Page 1

PLASMA

CUTTING TORCH

• Model PCH-62 Hand Torch

• Model PCM-62 Machine Torch

Instruction Manual

January 28, 2004 Manual No. 0-2817

Page 2

Page 3

WARNINGS

Read and understand this entire Manual and your employer’s safety practices before installing, operating, or servicing the equipment.

While the information contained in this Manual represents the Manufacturer's best judgement, the

Manufacturer assumes no liability for its use.

Plasma Cutting T o rc h

Model PCH-62 & PCM-62

Instruction Manual Number 0-2817

Published by

Thermal Dynamics Corporation

82 Benning Street

West Lebanon, New Hampshire, USA 03784

(603) 298-5711

www.thermal-dynamics.com

Copyright 2000 by

Thermal Dynamics Corporation

All rights reserved

Reproduction of this work, in whole or in part, without written permission of the publisher is prohibited.

The publisher does not assume and hereby disclaims any liability to any party for any

loss or damage caused by errors or omissions in this Manual, whether such errors r esult

from negligence, accident, or any other cause.

Printed in the United States of America

Publication Date: January 28, 2004

Record the following information for W arranty purposes:

Where Purchased: _______________________________________

Purchase Date: _______________________________________

Power Supply Serial #: _______________________________________

Torch Serial #: _______________________________________

Page 4

TABLE OF CONTENTS

SECTION 1:

GENERAL INFORMATION ............................................................................................... 1-1

1.01 Notes, Cautions and W arnings ..................................................................... 1-1

1.02 Important Safety Precautions ....................................................................... 1-1

1.03 Publications.................................................................................................. 1-2

1.07 Declaration of Conformity ............................................................................. 1-4

SECTION 2:

INTRODUCTION .............................................................................................................. 2-1

2.01 Scope of Manual .......................................................................................... 2-1

2.02 General Description ..................................................................................... 2-1

2.03 Specifications & Design Features................................................................. 2-1

2.04 Options And Accessories ............................................................................. 2-2

2.05 Introduction to Plasma.................................................................................. 2-2

SECTION 3:

INSTALLATION ................................................................................................................. 3-1

3.01 Introduction .................................................................................................. 3-1

3.02 Site Location ................................................................................................ 3-1

3.03 Unpacking .................................................................................................... 3-1

3.04 Setting Up Hand Torch ................................................................................. 3-1

3.05 Setting Up Machine Torch ............................................................................ 3-1

3.06 Connecting Torch ......................................................................................... 3-2

3.07 Gas Connection ........................................................................................... 3-4

SECTION 4:

OPERATION ..................................................................................................................... 4-1

4.01 Introduction .................................................................................................. 4-1

4.02 Functional Overview..................................................................................... 4-1

4.03 Getting Started............................................................................................. 4-1

4.04 Torch Parts Selection ................................................................................... 4-2

4.05 Cut Quality ................................................................................................... 4-2

4.06 General Cutting Information ......................................................................... 4-3

4.07 Hand Torch Operation .................................................................................. 4-4

4.08 Machine Torch Oper ation ............................................................................. 4-5

4.09 Recommended Cutting Speeds.................................................................... 4-6

4.10 Gouging ....................................................................................................... 4-7

Page 5

TABLE OF CONTENTS (continued)

SECTION 5:

SERVICE .......................................................................................................................... 5-1

5.01 Introduction .................................................................................................. 5-1

5.02 General Torch Maintenance ......................................................................... 5-1

5.03 Common Operating Faults ........................................................................... 5-2

5.04 Inspection and Replacement Consumable Torch Parts ................................ 5-2

5.05 Troubleshooting Guide ................................................................................. 5-3

5.06 T orch & Leads Troubleshooting .................................................................... 5-4

5.07 Servicing Hand Torch (PCH) Components ................................................... 5-6

5.08 Servicing Machine Torch (PCM) Components.............................................. 5-9

SECTION 6:

PARTS LISTS.................................................................................................................... 6-1

6.01 Introduction .................................................................................................. 6-1

6.02 Ordering Information .................................................................................... 6-1

6.03 Replacement Hand Torch Parts (Ergonomic Handle) ................................... 6-2

6.04 Replacement Machine Torch Parts ............................................................... 6-4

6.05 Replacement Torch Lead Parts ................................................................... 6-6

6.06 Complete Torch & Leads Assembly Replacement ........................................ 6-7

6.07 Options and Accessories .............................................................................6-8

6.08 T orch Spare P a rts Kits ................................................................................. 6-9

APPENDIX 1: TYPICAL SYSTEM SEQ UENCE OF OPERATION BLOCK DIAGRAMS ...........A-1

For CutMaster 50 Applications .............................................................................A-1

For P akMaster 50XL Plus Applications.................................................................A-2

APPENDIX 2: TORCH CONTROL CABLE WIRING DIAGRAM

FOR MECHANIZED SYSTEMS........................................................................................ A-3

APPENDIX 3: GENERAL APPLICATION NOTES..................................................................... A-4

APPENDIX 4: CUTMASTER 50 APPLICATION........................................................................A-6

APPENDIX 5: PAKMASTER 50XL PLUS APPLICATION.......................................................... A-8

APPENDIX 6: CE PAKMASTER 50XL PLUS APPLICATION..................................................A-10

APPENDIX 7: HAND TORCH CONNECTION .........................................................................A-12

Page 6

Page 7

SECTION 1:

GENERAL INFORMATION

1.01 Notes, Cautions and Warnings

Throughout this manual, notes, cautions, and warnings

are used to highlight important information. These highlights are categorized as follows:

NOTE

An operation, procedure, or background information which requires additional emphasis or is helpful in efficient operation of the system.

CAUTION

A procedure which, if not properly followed, may

cause damage to the equipment.

WARNING

A procedure which, if not properly followed, may

cause injury to the operator or others in the operating area.

1.02 Important Safety Precautions

WARNINGS

OPERATION AND MAINTENANCE OF

PLASMA ARC EQUIPMENT CAN BE DANGEROUS AND HAZARDOUS TO YOUR

HEALTH.

Plasma arc cutting produces intense electric and

magnetic emissions that may interfere with the

proper function of cardiac pacemakers, hearing aids,

or other electronic health equipment. Persons who

work near plasma arc cutting applications should

consult their medical health professional and the

manufacturer of the health equipment to determine

whether a hazard exists.

To prevent possible injury, read, understand and

follow all warnings, safety precautions and instructions before using the equipment. Call 1-603-2985711 or your local distributor if you have any questions.

GASES AND FUMES

Gases and fumes produced during the plasma cutting

process can be dangerous and hazardous to your health.

• Keep all fumes and gases from the breathing area.

Keep your head out of the welding fume plume.

• Use an air-supplied respirator if ventilation is not

adequate to remove all fumes and gases.

• The kinds of fumes and gases from the plasma arc

depend on the kind of metal being used, coatings

on the metal, and the different processes. Y ou must

be very careful when cutting or welding any metals which may contain one or more of the following:

Antimony Chromium Mercury

Arsenic Cobalt Nickel

Barium Copper Selenium

Beryllium Lead Silver

Cadmium Manganese Vanadium

• Always read the Material Safety Data Sheets

(MSDS) that should be supplied with the material

you are using. These MSDSs will give you the information regarding the kind and amount of fumes

and gases that may be dangerous to your health.

• For information on how to test for fumes and gases

in your workplace, refer to item 1 in Subsection 1.03,

Publications in this manual.

• Use special equipment, such as water or down draft

cutting tables, to capture fumes and gases.

• Do not use the plasma torch in an area where combustible or explosive gases or materials are located.

• Phosgene, a toxic gas, is generated from the vapors

of chlorinated solvents and cleansers. Remove all

sources of these vapors.

• This product, when used for welding or cutting, produces fumes or gases which contain chemicals

known to the State of California to cause birth defects and, in some cases, cancer . (California Health

& Safety Code Sec. 25249.5 et seq.)

ELECTRIC SHOCK

Electric Shock can injure or kill. The plasma arc process

uses and produces high voltage electrical energy. This

electric energy can cause severe or fatal shock to the operator or others in the workplace.

• Never touch any parts that are electrically “live” or

“hot.”

May 14, 2002 1-1 GENERAL INFORMATION

Page 8

• Wear dry gloves and clothing. Insulate yourself

from the work piece or other parts of the welding

circuit.

• Repair or replace all worn or damaged parts.

• Extra care must be taken when the workplace is

moist or damp.

• Install and maintain equipment according to NEC

code, refer to item 9 in Subsection 1.03, Publications.

• Disconnect power source before performing any service or repairs.

• Read and follow all the instructions in the Operating Manual.

FIRE AND EXPLOSION

Fire and explosion can be caused by hot slag, sparks, or

the plasma arc.

• Be sure there is no combustible or flammable material in the workplace. Any material that cannot be

removed must be protected.

• Ventilate all flammable or explosive vapors from

the workplace.

• Do not cut or weld on containers that may have held

combustibles.

• Provide a fire watch when working in an ar ea where

fire hazards may exist.

• Hydrogen gas may be formed and trapped under

aluminum workpieces when they are cut underwater or while using a water table. DO NOT cut alu-

minum alloys underwater or on a water table unless the hydrogen gas can be eliminated or

dissipated. Trapped hydrogen gas that is ignited

will cause an explosion.

NOISE

Noise can cause permanent hearing loss. Plasma arc processes can cause noise levels to exceed safe limits. You

must protect your ears from loud noise to prevent permanent loss of hearing.

• To protect your hearing from loud noise, wear pr otective ear plugs and/or ear muffs. Protect others

in the workplace.

• Noise levels should be measured to be sure the decibels (sound) do not exceed safe levels.

• For information on how to test for noise, see item 1

in Subsection 1.03, Publications, in this manual.

PLASMA ARC RAYS

Plasma Arc Rays can injure your eyes and burn your skin.

The plasma arc process produces very bright ultra violet

and infra red light. These arc rays will damage your eyes

and burn your skin if you are not properly protected.

• To protect your eyes, always wear a welding helmet or shield. Also always wear safety glasses with

side shields, goggles or other protective eye wear.

• Wear welding gloves and suitable clothing to protect your skin from the arc rays and sparks.

• Keep helmet and safety glasses in good condition.

Replace lenses when cracked, chipped or dirty.

• Protect others in the work area from the arc rays.

Use protective booths, screens or shields.

• Use the shade of lens as suggested in the following

per ANSI/ASC Z49.1:

Minimum Protective Suggested

Arc Current Shade No. Shade No.

Less Than 300* 8 9

300 - 400* 9 12

400 - 800* 10 14

* These values apply where the actual arc is clearly

seen. Experience has shown that lighter filters may

be used when the arc is hidden by the workpiece.

1.03 Publications

Refer to the following standards or their latest revisions

for more information:

1. OSHA, SAFETY AND HEALTH STANDARDS, 29CFR

1910, obtainable from the Superintendent of Documents,

U.S. Government Printing Office, Washington, D.C.

20402

2. ANSI Standard Z49.1, SAFETY IN WELDING AND

CUTTING, obtainable from the American Welding Society, 550 N.W. LeJeune Rd, Miami, FL 33126

3. NIOSH, SAFETY AND HEALTH IN ARC WELDING

AND GAS WELDING AND CUTTING, obtainable from

the Superintendent of Documents, U.S. Government

Printing Office, Washington, D.C. 20402

4. ANSI Standard Z87.1, SAFE PRACTICES FOR OCCUP A TION AND EDUCATIONAL EYE AND FACE PROTECTION, obtainable from American National Standards Institute, 1430 Broadway, New York, NY 10018

5. ANSI Standard Z41.1, STANDARD FOR MEN’S

SAFETY -TOE FOOTWEAR, obtainable from the American National Standards Institute, 1430 Broadway, New

York, NY 10018

GENERAL INFORMATION 1-2 May 14, 2002

Page 9

6. ANSI Standard Z49.2, FIRE PREVENTION IN THE USE

OF CUTTING AND WELDING PROCESSES, obtainable from American National Standards Institute, 1430

Broadway, New York, NY 10018

7. AWS Standar d A6.0, WELDING AND CUTTING CONTAINERS WHICH HAVE HELD COMBUSTIBLES, obtainable from American Welding Society, 550 N.W.

LeJeune Rd, Miami, FL 33126

8. NFPA Standard 51, OXYGEN-FUEL GAS SYSTEMS

FOR WELDING, CUTTING AND ALLIED PROCESSES, obtainable from the National Fire Protection

Association, Batterymarch Park, Quincy, MA 02269

9. NFPA Standard 70, NATIONAL ELECTRICAL CODE,

obtainable from the National Fire Protection Association, Batterymarch Park, Quincy, MA 02269

10. NFPA Standard 51B, CUTTING AND WELDING PROCESSES, obtainable from the National Fire Protection

Association, Batterymarch Park, Quincy, MA 02269

11. CGA Pamphlet P-1, SAFE HANDLING OF COMPRESSED GASES IN CYLINDERS, obtainable from the

Compressed Gas Association, 1235 Jefferson Davis

Highway, Suite 501, Arlington, VA 22202

12. CSA Standard W1 17.2, CODE FOR SAFETY IN WELDING AND CUTTING, obtainable from the Canadian

Standards Association, Standards Sales, 178 Rexdale

Boulevard, Rexdale, Ontario, Canada M9W 1R3

13. NWSA booklet, WELDING SAFETY BIBLIOGRAPHY

obtainable from the National Welding Supply Association, 1900 Arch Street, Philadelphia, PA 19103

14. American W elding Society Standard A WSF4.1, RECOMMENDED SAFE PRACTICES FOR THE PREPARATION FOR WELDING AND CUTTING OF CONT AINERS AND PIPING THAT HAVE HELD HAZARDOUS

SUBSTANCES, obtainable fr om the American Welding

Society, 550 N.W. LeJeune Rd, Miami, FL 33126

15. ANSI Standard Z88.2, PRACTICE FOR RESPIRATOR Y

PROTECTION, obtainable from American National

Standards Institute, 1430 Broadway, New York, NY

10018

May 14, 2002 1-3 GENERAL INFORMATION

Page 10

1.07 Declaration of Conformity

Manufacturer: Thermal Dynamics Corporation

Address: 82 Benning Street

W est Lebanon, New Hampshire 03784

USA

The equipment described in this manual conforms to all applicable aspects and regulations of the ‘Low Voltage Directive’

(European Council Directive 73/23/EEC as amended by Council Directive 93/68/EEC) and to the National legislation for

the enforcement of this Directive.

Serial numbers are unique with each individual piece of equipment and details description, parts used to manufacture a unit

and date of manufacture.

National Standard and Technical Specifications

The product is designed and manufactured to a number of standards and technical requir ements. Among them are:

* CSA (Canadian Standards Association) standard C22.2 number 60 for Arc welding equipment.

* UL (Underwriters Laboratory) rating 94VO flammability testing for all printed-circuit boar ds used.

* ISO/IEC 60974-1 (BS 638-PT10) (EN 60 974-1) (EN50192) (EN50078) applicable to plasma cutting equipment and associ-

ated accessories.

* Extensive product design verification is conducted at the manufacturing facility as part of the routine design and manufac-

turing process. This is to ensure the product is safe, when used according to instructions in this manual and related

industry standards, and performs as specified. Rigorous testing is incorporated into the manufacturing process to ensure

the manufactured product meets or exceeds all design specifications.

Thermal Dynamics has been manufacturing products for more than 30 years, and will continue to achieve excellence in our

area of manufacture.

Manufacturers responsible repr esentative: Steve W ard

Operations Director

Thermadyne Europe

Europa Building

Chorley N Industrial Park

Chorley , Lancashire,

England PR6 7BX

GENERAL INFORMATION 1-4 May 14, 2002

Page 11

1.08 Statement of Warranty

LIMITED WARRANTY: Thermal Dynamics® Corporation (hereinafter “Thermal”) warrants that its products will be free of defects in

workmanship or material. Should any failure to conform to this warranty appear within the time period applicable to the Thermal

products as stated below , Thermal shall, upon notification thereof and substantiation that the product has been stor ed, installed, operated,

and maintained in accordance with Thermal’s specifications, instructions, recommendations and recognized standard industry practice,

and not subject to misuse, repair , neglect, alteration, or accident, corr ect such defects by suitable r epair or replacement, at Thermal’s sole

option, of any components or parts of the product determined by Thermal to be defective.

THIS WARRANTY IS EXCLUSIVE AND IS IN LIEU OF ANY WARRANTY OF MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE.

LIMITATION OF LIABILITY: Thermal shall not under any circumstances be liable for special or consequential damages, such as, but

not limited to, damage or loss of purchased or replacement goods, or claims of customers of distributor (hereinafter “Purchaser”) for

service interruption. The remedies of the Purchaser set forth herein are exclusive and the liability of Thermal with respect to any

contract, or anything done in connection therewith such as the performance or breach thereof, or from the manufacture, sale, delivery,

resale, or use of any goods covered by or furnished by Thermal whether arising out of contract, negligence, strict tort, or under any

warranty, or otherwise, shall not, except as expressly provided herein, exceed the price of the goods upon which such liability is based.

THIS WARRANTY BECOMES INVALID IF REPLACEMENT PARTS OR ACCESSORIES ARE USED WHICH MAY IMPAIR THE

SAFETY OR PERFORMANCE OF ANY THERMAL PRODUCT.

THIS WARRANTY IS INVALID IF THE PRODUCT IS SOLD BY NON-AUTHORIZED PERSONS.

The limited warranty periods for Thermal products shall be as follows (with the exception of XL Plus Series, CutMaster Series , Cougar

and DRAG-GUN): A maximum of three (3) years from date of sale to an authorized distributor and a maximum of two (2) years from

date of sale by such distributor to the Purchaser, and with the further limitations on such two (2) year period (see chart below).

The limited warranty period for XL Plus Series and CutMaster Series shall be as follows: A maximum of four (4) years from date

of sale to an authorized distributor and a maximum of three (3) years from date of sale by such distributor to the Purchaser, and

with the further limitations on such three (3) year period (see chart below).

The limited warranty period for Cougar and DRAG-GUN shall be as follows: A maximum of two (2) years from date of sale to an

authorized distributor and a maximum of one (1) year from date of sale by such distributor to the Purchaser, and with the further

limitations on such two (2) year period (see chart below).

Parts

XL Plus & Parts Parts

PAK Units, Power Supplies CutMaster Series Cougar/Drag-Gun All Others Labor

Main Power Magnetics 3 Years 1 Year 2 Years 1 Year

Original Main Power Rectifier 3 Years 1 Year 2 Years 1 Year

Control PC Board 3 Years 1 Year 2 Years 1 Year

All Other Circuits And Components Including, 1 Year 1 Year 1 Year 1 Year

But Not Limited To, Starting Circuit,

Contactors, Relays, Solenoids, Pumps,

Power Switching Semi-Conductors

Consoles, Control Equipment, Heat 1 Year 1 Year 1 Year

Exchanges, And Accessory Equipment

Torch And Leads

Maximizer 300 To rch 1 Year 1 Year

SureLok Torches 1 Year 1 Year 1 Year

All Other To rches 180 Days 180 Days 180 Days 180 Days

Repair/Replacement Parts 90 Days 90 Days 90 Days None

Warranty repairs or replacement claims under this limited warranty must be submitted by an authorized Thermal Dynamics® repair

facility within thirty (30) days of the repair. No transportation costs of any kind will be paid under this warranty. Transportation

charges to send products to an authorized warranty repair facility shall be the responsibility of the customer. All returned goods shall

be at the customer’s risk and expense. This warranty supersedes all previous Thermal warranties.

Effective August 6, 2001

May 14, 2002 1-5 GENERAL INFORMATION

Page 12

GENERAL INFORMATION 1-6 May 14, 2002

Page 13

SECTION 2:

INTRODUCTION

2.01 Scope of Manual

This manual contains descriptions, operating instructions

and maintenance procedures for the PCH/M-62 Torch.

Service of this equipment is restricted to properly trained

personnel; unqualified personnel are strictly cautioned

against attempting repairs or adjustments not covered in

this manual, at the risk of voiding the Warranty.

Read this manual thoroughly. A complete understanding of the characteristics and capabilities of this equipment will assure the dependable operation for which it

was designed.

2.02 General Description

NOTE

Refer to Section 2.05, Introduction to Plasma, for

a more detailed description on plasma theory.

The T orch provides cutting capacity of up to 1/2 inch (12.7

mm) at 60 amperes drawn at the power supply.

In the torch, a single torch lead provides compr essed air

from a single source to be used as both the plasma and

secondary gas. The air flow is divided inside the torch

head. Single - gas operation allows for a smaller sized

torch and inexpensive operation.

2.03 Specifications & Design Features

Refer to Appendix Pages for additional specifications as

related to the Power Supply used.

A. Torch Configurations and Dimensions

1. Hand Torch

Available with torch head at 70° and 90° to the

torch handle. The hand torches include an ergonomic torch handle and torch trigger assembly.

2. Machine Torch

The standard machine torch has a fiberglass posi-

tioning tube with rack & pinch block assembly.

A vailable options include a kit with metal mount-

ing tube with rack & pinion assembly or a kit with

the pinion assembly only.

10.5 in

(267 mm)

3.0 in

(76.2 mm)

1.1in

(28 mm)

Plasma torches are similar in design to the common automotive spark plug. They consist of negative and positive sections which are separated by a center insulator.

Inside the torch, the pilot arc is initiated in the gap between the negatively charged electrode and the positively

charged tip. Once the pilot arc has ionized the plasma

gas, the superheated column of gas flows through the

small orifice in the torch tip, which is focused on the metal

to be cut.

10.0 in

(254 mm)

3.4 in

(86.4 mm)

1.1in

(28 mm)

14.1 in

(358 mm)

1.4 in

(35.6 mm)

0.6 in

(15.2 mm)

13.5 in (343 mm) Max

3.7 in (94 mm) Min

0.8 in

(20.3 mm)

5.1 in

(129.5 mm)

1.1 in

(28 mm)

A-02813

Figure 2-1 Torch Configurations and Dimensions

Manual 0-2817 2-1 INTRODUCTION

Page 14

B. Torch Leads Lengths

2.04 Options And Accessories

Hand Torch: 20 ft (6.1 m) or 50 ft (15.2 m)

Machine Torch: 25 ft (7.6 m) or 50 ft (15.2 m)

C. Torch Par ts

Gas Distributor , Electrode, Tip, Shield Cup

D. Par ts - In - Place (PIP)

Torch Head has built - in contacts

12vdc circuit rating.

E. Type of Cooling

Combination of ambient air and gas stream through

torch

F. Torch Ratings

Torch Ratings

Ambient

Temperature

Duty Cy cle

Maxi mu m C u r r e n t

Voltage (V

Arc Stri king Voltage

peak

)

100% @ 60 Amps @ 375 scfh

104° F

(40° C)

60 Amps

500V

12 kV

G. Plasma Power Supply Used With

• CutMaster 50

• PakMaster 50XL Plus

• CE CutMaster 50

• CE PakMaster 50XL Plus

H. Direct Contact Hazard

For exposed tip the recommended standoff is 1/8" 3/8" or 3.2 - 9.5 mm.

These items can be used to customize a standard system

for a particular application or to further enhance performance (refer to Section 6 for ordering information).

• Spare Parts Kits - V arious kits containing replace-

ment front - end torch parts for various applications.

• Circle Cutting Guide Kit - Easy add - on attach-

ments to allow for straight line, circle cutting, and

beveling with a hand torch. The guide fits both

the 70° and 90° hand torches.

• Standoff Cutting Guide - Simple push - on attach-

ment to allow for torch dragging without risk of

touching tip to workpiece.

• 1-3/8" Metal Mounting Tube with Rack & Pinion

Assembly

• Pinion Assembly - For machine torches.

• Computer Control (CNC) Cable 25 ft (7.6 m) or

50 ft (15.2 m)

• Hand Pendant Control Assembly - Used for ma-

chine applications. Hand Pendant Control has 20

ft. (6.1 m) cable which provides ON / OFF signals to the Power Supply.

• Extension Cable for Hand Pendant Control - 25 ft

(7.6 m) cable which can be added to the Hand

Pendant Control cable to provide a total control

cable length of 50 ft (15.2 m).

2.05 Introduction to Plasma

A. Plasma Gas Flow

Plasma is a gas which has been heated to an extremely

high temperature and ionized so that it becomes electrically conductive. The plasma arc cutting and gouging process use this plasma to transfer an electrical

arc to the workpiece. The metal to be cut or removed

is melted by the heat of the arc and then blown away.

While the goal of plasma arc cutting is separation of

the material, plasma arc gouging is used to remove

metals to a controlled depth and width.

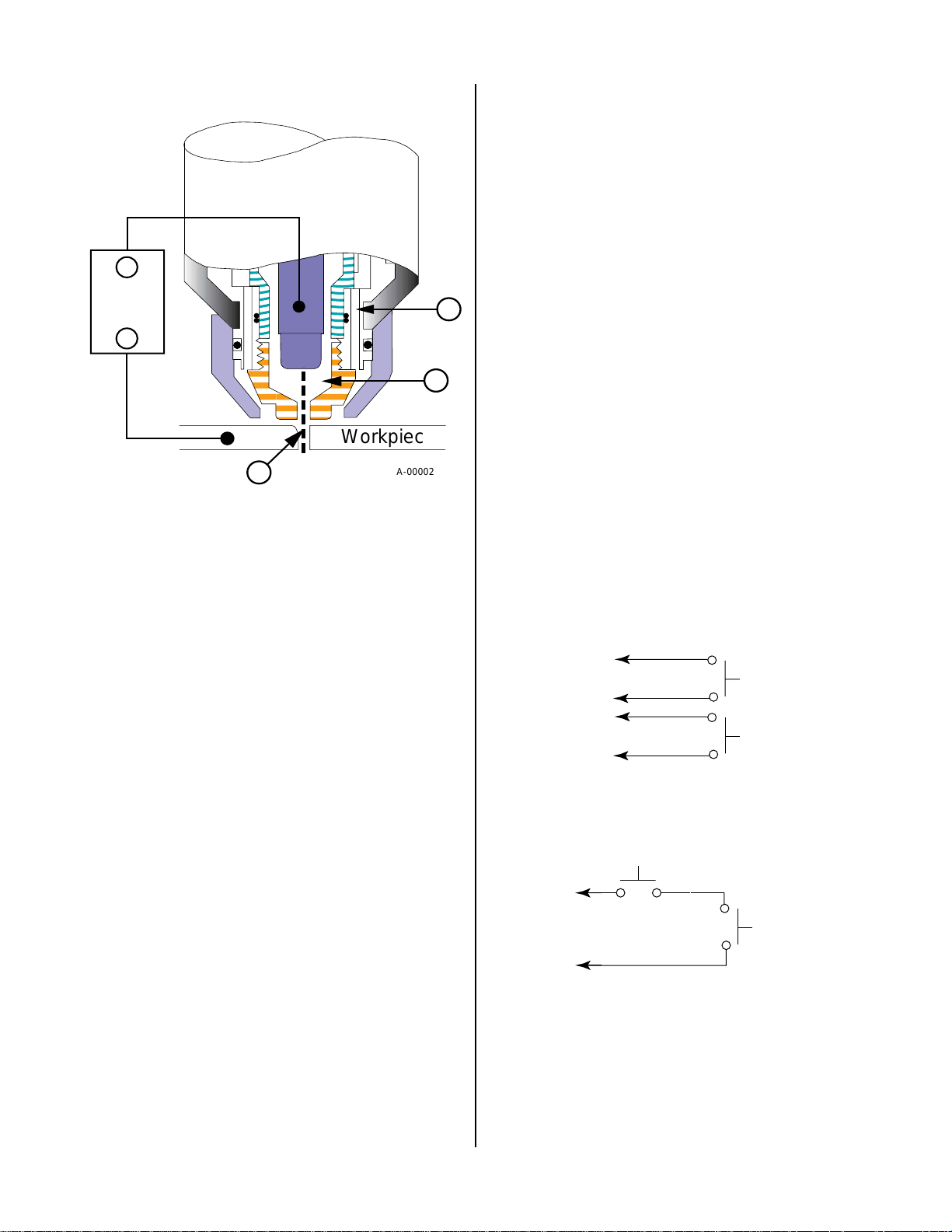

In a Plasma Cutting Torch a cool gas enters Zone B

(refer to Figure 2-2), where a pilot arc between the

electrode and the torch tip heats and ionizes the gas.

The main cutting arc then transfers to the workpiece

through the column of plasma gas in Zone C.

INTRODUCTION 2-2 Manual 0-2817

Page 15

_

Power

Supply

+

D. Capacitive Discharge (CD)

Because direct current (DC) alone is not sufficient to

strike and maintain the pilot arc, capacitive discharge

is also used. The high voltage jumps between the tip

and electrode with the DC following.

E. Main Cutting Arc

DC power is also used for the main cutting arc. The

negative output is connected to the torch electrode

through the torch lead. The positive output is con-

A

nected to the workpiece via the work cable and to

the torch through a pilot wir e.

F. Interlocks

Workpiece

C

Figure 2-2 Typical Torch Head Detail

By forcing the plasma gas and electric arc through a

small orifice, the torch delivers a high concentration

of heat to a small area. The stiff, constricted plasma

arc is shown in Zone C. Direct current (DC) straight

polarity is used for plasma cutting, as shown in the

illustration.

Zone A is used as a secondary gas that cools the torch.

This gas assists the high velocity plasma gas in blowing the molten metal out of the cut allowing for a

fast, slag - free cut.

B. Gas Distribution

The single gas used is internally split into plasma and

secondary gases.

The plasma gas flows into the torch through the negative lead, through the gas distributor , around the electrode, and out through the tip orifice.

The secondary gas flows down around the outside

of the torch gas distributor, and out between the tip

and shield cup around the plasma arc.

C. Pilot Arc

When the torch is started a pilot arc is established

between the electrode and cutting tip. This pilot arc

creates a path for the main arc to transfer to the work.

A-00002

B

One pressure switch acts as an interlock for the gas

supply. If supply pressure falls below minimum requirements the pressure switch will open, shutting

off the DC power, and the GAS Indicator will go off.

When adequate gas supply pressure is available the

pressure switch will close, allowing power to be resumed for cutting.

G. Parts - In - Place (PIP)

The torch head has built - in contacts called Parts - In

- Place (PIP). These two contacts are made through

the ring inside the shield cup when the shield cup is

installed. The torch will fail to operate if these contacts are not made.

To Control

Cable Wiring

A-03540

Torch Switch

PIP Pins

Torch Trigger

Shield Cup

Figure 2-5 Parts - In - Place (PIP) Diagram (Hand

Torch)

Torch Switch

To Control

Cable Wiring

PIP Pin

Shield Cup

PIP Pin

A-00458

Figure 2-3 Parts - In - Place (PIP) Diagram (Machine

Torch)

Manual 0-2817 2-3 INTRODUCTION

Page 16

INTRODUCTION 2-4 Manual 0-2817

Page 17

SECTION 3:

INSTALLATION

3.01 Introduction

This section describes installation of the Torch. These

instructions apply to the T orch and Leads Assemblies only .

Installation procedures for the Power Supply , Options and

Accessories are provided in Manuals specifically provided for those products.

The complete installation consists of:

• Site Selection

• Unpacking

• Setting Up T or c h

• Connecting T orch

• Gas Connection

3.02 Site Location

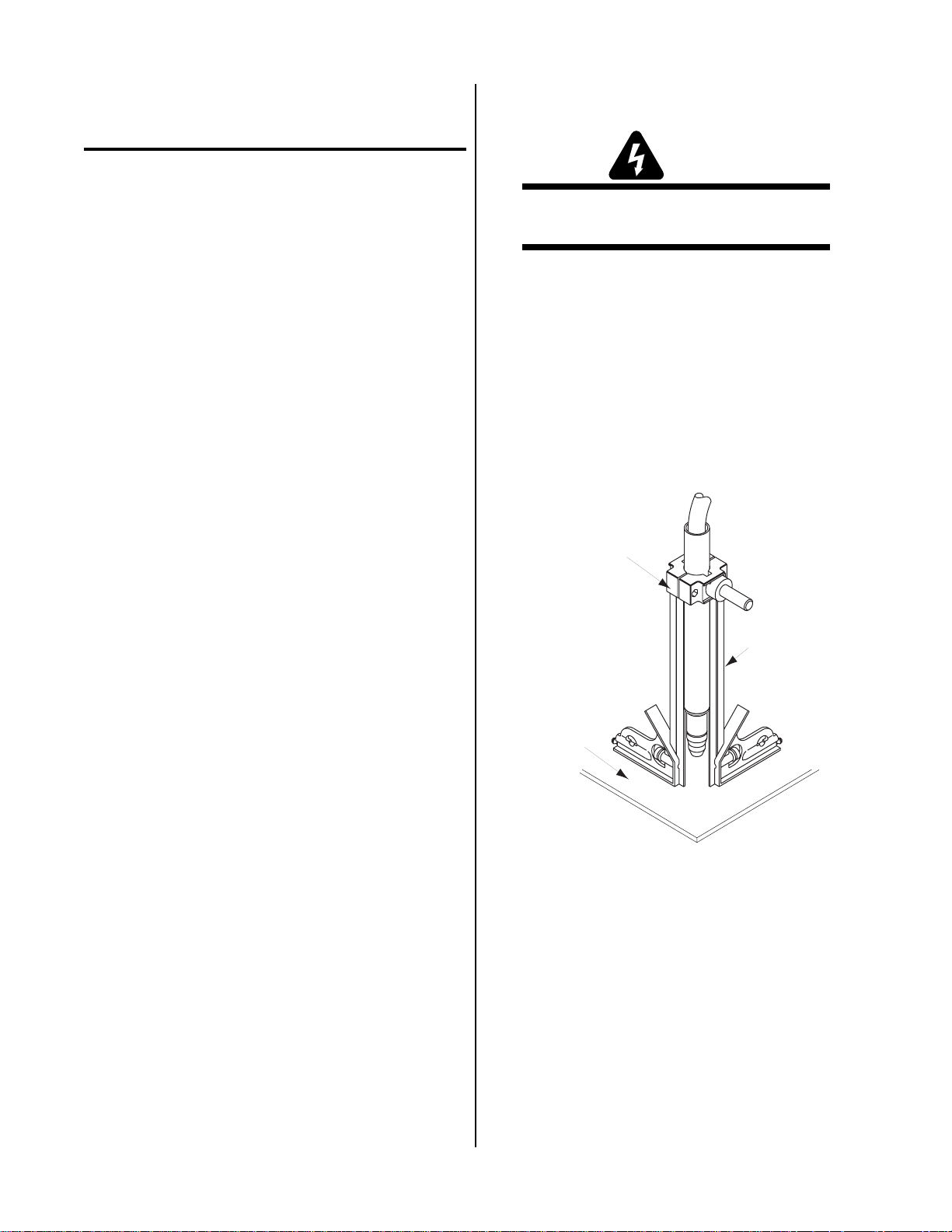

3.05 Setting Up Machine Torch

WARNING

Disconnect primary power at the source before disassembling the torch or torch leads.

The machine torch is factory assembled to the Power Supply. The standard machine torch includes a fiberglass

positioning tube with rack and pinch block assembly. A

metal mounting tube with rack & pinion assembly or the

pinion assembly only are available as options.

1. Mount the torch assembly on the cutting table.

2. T o obtain a clean vertical cut, use a squar e to align

the torch perpendicular to the surface of the workpiece.

Select a clean, dry location with good ventilation and adequate working space around all components.

Review the safety precautions in the front of this manual

to be sure that the location meets all safety requirements.

3.03 Unpacking

Each component of the system is packaged and protected

with a carton and packing material to prevent damage

during shipping.

1. Unpack each item and remove all packing material.

2. Locate the packing list(s) and use the list to identify

and account for each item.

3. Inspect each item for possible shipping damage. If

damage is evident, contact your distributor and / or

shipping company before proceeding with system

installation.

3.04 Setting Up Hand Torch

The hand torch is factory assembled to the Power Supply

and requires no special set up. The proper torch parts

(shield cup, tip, gas distributor, and electrode) must be

installed for the type of operation. Refer to Section 4.04,

Torch Parts Selection for more information.

Pinch Block

Assembly

Square

Workpiece

A-02591

Figure 3-1 Machine Torch Set - Up

3. The proper torch parts (shield cup, tip, gas distributor, and electrode) must be installed for the

type of operation. Refer to Section 4.04, Torch

Parts Selection for more information.

Manual 0-2817 3-1 INST ALLATION

Page 18

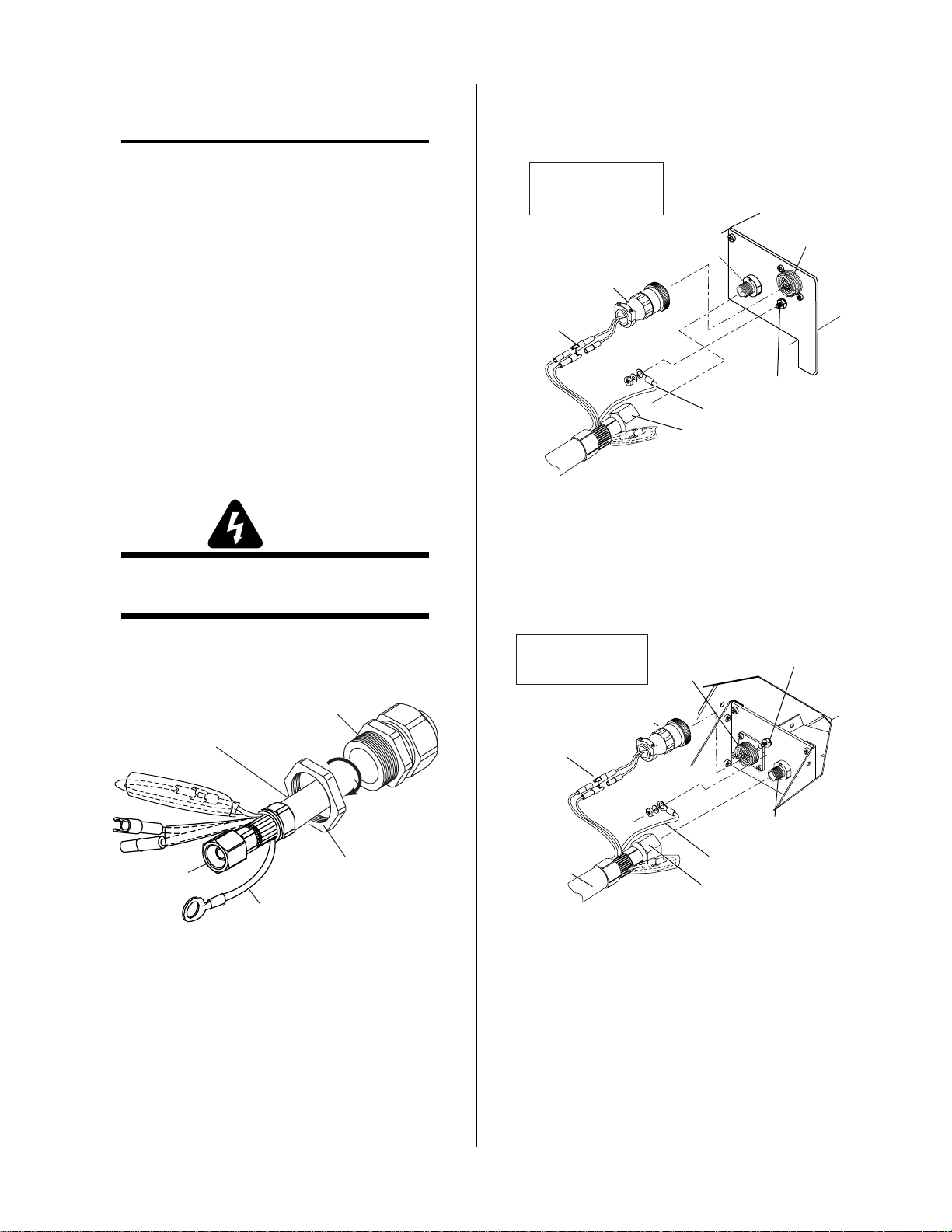

3.06 Connecting T orc h

NOTE

4. Connect the torch Negative / Plasma Lead to the

bulkhead connection inside the Power Supply.

Equipment ordered as a system will have the T or ch

factory connected to the Power Supply.

The instructions for connecting the Torch Leads to the

Power Supply are different depending on the type of

leads. This sub - section covers connecting the T o r ch for

the following applications:

A. Hand Systems

B. Machine Systems (Unshielded Leads)

C. Remote Pendant Control (Optional)

The T orch Leads must be pr operly installed to the Power

Supply for proper operation. If the torch leads were not

factory - installed, make all torch connections to the T or ch

Bulkhead Panel for the desired application.

A. Hand Systems

WARNING

Disconnect primary power at the source before disassembling the torch or torch leads.

Note: Actual Bulkhead

configuration may

differ from that shown.

Adapter

Adapter

Control Circuit

Connectors

Negative/Plasma

Lead Connection

Torch Lead

Assembly

or ATC Adapter

Pilot Lead

Negative/Plasma

Lead

Connector

Pilot Lead Stud

A-03542

Figure 3-3 Torch Lead Connections For CutMaster

50 Power Supply

1. Remove the nut from the Through - hole protector .

Torch Leads

Assembly

Negative /

Plasma Lead

Thru-Hole Protector

Thru-Hole Protector Nut

Pilot Lead

Art # A-03852

Figure 3-2 Through - hole protectorNut Removal

2. Pass the torch lead ends and the Through - hole

protector into the hole in the unit.

3. Secure the Through - hole protector with the nut

removed earlier.

Note: Actual Bulkhead

configuration may

differ from that shown.

Adapter

Control Circuit

Connectors

Torch Leads

Assembly or

ATC Adapter

A-03527

Adapter

Connector

Plug

Negative/Plasma

Pilot Lead Stud

Negative/Plasma Lead

Connection

Pilot Lead

Lead

Figure 3-4 Torch Lead Connections For PakMaster

50XL Plus Power Supply

5. Connect the T orch Leads Cables to the mating connectors on the Adapter supplied on the Power

Supply.

6. Remove the top nut and washer from the Pilot

Stud.

INST ALLATION 3-2 Manual 0-2817

Page 19

7. Place the lug on the Pilot Control Wire onto the

Adapter

(Supplied With

Power Supply)

Pilot Lead

Torch Lead

Assembly

Negative/Plasma

Lead

Adapter Connector

Pilot Lead

Stud

Negative/Plasma

Lead Connection

A-02828

Control (PIP) Circuit

Connectors

Shield Connectors

(Not Used)

Remote

Cable

Connector

stud and secure with the nut and washer removed

in the above Step.

8. Tighten the Through - hole protector onto the

Torch Leads.

9. Check the torch for proper parts assembly.

CAUTION

Note: Actual Bulkhead

configuration may

differ from that shown.

Shield Connectors

(Not Used)

Negative/Plasma

Lead Connection

Adapter

(Supplied With

Power Supply)

Adapter

Connector

The torch parts must correspond with the type of

operation. Refer to Section 4.04, Torch Parts Selection.

B. Machine Systems (Unshielded Leads)

1. Remove the Through - hole protector Nut from

the Through - hole protector.

Torch Leads

Assembly

Thru - Hole Protector

Art # A-03847

Thru - Hole

ProtectorNut

Control (PIP) Circuit

Connectors

Pilot Lead

Stud

Remote

Cable

Connector

Negative/Plasma

Torch Lead

Assembly

Pilot Lead

Lead

A-02768

Figure 3-6 Torch Lead Connections For CutMaster

50 Power Supply

Figure 3-5 Through - hole protector Nut Removal

2. The Adapter supplied with the Power Supply

must be installed per the following:

a. Inside the Power Supply Bulkhead area, route

the connector on the free end of the Adapter

through the Through - hole protector Nut.

b. Continue routing the connector out the hole

in the front of the Power Supply.

c. Pass the end of the torch lead and the Through

- hole protector into the hole in the unit while

routing the single black wire into the notch of

the Through - hole protector.

d. Tighten the Through - hole protector Nut to

secure the Through - hole protector to the

Power Supply.

3. Connect the torch Negative / Plasma Lead to the

Figure 3-7 Torch Lead Connections For PakMaster

50XL Plus Power Supply

bulkhead connection inside the Power Supply.

Manual 0-2817 3-3 INST ALLATION

Page 20

4. Connect the Control (PIP) Circuit Connectors to

the mating connectors on the Adapter supplied

on the Power Supply (see Warning).

WARNING

The Adapter supplied with the Power Supply has

two additional Shield Connectors that are used for

Shielded Systems only. These two connectors are

not used and need to be taped out of the way to

prevent contacting the Negative / Plasma or Pilot

Leads.

5. Remove the top nut and washer from the Pilot

Stud.

6. Place the lug on the Pilot Control Wire onto the

stud and secure with the nut and washer removed

in the above Step.

Remote Pendant/CNC

Cable Connector

Control

12

OK-To-Move

14

13

3

4

PIP

Circuit

Torch Control

Cable Connector

2

3

4

12

14

13

A-01366

Figure 3-8 Remote Pendant Connector Diagram

7. Tighten the Through - hole protector onto the

Torch Leads.

8. Check the torch for proper parts assembly.

CAUTION

The torch parts must correspond with the type of

operation. Refer to Section 4.04, Torch Parts Selection.

D. Remote Pendant Control (Optional)

In machine type operations the Power Supply has an

Adapter that has a cable connector supplied at each

end of the Adapter. One end is connected at the factory to the mating connector on the Power Supply

Bulkhead area. The other end allows connection of a

Remote Pendant. The remote pendant lead connector allows connection to a remote pendant or CNC

cable while using PIP connections in the Torch Assembly.

Connect the remote pendant control cable to the connector provided on the Adapter fr om the Power Supply.

NOTE

Refer to Appendix 2, Torch Control Cable Wiring

Diagram For Mechanized Systems, for detailed

schematic of the Adapter.

3.07 Gas Connection

A. Connection

Connect the gas, compressed air only, to the Power

Supply as described in the Manual supplied with the

Power Supply.

CAUTION

Air supply must be free of oil, moisture, and other

contaminants. Excessive oil and moisture may

cause double - arcing, rapid tip wear , or even complete torch failure. Contaminants may cause poor

cutting performance and rapid electrode wear.

B. Checking Air Quality

T o test the quality of air, place a welding filter lens in

front of the torch and turn on the gas. Any oil or

moisture in the air will be visible on the lens. Do not

initiate an arc!

C. Filtering

An in - line pneumatic dryer / evaporator type air

filter, capable of filtering to at least 5 microns, is required when using air from a compressor. This type

filter will insure that moisture, oil, dirt, chips, rust

particles, and other contaminants from the supply

hose do not enter the torch. For highly automated

applications, a refrigerated drier may be used

INST ALLATION 3-4 Manual 0-2817

Page 21

SECTION 4:

OPERATION

4.01 Introduction

This section provides a description of the Torch Assembly followed by operating procedures.

4.02 Functional Overview

The T orch is designed to operate with various Power Supplies to provide a plasma cutting system which can cut

most metals from gauge thickness up to 1/2 inch (12.7

mm). Using gouging torch parts the torch can be used

for plasma arc gouging up to 1/8 inch (3.2 mm) wide

and 1/8 inch (3.2 mm) deep in a single pass on carbon

steel.

NOTE

Refer to Appendix Pages for additional information as related to the Power Supply used.

4.03 Getting Started

This procedure should be followed at the beginning of

each shift:

NOTE

Refer to Appendix Pages for additional information as related to the Power Supply used.

E. Power On

Place the ON / OFF Switch on the Power Supply to

the ON position. If the RUN / SET or RUN / SET /

LATCH switch is in SET position, gas will flow. If

the switch is in RUN position there will be no gas

flow.

F. RUN / SET or RUN / SET / LATCH Switch

If the RUN / SET or RUN / SET / LATCH switch is

in SET position, gas will flow . If the switch is in RUN

position there will be no gas flow.

G. Current Output Level

At the Power Supply, set the desired current output

level between 20 - 40 amps for cutting or gouging.

H. Pressure Setting

Place the RUN / SET or RUN / SET / LA TCH switch

to the SET position. Adjust the gas pressure control

on the Power Supply for the proper gas pressur e (see

Note).

NOTE

WARNING

Disconnect primary power at the source before assembling or disassembling power supply, torch

parts, or torch and leads assemblies.

A. Torch Parts

Check that torch is properly connected and assembled. Install proper torch parts for the desired

application (refer to Section 4.04, Torch Parts Selection).

B. Input Power

Check the power source for proper input voltage.

Close main disconnect or plug the unit in to supply

primary power to the system.

C. Work Cable

Check for a solid work cable connection to the workpiece.

D. Gas Supply

Select desired single gas supply. Make sure gas

sources meet requirements (see Note). Check connections and turn gas supply on.

Refer to Appendix Pages for additional information as related to the Power Supply used.

I. Ready for Operation

Return the RUN / SET or RUN / SET / LATCH

switch to RUN position.

NOTES

For general cutting, use the RUN position which

provides normal torch operation where the torch

switch must be held throughout the main arc transfer.

For specific applications, use the LATCH position

where the torch switch can be r eleased after the main

arc transfer . The torch r emains activated until the

main arc breaks from the workpiece.

Refer to Appendix I for a typical detailed block diagram of Sequence of Operations.

The system is now ready for operation.

Start the pilot arc. On Hand T or ches press the T or ch T rig-

ger . On Machine T or ches press the switch on the Remote

Pendant or supply a Start Signal from the CNC control.

There is a 2 second pre-flow before the arc starts.

Manual 0-2817 4-1 OPERATION

Page 22

4.04 Torch Parts Selection

4.05 Cut Quality

The type of power supply and the type of operation to be

performed determine the torch parts to be used:

Type of operation:

Drag cutting, standoff cutting or gouging

Torch parts:

Shield Cup, Cutting Tip, Electrode and Gas Distributor

NOTE

Refer to Appendix Pages for additional information as related to the Power Supply used.

To change the torch parts for a different operation use

the following procedure:

NOTE

The tip and gas distributor are held in place by the

shield cup. Position the torch with the Shield cup

facing upward to prevent these parts from falling

out when the cup is removed.

1. Unscrew and remove the shield cup from the torch

head.

Torch Head Assembly

(70˚ Hand Torch Shown)

Electrode

Gas

Distributor

NOTES

Cut quality depends heavily on set-up and parameters such as torch standoff, alignment with the

workpiece, cutting speed, gas pressures, and operator ability.

Refer to Appendix Pages for additional information as related to the Power Supply used.

Cut quality requirements differ depending on application. For instance, nitride build-up and bevel angle may

be major factors when the surface will be welded after

cutting. Dross-free cutting is important when finish cut

quality is desired to avoid a secondary cleaning operation. The following cut quality characteristics are illustrated in the following figure.

Kerf Width

Cut Surface

Bevel Angle

Top

Spatter

Top Edge

Rounding

Dross

Build-Up

Cut Surface

Drag Lines

A-00007

Figure 4-2 Cut Quality Characteristics

Tip

A-02890

Shield Cup

Figure 4-1 Torch Parts

2. Tilt the torch head to remove the tip and gas distributor .

3. Remove the SureLok Electrode by pulling it straight

out of the Torch Head.

4. Install the desired SureLok Electrode by pushing it

straight into the torch head until it clicks.

5. Install the desired gas distributor and tip for the op-

eration into the torch head.

6. Hand tighten the shield cup until it is seated on the

torch head. If resistance is felt when installing the

cup, check the threads before proceeding.

A. Cut Surface

The desired or specified condition (smooth or rough)

of the face of the cut.

B. Nitride Build-Up

Nitride deposits can be left on the surface of the cut

when nitrogen is present in the plasma gas stream.

These build-ups may create difficulties if the material is to be welded after the cutting process.

C. Bevel Angle

The angle between the surface of the cut edge and a

plane perpendicular to the surface of the plate. A perfectly perpendicular cut would result in a 0° bevel

angle.

D. Top-Edge Rounding

Rounding on the top edge of a cut due to wearing

from the initial contact of the plasma arc on the workpiece.

OPERA TION 4-2 Manual 0-2817

Page 23

E. Bottom Dross Build-up

C. Edge Starting

Molten material which is not blown out of the cut

area and re-solidifies on the plate. Excessive dross

may require secondary clean-up operations after cutting.

F . Kerf Width

The width of the cut (or the width of material removed during the cut).

G. Top Spatter (Dross)

Top spatter or dross on the top of the cut caused by

slow travel speed, excess cutting height, or cutting

tip whose orifice has become elongated.

4.06 General Cutting Information

WARNINGS

Disconnect primary power at the source before disassembling the power supply, torch, or tor ch leads.

Frequently review the Important Safety Precautions in Section 1. Be sure the operator is equipped

with proper gloves, clothing, eye and ear protection. Make sure no part of the operator’s body

comes into contact with the workpiece while the

torch is activated.

CAUTION

Sparks from the cutting process can cause damage

to coated, painted, and other surfaces such as glass,

plastic and metal.

NOTE

Handle torch leads with care and protect them fr om

damage.

A. Piloting

Piloting is harder on parts life than actual cutting because the pilot arc is directed from the electrode to

the tip rather than to a workpiece. Whenever possible, avoid excessive pilot arc time to improve parts

life.

B. Torch Standoff

Improper standoff (the distance between the torch

tip and workpiece) can adversely affect tip life as well

as shield cup life. Standoff may also significantly

affect the bevel angle. Reducing standoff will generally result in a more square cut.

For edge starts, hold the torch perpendicular to the

workpiece with the front of the tip near (not touching) the edge of the workpiece at the point where the

cut is to start. When starting at the edge of the plate,

do not pause at the edge and force the arc to "reach"

for the edge of the metal. Establish the cutting arc as

quickly as possible.

D. Direction of Cut

Inside the torch, the plasma gas stream swirls as it

leaves the torch to maintain a smooth column of gas.

This swirl effect results in one side of a cut being mor e

square than the other . Viewed along the direction of

travel, the right side of the cut is more square than

the left.

Left Side

Cut Angle

Right Side

Cut Angle

Figure 4-3 Side Characteristics of Cut

To make a square-edged cut along an inside diameter of a circle, the torch should move counterclockwise around the circle. T o keep the squar e edge along

an outside diameter cut, the torch should travel in a

clockwise direction.

E. Dross

When dross is present on carbon steel, it is commonly

referred to as either “high speed dross", "slow speed

dross", or "top dross”. Dross present on top of the

plate is normally caused by too great a torch-to-plate

distance. "T op dross" is normally very easy to r emove

and can often be wiped off with a welding glove.

"Slow speed dross" is normally present on the bottom edge of the plate. It can vary from a light to heavy

bead, but does not adhere tightly to the cut edge, and

can be easily scraped off. "High speed dross" usually forms a narrow bead along the bottom of the cut

edge and is very difficult to remove. When cutting a

troublesome steel, it is sometimes useful to reduce

the cutting speed to produce "slow speed dross". Any

resultant cleanup can be accomplished by scraping,

not grinding.

A-00512

Manual 0-2817 4-3 OPERATION

Page 24

4.07 Hand T orch Operation

A. Standoff Cutting With Hand Torch

NOTE

For best performance and parts life, always use the

correct parts for the type of operation.

1. The torch can be comfortably held in one hand or

steadied with two hands. Position the hand to

press the Trigger on the torch handle. With the

hand torch, the hand may be positioned close to

the torch head for maximum control or near the

back end for maximum heat protection. Choose

the holding technique that feels most comfortable

and allows good control and movement.

NOTE

The tip should never come in contact with the workpiece except during drag cutting operations.

2. Depending on the cutting operation, do one of the

following:

a. For edge starts, hold the torch perpendicular

to the workpiece with the front of the tip on

the edge of the workpiece at the point where

the cut is to start.

b. For standoff cutting, hold the torch 1/8 - 3/8

in (3-9 mm) from the workpiece as shown below.

4. Once on, the main arc remains on as long as the

Torch Trigger is held down, unless the torch is

withdrawn from the work or torch motion is too

slow. If the cutting arc is interrupted, the pilot

arc comes back on automatically.

NOTE

Most cutting is performed with the power supply

in the RUN position. For specific applications, the

LATCH position may be pr eferred where the Torch

Trigger can be released after the main arc transfer .

The torch remains activated until the main arc

breaks from the workpiece.

5. To shut off the torch simply r elease the T orch Trigger . When the trigger is released a gas post-flow

will occur. If the Torch Trigger is pushed during

the post-flow , the cutting arc will r estart immediately when the torch is brought within range of

the workpiece.

B. Standoff Cutting Guide With Straight Edge

The Standoff Cutting Guide (option with some systems) can be used with a non-conductive straight

edge to make straight cuts by hand.

WARNING

The straight edge must be non-conductive.

Torch

Shield Cup

A-00024

Standoff

Distance 1/8" - 3/8"

Figure 4-4 Standoff Distance

3. With the torch in starting position, press and hold

the T orch Trigger. After an initial two second preflow, the pilot arc will come on and remain on

until the cutting arc starts.

Torch

Shield Cup

Standoff

Cutting Guide

Non-Conductive

Straight Edge

Cutting Guide

A-02792

Figure 4-5 Using Standoff Cutting Guide With

Straight Edge

The guide functions best when cutting 3/16 inch (4.7

mm) or greater solid metal with relatively smooth

surfaces. Use drag cutting for thinner metal.

OPERA TION 4-4 Manual 0-2817

Page 25

C. Drag Cutting With a Hand Torch

NOTE

Drag cutting works best on metal 3/16" (4.7 mm)

thick or less.

NOTE

For best parts performance and life, always use the

correct parts for the type of operation.

1. Install the drag cutting tip and set the output current to 35 amps or less.

2. The torch can be comfortably held in one hand or

steadied with two hands. Position the hand to

press the Trigger on the torch handle. With the

hand torch, the hand may be positioned close to

the torch head for maximum control or near the

back end for maximum heat protection. Choose

the holding technique that feels most comfortable

and allows good control and movement.

3. Keep the torch in contact with the workpiece during the cutting cycle.

4. Press the Torch Trigger, and after an initial two

second pre-flow, the pilot arc will come on and

remain on until the cutting arc starts.

5. Once on, the main arc remains on as long as the

Torch Trigger is held down, unless the torch is

withdrawn from the work or torch motion is too

slow. If the cutting arc is interrupted, the pilot

arc comes back on automatically.

The tip should never come in contact with the workpiece except during drag cutting operations.

2. Angle the torch slightly to direct blowback particles away from the torch tip (and operator) rather

than directly back into it until the pierce is complete.

3. In a portion of the unwanted metal start the pierce

off the cutting line and then continue the cut onto

the line. Hold the torch perpendicular to the workpiece after the pierce is complete.

4. Clean spatter and scale from the shield cup and

the tip as soon as possible. Spraying the shield

cup in anti-spatter compound will minimize the

amount of scale which adheres to it.

4.08 Machine T orch Operation

A. Cutting With Machine T orch

The machine torch can be activated by remote control pendant or by a remote interface device such as

CNC.

1. Use a square to check that the torch is perpendicular to the workpiece to obtain a clean, vertical cut.

NOTE

Most cutting is performed with the power supply

in the RUN position. For specific applications,

the LATCH position may be preferred where the

Torch Trigger can be released after the main arc

transfer . In the LATCH position, the tor ch remains

activated until the main arc breaks from the workpiece.

6. T o shut off the tor ch simply release the T orch Trigger . When the T rigger is r eleased a gas post-flow

will occur. If the Torch Trigger is pushed during

the post-flow , the cutting arc will r estart immediately when the torch is brought within range of

the workpiece.

D. Piercing With Hand T or ch

1. The torch can be comfortably held in one hand or

steadied with two hands. Position the hand to

press the Trigger on the torch handle. With the

hand torch, the hand may be positioned close to

the torch head for maximum control or near the

back end for maximum heat protection. Choose

the technique that feels most comfortable and allows good control and movement.

Pinch Block

Assembly

Square

Workpiece

A-02591

Figure 4-6 Checking Alignment

2. To start a cut at the plate edge, position the center

of the torch along the edge of the plate (refer to

Figure 4-7).

Manual 0-2817 4-5 OPERATION

Page 26

B. Travel Speed

Proper travel speed is indicated by the trail of the arc

which is seen below the plate ( Figure 4-7). The arc

can be one of the following:

1. Straight Arc

A straight arc is perpendicular to the workpiece

surface. This arc is generally recommended for

the best cut using air plasma on stainless or aluminum.

2. Leading Arc

The leading arc is directed in the same direction

as torch travel. A five degr ee leading arc is gener ally recommended for air plasma on mild steel.

3. Trailing Arc

The trailing arc is directed in the opposite direction as torch travel. Generally recommended for

Nitrogen Plasma.

Travel speed also affects the bevel angle of a cut.

When cutting in a circle or around a corner, slowing

down the travel speed will result in a squarer cut.

The power source output should be reduced also.

Refer to the approriate Power Supply Operating

Manual for any Corner Slowdown (CSD) adjustments

that may be required.

C. Piercing With Machine T orch

To pierce with a machine torch, the arc should be

started with the torch positioned as high as possible

above the plate while allowing the arc to transfer and

pierce. This standoff helps avoid having molten metal

blow back onto the front end of the torch.

When operating with a cutting machine, a pierce or

dwell time is required. Torch travel should not be

enabled until the arc penetrates the bottom of the

plate. As motion begins, torch standoff should be

reduced to the recommended 1/8 - 1/4 inch (3-6 mm)

distance for optimum speed and cut quality. Clean

spatter and scale from the shield cup and the tip as

soon as possible. Spraying or dipping the shield cup

in anti-spatter compound will minimize the amount

of scale which adheres to it.

Direction of Torch Travel

Standoff Distance

A-02590

Straight Arc

Trailing Arc

Leading Arc

Figure 4-7 Machine Torch Operation

For optimum smooth surface quality , the travel speed

should be adjusted so that only the leading edge of

the arc column produces the cut. If the travel speed

is too slow, a rough cut will be produced as the arc

moves from side to side in search of metal for transfer.

4.09 Recommended Cutting Speeds

Cutting speed depends on material, thickness, and the

operator’s ability to accurately follow the desired cut line.

The following factors may have an impact on system performance:

• Torch parts wear

• Air quality

• Line voltage fluctuations

• Torch standoff height

• Proper work cable connection

NOTES

This information represents realistic expectations

using recommended practices and well-maintained

systems. Actual speeds may vary up to 50% from

those shown.

Refer to Appendix Pages for cutting speed chart

information as related to the Power Supply used.

OPERA TION 4-6 Manual 0-2817

Page 27

4.10 Gouging

A-00025

35˚

Workpiece

Torch Head

Standoff Height

1/8 - 1/4"

Direction of Travel

WARNINGS

Be sure the operator is equipped with proper gloves,

clothing, eye and ear protection and that all safety

precautions at the front of this manual have been

followed. Make sure no part of the operator’s body

comes in contact with the workpiece when the torch

is activated.

Disconnect primary power to the system before

disassembling the torch, leads, or power supply.

CAUTIONS

35°), less material may be removed, requiring more

passes. In some applications, such as removing welds

or working with light metal, this may be desirable.

Sparks from plasma gouging can cause damage to

coated, painted or other surfaces such as glass, plastic, and metal.

Check torch parts. The torch parts must correspond

with the type of operation. Refer to Section 4.04,

Torch Parts Selection.

A. Gouging Parameters

Gouging performance depends on parameters such

as torch travel speed, current level, lead angle (the

angle between the torch and workpiece), and the distance between the torch tip and workpiece (standoff).

B. Tor ch Tra vel Speed

NOTE

Refer to Appendix Pages for additional information as related to the Power Supply used.

Optimum torch travel speed for gouging is dependent on current setting, and lead angle, and mode of

operation (hand or machine torch).

C. Current Setting

Figure 4-8 Gouging Angle and Standoff Distance

E. Standoff Distance

The tip to work distance affects gouge quality and

depth. Standoff distance of 1/8 - 1/4 inch (3 - 6 mm)

allows for smooth, consistent metal removal. Smaller

standoff distances may result in a severance cut rather

than a gouge. Standoff distances greater than 1/4

inch (6 mm) may result in minimal metal removal or

loss of transferred main arc.

F. Slag Build-up

Slag generated by gouging on materials such as carbon and stainless steels, nickels, and alloyed steels,

can be removed easily in most cases. Slag does not

obstruct the gouging process if it accumulates to the

side of the gouge path. However, slag build-up can

cause inconsistencies and irregular metal removal if

large amounts of material build up in front of the arc.

The build-up is most often a result of improper travel

speed, lead angle, or standoff height.

Current settings depend on torch travel speed, mode

of operation (hand or machine torch), and the amount

of material to be removed.

D. Lead Angle

The angle between the torch and workpiece depends

on the output current setting and torch travel speed.

At 40 amps, the recommended lead angle is 35°. At a

lead angle greater than 45° the molten metal will not

be blown out of the gouge and may be blown back

onto the torch. If the lead angle is too small (less than

Manual 0-2817 4-7 OPERATION

Page 28

OPERA TION 4-8 Manual 0-2817

Page 29

SECTION 5:

SERVICE

5.01 Introduction

This section describes basic maintenance procedures performable by operating personnel. No other adjustments

or repairs are to be attempted by other than properly

trained personnel.

WARNINGS

The inside of the torch should be cleaned with electrical contact cleaner using a cotton swab or soft wet

rag. In severe cases, the torch can be removed from

the leads and cleaned more thoroughly by pouring

electrical contact cleaner into the torch and blowing

it through with compressed air.

Refer to Section 5.07, Servicing Hand Torch (PCH)

Components, or Section 5.08, Servicing Machine

Torch Components (PCM) for disassembling the

Torch and Leads Assembly.

CAUTION

Dry the torch thoroughly before r einstalling.

Disconnect primary power at the source before disassembling the torch or torch leads.

Frequently review the Important Safety Precautions Section 1. Be sure the operator is equipped

with proper gloves, clothing, eye and ear protection. Make sure no part of the operator’s body comes

into contact with the workpiece while the torch is

activated.

CAUTION

Sparks from the cutting process can cause damage

to coated, painted, and other surfaces such as glass,

plastic and metal.

NOTE

Handle torch leads with care and protect them fr om

damage.

5.02 General T orch Maintenance

A. Cleaning Tor ch

Even if precautions are taken to use only clean air

with a torch, eventually the inside of the torch becomes coated with residue. This buildup can affect

the pilot arc initiation and the overall cut quality of

the torch.

WARNINGS

Disconnect primary power to the system before

disassembling the torch or torch leads.

DO NOT touch any internal torch parts while the

AC indicator light of the Power Supply is ON.

B. Checking Center Insulator

The center insulator separates the negative and positive sections of the torch. If the center insulator does

not provide adequate resistance, current which is intended for the pilot arc may be dissipated into the

torch head, resulting in torch failure.

WARNINGS

Disconnect primary power to the system before

disassembling the torch or torch leads.

DO NOT touch any internal torch parts while the

AC indicator light of the Power Supply is ON.

1. Remove the shield cup, tip, gas distributor, and

electrode from the torch. Disconnect the torch

leads from the power supply to isolate the torch

from power supply circuits.

2. Using an ohmmeter (set to 10K or higher), check

for continuity between the positive and negative

torch fittings. Infinite resistance (no continuity)

should be found. If continuity is found, refer to

subsection 5.06, Torch and Leads Troubleshooting.

C. O - Ring Lubrication

The external o - ring on the Torch Head Assembly

(shield cup) requires lubrication on a scheduled basis. This will allow the o - ring to remain pliable and

provide a proper seal. The o - ring will dry out, becoming hard and cracked, if the o - ring lubricant is

not used on a regular basis. This can lead to potential leaks of the secondary gas around the end of the

shield cup.

It is recommended to apply a very light film of o - ring

lubricant (Catalog # 8-4025) to the o - ring on a weekly

basis.

Manual 0-2817 5-1 SERVICE

Page 30

NOTE

DO NOT use other lubricants or grease, they may

not be designed to operate within high temperatures or may contain “unknown elements” that

may react with the atmosphere. This reaction can

leave contaminants inside the torch. Either of these

conditions can lead to inconsistent performance or

poor parts life.

5.03 Common Operating Faults

The following lists the more common cutting faults and

what is the possible cause:

1. Insufficient Penetration

a. Cutting speed too fast

b. Torch tilted too much

c. Metal too thick

d. Worn torch parts

e. Cutting current too low

f. Non - Genuine Thermal Dynamics Parts

2. Main Arc Extinguishes

a. Cutting speed too slow

b. Torch standoff too high from workpiece

5.04 Inspection and Replacement Consumable T or ch Parts

WARNINGS

Disconnect primary power to the system before

disassembling the torch or torch leads. DO NOT

touch any internal torch parts while primary power

is connected.

Remove the consumable torch parts per the following

procedure:

NOTE

The tip and gas distributor are held in place by the

shield cup. Position the torch with the shield cup

facing upward to prevent these parts from falling

out when the cup is removed.

1. Unscrew and remove the shield cup from the torch.

NOTE

Slag built up on the shield cup that cannot be removed may effect the performance of the system.

2. Inspect the cup for damage. Wipe it clean or replace

if damaged.

c. Cutting current too high

d. Work cable disconnected

e. Worn torch parts

f. Non - Genuine Thermal Dynamics Parts

3. Excessive Dross Formation

a. Cutting speed too slow

b. Torch standoff too high from workpiece

c. Worn torch parts

d. Improper cutting current

e. Non - Genuine Thermal Dynamics Parts

4. Short Torch Parts Life

a. Oil or moisture in air source

b. Exceeding system capability (material too thick)

c. Excessive pilot arc time

d. Air flow too low (incorrect pressure)

e. Improperly assembled torch

Torch Head Assembly

(70˚ Hand Torch Shown)

Electrode

A-02890

Gas

Distributor

Tip

Shield Cup

Figure 5-1 Front End Torch Parts Assembly

3. Remove the tip. Check for excessive wear (indicated

by an elongated or oversized orifice). Clean or replace the tip if necessary.

f. Non - Genuine Thermal Dynamics Parts

SERVICE 5-2 Manual 0-2817

Page 31

Good Tip

A-00942

Worn Tip

Figure 5-2 Tip Wear

This guide is set up in the following manner:

X. Symptom (Bold Type)

Any Special Instructions (Text Type)

1. Cause (Italic Type)

a. Check / Remedy (Text Type)

Locate your symptom, check the causes (easiest listed first)

then remedies. Repair as needed being sure to verify that

unit is fully operational after any repairs.

Troubleshooting

4. Remove the gas distributor and check for excessive

wear , plugged gas holes, or discoloration. Replace if

necessary.

5. Remove the SureLok Electrode by pulling it straight

out of the torch head. Refer to the following figure

and check the face of the electrode for excessive wear .

New Electrode

A-02794

Worn Electrode

Figure 5-3 Electrode Wear

6. Reinstall the SurLok electrode into the torch head by

pushing it straight into the torch head until it clicks.

7. Reinstall the gas distributor and tip into the torch head.

8. Hand tighten the shield cup until it is seated on the

torch head. If resistance is felt when installing the

cup, check the threads before proceeding.

5.05 Troubleshooting Guide

This subsection covers troubleshooting that requires

dissasembly and electronic measurements. It is helpful

for solving many of the common problems that can arise

with this torch assembly.

A. Torch will not pilot when torch switch is activated

1. Power Supply RUN / SET or RUN / SET / LATCH

switch in SET position

a. Place switch to RUN position

2. Parts - In - Place (PIP) not satisfied

a. Check canted coil spring inside shield cup

3. Faulty torch switch

a. Check continuity

4. Faulty torch parts

a. Inspect torch parts and replace if necessary. Re-

fer to subsection 5.04, Inspection and Replacement Consumable Torch Parts.

5. Gas pressure too high

a. Set proper operating gas pressure

6. Faulty components in torch and leads assembly.

a. Inspect torch assemblies and replace if neces-

sary . Refer to subsection 5.06, Torch and Leads

Troubleshooting.

7. Faulty components in power supply system components

a. Return for repair or have qualified technician

repair per Service Manual.

B. No cutting output

1. Torch not properly connected to power supply

a. Check that torch leads are properly attached

to power supply.

How to Use This Guide

The following information is a guide to help the Customer

determine the most likely causes for various symptoms.

2. Shield cup not properly installed on torch

a. Check that shield cup is fully seated against

torch head (do not overtighten).

3. Parts - In - Place (PIP) not satisfied

a. Check canted coil spring inside shield cup

Manual 0-2817 5-3 SERVICE

Page 32

4. Faulty components in torch and leads assembly

F. Torch cuts but not adequately

a. Inspect torch assemblies and replace if neces-

sary . Refer to subsection 5.06, Torch and Leads

Troubleshooting.

5. Faulty components in power supply system

a. Return for repair or have qualified technician

repair per Service Manual.

C. Limited cutting output with no control

1. Poor input or output connections to power supply

a. Check all input and output connections.

2. Faulty components in torch and leads assembly

a. Inspect torch assemblies and replace if neces-

sary. Refer to subsection 5.06, Torch & Leads

Troubleshooting.

3. Faulty components in power supply system

a. Return for repair or have qualified technician

repair per Power Supply Service Manual.

D. Erratic or improper cutting output

1. Poor input or output connections to power supply

1. Current set too low at power supply

a. Increase current setting

2. Torch is being moved too fast across workpiece

a. Reduce cutting speed (refer to Appendix Page

for the Power Supply being used).

3. Excessive oil or moisture in torch

a. Hold torch 1/8 inch (3 mm) from clean surface

while purging and observe oil or moisture

buildup (do not activate torch).

5.06 Torch & Leads Troubleshooting

A. General Information

Failures in the Torch & Leads can be isolated to the T orch

Head or T orch Lead components. To properly isolate the

failed part requires the use of an ohmmeter and a Hi Pot T ester.

WARNING

a. Check all input and output connections.

2. Current set too low at power supply

a. Increase current setting.

3. Torch is being moved too fast across workpiece

a. Reduce cutting speed (refer to Appendix Page

for the Power Supply being used).

4. Excessive oil or moisture in torch