Page 1

Technical Services

800-381-9312 | +1-401-781-8220

www.tyco-fire.com

Model AMD-1 Automatic Air Maintenance Device

Pressure Reducing Type with

Field-Adjustable Pressure Regulator

General

Description

The TYCO Model AMD-1 Automatic Air

Maintenance Device is an automatic,

eld-adjustable, pressure reducing

device. It is used to control the pressure in a dry pipe sprinkler system, preaction system, or dry pilot line system

of a dry pilot actuated deluge or preaction valve.

The Model AMD-1 Device is utilized

in applications where there is a compressed air (or nitrogen) source controlled at a higher pressure than the

desired system pressure. Pressure

sources include plant air supplies with

their own automatic compressor controls or nitrogen supplies with single-stage, cylinder-mounted pressure

regulators.

The Model AMD-1 Automatic Air Maintenance Device is a re-designation for

the Central Model D-2, Gem Model

F324, and Star Model S460.

NOTICE

The Model AMD-1 Automatic Air Maintenance Devices described herein

must be installed and maintained in

compliance with this document and

with the applicable standards of the

National Fire Protection Association,

in addition to the standards of any

authorities having jurisdiction. Failure

to do so may impair the performance

of these devices.

Owners are responsible for maintaining their fire protection system and

devices in proper operating condition.

The installing contractor or sprinkler

manufacturer should be contacted

with any questions.

Technical

Data

Approvals

UL and C-UL Listed

FM Approved

NYC Approved under MEA 206-02-E

Maximum Inlet Air (or Nitrogen)

Supply Pressure

200 psi (13,8 bar)

Field-Adjustable Outlet Pressure

Range

5 to 70 psi (0,4 to 4,8 bar)

Assembly

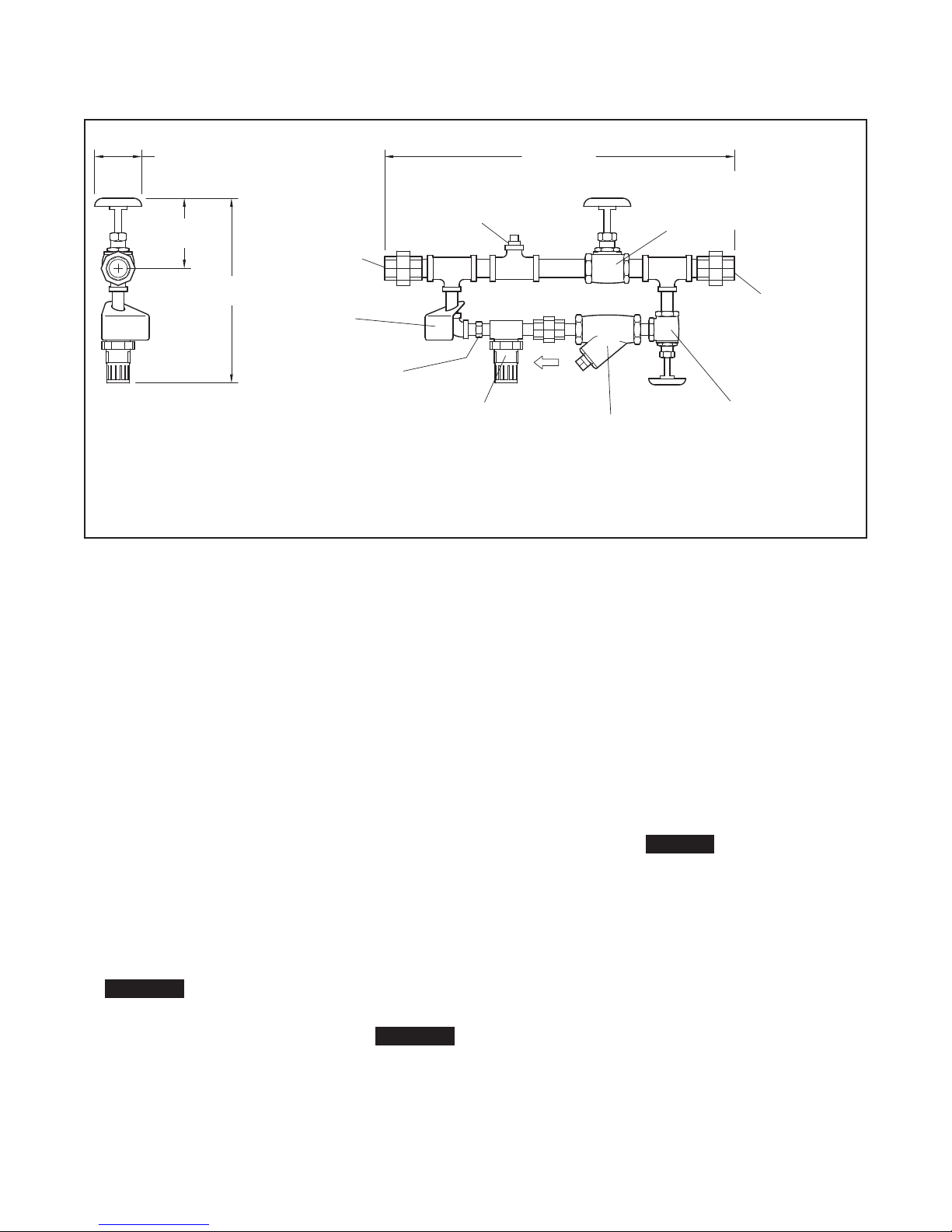

Major components illustrated in Figure

1 are factory assembled with galvanized steel nipples and malleable iron

pipe ttings.

Operation

The By-Pass Valve in the Model AMD-1

Automatic Air Maintenance Device is

opened to quickly ll the system during

initial pressurization. Once the re quired

system pressure has been reached,

the By-Pass Valve is closed and the Air

Supply Control Valve is left open to

place the Model AMD-1 Device in automatic operation.

When there is a small leak in the system, the Pressure Regulator automatically maintains system pressure at the

preset level. The 3/32 inch (2,4 mm) orice in the Restrictor Check Valve limits

the ow of air from the Pressure Regulator into the system to a value signicantly less than that exhausted by the

operation of a 5.6 K-factor sprinkler.

Installation

The TYCO Model AMD-1 Automatic Air

Maintenance Device must be installed

in accordance with the following

instructions.

NOTICE

Moisture build-up can adversely affect

performance. Suitable consideration

must be given to the removal of excessive moisture from the compressed air

supply.

1.

Make connections a minimum of

1/2 inch (DN15) pipe size between

the inlet air supply and the Model

AMD-1 Device, as well as between

the Model AMD-1 Device and the

system to pressurize.

2. Place a 1/2 inch (DN15), non-spring

loaded, rubber-faced, swing-type

check valve between the Model

AMD-1 Device and the system to

pressurize. A check valve of this

type is provided in the air supply

trim of TYCO dry pipe valves, preaction valves, and dry pilot trim.

Page 1 of 4 JULY 2010 TFP1221

Page 2

TFP1221

Page 2 of 4

2"

(50,8 mm)

3-1/4"

(82,6 mm)

8-1/2"

(215,9 mm)

1/2" NPT

OUTLET

CONNECTION

(TO SYSTEM)

LABEL

RESTRICTOR

CHECK VALVE

P/N 92-326-1-003

Setting

Procedure

The TYCO Model AMD-1 Automatic

Air Maintenance Device must be set

in accordance with the following

instructions.

1. Determine the pressure that meets

the minimum requirements of the

system to pressurize.

2. Close the Model AMD-1 By-Pass

Valve, and close the Model AMD-1

Air Supply Control Valve.

3. Open the control valve in the air

supply trim of the system to pressurize and then reduce the system

air pressure to 0 psi.

4. Close the control valve in the

air supply trim of the system to

pressurize.

5. Remove the system pressure gauge

from its connection and temporarily

install it in the 1/4 inch NPT Model

AMD-1 Gauge Test Port.

CAUTIO N

Before removing the plug, make

certain that the piping to which the

Model AMD-1 Gauge Test Port is

connected is at 0 psi. Failure to do

so may result in personal injury or

property damage.

6. Open the Air Supply Control Valve in

the Model AMD-1 Device.

16-1/8""

(409,6 mm)

1/4" NPT

GAUGE

TEST PORT

PRESSURE

REGULATOR

(ADJUSTABLE)

P/N 92-324-1-012

STRAINER

P/N 52-353-1-002

FIGURE 1

MODEL AMD-1

AUTOMATIC AIR MAINTENANCE DEVICE

7. While observing the relocated pressure gauge, adjust the output pressure of the Pressure Regulator. Pull

the knob out and away from the

Pressure Regulator body and then

slowly turn the knob clockwise, as

viewed from the knob end of the

Pressure Regulator, to increase

pressure, and counter-clockwise to

decrease pressure.

When decreasing pressure, the air

pressure must be relieved downstream of the Pressure Regulator

by temporarily opening the control

valve in the air supply trim of the

system to pressurize, assuming that

the system to pressurize is at 0 psi.

After the Pressure Regulator is set,

push the knob in and towards the

Pressure Regulator body to “snap”

it in a locked position.

8. Close the Air Supply Control Valve

in the Model AMD-1 Device.

9. Return the system air pressure

gauge to its normal location. Reinstall the 1/4 inch pipe plug in the

Model AMD-1 Gauge Test Port.

Apply pipe-thread sealant sparingly

to the plug threads only.

CAUTIO N

Before removing the pressure

gauge, make certain that the piping

to which the Model AMD-1 Gauge

Test Port is connected is at 0 psi.

Failure to do so may result in personal injury or property damage.

BY-PASS VALVE

(NORMALLY

CLOSED)

P/N 46-047-1-004

1/2" NPT

INLET CONNECTION

(FROM COMPRESSED

AIR SUPPLY)

AIR SUPPLY

CONTROL VALVE

(NORMALLY OPEN)

P/N 46-048-1-002

10. Open the control valve in the

air supply trim to the system to

pressurize.

11. Open the Air Supply Control Valve

in the Model AMD-1 Device.

12. Open the By-Pass Valve in the

Model AMD-1 Device.

13. Close the By-Pass Valve after the

system is pressurized to approximately 5 psi (0,4 bar) less than the

minimum required system pres sure

determined in Step 1.

14. After the system pressure stabilizes, note the value and compare

with the requirement. Re-adjust the

Pressure Regulator, as required.

NOTICE

If the system was over-pressurized during manual fill, open a

suitable connection to the system

and manually reduce the pressure

to the desired value. The Model

AMD-1 Automatic Air Maintenance

Device then automatically maintains

the preset system pressure. The

Restrictor Check Valve prevents

the Pressure Regulator from bleeding down the system pressure.

In order to minimize the time for

system trip in the event of a sprinkler operation, set the system pressure at the minimum required value.

Page 3

TFP1221

Page 3 of 4

Care and

Maintenance

The TYCO Model AMD-1 Automatic

Air Maintenance Device must be maintained and serviced in accordance with

the following instructions, in addition to

any specic requirements of the NFPA.

Any impairment must be immediately

corrected.

NOTICE

Before closing a fire protection system

main control valve for maintenance

work on the fire protection system

that it controls, obtain permission to

shut down the affected fire protection system from the proper authorities and notify all personnel who may

be affected by this action.

It is recommended that accumulated

moisture be removed from air supply

moisture ltration equipment at least

quarterly. More frequent inspections

may be necessary in particularly humid

environments.

After placing a re protection system

in service, notify the proper authorities

and advise those responsible for monitoring proprietary and/or central station alarms.

Responsibility lies with owners for the

inspection, testing, and maintenance of

their re protection system and devices

in compliance with this document, as

well as with the applicable standards of

the National Fire Protection Association

(for example, NFPA 25), in addition to

the standards of any other authorities

having jurisdiction. Contact the installing contractor or sprinkler manufacturer regarding any questions.

Automatic sprinkler systems are recommend to be inspected, tested, and

maintained by a qualied Inspection Service in accordance with local

requirements and/or national code.

The Model AMD-1 Device must be

inspected quarterly in accordance with

the following instructions.

1.

Verify that the By-Pass Valve is

closed.

2. Close the Model AMD-1 Air Supply

Control Valve and clean out the 1/4

inch Strainer located at the inlet to

the Restrictor Check Valve. Be sure

to reinstall the strainer screen and

tighten the cap securely.

3.

Open the Model AMD-1 Air Supply Valve and verify that the control valve in the air supply trim to the

system to pressurize is open.

4.

Verify that the system pressure is

essentially the same as the previously established requirement. If

not, adjust the system pressure as

follows:

a.

Close the system’s main control valve and open the main

drain valve. If the system is so

equipped, close the Accelerator

Control Valve.

b.

Follow Steps 1 through 14 in the

Setting Procedure section.

c.

Slowly open the Accelerator Control Valve, as applicable.

d.

Slowly open the main control

valve. After water begins to ow,

slowly close the main drain valve,

then completely open the main

control valve. The Model AMD-1

Automatic Air Maintenance

Device is now ready for service.

Limited

Warranty

Products manufactured by Tyco Fire

Suppression & Building Products

(TFSBP) are warranted solely to the

original Buyer for ten (10) years against

defects in material and workmanship

when paid for and properly installed

and maintained under normal use and

service. This warranty will expire ten

(10) years from date of shipment by

TFSBP. No warranty is given for products or components manufactured by

companies not afliated by ownership

with TFSBP or for products and components which have been subject to

misuse, improper installation, corrosion, or which have not been installed,

maintained, modied or repaired in

accordance with applicable Standards

of the National Fire Protection Association, and/or the standards of any other

Authorities Having Jurisdiction. Materials found by TFSBP to be defective

shall be either repaired or replaced, at

TFSBP’s sole option. TFSBP neither

assumes, nor authorizes any person

to assume for it, any other obligation

in connection with the sale of products or parts of products. TFSBP shall

not be responsible for sprinkler system

design errors or inaccurate or incomplete information supplied by Buyer or

Buyer’s representatives.

In no event shall TFSBP be liable, in

contract, tort, strict liability or under

any other legal theory, for incidental,

indirect, special or consequential damages, including but not limited to labor

charges, regardless of whether TFSBP

was informed about the possibility of

such damages, and in no event shall

TFSBP’s liability exceed an amount

equal to the sales price.

The foregoing warranty is made in lieu

of any and all other warranties, express

or implied, including warranties of merchantability and tness for a particular

purpose.

This limited warranty sets forth the

exclusive remedy for claims based on

failure of or defect in products, materials or components, whether the claim is

made in contract, tort, strict liability or

any other legal theory.

This warranty will apply to the full

extent permitted by law. The invalidity,

in whole or part, of any portion of this

warranty will not affect the remainder.

Ordering

Procedure

Contact your local distributor for availability. When placing an order, indicate the full product name, including

description and Part Number (P/N).

Model AMD-1 Device

Specify: Model AMD-1 Automatic Air

Maintenance Device,

P/N 52-324-2-002.

Replacement Parts

Specify: (description) for use with the

Model AMD-1 Automatic Air Maintenance Device, P/N (from Figure 1).

Page 4

TFP1221

Page 4 of 4

Copyright © 2007 - 2010 Tyco Fire Suppression & Building Products. All rights reserved.

Loading...

Loading...