Page 1

T"-HEAD* Crimping Tools

59170, 59250, 59275, 59300,

69692-1, and 69693-1

PROPER USE GUIDELINES

CumulativeTrauma Disorderscan resultfrom theprolonged useof manually poweredhand tools.Hand toolsare intendedfor occasionaluseand lowvolume

applications. A wide selection of powered application equipment for extended-use, production operations is available.

S

PIDG insulation restricting terminals with

TEFLONt coating, used on stranded copper

wire sizes 26 through 14.

S

PIDG Radiation Resistant Terminals and

Splices on stranded copper wire sizes 26

through 14.

S

PLASTI–GRIP* Terminals on solid or stranded

copper wire sizes 22 through 14.

S

PLASTI–GRIP Butt Splices on solid or

stranded copper wire sizes 26 through 22.

S

Spare Wire Caps on solid or stranded copper

wire sizes 22 through 14.

NOTE

i

Dimensions on this sheet are in millimeters [with

inch equivalent dimensions in brackets]. Figures

and illustrations are for identification only and are

not drawn to scale.

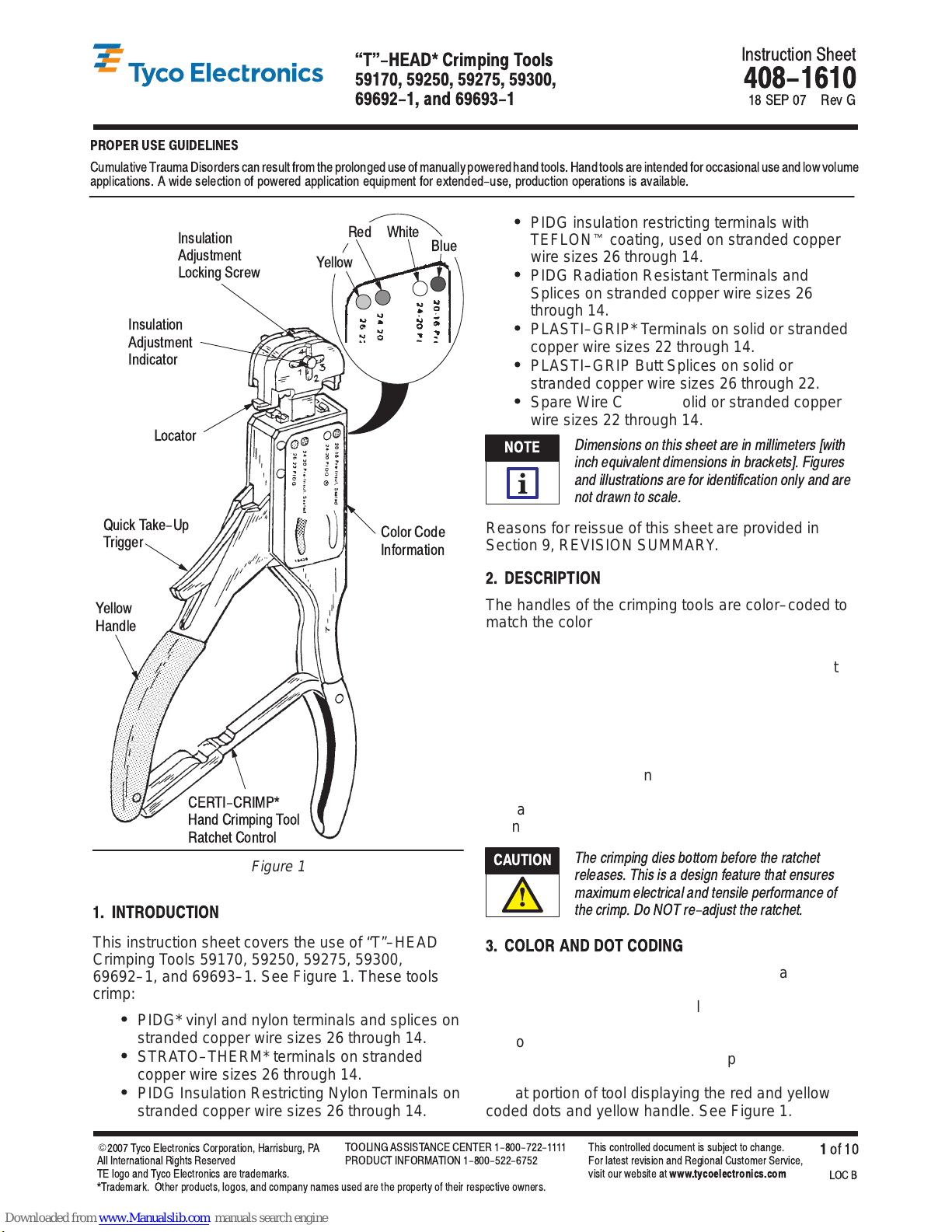

Insulation

Adjustment

Locking Screw

Insulation

Adjustment

Indicator

Locator

Yellow

Red

White

Blue

Instruction Sheet

408-1610

18 SEP 07 Rev G

Quick Take-Up

Trigger

Yellow

Handle

CERTI-CRIMP*

Hand Crimping Tool

Ratchet Control

Figure 1

Color Code

Information

1. INTRODUCTION

This instruction sheet covers the use of “T”–HEAD

Crimping Tools 59170, 59250, 59275, 59300,

69692–1, and 69693–1. See Figure 1. These tools

crimp:

S

PIDG* vinyl and nylon terminals and splices on

stranded copper wire sizes 26 through 14.

S

STRATO–THERM* terminals on stranded

copper wire sizes 26 through 14.

S

PIDG Insulation Restricting Nylon Terminals on

stranded copper wire sizes 26 through 14.

Reasons for reissue of this sheet are provided in

Section 9, REVISION SUMMARY.

2. DESCRIPTION

The handles of the crimping tools are color–coded to

match the color coding of the product to be applied.

The insulation adjustment indicator is used to control

crimp height of the insulation barrel. It can be set at

any of four positions corresponding to insulation

diameter.

Tools also feature a locator, quick take–up trigger, and

color code information.

The CERTI–CRIMP hand crimping tool ratchet control

ensures full crimping of the product. Once engaged,

the ratchet will not release until the handles have

been FULLY closed.

CAUTION

!

The crimping dies bottom before the ratchet

releases. This is a design feature that ensures

maximum electrical and tensile performance of

the crimp. Do NOT re-adjust the ratchet.

3. COLOR AND DOT CODING

Note that tool handles and terminal, splice and cap

insulation are color coded for a given wire range as

listed in Figure 2. Crimp the color coded terminal,

splice or cap in the matching color coded portion of

the tool. For example, when using Hand Tool 59275,

yellow coded PIDG terminals and splices and red

coded pre–insulated seated splices must be crimped

in that portion of tool displaying the red and yellow

coded dots and yellow handle. See Figure 1.

E

2007 TycoElectronicsCorporation,Harrisburg,PA

All International Rights Reserved

TE logo and Tyco Electronics aretrademarks.

*Trademark. Other products, logos, and company names used are the property of their respective owners.

TOOLING ASSISTANCE CENTER 1-800-722-1111

PRODUCT INFORMATION1-800-522-6752

This controlled document is subject to change.

For latest revision and Regional Customer Service,

visit our website at

www.tycoelectronics.com

1

of 10

LOC B

Page 2

T"-HEAD Crimping Tools

408-1610

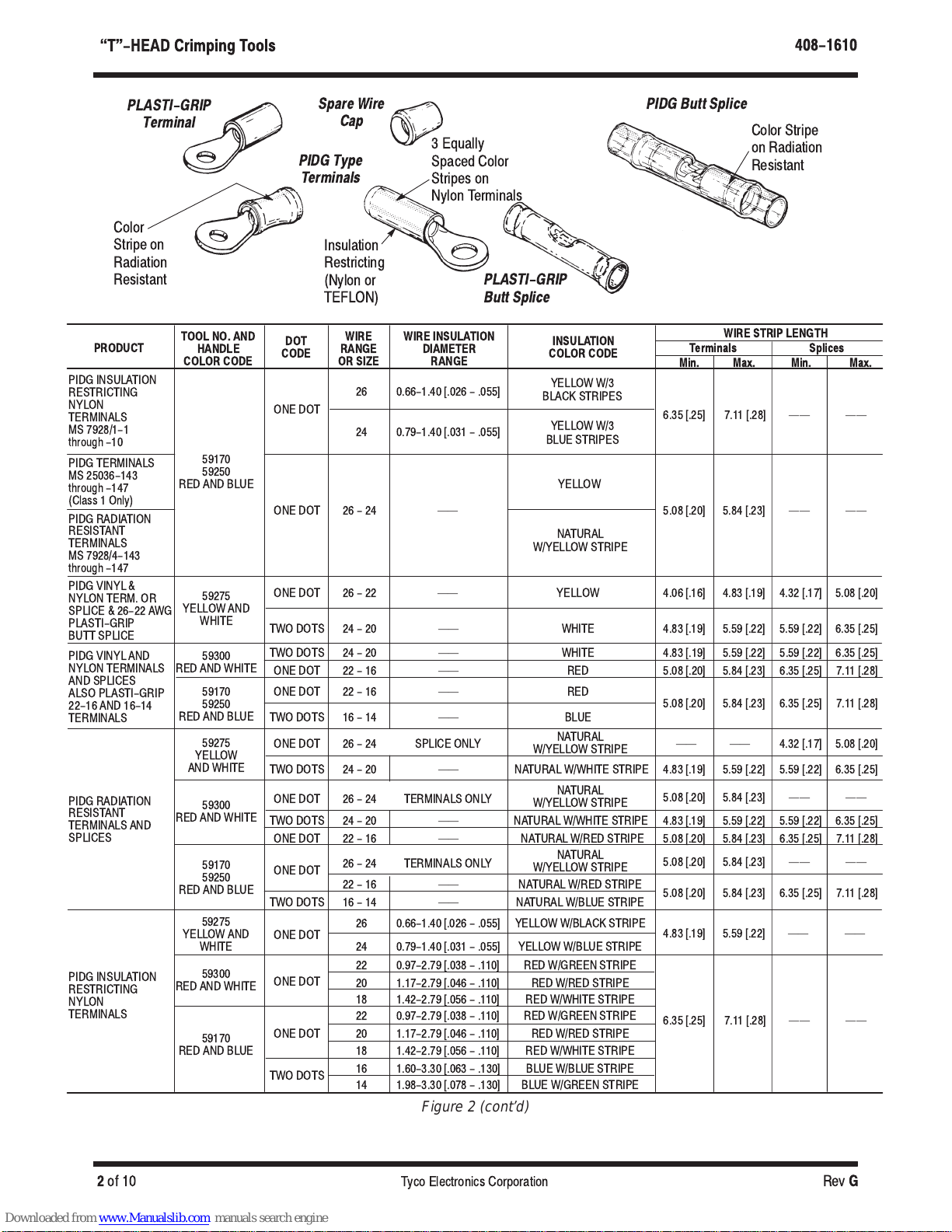

PLASTI-GRIP

Terminal

Color

Stripe on

Radiation

Resistant

PRODUCT

PIDG INSULATION

RESTRICTING

NYLON

TERMINALS

MS 7928/1-1

through -10

PIDG TERMINALS

MS 25036-143

through -147

(Class 1 Only)

PIDG RADIATION

RESISTANT

TERMINALS

MS 7928/4-143

through -147

PIDG VINYL &

NYLON TERM. OR

SPLICE & 26-22 AWG

PLASTI-GRIP

BUTT SPLICE

PIDG VINYL AND

NYLON TERMINALS

AND SPLICES

ALSO PLASTI-GRIP

22-16 AND 16-14

TERMINALS

PIDG RADIATION

RESISTANT

TERMINALS AND

SPLICES

PIDG INSULATION

RESTRICTING

NYLON

TERMINALS

TOOL NO. AND

HANDLE

COLOR CODE

59170

59250

RED AND BLUE

59275

YELLOW AND

WHITE

59300

RED AND WHITE

59170

59250

RED AND BLUE

59275

YELLOW

AND WHITE

59300

RED AND WHITE

59170

59250

RED AND BLUE

59275

YELLOW AND

WHITE

59300

RED AND WHITE

59170

RED AND BLUE

Spare Wire

Cap

PIDG Type

Terminals

3 Equally

Spaced Color

Stripes on

PIDG Butt Splice

Color Stripe

on Radiation

Resistant

Nylon Terminals

Insulation

Restricting

ĊĊ

ĊĊ

PLASTI-GRIP

Butt Splice

INSULATION

COLOR CODE

YELLOW W/3

BLACK STRIPES

YELLOW W/3

BLUE STRIPES

YELLOW

NATURAL

W/YELLOW STRIPE

YELLOW

WHITE

NATURAL

W/YELLOW STRIPE

NATURALW/WHITE STRIPE

NATURAL

W/YELLOW STRIPE

NATURAL

W/YELLOW STRIPE

YELLOW W/BLACK STRIPE

YELLOW W/BLUE STRIPE

WIRE STRIP LENGTH

Terminals Splices

Min. Max. Min. Max.

6.35 [.25] 7.11[.28] ĊĊ ĊĊ

5.08 [.20] 5.84 [.23] ĊĊ ĊĊ

4.06 [.16] 4.83 [.19] 4.32 [.17] 5.08 [.20]

4.83 [.19] 5.59 [.22] 5.59 [.22] 6.35[.25]

5.08 [.20] 5.84 [.23] 6.35 [.25] 7.11[.28]

ĊĊ ĊĊ 4.32 [.17] 5.08 [.20]

4.83 [.19] 5.59 [.22] 5.59 [.22] 6.35[.25]

5.08 [.20] 5.84 [.23] ĊĊ ĊĊ

5.08 [.20] 5.84 [.23] ĊĊ ĊĊ

5.08 [.20] 5.84 [.23] 6.35 [.25] 7.11[.28]

4.83 [.19] 5.59 [.22] ĊĊ ĊĊ

6.35 [.25] 7.11[.28] ĊĊ ĊĊ

(Nylon or

TEFLON)

DOT

CODE

ONE DOT

ONE DOT 26 - 24 ĊĊ

ONE DOT

TWO DOTS

TWO DOTS 24 - 20 ĊĊ WHITE 4.83 [.19] 5.59 [.22] 5.59 [.22] 6.35[.25]

ONE DOT 22 - 16 ĊĊ RED 5.08 [.20] 5.84 [.23] 6.35 [.25] 7.11[.28]

ONE DOT 22 - 16 ĊĊ RED

TWO DOTS 16 - 14 ĊĊ BLUE

ONE DOT 26 - 24 SPLICE ONLY

TWO DOTS 24 - 20 ĊĊ

ONE DOT 26 - 24 TERMINALS ONLY

TWO DOTS 24 - 20 ĊĊ NATURALW/WHITE STRIPE 4.83 [.19] 5.59 [.22] 5.59 [.22] 6.35[.25]

ONE DOT 22 - 16 ĊĊ NATURAL W/RED STRIPE 5.08 [.20] 5.84 [.23] 6.35 [.25] 7.11 [.28]

ONE DOT

TWO DOTS 16 - 14 ĊĊ NATURALW/BLUE STRIPE

ONE DOT

ONE DOT

ONE DOT

TWO DOTS

WIRE

RANGE

OR SIZE

26

24

26-22

24-20

26 - 24 TERMINALS ONLY

22 - 16 ĊĊ NATURALW/RED STRIPE

26

24

22 0.97-2.79 [.038 - .110] RED W/GREEN STRIPE

20 1.17-2.79 [.046 - .110] REDW/RED STRIPE

18 1.42-2.79 [.056 - .110] RED W/WHITE STRIPE

22 0.97-2.79 [.038 - .110] RED W/GREEN STRIPE

20 1.17-2.79 [.046 - .110] REDW/RED STRIPE

18 1.42-2.79 [.056 - .110] RED W/WHITE STRIPE

16 1.60-3.30 [.063 - .130] BLUE W/BLUESTRIPE

14 1.98-3.30 [.078 - .130] BLUE W/GREEN STRIPE

WIRE INSULATION

DIAMETER

RANGE

0.66-1.40 [.026 - .055]

0.79-1.40 [.031 - .055]

0.66-1.40 [.026 - .055]

0.79-1.40 [.031 - .055]

Figure 2 (cont’d)

of 10

Tyco Electronics Corporation

Rev

G2

Page 3

T"-HEAD Crimping Tools

408-1610

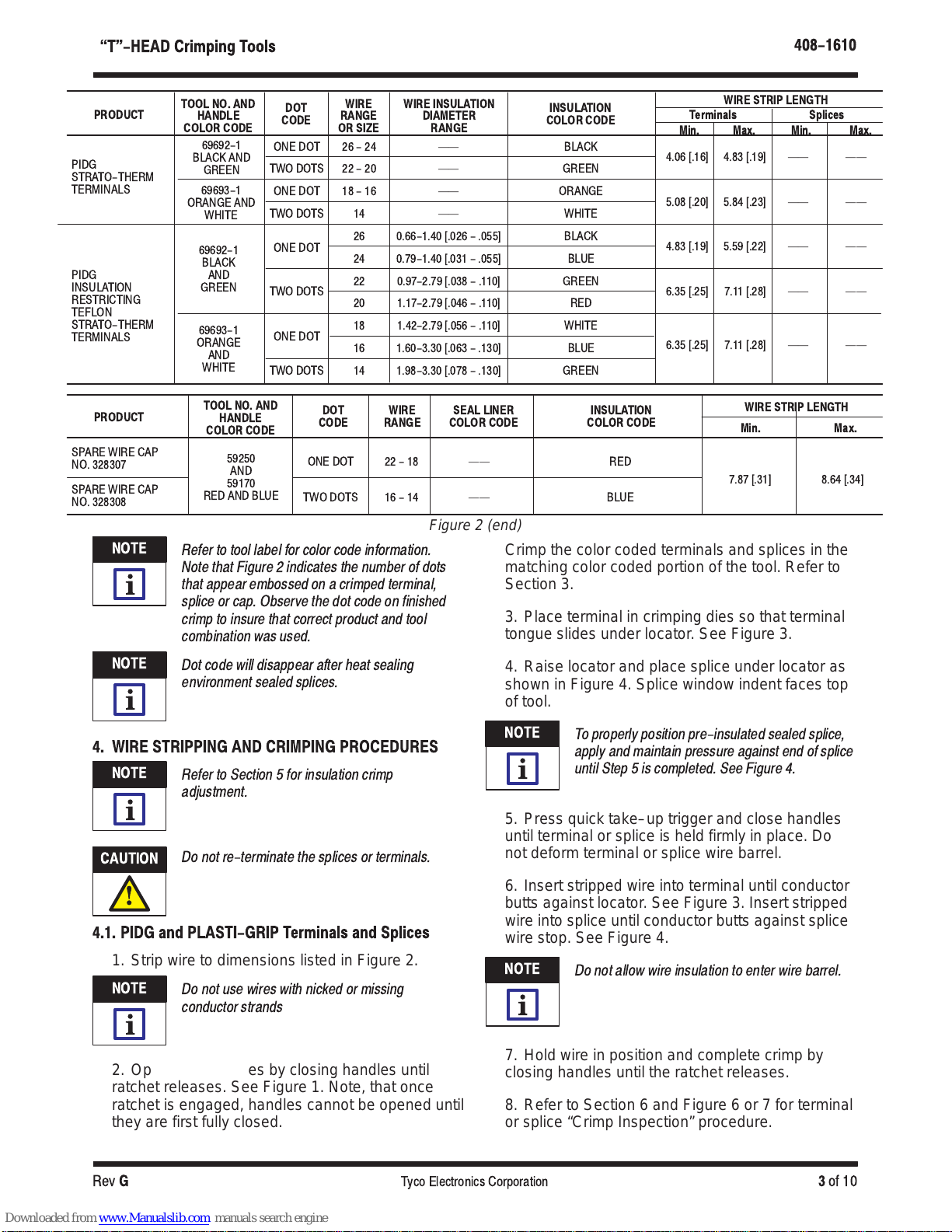

PRODUCT

PIDG

STRATO-THERM

TERMINALS

PIDG

INSULATION

RESTRICTING

TEFLON

STRATO-THERM

TERMINALS

PRODUCT

SPAREWIRE CAP

NO. 328307

SPAREWIRE CAP

NO. 328308

NOTE

i

TOOL NO. AND

HANDLE

COLOR CODE

69692-1

BLACK AND

GREEN

69693-1

ORANGE AND

WHITE

69692-1

BLACK

AND

GREEN

69693-1

ORANGE

AND

WHITE

TOOL NO. AND

HANDLE

COLOR CODE

59250

AND

59170

RED AND BLUE

DOT

CODE

ONE DOT 26 - 24 BLACKĊĊ

TWO DOTS 22 - 20 GREENĊĊ

ONE DOT 18 - 16 ORANGEĊĊ

TWO DOTS 14 WHITEĊĊ

ONE DOT

ONE DOT

TWO DOTS 14 GREEN1.98-3.30 [.078 - .130]

WIRE

RANGE

OR SIZE

26 BLACK0.66-1.40 [.026 - .055]

24 BLUE0.79-1.40 [.031 - .055]

22 GREEN0.97-2.79[.038 - .110]

20 RED1.17-2.79 [.046 - .110]

18 WHITE1.42-2.79 [.056- .110]

16 BLUE1.60-3.30 [.063 - .130]

DOT

CODE

ONE DOT 22 - 18 ĊĊ RED

TWO DOTS 16 - 14 ĊĊ BLUE

WIRE INSULATION

DIAMETER

RANGE

WIRE

RANGE

Figure 2 (end)

Refer to tool label for color code information.

Note that Figure 2 indicates the number of dots

that appear embossed on acrimped terminal,

splice or cap. Observe the dot codeon finished

crimp to insure that correct product andtool

combination was used.

SEAL LINER

COLOR CODE

Crimp the color coded terminals and splices in the

matching color coded portion of the tool. Refer to

Section 3.

3. Place terminal in crimping dies so that terminal

tongue slides under locator. See Figure 3.

INSULATION

COLOR CODE

INSULATION

COLOR CODE

WIRE STRIP LENGTH

Terminals Splices

Min. Max. Min. Max.

4.06 [.16] 4.83 [.19] ĊĊ ĊĊ

5.08 [.20] 5.84 [.23] ĊĊ ĊĊ

4.83 [.19] 5.59 [.22] ĊĊ ĊĊ

6.35 [.25] 7.11[.28] ĊĊ ĊĊTWO DOTS

6.35 [.25] 7.11[.28] ĊĊ ĊĊ

WIRE STRIP LENGTH

Min. Max.

7.87 [.31] 8.64 [.34]

NOTE

Dot code will disappear after heat sealing

environment sealed splices.

i

4. WIRE STRIPPING AND CRIMPING PROCEDURES

NOTE

Refer to Section 5 for insulation crimp

adjustment.

i

CAUTION

!

4.1. PIDG and PLASTI-GRIP Terminals and Splices

1. Strip wire to dimensions listed in Figure 2.

NOTE

Do not re-terminate the splices or terminals.

Do not use wires with nicked or missing

conductor strands

i

2. Open crimping dies by closing handles until

ratchet releases. See Figure 1. Note, that once

ratchet is engaged, handles cannot be opened until

they are first fully closed.

4. Raise locator and place splice under locator as

shown in Figure 4. Splice window indent faces top

of tool.

NOTE

To properly position pre-insulated sealed splice,

apply and maintain pressure against end of splice

i

until Step 5 is completed. See Figure 4.

5. Press quick take–up trigger and close handles

until terminal or splice is held firmly in place. Do

not deform terminal or splice wire barrel.

6. Insert stripped wire into terminal until conductor

butts against locator. See Figure 3. Insert stripped

wire into splice until conductor butts against splice

wire stop. See Figure 4.

NOTE

Do not allow wire insulation to enterwire barrel.

i

7. Hold wire in position and complete crimp by

closing handles until the ratchet releases.

8. Refer to Section 6 and Figure 6 or 7 for terminal

or splice “Crimp Inspection” procedure.

G

Tyco Electronics Corporation

3

of 10Rev

Page 4

T"-HEAD Crimping Tools

408-1610

PIDG and PLASTI-GRIP Terminals

C" B" C" B"

C" B"

Terminal Barrel

Rests Against

Locator

Conductor Butts

Against Locator

Terminal Tongue

Slides Under

Locator

Environmental

Sealed Splice

C" B"

B" Equals Wire Barrel

C" Equals Insulation Barrel

First

Crimp

Window Indent

Faces Top of

Tool

Window

Indent

Wire Stop

PIDG

Terminal

PLASTI-GRIP

Terminal

B" Equals Wire Barrel

C" Equals Insulation Barrel

Figure 3

BUTT Splices

PIDG

PLASTI-GRIP

C" B"

PIDG Insulation

C" B"

Restricting

Window

Indent

Wire Stop

Window

Indent

Wire Stop

4.2. Spare Wire Caps

1. Strip wire to dimensions listed in Figure 2. Crimp

the color coded portion of the tool. Refer to

Section 3.

NOTE

Do not use wire with nicked ormissing conductor

strands.

i

2. Place tool insulation adjustment indicator in

Position 4.

3. Close tool handles until crimping jaws partially

close, but leave enough space for cap to be

inserted between dies.

4. Raise locator so that end of cap rests against

the recessed surface of the locator as shown in

Figure 5.

Spare Wire Caps

Insulation

Adjustment

Indicator at

Position 4

Wire

Barrel

Locator

Raise Locator so

that End of Cap Rests

Against Recessed

Surface of Locator

Figure 5

Conductor Butts

Against Wire Stop

Second

Crimp

Window Indent

Faces Top of Tool

Figure 4

of 10

5. Squeeze quick take–up trigger and close

handles until cap is held firmly in place. Do not

deform cap wire barrel.

6. Insert stripped wire into cap until conductor

bottoms in cap.

7. Hold wire in position and complete crimp by

closing handles until the ratchet releases. Handles

will open automatically and crimped cap may be

removed.

8. Refer to Section 6 and Figure 7 wire cap crimp

inspection procedure.

Tyco Electronics Corporation

Rev

G4

Page 5

T"-HEAD Crimping Tools

408-1610

Accept Reject

A Dot Code (1 or 2 Dots) Must

1

2 6

Appear on All Crimped Items

1

5

2

5

PIDG &

3

8

4

5

PLASTI-GRIP

8

7

4

Terminals

353837

3

PIDG

Butt Splice

Wire

Stop

6

3

4

6

2

1

Wire Barrel Dies Crimped

Splice Insulation

3

8

5

2

1

1

Insulation barrel is in firm contact with wire insulation.

2

Correct color code, dot code, and tool combination.

Wire size is within wire range stamped under terminal

3

tongue or on center of splice.

4

Crimp centered on wire barrel.

End of conductor is flush with, or extends beyond end

5

of terminal wire barrel.

End of conductor against wire stop of splice, or at least

6

flush with, or extended slightly beyond wire barrel.

7

Wire insulation does not enter wire barrel.

8

No nicked or missing conductor strands.

5. INSULATION CRIMP ADJUSTMENT

5.1. PIDG Terminals and Splices

NOTE

PIDG terminals and splices feature a wire

insulation grip".

i

Each tool has four insulation crimp positions. See

Figure 1.

1

2

3

4

5

6

7

8

9

Figure 6

6

Wire insulation extruded. (Insulation crimp too tight on PIDG

terminals and splices) See Section 5.

Wrong dot code and color code combination. See Figure 2.

Wire size is not within wire range stamped on terminal

tongue or splice.

Crimp not centered on wire barrel. (Terminal was not butted

against locator. See Figure 3.)

End of conductor is not flush with or extending beyond end

of wire barrel. (Check for correct strip length.)

Excessive flash or extruded insulation, (wrong tool,

terminal, or splice combination, or damaged dies).

Wire insulation entered wire barrel.

Nicked or missing conductor strands.

Splice was reversed in dies (tool’s locator was not seated in

window indent of splice).

1. Loosen insulation adjustment locking screw (see

top of tool) and turn indicator to Position 4.

2. Place terminal or splice in tool dies.

3. Insert UNSTRIPPED wire into ONLY the

insulation barrel (see Figure 3 or 4) of terminal or

splice.

4. Perform a crimp (Section 4). Remove crimped

terminal or splice and check insulation grip as

follows: Bend the wire back and forth once.

Terminal or splice should retain grip on wire

insulation.

G

Tyco Electronics Corporation

5

of 10Rev

Page 6

T"-HEAD Crimping Tools

408-1610

Accept Reject

A Dot Code (1 or 2 Dots) Must

Appear on All Crimped Items

1

5

2

11

9

4

7

2

1

No flash or extruded insulation.

Correct color code, dot code, and tool combination.

2

Dot coding disappears on sealed splices when they

are heat sealed.

3

Correct wire size used.

4

Wire insulation does not enter wire barrel of splice.

End of conductor against wire stop of splice, or at least

5

flush with, or extended slightly beyond wire barrel.

6

End of conductor bottomed in cap.

7

Full width of crimp is over wire barrel.

8

No nicked or missing conductor strands.

9

Crimp centered on wire barrel.

10

Splice insulation is in contact with wire insulation.

8

1

4 8 6

5

3

Wire Stop

3

PLASTI-GRIP

Butt Splice

Spare Wire Cap

1

2

3

4

5

6

7

8

9

10

11

7

Excessive flash or extended insulation. (Crimped in

smaller dies on wrong side of tool.) Also, check for

damaged dies.

Wrong dot code and color code combination. See Figure 2.

Incorrect wire size used.

Wire insulation entered wire barrel.

End of conductor is not flush with or extending beyond

end of wire barrel. (Check strip length.)

End of conductor not bottomed in cap.

Half of crimp off end of wire barrel (Cap was not bottomed

in recess of locator.)

Nicked or missing conductor strands.

Crimp not centered on wire barrel. (Tool locator not

seated in window indent.)

Splice insulation is not in contact with wire insulation.

1

2

5

9

8

4

5

1

6

8

2

3

3

5. If wire pulls out, set insulation adjustment

indicator to next tighter position — Position 3.

6. Perform a crimp and repeat adjustment as

necessary until desired insulation grip is obtained.

Do not use a tighter setting than required.

7. Tighten insulation adjustment locking screw (see

top of tool).

of 10

Figure 7

5.2. PLASTI-GRIP Terminals and Splices

NOTE

i

1. Set insulation adjustment indicator in Position 4

for wire having a large insulation diameter.

2. Set insulation adjustment indicator in Position 3

for wire having a medium insulation diameter.

Tyco Electronics Corporation

PLASTI-GRIP terminals and splices feature a

wire insulation support" only.

Rev

G6

Page 7

T"-HEAD Crimping Tools

408-1610

3. Set insulation adjustment indicator in Position 2

for wire having a small insulation diameter.

4. Set insulation adjustment indicator in Position 1

for wire having thin wall insulation. Terminal or

splice insulation should ideally be in contact with

wire insulation.

6. CRIMP INSPECTION

Inspect crimped terminals, splices and spare wire

caps by checking the features described in Figure 6

or 7.

Use only the crimped items that meet the conditions

shown in the ACCEPT column.

REJECT terminals, splices, and spare wire caps can

be avoided through careful use of instructions and by

performing regular tool maintenance as instructed in

this document.

NOTE

i

Locators in Crimping Tools69692-1 and

69693-1 are locked in the down position. Refer

to Instruction Sheet 408-7424 forcrimp height

inspection of these tools.

7. MAINTENANCE AND INSPECTION

NOTE

Make certain the degreasing compounddoes not

attack paint or plastic materials.

i

Remove remaining degreasing compound with a lint

free cloth. When degreasing compounds are not

available, tool may be wiped clean with a lint free

cloth. Relubricate tool, as instructed in Paragraph 7.3

before placing it back in service.

7.2. Visual Inspection

1. Visually inspect the tool for missing parts, then

operate the tool and note the return action of the

spring–loaded handles. If parts are missing or

defective, refer to Figure 12 for customer

replaceable parts.

2. Visually inspect the die closure surfaces for

flattened, broken, pitted, or chipped conditions.

Although dies may gage within permissible limits,

worn or damaged die closure surfaces are

objectionable and can affect the quality of the

crimp. Examples of possible damaged die closure

surfaces are shown in Figure 8.

Flattened

Broken Corner

Tyco Electronics recommends that a

maintenance/inspection program be performed

periodically to ensure dependable and uniform

terminations. Tools should be inspected at least once

a month. Frequency of inspection may be adjusted to

suit your requirements through experience.

Frequency of inspection is dependent upon:

1. The care, amount of use, and handling of the

tool.

2. The type and size of the products crimped.

3. The degree of operator skill.

4. The presence of abnormal amounts of dust and

dirt.

5. Your own established standards.

All tools are inspected before packaging. Since there

is a possibility of tool damage in shipment, new tools

should be inspected in accordance with Section 7

when received in your plant. Due to the precision

design,

it is important that no parts of these tools be

interchanged except those replacement parts listed in

Figure 12.

7.1. Cleaning

The tool should be immersed (handles partially

closed) in degreasing compound to remove

accumulated dirt, grease, and foreign matter.

Chipped

Edge

Figure 8

Pitted

7.3. Lubrication

Lubricate all pins, pivot points, and bearing surfaces

with SAE 20 motor oil as follows:

Tools used in daily production—Lubricate daily

Tools used daily (occasional)—Lubricate weekly

Tools used weekly—Lubricate monthly

Wipe excess oil from tool, particularly from crimping

area. Oil transferred from the crimping area onto

certain terminations may affect the electrical

characteristics of an application.

G

Tyco Electronics Corporation

7

of 10Rev

Page 8

T"-HEAD Crimping Tools

408-1610

7.4. Gaging the Crimping Chamber

Each tool is inspected for proper die closures before

packaging. An inspection should be performed

periodically to check the tool die closures for

excessive wear.

NOTE

i

This inspection requires the use of plug gages

conforming to the dimensions listed in Figures 9 and

10. Tyco Electronics does not manufacture or market

these gages.

To gage the crimping area(s), refer to Figure 11 and

proceed as follows:

1. Clean oil or dirt from the crimping chamber and

plug gage.

2. Close handles of tool until wire barrel dies are

bottomed. Do not apply additional pressure to tool

handles.

3. With wire barrel dies bottomed, inspect the wire

barrel crimping chamber using the proper plug

gage. Lift the spring–loaded locator up and hold

gage in straight alignment with the crimping

chamber. Carefully try to insert, without forcing, the

GO element. See Figure 11, Detail A. The GO

element must pass completely through the

crimping area.

4. Try to insert the NO–GO element. The NO–GO

element may enter partially, but must not pass

completely through the crimping area.

5. Set insulation adjustment indicator in Position 1.

Measure both insulation crimping chambers with

the proper GO plug gages in the same manner as

Steps 2 and 3. See Figure 11, Detail B.

The following plug gaging informationfor

insulation crimping chambers is provided for

customers specifically requiringthis information.

If plug gaging is not required, inspectthe die

closures using an alternate procedure,i.e.,

performing the Insulation Crimp Adjustment"

(see Section 5) and VisualInspection" (see

Paragraph 7.2).

crimping areas do not conform to the inspection, the

tool must be repaired. Refer to Section 8,

REPLACEMENT AND REP AIR.

7.5. Ratchet Control Inspection

Obtain a .025–mm [.001–in.] shim that is suitable for

checking the clearance between the bottoming

surfaces of the crimping dies. To inspect the

CERTI–CRIMP hand crimping tool ratchet control:

1. Perform a crimp using the largest wire size for

your tool.

2. While holding the wire in place, squeeze the tool

handles together until the ratchet releases. Hold

the tool in this position, maintaining just enough

pressure to keep the dies closed.

3. Check the clearance between the bottoming

surfaces of the crimping dies. If the clearance is

.025 [.001] or less, the ratchet is satisfactory. If

clearance exceeds .025 [.001], the ratchet is out of

adjustment, and must be repaired. Refer to Section

8, REPLACEMENT AND REP AIR. If the tool

conforms to these inspection procedures, lubricate

it with a THIN coat of any good SAE 20 motor oil

and return it to service.

8. REPLACEMENT AND REPAIR

Replacement parts are listed in Figure 12. Parts other

than those listed in Figure 12 should be replaced by

Tyco Electronics to ensure quality and reliability of the

tool. Order replacement parts through your Tyco

Electronics Representative, or call 1–800–526–5142,

or send a facsimile of your purchase order to

1–717–986–7605, or write to:

CUSTOMER SERVICE (38–35)

TYCO ELECTRONICS CORPORA TION

P.O. BOX 3608

HARRISBURG, P A 17105–3608

For tool repair service, please contact a Tyco

Electronics Representative at 1–800–526–5136.

6. Set insulation adjustment indicator in Position 4.

Measure both insulation crimping chambers with

the proper NO–GO plug gages in the same

manner as Steps 2 and 4. See Figure 11, Detail B.

If the crimping areas conform to the gage inspection,

the tool is considered dimensionally correct. If the

of 10

9. REVISION SUMMAR Y

Since the previous release of this sheet, the following

changes were made:

S

Updated document to corporate requirements

S

Added NOTE to Figure 12

Tyco Electronics Corporation

Rev

G8

Page 9

T"-HEAD Crimping Tools

59170 and 59250

59275

59300

59170 and 59250

3.18 [.125]

59275

0.762-0.770 [.0300-.0303]

2.029-2.032 [.0799-.0800]

2.36 [.093]

59300

0.762-0.770 [.0300-.0303]

2.791-2.794 [.1099-.1100]

3.18 [.125]

TOOL

WIRE SIZE

SOLDER SLUG

WIDTH

69692-1

69693-1

408-1610

Suggested Plug Gage Design - Wire Barrel Crimping Chamber

Die Closure

Configuration

TOOL WIRE SIZE

NUMBER AWG

22-16 2.769 - 2.776 [.1090 - .1093] 2.918 - 2.921 [.1149 - .1150]

16-14 3.023 - 3.030 [.1190 - .1193] 3.172 - 3.175 [.1249 - .1250]

26-22 1.600 - 1.608 [.0630 - .0633] 1.750 - 1.753 [.0689 - .0690]

24-20 2.261 - 2.268 [.0890 - .0893] 2.410 - 2.413 [.0949 - .0950]

24-20 2.261 - 2.268 [.0890 - .0893] 2.410 - 2.413 [.0949 - .0950]

22-16 2.769 - 2.776 [.1090 - .1093] 2.918 - 2.921 [.1149 - .1150]

Use solder slug and crimp height comparator. (Reference 408-7424)

TOOL

NUMBER

69692-1

69693-1

WIRE SIZE

AWG

26-24 2.34 + 0.05 [.092 + .002] 1/8 Diameter

22-20 2.69 + 0.05 [.106 + .002] 1/8 Diameter

18-16 3.35 + 0.05 [.132 + .002] #18 - 1/8 Dia. #16 - 3/16 Dia.

14 3.86 + 0.05 [.152 + .002] 3/16 Diameter

50.8 [2.00] Min. Typ.

GO NO-GO

SOLDER SLUG

CRIMP HEIGHT

Figure 9

NO-GO Dim.GO Dim.

B" Dia.B" Dia.

GAGE ELEMENT DIMENSION B"

SOLDER SLUG

DIAMETER REFERENCE

Die Closure

Configuration

TOOL WIRE SIZE

NUMBER AWG

NO.

AWG

26-24 0.635 [.0250] 1.905 [.0750] 1/8 Diameter 2.36 [.093]

22-20 0.889 [.0350] 2.159 [.0850] 1/8 Diameter 2.36 [.093]

18-16 O.762 [.0300] 2.794 [.1100] #18 - 1/8 Dia. #16 - 3/16 Dia. 3.18 [.125]

14 1.016 [.0400] 3.048 [.1200] 3/16 Diameter 3.18 [.125]

Set Insulation Adj. Indicator

Suggested Plug Gage Design - Insulation Crimping Chamber

GO Dim.

D"

D"

GO NO-GO

C"

GAGE ELEMENT DIMENSION D"

GO NO-GO

22-16 0.762 - 0.770 [.0300 - .0303] 2.791 - 2.794 [.1099 - .1100]

16-14 1.016 - 1.024 [.0400 - .0403] 3.045 - 3.048 [.1199 - .1200]

26-22

24-20

24-20

22-16

Use solder slug and crimp height comparator. (Reference 408-7424)

DIE CLOSURE DIM'S. C"

Set Insulation Adj. Indicator

at No. 1 Posn (GO)

at No. 4 Posn (NO-GO)

6.35 [.250] Typ.

DIAMETER REFERENCE

Figure 10

NO-GO Dim.

W"

WIDTH

W" (Max.)

W" (MAX.)

G

Tyco Electronics Corporation

9

of 10Rev

Page 10

T"-HEAD Crimping Tools

408-1610

Inspection of Wire Barrel

Crimping Dies

Detail A Detail B

Wire Barrel

Dies are

Bottomed

But Not Under

Pressure

GO gage must pass completely

through the die closure.

Inspection of Insulation

Crimping Dies

Insulation

Adjustment

Indicator

Insulation

Adjustment

Indicator in

Position 1

GO gage must pass completely

through the die closure.

Insulation

Adjustment

Indicator in

Position 4

NO-GO gage may enter partially, but must not

pass completely through the dieclosure.

(With Handles Closed)

Approx. Dim.

73.03 [2.875] (Short Handle)

73.03 [2.875] (Long Handle)

Figure 11

Approx.

203.2 [8.00] (Short Handle)

244.48 [9.625] (Long Handle)

NO-GO gage may enter partially, but must not

pass completely through the dieclosure.

NOTE

Some tools require the

removal of the locator

i

to gage the tool.

1

2

ITEM DESCRIPTION 59170SHORT HANDLE

59250 LONG HANDLE

1 Support, Locator ĊĊ ĊĊ 59755-1 59755-2 1

2 Screw ĊĊ ĊĊ 1-21002-3 1-21002-3 2

of 10

TOOL NUMBERS AND REPLACEMENT PART NUMBERS

59275 SHORT HANDLE

59300 LONG HANDLE

69692-1

LONG HANDLE

Figure 12

Tyco Electronics Corporation

69693-1

LONG HANDLE

QTY PER

ASSY

Rev

G10

Loading...

Loading...