE

14A OR 14B)

Page 15

TFP610

6" (152,4 mm) TYP.

DIRECTIONAL SPRINKLERS

SPRINKLERS

BB ATTIC

36" (914,4 mm)

22" (558,8 mm) MAX.

DIRECTIONAL

SPRINKLER

OR FULL WALL

DIRECTIONAL

SPRINKLER

(304,8 mm)

"V"

Page 15 of 28

AREA OUTSIDE OF MECHANICAL SPACE

FIGURE 16F

OR SIMILAR COMPARTMENTAL SPACE

When a BB Sprinkler is 36 in. (914,4 mm) or greater above

the space, and 36 in. (914,4 mm) or greater clearance

above the space is present, additional sprinklers are not

needed.

When a BB Sprinkler is 36 in. (914,4 mm) or greater above

the space, and a 12 to 36 in. (304,8 to 914,4 mm) clearance above the space is present, Intermediate Level Standard Sprinklers are to be installed to protect the obstructed

area.

Otherwise, the area beyond the mechanical space is to be

protected as shown by installing Standard Spray Sprinklers

as necessary or by constructing a shear wall and installing

SD Sprinklers.

Note: In all cases, the mechanical space or similar compartmented

space is to be sprinklered per its respective hazard rating and separated from the light hazard attic space by construction that has a

fire resistance rating based on the water supply duration required

for the hazard rating within the mechanical space or similar compartmented space.

NO

ADDITIONAL

SPRINKLERS

REQUIRED

36" (914,4 mm)

OR GREATER

SPRINKLER

OR GREATER

FIGURE 16G

PIGGYBACK TRUSSES

When a BB Sprinkler can be installed below or between

stiffeners and maintain the 16 to 22 in. (404,4 to 558,8

mm) distance to the peak, as well as the “V” and “H”

clearance to the stiffeners, additional sprinklers are not

required.

When the stiffeners are located a minimum of 12 in.

(304,8 mm) below the BB Sprinkler, the stiffeners are

7-1/2 in. (190,5 mm) maximum in width, the openings are

12 in. (304,8 mm) minimum, and there is 70% minimum

open area, additional sprinklers are not required.

Otherwise, additional sprinklers are required as shown.

H

BB2

V + 10"

16" (406,4 mm) MIN.

BB3

0"

0"

V + 8"V > 0"

BOTTOM

PLANE OF

STIFFENERS

"V"

"H"

STIFFENERS

V

BB1

0"

0"

V + 15"

STANDARD

SPRAY SPRINKLER

12" (304,8 mm) TO

36" (914,4 mm)

INTERMEDIATE

LEVEL

STANDARD SPRAY

SPRINKLER

STANDARD

SPRAY SPRINKLER

SPRINKLER

LESS THAN

12" (304,8 mm)

PROTECT WITH

STANDARD SPRAY

MECHANICAL

SPACE

4" (101,6 mm) TO

6" (152,4 mm) TYP.

MECHANICAL

SPACE

BB ATTIC

MECHANICAL SPACE

-OR-

36" (914,4 mm)

OR GREATER

BB ATTIC

SPRINKLER

4" (101,6 mm) TO

STANDARD

SPRAY SPRINKLER

ADD SHEAR WALL AND

PROTECT WITH SINGLE

TOP OF

DEFLECTOR

STIFFENERS

3-1/2" MIN.

(88,9 mm)

AIR SPACE

7-1/2" MAX.

(190,5 mm)

INTERMEDIATE

LEVEL

STANDARD

SPRINKLER

SINGLE

BB ATTIC

SPRINKLER

BB ATTIC

SPRINKLER OR

STANDARD SPRAY

SPRINKLER

INSTALL

DRAFT CURTAIN

BB ATTIC

SPRINKLER

70% MINIMUM

OPEN AREA

12" MIN.

(304,8 mm)

LESS THAN

70% OPEN AREA,

OPENINGS LESS THAN

12" (304,8 mm) WIDE,

OR STIFFENERS

GREATER THAN

7-1/2" (190,5 mm)

WIDE

12" MIN.

SINGLE

(Obstructions to Water Distribution for Attic Sprinklers Differ from Standard Sprinklers as Shown)

FIGURE 16 (2 OF 2) OBSTRUCTIONS TO WATER DISTRIBUTION — BB, SD, AND HIP

Page 16

TFP610

OPTION A

OPTION B

OPTION B

OPTION A

OBSTRUCTION

OBSTRUCTION

Page 16 of 28

FIGURE 17A

EXPOSED CPVC

WITH AP SPRINKLERS

AND

BRANCHLINE OVER

JOISTS

FIGURE 17B

EXPOSED CPVC

WITH AP SPRINKLERS

AND

BRANCHLINE WITHIN

JOISTS

3'-0" MAX.

(0,9 m)

JOIST

12" MIN.

(304,8 mm)

NON-COMBUSTIBLE

INSULATION FOR FIRE

PROTECTION OF CPVC

PIPE, NOT FREEZE

PROTECTION

3'-0" MAX.

(0,9 m)

6" MIN.

(152,4 mm)

CEILING

NON-COMBUSTIBLE

INSULATION FOR FIRE

PROTECTION OF CPVC

PIPE, NOT FREEZE

PROTECTION

AP

SPRINKLER

AP

SPRIG

6" MIN.

(152,4 mm)

12" MIN.

(304,8 mm)

CEILING

AP

SPRINKLER

AP

SPRIG

JOIST

10'-0" MAX.

(3,0 m)

JOIST

12" MIN.

(304,8 mm)

NON-COMBUSTIBLE

INSULATION FOR FIRE

PROTECTION OF CPVC

PIPE, NOT FREEZE

PROTECTION

10'-0" MAX.

(3,0 m)

6" MIN.

(152,4 mm)

CEILING

NON-COMBUSTIBLE

INSULATION FOR FIRE

PROTECTION OF CPVC

PIPE, NOT FREEZE

PROTECTION

AP

SPRINKLER

AP

SPRIG

6" MIN.

(152,4 mm)

12" MIN.

(304,8 mm)

CEILING

AP

SPRINKLER

AP

SPRIG

JOIST

FIGURE 18

OBSTRUCTIONS TO WATER

DISTRIBUTION FOR

MODEL AP SPRINKLERS

A

C

D

ELEVATION VIEW PLAN VIEW

A

B

AP

SPRINKLER

AP

SPRINKLER

OBSTRUCTION

A ≥ 3C or 3D

A ≤ 24" (609,6 mm)

(Use dimension C or D,

whichever is greater)

≤6"

(≤152,4 mm)

>6" to 9"

(>152,4 mm to 228,6 mm)

>9" to 12"

(>228,6 mm to 304,8 mm)

>12" to 15"

(>304,8 mm to 381,0 mm)

>15" to 18"

(>381,0 mm to 457,2 mm)

>18" to 24"

(>457,2 mm to 609,6 mm)

>24" to 30"

(>609,6 mm to 762,0 mm)

>30"

(>762,0 mm)

C

Horizontal

Distance

(A)

D

AP

SPRINKLER

A

Minimum

Vertical Distance

Below Deector

(B)

3"

(76,2 mm)

4"

(101,6 mm)

6"

(88,9 mm)

8"

(203,2 mm)

9-1/2"

(241,3 mm)

12-1/2"

(317,5 mm)

15-1/2"

(393,7 mm)

18"

(457,2 mm)

Page 17

TFP610

ARMOVER

MODEL AP

OR STANDARD

SPRAY

Page 17 of 28

A = 6" (150 mm) MAX.

A

B

A

B = 12" (300 mm) MAX.

A

ANGLE SPRIG

ARMOVER SPRIG

BRANCHLINE

VERTICAL SPRIG

VERTICAL RISER VERTICAL RISER

B

BRANCHLINE

DIRECT MOUNT

FIGURE 19

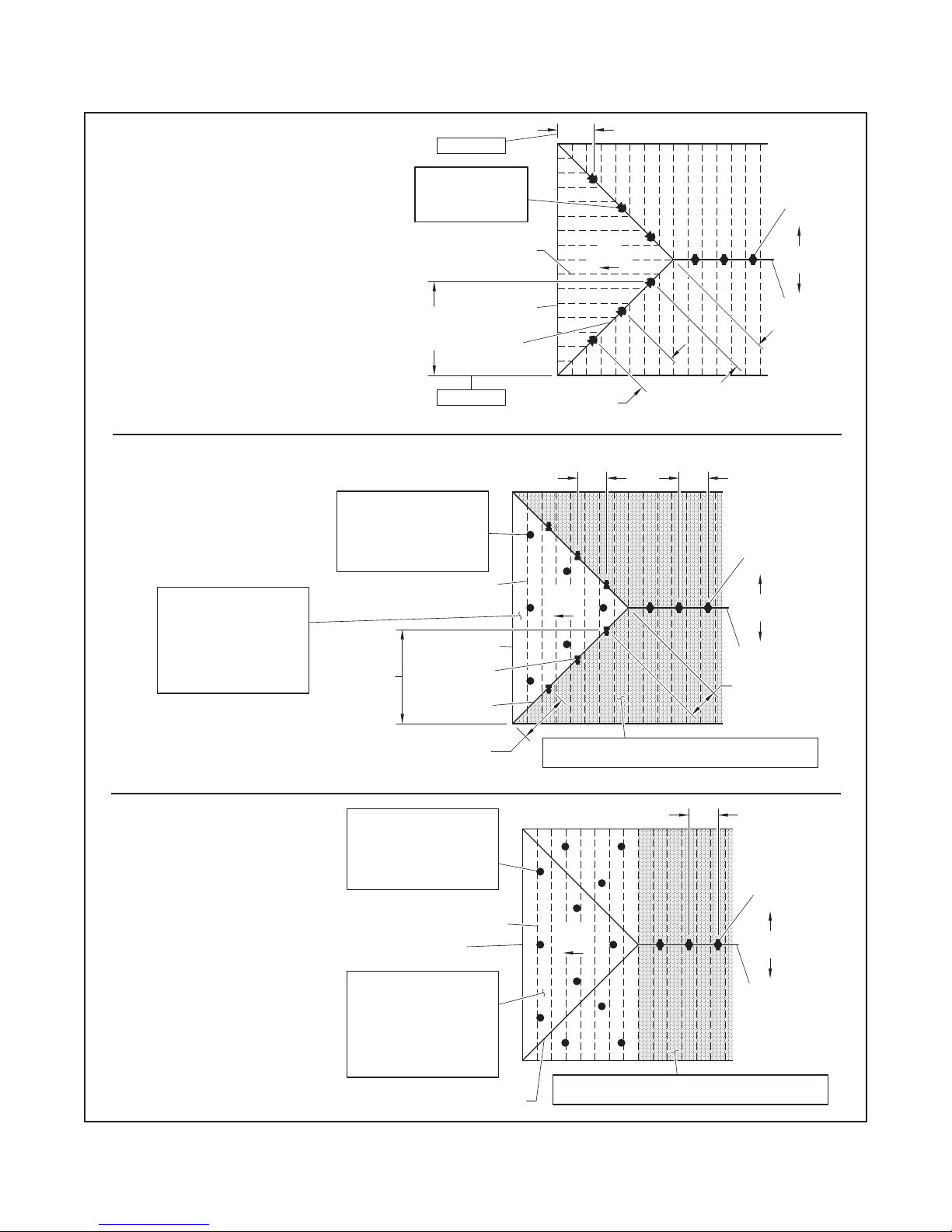

HYDRAULIC CALCULATIONS

Attic sprinklers must be calculated in conformance with these guidelines. In all cases, the design area shall include the

most hydraulically demanding sprinklers. More than one set of calculations may be required to prove different situations.

For individual areas requiring more than four AP Sprinklers, the maximum area of attic protected by AP Sprinklers is limited

to 3000 ft2 (279 m2) in any single area. Areas must be separated by a minimum of 15 ft (4,6 m) by an area protected by BB,

SD,or HIP Sprinklers, in order to be considered separate areas.

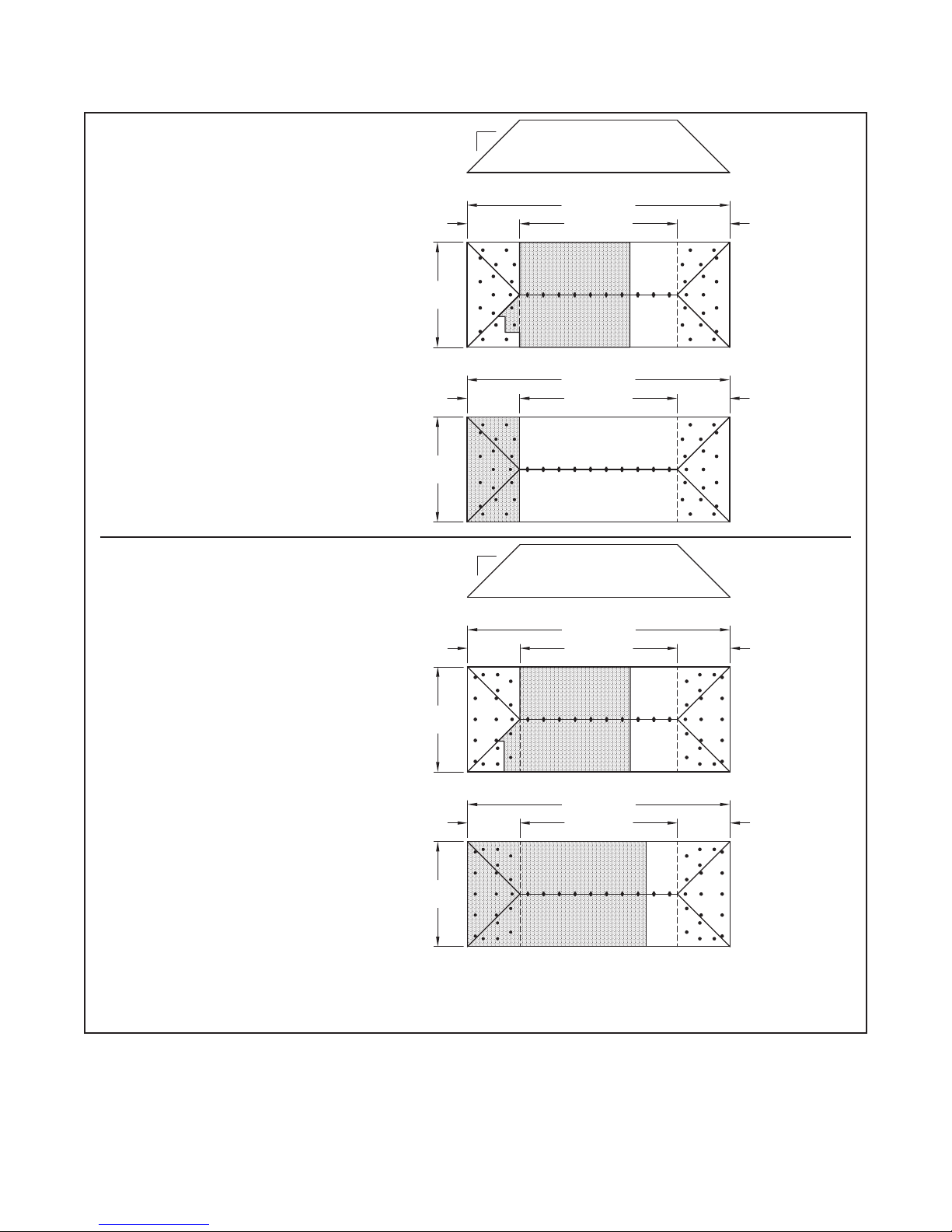

The hydraulic calculations have been divided into three parts as follows:

• FIGURE 20-A: “Attics Protected Entirely By BB, SD, and HIP Attic Sprinklers”.

20-A-1 (Page 18) BB Sprinklers

20-A-2 (Page 18) BB and HIP Sprinklers

20-A-3 (Page 19) BB and SD Sprinklers

20-A-4 ( Page 19) SD Sprinklers

20-A-5 (Page 19) SD and HIP Sprinklers

20-A-6 (Page 19) HIP Sprinklers

• FIGURE 20-B: “Attics Protected With A Mixture Of BB. SD, and HIP Attic Sprinklers And AP Sprinklers”.

20-B-1 (Page 20) SD Sprinklers and AP Sprinklers At The Ridge

20-B-2 (Page 20) BB Sprinklers and AP Sprinklers At The Eaves or Beyond An Obstruction

20-B-3 (Page 21) BB Sprinklers and AP Sprinklers At The Hip

20-B-4 (Page 21) BB Sprinklers, SD Sprinklers, HIP Sprinklers, and AP Sprinklers At The Hip

20-B-5 (Page 22) BB, SD, or HIP Sprinklers and AP Sprinklers in a Dormer, at a Cross, or at an Ell

20-B-6 (Page 22) BB,SD, or HIP Sprinklers and AP Sprinklers Separated By Compartmentalization

• FIGURE 20-C: “Attics Protected With A Mixture Of BB. SD, and HIP Attic Sprinklers And Standard Spray

Sprinklers”.

20-C-1 (Page 23) SD Sprinklers and Standard Spray Sprinklers At The Ridge

20-C-2 (Page 23) BB Sprinklers and Standard Spray Sprinklers At The Eaves or Beyond An Obstruction

20-C-3 (Page 24) BB Sprinklers and Standard Spray Sprinklers At The Hip

20-C-4 (Page 25) BB Sprinklers, SD Sprinklers, HIP Sprinklers, and Standard Spray Sprinklers At The Hip

20-C-5 (Page 26) BB, SD, or HIP Sprinklers and Standard Spray Sprinklers in a Dormer, at a Cross, or at an Ell

20-C-6 (Page 26) BB, SD, or HIP Sprinklers and Standard Sprinklers Separated By Compartmentalization

MODEL BB

BACK TO BACK

MODEL SD

SINGLE DIRECTIONAL

FIGURE 20

HYDRAULIC CALCULATIONS

MODEL HIP

Page 18

TFP610

DRY SYSTEM SHOWN

DRY SYSTEM SHOWN

Page 18 of 28

FIGURE 20-A-1. BB SPRINKLERS

•

Wet Systems: Calculate the most

demanding ve sprinklers.

•

Dry Systems: Calculate the most

demanding seven sprinklers. See

the adjacent gure.

RIDGE

HIP

RIDGE

FIGURE 20-A-2. BB AND HIP

SPRINKLERS

•

Wet Systems: Calculate the most

demanding ve sprinklers.

•

Dry Systems: Calculate the most

demanding seven sprinklers. Then

calculate the most demanding

contiguous nine sprinklers with a

maximum of seven to be BB Sprinklers. See the adjacent gures. Use

the most demanding calculation.

DRY SYSTEM SHOWN

HIPVALLEY

RIDGE

Page 19

TFP610

DRY SYSTEM SHOWN

DRY SYSTEM SHOWN

DRAFT CURTAIN

DRY SYSTEM SHOWN

DRAFT CURTAIN

WET SYSTEM SHOWN

Page 19 of 28

FIGURE 20-A-3. BB AND SD

SPRINKLERS

•

Wet Systems: Calculate the most

demanding ve BB Sprinklers

plus two SD Sprinklers.

•

Dry Systems: Calculate the most

demanding seven BB Sprinklers

plus up to two SD Sprinklers. See

the adjacent gure.

FIGURE 20-A-4. SD SPRIN-

KLERS

•

Wet Systems: Calculate the most

demanding ve SD Sprinklers.

•

Dry Systems: Calculate the most

demanding nine SD Sprinklers.

See the adjacent gure.

FIGURE 20-A-5. SD AND HIP

SPRINKLERS

•

Wet Systems: Calculate the most

demanding ve sprinklers.

•

Dry Systems: Calculate the most

demanding nine sprinklers with

a maximum of seven to be SD

Sprinklers. See the adjacent

gure.

OBSTRUCTION

RIDGE

RIDGE

WALL OR

AT RIDGE

HIP

RIDGE

WALL OR

AT RIDGE

FIGURE 20-A-6. HIP SPRIN-

KLERS

•

Wet Systems: Calculate the most

demanding ve sprinklers. See

the adjacent gure.

•

Dry Systems: Calculate the most

demanding nine sprinklers.

HIP

HIP

HIP

HIP

Page 20

TFP610

DRY SYSTEM SHOWN

WALLS OR

CURTAINS

OBSTRUCTION

DRY SYSTEM SHOWN

Page 20 of 28

FIGURE 20-B-1. SD SPRINKLERS

AND AP SPRINKLERS AT THE

•

Wet Systems: Calculate the most

demanding ve sprinklers of one

type. Use the most demanding

calculation.

•

Dry Systems: Calculate the most

demanding nine SD Sprinklers,

and then calculate the most

demanding seven AP Sprinklers.

Use the most demanding calculation. See the adjacent gure.

RIDGE

RIDGE

DRAFT

RIDGE

FIGURE 20-B-2. BB OR SD

SPRINKLERS AND AP SPRIN-

KLERS AT THE EAVES OR BE-

YOND AN OBSTRUCTION

•

Wet Systems: Calculate the

most demanding ve BB or SD

Sprinklers plus up to two most

demanding AP Sprinklers.

•

Dry Systems: Calculate the most

demanding seven BB or SD

Sprinklers plus up to two most

demanding AP Sprinklers. See the

adjacent gures.

DRY SYSTEM SHOWN

RIDGE

DRY SYSTEM SHOWN

Page 21

TFP610

AREA 2

AREA 1

AREA 3

15'-0" (4,6 m)

SPACING WHEN

WALL OR

CURTAIN

15'-0" (4,6 m)

SPRINKLERS

SPRINKLERS

Page 21 of 28

BB SPRINKLERS AND AP SPRIN-

FIGURE 20-B-3.

KLERS AT THE HIP

Where the total number of AP Sprinklers

at the hip is greater than four:

•

Wet Systems: Calculate the most

demanding ve BB Sprinklers

plus the two most demanding

AP Sprinklers. Then calculate

the most demanding area up to

150 0 ft2 (137 m2) having AP Sprinklers, for example, Area 2 in the

adjacent upper gure. Use the most

demanding calculation.

•

Dry Systems: Calculate the most

demanding seven BB Sprinklers

plus the two most demanding

AP Sprinklers. Then calculate

the most demanding area up to

1950 f t2 (181 m2) having AP Sprinklers, for example, Area 2 in the

adjacent upper gure. Use the most

demanding calculation.

FIGURE 20-B-4. BB SPRINKLERS,

SD SPRINKLERS, HIP SPRIN-

KLERS, AND AP SPRINKLERS AT

THE HIP

Where the total number of AP Sprinklers

at the hip is four or less:

• Wet Systems: Calculate the most demanding ve BB, SD, or HIP Sprinklers plus up to two most demanding

AP Sprinklers.

•

Dry Systems: Calculate the most

demanding nine BB, SD, or HIP

Sprinklers plus up to two most

demanding AP Sprinklers (Of the

nine BB, SD, or HIP Sprinklers,

calculate up to a maximum of seven

BB Sprinklers, see adjacent upper

gure).

Where the total number of AP Sprinklers

at the hip is greater than four:

•

Wet Systems: Calculate up to the

most demanding ve BB, SD, or

HIP Sprinklers plus the two most

demanding AP Sprinklers. Then

calculate the most demanding area

up to 1500 ft2 (137 m2) having AP

Sprinklers, for example, Area 2. Use

the most demanding calculation.

•

Dry Systems: Calculate up to the

most demanding nine BB, SD, or

HIP Sprinklers, plus the two most

demanding AP Sprinklers, and then

calculate the most demanding area

up to 1950 ft2 (181 m2) having AP

Sprinklers, for example, Area 2. Use

the most demanding calculation.

STAGGERED

MORE THAN

ONE ROW

DRAFT

AREA 2

WITH AP

WITH AP

SPRINKLERS

WITH BB

SPRINKLERS

MINIMUM

SEPARATION

RIDGE

DRY SYSTEM SHOWN

AREA 1

WITH BB & SD

SPRINKLERS

MINIMUM

SEPARATION

WITH AP

SPRINKLERS

AREA 3

WITH AP

Page 22

TFP610

SPRINKLERS

SPRINKLERS

Page 22 of 28

FIGURE 20-B-5. BB, SD, OR HIP

SPRINKLERS AND AP SPRIN-

KLERS IN A DORMER, AT A

CROSS, AT A HIP, OR AT AN ELL

Where the quantity of AP Sprinklers

in each dormer, cross, or ell is four or

less (see the adjacent figure) and all

of the dormers, crosses and ells meet

the maximum four AP Sprinkler criteria, calculate the BB, SD, or HIP Sprinkler demand as described in Part A-1

through A-6 or Part B-1 through B-4,

plus up to two of the most demanding

AP Sprinklers in the dormer, cross, or

ell that is adjacent to the BB, SD, or HIP

Sprinklers that are being included in the

demand calculation.

Where the quantity of AP Sprinklers in

any dormer, cross, or ell is greater than

four, refer to Figure B- 3.

AP

SPRINKLERS

(4 OR LESS)

AP

SPRINKLERS

(4 OR LESS)

FIGURE 20-B-6. BB,SD, OR HIP

SPRINKLERS AND AP SPRIN-

KLERS SEPARATED BY

COMPARTMENTALIZATION

•

Wet Systems: Calculate the BB,

SD, or HIP Sprinkler demand as

described in Part A-1 through A-6 or

Part B-1 through B-4. Then calculate

the most demanding area up to

150 0 ft2 (137 m2) having AP Sprinklers. Use the most demanding

calculation. See the adjacent gure.

•

Dry Systems: Calculate the BB,

SD, or HIP Sprinkler demand as

described in Part A-1 through A-6 or

Part B-1 through B-4. Then calculate

the most demanding area up to

1950 f t2 (181 m2) having AP Sprinklers. Use the most demanding

calculation. See the adjacent gure.

AP

(4 OR LESS)

WALL

RIDGE

RIDGE

DORMER

BUILT ON TOP

OF ROOF OR

SHEATHING

AP

(4 OR LESS)

Page 23

DRY SYSTEM SHOWN

WALLS OR

CURTAINS

DRY SYSTEM SHOWN

OBSTRUCTION

FIGURE 20-C-1. SD SPRINKLERS

FIRST CALCULATION

NOTE:

Dry Pipe = 1500 SQ. FT. (NFPA Light Hazard) x 1.3 x 1.3 = 2535 SQ. FT.

AND STANDARD SPRAY SPRIN-

KLERS AT THE RIDGE

•

Wet Systems: Calculate the most

demanding ve sprinklers of one

type. Use the most demanding

calculation.

•

Dry Systems: Calculate the most

demanding nine SD Sprinklers. Then

calculate the most demanding seven

Standard Spray Sprinklers. Use the

most demanding calculation. See

the adjacent gures.

FIGURE 20-C-2. BB SPRINKLERS

AND STANDARD SPRAY SPRIN-

KLERS BEYOND AN OBSTRUCTION

•

Wet Systems: Calculate the most

demanding ve BB Sprinklers plus

up to two most demanding Standard

Spray Sprinklers.

•

Dry Systems: Calculate the most

demanding seven BB Sprinklers plus

up to two most demanding Standard

Spray Sprinklers. See the adjacent

gures.

TFP610

Page 23 of 28

RIDGE

DRAFT

RIDGE

FIGURE 20-C-3. BB SPRINKLERS

AND STANDARD SPRAY SPRIN-

KLERS AT THE HIP

Where the total number of standard

spray sprinklers at the hip is greater

than four:

•

Wet Systems: Calculate the most

demanding ve BB Sprinklers plus

up to two most demanding Standard

Spray Sprinklers. Then calculate the

most demanding remote design

area, including all sprinkler types, as

per NFPA 13. That is, area reduction

for quick response and 30%

increase for sloped ceilings. Use the

most demanding calculation.

•

Dry Systems: Calculate the most

demanding seven BB Sprinklers

plus up to two most demanding

Stand Spray Sprinklers. Then

calculate the most demanding

design area, including all sprinkler

types, as per NFPA 13. That is, 30%

increase for sloped ceilings and 30%

increase for dry systems. Include all

sprinkler types within this area. See

the adjacent gure. Use the most

demanding calculation.

RIDGE

DRY SYSTEM SHOWN

SECOND CALCULATION

RIDGE

2535 SQ. FT.

(235,5 SQ. METERS)

DRY SYSTEM SHOWN

Page 24

TFP610

NOTE:

Dry Pipe = 1500 SQ. FT. (NFPA Light Hazard) x 1.3 x 1.3 = 2535 SQ. FT.

Page 24 of 28

FIGURE 20-C-4. BB SPRINKLERS,

SD SPRINKLERS, HIP SPRIN-

KLERS, AND STANDARD SPRAY

SPRINKLERS

AT THE HIP

Where the total number of Standard